Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

273results about How to "Reduce broken ends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling with 100aste newsprint paper deinked pulp esterase

InactiveCN101220567AReduce contentGuaranteed uptimePulp de-wateringPaper recyclingProcessing costPollution

The invention discloses a method that uses esterase obtained by 100 percent deinking and desizing of wasted newspaper controls sticky which mainly aims at producing the low fixed amount newspaper by using the 100 percent deinking and desizing of the wasted newspaper, adopts Optimyze 525 esterase control sticky and produces the newspaper with 45g / mm<2> fixed amount. The invention has the advantages of reducing the dosage of the sticky in the paper pulp, leading the sticky removing rate to be about 20 percent to 40 percent, reinforcing the operating performance of a paper machine, and helping to improve the speed and the output of the paper machine; by adopting deinking and desizing of 100 percent wasted newspaper to make 45g / m<2> lowing amount offset newsprint, the obtained products have good quality, chemical pulp and groundwood pulp which are high in pollution and high consumption are eliminated, the manufactory cost of the pulp material and the processing cost of the water are reduced, and the discharged waste water and the pollutants are reduced.

Owner:GUANGDONG IND TECHN COLLEGE +1

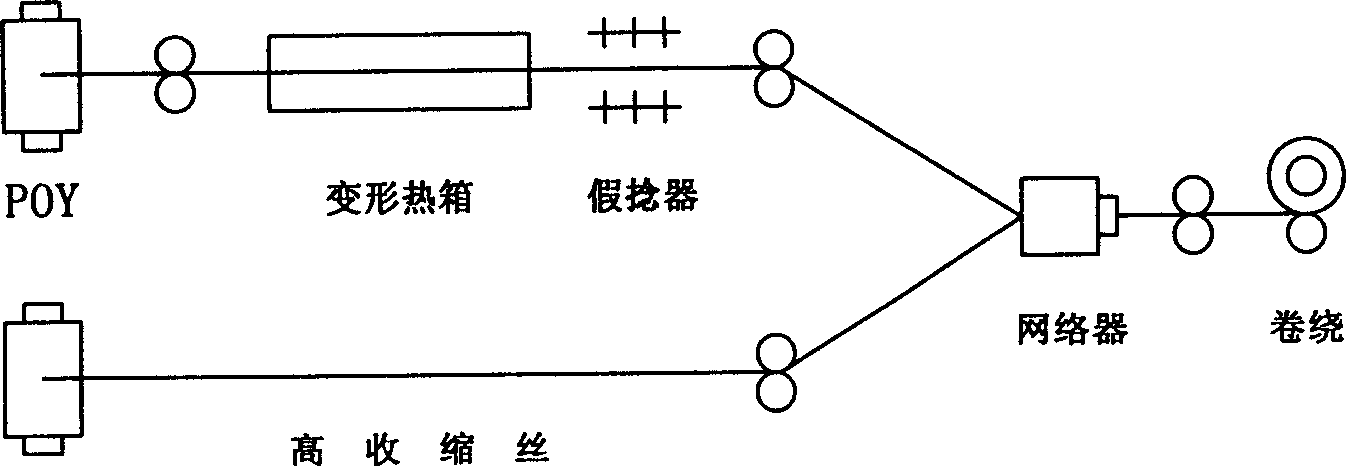

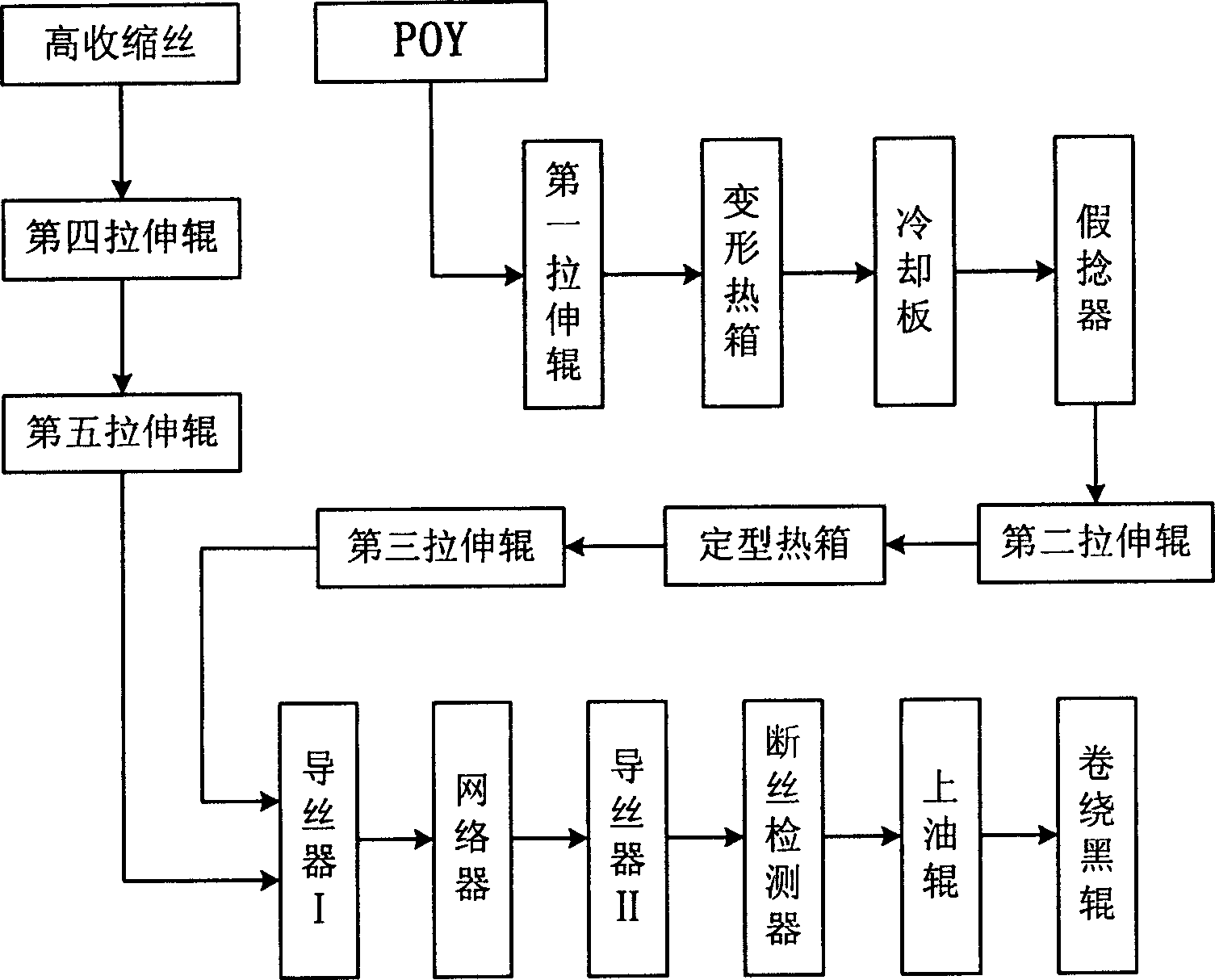

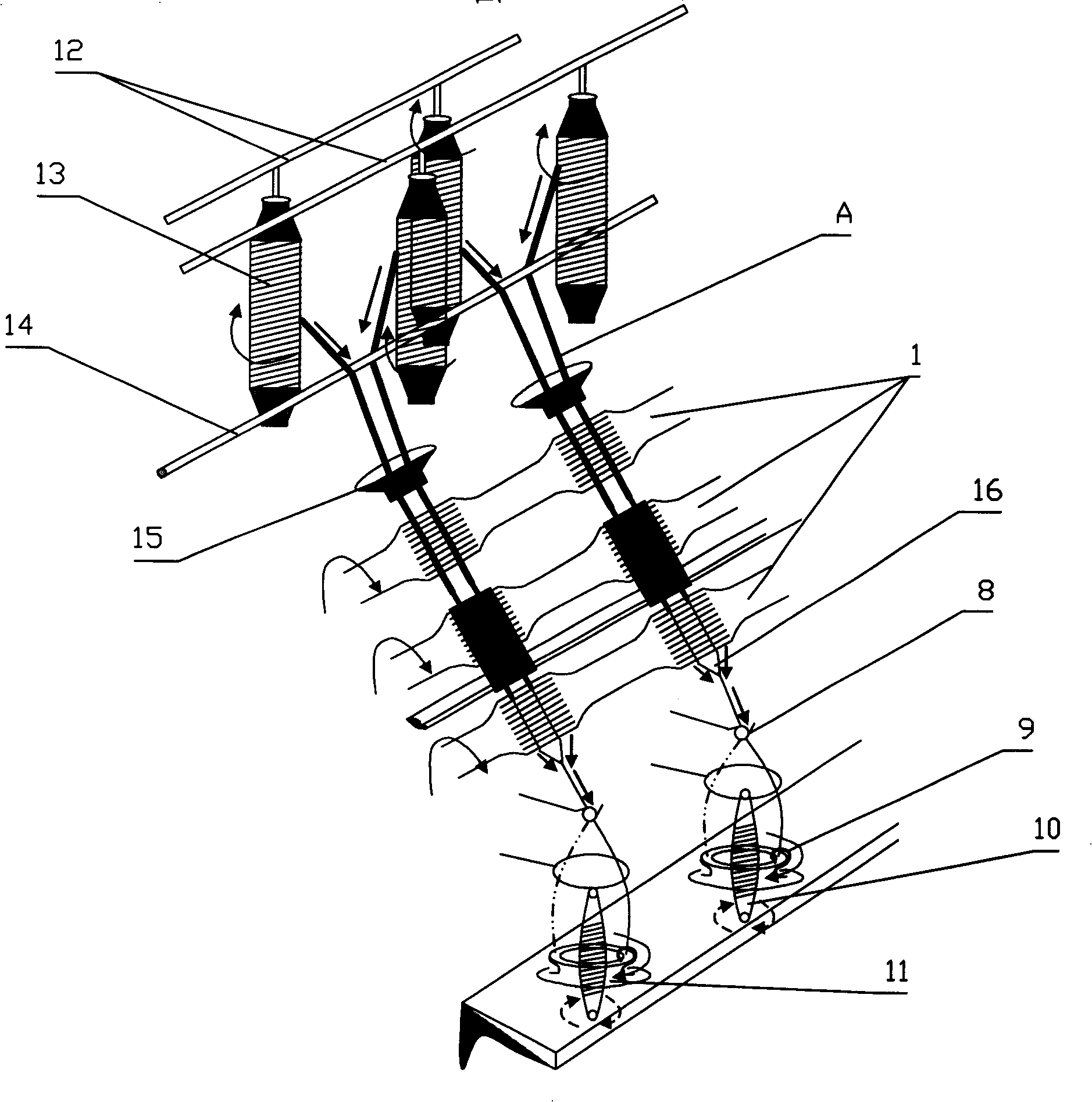

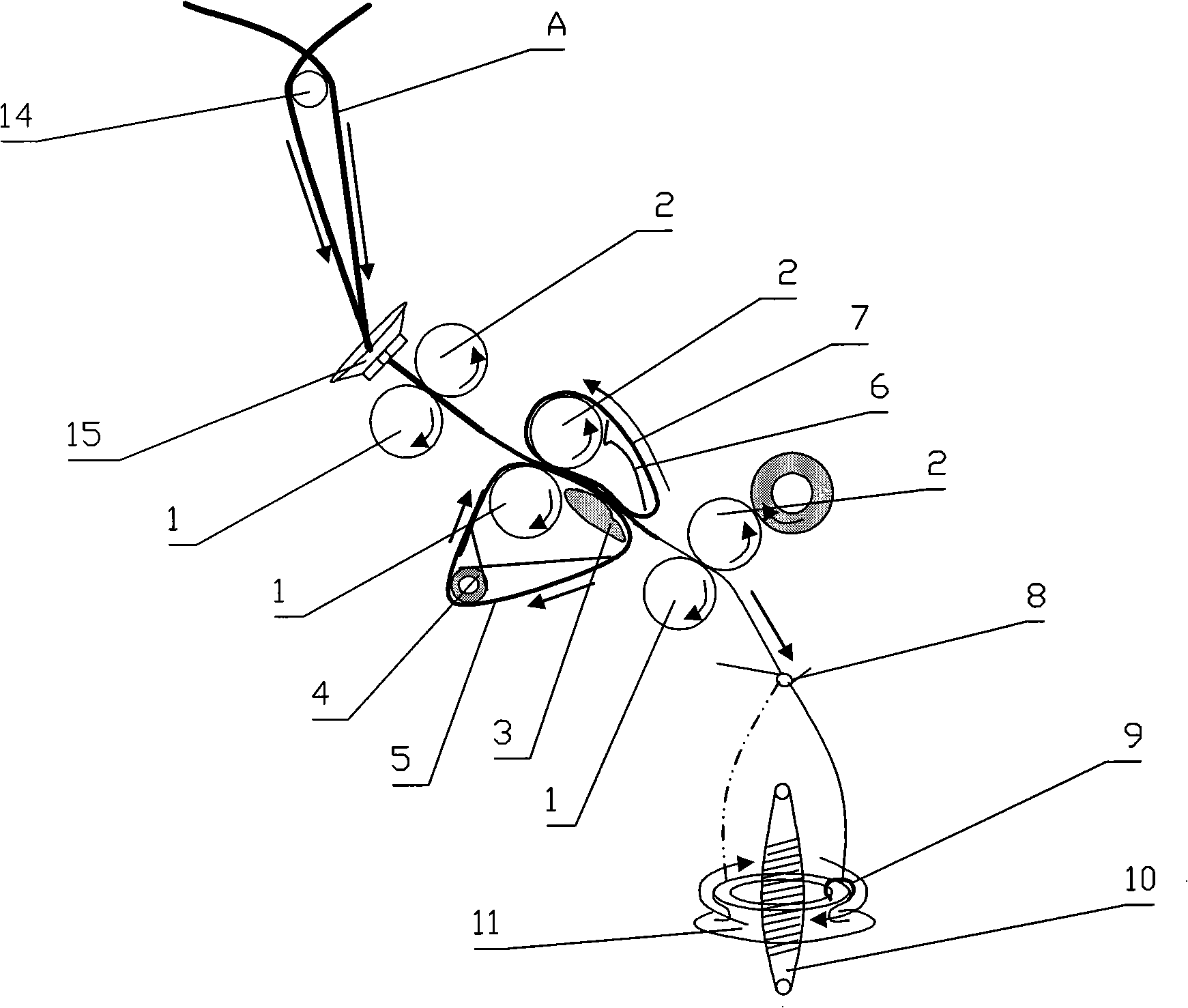

Process for preparing plied yarn by one-step process using textured yarn and highly retractable yarn

The invention relates to a process for preparing plied yarn by one-step process using textured yarn and highly retractable yarn, comprising: having the draw texturising machine as main processing device, drawing and deforming the pre-oriented yarn POY, heating moulding the produced deforming yarn by the heat moulding box and the third drawing roll; meanwhile, setting the fourth and fifth drawing roll on the draw texturising machine, feeding and drawing the highly retractable yarn, sending into network device for combining with the deformation yarn, detecting and oiling by guide, detector and oiling roll, finally winding to obtain the resultant yarn. The invention increases the moulding procedure of the deformation yarn, solves the problem the moulding the yarn combining in a single step. The resultant yarn has a good fastness and uniformity of the network degree, little yarn breakage which can be used to produce the material like wool fabrics, polyester peach skin, suede nap.

Owner:中国石化仪征化纤股份有限公司

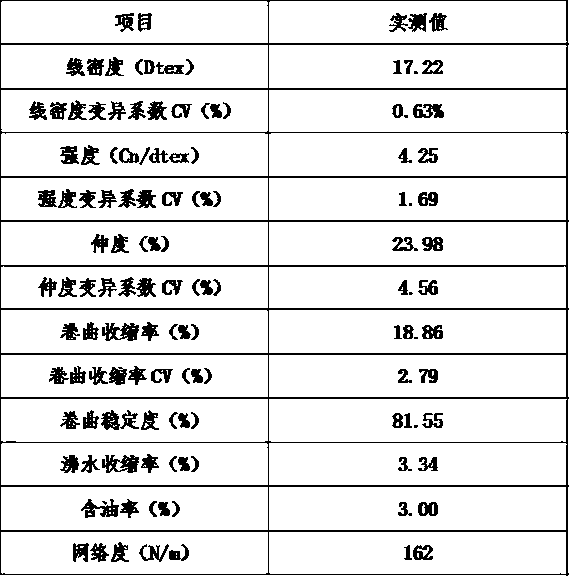

Polyester drawn textured yarn and production process thereof

The invention discloses a polyester drawn textured yarn, which is continuously produced by polyester. The polyester drawn textured yarn is characterized in that the specification is 75D / 288F, and a product has excellent performance. The invention also discloses production process thereof, which comprises the following steps of: performing esterification reaction on pure terephthalic acid and glycol serving as raw materials; then performing pre-polycondensation and final polycondensation to prepare polyester melt for direct spinning; and adopting a POY-DTY circular blast cooling process route, wherein the viscosity of the prepared polyester melt is 0.650. The production process has the advantages of reasonable process, good fiber spinnability, excellent physical indexes, few broken filaments and broken ends, high switching success ratio, 95 percent of full-package rate, smooth subsequent processing, light and soft texture and good style of woven fabrics, and application in fabrics and linings of high-grade down jackets and fabrics of sportswear and casual wear.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

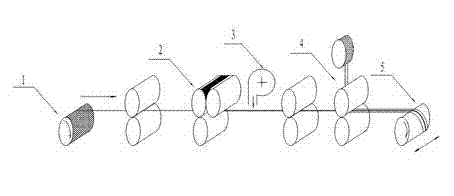

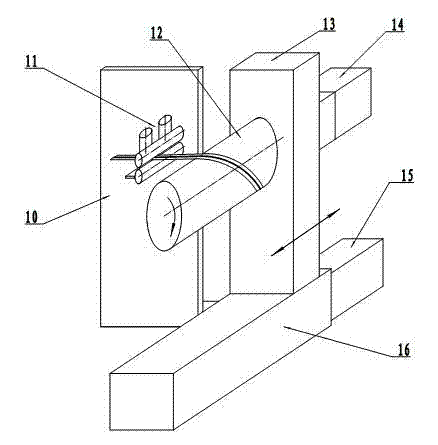

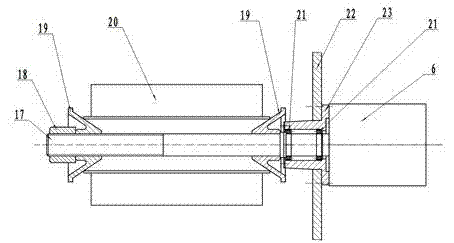

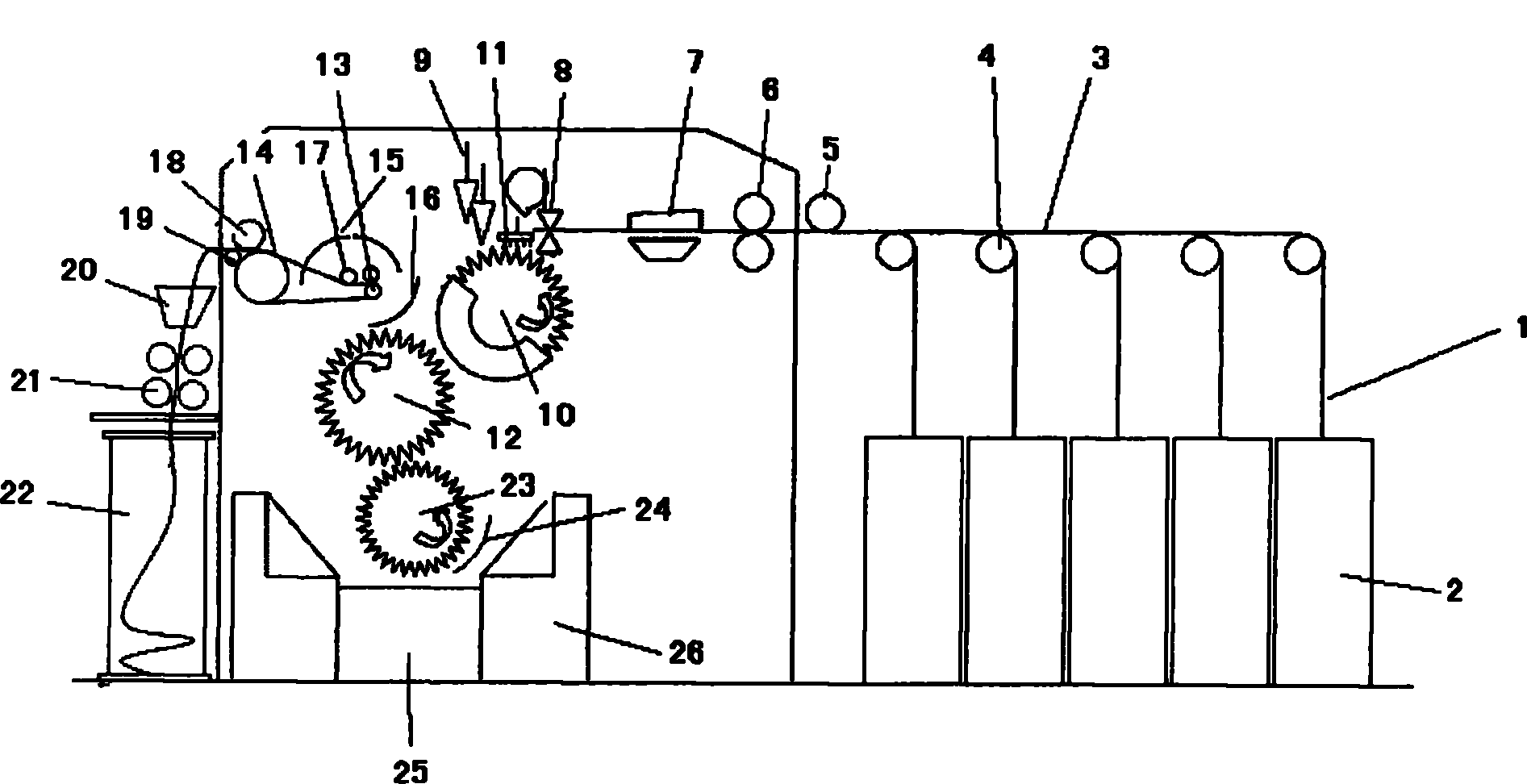

Method for preparing fiber prepreg filaments by hot-melt method and device thereof

The invention relates to a method for preparing fiber prepreg filaments by a hot-melt method and a device thereof. The method provided by the invention comprises the following steps of: 1) placing carbon fiber cone yarns on an unreeling device of a hot-melt prepreg machine according to prepreg production needs; 2) carrying out impregnation on fiber to obtain fiber prepreg; 3) cooling by blowing, entering into a filming device, flattening, spacing, applying and rolling to press and plaster the fiber prepreg at the center of an isolated film to obtain coated fiber prepreg; 4) entering into a reeling device to realize spiral reeling under the control of a reeling controller and a total controller. Therefore, the fiber prepreg filaments are prepared. The invention has the following beneficial effects: the invention is suitable for raw material preparation of fiber reinforced composite products by dry winding or placement moulding production; the reeling length for single fiber prepreg can reach over 3000m, thus reducing the frequency of changing carbon fiber yarns during the production process, raising the production efficiency, decreasing fiber breakage in the product and improving comprehensive performance of the product.

Owner:WUHAN UNIV OF TECH

Prepn process of copolyester capable of being dyed deeply with cationic dye

ActiveCN101020743AImprove rheologySolve the problem of self-aggregationDyeing processMonocomponent polyesters artificial filamentCopolyesterDiol

The preparation process of copolyester capable of being dyed deeply with cationic dye includes the following steps: 1. esterification of terephthalic acid and ethylene glycol in the molar ratio of 1-1.3 under the action of catalyst to prepare glycol terephthalate; 2. adding SIPE solution, polyalkylidene diol or fatty diol derivative and titania solution into glycol terephthalate melt through stirring to produce polycondensation, and pelletizing. Thus produced copolyester has SIPM content of 2.6-3.0 wt%, homogeneously dispersed titania, bright color and excellent texture.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

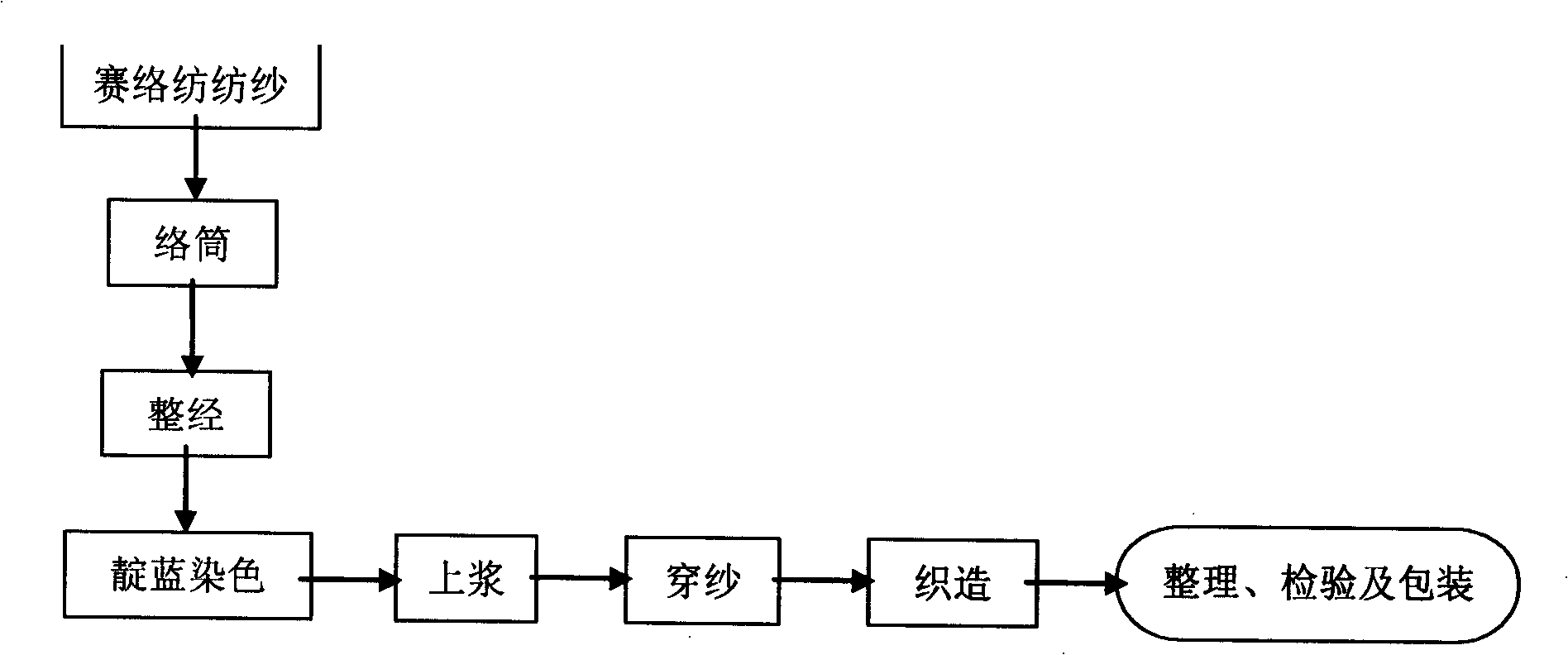

Process for manufacturing sirospun yarn jean facing material

The invention discloses a manufacture technique of a siro yarn jean fabric, in which, firstly an advanced siro yarn spinning technology is adopted to manufacture the siro yarn; the spun siro yarn is wound; then the wound siro yarn which is used as a warp is warped, dyed and starched be manufactured into a beam; then the siro yarn is used as the warp and the siro yarn, a rotor spun yarn or a ring yarn are used as an abb to be woven on a loom according to the fabric weave and the weaving technique of the jean to manufacture a grey fabric and finally the grey fabric is made into a finished product through subsequent finishing. As the siro yarn with better quality is adopted as the warp, the method has the advantages of easy yarn splitting, few broken ends, uniform colorizing, reducible sizing quality requirement as well as high heddle draft and reeding efficiency during the dyeing process, clear cut, uniform tension, few broken ends and stopping, few fly wastes in a workshop and on a machine station as well as being beneficial to the cleanness of the workshop and the maintenance of the machine station when weaving.

Owner:佛山市致兴纺织服装有限公司

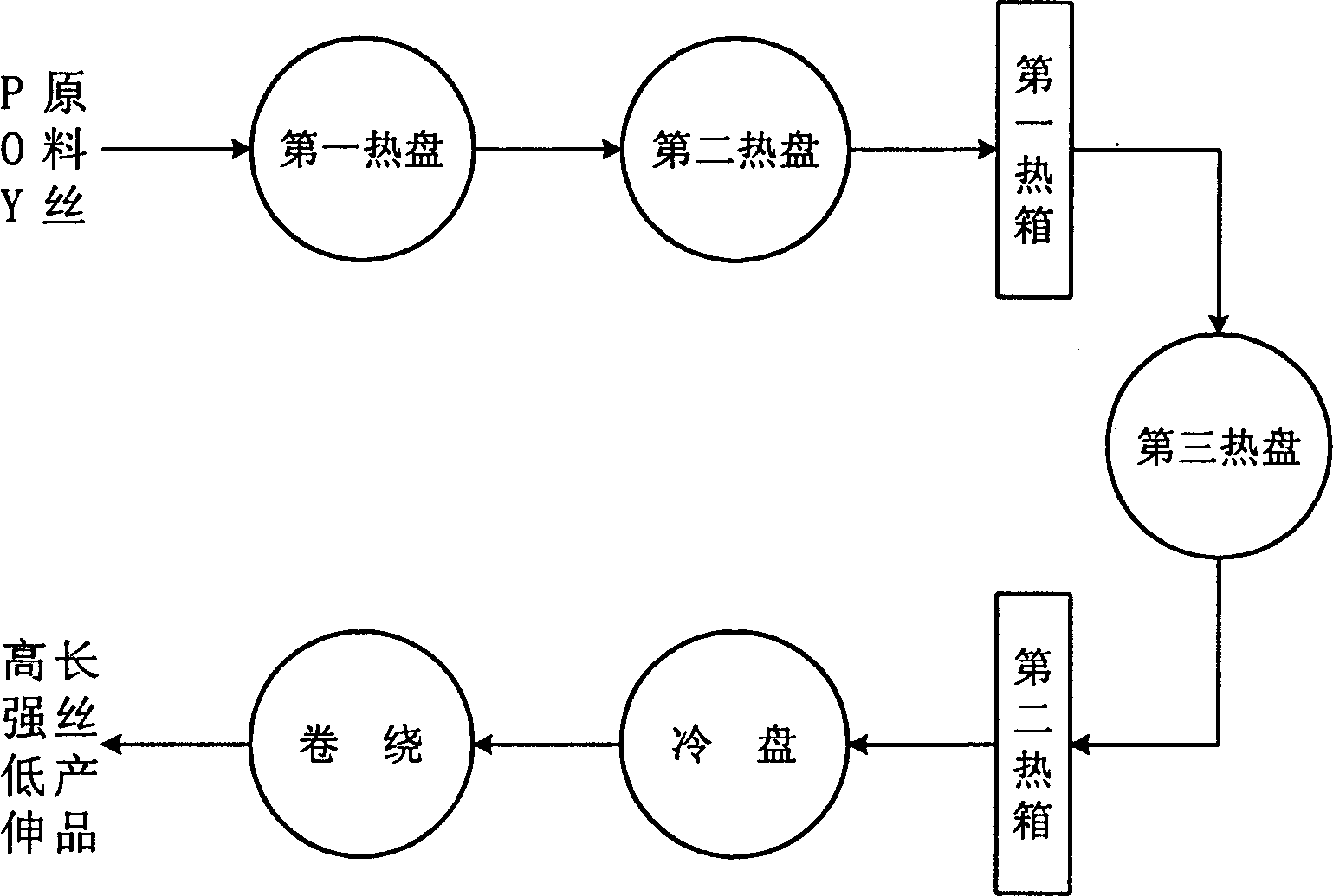

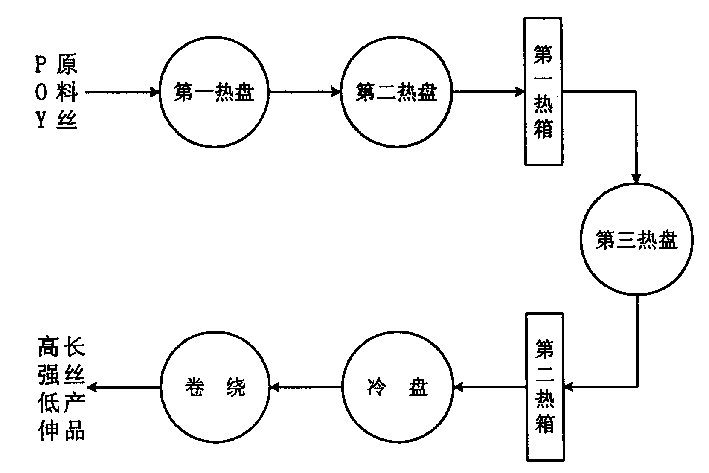

Manufacture of high tenacity low-stretch polyester filaments

InactiveCN1448547AWide variety of sourcesIncrease production capacityMelt spinning methodsYarnHigh intensityUltimate tensile strength

The present invention relates to Dacron producing process, and is especially preparation process of high-strength and low-elongation Dacron filament for sewing thread. The preparation process with routine pre-oriented POY filament includes successive first high-power drafting in the first and the second heating discs, high temperature tensed heat setting in the first heating box and the third heating box, the second drafting and the high temperature relax heat setting in the second heating box. In the process, POY filament has good drafting performance, no teasing and breaking, and the final product has high strength, low elongation and less heat shrinkage.

Owner:SINOPEC YIZHENG CHEM FIBER

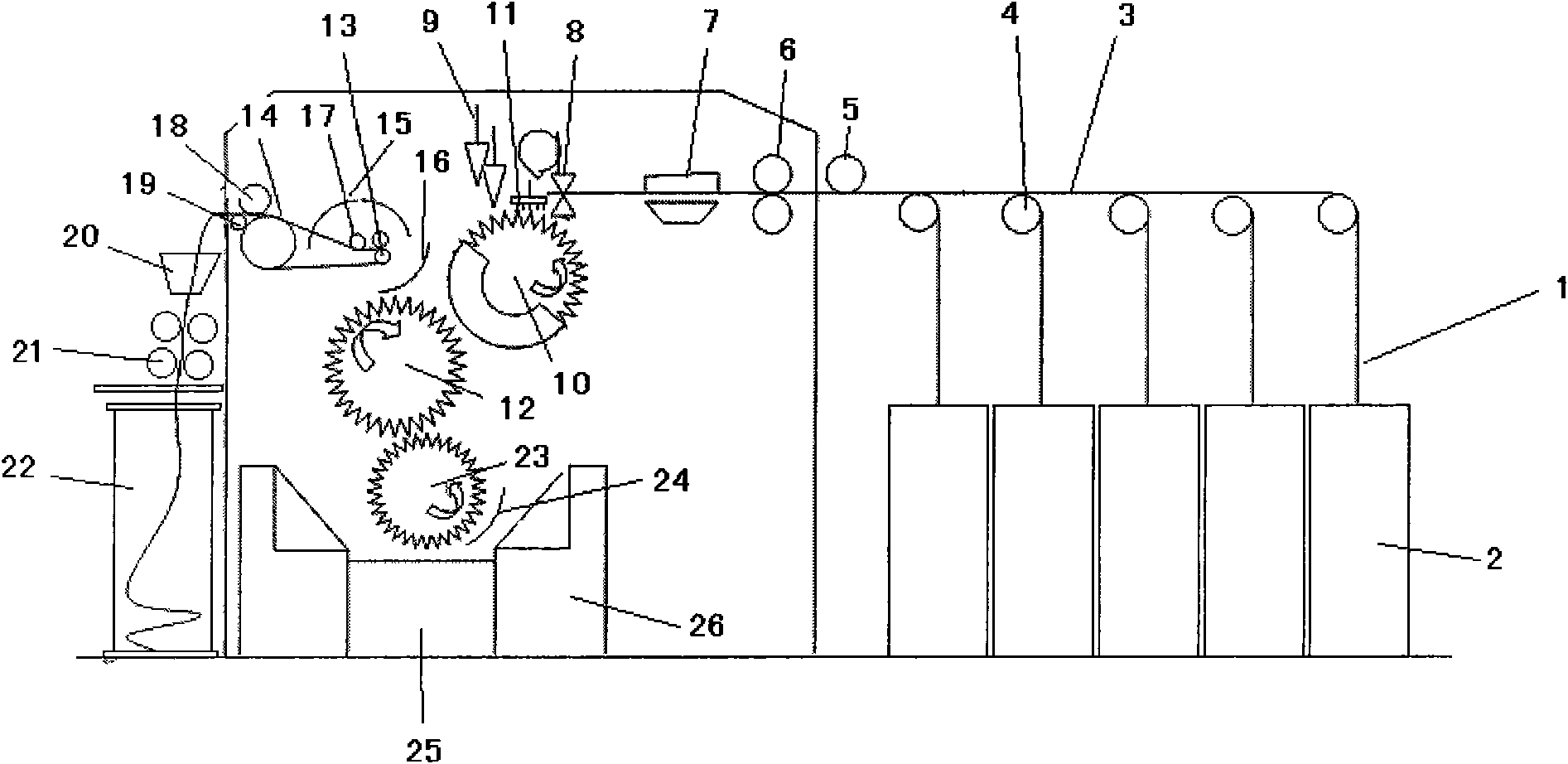

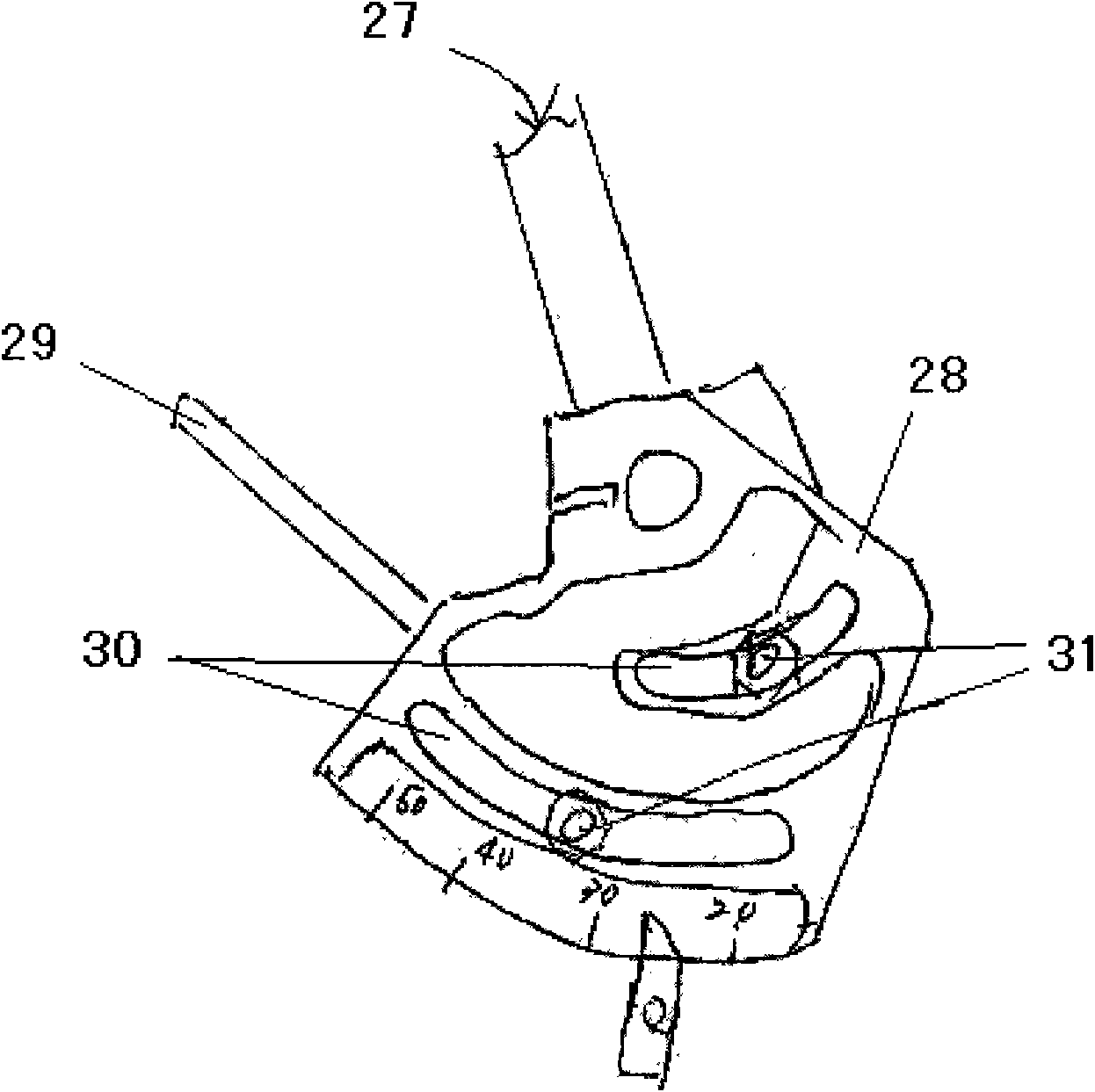

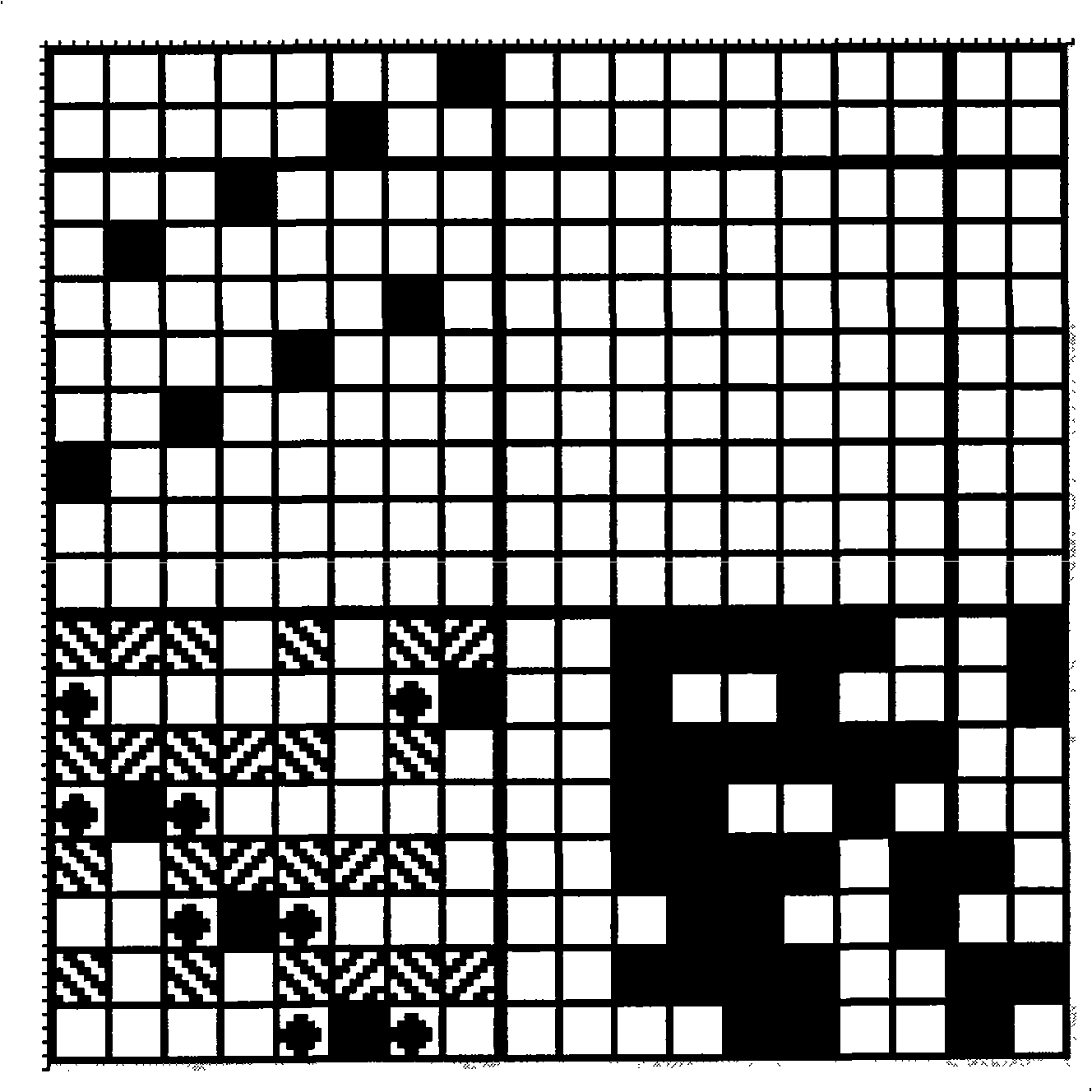

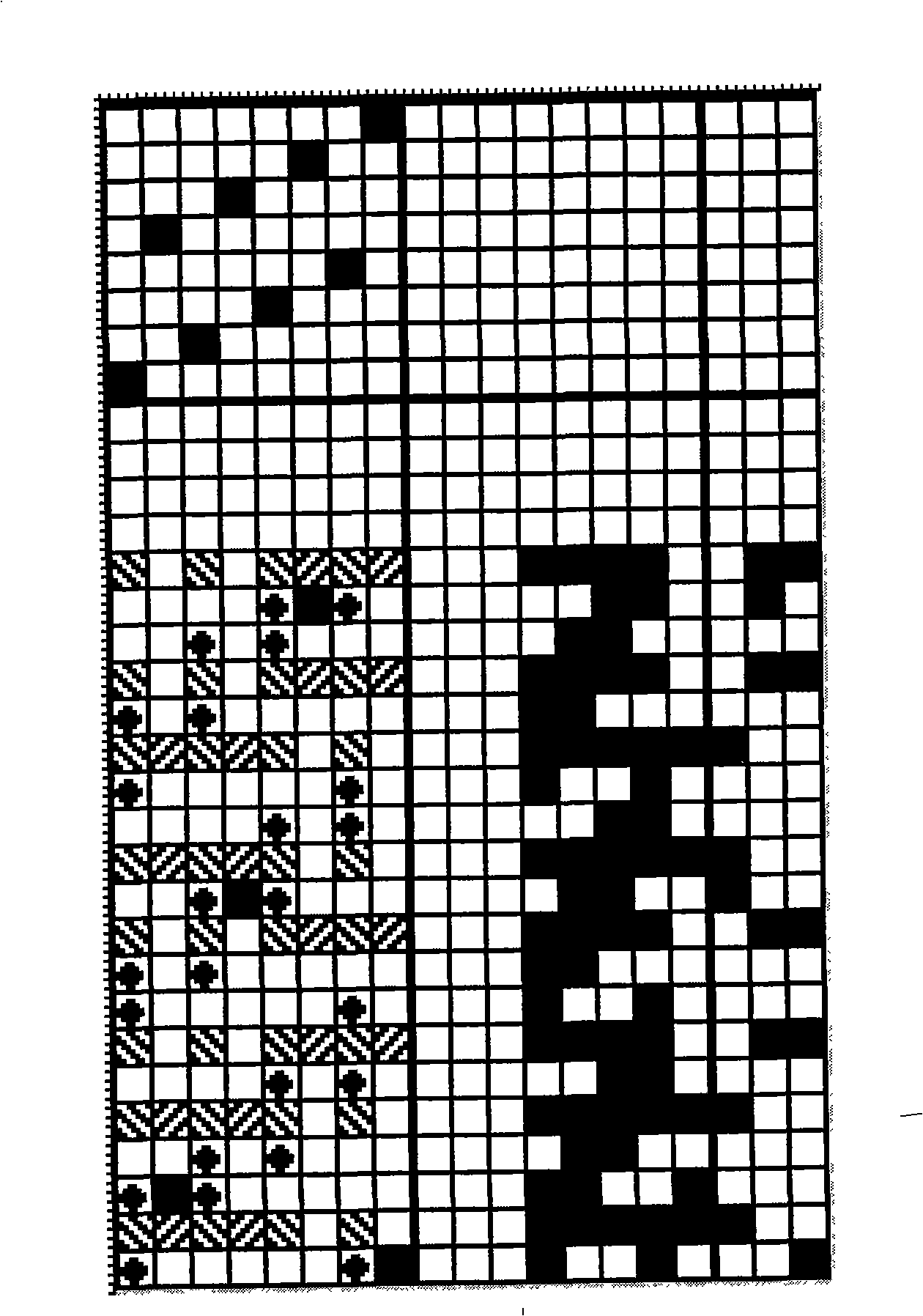

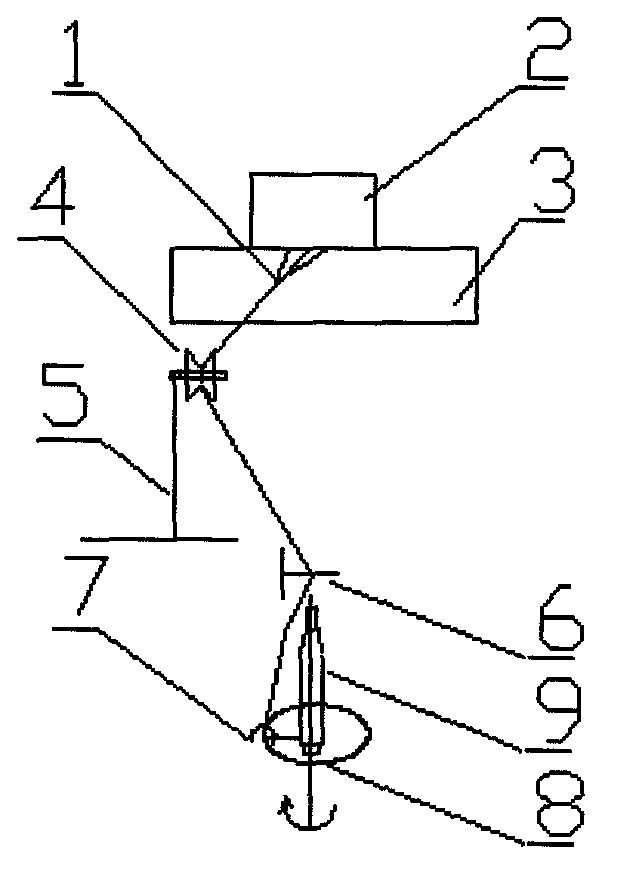

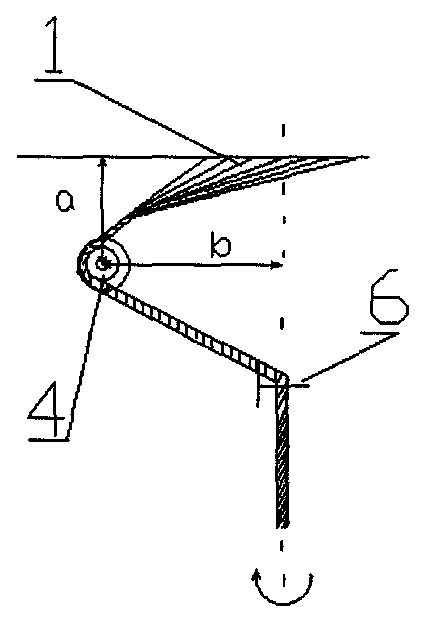

Sesaron combing and sorting method and device

ActiveCN101824676AEfficient removalIncrease the degree of splittingSafety devices for fibre treatmentCombing machinesCombingEngineering

The invention relates to a sesaron combing and sorting method and a device; combed ramie stripes with different specifications and lengths are obtained through a plurality of layers of combing; the split degree of the ramie stripes is decided by comb needle models used in all the layers of combing; and the lengths of the ramie stripes are changed by adjusting a pulling vehicle. In a combing and sorting mechanism of the device, circular comb needle strips are lined in a circumference of 0 to 270 degrees respectively through a rack method and a rack and needle row combined method, and top combs are in a single row or a plurality of rows. A pulling separation mechanism comprises the pulling vehicle, the pulling vehicle is arranged on a regulation frame, the regulation frame is provided with a rod and a circular arc-shaped chute, a bolt is inserted into the circular arc-shaped chute, the bolt is fastened on a frame, the bolt is loosened, and the regulation frame can slide along the circular arc-shaped chute by triggering the rod. At least two pairs of curl rollers are arranged in a strip discharge mechanism. The ramie stripe fibers processed by the method and the device are even and uniform, have short fiber rate, uniform fiber length and low ultra-long length fiber content, so that the fibers are more parallel and straighter, the operation is convenient, the efficiency is high, and the labor intensity is low.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

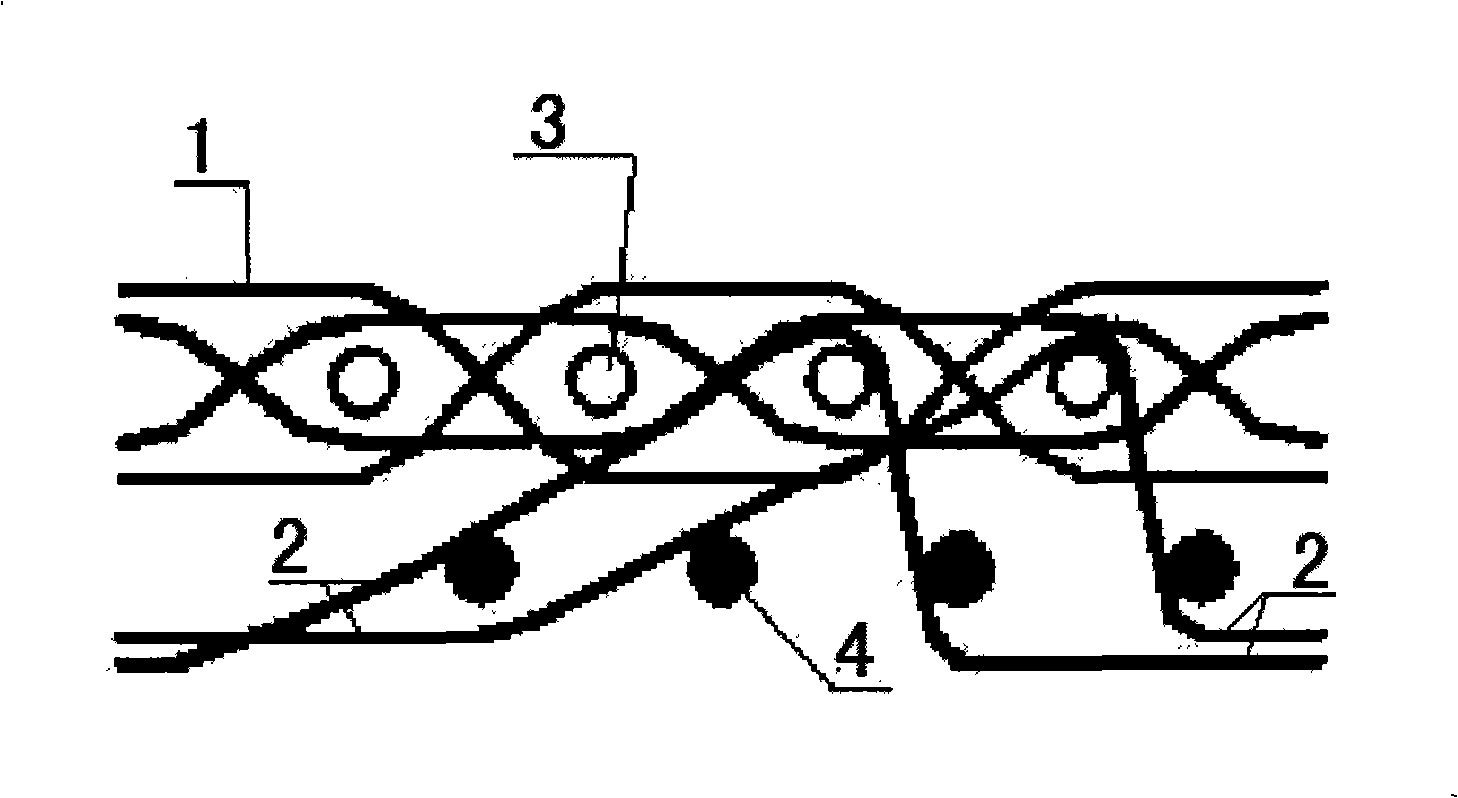

Ramie / terylene double fabric for textile wall cloth and curtain cloth and preparing method thereof

The invention relates to a ramee / terylene double woven fabric used for wall cloth and window blind fabrics, which comprises a surface layer and an inner layer, wherein, the surface layer is weaved by ramee yarns and the inner layer is weaved by terylene yarns, or the surface layer is weaved by terylene yarns and the inner layer is weaved by ramee yarns, and the surface layer and the inner layer are bond into a whole by binding joints which are not exposed on the right side and the reverse side of the fabric. The preparation method of the ramee / terylene double woven fabric adopts the ramee yarns and the terylene yarns as raw materials, and comprises a preparation procedure and a weaving procedure, and the fabric is prepared by adopting a shuttleless loom or loom with shuttles according to selected structure. When weaving by adopting the shuttleless loom, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting and winding; and when weaving by adopting the loom with shuttles, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting, winding and weft winding.

Owner:北京青山绿水苎麻制品有限公司 +1

High-count single-warp single-abb worsted plus material and processing method thereof

The invention discloses a high denier single spinning plus material and the processing method. The plus material is spinned by the wool or mixed spinning by wool and other fiber which the general branch is 35-60S / 1. It includes the worsted spinning product such as gabardine, flower wool, varnish, women wool and tribute wool, or the modified plus material. The material yarn count is 35-60S / 1 and the proportion is 80-300g / m2. The invention has the high yarn product, good producing efficiency, less cut end, low cost. The spinning does not need the yarn gathers and twist process. It can not need sizing, the wool burning process is not needed. Especially in using wool, it can decrease about 20% cost.

Owner:JIANGSU DANMAO TEXTILE

Guide wheel system positioning spinning method

The invention relates to a guide wheel system positioning spinning method and belongs to the technical field of textile processing. Guide wheels are additionally mounted on a front roll of a ring throstle and in front of a front roller. A groove of the guide wheel is V-shaped. A V-shaped bottom of the guide wheel groove is located in one side of a common tangent face of the front roll and the front roller. A shaft of the guide wheel is perpendicular to the common tangent face, yarn is output from a jaw formed by the front roll and the front roller, guided by the guide wheel, and wound on a ring bobbin through a yarn guide hook, a steel collar and a steel wire ring. A non-twist section of the yarn output from a front jaw is eliminated, and spinning efficiency is improved. Yarn texture is more compact, yarn hair is strong, and evenness of yarn is more excellent. The method is suitable for all technical ring throstle spinning systems, simple to modify and convenient to operate and use.

Owner:WUHAN TEXTILE UNIV

Colored polyester filament yarn with diamond blinking effect and method for manufacturing colored polyester filament yarn

ActiveCN103114346AReduce consumptionReduce manufacturing costArtificial thread manufacturing machinesMonocomponent polyesters artificial filamentCooling downWidth ratio

The invention discloses a colored polyester filament yarn with a diamond blinking effect and a method for manufacturing the colored polyester filament yarn. The method includes steps of preliminarily crystallizing and drying super-lustrous polyester chips; melting and extruding the dried super-lustrous polyester chips via a screw extruder and simultaneously injecting color master-batches into the screw extruder by a color master-batch injector; and spinning to obtain a winding yarn; laterally blowing wind to cool down the spun winding yarn; applying oil to the winding yarn by an oiler; feeding the winding yarn to perform drafting for the winding yarn in a drafting procedure; and adding the winding yarn into a net and winding and molding the winding yarn. The colored polyester filament yarn and the method have the advantages that the polyester filament yarn realizes a bright and lustrous effect, the length-width ratio of a flat hole pattern is increased to the greatest extent on the premise of guaranteeing high spinnability, and the style of a product can be affected greatly (a fabric is in a scaly style); fuzziness and broken ends can be greatly reduced by the method; and energy consumption and the production cast can be greatly reduced.

Owner:ZHONGRUN SCI & TECH

Making process of RE luminous fiber

InactiveCN1374415AReduce the impact of high temperature price reductionAvoid damageMelt spinning methodsArtifical filament manufactureTextile technologyPolyester

The present invention relates to the field of textile technology and is especially one making process of luminous RE fiber. The present invention features that stoved viscosity-increasing polyester slice is mixed with luminous agent and nano scale assisant to produce luminous agglomerate; the agglomerate is mixed with bright yarn slice; the mixture is stoved at certain temperature and spun in screw machine to form POY yarn, and the POY yarn is further processed in a high speed stretch yarn machine to produce DTY yarn. The luminous fiber thus produced contains no harmful elements, such as P and Pb, is non-toxic and has no negative effect on human body and environment.

Owner:无锡宏源化纤实验厂

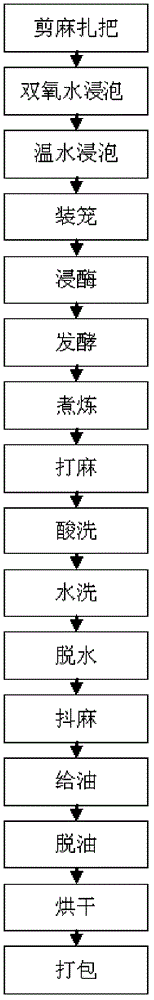

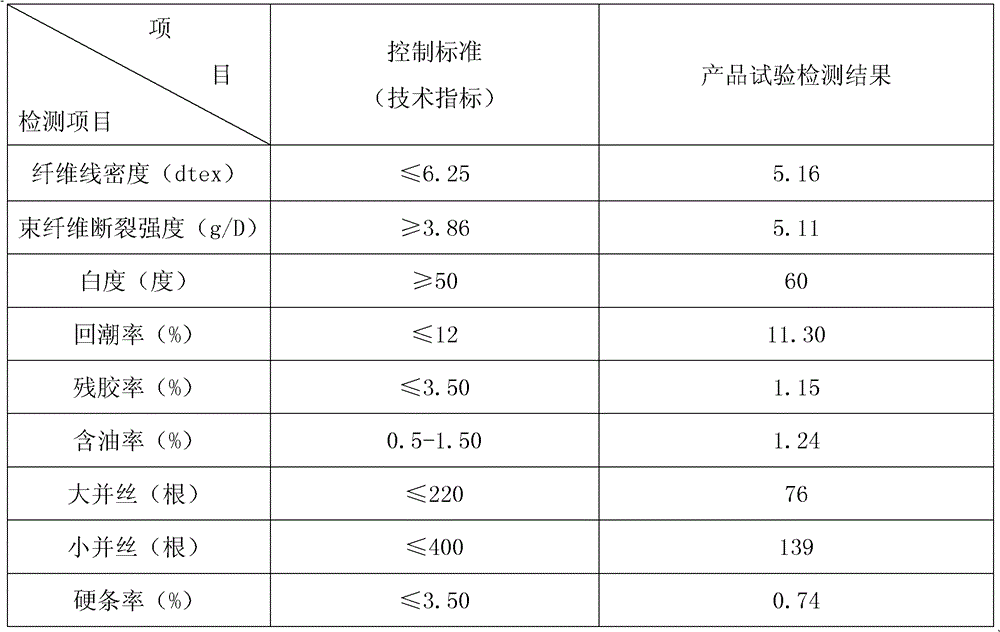

Compound biological enzyme degumming method for ramie

InactiveCN102747434AImprove product qualityReduce manufacturing costVegetable materialChemistryEnzyme

The invention discloses a compound biological enzyme degumming method for ramie. The method mainly comprises: sequentially carrying out treatments of ramie cutting, bundle trussing, soaking with hydrogen peroxide, soaking with warm water, cage filling, immersion in enzyme, fermentation, boiling, ramie bundle beating, pickling, water washing, dehydration, ramie shaking, oil preparing, oiling, deoiling and drying on raw ramie, and carrying out packaging and warehousing on the dried refined ramie. The method of the present invention has the following advantages that: a degumming process is simple, a period is short, the whole process has characteristics of easy control and no pollution, production cost is low, the prepared refined ramie has characteristics of stable and reliable quality, and substantial improvement of combing and spinning performance, wherein a finished product rate is more than 67%.

Owner:安徽省华龙麻业有限公司

Polyamide yarn production technology

InactiveCN104674366AImprove performanceImprove dyeing effectFilament forming substance formingMelt spinning methodsPolyamidePulp and paper industry

The invention discloses a polyamide yarn production technology. The polyamide yarn production technology comprises the following steps of treating raw materials, drying, preparing POY yarns, preparing DTY yarns, carrying out net treatment, classifying and packaging. According to the technology, an anti-oxidant, an anti-static agent and an antibacterial agent are added in the raw materials, so that the performances of a chinlon 66 finished product is improved, and the produced chinlon yarns have the anti-bacterial and anti-static effects; a easily dyeable agent is also added in the raw materials, so that the dyeing performance of the finished product is improved; by utilizing the production processes of the POY and DTY net yarns, yarn floating is prevented, and net breaking is low, so that the fluffy property and the good elasticity of the chinlon yarns are kept, the chinlon yarns also have the cycle property and net points, the stability is good, the compactness of the long yarns is improved, and the handfeel and the comfort of the finished product are effectively improved.

Owner:ZHEJIANG YINAN FIBER TECH

Production method of special-shaped superbright fully drawn yarn-low-elastic yarn

The invention provides a method for producing abnormal superbright fully drawn yarns-low stretch yarns, namely a method for preparing abnormal FDY polyester filament yarns into DTY polyester filament yarns. The main DTY technological flow is as follows: after stretching and twisting, heat-setting, oil application and winding of the abnormal FDY filament yarns, the FDY polyester filament yarns are prepared into the DTY polyester filament yarns. The method solves the problems of poor abnormity maintenance and size stability of the abnormal DTY polyester filament yarns and boardy hand feeling of the FDY polyester filament yarns and compensates the defects in the prior art.

Owner:JIANGSU HENGLI CHEM FIBER

Full-drawn yarn of super fine polyester and manufacturing process thereof

InactiveCN101724923AImprove spinnabilityImprove stylingArtificial filament heat treatmentMelt spinning methodsYarnAdditional values

The invention relates to a full-drawn yarn of super fine polyester manufactured by using polyester continuously. The full-drawn yarn of super fine polyester with a specification of 75D / 192F is manufactured by a one-step process route of circular blowing, cooling and spinning, and the yarn has good performance. The manufacturing process of the full-drawn yarn of super fine polyester comprises the following steps of: esterifying phthalic acid and glycol by using the refined raw material, preparing the melted polyester by the prepolycondensation and the final polycondensation, and directly spinning the melted polyester. The manufacturing process route comprises melted polyester, conveying the melted polyester, a spinning box, a metering pump, a member, circular blowing cooling, bundling and oiling, a paved path, a first hot roller, an interlacer, a second hot roller and winding. The invention has advantages of reasonable manufacturing processing, good fibre spinnabilitty, smooth weaving, light, flexible quality of the fabric and good style of the fabric, thereby meeting weaving request of fabric and lining of high-grade clothes and improving the grade and the additional value of products.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

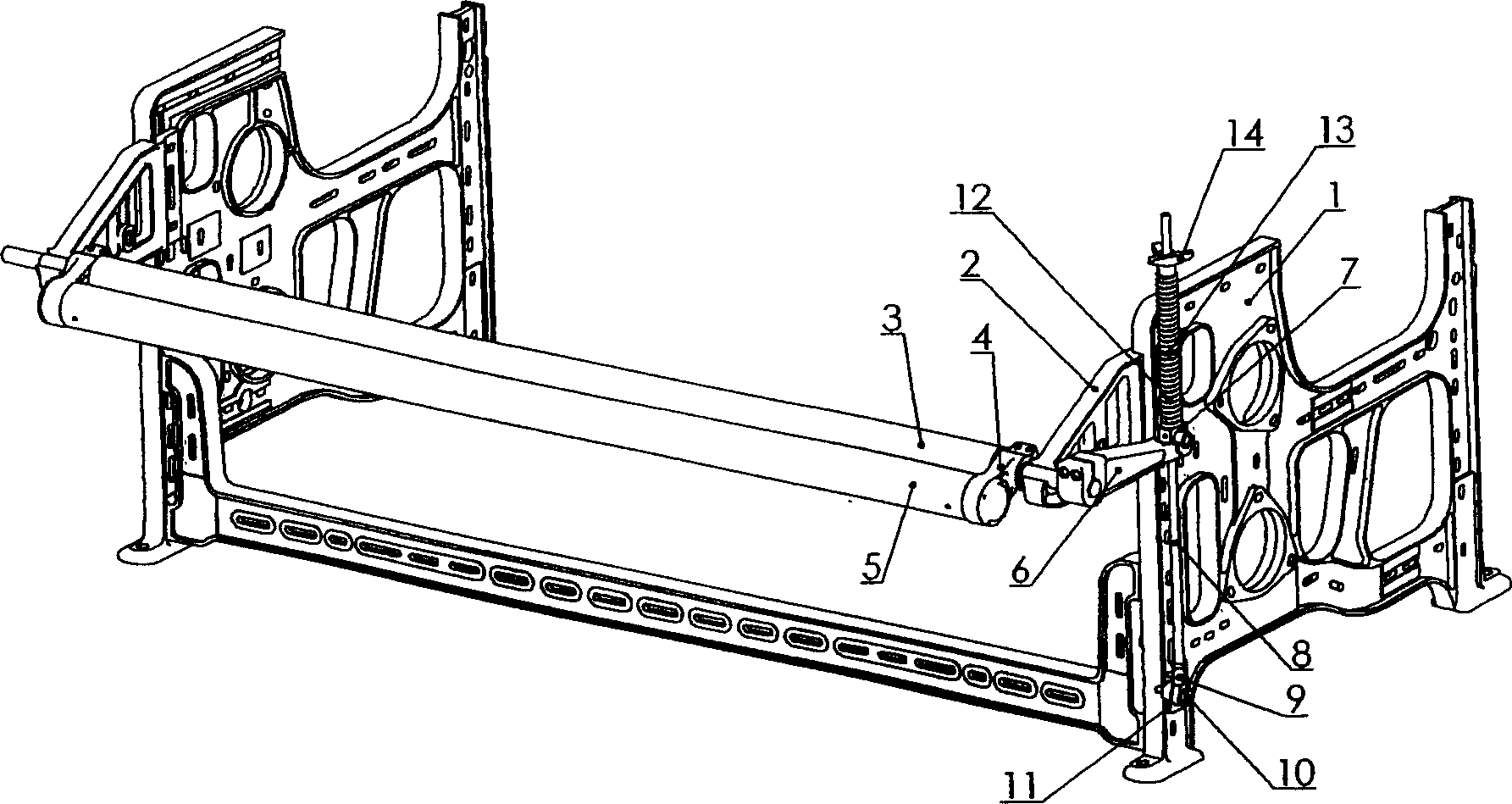

Bottom warp feeding tension balance regulating mechanism for towel rapier loom

The invention relates the towel gripper loom ground warp and run-in warp tension balance controlling mechanism, comprising back rail pin, back bar conjunction, ranging arm conjunction, stretch roll conjunction installed on ranging arm conjunction by axle bearing, balance bar fixed on back bar conjunction, counterbalancing mass on the back end of balance bar. The lower end of tension balance bar is fixed on wall plate, and the tension balance bar comprises adjustment hand-wheel, compression spring, spring positioning disk and counterbalancing mass, and the adjustment hand-wheel is connected with tension balance bar by thread. The mechanism has the following advantages: 1 reducing cutting end; 2 reducing friction and reducing broken ends; 3 making the tension on loom stable.

Owner:邹荣金

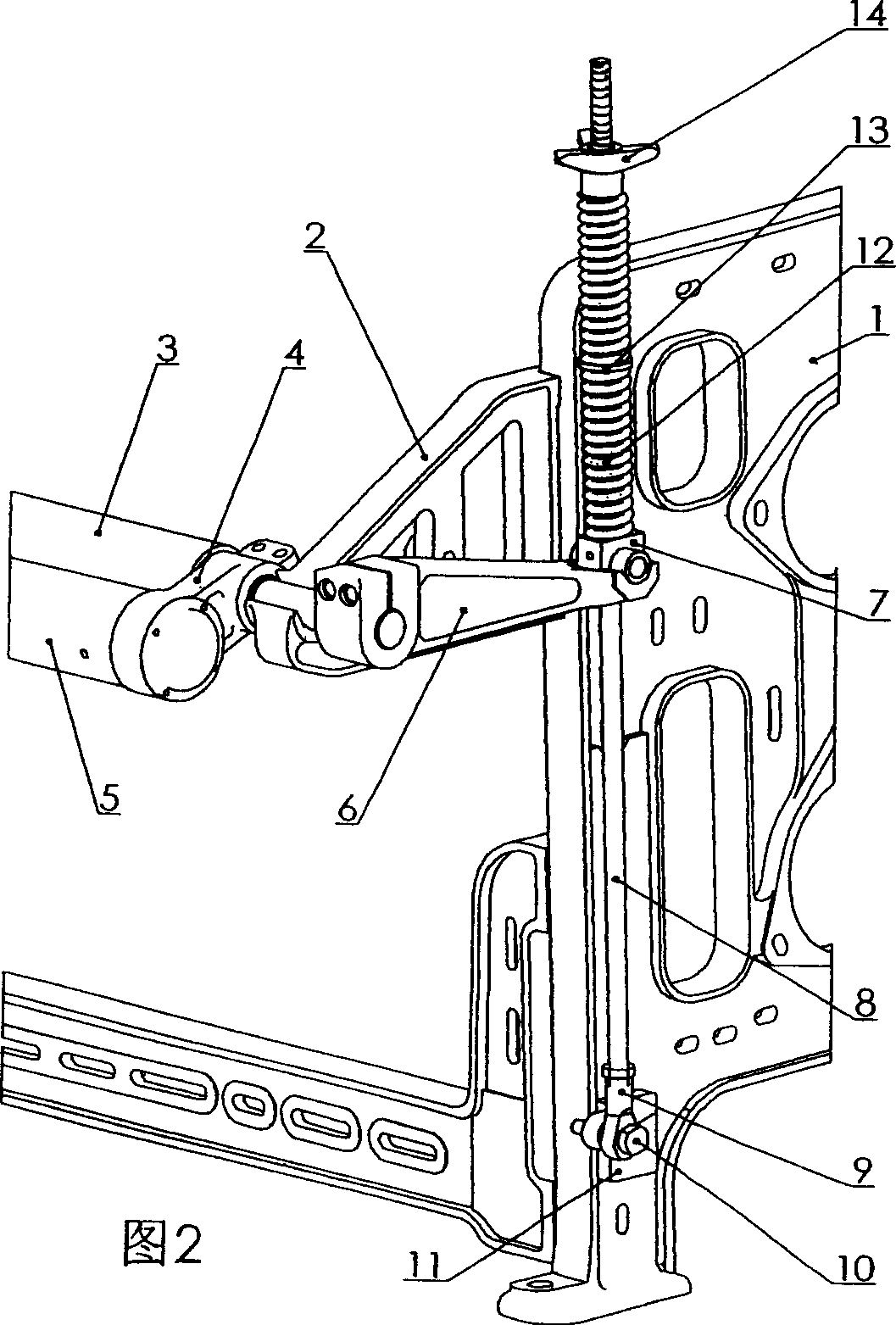

Double-fibre compact spinning device

The invention provides a novel double-fiber close spinning device, consisting of two main parts of a double top roller subassembly and a hollow roller subassembly, wherein in the double top roller subassembly, a top roller(2) and a top roller(4) are arranged on a top roller frame(5), on which an airflow orientation block(11) is arranged by a positioning board(10), a spring(3) is arranged on the top roller frame(5), a permanent magnet(12) is arranged on the airflow orientation block(11); in the hollow roller subassembly, a wide vacuum nozzle(7), an air suction base(9) and a baffle board(6) are jointly assembled in hollow roller rings(8), which are arranged on a main shaft(14) in pairs; the double top roller subassembly is arranged on a cradle(1) and exerts pressure on the hollow roller subassembly. The yarn spun by the device has few hairy feathers and little fly waste and is low in fiber strength.

Owner:陆节 +1

Polyphenylene sulfide short fiber spinning oil and preparation method thereof

ActiveCN103409855ASuitable for antistaticSuitable smoothnessSynthetic polymer filament chemical after-treatmentSpin effectAntistatic agent

The invention discloses a polyphenylene sulfide short fiber spinning oil and a preparation method thereof. The polyphenylene sulfide short fiber spinning oil comprises the following compound raw materials by weight percentage: 25-50 percent of antistat, 15-25 percent of smoothing agent, 18-35 percent of saturant, 5-20 percent of emulsifier and 2-8 percent of modifier. According to the weight percentage of each raw material component, the accurately metered antistat, smoothing agent, saturant, and emulsifier are pumped into a reaction pot, heated to 50-80 DEG C, and uniformly mixed; the modifier is pumped into the reaction pot, agitated for 1-3 h, cooled, filtered, unloaded and packaged. The polyphenylene sulfide short fiber spinning oil has good anti-static electricity performance, smoothness, saturation and the like, is uniform and stable in oil loading, can ensure smooth operation of spinning production and postprocessing working procedure, and satisfies production requirements on spinning effect and the mechanical performance of the fiber.

Owner:天津工大纺织助剂有限公司

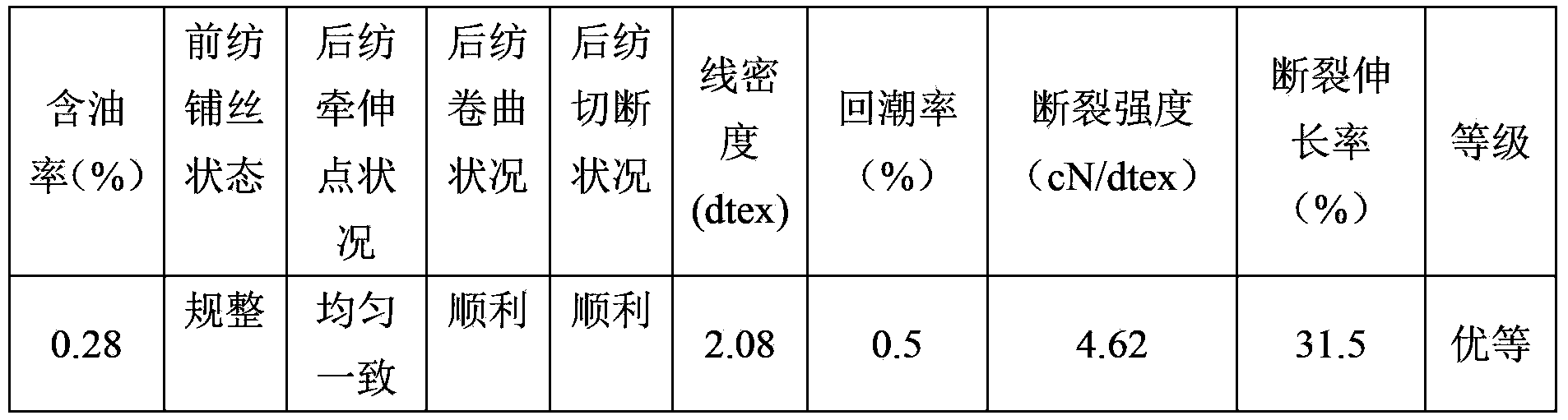

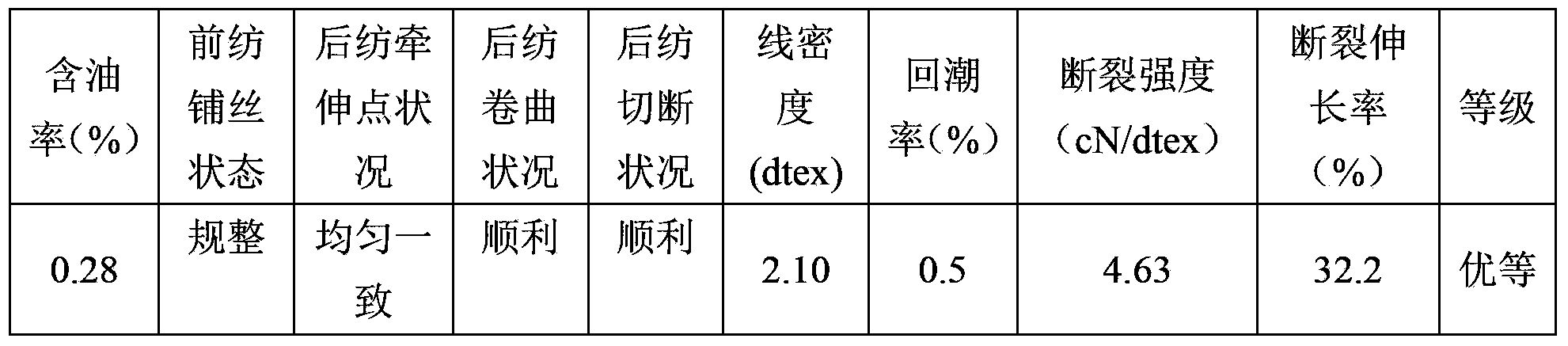

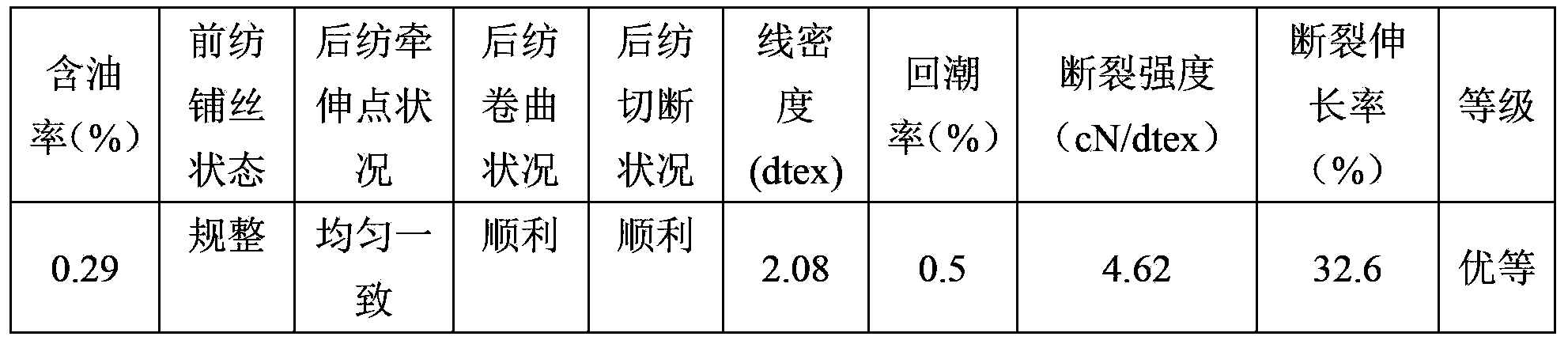

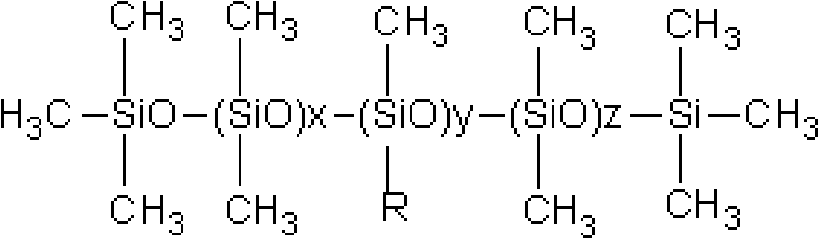

Finishing oil for manufacturing of continuous silicone carbide fiber and application process thereof

ActiveCN101613952AReduce broken endsImprove clusteringFibre treatmentFibre chemical featuresProduction lineEmulsion

The invention discloses finishing oil for the manufacturing of continuous silicone carbide fiber and an application process thereof. The finishing oil for the manufacturing of the continuous silicone carbide fiber is a modified organic silicone oil water solution or emulsion prepared by adding water into modified organic silicone oil, and the modified organic silicone oil is polysiloxane containing different active groups. The finishing oil has a simple preparation method. The finishing oil is applied to the manufacturing of the continuous silicone carbide fiber, has the characteristics of simple process, convenient operation, easy implementation on production lines of SiC fiber and the like, can effectively reduce the mechanical damage to PCS fiber when the PCS fiber passes through guide rolls, reduce broken filaments and broken ends of the fiber, improve the convergence and filament bundling strength of the fiber, and improve the mechanical properties and the uniformity of the prepared SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

Water-borne copolymerized (amide-ester) as well as preparation method and application thereof

The invention discloses water-borne copolymerized (amide-ester) as well as a preparation method and application thereof. Caprolactam, meta-benzene sulfonate, binary carboxylic acid or ester thereof and dihydric alcohol are adopted as materials, heated up firstly to carry out esterification reaction, then carry out ring-opening caprolactam reaction by preserving heat and pressure, and finally carry out polycondensation to prepare the water-borne copolymerized (amide-ester). The resin is not only good in water solubility, but also excellent in adhesion force; while being used for spinning and sizing, the water-borne copolymerized (amide-ester) has extremely strong adhesive force for polyamide fiber (chinlon), and can attach feathers very well, so that a head breaking phenomenon due to a plurality of regenerated feathers as the sizing agent is attached with the feathers is avoided; finally, the production efficiency and quality of fabrics can be improved.

Owner:江苏光辉粘合科技有限公司

Photochromic fiber making method

InactiveCN104047069AExtended drying timeTo achieve slice drying effectFilament forming substance formingMelt spinning methodsMasterbatchYarn

The invention discloses a photochromic fiber making method which is realized by the following steps: (1) under vacuum conditions, drying light nylon slices with a low melting point, cooling to the room temperature, and excluding vacuum to discharge; (2) taking a certain quality of the dried nylon slices obtained by the step (1), adding a photochromic agent, a dispersing agent, a coupling agent, a heat stabilizer and an antioxidant, melting at 165 to 180 DEG C to prepare masterbatch; (3) taking the following raw materials by mass to mix: 70-90% of the nylon slices obtained by the step (1) and 10-20% of the masterbatch obtained by the step (2), and preparing photochromic POY (pre-oriented yarn) by melt spinning; and (4) drawing the photochromic POY to obtain the photochromic FDY (fully drawn yarn). The photochromic fiber is good in color changing effect, good in comprehensive application performance and low in production cost.

Owner:YIXING ZHENGTAI CHEM FIBER +1

Method for preparing ultra-fine denier skin-affinity polyester filaments

The invention discloses a method for preparing ultra-fine denier skin-affinity polyester filaments. The method comprises the steps of POY precursors, pre-interlace, first feeding roller, first deformation heat box, cooling plate, false twister, second feeding roller, intermediate interlace, second heat box, third feeding roller, oiling roller, DTY winding shaping and spinning cake inspection, wherein the intermediate interlace procedure can be removed, the temperature of the first deformation heat box is 165 DEG C-175 DEG C, the temperature of the second heat box is 130 DEG C-140 DEG C, the draft ratio is 1.58-1.68, the false twist ratio is 1.66-1.80, and the interlace air pressure is 0.03-0.15 MPA. The method has the advantages of being simple and easy to operate, fabric prepared by polyester filaments prepared by means of the method has the advantages of being more flexible, good in comfort performance and strong in visual and tactile feeling.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Preparation method of PPS fibers with self-extinguishment and free of molten drops

ActiveCN105113209AHigh glass transition temperatureImprove creep resistanceFibre typesFiberTemperature resistance

The invention discloses a preparation method of PPS fibers with self-extinguishment and free of molten drops. The preparation method comprises the following steps: soaking a pure polyphenylene sulfide fiber serving as a raw material into an oxidant solution, controlling the soaking temperature and the soaking time by selecting the type of an oxidant, adjusting the oxidization degree of sulfur atoms on the surface of the fiber, performing solvent separation after an reaction, and washing and drying the PPS fibers. The preparation method is simple and feasible, and a complicated fiber modification method is eliminated; the performances, such as oxidization resistance, high-temperature resistance, creep resistance and molten drop resistance, of the prepared PPS fibers are greatly improved.

Owner:TIANJIN POLYTECHNIC UNIV

Silver-element fibre spinning technology

The invention relates in particular to a new sliver-element fibre spinning technology, belonging to the spinning engineering field of textile industry production, comprising the following steps: pre-opening silver-element fibre to 80% by an opening machine; maintaining the blowing integrated beater speed in the blowing process of less than 600r / m and the beater frequency of sliver-element fibre per gram of less than 0.55; blocking the noil airdraft opening when carding cotton; using a flatbed drawing frame and a wool-top-proof conducting bar device with the drawing funnel caliber of 5.2mm; keeping the roving cycles of 33-38 cycle / 10cm, spinning frame guide stroke of 3-6mm; maintaining the groove drum speed in spooling less than or equal to 700 meter / minute and using a photoelectric type flaw-cutting device. Compared with the existing technology, the invention has the advantages of effective control of noil rate of blowing and cotton carding, small fibre damage, little nep, removal of belt roller wound by drawing and roving, smooth passage and winding, less broken ends, higher intrinsic quality of semi-manufactured goods, less flaws and better resultant yarn quality.

Owner:SHANGHAI FEILIAN TEXTILE

Polyester DTY (draw texturing yarn) oil agent and preparation method thereof

The invention discloses a polyester DTY (draw texturing yarn) oil agent and a preparation method of the polyester DTY oil agent. The polyester DTY oil agent comprises the following compounded raw materials in percentage by weight: 75-95 percent of a smoothing agent, 3-15 percent of an emulsifying agent and 2-15 percent of an additive, wherein the sum of all components is 100 percent. The preparation method of the polyester DTY oil agent comprises the following process steps: according to the weight percentage of all raw material components of the polyester DTY oil agent, extracting the accurately metered smoothing agent into a reaction kettle, performing reaction at the temperature of 30-70 DEG C, and uniformly stirring the smoothing agent; then extracting the emulsifying agent and the additive into the reaction kettle, stirring the emulsifying agent and the additive for 3-8h, and performing cooling, filtering, discharging and packaging to obtain the polyester DTY oil agent.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of high-flowability positive ion modified copolyester

The invention relates to a preparation method of high-flowability positive ion modified copolyester. Binary acid I, dihydric alcohol I and high-flowability branched structure modifiers are uniformly mixed and then subjected to esterification reaction, and isophthalic acid-5-sodium sulfonate and dihydric alcohol II esterification products are led in after esterification reaction and subjected to pre-condensation reaction and final polycondensation reaction to prepare the high-flowability positive ion modified copolyester. The high-flowability branched structure modifiers are more than one of pyromellitic anhydride, cyclopentane tetracarboxylic anhydride, benzophenone tetracarboxylic dianhydride, trimellitic anhydride, mellophanic dianhydride, pyromellitic acid, cyclopentane tetracid, benzophenone tetracid, trimellitic acid and mellophanic acid, and the dihydric alcohol II is more than one of butanediol, pentanediol, hexanediol, heptanediol, octylene glycol, nonanediol and decanediol. Two modified components are introduced, so that flow-activation energy is remarkably reduced, acting force of the copolyester and tube walls in the flowing process is reduced, and melt viscosity loss iseffectively controlled.

Owner:DONGHUA UNIV

Herbal mixed polyamide fiber and preparation method

InactiveCN108998852AExtended service lifeGood antioxidantArtifical filament manufactureMonocomponent polyamides artificial filamentOxidation resistantChemistry

The invention provides herbal mixed polyamide fiber, and belongs to the field of textile fibers. The polyamide fiber comprises the following formulating raw materials in parts by weight: 100-120 partsof polyamide slice, 0.5-1 part of a dispersant, 0.2-0.8 part of zinc stearate, 1.5-2 parts of SanstabTPO330 and 15-25 parts of functional fusion masterbatches. The herbal mixed polyamide fiber prepared by a preparation method provided by the invention has the advantages of good antioxidation and heat resistance, and under the condition of 150 DEG C thermal oxidation treatment, the yellowing gradeis higher than 4.0. During preparation of the herbal mixed polyamide fiber prepared by the preparation method provided by the invention, a herbal plant-sourced component is added, and the prepared herbal mixed polyamide fiber has the functionality of a plant extract itself, has moisture-absorbing and antistatic effects, and also has the characteristics of antioxidation, light resistance, heat resistance and long service life.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Elastic nonwoven and preparing method thereof

InactiveCN106637681AAchieve a sense of drapeAchieve resilienceMelt spinning methodsNon-woven fabricsElastomerPolymer science

The invention relates to elastic nonwoven, and belongs to the technical field of nonwoven. The elastic nonwoven is prepared from, by weight, 50-80% of ethyl propylene coelastomer, 17-49% of polypropylene chips and 1-3% of flexibility modifier. The preparing method comprises the steps of mixing the polypropylene chips, the flexibility modifier and ethyl propylene coelastomer in proportion, and stirring and mixing the mixture to be uniform; feeding the mixture into a screw extruder and conducting melting plastification mixing through heating, then conveying the material into a spinning die to be subjected to spinning, and adopting narrow-gap positive pressure drafting and sideblowing cooling to form strands; after the strands cool down, making the strands sucked into a drafting machine under the negative pressure of the inlet of the drafting machine, and conducting cross lapping with the subsidiary of a suction ventilator below a web curtain to form a fluffy fiber layer; using a sealing roller to conduct prepressing and sizing on the fluffy fiber layer, afterwards using a hot mill to conduct hot milling adhesion reinforcing to form the elastic nonwoven. According to the elastic nonwoven and preparing method thereof, the problem that the nonwoven is low in ductility is solved; meanwhile, flexibility and elasticity of the nonwoven are improved.

Owner:ZHANGJIAGANG JUNMA NON WOVEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com