Water-borne copolymerized (amide-ester) as well as preparation method and application thereof

A technology of copolymerization and amide, applied in the field of textile sizing water-based copolymer (amide-ester) and its preparation, can solve the problems of insufficient adhesion of polyamide fibers, poor adhesion hairiness, affecting production efficiency and fabric quality, etc. Water-solubility, good adhesion, and the effect of reducing regenerated hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

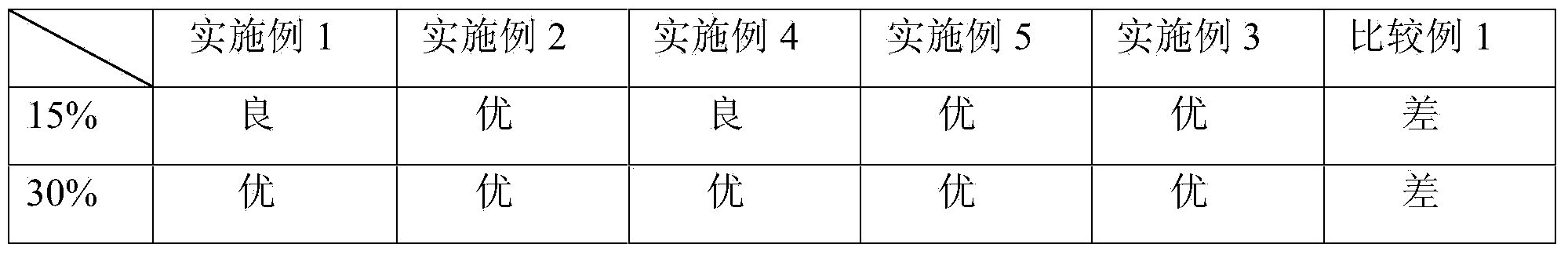

Examples

Embodiment 1

[0031] Dimethyl isophthalate-5-sodium sulfonate 15kg (molecular weight: 296.23, 50.64mol), isophthalic acid 4.8kg (molecular weight: 166.13, 28.89mol), phthalic anhydride 25kg (molecular weight: 148.11, 168.79mol ), 4.7kg of terephthalic acid (molecular weight: 166.13, 28.29mol), 23kg of ethylene glycol (molecular weight: 62.068, 370.56mol), and 0.9g of dibutyltin oxide were put into a 100L stainless steel reactor, under nitrogen Under the system, stir at a speed of 55-80rpm, and gradually raise the temperature to 210°C and keep it warm for 1.5 hours, then raise the temperature to 220-260°C and react for about 2 hours. When the quality of the by-product water reaches 90% of the theoretical value, add 2.5kg of caprolactam (molecular weight: 133.16, 18.77mol) and 0.8g of sodium phosphate, maintained at 250°C and 2Mpa pressure, reacted for 1 hour. Cool down to about 200°C, add 15g of antimony trioxide and 12g of phosphoric acid, continue to heat up and decompress slowly, adjust t...

Embodiment 2

[0034] Dimethyl isophthalate-5-sodium sulfonate 15kg, isophthalic acid 14kg (molecular weight: 166.13, 84.27mol), phthalic anhydride 16.7kg (molecular weight: 148.11, 112.75mol), terephthalic acid 4.7kg kg (molecular weight: 166.13, 28.29mol), ethylene glycol 25.5kg (molecular weight: 62.068, 410.84mol), and 1g of manganese acetate were put into a 100L stainless steel reactor, stirred at a speed of about 60rpm under a nitrogen system, and Gradually raise the temperature to 210°C and keep it warm for 1 hour, and then raise the temperature to 220-240°C for about 2.5 hours. When the quality of the by-product water reaches 96% of the theoretical value, add 4kg caprolactam (molecular weight: 133.16, 30.04mol) and 0.8g of sodium phosphate, maintain the temperature at 255°C, under the pressure of 2.5Mpa, react for 1 hour. Cool down to about 190°C, add 16g of isobutyl titanium and 15g of phosphorous acid, continue to heat up and decompress slowly, adjust the speed to about 60rpm, cont...

Embodiment 3

[0037] 11.6kg of isophthalic acid-5-sodium sulfonate (molecular weight: 268.24, 43.24mol), 12kg of isophthalic acid (molecular weight: 166.13, 72.23mol), 17.1kg of phthalic anhydride (molecular weight: 148.11, 115.45mol), 9.6kg of terephthalic acid (molecular weight: 166.13, 57.79mol), 22kg of ethylene glycol (molecular weight: 62.068, 354.45mol), and 1.2g of dibutyltin oxide were put into a 100L stainless steel reactor, under nitrogen system, Stir at 70rpm, gradually raise the temperature to 220°C and keep it warm for 1 hour, then raise the temperature to 235°C for about 2.5 hours, when the quality of the by-product water reaches 92% of the theoretical value, add 6kg caprolactam (molecular weight: 133.16, 45.06 mol) and 1g of sodium phosphate, maintain the temperature at 250°C and the pressure of 2.5Mpa, and react for 1.5 hours. Cool down to about 200°C, add 15g of antimony trioxide and 10g of phosphorous acid, continue to heat up and decompress slowly, adjust the speed to ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com