Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158results about How to "Improve clustering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

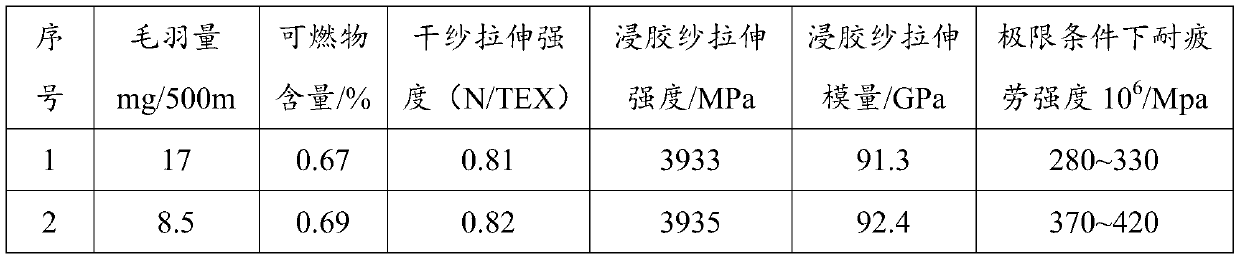

Preparation method of carbon fiber precursor oil agent

InactiveCN104179019ASimple process operationStrong permeabilityCarbon fibresTemperature resistanceEmulsion

The invention discloses a preparation method of a carbon fiber precursor oil agent. The method comprises the following steps: putting a composite emulsifier and a characteristic composite modified silicone oil in a weight ratio of (1-4) to (3-10) into a high-shear emulsifying machine; evenly stirring; adding a composite assistant; dropwise adding an appropriate amount of deionized water; stirring for 20-120 minutes; and adjusting the pH value to 3-10, thereby obtaining a light blue, light yellow or white emulsion, namely the carbon fiber precursor oil agent. According to the method, the technology operation is simple and can be directly applied to an industrial production line. When in use, the oil agent prepared by the method has good permeability, high temperature resistance and good process stability, and can well enhance the bunching performance of fibers and well protect the fibers in the whole process of pre-oxidation as well as in the initial stage of low-temperature carbonization, thereby greatly reducing the phenomena of monofilament adhesion and doubling, reducing the surface detects of the fibers, and enhancing the performance of the fibers.

Owner:ZHONGFU SHENYING CARBON FIBER

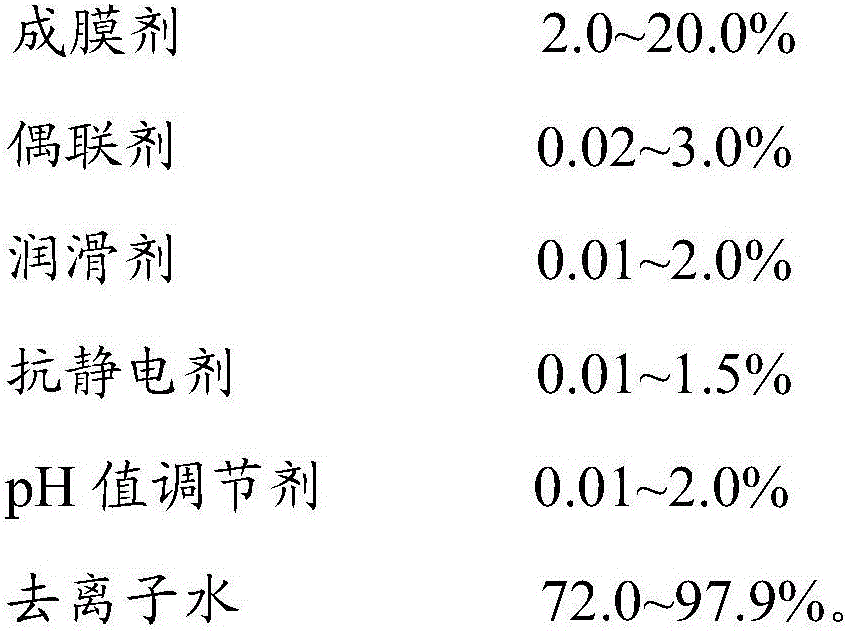

Chopped glass fiber sizing agent for bulk molding compounds (BMC) for reinforcing thermosetting resin

The invention discloses a chopped glass fiber sizing agent for reinforcing thermosetting resin, which is prepared by the components by weight percent: (1) 0.2-1.5% of coupling agent; (2) 3.0-20.0% of binding agent that is cross-linked polyurethane emulsion or the mixture of the cross-linked polyurethane emulsion and medium and high molecular weight epoxy emulsion, wherein the contents of the cross-linked polyurethane emulsion and the medium and high molecular weight elastic epoxy ester emulsion are based on the respective solid content; (3) 0.0-1.2% of lubricating agent; (4) 0.05-0.8% of antistatic agent; (5) 0.1-2% of pH value conditioning agent; and (6) the balance of deionized water, wherein the total weight of all the components is 100%. The chopped glass fiber sizing agent improves the bundling property of chopped glass fiber, reduces the broken filament, improves the mixing uniformity and the fluidity of the glass fiber and the BMC resin paste, and improves the mechanical strength and the appearance performance of BMC products.

Owner:JUSHI GRP CO

Quick-frozen roughage dumpling wrapper and preparation method thereof as well as quick-frozen roughage dumpling

The invention provides a quick-frozen roughage dumpling wrapper and a preparation method thereof, wherein the preparation method comprises the following steps: mixing 4-6 weight parts of roughage with 0.5-1.5 weight parts of corn starch, then adding the obtained mixture into water at a temperature more than 80 DEG C so as to make dough with boiling water; adding 3-5 weight parts of wheat flour into the obtained dough, uniformly mixing the wheat flour with the dough, then kneading the mixture into dough; and cutting the dough into pieces, then rolling the pieces into dumpling wrappers. The invention also provides a quick-frozen roughage dumpling and a preparation method thereof, wherein the preparation method comprises the following steps: putting stuffing on the dumpling wrapper above andkneading the dumpling wrapper so as to obtain a dumpling; and carrying out freeze preservation on the obtained dumpling. The dumpling wrapper prepared by using the method provided by the invention isrich in nutrition and high in gluten degree, does not contain chemical additives, and can be stored in a refrigeration house for a long time without cracking.

Owner:赫秋软

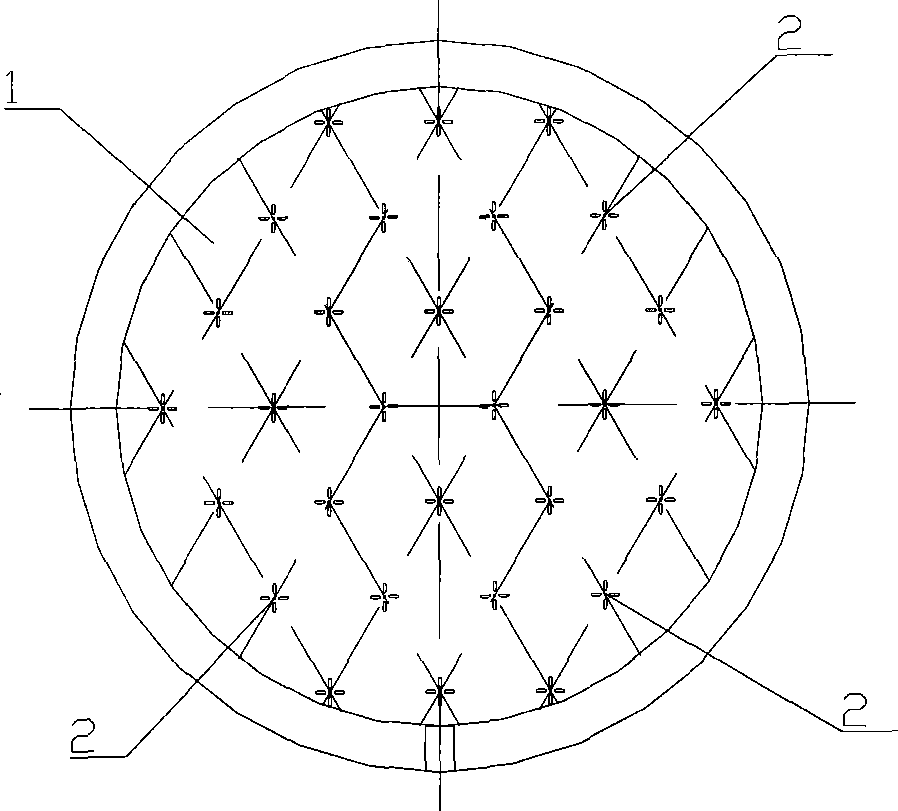

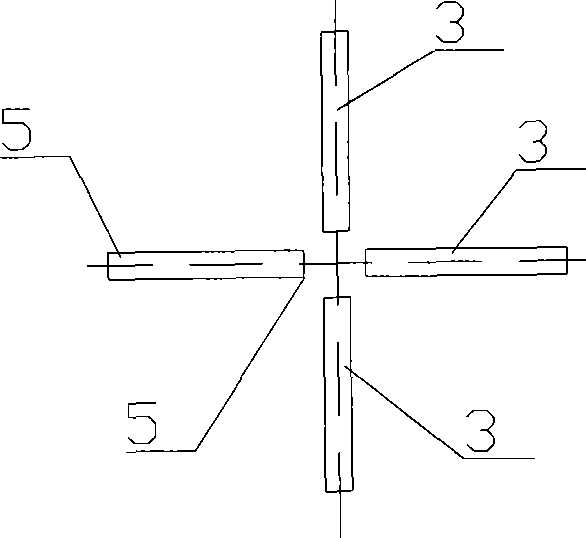

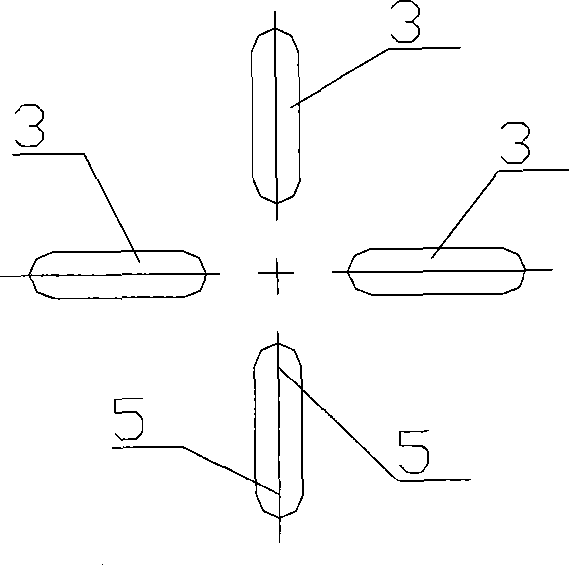

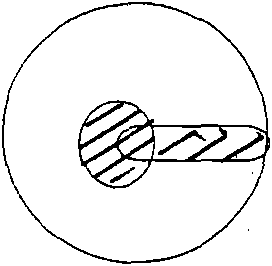

Strange-shaped fibre processing technique and spinning jet used in the technique

InactiveCN101429685AHigh degree of abnormalityImprove fiber qualityArtificial filament physical treatmentFibre typesFiberPolymer science

The invention belongs to the field of chemical fiber shaping, and discloses a technology for processing a profiled fiber and a spinneret plate used by the technology. The processing technology comprises the following steps: a. high polymer melts are spouted from spray slits of each spinneret orifice on the spinneret plate via heating and pressurizing; b. the high polymer melts spouted from the spray slits of each spinneret orifice expand because of Barus effect, and are spliced one another to form the profiled fiber; and c. the processed profiled fiber is oiled. The structure of the spinneret plate is as follows: a plurality of spinneret orifices are distributed on the plate body to form a spinneret orifice array, wherein each spinneret orifice comprises at least two immediate spray slits. The profiled fiber has excellent degree of profile, good performances such as silkiness, hydroscopic property.

Owner:GUANGDONG XINHUI MEIDA NYLON

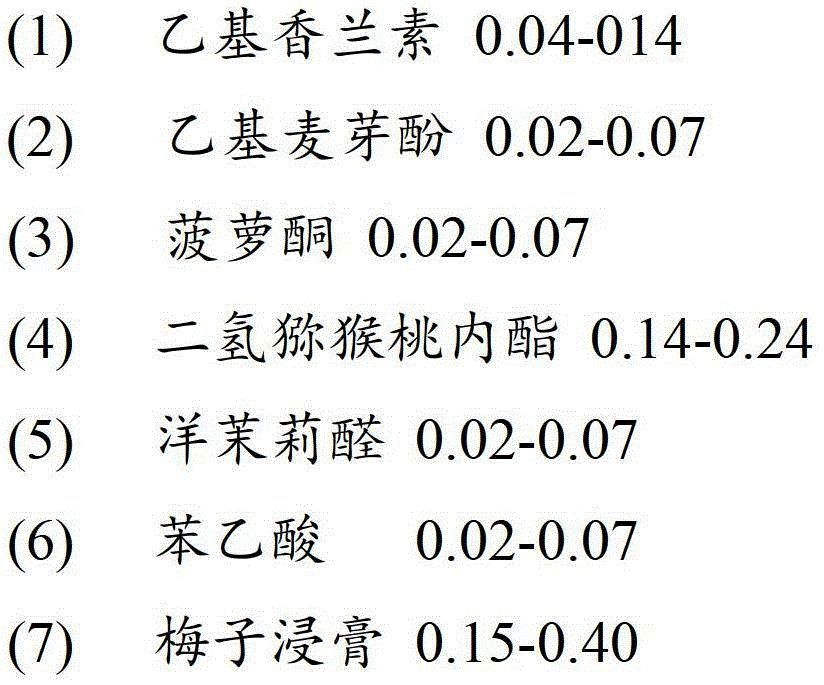

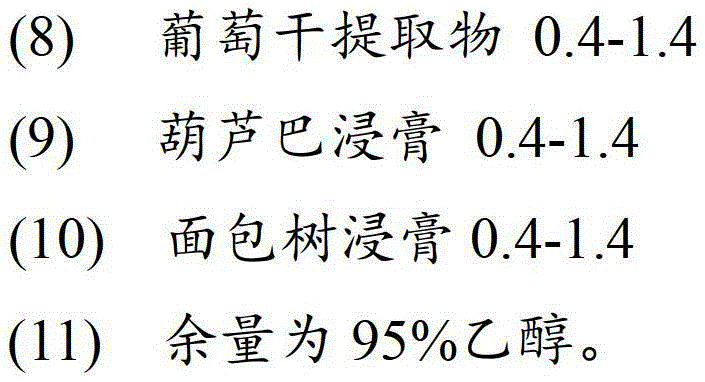

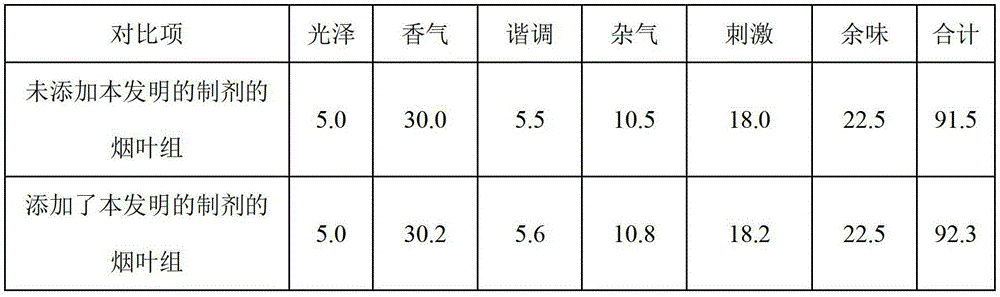

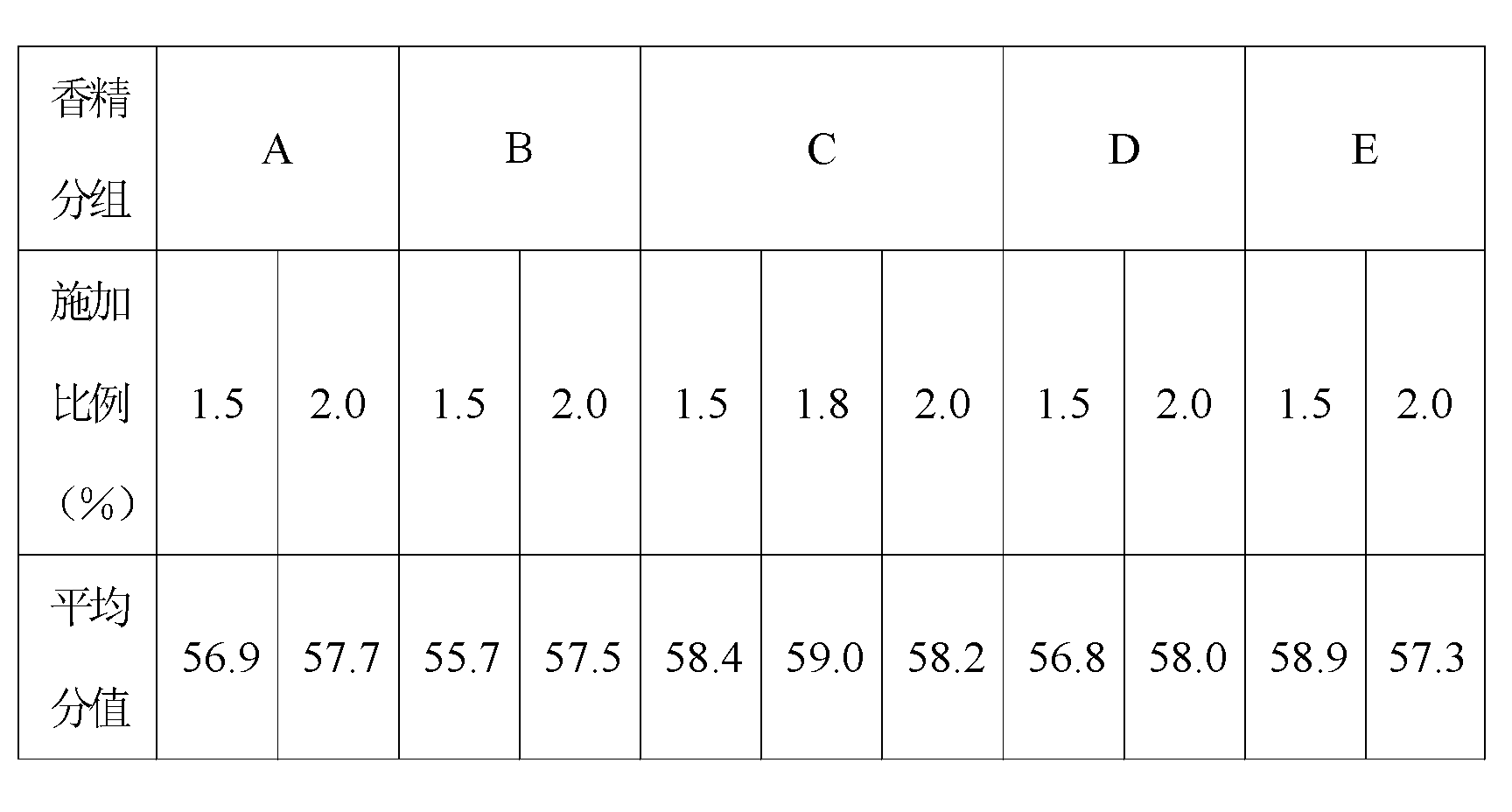

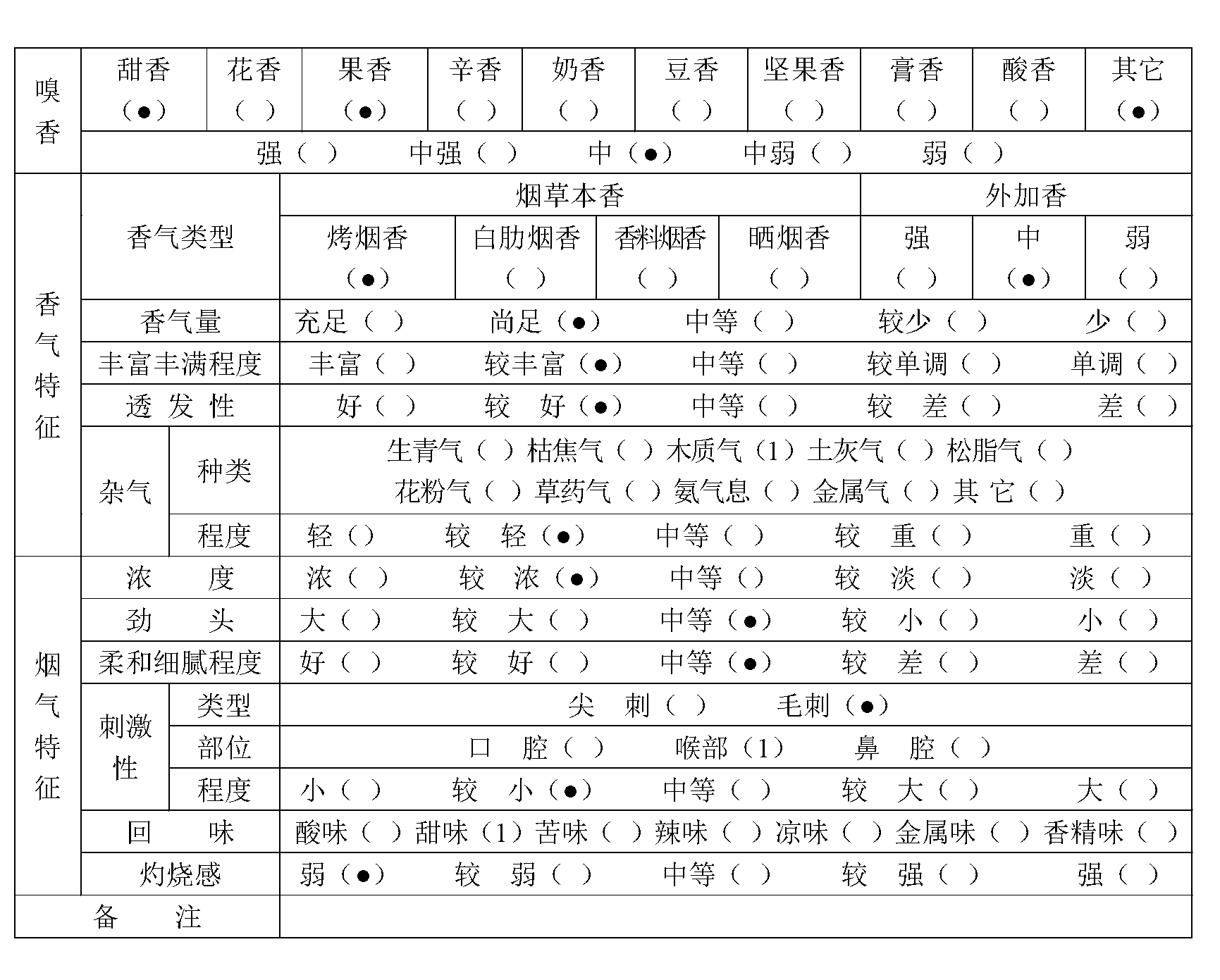

Enriching and thickening functional cluster substance preparation capable of obviously increasing richness and lumping of cigarette smoke

ActiveCN103141936AIncrease the sense of thicknessImprove clusteringTobacco treatmentEssential-oils/perfumesPhenyl acetic acidEthyl vanillin

The invention discloses an enriching and thickening functional cluster substance preparation capable of obviously increasing richness and lumping of cigarette smoke, relates to a tobacco additive, and aims to provide the enriching and thickening functional cluster substance preparation capable of obviously increasing the richness and the lumping of the cigarette smoke, which has the capabilities of enriching, thickening and improving the cigarette aroma and richness. The preparation is characterized in that the raw materials for preparing the preparation comprise the following basic raw materials in percentage by weight: ethyl vanillin, ethyl maltol, pineapple ketone, dihydroactinidiolide, heliotropin, phenyl acetic acid, plum extract, raisin extract, fenugreek concrete, breadfruit concrete and the balance of 95 percent ethanol. The preparation can be widely used in all the cigarette factories throughout the country.

Owner:SHENZHEN TOBACCO IND

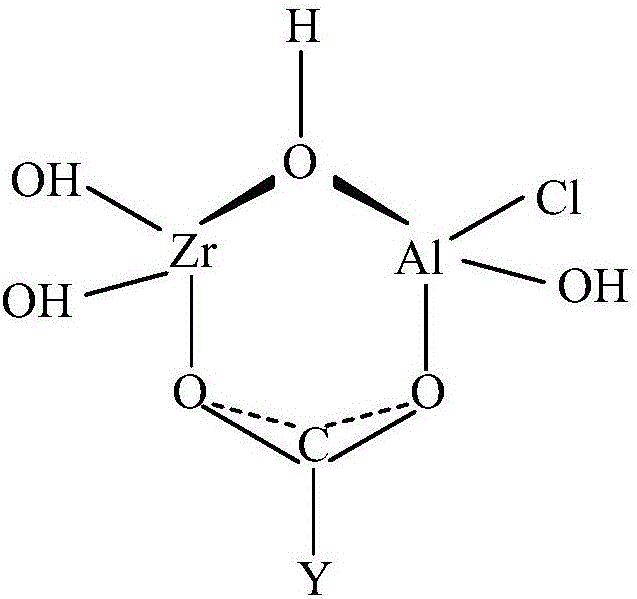

Infiltration agent of chopped glass fiber for reinforcing cement

The invention discloses an infiltration agent of chopped glass fiber for reinforcing cement. The infiltration agent comprises the following components by weight percent: (1) 0.2-1.5% of coupling agent which is combination of 3-amino propionic triethoxy silane and 3-methacryloyloxyethyl propyl trimethoxysilane; (2) 3.0-30.0% of a film-forming agent, which is crosslinked polyacrylic dispersion or combination of crosslinked polyacrylic acid dispersion and a bisphenol A epoxy emulsion with medium-high molecular weight, wherein the molecular weight of the epoxy resin in the bisphenol A epoxy emulsion with medium-high molecular weight is 1200-6000; (3) 0.01-2.0% of a nonionic lubricant; (4) 0.05-1.0% of organic antistatic agent; (5) 0.1-2% of pH value modifier; (6) 63.5-96.64% of deionized water. A glass fiber yarn produced by using the infiltration agent has the advantages of being good in bundling property, easy to chop, and resistant to alkaline corrosion of cement, the produced cement product is high in mechanical strength, and the product is bright and clean in appearance.

Owner:JUSHI GRP CO

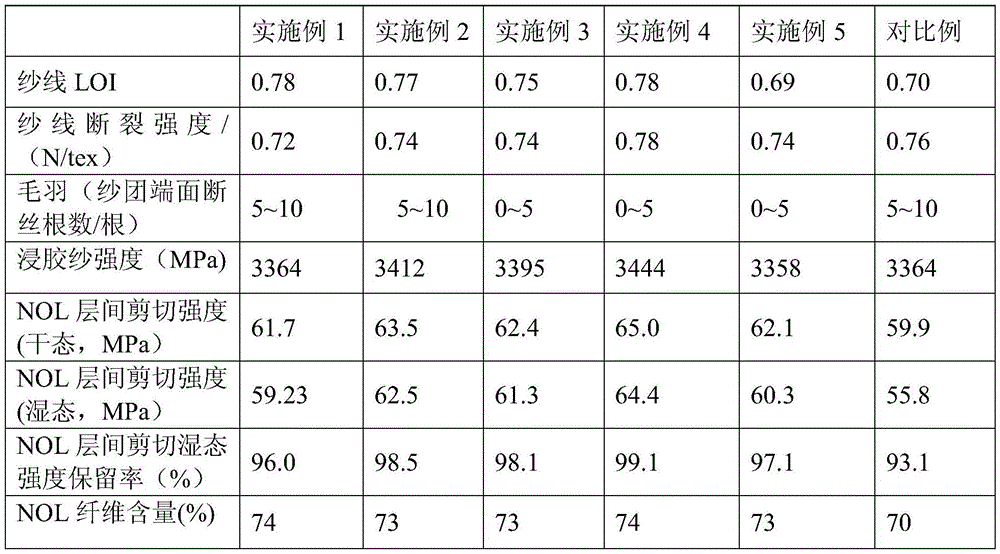

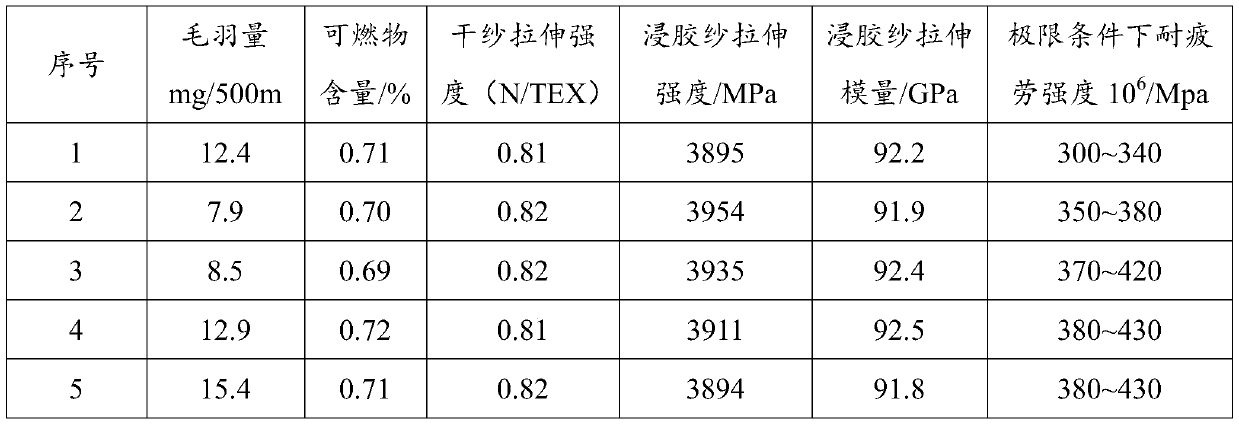

High-performance fiberglass winding yarn sizing agent and preparation method thereof

The invention relates to a high-performance fiberglass winding yarn sizing agent. Solid containing substances of the sizing agent account for 5%-7% of the total mass of the sizing agent, and the rest is deionized water, wherein the solid containing substances of the sizing agent comprise, by mass, 55%-80% of epoxy resin emulsion, 10%-27% of a nonionic lubricant, 5%-18% of a silane coupling agent, 0.5%-2.5% of a wetting agent and 1%-5.5% of organic acid, and the total mass of the solid containing substances is 100%. The sizing agent enables fiberglass to achieve the excellent processability and less hairness and is good in compatibility with epoxy resin, polyester resin, vinyl resin and thermosetting resin and high in interfacial strength, and a composite material has the excellent wet-state shear strength retention rate.

Owner:SINOMA SCI & TECH

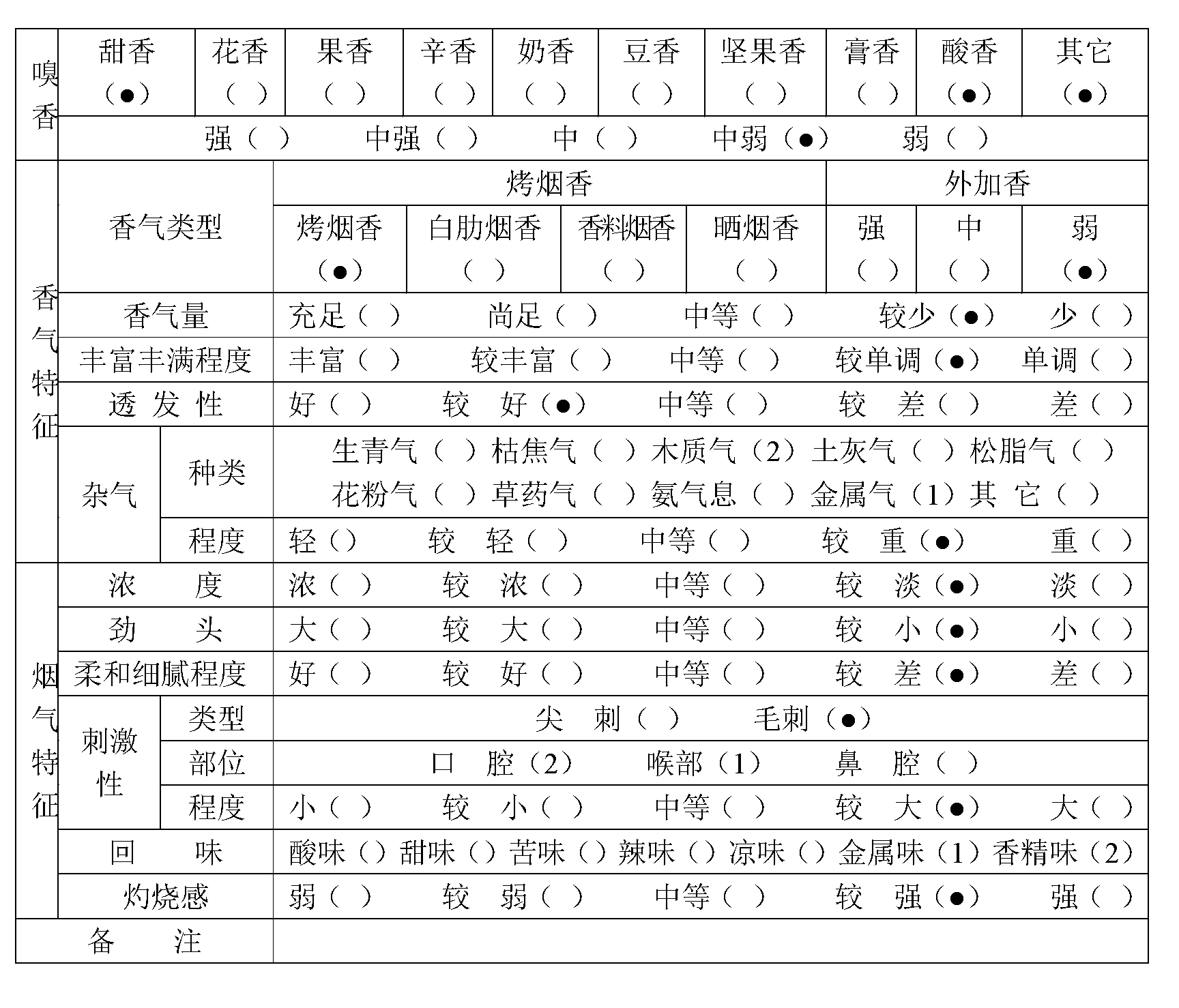

Casing flavor for expanded cut tobacco

ActiveCN103305342ARich fragranceIncrease sweetnessTobacco preparationTobacco treatmentThroat irritationMetal impurities

The invention discloses a casing flavor for an expanded cut tobacco. The casing flavor comprises the following components in parts by weight: 8-15 parts of a Zimbabwe tobacco leaf extract, 5-12 parts of a Brazil tobacco leaf extract, 3-8 parts of honey, 1-3 parts of 10% by mass of a red jujube extract, 2-5 parts of 1% by mass of phenylacetaldehyde, 5-8 parts of 1% by mass of guaiac wood oil, 0.5-2 parts of a fenugreek fluid extract, 1-3 parts of a liquorice fluid extract, 2-5 parts of maple syrup, 1-2 parts of 10% by mass of an orris root extract, 10-25 parts of water and 12-61.5 parts of propanediol. After the casing flavor is added into the expanded cut tobacco, the sensory quality shortages of insufficient fragrance, high metal impurity gas content, high irritation, metallic flavor residues and the like in the existing expanded cut tobacco are overcome, the fragrance content is increased, the expanded cut tobacco is endowed with fragrance and sweetness of a fruit and is enriched in fragrance, the throat irritation is reduced, and the sensory quality of the expanded cut tobacco is remarkably improved.

Owner:HUBEI CHINA TOBACCO IND +1

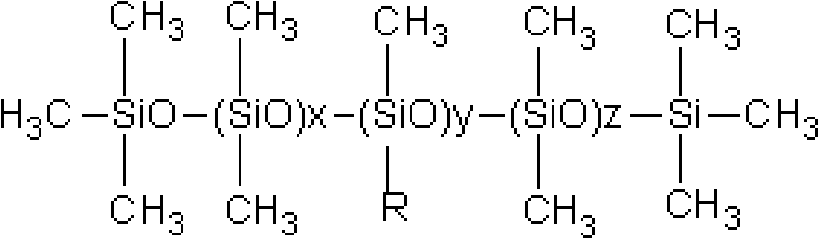

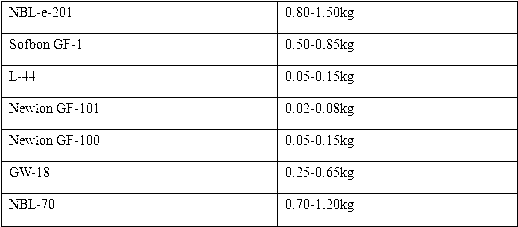

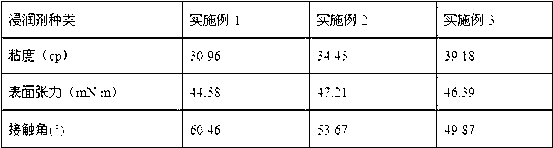

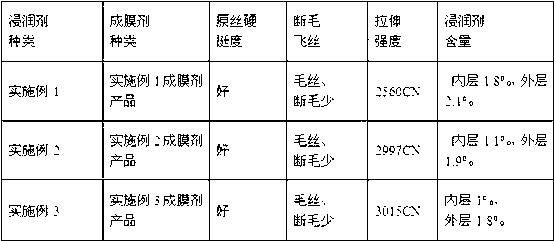

Finishing oil for manufacturing of continuous silicone carbide fiber and application process thereof

ActiveCN101613952AReduce broken endsImprove clusteringFibre treatmentFibre chemical featuresProduction lineEmulsion

The invention discloses finishing oil for the manufacturing of continuous silicone carbide fiber and an application process thereof. The finishing oil for the manufacturing of the continuous silicone carbide fiber is a modified organic silicone oil water solution or emulsion prepared by adding water into modified organic silicone oil, and the modified organic silicone oil is polysiloxane containing different active groups. The finishing oil has a simple preparation method. The finishing oil is applied to the manufacturing of the continuous silicone carbide fiber, has the characteristics of simple process, convenient operation, easy implementation on production lines of SiC fiber and the like, can effectively reduce the mechanical damage to PCS fiber when the PCS fiber passes through guide rolls, reduce broken filaments and broken ends of the fiber, improve the convergence and filament bundling strength of the fiber, and improve the mechanical properties and the uniformity of the prepared SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

A method for preparing an esterified starch film former for glass fiber wetting

The present invention discloses a method for preparing an esterified starch film former for glass fiber wetting, and the method is characterized in that the product of the esterified starch film former for glass fiber wetting is obtained by: placing corn starch into a reactor, adding water, heating to a temperature of 70-90 DEG C under stirring, reacting for 0.5- 2h, and cooling to 30-60 DEG C; adjusting a pH value to 4-7, adding isoamylase, after reacting for 0.5-6h, heating to a temperature of 80-90 DEG C for 20 min for enzyme deactivation, and filtering to remove the enzyme and obtain a reaction solution; and cooling the reaction solution to a temperature of 25-55 DEG C, adding an acid anhydride, adding an alkaline catalyst, maintaining the pH value being 7-10, reacting for 2-10h, adjusting the pH value to be 6-7, cooling to the room temperature, suction filtering, and drying a solid. The product of the film former has the advantages of a good film forming property and an easy post-treatment process, and has excellent effects of bundling and protecting the glass fiber in the production process of the glass fiber.

Owner:SOUTHWEAT UNIV OF SCI & TECH

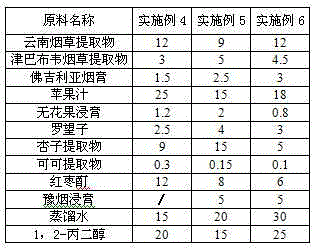

Blended essence for tobacco fragrance increase and preparation method of blended essence

InactiveCN105154234AIncrease the amount of aromaIncrease smoke concentrationTobacco treatmentEssential-oils/perfumesBiotechnologyCocoa Extract

The invention discloses a blended essence for tobacco fragrance increase. The blended essence is obtained by mixing the following raw materials in parts by weight: 8-15 parts of a Yunnan tobacco extract, 2-6 parts of Zimbabwe tobacco extract, 1-3 parts of Virginia tobacco paste, 15-25 parts of apple juice, 0.5-2 parts of a fig extract, 2.5-4 parts of tamarinds, 5-15 parts of an apricot extract, 0.1-0.3 part of a cocoa extract, 5-15 parts of a red date tincture, 10-30 parts of 1,2-propylene glycol and an appropriate amount of distilled water. The invention also discloses a preparation method of the blended essence for tobacco fragrance increase. The blended essence for tobacco fragrance increase ensures that tobaccos are rich in clear and sweet or heavy tobacco fragrance according to cut tobaccos of different production places; by adding the apple juice, the tamarinds, the red date tincture and the fig extract, the smoke and tobacco fragrance are soft and delicate and additionally have a fruit fragrance, the mouthfeel is improved, and the irritation of tobacco is reduced; and by adding the apricot extract, the smoke concentration is improved, and the agglomeration property and explosive force of the smoke are enhanced. The preparation method of the blended essence for tobacco fragrance increase is simple to operate and is low in cost.

Owner:湖南嘉利香料有限公司

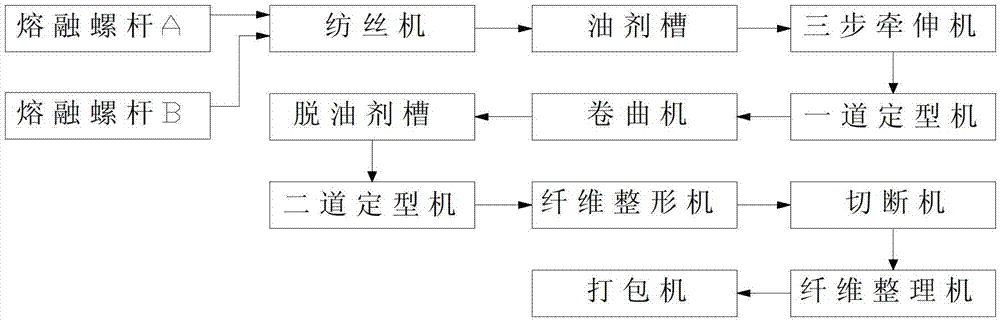

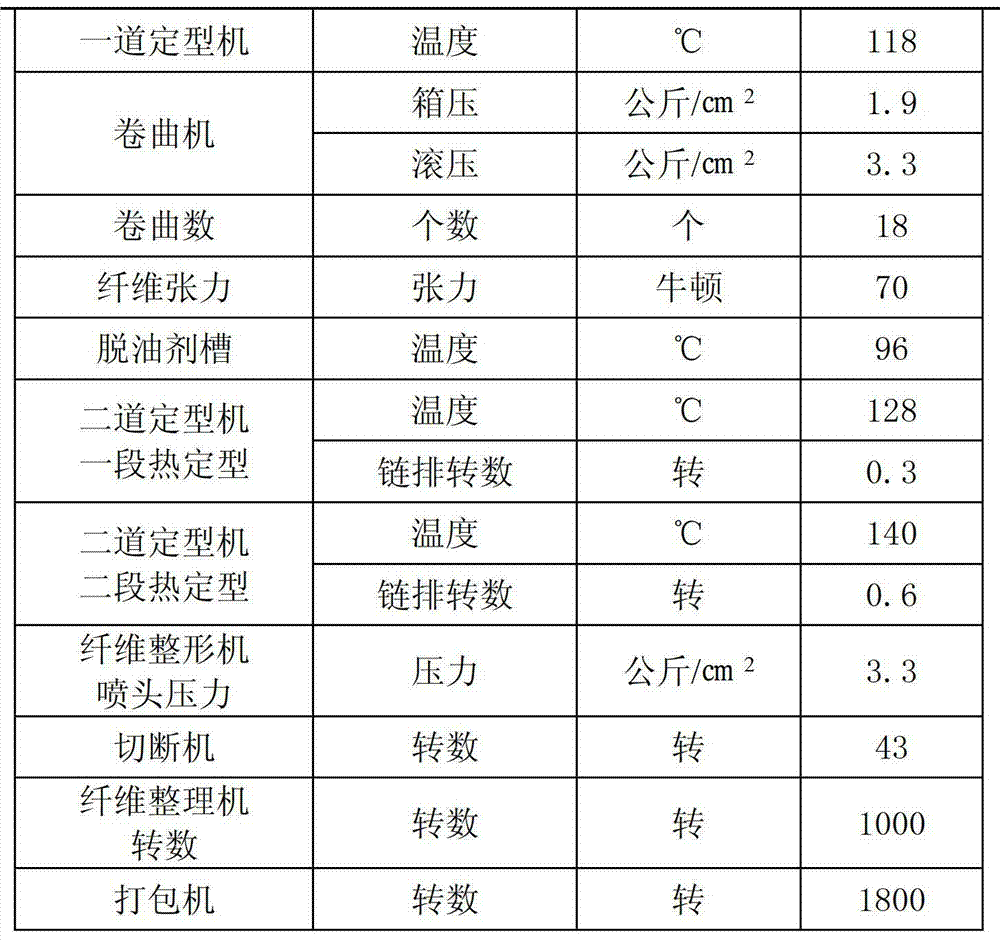

Preparation method for oil-free polypropylene staple fibers with static electricity

ActiveCN103320880AImprove cohesionImprove clusteringArtificial thread manufacturing machinesMelt spinning methodsFiber bundleMetering pump

The invention provides a preparation method for oil-free polypropylene staple fibers with static electricity, and belongs to the field of polypropylene fiber preparation methods. According to the method, polypropylene slices are added into a melting screw A and a melting screw B to serve as a cover layer and a core layer respectively; the cover layer and the core layer are added into a metering pump of a spinning machine; formed fibers pass through an oil agent groove oiling rod, a three-step drawing machine, a first setting machine, a crimping machine, an oil agent removal groove and a second setting machine to become fiber bundles; the fiber bundles pass through a fiber shaping machine and a fiber cutting machine to become the oil-free polypropylene staple fibers with static electricity; melt indexes of the polypropylene slices added into the melting screw A and the melting screw B are 64g / 10min and 32g / 10min respectively; the temperature of the oil agent removal groove is 96 DEG C to 100 DEG C; the pressure of a sprayer nozzle of the fiber shaping machine is 3.3 to 3.7 kg / cm2. The polypropylene staple fibers acquired through the preparation method provided by the invention have the oil content of 0% and the specific resistance of 10<10> ohm*cm to 10<8>ohm*cm.

Owner:JILIN PROVINCE HUAFANG ELECTROSTATIC MATERIAL TECH CO LTD

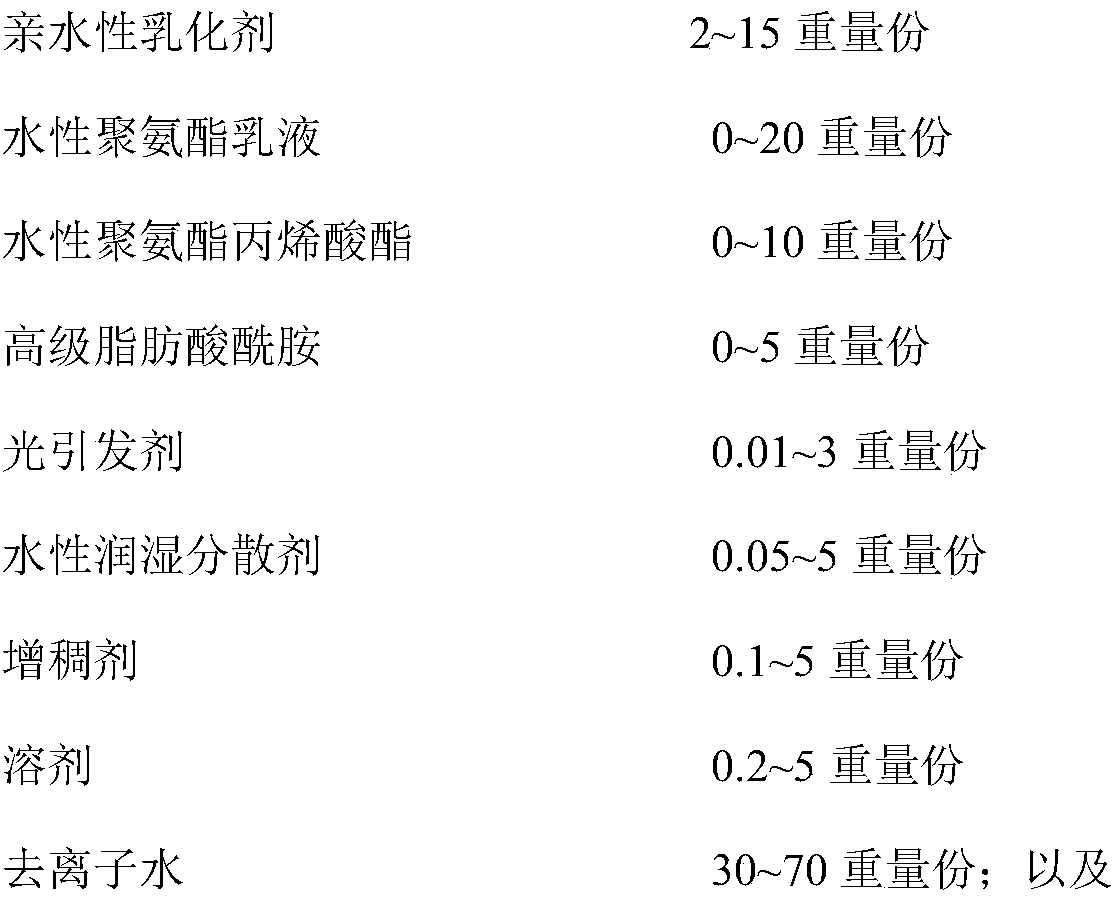

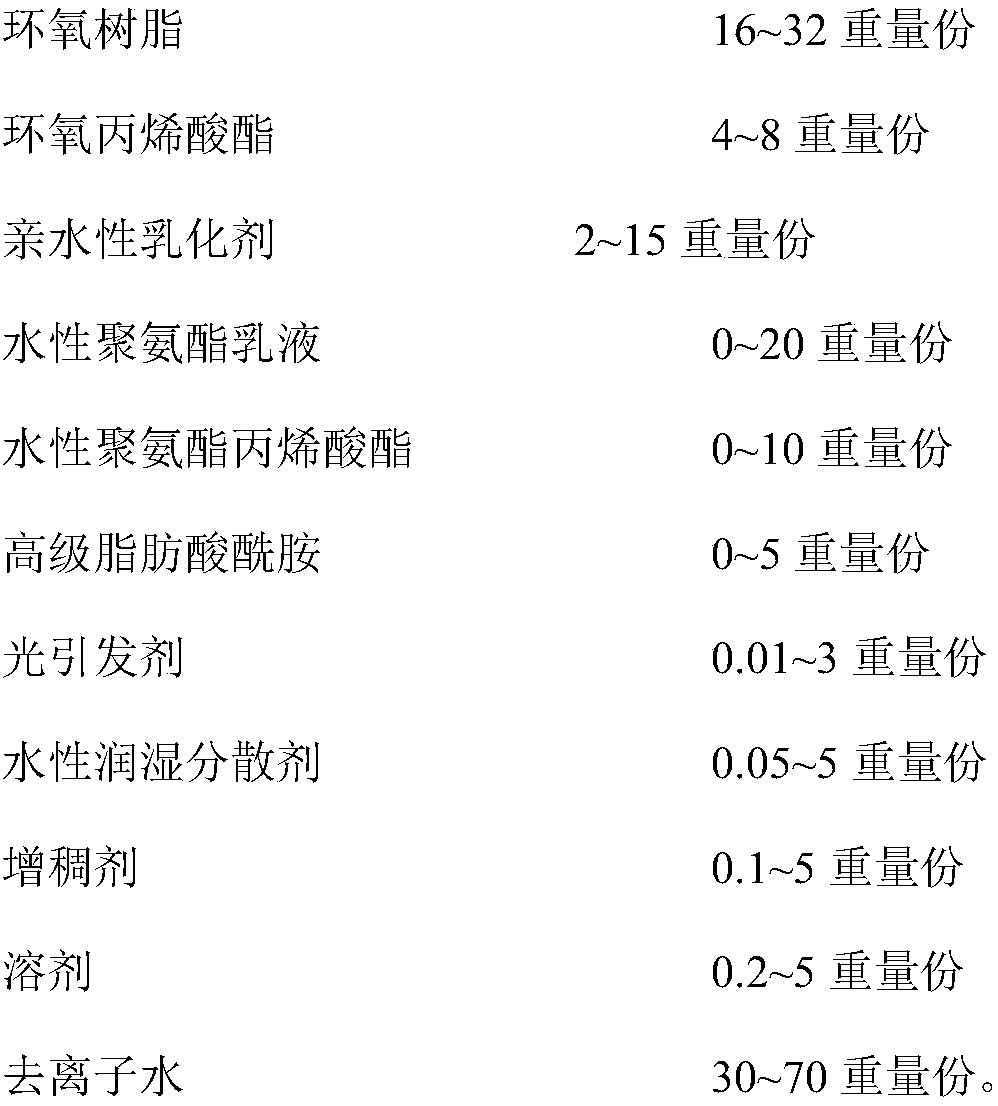

A waterborne carbon fiber sizing agent and a preparing method thereof

ActiveCN109385899AImprove performanceIncrease productivityCarbon fibresGrip property fibresEpoxyCarbon fibers

A waterborne carbon fiber sizing agent and a preparing method thereof are disclosed. The sizing agent is prepared from, by weight, 16-32 parts of epoxy resin, 4-8 parts of epoxy acrylate, 2-15 parts of a hydrophilic emulsifier, 0-20 parts of aqueous polyurethane emulsion, 0-10 parts of aqueous urethane acrylate, 0-5 parts of higher fatty acid amide, 0.01-3 parts of a photoinitiator, 0.05-5 parts of an aqueous wetting and dispersing agent, 0.1-5 parts of a thickening agent, 0.2-5 parts of a solvent and 30-70 parts of deionized water. The sizing agent is a waterborne carbon fiber sizing agent combining heat-curing and photo-curing. Carbon fibers sized by the sizing agent can be dried through a high-temperature drying manner and then cured through a photo-curing manner so that the performanceof the sizing agent is further improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Preparation method of magnolia fruit extract and application thereof in cigarette

ActiveCN102793264AReduce agglomerationImprove clusteringTobacco treatmentEssential-oils/perfumesSmokeBiotechnology

The invention relates to a preparation method of a magnolia fruit extract, which is characterized in that the magnolia fruits as raw material are processed to the magnolia fruit extract by the steps of baking, pulverizing, solvent extraction and concentration. The magnolia fruit extract is added into tobacco shreds, so as to greatly reduce undesired gases in the smoke, reduce irritation of the smoke, improve the concentration and agglomeration of the smoke, improve the smoking property and enhance elegant flavor of the smoke. The preparation method is advantageous in developing the new use of magnolia fruits by use of the common solvents and methods and providing a new natural tobacco flavor.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

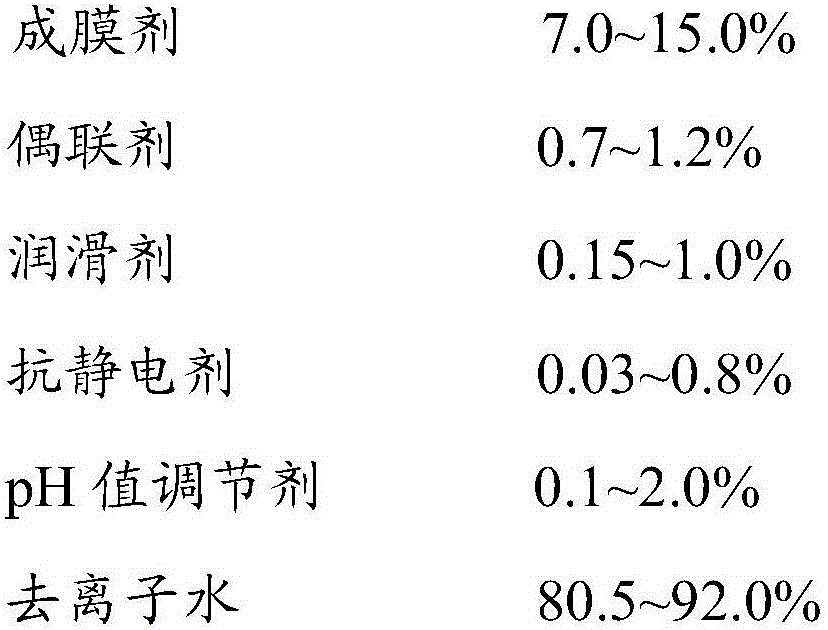

Glass fiber impregnating compound high in permeating speed and application thereof in producing twistless roving

The invention discloses a glass fiber impregnating compound which is prepared from, by weight, 0.02-3.00% of a coupling agent, 3.00-30.00% of a film forming agent, 0.02-2.00% of a lubricating agent, 0.02-0.80% of an antistatic agent, 0.01-2.00% of a pH adjusting agent and deionized water. The film forming agent is prepared by mixing nanosilicon dioxide modified polyester emulsion, PVAc emulsion and polyurethane modified epoxy emulsion, and the content of the nanosilicon dioxide modified polyester emulsion is not smaller than that of the polyurethane modified epoxy emulsion. The invention further provides application of the glass fiber impregnating compound in producing twistless roving. The twistless roving produced through the impregnating compound is high in permeating speed, good in choppability, good in production smoothness and good in compatibility with enhanced resin, production efficiency and the mechanical strength of a produced composite product are greatly improved, and the glass fiber impregnating compound is applicable to an injection process or a centrifugal casting molding process.

Owner:JUSHI GRP CO

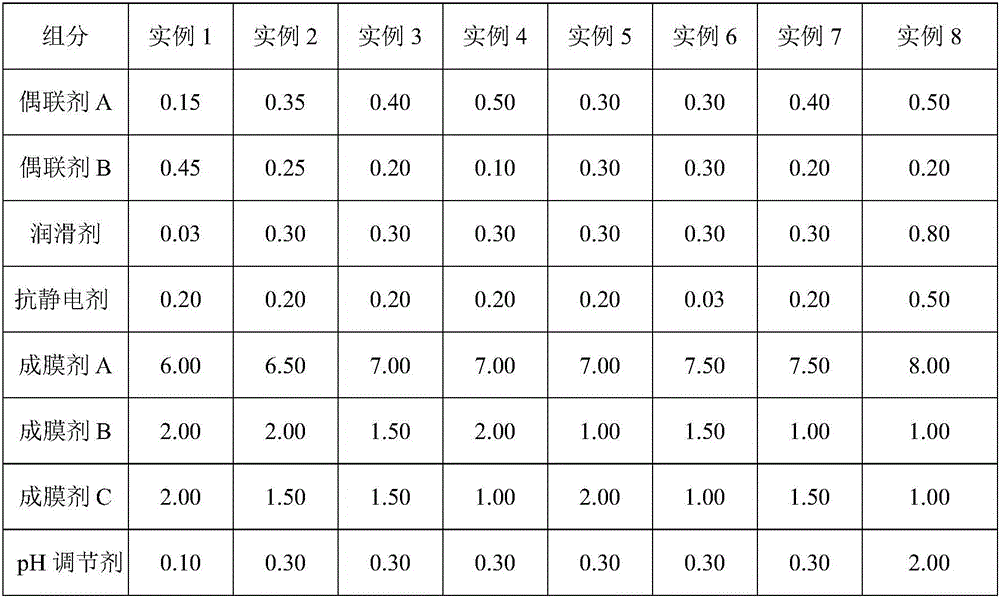

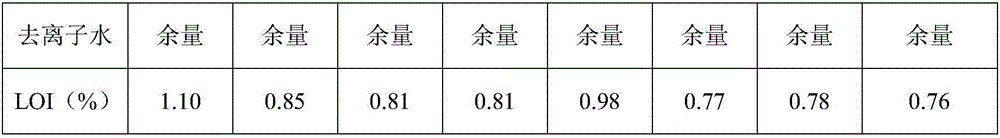

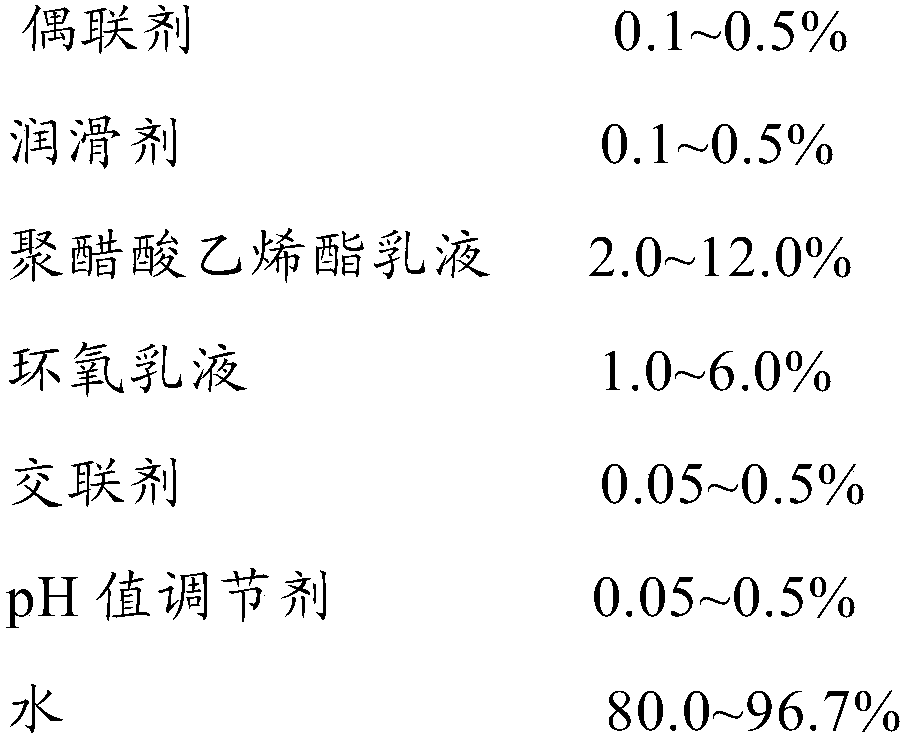

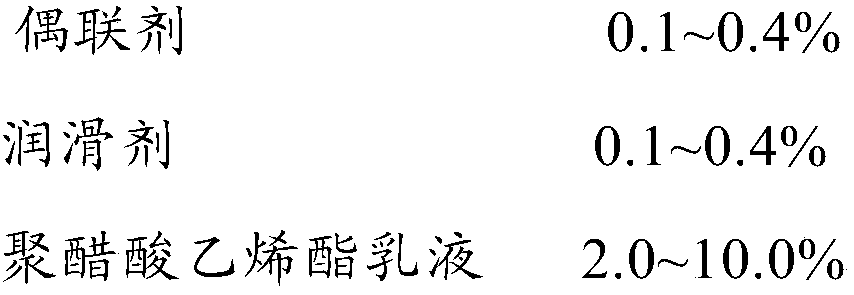

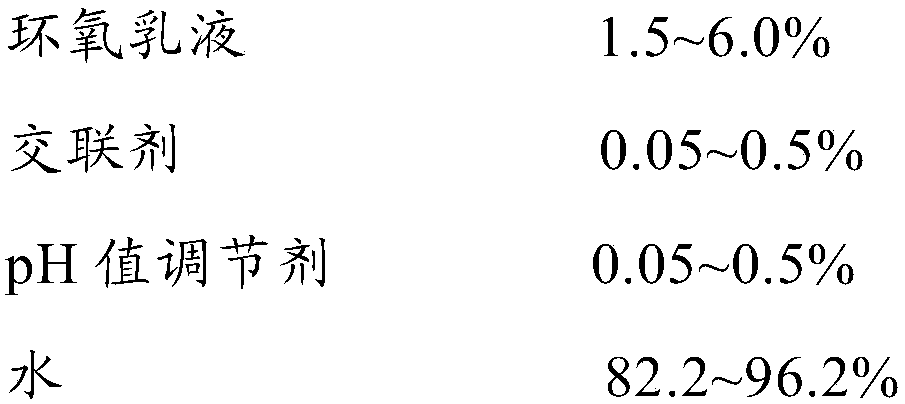

Glass fiber sizing agent and application thereof

The invention provides a glass fiber sizing agent. The glass fiber sizing agent is prepared from the following components in mass by percentage: 0.1 to 0.5% of coupling agent, 0.1 to 0.5% of lubricant, 2.0 to 12.0% of polyvinyl acetate emulsion, 1.0 to 6.0% of epoxy emulsion, 0.05 to 0.5% of crosslinking agent, 0.05 to 0.5% of pH adjusting agent, and 80.0 to 96.7% of water. The epoxy emulsion is abisphenol A type epoxy resin emulsion, and the polyvinyl acetate emulsion comprises a crosslinked polyvinyl acetate and a plasticized modified polyvinyl acetate, wherein the mass ratio of the crosslinked polyvinyl acetate and the plasticized modified polyvinyl acetate is (1 to 1) to (5 to 1). By using the sizing agent of the invention, the produced glass fiber yarn can not only improve the colorand breaking strength of the yarn, but also effectively improve the fluidity of the glass fiber and improve the compatibility with a matrix resin, and an SMC material for a sewage degrading tank obtained by reinforcing the glass fiber sizing agent can be improved has the advantages of uniform glass fiber distribution, smooth surface, high product yield and good mechanical properties.

Owner:JUSHI GRP CO

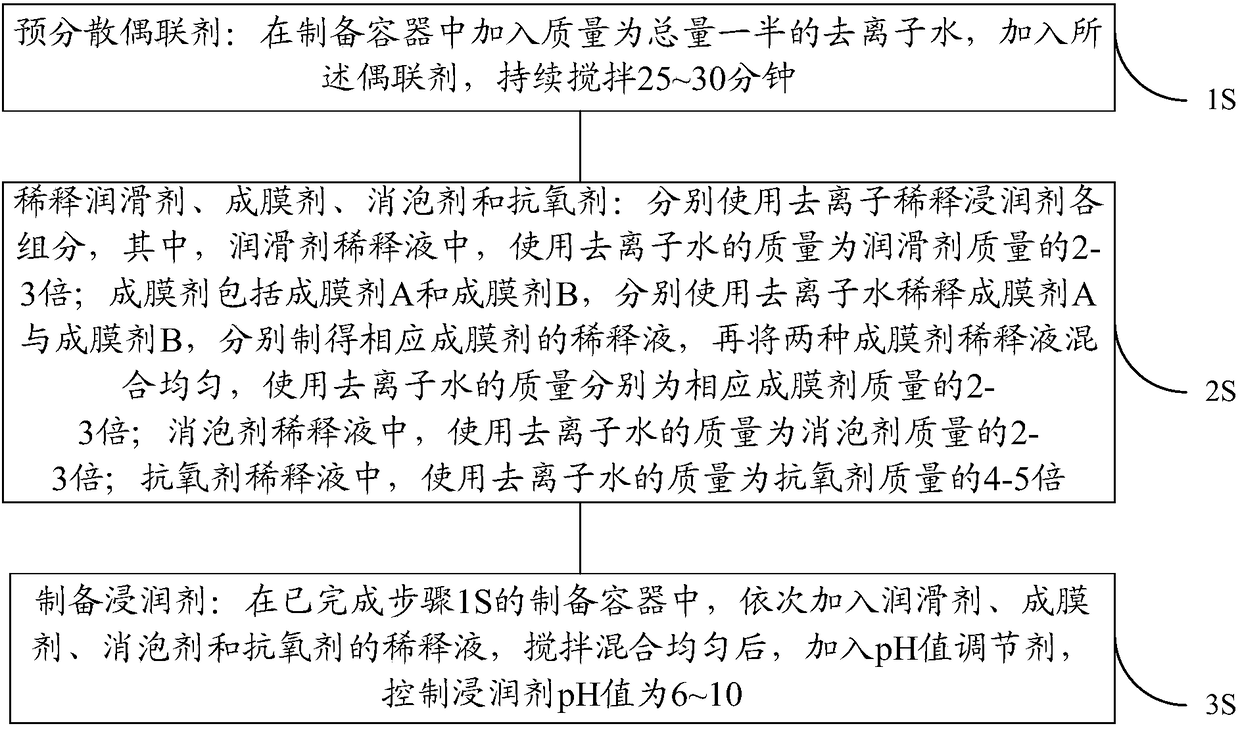

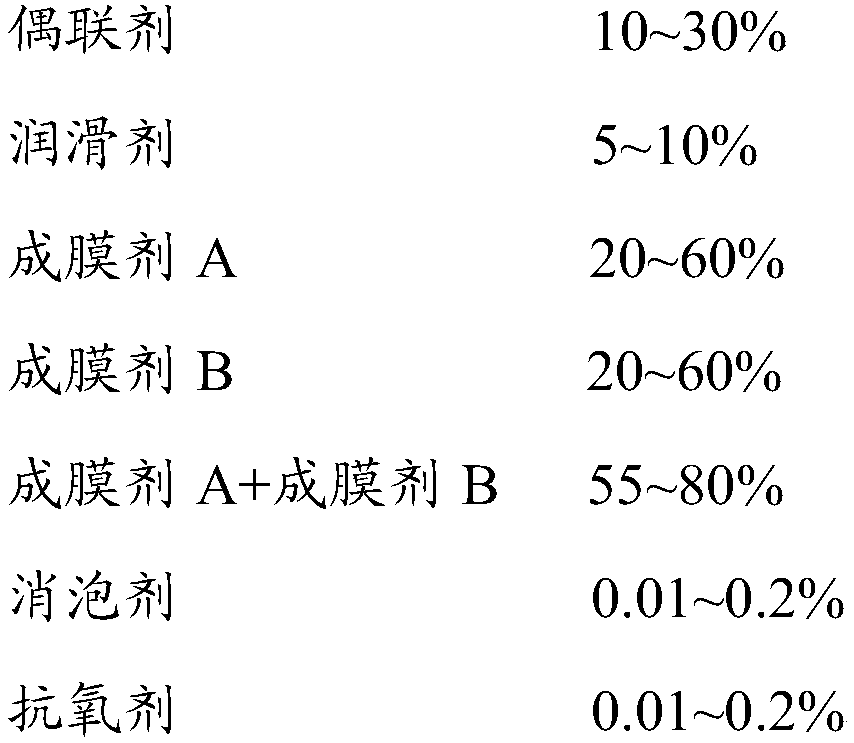

Glass fiber wetting agent, preparation method and uses thereof

The present invention provides a glass fiber wetting agent, which comprises a coupling agent, a lubricant, a film forming agent A, a film forming agent B, an antifoaming agent, an antioxidant, a pH value adjusting agent and deionized water, wherein the solid of the wetting agent accounts for 2-6% of the total mass of the wetting agent. According to the present invention, the wetting agent with characteristics of excellent glass fiber dispersibility, less hairiness and good compatibility effect is prepared by compounding different types of the film forming agents and matching with the suitablecoupling agent, the suitable lubricant, the suitable antifoaming agent, the suitable antioxidant and the suitable pH value adjusting agent. The invention further provides a preparation method of the glass fiber wetting agent, and uses of the glass fiber wetting agent in the CFRT process of glass fiber reinforced polypropylene resins.

Owner:JUSHI GRP CO

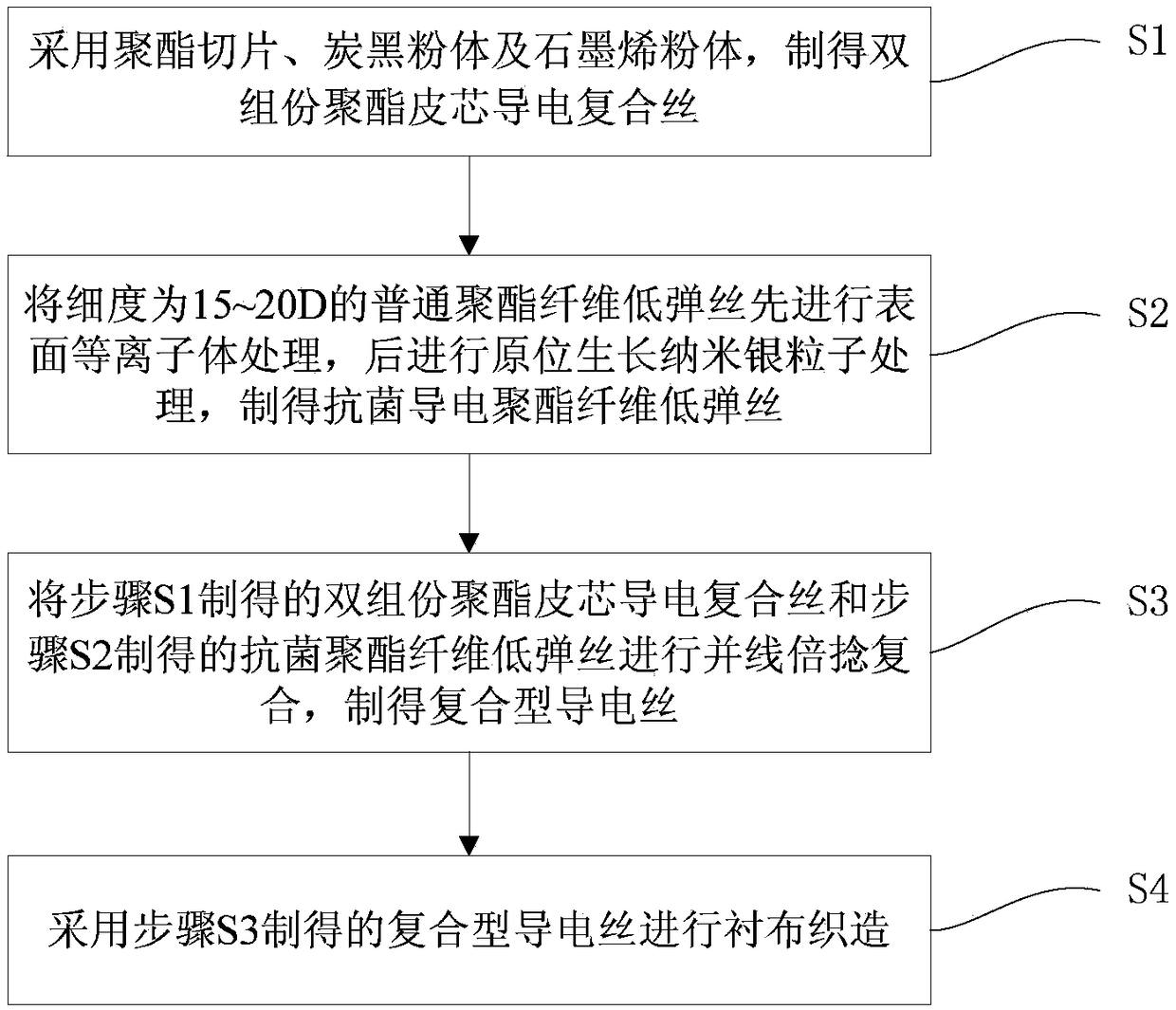

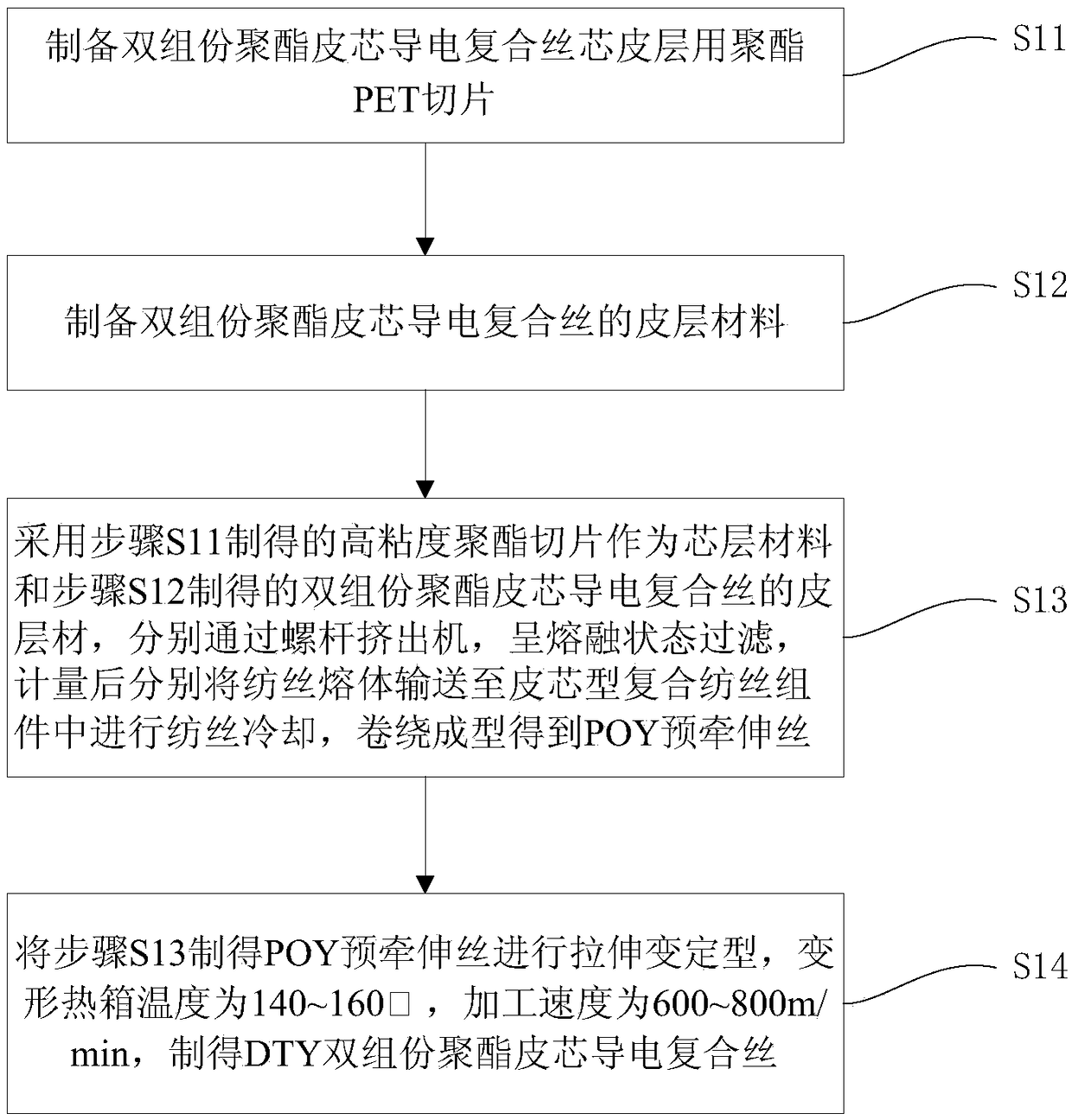

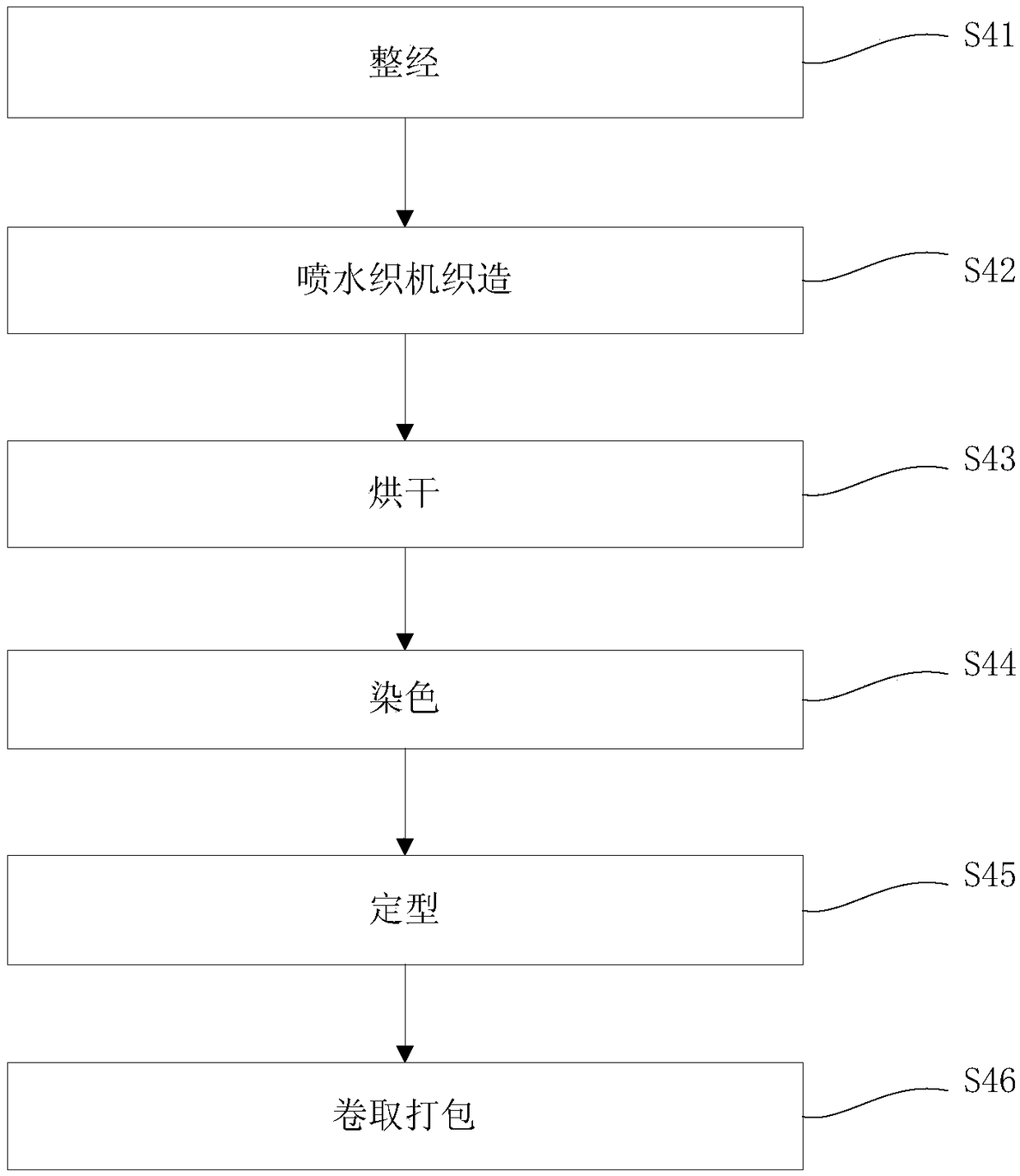

Dacron conductive lining cloth and production process thereof

ActiveCN109371527ASoft touchImprove washing resistanceElectroconductive/antistatic filament manufactureLiquid/gas/vapor treatment of propelled fabricsPolyesterYarn

The invention relates to a dacron conductive lining cloth and a production process thereof. The production process includes the following steps that polyester chips, carbon black powder and graphene powder are adopted, and double-component polyester skin core conductive composite filaments are prepared; common polyester fiber low stretch yarn is subjected to surface treatment, and antibacterial conductive polyester fiber low stretch yarn is prepared; the prepared double-component polyester skin core conductive composite filaments and the prepared antibacterial conductive polyester fiber low stretch yarn are subjected to doubling and double-twisting compounding, and composite conductive filaments are prepared; the composite conductive filaments are used for weaving the lining cloth. The defects such as poor conductivity, poor softness, washing intolerance and the complex processing process of conductive fibers in the prior art are overcome, the dacron conductive lining cloth has excellent washing resistance, dyeing performance and conductivity, is resistant to abrasion and bending and soft in hand feeling, still can keep good conductivity after being machine-washed multiple times, is good in strength, soft and not crispy, and meets the comprehensive requirements of the strength, softness and conductivity of high-grade antistatic clothing on antistatic lining cloths.

Owner:南通源佑纺织科技有限公司

Production process for fine denier cross-shaped profiled polyester filament yarn

InactiveCN104278341AReduce problemsTo ensure the degree of irregularityFilament forming substance formingMelt spinning methodsProduction linePreservative

The invention discloses a production process for fine denier cross-shaped profiled polyester filament yarn. An FDY one-step method production line is adopted, PET slices are pre-crystallized and dried until the water content of the slices is lower than or equal to 20 ppm, the slices are extruded through a screw extruder in a fusion mode, a spinneret plate with cross-shaped spinneret orifices is adopted for spinning, the spinning temperature is 290-295 DEG C, cross air blasting cooling is carried out on nascent fibers obtained through spinning, air temperature is 26-30 DEG C, air speed is 0.3-0.5 m / s, a slow cooler is added before cross air blasting cooling, and then oil nozzle oiling, stretching setting, meshing and winding are conducted. According to the method, the occurrence frequency of broken ends and broken filaments is reduced, and spinnability is improved while the profile degree is guaranteed; uniformity of thick and thin knobs, production efficiency and product quality are improved, product cost is reduced, labor is saved, and the production difficulty is lowered; preservatives are added into oiling agents, so that the bundling property and the antistatic property of the yarn are improved.

Owner:JIANG SU TIANDI CHEM FIBER

Structure-enhanced SMC (Sheet Moulding Compound) glass fibre impregnating agent and application thereof in production of twistless roving

Owner:JUSHI GRP CO

Sizing agent for carbon fiber

InactiveCN101982602AIncrease cross-linking pointImprove the interface bonding strengthCarbon fibresFiberCarbon fibers

The invention discloses a sizing agent for a carbon fiber, belonging to the fields of organic chemistry and fiber materials. The sizing agent is an epoxy water emulsion added with an aqueous curing agent, wherein the aqueous curing agent is modified epoxy amine curing agent, namely an amidated amine curing agent obtained by a reaction between a mono-fatty acid and an epoxy amine curing agent, a polyamide curing agent obtained by a reaction between a dimer acid and an epoxy amine curing agent and a curing agent obtained by a reaction between an epoxy amine curing agent and epoxy resin; the epoxy emulsion uses bisphenol A epoxy resin as the main body, and the epoxy equivalent is 200-500; the amount of the aqueous curing agent is 10% to 40% of theoretical one, and the theoretical amount should be calculated as follows: W=(Namine / NEP)*100, wherein Namine is the amine hydrogen equivalent of the curing agent, NEP is the epoxy equivalent of the epoxy resin, and W is the theoretical amount of the curing agent required by 100 grams of epoxy resin. The sizing agent is safe and healthy, the stability and the bundling performance are further improved, and the interface bonding strength of the composite material is enhanced.

Owner:BEIJING UNIV OF CHEM TECH

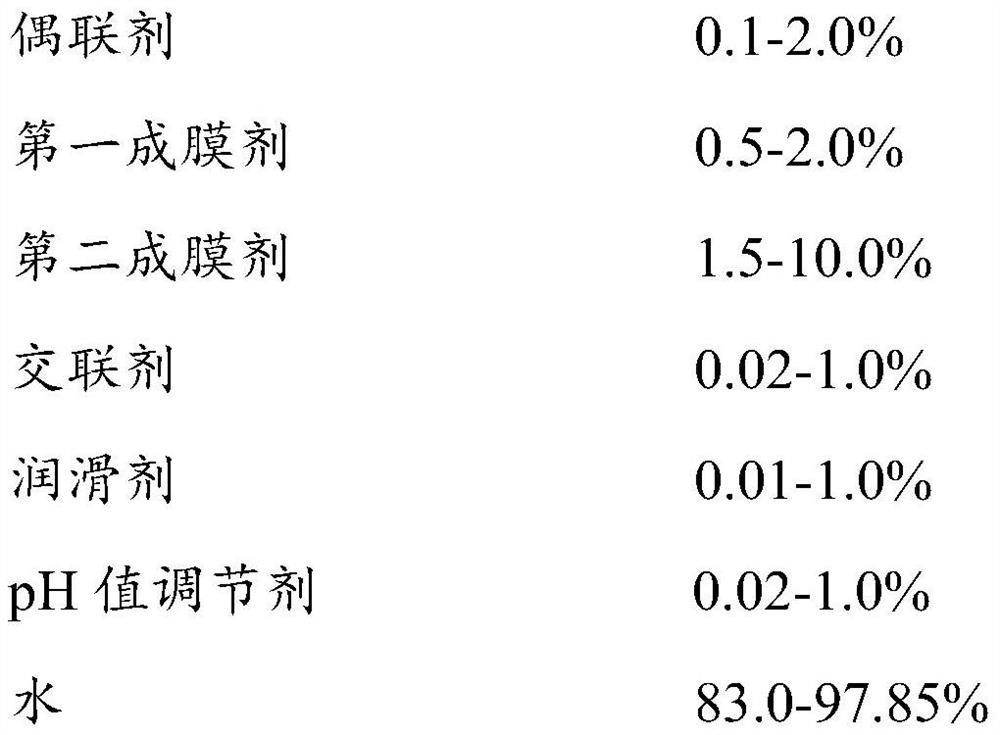

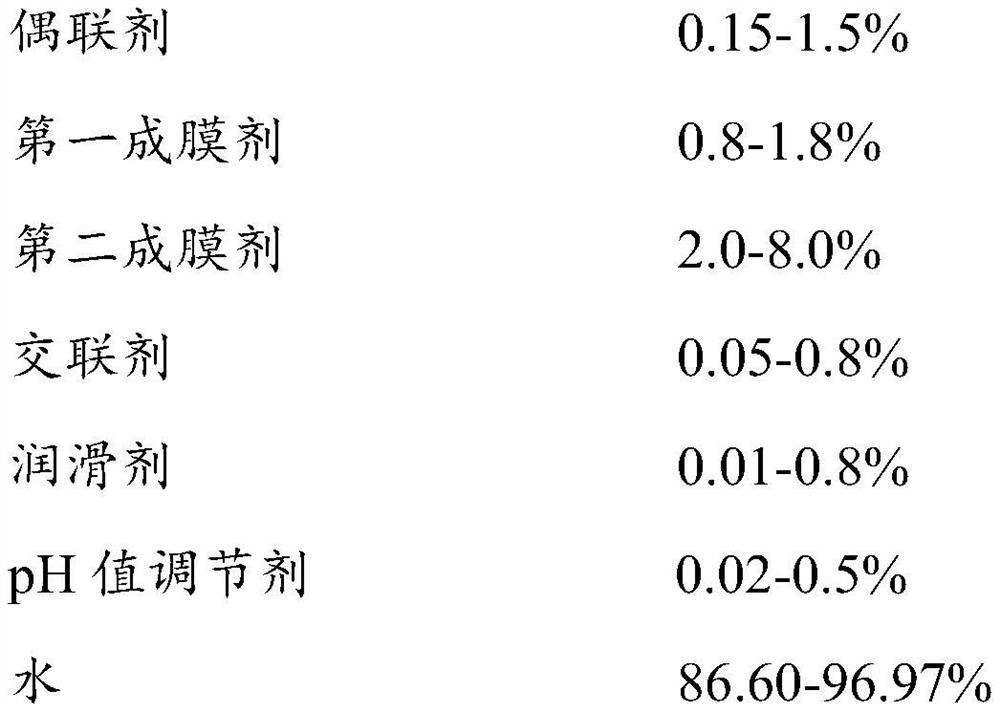

Reinforced glass fiber impregnating compound as well as preparation method and application thereof

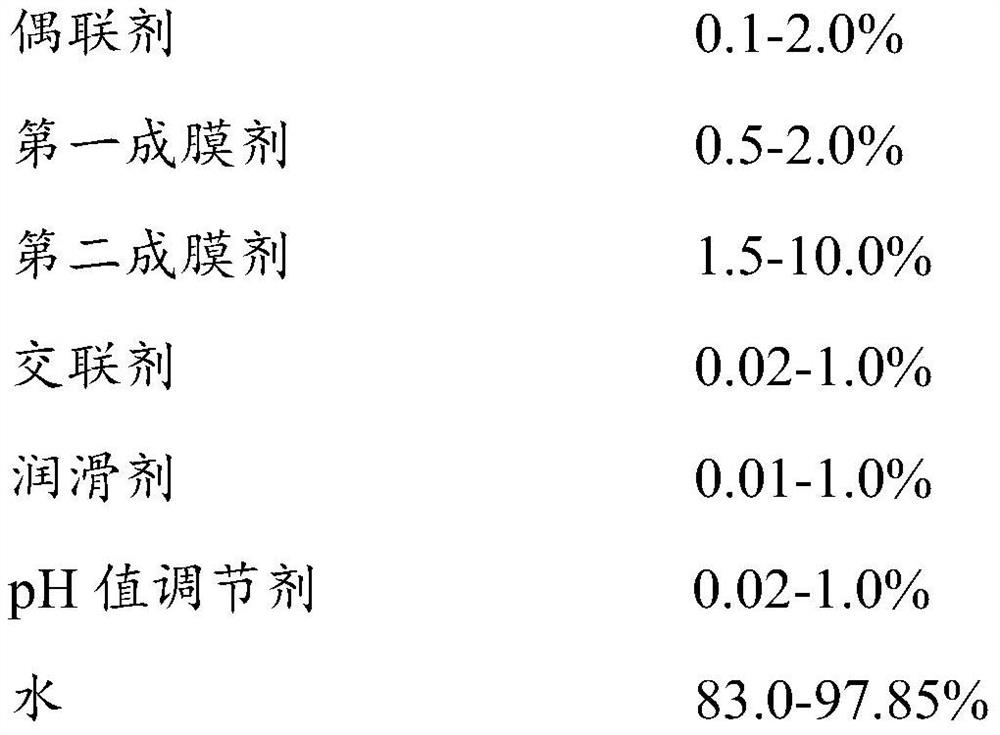

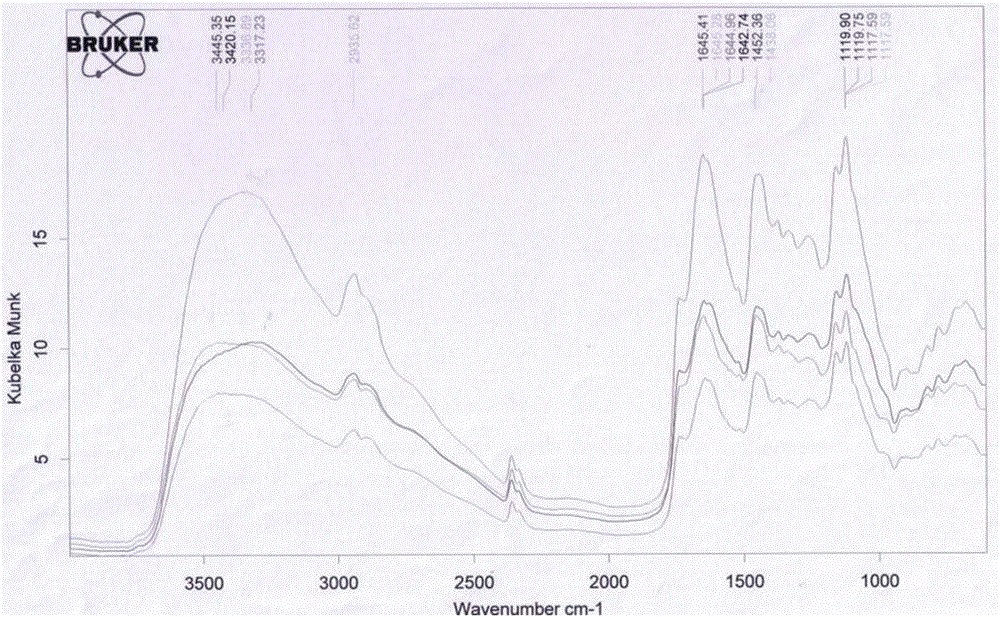

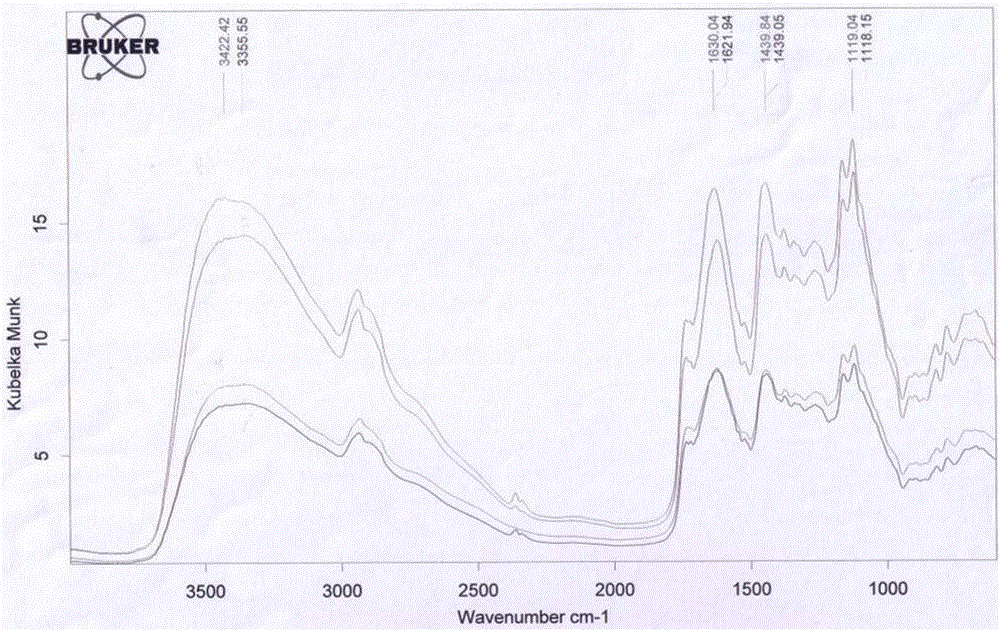

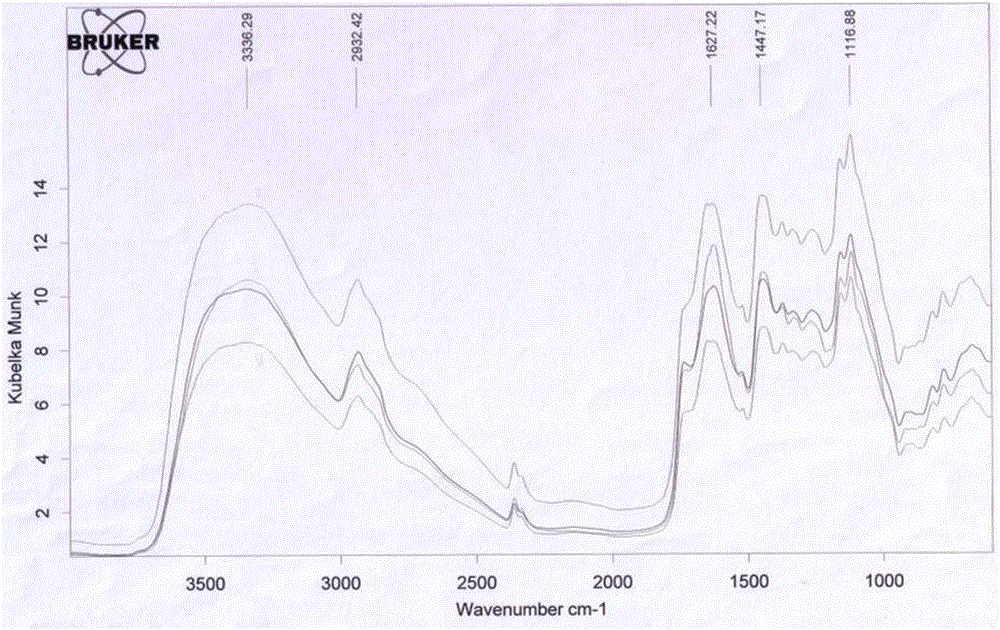

The invention provides a reinforced glass fiber impregnating compound which comprises the following components in percentage by mass: 0.1-2.0% of a coupling agent, 0.5-2.0% of a first film forming agent; 1.5-10.0% of a second film forming agent; 0.02-1.0% of a cross-linking agent; 0.01%-1.0% of a lubricating agent; 0.02-1.0% of a pH value adjusting agent; and 83.0-97.85% of water; the coupling agent is a silane coupling agent, and the coupling agent is a mixture of a first coupling agent and a second coupling agent; the first film-forming agent is a polyurethane emulsion; and the second film-forming agent is an epoxy emulsion. The compound provided by the invention not only can effectively improve the fluidity, impregnation performance and product surface performance of glass fibers, but also can improve the bundling performance and compatibility with resin, can be used in the production of epoxy resin SMC materials, and obviously improves the mechanical properties of the epoxy resin SMC materials.

Owner:JUSHI GRP CO

Compound enzyme preparation for improving tobacco quality and application thereof

The invention discloses a compound enzyme preparation for improving quality of tobaccos and application thereof. The compound enzyme preparation comprises is prepared from liquid glucoamylase, acid proteinase, pectinase and compound cellulase according toby a weight ratio of (1-2) to (1-3) to (1-3) to (2-4). Through the compound enzyme preparation for improving quality of the tobaccos and the application method thereof, the sensory quality of the tobaccos can be improved; the application range of the tobacco raw material in the formula of the compound active enzyme preparation can be expanded; the defects of offensive odor, hot feeling, insufficient sweetness and insufficient aroma of the tobaccos can be improved; the availability and the use value of the tobaccos can be expanded.

Owner:CHINA TOBACCO SHANDONG IND

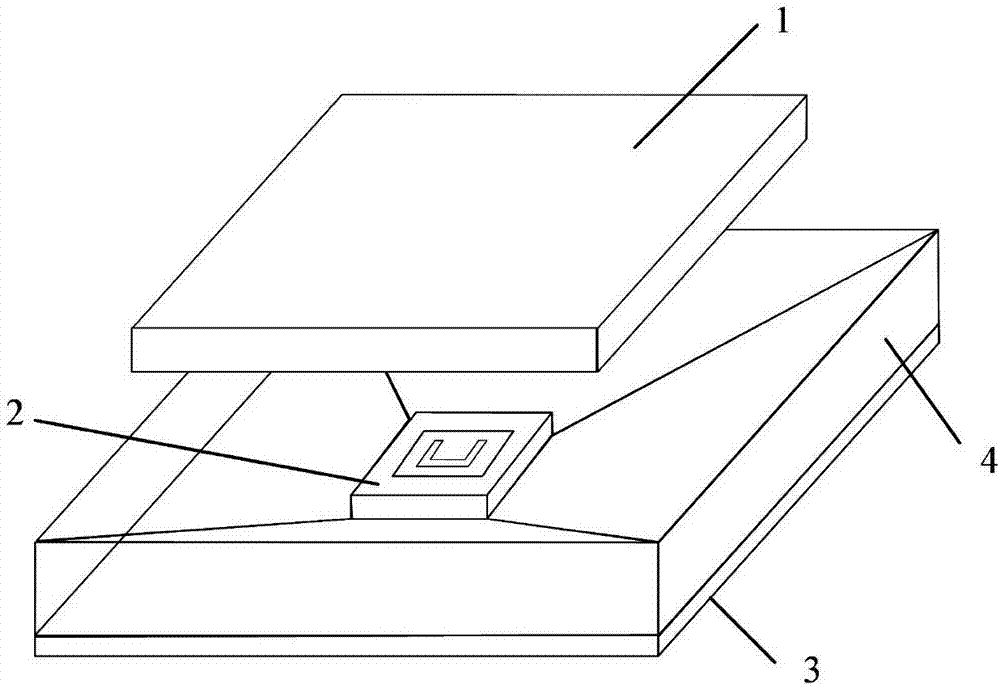

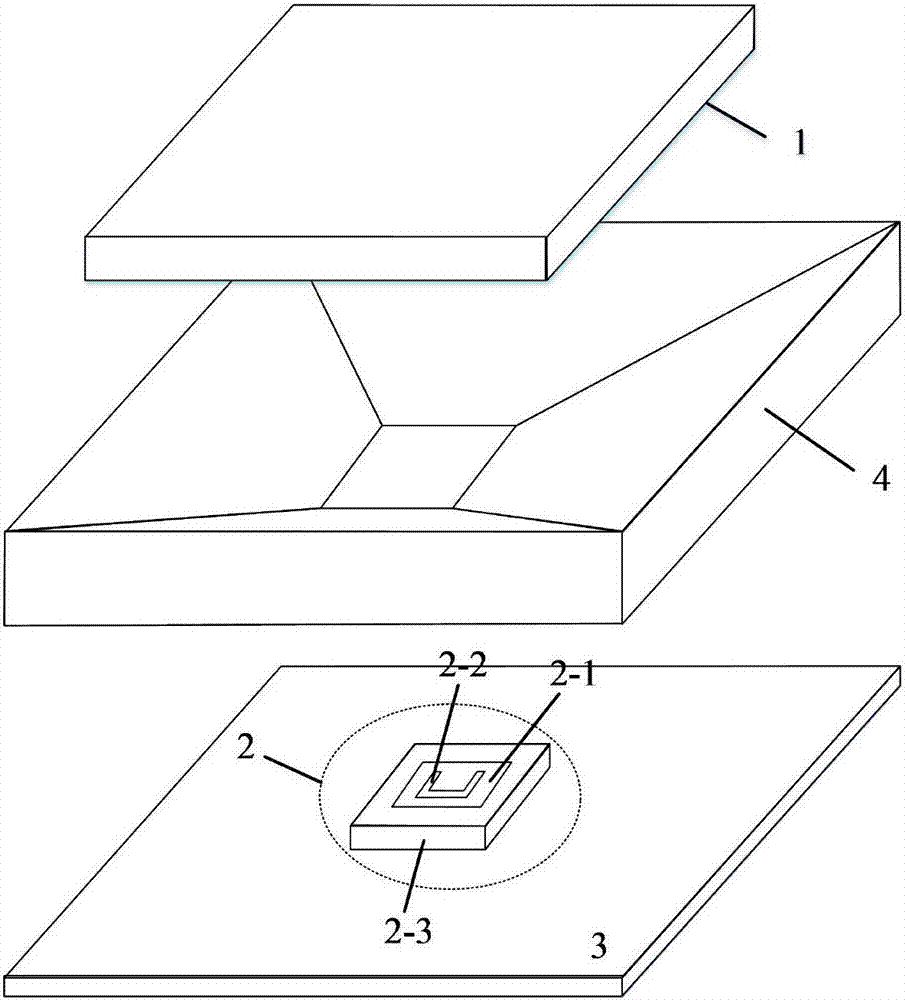

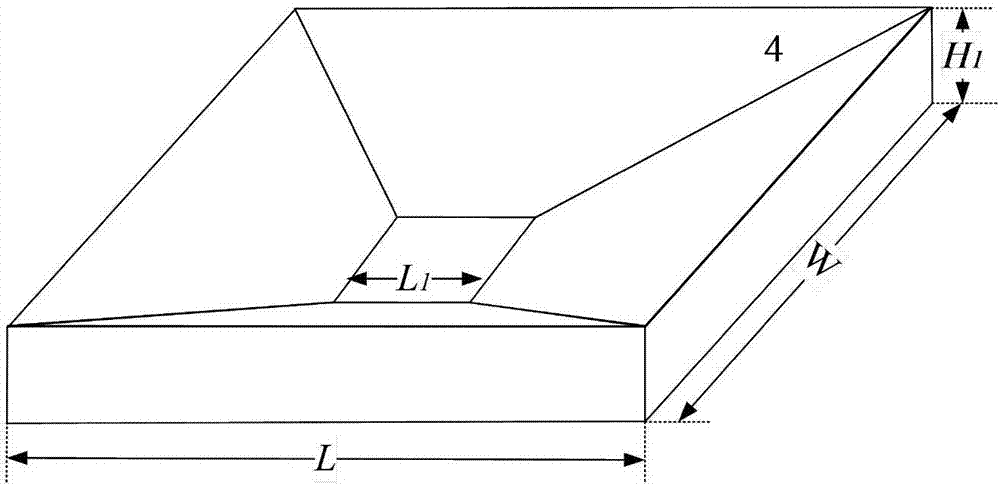

Broadband resonant cavity antenna with gradient structure

InactiveCN107482313ALight structureLow profileRadiating elements structural formsAntenna earthingsResonant cavityPhase difference

The invention belongs to the technical field of resonant cavity antennas and discloses a broadband resonant cavity antenna with a gradient structure. The antenna comprises a dielectric reflective coating layer which is arranged at a position above a metal floor with a distance of a half wavelength. A resonant cavity is formed by the dielectric reflection coating layer and the metal floor, and a U-shaped slot patch antenna is arranged in the cavity. A metal wedge structure with a gradient height is arranged just above the metal floor. The gain bandwidth of the resonant cavity antenna can be significantly improved by the gradient metal wedge structure, and at the same time, the characteristic of a low profile is maintained. The profile height of the antenna is just a half wavelength of a center frequency, by using measures of loading the gradient metal wedge structure and reducing a reflection coating layer aperture size, a phase difference caused by different reflection paths between the floor and the reflection coating layer is compensated, and thus the field distribution in the resonant cavity is more uniform, the gain of the antenna is higher than 15dBi, and a 3dB gain bandwidth is increased from 11.3% to 22.6%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Film forming agent suitable for glass fibers, impregnating agent comprising same, and preparation method and applications of impregnating agent

The invention relates to the technical field of impregnating agents, and discloses a film forming agent suitable for glass fibers, an impregnating agent comprising the same, and a preparation method and applications of the impregnating agent. The film forming agent comprises emulsified bisphenol A type epoxy resin and polyester type polyurethane. Through the emulsification effect of a surfactant, the interfacial energy of a system is reduced, the stability of epoxy resin emulsion is improved, and thus the function of the epoxy resin emulsion can be better exerted. The polyester polyurethane film forming agent has a large molecular weight and a strong yarn-wrapping performance and easily forms a compact film on the surface of glass fibers, thus the glass fibers are isolated from the external environment, water will not enter the cracks of the glass fibers, the elasticity and wear resistant performance of yarns are improved, the anti-fatigue performance of yarns is strengthened, at the same time, the bundling force is high, and the phenomenon of yarns such as natural draping, non-uniform tension force, and the like, is effectively relieved.

Owner:SINOMA SCI & TECH

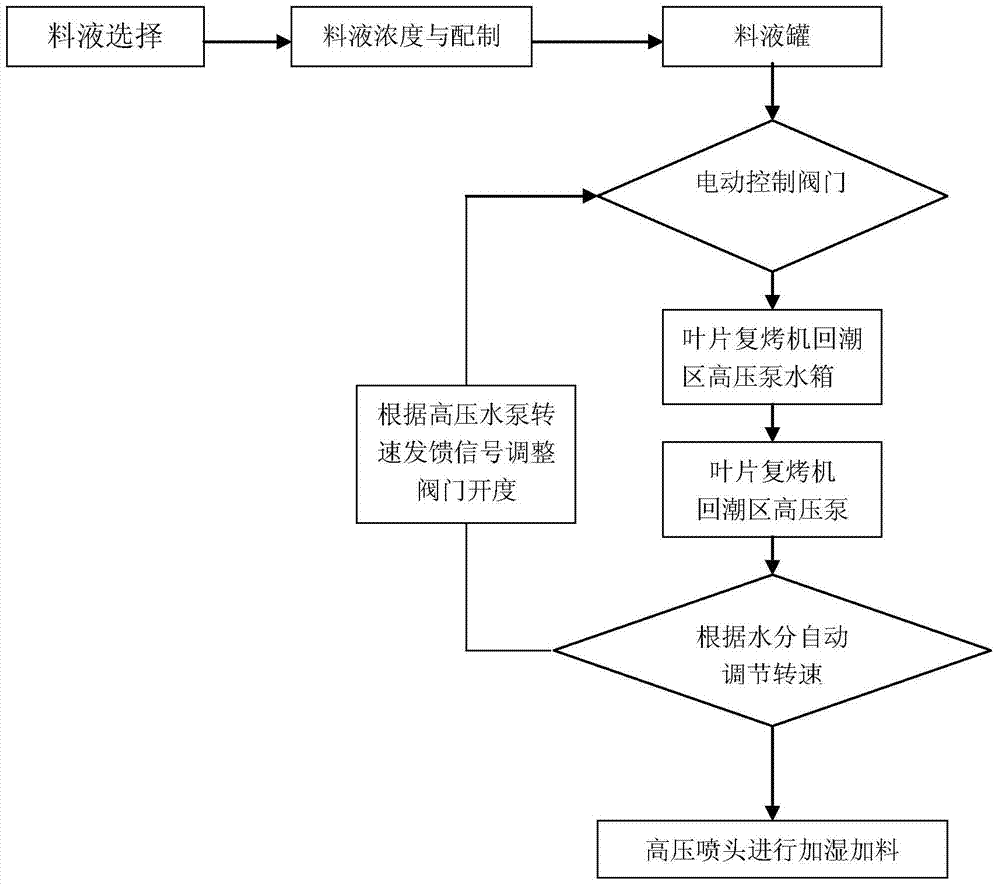

Feeding method in processes of tobacco leaf threshing and re-drying

ActiveCN103610225AIncrease profitImprove atomization effectTobacco preparationEngineeringHigh pressure water

The invention relates to a feeding method in processes of tobacco leaf threshing and re-drying. Feed liquid is selected according to quality characteristics of tobacco leaves and added into a moisture regain section of a re-drying machine according to the 0.4% proportion of tobacco leaf weight, high-pressure water is used for carrying the feed liquid to be sprayed on the tobacco leaves of the moisture regain section after sprayer nozzle atomizing, and the temperature at the moisture regain section is controlled to be 55-65 DEG C. The feeding method is even in feeding, high in feed liquid utilization rate and good in feeding effect and keeps a biological agent active, and therefore the purposes that tobacco leaves are safely stored, the quality of the tobacco leaves is improved, and use value of the tobacco leaves is improved are achieved. The feeding is performed on the moisture regain section of the re-drying machine, so that feeding evenness and tobacco lamina safety are guaranteed.

Owner:CHINA TOBACCO SHANDONG IND

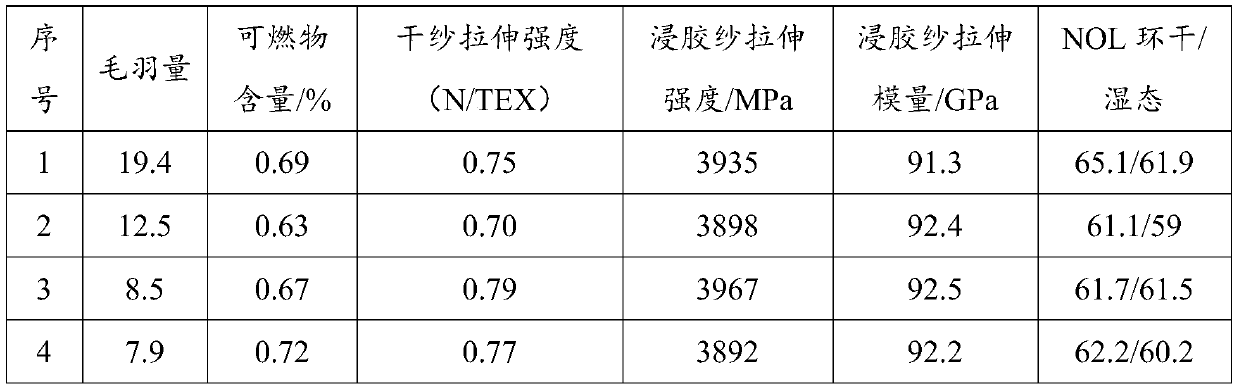

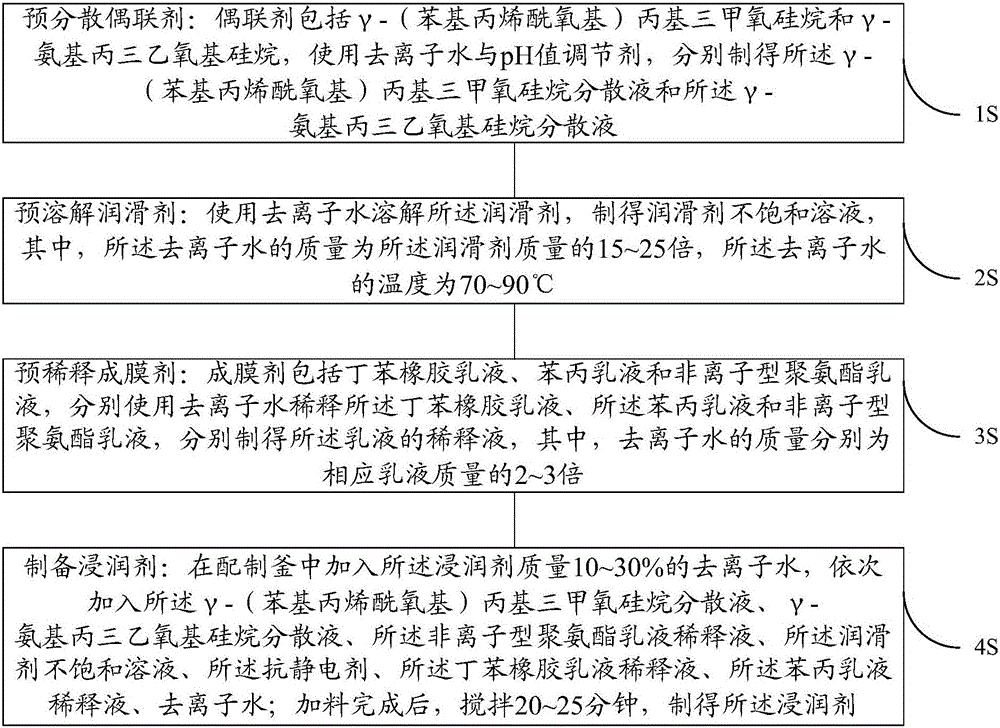

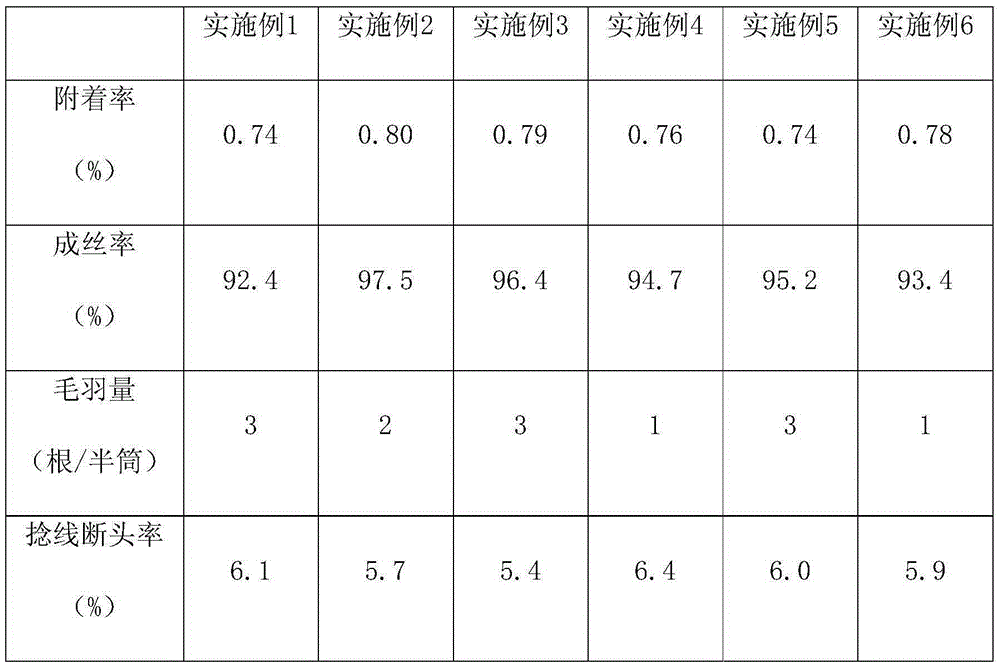

Glass fiber soakage agent for reinforcing ABS plastic and AS plastic and preparation method and application of glass fiber soakage agent

The invention provides a glass fiber soakage agent for reinforcing ABS plastic and AS plastic and a preparation method of the glass fiber soakage agent. The soakage agent is prepared from a coupling agent, a lubricating agent, an antistatic agent, a pH value adjusting agent, a film-forming agent and deionized water, wherein the film-foaming agent is prepared from a styrene-butadiene rubber latex, a styrene-acrylic emulsion and a nonionic polyurethane emulsion, and the film-forming agent accounts for 2.0%-20.0% by mass of the soakage agent. The preparation method of the soakage agent comprises the steps of pre-dispersing the coupling agent, pre-dissolving the lubricating agent, pre-diluting the film-forming agent, preparing the soakage agent and the like. By means of the soakage agent, the physical and chemical properties of the surfaces of glass fibers can be changed, the glass fibers are good in bundling, the compatibility of the glass fibers with the ABS and AS plastic can be effectively improved, and produced AS and ABS plastic products have the advantages of being high in impact strength, good in product appearance, long in service life and the like.

Owner:JUSHI GRP CO

High-wettability glass fiber impregnating compound and preparation method thereof

The invention provides a high-wettability glass fiber impregnating compound and a preparation method thereof. The high-wettability glass fiber impregnating compound is specifically prepared in steps as follows: (1), citric acid and oxalic acid are added to softened deionized water, the PH (potential of hydrogen) value of a solution is adjusted, the mixture is uniformly stirred until components are completely mixed, a non-ionic surfactant and a cationic surfactant are slowly added, the mixture is uniformly stirred until the components are completely dissolved, and a solution containing a coupling agent is obtained; (2), a lubricating agent, a cross-linking agent, a polyoxyethylene type surfactant, fatty acid ester sulfate and hydrolyzed chitosan are added to the softened deionized water, the mixture is heated and stirred until the components are completely dissolved, then the mixture is cooled at the room temperature, and an aid solution is obtained; (3), waterborne epoxy resin with epoxide equivalent being 415-437 and waterborne polyurethane in the volume ratio being 1: (0.3-1) are added to the deionized water to be diluted, then the mixture is uniformly stirred, and a diluted tow collecting agent is obtained; (4), the aid solution and the diluted tow collecting agent are slowly added to the solution containing the coupling agent, uniformly stirred, left to stand and defoamed, and the high-wettability glass fiber impregnating compound is obtained.

Owner:HUZHOU BOREN TEXTILES

Multicomponent white conductive fiber and preparation method thereof

InactiveCN101676450AImprove the shortcomings of limited application rangeHigh whitenessElectroconductive/antistatic filament manufactureFilament/thread formingPolymer scienceCarbon nanotube

The invention discloses multicomponent white conductive fiber and a preparation method thereof. The conductive fiber comprises first polymer containing conductive powder and second polymer mainly containing fibre-forming polymer, wherein the first polymer is partially coated in the second polymer and the perimeter of the contact surface of the first polymer and second polymer accounts for 85%-98%of the perimeter of the first polymer. The invention is characterized in that light nanometer conductive powder is used so as to improve the defect that owning to the dark color of carbon black and carbon nanotubes, the application of the conductive fiber is limited; the open eccentric core and C-type spinneret plates are used to ensure the full exposure of conductive component and increase the whiteness of the conductive fiber; the conductive component is partially embedded in the fibre-forming polymer so as to reduce the exposure of conductive component, increase the collection property of monofilament, benefit the post-processing and ensure that during the post-processing and textile-using processes, the conductive component is not easy to drop off, thus achieving the permanent conductive effect.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

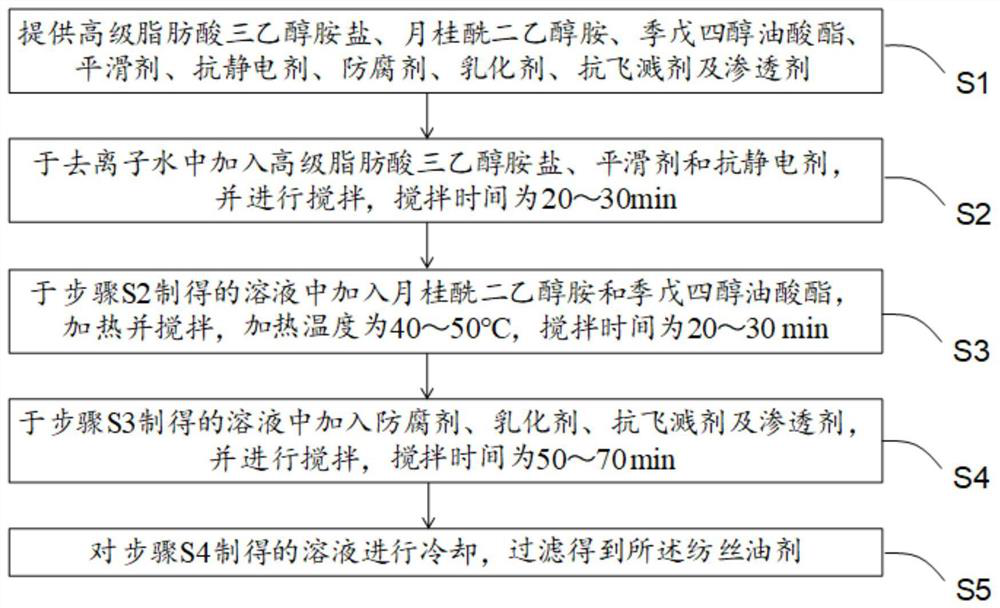

Polyester spinning oil and preparation method thereof

InactiveCN111691013AImprove clusteringImprove wettabilitySynthetic polymer filament chemical after-treatmentPolyesterYarn

The invention discloses polyester spinning oil. The polyester spinning oil is prepared from higher fatty acid triethanolamine salt, lauroyl diethanolamine, pentaerythritol oleate, a smoothing agent, an antistatic agent, a preservative, an emulsifying agent, an anti-splashing agent, and a permeating agent. According to the polyester spinning oil and the preparation method thereof, the bundling performance of the oil can be improved very well by taking the higher fatty acid triethanolamine salt as a bundling agent; the pentaerythritol oleate and the lauroyl diethanolamine have good heat resistance and viscosity properties, and can improve the wettability and temperature resistance of the oil very well; the anti-splashing agent is added, so that the viscosity of the oil is improved, and meanwhile, the tension surface of the oil is greatly increased; therefore, the attachment degree of the oil is high; the permeating effect of the oil is good through the permeating agent; and more oil permeates into yarns.

Owner:科凯精细化工(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com