Dacron conductive lining cloth and production process thereof

A production process and interlining technology, which is used in the manufacture of conductive/antistatic filaments, textiles, yarns, etc., can solve the problems of lack of toughness, reduced fabric softness and hand feel, and easy separation of conductive substances, and achieve excellent conductive properties, The effect of excellent washing resistance and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

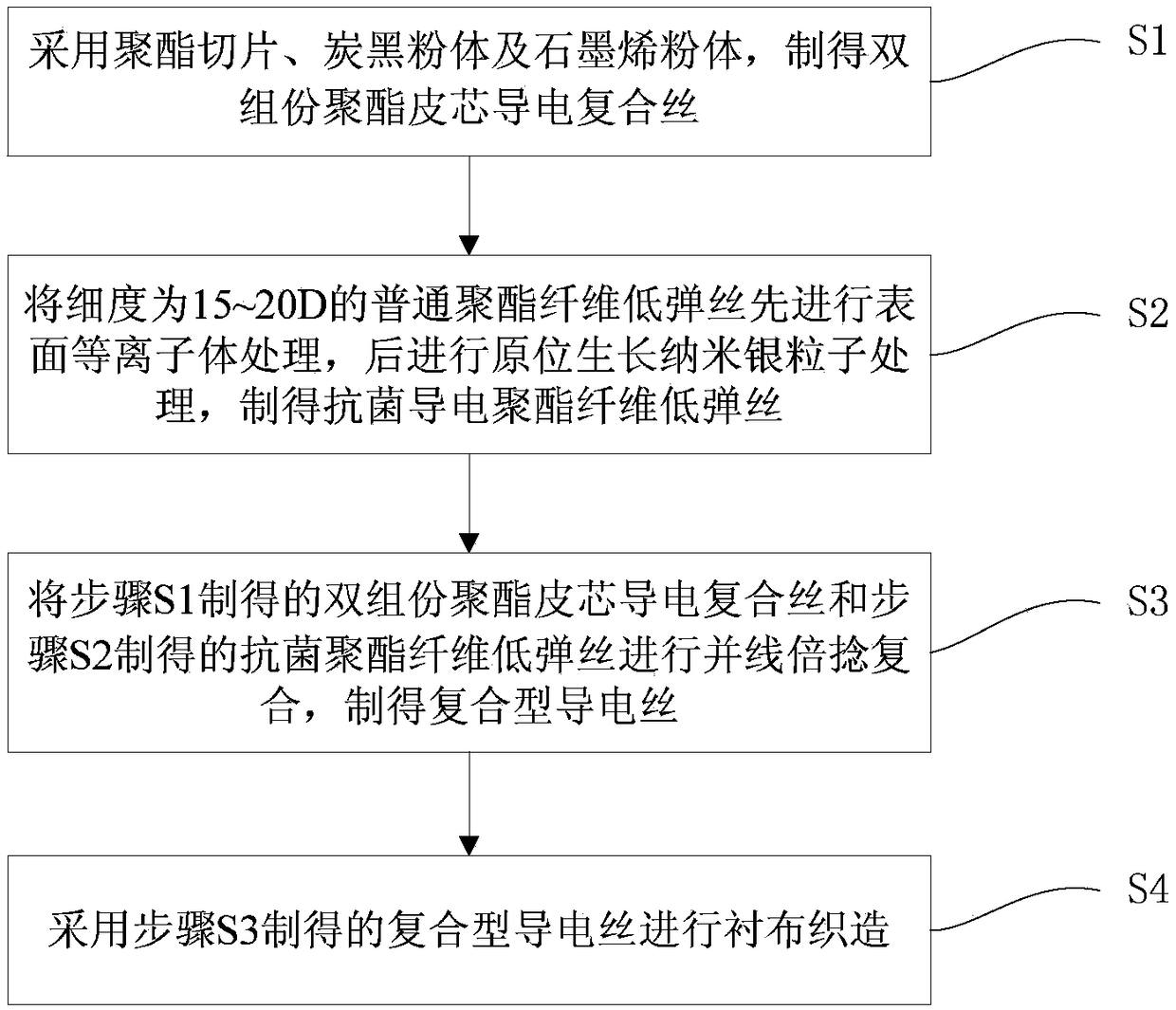

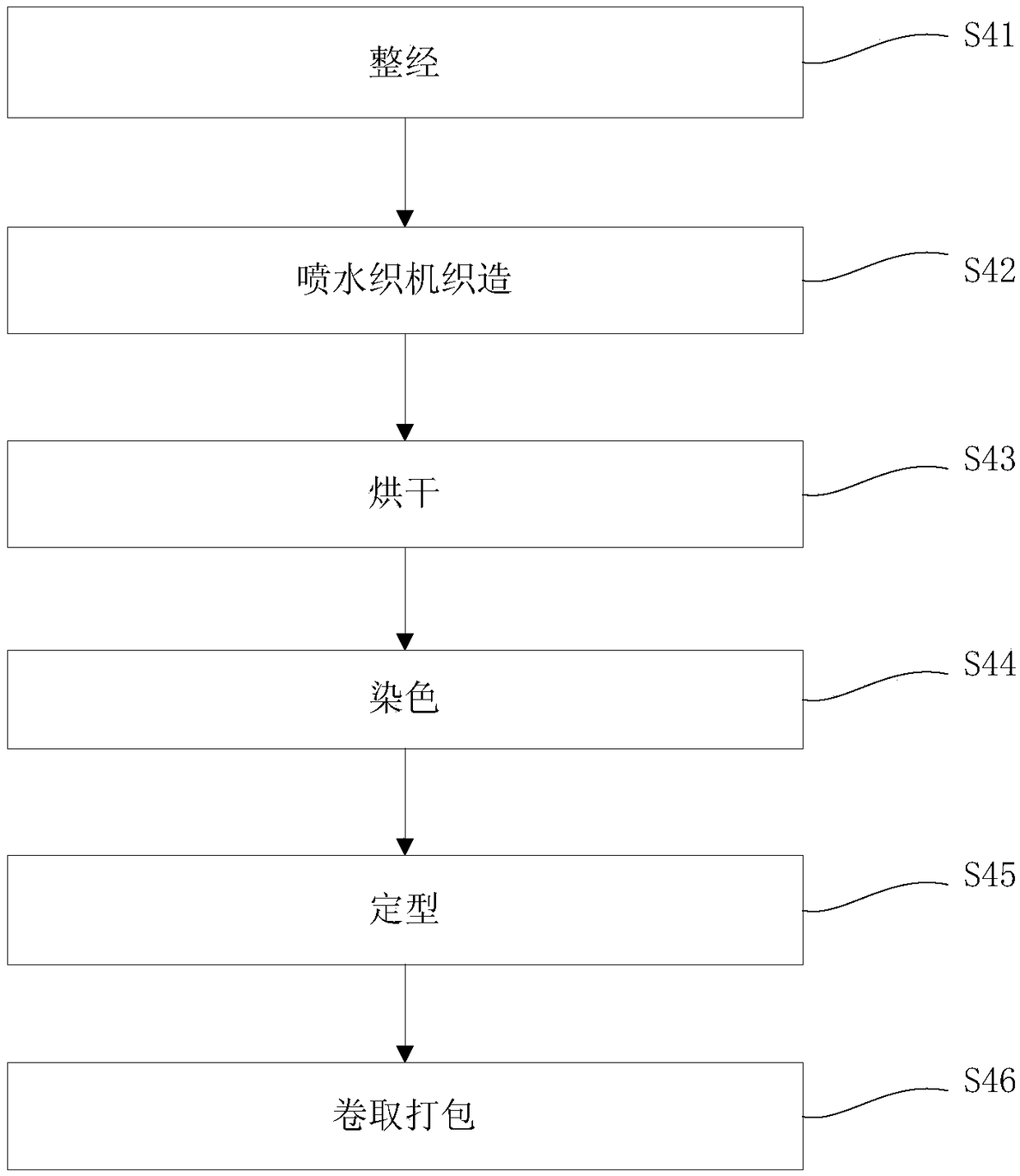

[0060] as attached figure 1 Shown, a kind of production technology of polyester conductive interlining comprises the following steps:

[0061] S1. Using polyester PET slices, carbon black powder and graphene powder to prepare a two-component polyester sheath-core conductive composite wire.

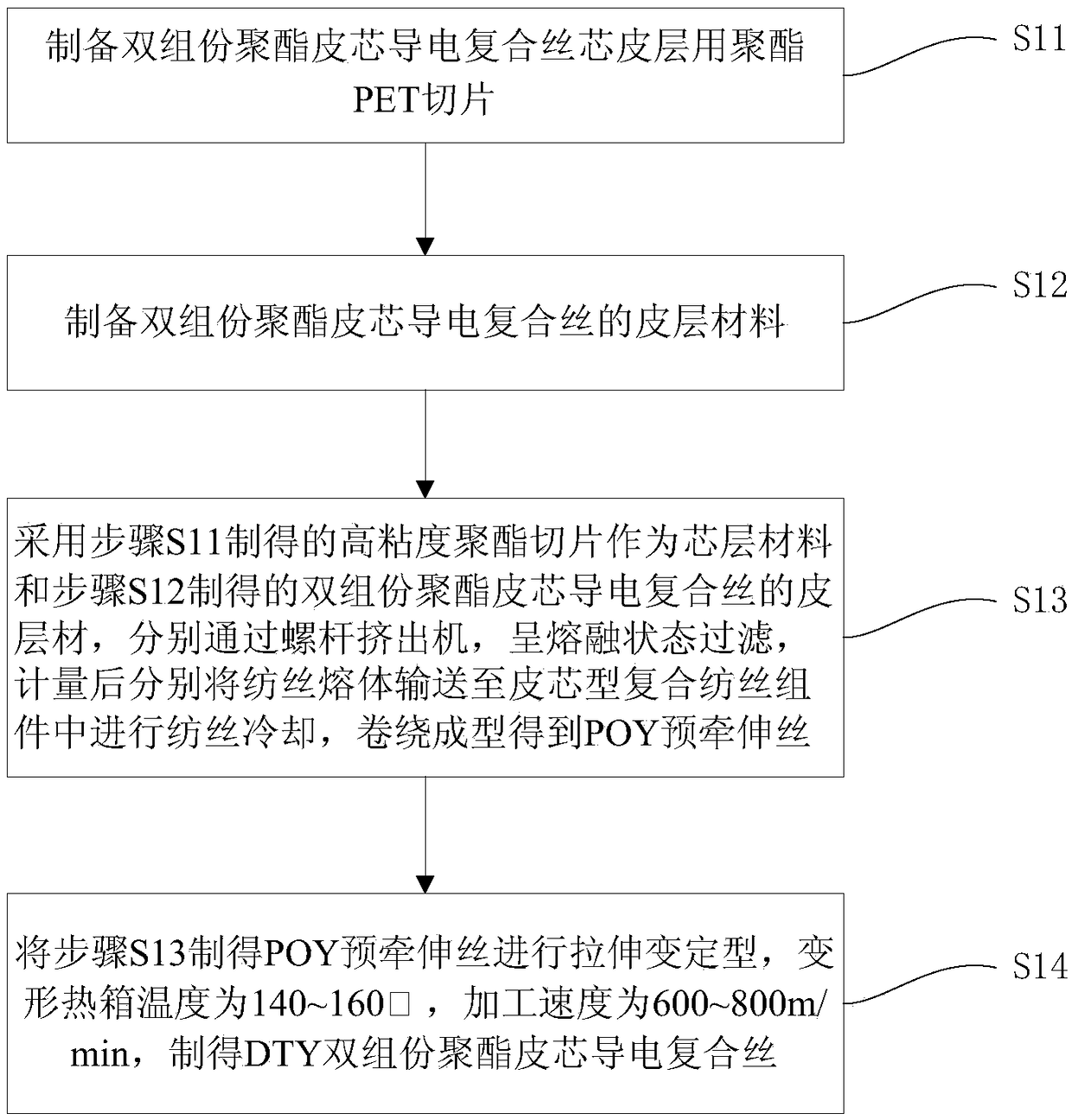

[0062] as attached figure 2 Shown, the preparation of two-component polyester sheath-core conductive composite wire comprises the following steps:

[0063] S11. Prepare two-component polyester sheath-core conductive composite wire core cortex with polyester PET slices, and pre-crystallize the polyester PET slice raw materials. The pre-crystallization temperature is 175 ° C, and the pre-crystallization time is 12 minutes; then perform solid phase Polymerization and drying, the temperature of solid-state polymerization is 215°C, and the time of solid-state polymerization is 22h; high-viscosity polyester PET chips are obtained, the viscosity of high-viscosity polyester PET chips is 1.0dl / g...

Embodiment 2

[0095] as attached figure 1 Shown, a kind of production technology of polyester conductive interlining comprises the following steps:

[0096] S1. Using polyester PET slices, carbon black powder and graphene powder to prepare a two-component polyester sheath-core conductive composite wire.

[0097] as attached figure 2 Shown, the preparation of two-component polyester sheath-core conductive composite wire comprises the following steps:

[0098] S11. Prepare two-component polyester sheath-core conductive composite wire core skin layer with polyester PET slices, and pre-crystallize the polyester PET slice raw materials. The pre-crystallization temperature is 200 ° C, and the pre-crystallization time is 8 minutes; then carry out solid phase Polymerization and drying, the temperature of solid-state polymerization is 240°C, and the time of solid-state polymerization is 18h; high-viscosity polyester PET chips are obtained, the viscosity of high-viscosity polyester PET chips is 1....

Embodiment 3

[0130] as attached figure 1 Shown, a kind of production technology of polyester conductive interlining comprises the following steps:

[0131] S1. Using polyester PET slices, carbon black powder and graphene powder to prepare a two-component polyester sheath-core conductive composite wire.

[0132] as attached figure 2 Shown, the preparation of two-component polyester sheath-core conductive composite wire comprises the following steps:

[0133] S11. Prepare two-component polyester sheath-core conductive composite wire core cortex with polyester PET slices, pre-crystallize the polyester PET slice raw materials, the pre-crystallization temperature is 185-190 ° C, and the pre-crystallization time is 10 minutes; then carry out Solid phase polymerization, drying, the temperature of solid phase polymerization is 220 ~ 230 ℃, and the time of solid phase polymerization is 19.5h; high viscosity polyester PET chips are obtained, the viscosity of high viscosity polyester PET chips is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com