Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Increase smoke concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of material with tobacco fragrance

The invention discloses a preparation method of a material with tobacco fragrance. The preparation method is characterized by sequentially comprising the following steps: 1, drying and pulverizing tobacco raw materials, then conducting extraction through an ethanol solution, conducting solid-liquid separation, then conducting decompression condensation on filter liquor, and obtaining tobacco extract A; adding a bio-enzyme preparation to obtained filter residues for conducting enzymatic hydrolysis, conducting solid-liquid separation, then conducting decompression condensation on filter liquor, and obtaining tobacco extract B; mixing the exact B, amino compounds and polyalcohol, conducting heating, making the mixture react, and obtaining a tobacco reagent C; 4, mixing the tobacco exact A and the tobacco reagent C in a certain proportion, and obtaining the material with tobacco fragrance. The preparation method of the material with tobacco fragrance is applicable to different varieties of tobacco products, and real, abundant and rich original tobacco fragrance can be supplied to the tobacco products.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

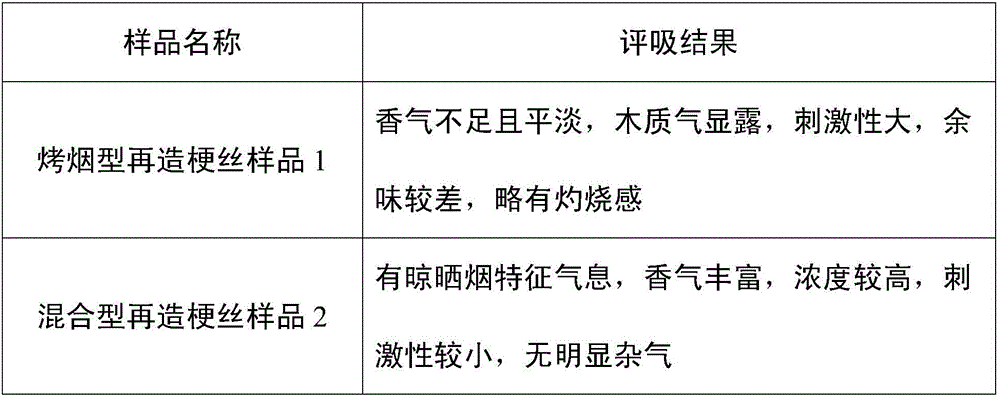

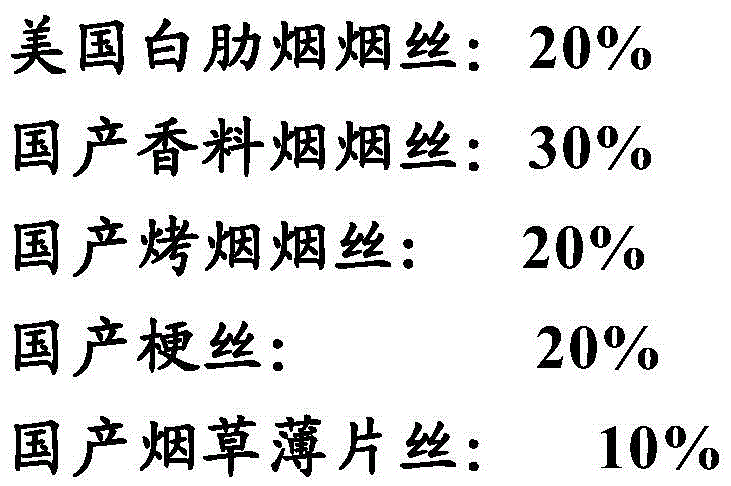

Preparation method of mixed type regenerated cut stems

InactiveCN105707970AIncrease the amount of aromaIncrease smoke concentrationTobacco preparationTobacco treatmentUniform - qualityPre treatment

The invention discloses a method for preparing mixed reconstituted shredded stems, which is characterized in that it comprises the following steps: S01, preparation of blank shredded stems: the pretreated tobacco stems are sequentially cut into shreds, extracted, separated from solid and liquid, and dried Drying process to produce blank shredded stems with uniform quality; S02, sequentially extracting mixed tobacco raw materials, separating solid and liquid, and concentrating the extract to obtain a backfill stock solution; S03, adding a functional flavoring liquid to the backfill stock solution , preparing a backfill solution; S04, spraying the backfill solution evenly on the blank cut stems, fully stirring and mixing, and then drying to obtain a mixed-type reconstituted cut stem finished product. The invention provides a method for preparing mixed reconstituted cut stems. The mixed reconstituted cut stems prepared by this method can significantly increase the aroma and smoke concentration of reconstituted cut stems, enhance the sense of satisfaction and comfort when smoking, and improve the quality of reconstituted cut stems. Stem product quality.

Owner:CHINA TOBACCO JIANGSU INDAL

Electronic cigarette liquid solvent and preparation method for same

InactiveCN104068470AIncrease smoke concentrationIncrease sense of fulfillmentTobacco treatmentTobacco devicesBiochemical engineeringGlycerol

The invention provides an electronic cigarette liquid solvent and a preparation method for the same. The electronic cigarette liquid solvent provided by the invention is obtained after mixing solvents of propylene glycol, glycerol, 1,3-butanediol, d-sorbitol solution, xylitol solution and the like, and the formula comprises 20-60 parts of propylene glycol, 30-50 parts of glycerol, 10-30 parts of 1,3-butanediol, 1-10 parts of d-sorbitol solution and 1-10 parts of xylitol solution. By using the electronic cigarette liquid solvent provided by the invention in the electronic cigarette liquid formula, the smoke concentration of an electronic cigarette can be effectively increased, the fulfilling sense of the oral cavity can be improved, and the remaining taste can be improved. The preparation method for the electronic cigarette liquid solvent is simple and practicable, and provides a good basis for development for an electronic cigarette liquid.

Owner:嘉兴市得百科新材料科技有限公司

Preparation method of smoking material for cigarette realizing no combustion under heating and smoking material obtained through preparation method

PendingCN108926028AIncrease smoke concentrationAroma style characteristics are adjustable and controllableTobacco treatmentCombustionVolumetric Mass Density

The invention discloses a preparation method of a smoking material for a cigarette realizing no combustion under heating and the smoking material obtained through the preparation method. The preparation method comprises the following steps: grinding dried plants, thus obtaining powder A; adding water into a smoke forming agent for adjusting the density of the liquid to be 1.1-1.4 g / mL, thus obtaining atomized liquid B; and mixing the powder A and the atomized liquid B, carrying out granulating or pelleting, and carrying out drying, thus obtaining the smoking material for the cigarette realizing no combustion under heating, which contains no tobacco elements. The method has the advantages the technological operation is simple, the cost is low, and the prepared granule-shaped or pill-shapedsmoking material used for the cigarette realizing no combustion under heating has the advantages that the concentration of smoke is high, and the aroma style characteristic, the taste and the puff number can be adjusted and regulated.

Owner:周谦 +2

Tobacco material suitable for heating non-combustion device and preparing method of tobacco material

ActiveCN105433430AImprove heating conditionsIncrease smoke concentrationTobacco treatmentWater contentEngineering

The invention belongs to the technical field of tobaccos, and particularly relates to a tobacco material suitable for heating a non-combustion device and a preparing method of the tobacco material. The tobacco material is prepared from, by mass, 30-80 parts of tobacco powder, 10-30 parts of tobacco extract, 5-30 parts of polyhydric alcohols, 1-5 parts of an expanding auxiliary, 0.1-5 parts of a heat conducting material, 1-5 parts of a dispersing auxiliary and 0.1-5 parts of a natural antibacterial agent, and the water content is 8-15%. Compared with other tobacco materials for heating the non-combustion device in the prior art, the tobacco material has the obvious advantages that the smoke concentration is obviously increased, smoke release uniformity is obviously improved, the quality is more stable, and the application range is wide.

Owner:CHINA TOBACCO HENAN IND +1

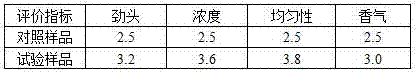

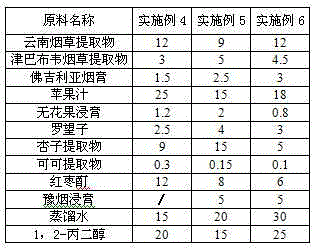

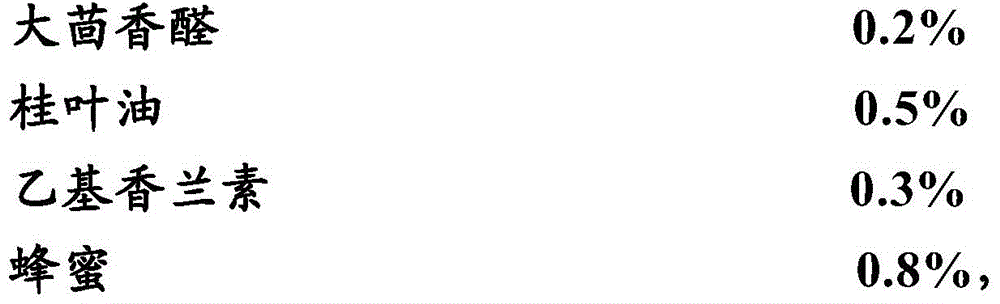

Blended essence for tobacco fragrance increase and preparation method of blended essence

InactiveCN105154234AIncrease the amount of aromaIncrease smoke concentrationTobacco treatmentEssential-oils/perfumesBiotechnologyCocoa Extract

The invention discloses a blended essence for tobacco fragrance increase. The blended essence is obtained by mixing the following raw materials in parts by weight: 8-15 parts of a Yunnan tobacco extract, 2-6 parts of Zimbabwe tobacco extract, 1-3 parts of Virginia tobacco paste, 15-25 parts of apple juice, 0.5-2 parts of a fig extract, 2.5-4 parts of tamarinds, 5-15 parts of an apricot extract, 0.1-0.3 part of a cocoa extract, 5-15 parts of a red date tincture, 10-30 parts of 1,2-propylene glycol and an appropriate amount of distilled water. The invention also discloses a preparation method of the blended essence for tobacco fragrance increase. The blended essence for tobacco fragrance increase ensures that tobaccos are rich in clear and sweet or heavy tobacco fragrance according to cut tobaccos of different production places; by adding the apple juice, the tamarinds, the red date tincture and the fig extract, the smoke and tobacco fragrance are soft and delicate and additionally have a fruit fragrance, the mouthfeel is improved, and the irritation of tobacco is reduced; and by adding the apricot extract, the smoke concentration is improved, and the agglomeration property and explosive force of the smoke are enhanced. The preparation method of the blended essence for tobacco fragrance increase is simple to operate and is low in cost.

Owner:湖南嘉利香料有限公司

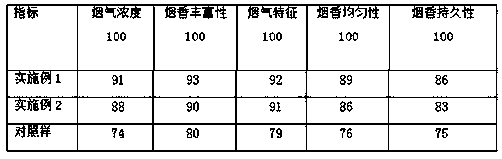

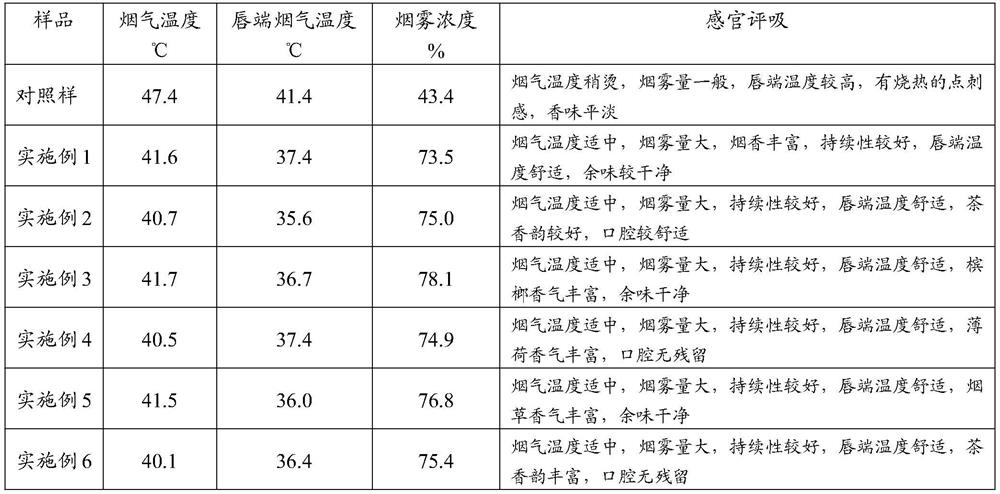

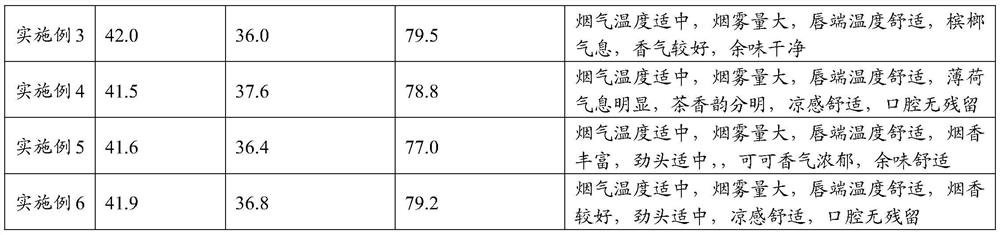

High-aroma heat-not-burn tobacco and preparation method thereof

InactiveCN108703398AIncrease smoke concentrationSmoke features are obviousTobacco preparationTobacco treatmentFlavorAlcohol

The invention belongs to the technical field of cigarettes and particularly relates to high-aroma heat-not-burn tobacco and a preparation method thereof. The preparation method is characterized by including the steps of (1) microwave swelling; (2) tobacco leaf crushing; (3) suspension preparing; (4) spraying; (5) drying and balancing, wherein the step (3) of suspension preparing includes: mixing well a mixture of a polyol, purified water, anhydrous ethyl alcohol, tobacco extract, a tobacco flavor, a binder and a dispersing aid, and leaf particles of the step (2) in a certain mass ratio to obtain homogenous suspension. The tobacco particles and the flavor are made into the suspension that is sprayed to microwave-swelled tobacco stems, and the defects are overcome that, for instance, the traditional heat-not-burn tobacco smoke has low concentration, poor aroma richness, obscure smoke characteristics, non-uniform aroma, and poor duration.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

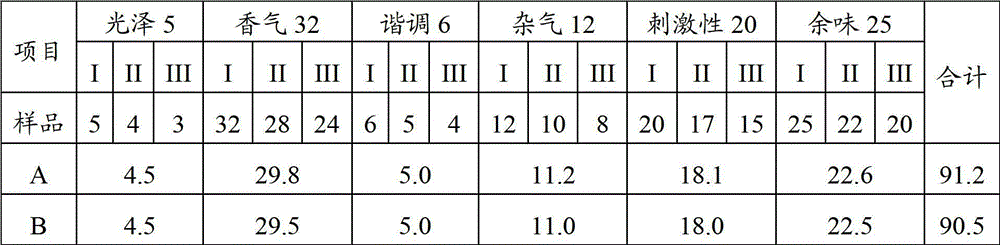

Tobacco composition for paper-making method reconstituted tobacco leaves and application thereof to heat-not-burn cigarettes

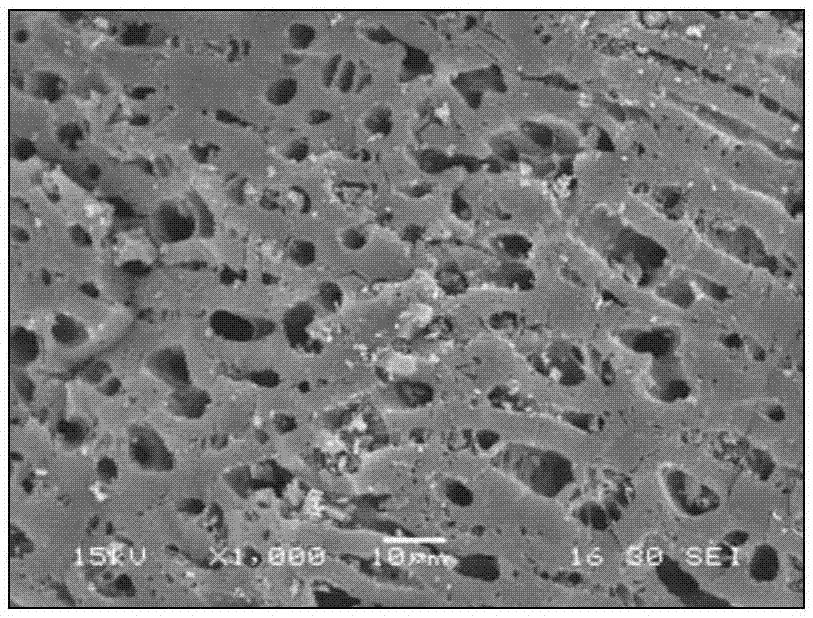

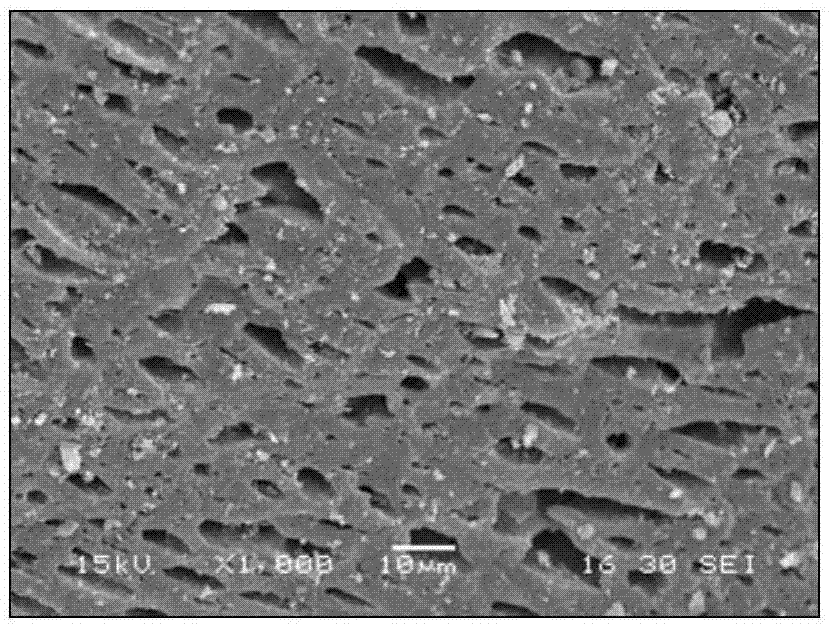

InactiveCN110150723AIntact void structurePromote absorptionTobacco preparationTobacco treatmentHeat not burnEngineering

The invention discloses a tobacco composition for paper-making method reconstituted tobacco leaves and application thereof to heat-not-burn cigarettes. The tobacco composition is prepared from a stemgroup raw material and a leaf group raw material dividedly, based on a conventional paper-making reconstituted tobacco leaf process, a stem group tobacco powder wet part is added into a film base before film base forming, leaf group tobacco powder is added into coating liquid, and the core material paper-making method reconstituted tobacco leaves applied to the heat-not-burn cigarettes are prepared. By utilizing the tobacco composition, the absorption property of the film base of the paper-making method reconstituted tobacco leaves can be improved, the adding requirement of a high-content smoke agent is met, an aroma framework of the heat-not-burn cigarettes is perfected, the quality pursuit of the heat-not-burn cigarettes is reached in the aspect of sensory quality, the aroma quality is good, the smoke concentration is high, the strength is high, the texture is fine and smooth, mixed gas slightly exists, the remaining taste is clear, and harmoniousness is good.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

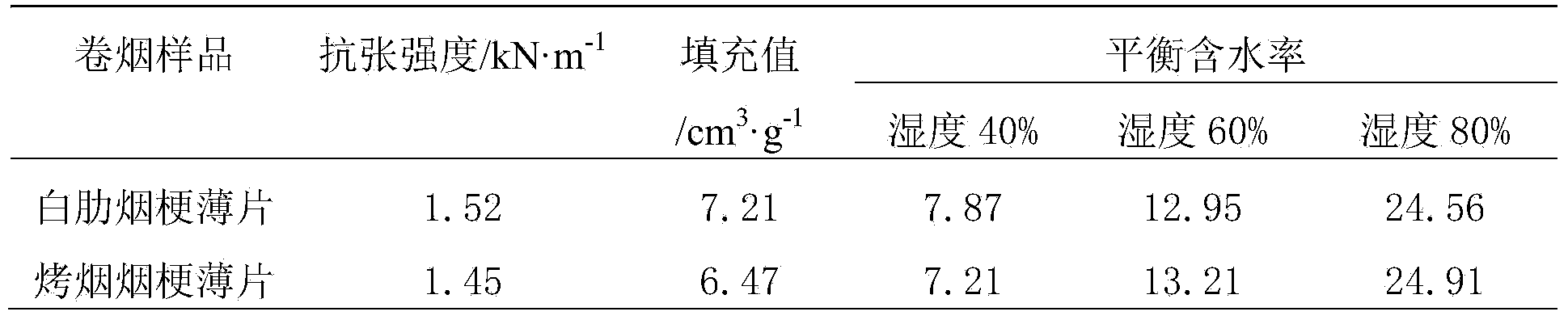

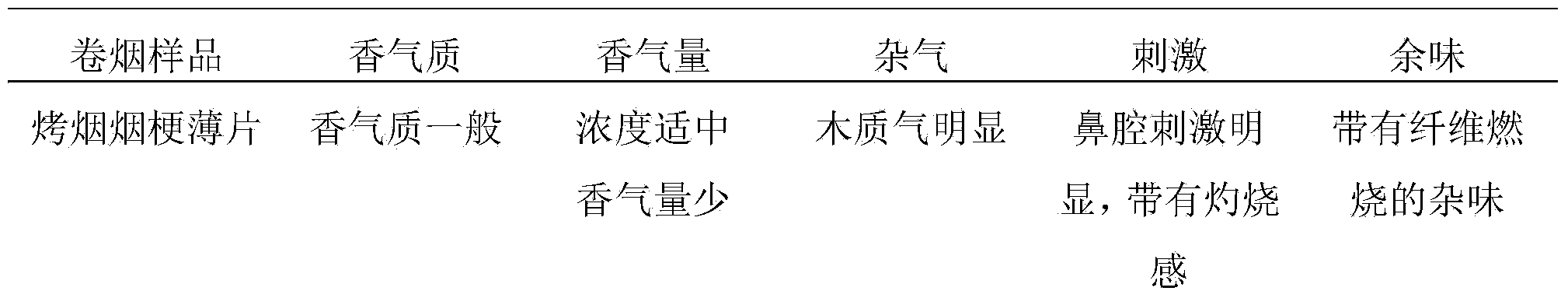

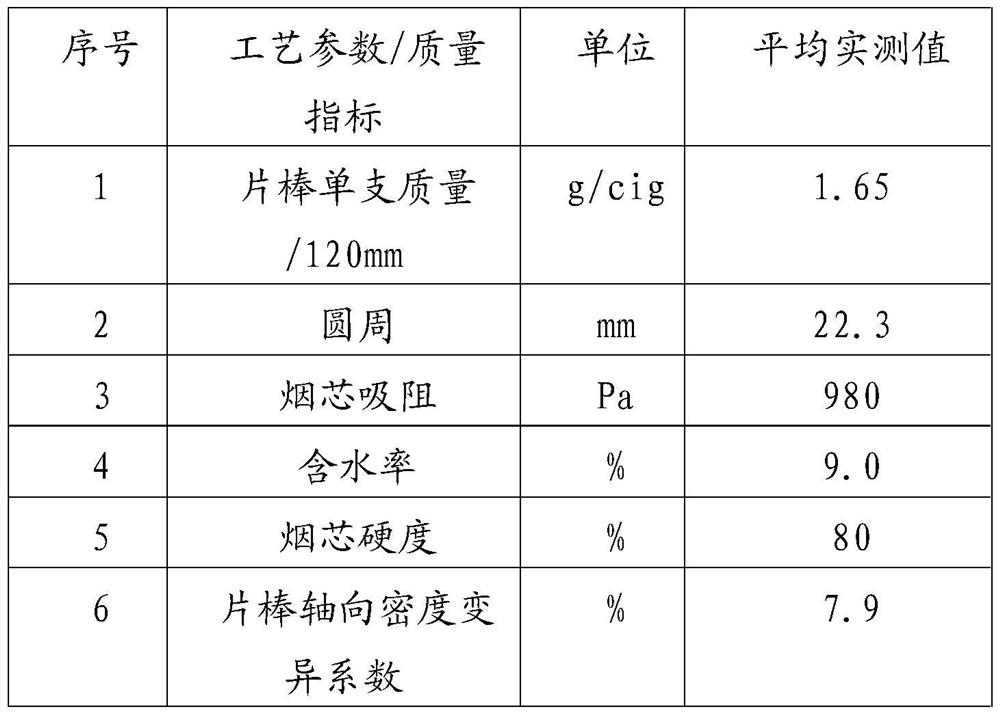

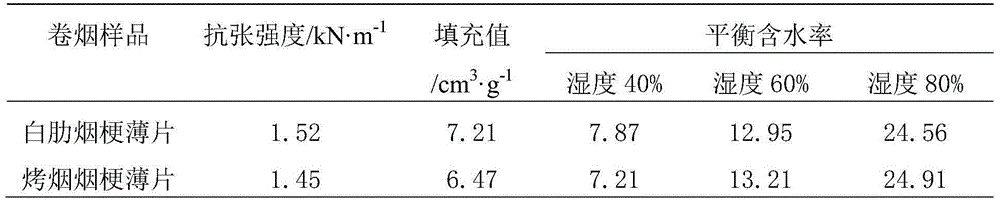

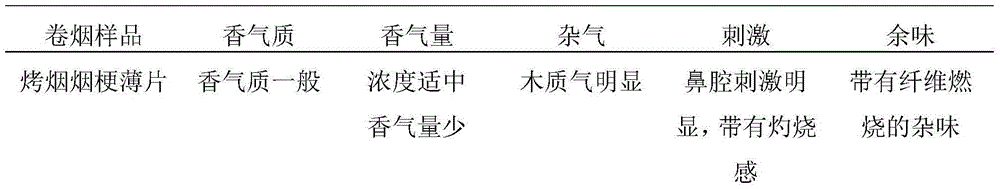

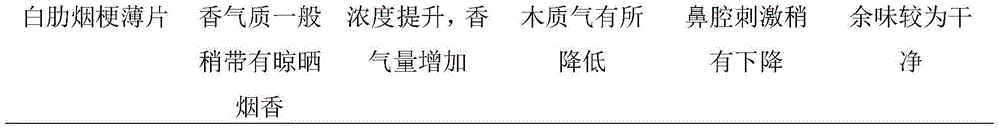

Method for manufacturing cigarette paper making process slices with burley tobacco stems as raw materials

The invention discloses a method for manufacturing cigarette paper making process slices with burley tobacco stems as raw materials. The burley tobacco stems are used as one of the raw materials, flue-cured tobacco powder and other raw materials are also used, and the method for manufacturing and obtaining the cigarette paper making process slices with a paper making process comprises the following steps that the tobacco stems and the tobacco powder are dipped and extracted respectively, and extracting solutions and dipped and extracted tobacco stem residues and tobacco powder residues are obtained through filtration; slice paper bases are obtained by carrying out defibrination, slice making, squeezing and drying on the tobacco stem residues or the tobacco powder residues; the extracting solutions are applied back to the slice paper bases as coating solutions. Easily-obtained agricultural raw materials are utilized in the method, the aroma amount and the smoke concentration of the manufactured cigarette paper making process slices are improved, offensive odors are obviously reduced, tastes are improved, and sense comfort is improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

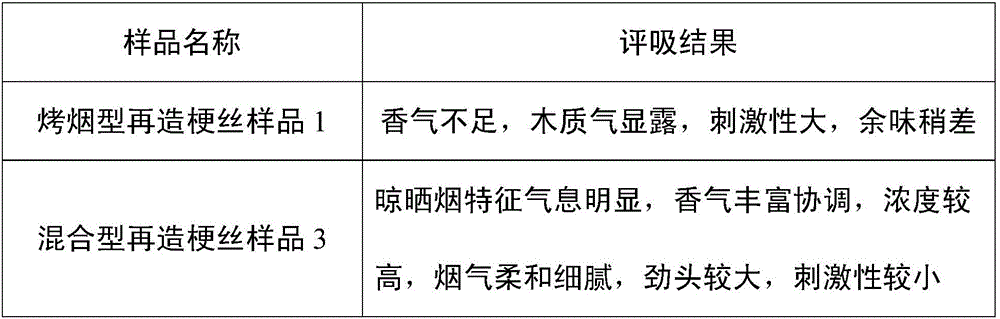

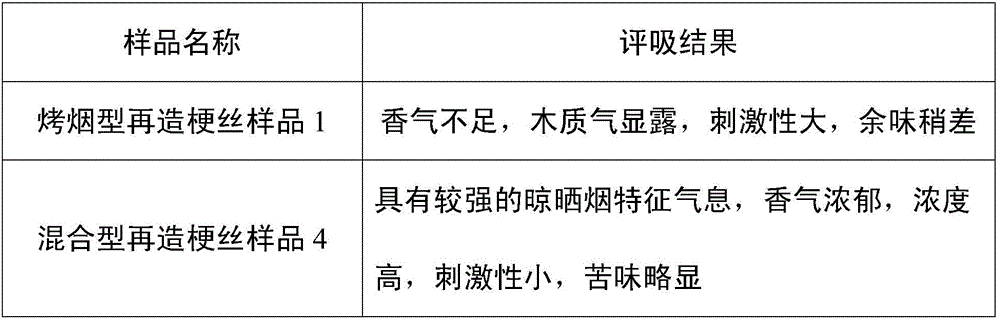

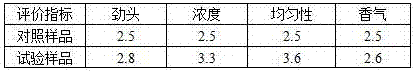

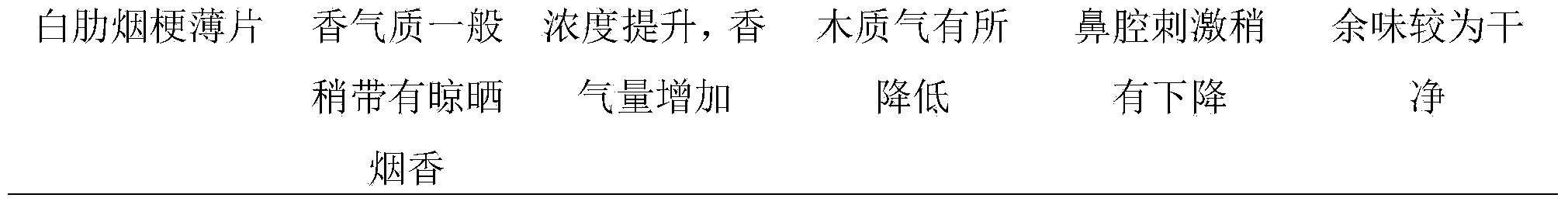

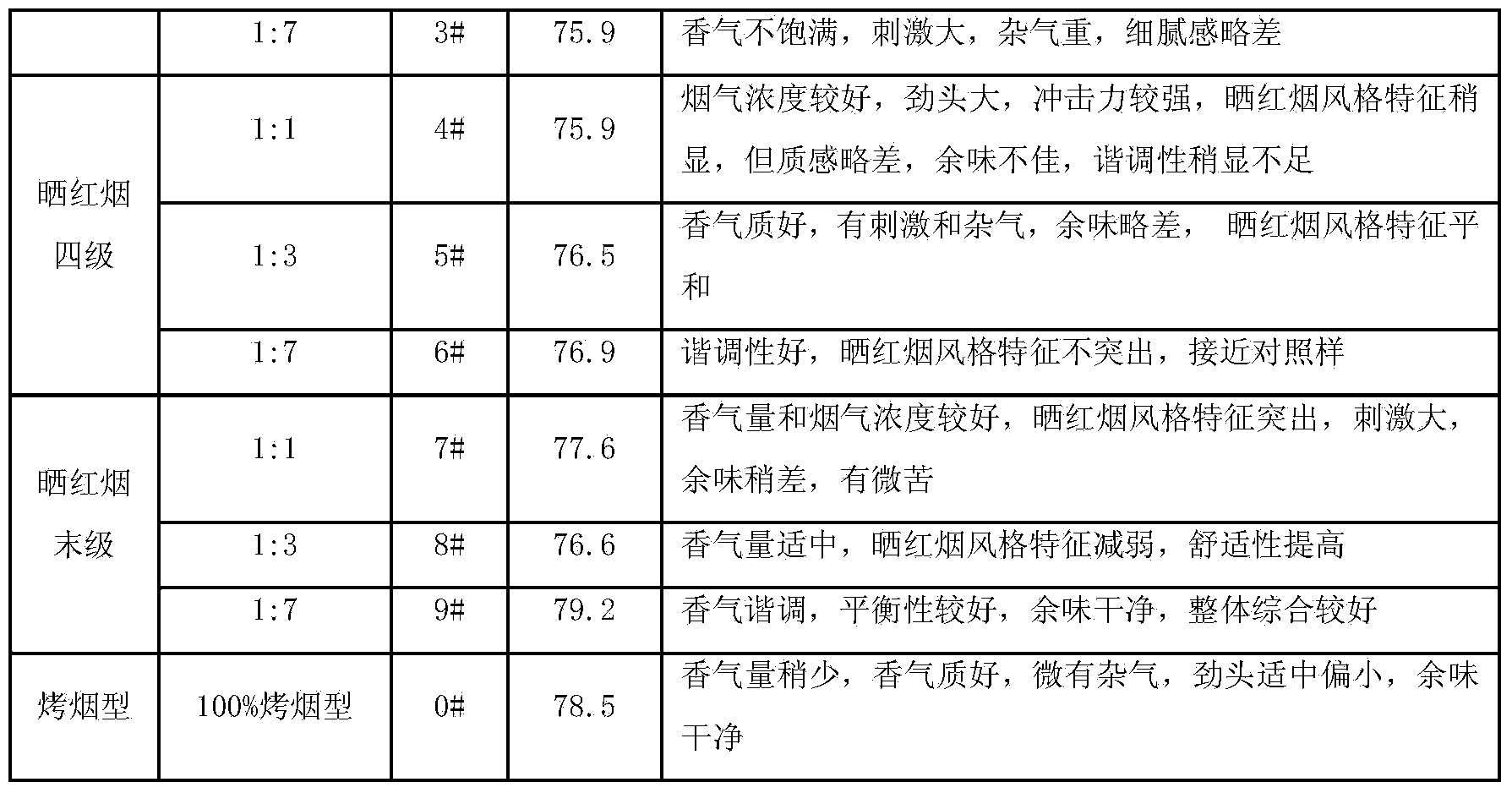

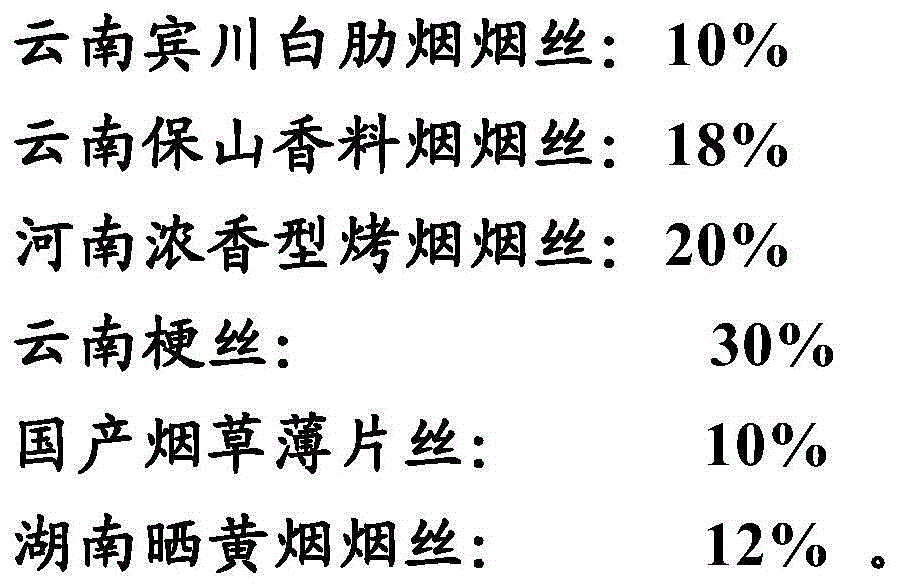

Method for preparing paper-making-method reconstituted tobacco with sun-cured red tobacco style characteristic

InactiveCN103462209AIncrease the amount of aromaIncrease smoke concentrationTobacco preparationTarFlue

The invention relates to a method for preparing paper-making-method reconstituted tobacco with sun-cured red tobacco style characteristic, and belongs to the technical field of paper-making-method reconstituted tobacco. The method comprises the steps of: a. by taking water as a solvent, respectively extracting sun-cured red tobacco and flue-cured tobacco for 40 minutes at the extraction temperature of 60 DEG C to 65 DEG C according to the material-solution ratio of 1:7, performing solid-solution separation, respectively concentrating flue-cured tobacco extracting solution and sun-cured red tobacco extracting solutionby adopting an evaporation method, and preparing into extracts for being used by a flue-cured tobacco type film base; b. mixing the flue-cured tobacco extract and the sun-cured red tobacco extract according to the mass ratio of (1:1)-(1:7), then adding 4% by mass percentage of glycerin as a humectant, blending into coating solution, the density of which is 1.15g / ml-1.25g / ml, with water, coating the flue-cured tobacco type film base with the coating solution, and drying and slitting to obtain the paper-making-method reconstituted tobacco with the sun-cured red tobacco style characteristic. The method has the advantages that the method is simple and easy, the fragrance volume and tobacco concentration of the reconstituted tobacco can be improved, and the fragrance quality can be enhanced; the design demand on low tar and high fragrance can be realized, and the product style characteristic has differentiation which can meet the specific demand of the market.

Owner:YUNNAN RES INST OF TOBACCO SCI

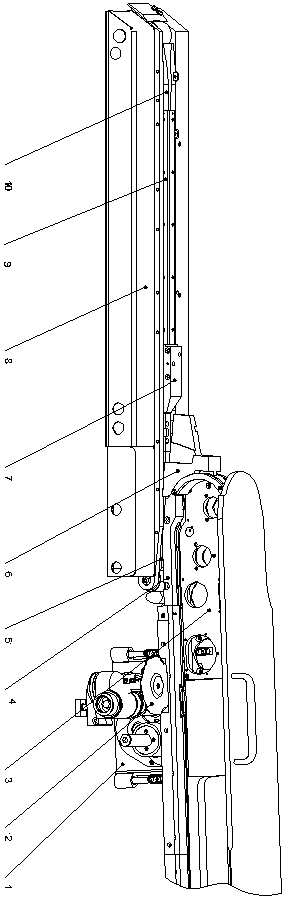

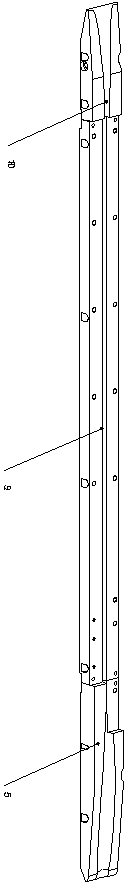

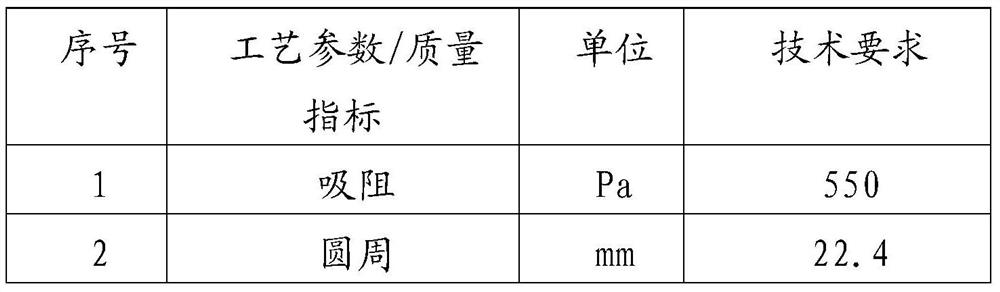

Method for increasing production quality stability of thin cigarettes

ActiveCN108323788ASimple structureImprove stabilityTobacco preparationTobacco treatmentCombustionHazardous substance

The invention relates to a method for increasing the production quality stability of thin cigarettes and belongs to the technical field of cigarette production. The method includes: selecting tobaccocutting width, selecting drying intensity and moisture, purifying cut tobacco, optimizing tobacco structures, reasonably screening and selecting, selecting the type of a cigarette making machine, improving the cigarette making machine, and optimizing the parameters of the cigarette making machine. Compared with the prior art, the method has the advantages that the weight standard deviation of thethin cigarettes produced by the method is lowered from 13mg to 11mg, and the smoking resistance standard deviation of the thin cigarettes is lowered from original 90pa to 40pa; the produced cigarettesare low in main stream smoke tar content and CO content, sufficient combustion is achieved due to the fact that the looseness and filling value of the cut tobacco are increased, few harmful substances are generated during smoking, and low tar and CO generation quantity is achieved; the sensory quality of the produced cigarettes is improved the cigarettes are low in smoking resistance due to the fact that the looseness and filling value of the cut tobacco are increased, and the cigarettes are full and penetrating in aroma and high in smoke concentration.

Owner:CHINA TOBACCO HENAN IND +1

Tobacco sheet and production method thereof

ActiveCN102972860ARich aromaGood compatibilityTobacco preparationTobacco treatmentCelluloseEngineering

The invention relates to the field of tobacco product processing, in particular to a tobacco sheet and a production method thereof. The tobacco sheet is produced from the following raw materials in parts by weight: 20-30 parts of elsholtzia, 70-80 parts of tobacco, 3-4 parts of guar gum, 1 part of liquorice cream and 8 parts of cellulose. According to the invention, the smoke concentration of the tobacco sheet can be effectively increased, the clustering feel of the tobacco sheet can be effectively improved, impurity gases and the irritation of the sheet are reduced, and the mouth feel of the rolling-process sheet is remarkably improved. The production method is simple to operate and low in production cost, and is suitable for the large-scale industrial production of the rolling-process tobacco sheet.

Owner:JILIN TOBACCO IND

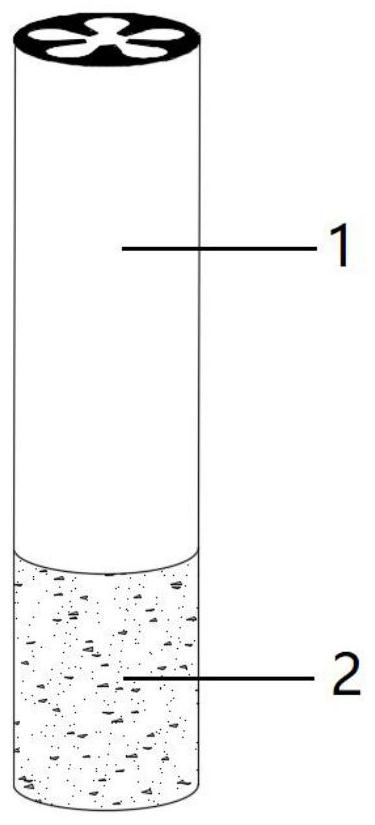

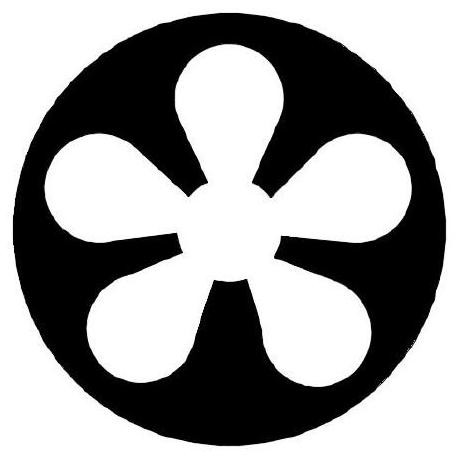

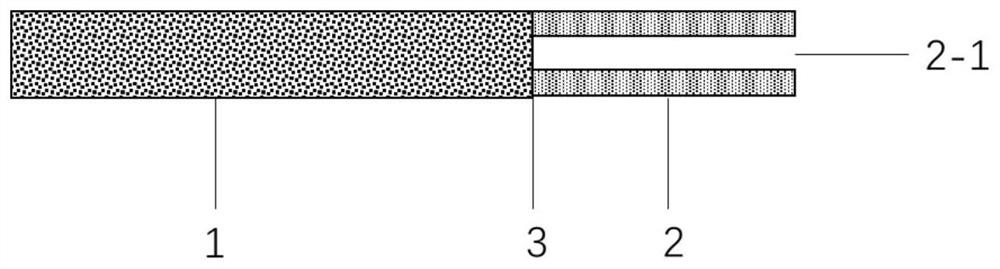

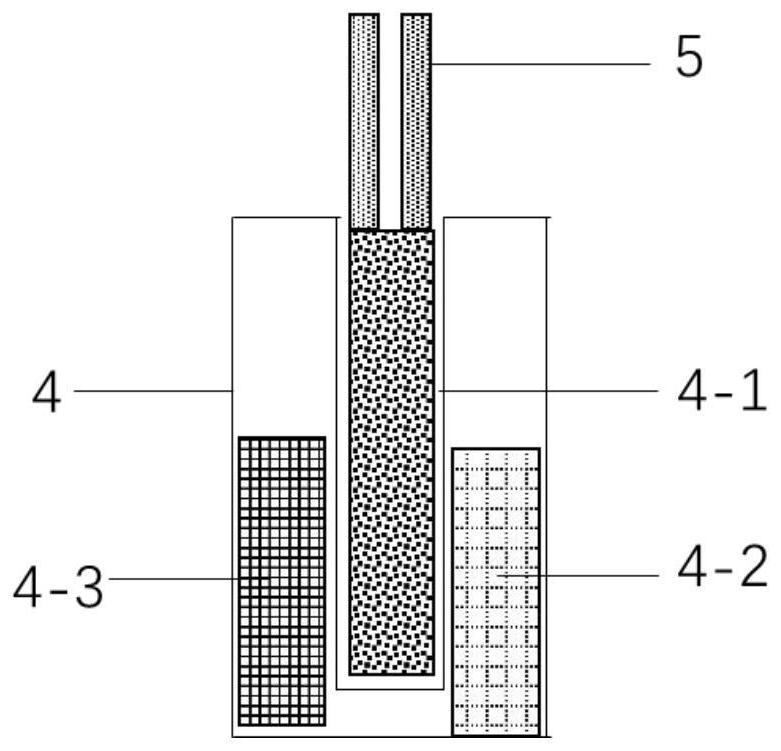

Heat-not-burn article having high smoke concentration

The invention relates to a heat-not-burn product with high smoke concentration. The heat-not-burn product is of a rod-shaped structure formed by connecting a fuming section and a supporting and cooling section through a paper material or a thin film material in the longitudinal axis direction, or of a rod-shaped structure formed by connecting tubular materials in a sleeving mode. According to theinvention, the total amount of volatile components in smoke generation materials and a rear end supporting structure are improved, the smoke generation amount is increased, the smoke cooling effect isguaranteed, meanwhile, the interception rate is reduced, the smoke concentration of the heat-not-burn product with the high smoke concentration is increased by 30% or above compared with that of a mainstream product sold on the market at present. Product consumption experience is significantly enhanced.

Owner:云南纯旭生物科技有限公司

Fragrance generating material used in interlayer of nonflammable heating cigarette and preparation method of material

ActiveCN107752122AModerate concentrationReduce stimulationTobacco treatmentTobacco devicesAdditive ingredientMaterials science

The invention relates to a fragrance generating material used in an interlayer of a nonflammable heating cigarette and a preparation method of the material. The preparation method includes the steps of preparing a coating material and conducting coating and the like. The fragrance generating material is prepared by the coating materials in which natural extracts serve as main ingredients, and thefragrance quality is more similar to that of a traditional cigarette. Meanwhile, the fragrance generating material is applied to the nonflammable heating cigarette, and can improve the heat conductionuniformity of the cigarette and increase the smoke generating amount of the cigarette, and the effect of improving the smoking quality of the overall cigarette is achieved; the fragrance material canbe effectively utilized when the nonflammable heating cigarette is smoked.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

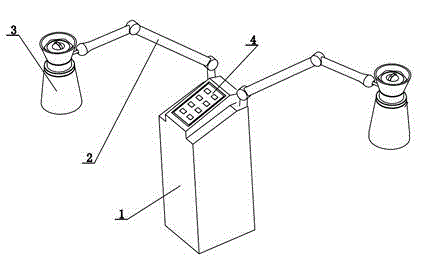

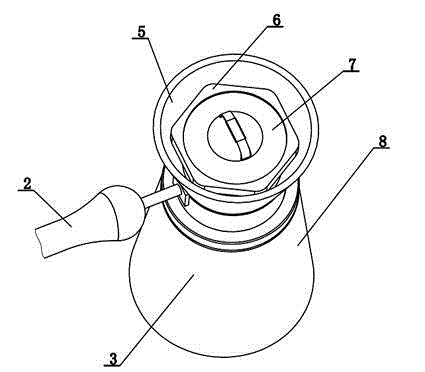

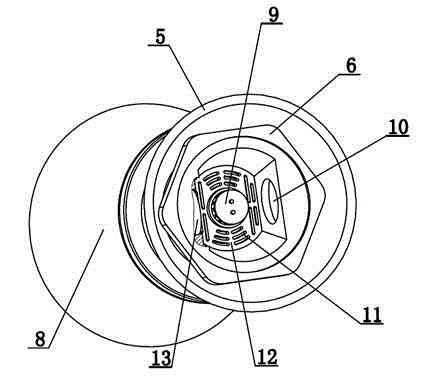

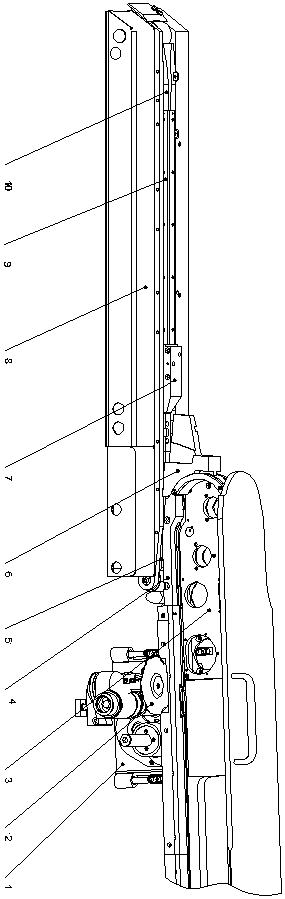

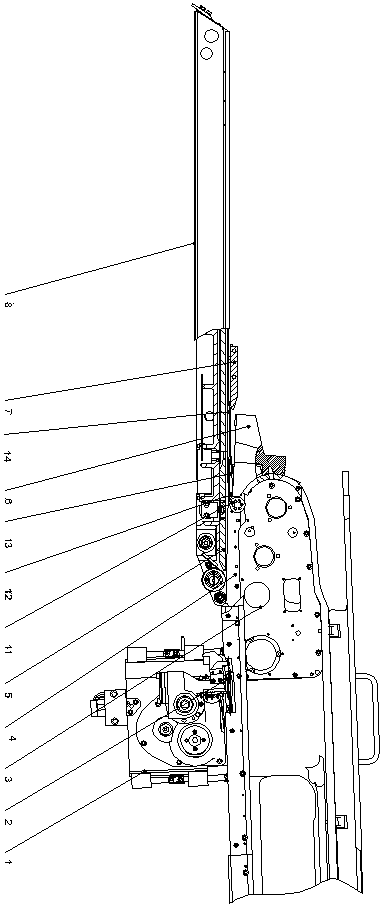

Light-medicine integrated moxibustion therapy apparatus

InactiveCN104958175APromote full volatilizationIncrease profitDevices for heating/cooling reflex pointsMedical devicesMedical equipmentControl system

The invention discloses a light-medicine integrated moxibustion therapy apparatus, pertaining to the technical field of medical equipment. The moxibustion therapy apparatus comprises a base, support arms, light-medicine moxibustion therapy devices and a control system. One ends of the support arms are mounted to the base and the other ends of the support arms are fixedly connected with the light-medicine moxibustion therapy devices. Each light-medicine moxibustion therapy device comprises a shell, in which a medicine bin and a heating device are arranged. Two side walls of the medicine bin are fixedly provided with axial flow fans. Multiple red light sources and infrared light sources are arranged on the circular surface at the lower end of the shell. Heating plates, temperature measurement components, the red light sources and the infrared light sources are all connected to the control system. The light-medicine integrated moxibustion therapy apparatus is provided with a dumping disconnecting protective switch. The light-medicine integrated moxibustion therapy apparatus has following beneficial effects: utilization rate of medicine is improved; according to needs of a patient and the type of medicine, temperature can be flexibly controlled; and by adoption of a flow-guide cover, medicine can be easily collected in order to increase smoke concentration and target ability of medicine.

Owner:ANYANG XIANGYU MEDICAL EQUIP

Formula of cigarette cartridge

InactiveCN110367585ALess irritatingGood sensory qualityTobacco treatmentTobacco devicesAdditive ingredientGlycerol

The invention provides a formula of a cigarette cartridge. According to the formula, the cigarette cartridge is prepared from tobacco leaf extract, tobacco essence, a tobacco flavor, a tobacco juice solvent and deionized water, specifically, the cigarette cartridge is prepared from the following ingredients in percentage by mass: 6%-15% of the tobacco leaf extract, 8%-22% of the tobacco essence, 4%-10% of the tobacco flavor, 30%-45% of the tobacco juice solvent, and 12%-22% of the deionized water, wherein the tobacco juice solvent is prepared from the following ingredients: propylene glycol, glycerol, 1,3-butanediol, sorbitol solution and xylitol solution, specifically, the tobacco juice solvent is prepared from the following ingredients in percentage by mass: 20%-60% of propylene glycol,30%-50% of glycerol, 10%-30% of 1,3-butanediol, 1%-10% of sorbitol solution, and 1%-10% of xylitol solution. For the formula of the cigarette cartridge, improvement is carried out on the formula of the traditional cigarette cartridge, through the use of the tobacco essence and the tobacco flavor, the irritation generated when tobacco juice is smoked later is reduced, the tobacco juice solvent in the cigarette cartridge is improved, then the smoke concentration and mouth filling sense of the electronic cigarette are effectively improved, and thus the smoking of most smokers can be well satisfied.

Owner:杭州黑普酒业有限公司

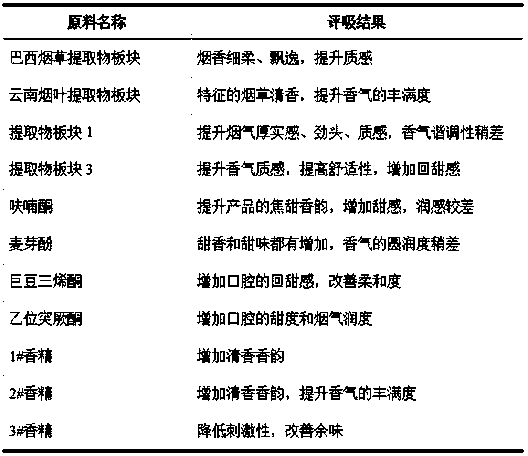

Coating, coating liquid and application thereof to preparation of heat-doesn't-burn dry-method reconstituted tobacco

InactiveCN108497544AIncrease smoke concentrationImprove satisfactionTobacco preparationTobacco treatmentIrritationFood science

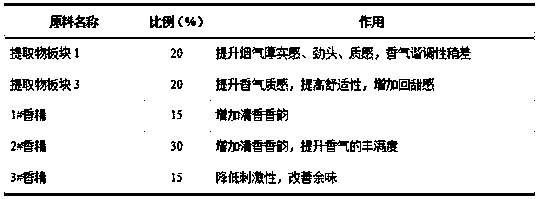

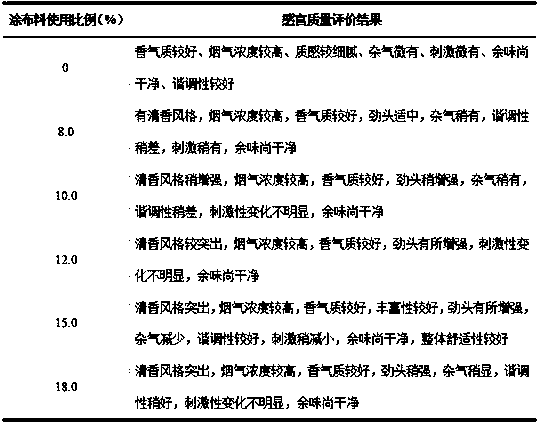

The invention discloses coating, coating liquid and application thereof to preparation of heat-doesn't-burn dry-method reconstituted tobacco. The coating is prepared from, by mass, 15-20% of extract cakes 1, 20-25% of extract cakes 3, 10-15% of No.1 essence, 20-30% of No.2 essence and 15-25% of No.3 essence. The coating can be organically combined and coordinate with the aroma of the dry-method reconstituted tobacco, the tobacco is endowed with the clean aroma style, meanwhile has high smoke concentration, good aroma, high thickness and plumpness and good harmony and can bring high satisfaction and comfort, and the offensive odor and irritation are reduced.

Owner:CHINA TOBACCO GUANGDONG IND +1

Method for manufacturing thick-pulp-method sheet of heating cigarette

ActiveCN112056610AIncrease nicotine contentIncrease smoke concentrationTobacco preparationTobacco treatmentChemistryBiology

The invention discloses a method for manufacturing a thick-pulp-method sheet of a heating cigarette. The method comprises the following steps of (1) designing a raw material formula; (2) loosening andregaining moisture; (3) shredding; (4) warming and humidifying cut tobacco; (5) feeding the cut tobacco; (6) storing and fermenting; (7) drying the cut tobacco; (8) air-cooling the cut tobacco; (9) cooling the cut tobacco; (10) crushing the cut tobacco; (11) storing tobacco powder; (12) preparing pulp; (13) tape-casting; (14) drying; (15) slitting; and (16) packaging. According to the method, theexisting expanded cut tobacco production line technology and equipment are utilized, a thick-pulp-method sheet production process is combined, Maillard reactants and tobacco extracts are added by adopting a cut tobacco feeding and multi-process feeding method, the content of aroma substances in the heating cigarette is increased, and the physical performance of the special sheet is improved by adding nano-cellulose, so that the problems that the content of the aroma substances in the heating cigarette is insufficient and the heating cigarette is difficult to roll are solved.

Owner:CHINA TOBACCO HENAN IND

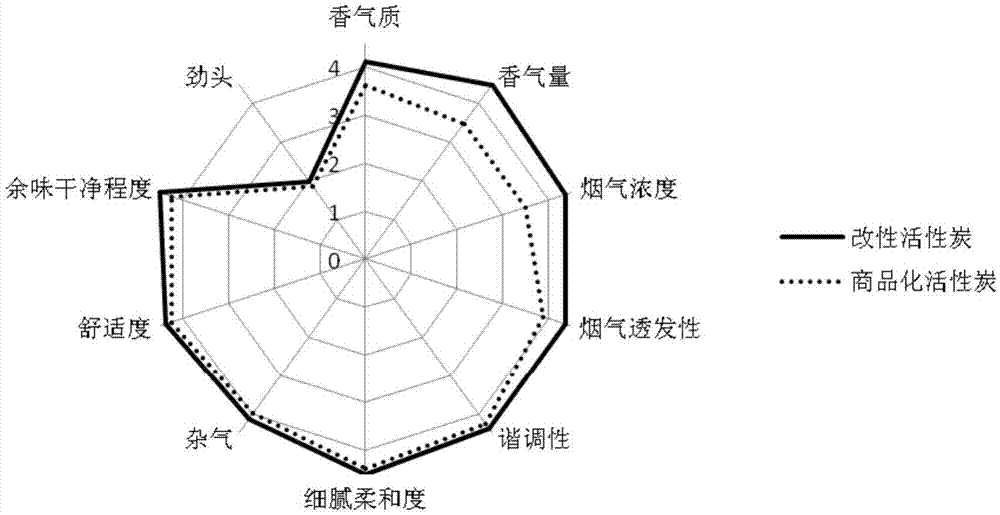

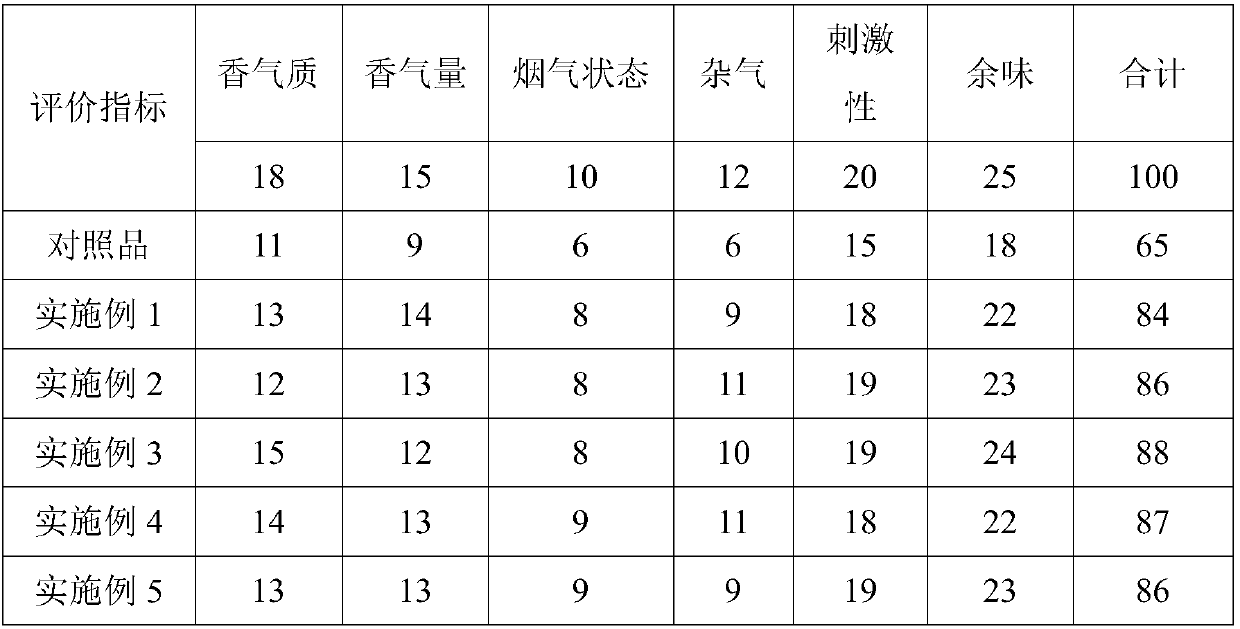

Method for dipping and modifying activated carbon, and application

InactiveCN107080287AImprove aromaRelieves dryness and irritationGas treatmentOther chemical processesTransmission propertiesPre treatment

The invention provides a method for dipping and modifying activated carbon. The method comprises the steps: adding the activated carbon into an aqueous solution of acid, dipping and modifying, and drying to obtain the modified activated carbon. The method for dipping and modifying the activated carbon provides a simple and flexible activated carbon acid modification method by aiming at the defects of the existing technology of modifying the activated carbon for cigarettes, does not need pretreatment and does not need to perform treatment on the activated carbon by high-temperature pressure or heating refluxing methods; and the specific surface area and the micro-mesoporous volume of the modified activated carbon are remarkably changed. The modified activated carbon prepared by the method is applied to cigarette filters, and remarkably improves the smoking aroma quality, the aroma quantity, the smoke concentration and the smoke transmission property of the smoke as well as relieves dry sensation and stimulation sensation of the cigarette smoke as compared with the commercialized unmodified activated carbon so as to improve the smoking odor of the cigarettes integrally.

Owner:SHANGHAI TOBACCO GRP CO LTD

Preparation method of Maillard reaction product of figs for cigarettes

InactiveCN108048215AIncrease smoke concentrationImprove aromaTobacco preparationEssential-oils/perfumesSmokeBrowning reaction

The invention provides a preparation method of a Maillard reaction product of figs for cigarettes. The figs are baked and subjected to water extraction, a preliminary extraction solution of the figs is obtained and then subjected to anaerobic fermentation through lactic acid bacteria, ethanol is added, an ethanol precipitation solution is prepared, filtration and concentration are performed, wateris added for dilution, extraction with ethyl acetate is performed, an ethyl acetate extraction phase is concentrated under reduced pressure, a fig extract is obtained and subjected to a heating reaction with proline, sodium glutamate and stronger ammonia water in a Maillard reaction tank, a humectant is added, and the Maillard reaction product of figs for cigarettes is prepared. The smoke concentration and the aroma can be increased, and the Maillard reaction product has better application effects in the aspects of reducing stimulation to the throat, reducing smokiness of smoke and the oral aftertaste, increasing the oral sweetness and endowing the cigarettes with characters and styles.

Owner:HUBEI CHINA TOBACCO IND

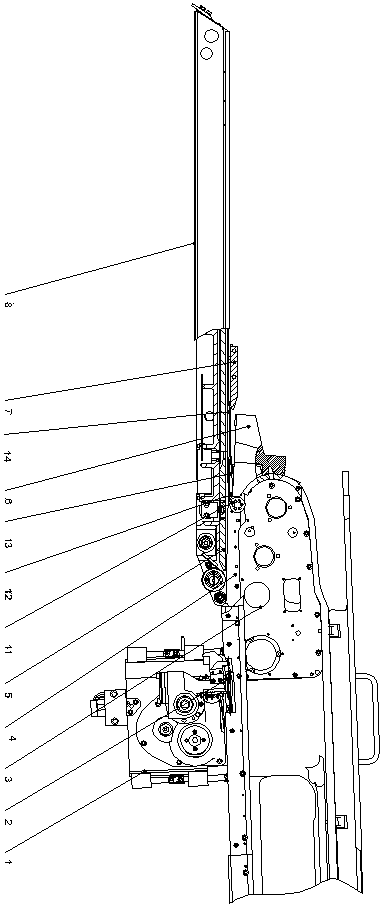

Method for reducing consumption of raw materials for thin cigarettes

ActiveCN108323789AReduce suction resistanceReduce consumptionTobacco preparationTobacco treatmentHazardous substanceTar

The invention provides a method for reducing consumption of raw materials for thin cigarettes, and belongs to the technical field of production of cigarettes. The method comprises the steps of selection of shredding width and water, selection of drying intensity, purification of cut tobaccos, optimization of cut tobacco structures, reasonable sieving and selection, selection of types of cigarettemaking machines, improvement of the cigarette making machines and optimization of parameters of the cigarette making machines. Compared with the prior art, the method has the advantages that resistance to suction of made thin cigarettes is small, consumption of a process is low, and consumption of the thin cigarettes is reduced to be 21.5 kg per case from the original 23 kg per case; the tar amount and CO amount of main stream smoke of the made cigarette are low, because the looseness and filling value of the cut tobaccos are increased, the cut tobaccos are combusted fully and completely, thegenerated harmful substances are less during smoking, and generation amounts of tar and CO are small; and the sensory quality of the made cigarettes is improved, because the looseness and filling value of the cut tobaccos are high, the resistance to suction of the cigarettes is low, the aroma of the cigarettes is plump and volatile, and the concentration of smoke is high.

Owner:CHINA TOBACCO HENAN IND +1

Preparation method and application of tobacco after-run spice having fragrance of sun-cured red tobacco

ActiveCN108497547AIncrease smoke concentrationIncrease concentrationTobacco preparationTobacco treatmentMaillard reactionCellulose

The invention discloses a preparation method of a tobacco after-run spice having fragrance of sun-cured red tobacco. The preparation method comprises the following steps: firstly, taking after-run asan extracting solvent, and introducing characteristic fragrance of the sun-cured red tobacco; then, adding complex plant hydrolase, amylase and resinase so as to achieve effects of removing impurities, enhancing aroma and coordinating taste; then, conducting alcohol precipitation treatment so as to remove such macromolecular compounds as pectin, protein, cellulose and the like; then, implementingMaillard aroma enhancement by taking an after-run extracting solution as a Maillard reaction precursor; and finally, conducting separating and recombination compounding on various stages of aroma substances via three stages of molecular distillation means. The invention also discloses an application of the tobacco after-run spice having the fragrance of sun-cured red tobacco in electronic cigarettes; and with the application of the tobacco after-run spice, sensory smoking quality of the electronic cigarettes is obviously improved, and fragrance concentration and richness of smoke are improved;therefore, the tobacco after-run spice has a broad application prospect.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Manufacturing method of heating cigarette aroma enhancement rolling method sheet

ActiveCN112056611AIncrease nicotine contentIncrease smoke concentrationTobacco preparationTobacco treatmentMaillard reactionProduction line

The invention discloses a manufacturing method of a heating cigarette aroma enhancement rolling method sheet. The manufacturing method comprises the following steps of (1) raw material formula design;(2) loosening and moisture regaining; (3) shredding; (4) cut tobacco heating and humidifying; (5) cut tobacco feeding; (6) storage and fermentation; (7) cut tobacco drying; (8) cut tobacco air cooling; (9) cut tobacco cooling; (10) crushing; (11) tobacco powder storage; (12) dry and wet material mixing; (13) rolling forming; (14) drying; (15) slitting; and (16) packaging. The existing expanded cut tobacco production line technology and equipment are used; the rolling method sheet production process is combined; Maillard reactants and tobacco extracts are added by using a cut tobacco feeding and multi-work-procedure feeding method; the content of aroma substances in the heating cigarette is improved; and the physical performance of the special sheet is improved through adding nanometer cellulose, so that the problems of insufficient aroma substance content and rolling difficulty of the heating cigarette are solved.

Owner:CHINA TOBACCO HENAN IND

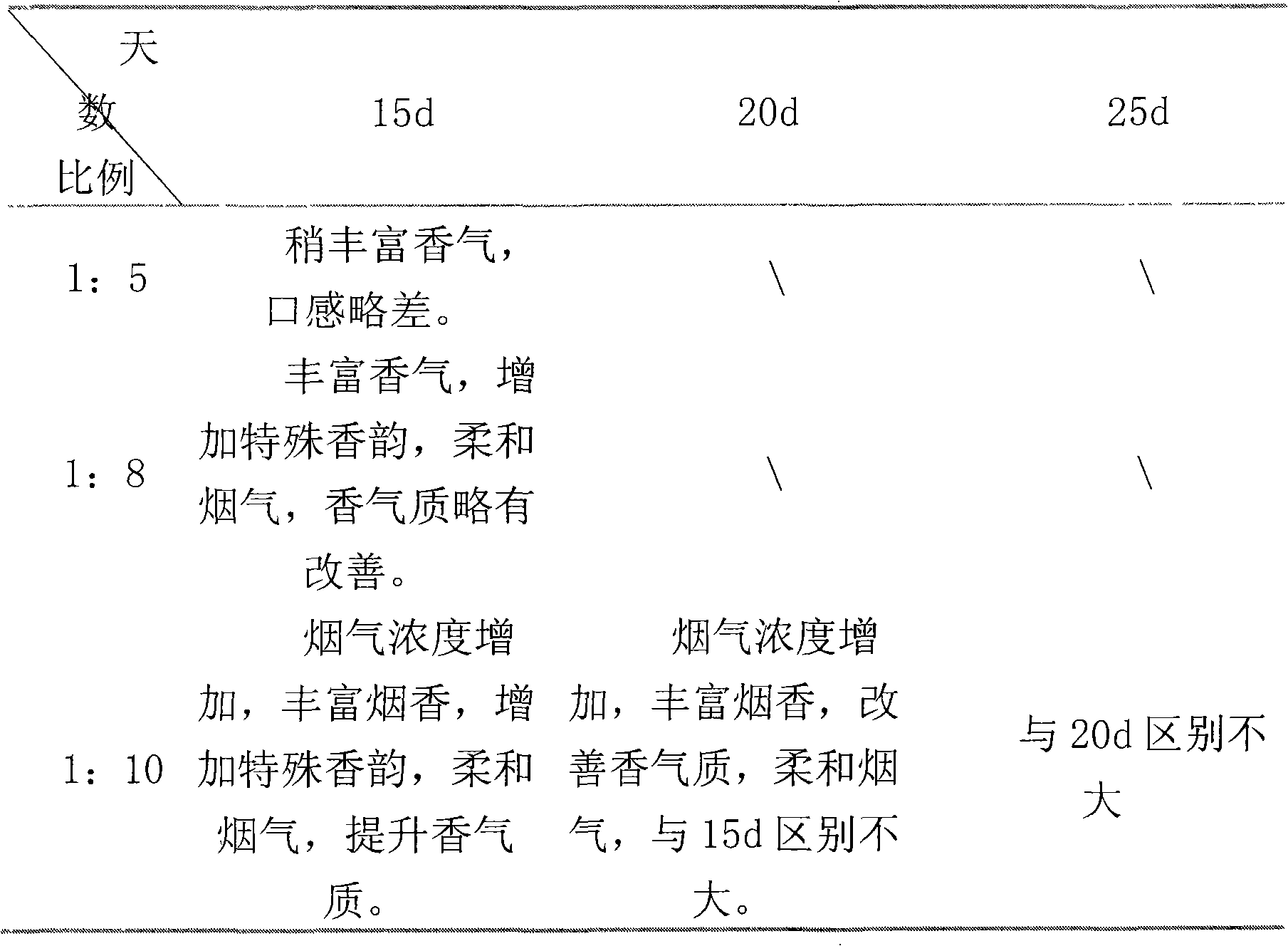

Mixed tincture for cigarettes and preparation method and application thereof in tobacco essence

InactiveCN101928637AImprove flavor qualityRich aromaTobacco treatmentEssential-oils/perfumesFlavorAmomum

The invention discloses a mixed tincture for cigarettes and preparation and application thereof in a tobacco essence. The mixed tincture for the cigarettes is obtained by the steps of: uniformly mixing tsaoko amomum fruit, dill and fortune eupatorium herb in a weight ratio of 1:4-6:2-3; grinding the mixture; extracting the mixture with 50 to 60 percent solution of ethanol; and filtering the extracted product to obtain filtrate, namely, the mixed tincture for the cigarettes. The mixed tincture serving as an essence additive of the tobacco essence has the advantages of remarkable effect, capability of increasing smoke concentration, rich cigarette fragrance, addition of special fragrance, soft smoke, high fragrance quality, improved mouth-feel, high stability and the like.

Owner:HUBEI CHINA TOBACCO IND +1

Preparation and application of fuming matrix raw material of heat-not-burn cigarette

InactiveCN110839938ASmall attenuationIncrease smoke concentrationTobacco preparationTobacco treatmentBurn cigaretteRaw material

The invention relates to preparation and an application of a fuming matrix raw material of a heat-not-burn cigarette. A tobacco raw material is subjected to synergic expansion through steam microwave,and then an extraction material liquid is added uniformly; the mixture is stored in a constant-temperature and constant-humidity environment for a period of time, and the to-be-extracted material liquid is uniformly absorbed by the tobacco raw material; the tobacco raw material is crushed to the particle size of 100-200 meshes through a low-temperature crushing technology to obtain a raw materialof a fuming matrix; and then a heat-not-burn fuming matrix is prepared from the raw material of the fuming matrix, and shredding is carried out to prepare the heat-not-burn cigarette. According to the heat-not-burn cigarette prepared from the tobacco shred material, the cigarette is high in smoke gas concentration, strong in physiological satisfaction and prominent in characteristic aroma, the attenuation of smoke gas in the smoking process is reduced, and the smoking quality is improved.

Owner:CHINA TOBACCO HENAN IND

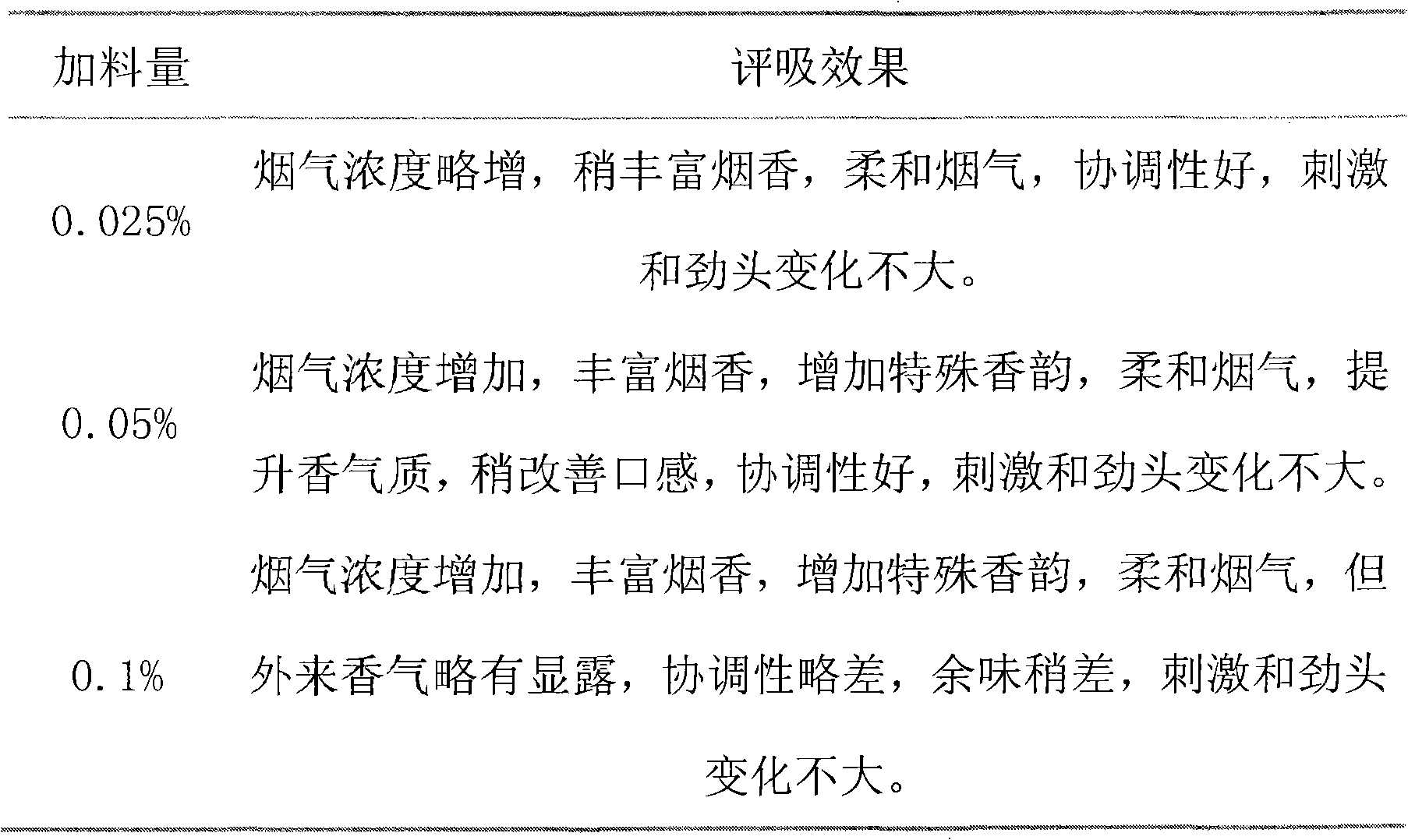

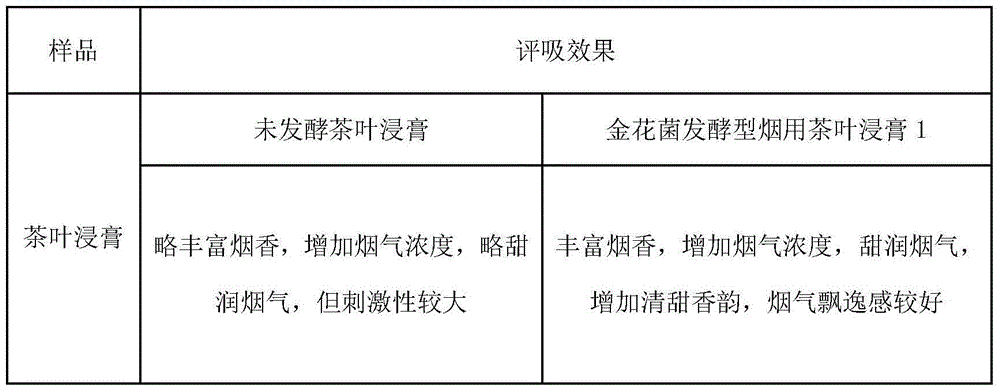

Preparation method of golden flower fungus fermentation type cigarette tea extract

InactiveCN104403800AImprove qualityReduce the irritation of cigarettesTobacco treatmentEssential-oils/perfumesSweetnessFermentation

The invention provides a preparation method of a golden flower fungus fermentation type cigarette tea extract. The preparation method comprises the following steps: (1) inoculating tea and golden flower fungus after sterilizing the tea, wherein the volume mass percent of the golden flower fungus being 6%; the volume mass percent of added water being 30%; inoculating by cultivating for 7 days at 28-30 DEG C; (2) mixing the tea inoculated from the step (1) and water according to the ratio of material to liquor of 1:(6-10), carrying out heating reflux for 1-3 hours, cooling and filtering to obtain filtrate; (3) concentrating the filtrate to obtain the golden flower fungus fermentation type cigarette tea extract. By adding the golden flower fungus fermentation type cigarette tea extractum, aroma of a cigarette is abundant, sweet feeling is obvious, freshness and sweetness and flavour are added, elegant feeling is good, irritation is reduced, and the golden flower fungus fermentation type cigarette tea extract has strong practicability.

Owner:HUBEI CHINA TOBACCO IND +1

Method for manufacturing cigarette paper making process slices with burley tobacco stems as raw materials

ActiveCN103519340BLoose structureLoose and machinableTobacco preparationFiltrationPulp and paper industry

Owner:CHINA TOBACCO ANHUI IND CO LTD

A Chinese-style mixed cigarette and its preparation method

ActiveCN103815539BRich and beautiful aromaIncrease aromaTobacco preparationTobacco treatmentFlavorEnvironmental health

Owner:CHINA TOBACCO FUJIAN IND

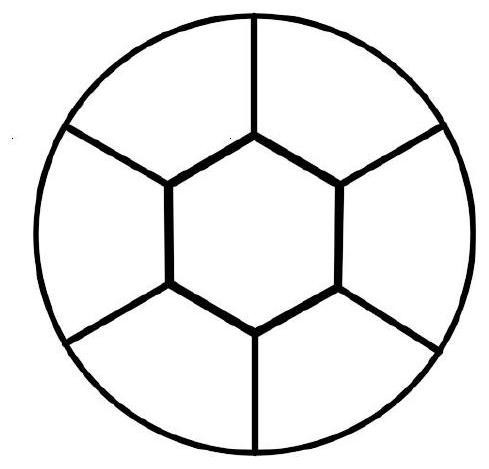

Binary heat-not-burn smoke cartridge suitable for circumferential heating

The invention relates to a binary heat-not-burn smoke cartridge suitable for circumferential heating. The binary heat-not-burn smoke cartridge is formed by wrapping a smoke generation section and a smoke constraint section with outer-layer wrapping paper. The binary heat-not-burn smoke cartridge suitable for circumferential heating has the advantages of being high in smoke concentration and low insmoke temperature, can also be used as a conventional cigarette for smoking, is rich in smoking section material using variety and sufficient in smoking section heating, provides enough fragrance amount and smoke amount, is simple in structure, facilitates industrial production, and has a good application prospect.

Owner:云南纯旭生物科技有限公司

Binary structure heat-not-burn article adapted for electromagnetic heating

PendingCN112617287ASimple structureEase of industrial productionTobacco treatmentThermodynamicsFlue gas

The invention relates to a binary structure heating non-combustible product suitable for electromagnetic heating, which is formed by sequentially wrapping a fuming section and a flue gas constraint section with outer layer wrapping paper, the fuming section is inserted into an electromagnetic heater, and part or all of the flue gas constraint section is positioned outside the electromagnetic heater; the binary structure heating non-combustible product suitable for electromagnetic heating has the advantages of being large in smoke generation amount, low in smoking gas temperature and the like, is suitable for central heating, circumferential heating or central and circumferential heating, is simple in structure and easy to industrialize, and has a very good industrial application prospect.

Owner:云南纯旭生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com