Preparation method of golden flower fungus fermentation type cigarette tea extract

A golden flower fungus and fermentation type technology, which is applied in the field of preparation of golden flower fungus fermented tobacco tea extract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

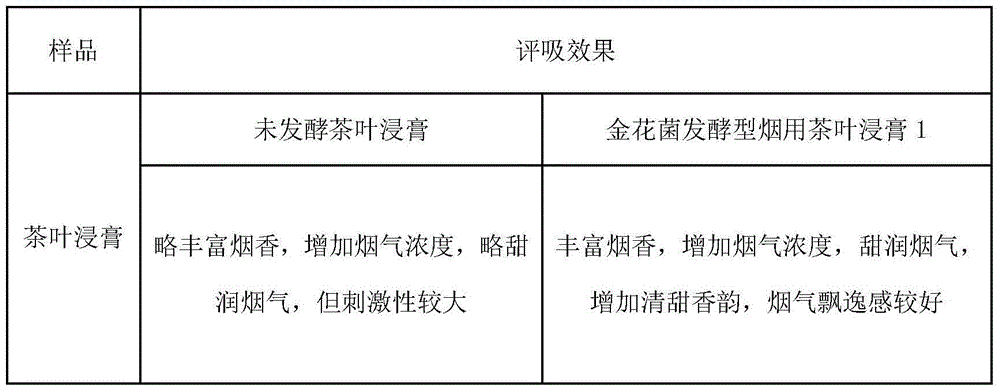

Image

Examples

Embodiment 1

[0015] 1) Fermentation of golden flower fungus: mix black tea, green tea and oolong tea with high-pressure steam sterilization for 20 minutes, then inoculate with golden flower fungus, the inoculation amount is 6% (ml / g), the amount of water added is 30% (ml / g), and cultured at a constant temperature of 28°C 7d;

[0016] 2) Tea extract: according to the ratio of material to liquid ratio of 1:8 (the ratio of tea to water), reflux extraction at 100°C for 2 hours, let stand and cool, and then filter through filter cloth to obtain the filtrate;

[0017] 3) Post-treatment of the fermented product: Concentrate the filtrate to 1.1000 (at 20°C) for the first time at 80°C, add 5 times the volume of an alcohol solution with a mass fraction of 95% to dissolve, and cool and settle at -20°C for 18 hours; use a filter cloth Filter large particles of impurities, and then use 0.45 μm pore size microporous filter membrane to suction filter. The clarified filtrate obtained by suction filtration...

Embodiment 2

[0019] 1) Fermentation of golden flower fungus: mix black tea with high-pressure steam sterilization for 20 minutes, inoculate with golden flower fungus, inoculate 6% (ml / g), add water 30% (ml / g), and incubate at 30°C for 7 days;

[0020] 2) Tea extract: According to the ratio of material to liquid ratio of 1:6 (the ratio of tea to water), reflux extraction at 100°C for 1 hour, let stand and cool, and then filter through filter cloth to obtain the filtrate;

[0021] 3) Post-treatment of the fermented product: Concentrate the filtrate to 1.1000 (at 20°C) for the first time at 80°C, add 3 times the volume of an alcohol solution with a mass fraction of 95% to dissolve, and cool and settle at -20°C for 24 hours; use a filter cloth Filter large particles of impurities, and then use 0.45 μm pore size microporous filter membrane to suction filter. The clarified filtrate obtained by suction filtration is concentrated and collected for the second time under reduced pressure. °C) g / cm ...

Embodiment 3

[0023] 1) Fermentation of golden flower fungus: inoculate oolong tea with golden flower fungus after high-pressure steam sterilization for 20 minutes, the inoculation amount is 6% (ml / g), the amount of water added is 30% (ml / g), and cultured at 29°C for 7 days;

[0024] 2) Tea extract: According to the ratio of material to liquid ratio of 1:10 (the ratio of tea to water), reflux extraction at 100°C for 3 hours, let it cool down and then filter it with a filter cloth to obtain the filtrate;

[0025] 3) Post-treatment of the fermented product: Concentrate the filtrate to 1.1000 (at 20°C) for the first time at 80°C, add 4 times the volume of an alcohol solution with a mass fraction of 95% to dissolve, and cool and settle for 20 hours at -20°C; use a filter cloth Filter large particles of impurities, and then use 0.45 μm pore size microporous filter membrane to suction filter. The clarified filtrate obtained by suction filtration is concentrated and collected for the second time un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com