Heat-not-burn article having high smoke concentration

A heat-not-burn, smoke-concentration technology, applied in the fields of tobacco, cigar manufacturing, and application, can solve the problems of low smoke concentration, reducing the smoke concentration and shortage of heat-not-burn products, and achieve long-lasting smoke and maintain smoke stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Example 1: High smoke concentration heat-not-burn product of the present invention

[0100] The implementation mode of this embodiment is as follows:

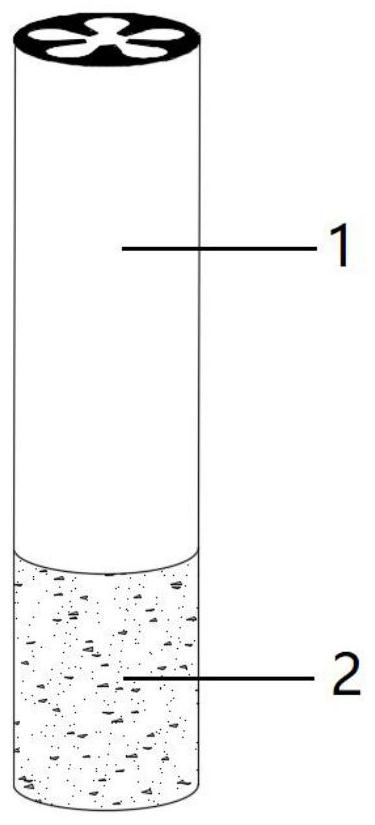

[0101] The high-smoke concentration heat-not-burn product of the present invention is a rod-shaped structure formed by connecting the smoke-generating section and the supporting cooling section along the longitudinal axis with coated paper. The circumference of the heat-not-burn product is 8mm, and the smoke The length of the section is 14mm, and the length of the supporting cooling section is 40mm;

[0102] Wherein, the smoking section is 35 parts by weight of smoking agent, 1.0 parts by weight of supercritical tobacco absolute volatile spices, 9 parts by weight of light calcium carbonate porous adsorption material and 60 parts by weight of tobacco leaf herbal raw material powder with a particle size of 160 mesh Composed; the smoking agent is composed of 59 parts by weight of glycerin, 36 parts by weight of propylene g...

Embodiment 2

[0106] Embodiment 2: High smoke concentration heat-not-burn product of the present invention

[0107] The implementation mode of this embodiment is as follows:

[0108] The high-smoke concentration heat-not-burn product of the present invention is a rod-shaped structure formed by socketing the smoke-generating section and the supporting cooling section along the longitudinal axis with silica gel tubular material. The circumference of the heat-not-burn product is 10mm, and the The length is 12mm, and the length of the supporting cooling section is 30mm;

[0109] Wherein, the smoking section is composed of 32 parts by weight of smoking agent, 1.5 parts by weight of tobacco absolute volatile fragrance, 7 parts by weight of activated carbon porous adsorption material and 46 parts by weight of expanded tobacco stem tobacco material with a particle size of 100 mesh; The smoking agent described above is composed of 64 parts by weight of glycerin, 42 parts by weight of propylene glyc...

Embodiment 3

[0113] Example 3: High smoke concentration heat-not-burn product of the present invention

[0114] The implementation mode of this embodiment is as follows:

[0115] The high-smoke concentration heat-not-burn product of the present invention is a rod-shaped structure formed by connecting the smoke-generating section and the supporting cooling section with polyethylene film material along the longitudinal axis. The circumference of the heat-not-burn product is 5mm, and the The length is 10mm, and the length of the supporting cooling section is 35mm;

[0116] Wherein, the smoking section is composed of 25 parts by weight of fuming agent, 1.9 parts by weight of volatile fragrance of lemongrass distillate oil, 8 parts by weight of diatomite porous adsorption material and 40 parts by weight of 200-mesh tea herb raw material powder The smoking agent is composed of 50 parts by weight of glycerin, 25 parts by weight of propylene glycol, 3 parts by weight of glyceryl capricate and 4 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com