Tobacco material suitable for heating non-combustion device and preparing method of tobacco material

A technology for heating non-combustion and heat-conducting materials, which is applied in the field of tobacco, can solve the problems that heat-conducting materials have no specific application and need further research, and achieve the effects of improving heating conditions, increasing smoke concentration, and uniform smoke release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

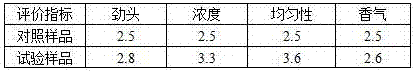

Embodiment 1

[0031] The tobacco material suitable for heating non-combustion devices provided by this embodiment is columnar, and the specific dosage of each material is: 40 parts of tobacco stem powder, 15 parts of tobacco water extract, and 20 parts of glycerol. , 2 parts of potato starch, 1 part of aluminum powder, 2 parts of hijiki polysaccharide and 0.5 part of tea extract;

[0032] The tobacco stem powder is the tobacco stem in the cigarette production process, and the particle size is 40 mesh;

[0033] Described potato starch is conventional commercially available product;

[0034] The tobacco water extract can be prepared by using specific similar commercially available products, or it can be prepared by referring to the following method: take the waste tobacco powder in the cigarette production process, add water after drying according to the ratio of material to liquid 1:3 (w / w) After soaking at 80°C for 3 hours, solid-liquid separation was carried out, and the filtrate was conc...

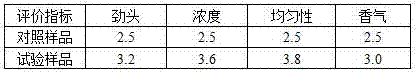

Embodiment 2

[0047] The tobacco material suitable for heating non-combustion devices provided by this embodiment is granular, and the specific dosage of each material is: 60 parts of shredded tobacco powder, 25 parts of tobacco alcohol extract, and 30 parts of propylene glycol. , 5 parts of corn flour, 0.5 part of graphene-aluminum powder compound, 4 parts of lentinan and 1 part of bamboo leaf extract (commercially available, flavonoid content 20%);

[0048] The shredded tobacco sheet powder is shredded tobacco sheet in the cigarette production process, and the particle size is 50 mesh;

[0049] Described corn flour is conventional commercially available product;

[0050] The tobacco alcohol extract can be prepared by using specific similar commercially available products, or it can be prepared by referring to the following method: take waste tobacco powder in the cigarette production process, add 95 % ethanol, extracted at 70°C for 5 hours, separated from solid and liquid, and the filtra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com