Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

203results about How to "Simple process operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepn of nano-cobaltosic oxide powder

InactiveCN1344682ASimple process operationParameters are easy to controlCobalt oxides/hydroxidesCobalt carbonatesCobalt ionsCobalt(II,III) oxide

The present invention relates to chemical industry technology. The preparation of nanometer cobaltosic oxide powder includes purifying material, cobalt salt deposition, solid-liquid separation and solid calcination. Cobalt sheet is dissolved in nitric acid while being heated and high purity water is added to regulate solution density and pH value so as to obtain cobalt nitrate solution of 1.5-1.65 g / cu cm density and pH 4-5; ammonium bicarbonate suspension in 14-30 wt% is prepared with ammonium bicarbonate and water; cobalt nitrate solution is added into the suspension slowly to result in weight ratio of carbonate radical to cobalt ion being 2.4-2.6; and the wet cobalt carbonate material is heated to 300-450 deg.c for 3-6 hr to obtain black Co3O4 powder.

Owner:SHANDONG UNIV +1

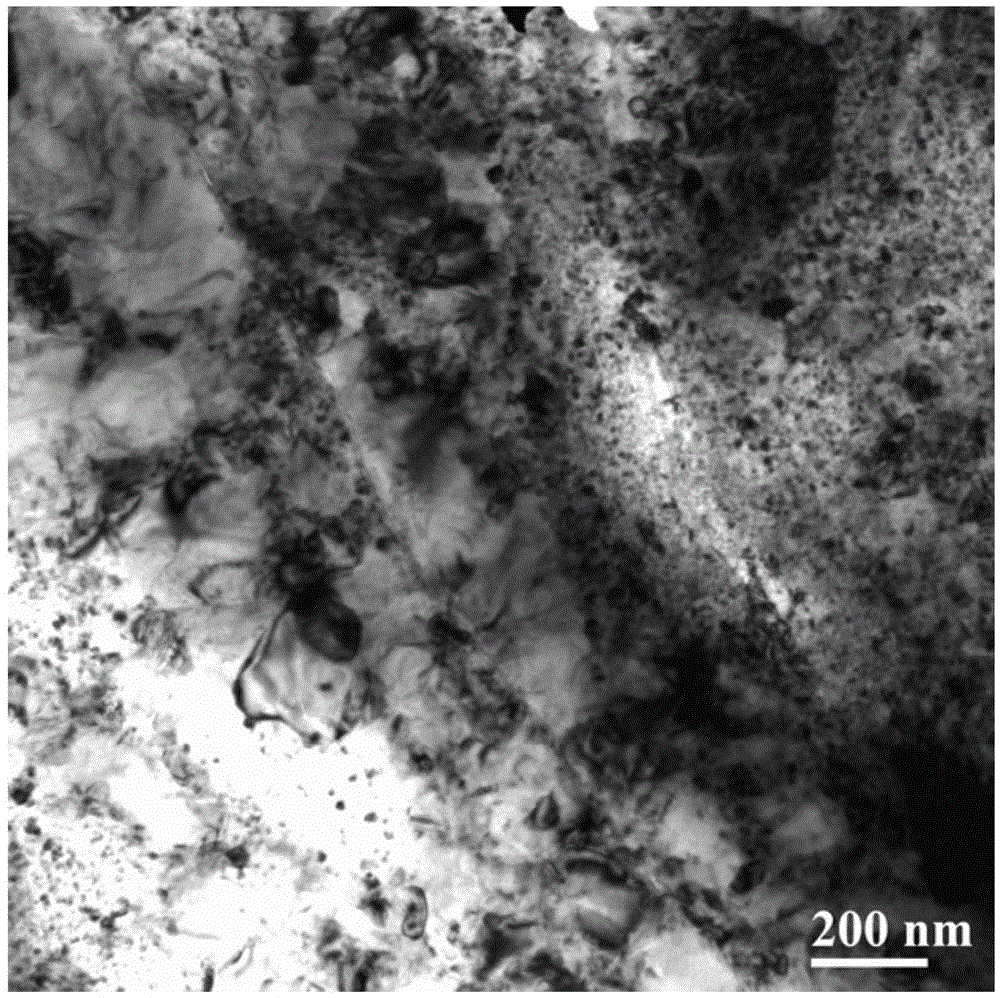

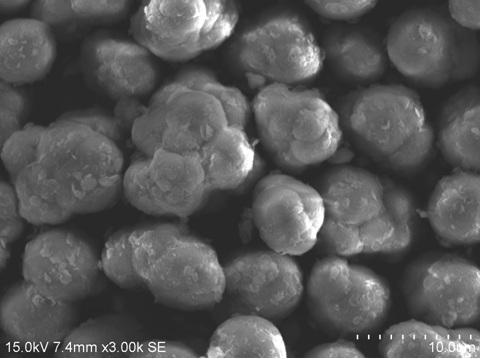

Graphene oxide microsphere and graphene microsphere and preparation methods thereof

The invention discloses a graphene oxide microsphere and a graphene microsphere and preparation methods thereof. The graphene oxide microsphere and the graphene microsphere respectively comprise a three-dimensional porous structure mainly formed by assembling graphene oxide slices or reduced graphene oxide slices, wherein the three-dimensional porous structure comprises a simulated erythrocyte structure. The preparation method of the graphene oxide microsphere comprises the following steps: (1) electrostatic spraying: carrying out electrostatic spraying treatment on a precursor solution, so that a microsphere-shaped liquid drop is formed; and (2) wet collection: injecting a solidification liquid into the microsphere-shaped liquid drop, so that the graphene oxide microsphere is prepared. The preparation method of the graphene microsphere comprises the following step: preparing the graphene oxide microsphere into the graphene microsphere by utilizing a chemical reduction method. The preparation methods are simple to operate and convenient to regulate and control. The prepared graphene microsphere is high in purity, and the raw materials are obtained easily, so that the production cost is low and the production efficiency is high. Therefore, the graphene microsphere can be prepared in batches.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for preparing hollow or clad nickel alloy spherical powder

The present invention method of hollow or coating type nickel alloy spherical powder includes the following steps: dissolving nickel salt, adding alkali liquor and reducing agent, utilizing alkaline colloidal kernel generated by self-body reaction as core, using the colloidal kernel surface as active center, self-catalyzing reducing agent and nickel iron reaction to form nickel alloy shell body on colloidal kernel surface, make after-treatment so as to obtain the hollow or coated type nickel alloy spherical powder. Said invention can be used in the fields of high-effective catalyst, adsorbing agent, photoelectric and electromagnetic device, microwave absorption material and bio-pharmaceutical industry, etc.

Owner:SHANGHAI JIAO TONG UNIV

Method for extracting phospholipid-rich krill oil from Antarctic krill

ActiveCN102766530ASimple process operationProcess environmental protectionFatty-oils/fats productionEnzymeKrill oil

Owner:辽渔南极磷虾科技发展有限公司

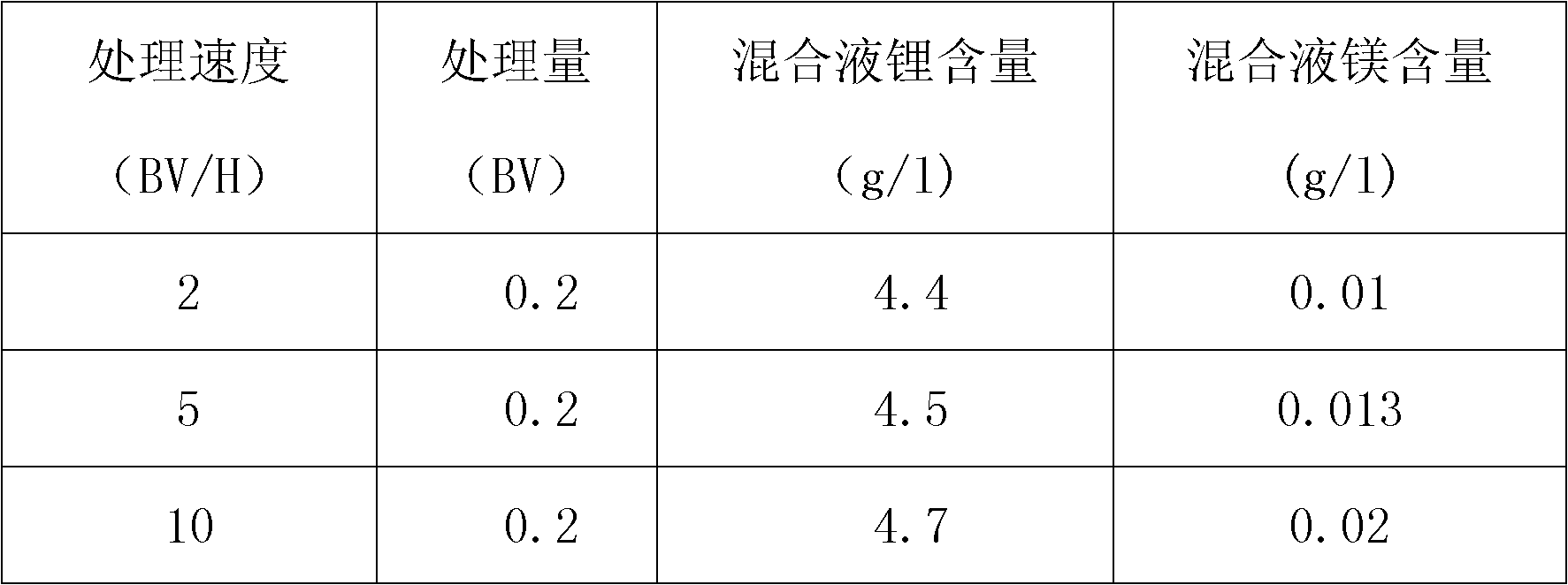

Novel method for extracting lithium from salt lake brine

ActiveCN102070162ASimple process operationReduce manufacturing costLithium compoundsProcess efficiency improvementLithium carbonateChemistry

The invention discloses a method for extracting lithium from lithium-containing brine. The method comprises the following steps: (1) concentrating salt lake brine through evaporation in a solarization pool or through forced evaporation to ensure that the lithium content reaches 400mg / l-30g / l; and (2) passing the concentrated salt lake brine obtained in the step (1) through cation exchange resin at the rate of 1-30 BV / H to remove magnesium in the salt lake brine, and carrying out concentration and precipitation to obtain lithium carbonate. The method has the advantages of low consumption of chemical raw materials, simple technique and no pollution, and is easy to operate.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Method for preparing sodium metavanadate

ActiveCN101723455ALess types of raw materialsSimple process operationVanadium compoundsSodium metavanadateSodium hydroxide

The invention discloses a method for preparing sodium metavanadate, which comprises the following steps: a. adjusting the pH value of a leach solution obtained by sodium treatment and vanadium extraction to 1.1-1.6 by an inorganic acid, then heating the leach solution to 90 DEG C until boiling, and keeping for 60-90 minutes to generate solid sodium polyvanadate; b. adding sodium hydroxide solution to the obtained solid sodium polyvanadate, and stirring the obtained solid-liquid mixture, so that the pH value of the solution in the solid-liquid mixture is 8-8.5; and c. heating the solid-liquid mixture to 90 DEG C until boiling to generate solid sodium metavanadate. By the method, high-purity sodium metavanadate can be prepared and the method has small consumption of alkali and low cost.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

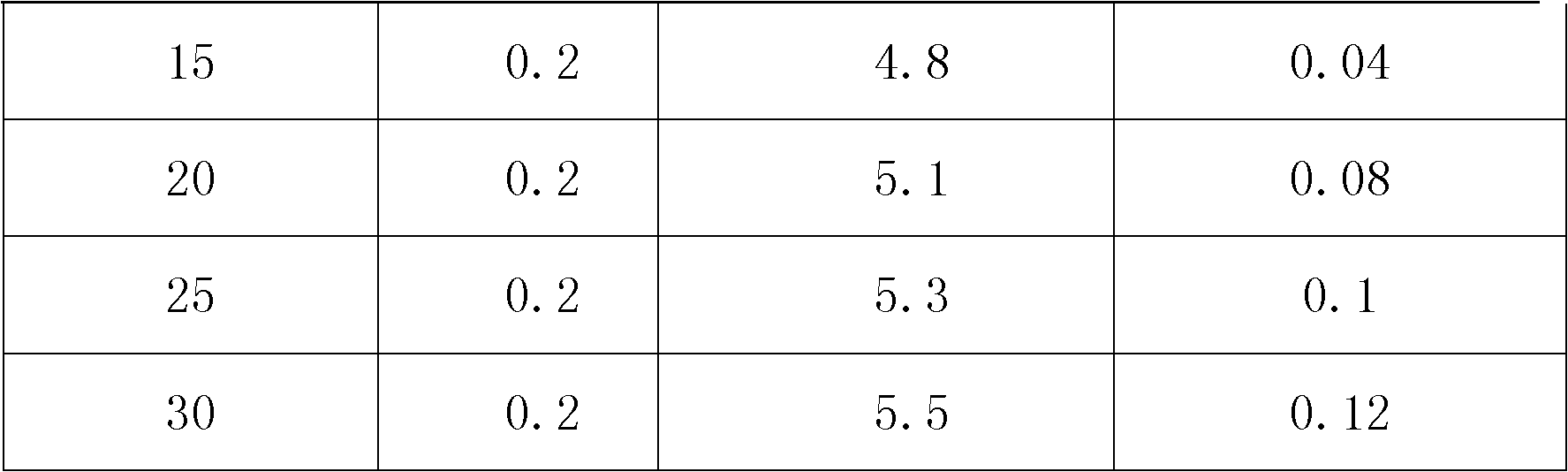

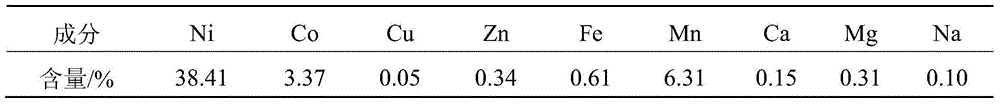

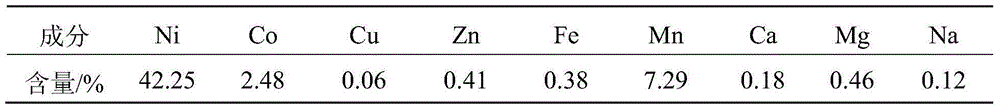

Method for separating nickel and cobalt from manganese in high manganese-cobalt ratio nickel-cobalt-manganese raw material

ActiveCN104831065AShort processSimple process operationProcess efficiency improvementThermal insulationNickel

The invention discloses a method for separating nickel and cobalt from manganese in a high manganese-cobalt ratio nickel-cobalt-manganese raw material. The method comprises the following steps of mixing a high manganese-cobalt ratio nickel-cobalt-manganese raw material and an ammoniacal leaching agent under control of an ammoniacal leaching agent initial concentration, leaching time and a leaching temperature, adding a reducer into the high manganese-cobalt ratio nickel-cobalt-manganese raw material-ammoniacal leaching agent mixed leaching system, after full reaction, and carrying out thermal insulation aging and solid-liquid separation to obtain nickel-cobalt ammoniacal leachate and high-manganese leaching residue. The method realizes separation of nickel and cobalt from manganese in the high manganese-cobalt ratio nickel-cobalt-manganese raw material. The method has simple processes, realizes thorough separation of nickel and cobalt from manganese and high nickel and cobalt content and low impurity content of the leachate, has a high valuable metal comprehensive recovery rate, and has less equipment investment and a low production cost.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

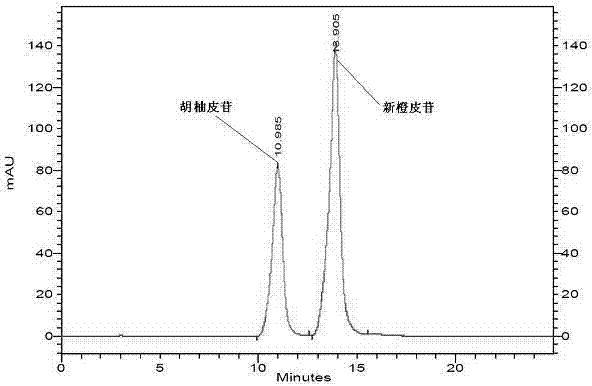

Process for compressively utilizing grapefruits

ActiveCN102326746AImprove overall utilizationSimple process operationConfectioneryTea substituesFruit juiceEssence oil

The invention discloses a process for compressively utilizing grapefruits, which is used for overcoming the defect that a grapefruit raw material and active substances in grapefruit peel cannot be utilized effectively in the prior art. The process comprises the following steps of: (1) sorting grapefruits, cleaning and separating peel and pulp of the grapefruits; (2) extracting active substances, grapefruit essential oil and peel residues from peel serving as a raw material and preparing concentrated fruit juice from the pulp serving as a raw material; and (3) 1, preparing grapefruit jam from the peel residues and the pulp serving as raw materials; 2, preparing grapefruit juice from the concentrated fruit juice or the grapefruit jam serving as a raw material; 3, preparing grapefruit tea from the peel residues and the concentrated fruit juice serving as raw materials or the grapefruit jam serving as a raw material; and 4, preparing preserved grapefruits from the peel residues and the concentrated fruit juice serving as raw materials, the grapefruit jam serving as a raw material or the peel residues serving as a raw material. By adopting the process, different grapefruit products canbe prepared by making full use of the grapefruits, and biological active substances in the grapefruit peel are fully utilized; and the process is convenient to operate, and has high production efficiency.

Owner:ZHEJIANG JINMING BIOLOGICAL SCI & TECH

Remanufacturing method for scrap titanium chips through ball milling-equal channel angularpressing

InactiveCN105618501AExcellent technical indicatorsSimple process operationCleaning using liquidsGrain treatmentsScrapSwarf

The invention provides a remanufacturing method for scrap titanium chips through ball milling-equal channel angular pressing. The remanufacturing method sequentially comprises the step of recovering and pretreating titanium chips, the step of performing ball milling treatment on the titanium chips, the step of loading the titanium chips into an equal channel angular pressing mold, the step of performing preprocessing at a room temperature through the equal channel angular pressing, the step of curing and processing at a high temperature, and the step of quenching. The ball milling-equal channel angular pressing composite technique provided by the invention is simple and practical to operate and high in controllability. Through remanufacturing, not only can nanometer block titanium materials (smaller than 200nanometers) with full densification be obtained, but also the metallurgical defect of the continuous distribution and gathering of large sliced oxides can be eliminated. In addition, the shapes of the titanium chips are refined and reformed, and anisotropy caused by deformation texture in hexagonal close packed titanium materials is restrained. The yield strength of the remanufactured nanometer titanium materials reaches to the level of 5-grade titanium, the distribution of nanometer particles of the oxides presents a dispersed uniform state, and through the isotropy of the properties of the materials, the remanufacturing of scrap titanium resources for value increase at low cost is realized.

Owner:SHANGHAI DIANJI UNIV

Preparation method of carbon fiber precursor oil agent

InactiveCN104179019ASimple process operationStrong permeabilityCarbon fibresTemperature resistanceEmulsion

The invention discloses a preparation method of a carbon fiber precursor oil agent. The method comprises the following steps: putting a composite emulsifier and a characteristic composite modified silicone oil in a weight ratio of (1-4) to (3-10) into a high-shear emulsifying machine; evenly stirring; adding a composite assistant; dropwise adding an appropriate amount of deionized water; stirring for 20-120 minutes; and adjusting the pH value to 3-10, thereby obtaining a light blue, light yellow or white emulsion, namely the carbon fiber precursor oil agent. According to the method, the technology operation is simple and can be directly applied to an industrial production line. When in use, the oil agent prepared by the method has good permeability, high temperature resistance and good process stability, and can well enhance the bunching performance of fibers and well protect the fibers in the whole process of pre-oxidation as well as in the initial stage of low-temperature carbonization, thereby greatly reducing the phenomena of monofilament adhesion and doubling, reducing the surface detects of the fibers, and enhancing the performance of the fibers.

Owner:ZHONGFU SHENYING CARBON FIBER

Preparation method of solar energy heat absorbing coating using nickel or nickel alloy hollow ball as absorbent

InactiveCN101284958ASimple equipmentSimple process operationPigmenting treatmentRadiation-absorbing paintsSolventMetallic Nickel

The invention relates to a method for making a solar endothermic coating by using a nickel or nickel alloy hollow sphere as an absorbent. The method comprises the following steps that: firstly nickel or nickel alloy hollow sphere powder made by autocatalytic reduction, resin and solvent are mixed according to a certain proportion to obtain an even paint; secondly, the paint is evenly coated on a substrate with a glazed surface by a spray finishing method to form a coating with even thickness; finally, the coating is kept warm and dried under a certain temperature, thereby obtaining the solar an endothermic coating. The method for making the solar endothermic coating by using the nickel or nickel alloy hollow sphere as the absorbent adopts simple equipment and simple and feasible process; the prepared solar endothermic coating is a metal-resin type composite coating; the absorbent is nickel or nickel alloy powder with a hollow structure; a filling agent is made of macromolecule resin; the thickness of the coating is controlled between 10 and 100 mu m; the color of the coating is gray-black or black. Through choosing the nickel or nickel alloy powder with different grain diameters and components as the absorbent, the solar endothermic coating with absorptivity between 0.96 and 0.98 can be prepared.

Owner:SHANGHAI JIAO TONG UNIV

Method for treating phthalate wastewater by means of catalyzing persulfate by utilization of supported activated carbon in microwave inducement manner

ActiveCN105565465AGood stabilitySimple process operationWater/sewage treatment by irradiationWater contaminantsActivated carbonEnvironmental chemistry

The invention relates to a method for treating phthalate wastewater by means of catalyzing persulfate by utilization of supported activated carbon in a microwave inducement manner, belonging to the technical field of phthalate wastewater treatment. The method comprises the following steps of adding a sodium persulfate solution with a concentration of 0.3 to 0.4 mM into phthalate wastewater with a concentration of 1500 to 3500 (mu)g / L according to a volume ratio of 0.5 to 1 percent, adjusting a pH value of the solution to be 6.0 to 9.0, then adding an activated carbon supported metal catalyst according to a proportion of 1 to 2 permillage, uniformly stirring, putting in a frequency conversion microwave reactor, setting a temperature of 70 to 80 DEG C, continuously reacting for 25 to 30 minutes, and taking a mixed solution to measure a phthalate concentration, wherein the phthalate removal rate reaches above 90 percent. The method disclosed by the invention has the advantages that microwave, supported activated carbon and persulfate act synergistically; the thermal effect and non-thermal effect of the microwave, the strong oxidation effect of the persulfate as well as the adsorptive catalysis and heat sensitization effects of the supported activated carbon are sufficiently exerted; the effects of simplicity and high efficiency in technological operation, easiness in implementation, freeness from secondary pollution, high oxidation efficiency and good removal effect are achieved.

Owner:广州中德环境技术研究院有限公司

Machining method for titanium mobile phone shell or titanium alloy mobile phone shell

InactiveCN107097049AHigh dimensional accuracySimple process operationTelephone set constructionsTitaniumForging

The invention discloses a machining method for a titanium mobile phone shell or a titanium alloy mobile phone shell. The machining method comprises the following steps of (1) board blanking, (2) heating, (3) forging and performing, (4) welding, (5) heating, (6) first-time forging, (7) CNC excess material milling, (8) sand blasting for oxidation layer removing, (9) heating, (10) secondary finish forging, (11) edge cutting and burr removing, (12) sand blasting for oxidation layer removing, (13) stress relief annealing under vacuum and (14) CNC finish machining. According to the machining method for the titanium mobile phone shell or the titanium alloy mobile phone shell, raw material input can be saved, the technology is simple, the production efficiency is improved, and the production cost is reduced.

Owner:倪金土

Cleaning liquid for regenerated SCR (silicon controlled rectifier) denitration catalyst and method for regenerating SCR denitration catalyst

InactiveCN103816946ASimple process operationGood regeneration effectCatalyst regeneration/reactivationPenetration enhancerSulfuric acid

The invention provides a cleaning liquid for a regenerated SCR (silicon controlled rectifier) denitration catalyst. The cleaning liquid can treat an inactivated catalyst, so that the denitration performance of the catalyst can be recovered; the waste solid pollution is relieved, and the running cost of flue gas denitration engineering of a coal-fired power plant can be reduced. The cleaning liquid comprises the following components in percentage by weight: 0.1-1 percent of a penetration enhancer JFC, 0.1-1 percent of an emulsifier OP-10, 0.1-1 percent of a leveling agent peregal O, 1-10 percent of a sulfuric acid, 0.5-5 percent of vanadyl sulfate, 1-5 percent of ammonium metatungsten, 0.1-1 percent of a corrosion inhibitor and the balance of water; the total mass percentage of all the substances is 100; the substances are mechanically stirred after being mixed for 20-30 minutes, so that the cleaning liquid is obtained.

Owner:无锡华光新动力环保科技股份有限公司

Novel spraying technology for corrosion prevention and abrasion prevention of boiler

InactiveCN104878344ASimple process operationImprove work efficiencyMolten spray coatingCorrosion resistantThermal spraying

The invention belongs to the technical field of corrosion prevention and abrasion prevention of boilers, and provides a novel spraying technology for corrosion prevention and abrasion prevention of a boiler, so as to solve the problem in the prior art that the surface of the internal water wall of a boiler is easy to corrode. The novel spraying technology comprises the following steps: adopting supersonic arc spraying, and using an iron-based self-adhesion alloy wire for carrying out bottom spraying with the thickness of not smaller than 0.05 mm; then, using an LX88A ultrahard abrasion-resistant alloy wire or a 45CT Ni-Cr-Ti alloy wire as an anti-abrasion spraying material for carrying out spraying with the coating thickness of 0.5-0.6 mm; using an LG-3 type high-temperature abrasion-resistant anti-corrosion special hole-sealing agent to perform hole-sealing on the surface of the thermal spraying coating of the metal, so as to enable the whole coating to be more compact and further achieve the effect of sealing capillary pores. According to the invention, the working efficiency is high, materials are saved, no pollution is realized, and the energy consumption is low; the operation of the technology is convenient, the problem that the possibility of corrosion of the boiler is high during the actual running of the boiler can be effectively solved, and the boiler maintenance cost is reduced; a coating formed by the technology is corrosion-resistant and has excellent abrasion resistance, stability, corrosion resistance and stress cracking resistance, and the corrosion prevention time of the coating can be prolonged to be one year or above, so that the fact that service life of the boiler is prolonged by one year or above is ensured.

Owner:SHANXI HUAHUI HENGYUAN ANTICORROSION ENG

Method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by use of eutectic solvent

ActiveCN103272407ASimple process operationLow costLiquid solutions solvent extractionSolventFormic acid

The invention belongs to the field of chemical technology and specifically relates to a method for removing residual formic acid in epoxidized fatty acid methyl esters or epoxidized soybean oil by the use of a eutectic solvent. The method provided by the invention comprises the following specific steps: sending crude epoxidized fatty acid methyl esters or crude epoxidized soybean oil which contains 0.2-15wt% of formic acid and is obtained by a epoxidation process through a formic acid method into an extraction kettle, adding a certain amount of an extractant under the condition of stirring, stirring for a period of time, standing for layering, sending a material on the upper layer into a vacuum dehydration kettle for further dehydration and refining, pouring an extract on the lower layer into an extractant regeneration kettle; heating under the condition of pressure reduction to distill formic acid in the extract, recycling the formic acid steam after being condensed in a condenser, and sending residual extractant left in the extractant regeneration kettle into the extraction kettle for recycling. The method provided by the invention has advantages of no discharge of waste water, high formic acid removal rate, simple technological operation, environmental protection, safety and low cost, and is suitable for both small-scale device and large-scale device production.

Owner:石家庄搏澳增塑材料科技有限公司

Botanical mosquito repellent and preparation method thereof

ActiveCN103520059AReduce manufacturing costSimple process operationCosmetic preparationsToilet preparationsBody regionChemistry

The invention relates to a botanical mosquito repellent and a preparation method thereof. The mosquito repellent is prepared from ailanthus peel extracting solution, aloe extracting solution, mixed volatile oil, surfactant and ethyl alcohol, wherein the ailanthus peel extracting solution is prepared through heating and back flowing ailanthus powder in water 4-5 times of mass of the ailanthus powder and filtering and concentrating till the ailanthus peel extracting solution is 10% of the total liquid medicine amount; the aloe extracting solution is prepared through steps of carrying out ultrasonic extraction on aloe powder by ethyl alcohol with concentration of 60wt% according to the material liquid massic volume ratio of 1:(50-70) and concentrating the filtrate till the aloe extracting solution is 20% of the total liquid medicine amount; and the volatile oil is prepared by distilling the mozzie buster, lavender and mint leaf through water vapor and then extracting. The mosquito repellent adopts natural vegetable drug, contains no chemical mosquito repelling components, and can be directly sprayed or applied on naked body parts; the mosquito repelling effect is over 91%; the effective time of the mosquito repellent is as long as 5 hours; and the mosquito repellent is fragrant, so that a user feels fresh and cool and comfortable. The preparation method has low production cost and simple technological operation, and the mosquito repellent prepared by the method has long effective time, does not contaminate the environment, and has high degree of safety to human bodies.

Owner:镇江南方电子有限公司

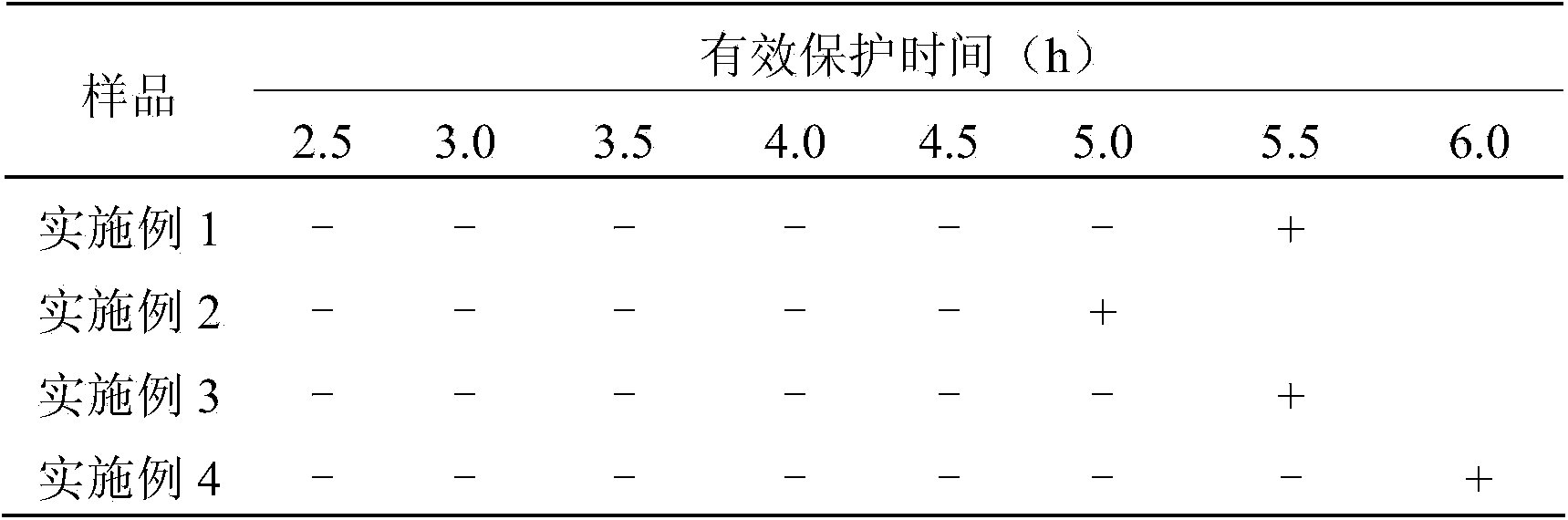

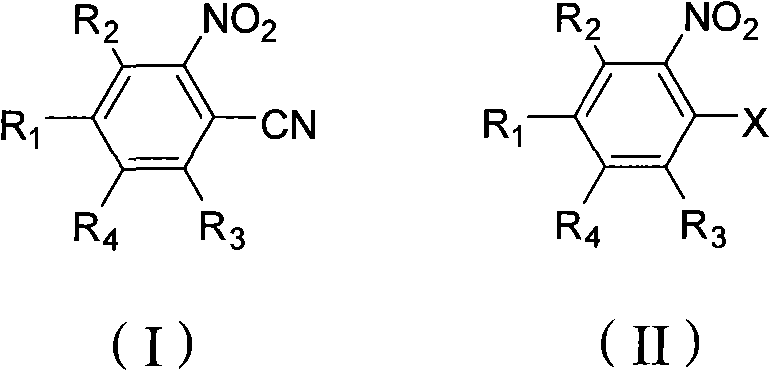

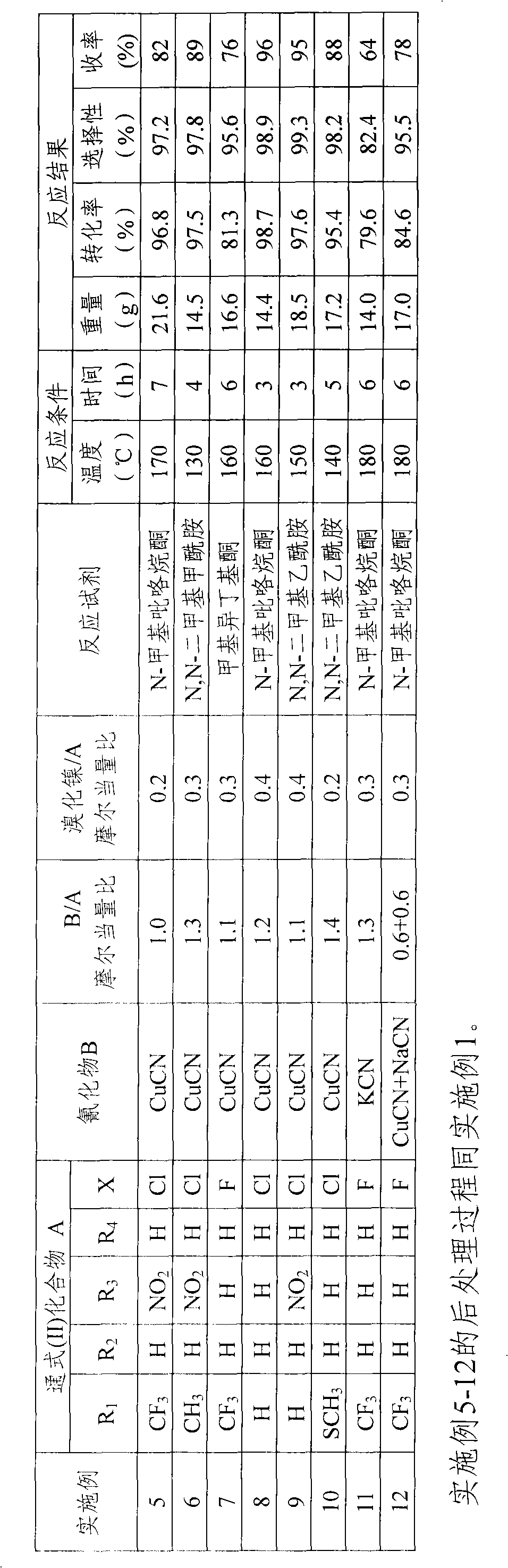

Preparing method of ortho-nitrobenzonitrile series compound

ActiveCN101585783AHigh reaction selectivity and conversionSimple process operationPhysical/chemical process catalystsPreparation by cyanide reactionMedicinal chemistryBromide

The present invention provides a preparing method of ortho-nitrobenzonitrile series compound, wherein, R1 and R3 are simultaneously or respectively as hydrogen, C1-C6 hydrocarbyl, C1-C3 halohydrocarbon, C1-C3 sulfenyl, C1-C3 sulfonyl, fluorine, fluorine, chlorine, bromium, nitro, R2 and R4 are simultaneously or respectively as hydrogen, C1-C6 alkoxyl, characterized in that, the ortho-nitrobenzonitrile series compound can be reacted to prepare by the compound and the cyanide of general formula (II) under the action of the catalyst nickelous bromide; wherein, the definitions of the R1-R4 groups in the general formula (II) are the same as the general formula (I), X is as or fluorine. The method adopts the new catalyst nickelous bromide and has characteristics of high reaction conversion rate and selectivity and short reaction time, and is easy for the industrial production.

Owner:NUTRICHEM LAB CO LTD

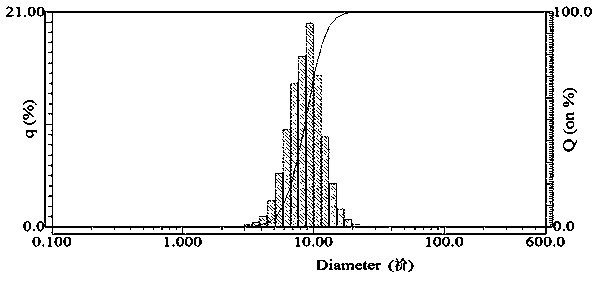

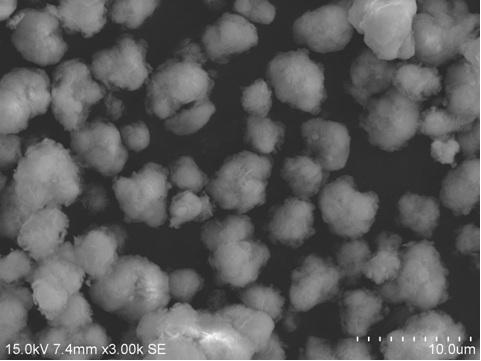

Preparation method of sphere-like manganese-rich ternary precursor

PendingCN111498908ASimple process operationReduce manufacturing costCell electrodesSecondary cellsSulfuric acidParticle-size distribution

The invention discloses a preparation method of a sphere-like manganese-rich ternary precursor. The method comprises the following steps: mixing and dissolving nickel sulfate, cobalt sulfate and manganese sulfate to prepare a nickel-cobalt-manganese sulfate mixed solution, adding the nickel-cobalt-manganese sulfate mixed solution and a precipitant solution into a reaction kettle in a parallel flowmanner, adding a complexing agent in a parallel flow manner, controlling the pH value to be 6.8-10.0, the reaction temperature to be 40-80 DEG C and the stirring speed to be 200-800 r / min, and agingthe obtained turbid liquid in the reaction kettle for 5-20 hours after the solution is dropwise added; and after aging is finished, filtering and washing the turbid liquid, and finally, carrying out vacuum drying at 80 DEG C for 10-20 hours to obtain the sphere-like manganese-rich ternary precursor. The sphere-like manganese-rich ternary precursor prepared by the method is good in sphericity degree, narrow in particle size distribution, uniform in particle size, high in tap density, simple in process method and less in pollution.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Tagatose producing process

InactiveCN1985624ASimple process operationProduct separation is simpleFood preparationChemistrySweetening

The present invention discloses tagatose producing process. The tagatose producing process includes the following steps: dissolving galactose in water, isomerization reaction with sodium aluminate at 10-37deg.c for 1-3 hr to produce tagatose solution, cooling the solution, and adding acid capable of reacting with sodium aluminate to produce precipitate to eliminate sodium aluminate and obtain pure tagatose solution. The technological process is simple and suitable for large scale production, and has low reaction temperature, easy product separation and no environmental pollution. The produced tagatose is used as natural sweetening agent and may find its wide application in food, medicine, cosmetics, etc.

Owner:GUANGDONG FOOD IND INST

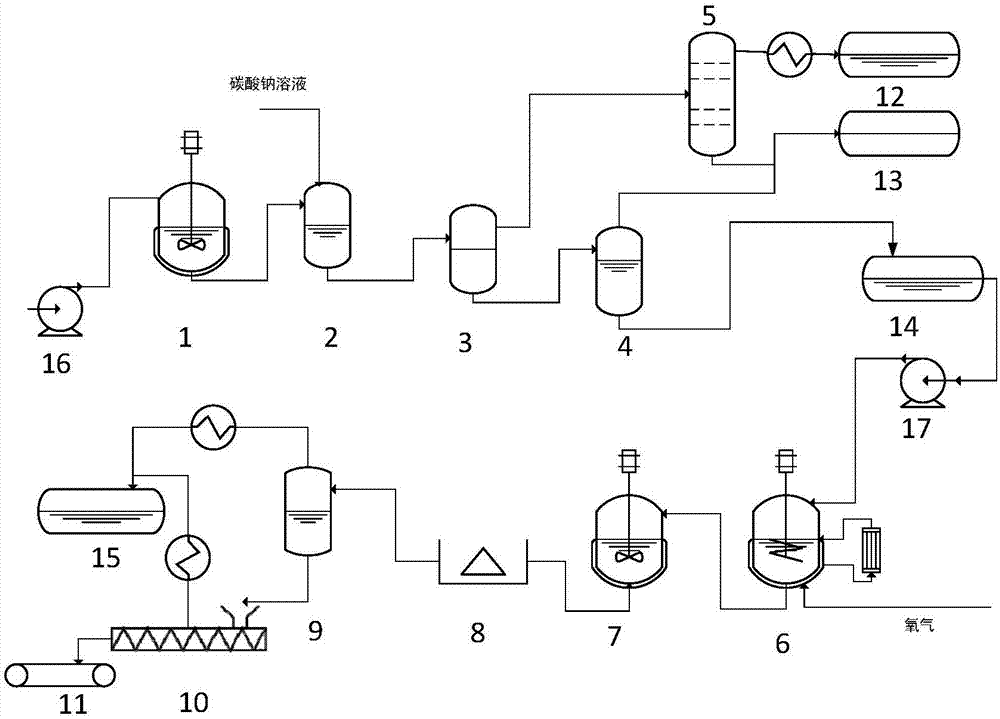

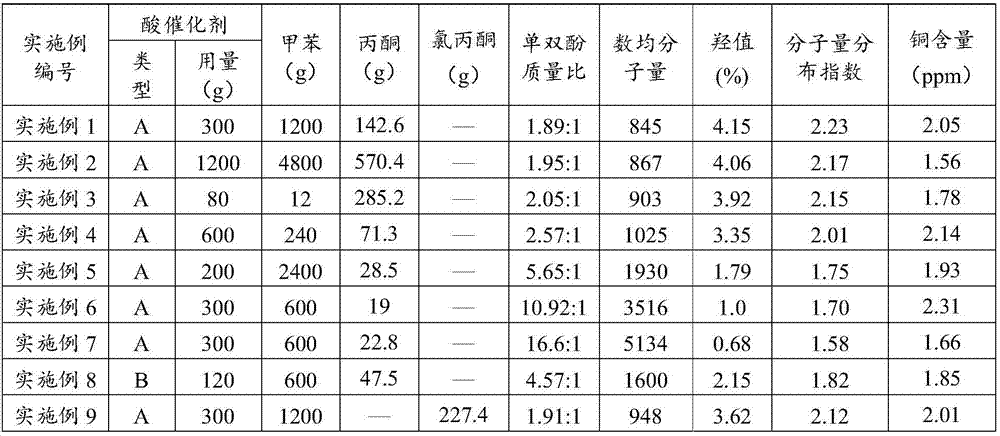

Dihydroxyl polyphenyl ether and preparation method thereof

ActiveCN107353401ASimple process operationReduce manufacturing costEther preparation by compound dehydrationSolventPrinted circuit board

The invention provides dihydroxyl polyphenyl ether and a preparation method thereof. The preparation method of the dihydroxyl polyphenyl ether provided by the invention comprises the following steps of introducing an oxygen-containing gas into a reaction solution prepared from a solvent, a metallic salt and an amine compound to carry out oxidative coupling to obtain a monomer product, and then terminating a reaction, so as to obtain the dihydroxyl polyphenyl ether. The preparation method of the dihydroxyl polyphenyl ether provided by the invention is simple in technical operation, low in production cost and high in production efficiency, and can be used for meeting the industrialized production requirement of the dihydroxyl polyphenyl ether with a low molecular weight. A product of the dihydroxyl polyphenyl ether provided by the invention is low in molecular weight, stable in molecular weight control and uniform in molecular weight distribution, good in compatibility with other matrix resin such as PCB (Printed Circuit Board) and excellent in reaction performance, and is ideal matrix resin for preparing a high-frequency copper-clad board.

Owner:宋立旺

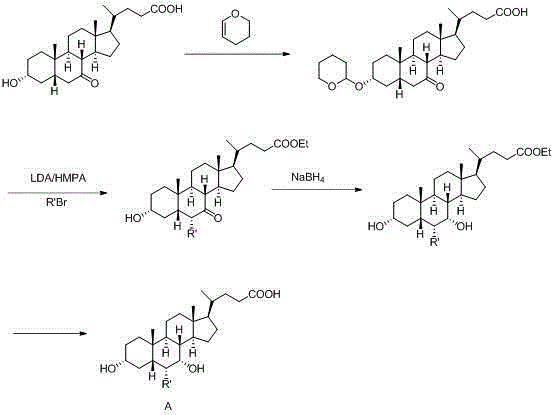

Method for preparing 6alpha-alkylchenodeoxycholic acid

InactiveCN106279328ASimple process operationSave equipment investment and energySteroidsDeoxycholic acidAlkyl

The invention discloses a new method for preparing 3alpha, 7alpha-dihydroxy-6alpha-alkyl-5beta-cholanic acid I. According to the method, a pressurized reaction is not required, separation and purification of an intermediate are not required, the required product can be obtained by one-pot method, reaction conditions are mild, and yield is high. The method of the invention is suitable for industrial production.

Owner:YAOPHARMA CO LTD +1

Preparation method of tungsten-plated SiC particle reinforced copper-based composite material used for electronic packaging

InactiveCN101624665ASimple preparation processSimple process operationSemiconductor/solid-state device manufacturingAlloy elementTungsten

The invention discloses a preparation method of a tungsten-plated SiC particle reinforced copper-based composite material used for electronic packaging. The raw material comprises the following components and volume percentage: 50 percent to 75 percent of tungsten-plated SiC particles, 0.5 percent to 3 percent of adding elements and 22 percent to 49.5 percent of Cu matrix, wherein the adding elements are one or more of Fe, Co and Ni. The composite material is prepared by adopting the techniques of mixing powder, pressing, infiltrating and repressing, wherein the Cu matrix are Cu metal powder and Cu metal blocks which are respectively added before and after pressing blanks. The preparation method adopts SiC particles with tungsten-plated surfaces, adds alloy elements, greatly improves mutual wettability among object phases, therefore, the prepared material has excellent thermal conductivity, thermal expansion coefficient and mechanical property; the adopted liquid-phase infiltrating method has the advantages of simple operation, low cost, high material compactness and applicability to scale production.

Owner:SHANGHAI JIAO TONG UNIV

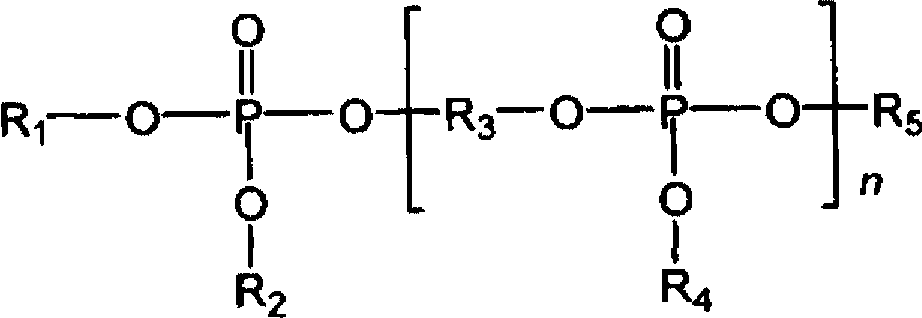

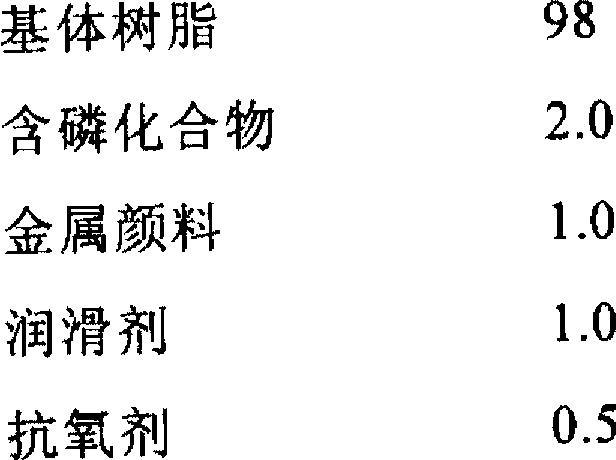

Highly metallic resin composition and preparation method thereof

The invention relates to a highly metallic resin composition and a preparation method thereof. The highly metallic resin composition comprises the following components in part by weight: 90 to 99 parts of matrix resin, 1 to 10 parts of phosphorous compound, 0.1 to 4.0 parts of metallic pigment, 0.1 to 1.0 part of lubricant and 0.1 to 1.0 part of antioxidant. The preparation method of the highly metallic resin composition comprises the following steps of: after premixing the raw materials in a low speed mixer, feeding the mixture into a double-screw extruder; under the action of conveying, shearing and mixing of screws, melting and compounding the materials; and then carrying out extrusion, bracing, cooling and sized dicing to obtain the highly metallic resin composition. Compared with the prior art, the resin composition disclosed by the invention has the advantages that the metallic texture is promoted and is closer to a paint spraying effect; the implementing cost is low; the highly metallic resin composition is simple to operate and can be directly formed by methods of injection molding, extrusion, blow molding and the like; and an innovative appearance solution is provided.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Natural fruit and vegetable cleaning agent and preparation process thereof

InactiveCN101993798ASimple process operationLow costNon-surface-active detergent compositionsSodium carbonateFertilizer

The invention relates to a natural fruit and vegetable cleaning agent and a preparation process thereof, and belongs to the technical field of household environmental-friendly products. The natural fruit and vegetable cleaning agent is prepared from raw materials such as coconut oil, aloe, sodium carbonate and deionized water according to the weight part ratio, can effectively remove and degrade harmful residues in fruits and vegetables, such as pesticides, chemical fertilizers and the like, does not change the taste of food, can prolong the shelf life of the food, is safe and nontoxic, and is suitable for various fruits, raw melons, fruits and vegetables and tableware; and the food can be directly eaten after being sterilized.

Owner:张艳冰

Preparation method for soluble pearl powder

InactiveCN102342904ASimple process operationGood effectCosmetic preparationsPowder deliveryEmulsionProtease

The invention provides a preparation method for soluble pearl powder. The preparation method comprises the following steps of: cleaning the fresh water nuclear-free pearls; airing the nuclear-free pearls; crushing the nuclear-free pearls to reach 200-400 meshes; adding 1000-2000ml water in terms of 1000g pearl powder; adding 100-1000g sugar in proportion; mixing the mixture to form emulsion; adding lactic acid bacteria with the purity of above 95%; uniformly mixing the mixture; filling the mixture in a fermentation tank; sealing the fermentation tank; heating the mixture to 35-65 DEG C; continuously mixing the mixture; fermenting the mixture for 24-120 hours; cooling the mixture to 35-55 DEG C; adding acidic protease and debitterizing protease; retaining the temperature between 40 DEG C and 50 DEG C; continuously mixing the mixture; subjecting the mixture to enzymolysis for 2-6 hours; heating the mixture to 60-100 DEG C; and sterilizing the mixture for 5-40 minutes to prepare mother liquid. The preparation method has the advantages of simplicity in operation process, more obvious effect and easiness for dissolution and absorption; the product is closer to the nature; prepared product is free of bitterness and fishy smell, and does not need to be neutralized by adding alkali; and product quality meets a new standard.

Owner:湖南今珠生物股份有限公司

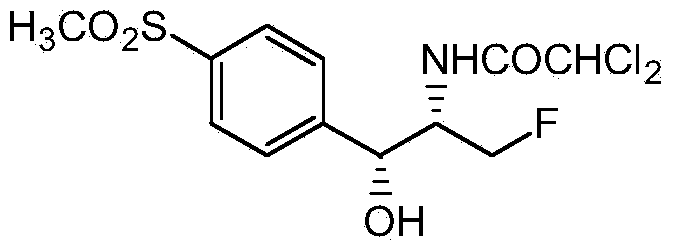

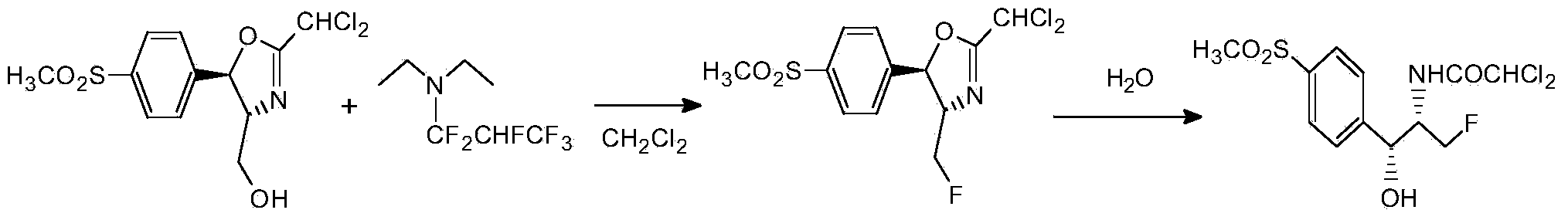

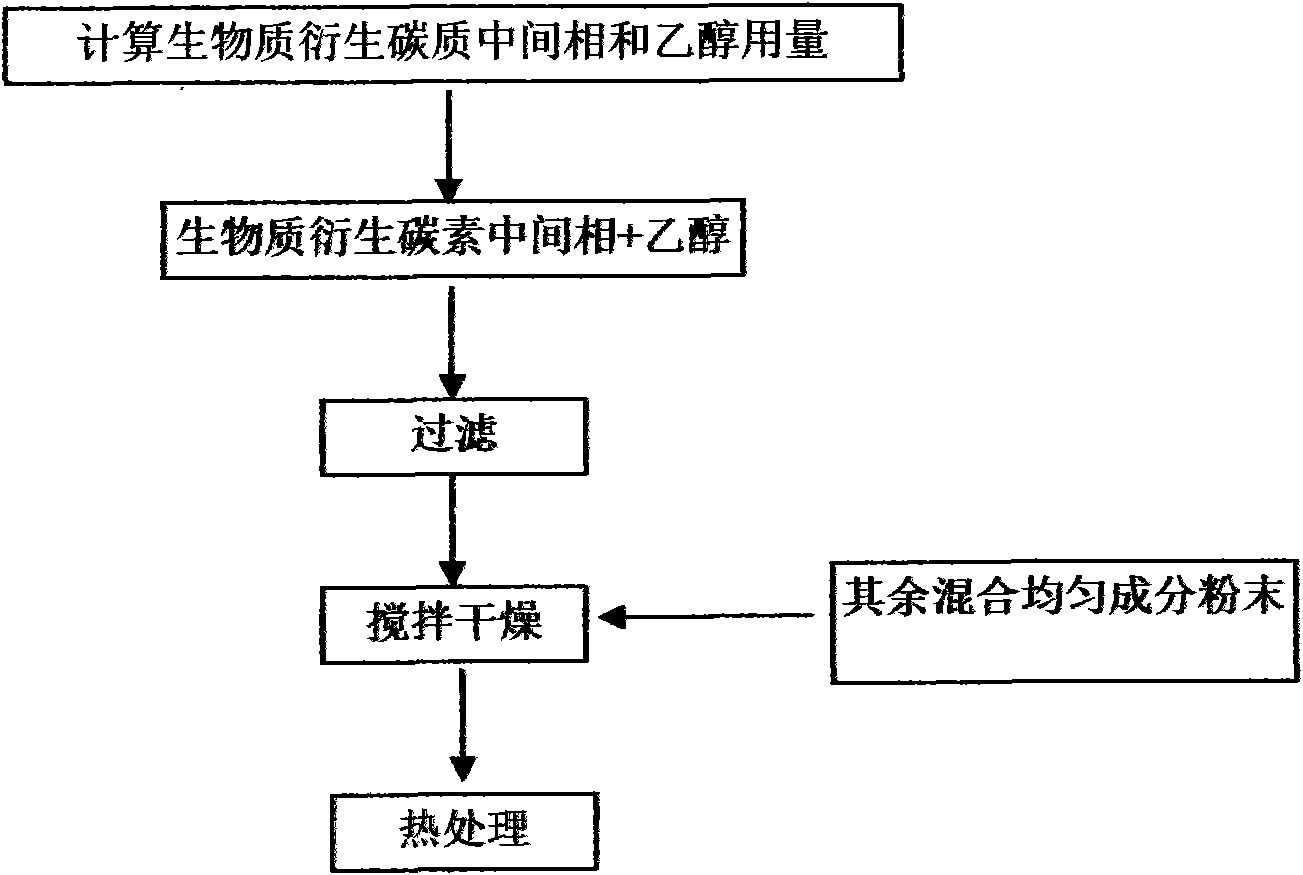

Novel synthetic method of high-purity florfenicol

InactiveCN103980168ASimple process operationEnvironmentally friendlyOrganic chemistryOrganic compound preparationSolventIshikawa reagent

The invention provides a novel synthetic process of high-purity florfenicol. The process comprises the following steps: by taking a compound D-threo form-2-(dichloromethyl)-4,5-dihydro-5-[p-(methylsulfonyl)phenyl]-4-oxazole methanol as an initial raw material, carrying out fluoro-substitution by using an Ishikawa reagent; crystallizing and purifying to obtain a high-purity fluoro product (4S,5S)-2-(dichloracetyl)-4-(methyl fluoride)-5-[4-(methylsulfonyl)phenyl]-4, 5-dihydrooxazole; and further carrying out a hydrolysis reaction directly on the high-purity fluoro product without being added into an organic solvent to directly obtain a high purity florfenicol product. According to the production process, the fluoro intermediate product is crystallized and purified to obtain a high purity product by adopting a direct hydrolysis process without using the organic solvent, so that the novel synthetic method is simple in process operation, environmental friendly, high in product purity, few in impurity, free from solvent residue and low in cost.

Owner:京山瑞生制药有限公司 +1

Method for preparation of high-activity compound organic fertilizer by waste acid liquid of D-glucosamine hydrochloride

ActiveCN101993257AChange the ecological environmentSimple process operationClimate change adaptationBioloigcal waste fertilisersChemistryOrganic compound

The invention relates to a method for the treatment of organic process waste liquid of high-acidity black ammonic sugar, especially to a method for the preparation of high-activity compound organic fertilizer by waste acid liquid of D-glucosamine hydrochloride. The method for the preparation of high-activity compound organic fertilizer by waste acid liquid of D-glucosamine hydrochloride comprisesthe following steps of: concentrating waste mother liquid to recover hydrochloric acid, neutralizing dregs and slurry with KOH alkali liquor; adding chitosan to neutralized liquid for being stirred and sufficiently dissolved; heating up and adding the neutralized liquid with mixed enzyme for enzymolysis, and then destroying enzyme; regulating PH with the KOH alkali liquor and simultaneously adding missing microelement-containing organic compound; and pump-filtering the above liquid and using the liquid as fertilizer after filtration or as solid fertilizer after drying. The compound chitosan fertilizer of the invention is suitable for the growth of various crops and the improved soil, thereby zeroing waste water discharge and changing economic environment. The method is simple in operation, convenient for being performed and suitable for the conversion of a large amount of waste water into fertilizer.

Owner:林大昌

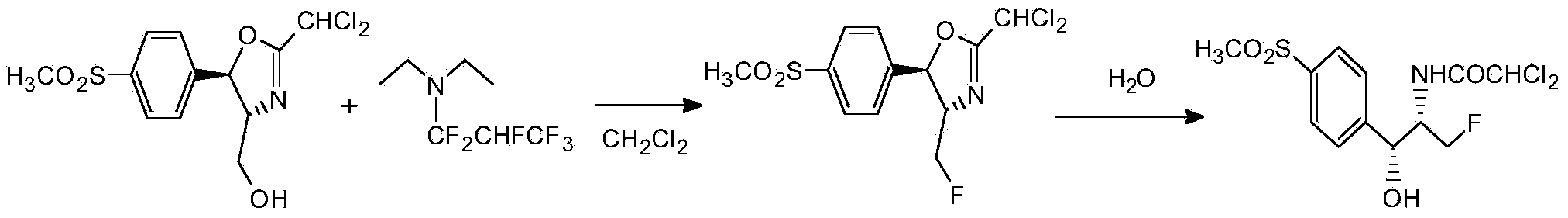

Method for adding carbon substance in the preparation of electric contact material

ActiveCN101654746ASimple process operationAvoid uneven particle agglomerationCarbon particleOrganic matter

The invention relates to a method for adding carbon substance in the preparation of electric contact material in the material technical field. The invention adopts a biomass derivative carbonaceous intermediate phase as material and uses the ethanol solution for dipping the metallic powder. After drying powder, the organic matters on the metallic powder surface form submicron or nanometer carbon particles in a heat treatment way, thus realizing the pollution-free uniform dispersion addition. The solution addition type brings easy operation and no external pollution. The submicron or nanometercarbon particles are uniformly dispersed in the electric contact material matrix so as to improve the comprehensive properties of the electric contact material. And the carbon substance is rich and cheap.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Ion pair dual water phase method for extracting and separating pyrroloquinoline quinone

ActiveCN105294687AHigh recovery rateSimple process operationOrganic chemistryChemistryAmmonium hydroxide

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com