Process for manufacturing sirospun yarn jean facing material

A manufacturing process, twin yarn technology, applied in the manufacturing process of twin yarn denim fabrics, can solve the problems of ring-spun yarns such as excessive hairiness, difficult yarn separation, and many flying flowers, so as to reduce the quality requirements of sizing and draw in healds. High reeding efficiency and less hairiness on the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

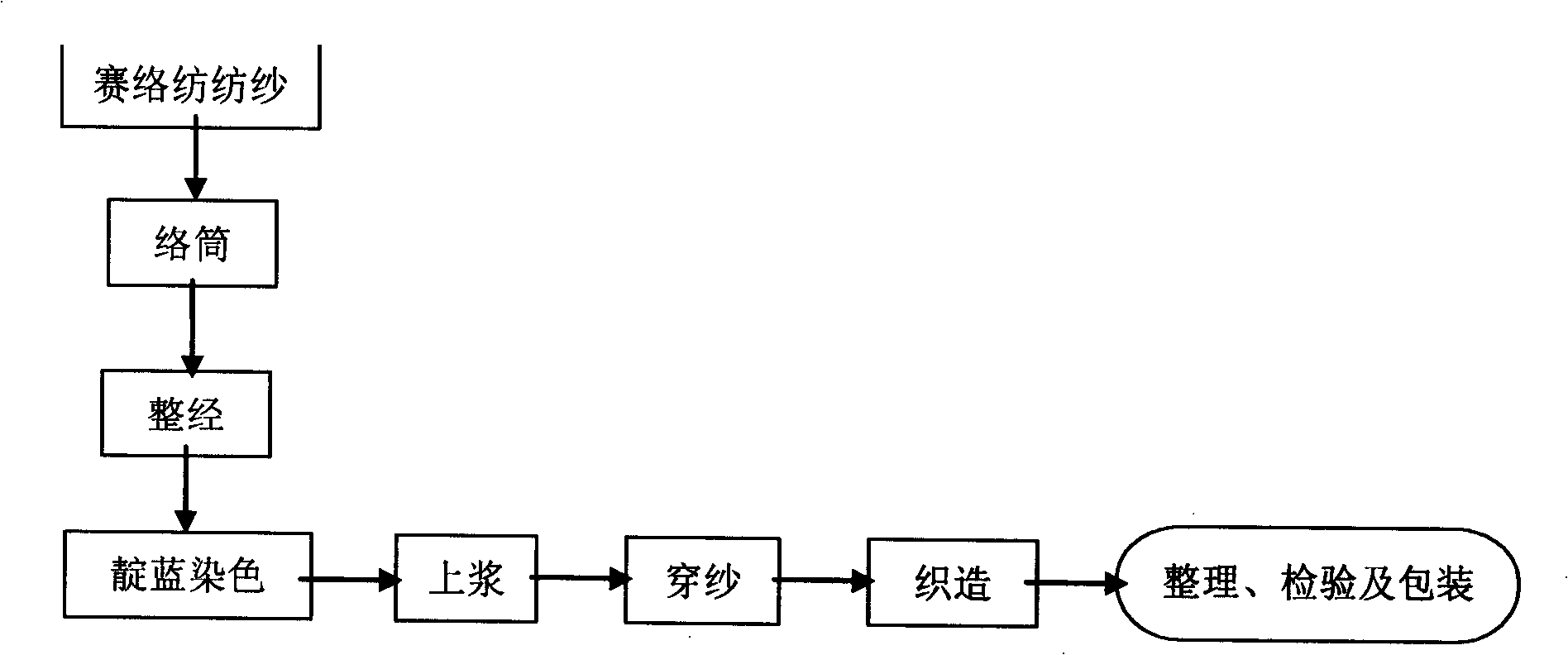

[0020] refer to Figure 1 to Figure 4 , the manufacturing process of a kind of siro yarn denim fabric of the present invention, first adopts siro spinning technology to produce siro yarn, the spun siro yarn is carried out winding, then the siro yarn after winding Warping, dyeing with indigo or other dyes and sizing as warp yarns to make looms, then using twin yarns as warp yarns and twin yarns, rotor yarns or ring spun yarns as weft yarns on the shuttle loom according to the fabric structure of denim Weaving with the weaving process to become gray cloth, and finally the gray cloth is made into finished products after subsequent finishing. Wherein, the subsequent finishing of the gray cloth includes sequentially performing singeing, grouting, skewing, pre-drying, spraying or steam wetting, rubber blanket shrink-proofing, woolen blanket drying, finished product inspection and packaging.

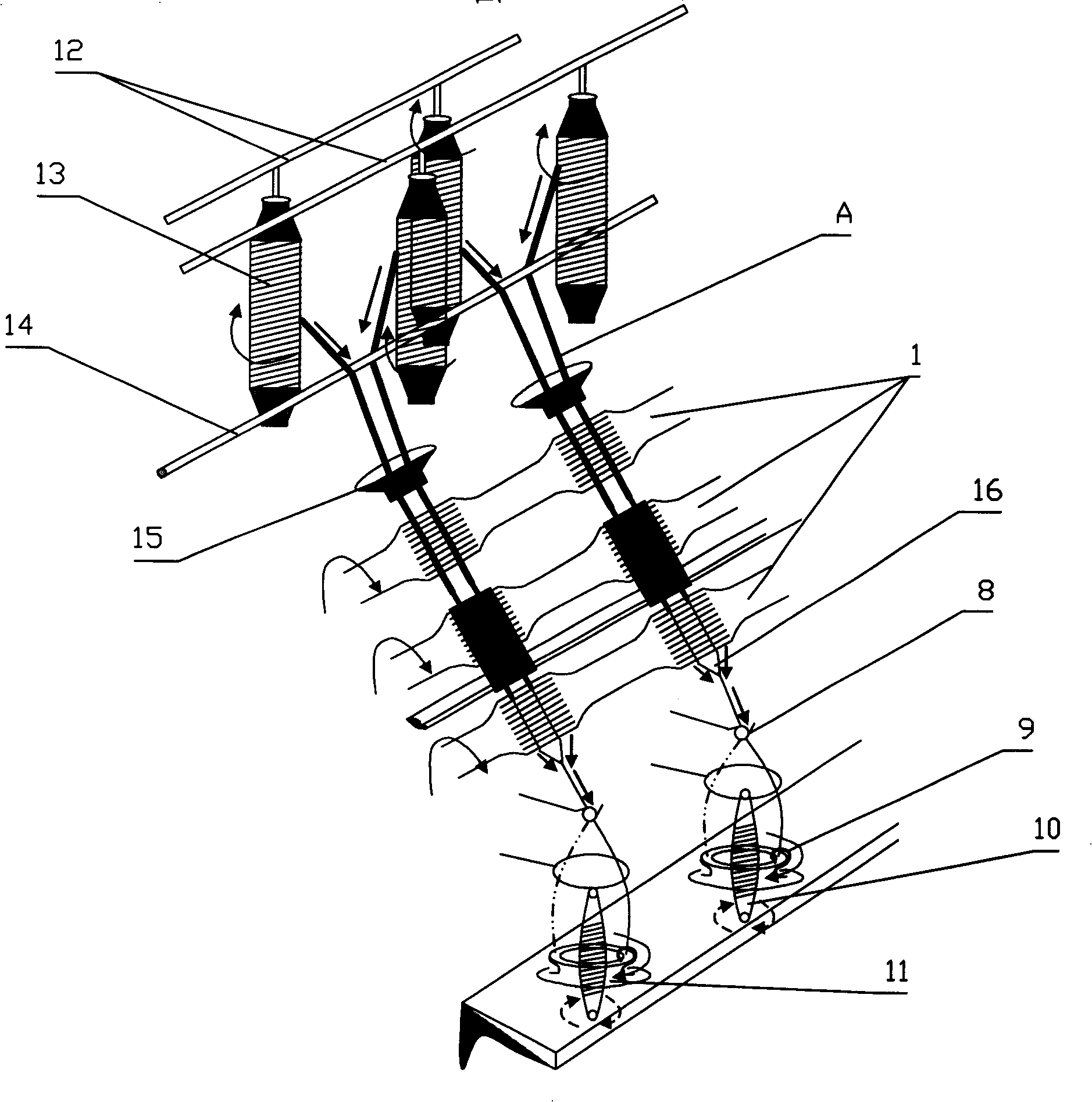

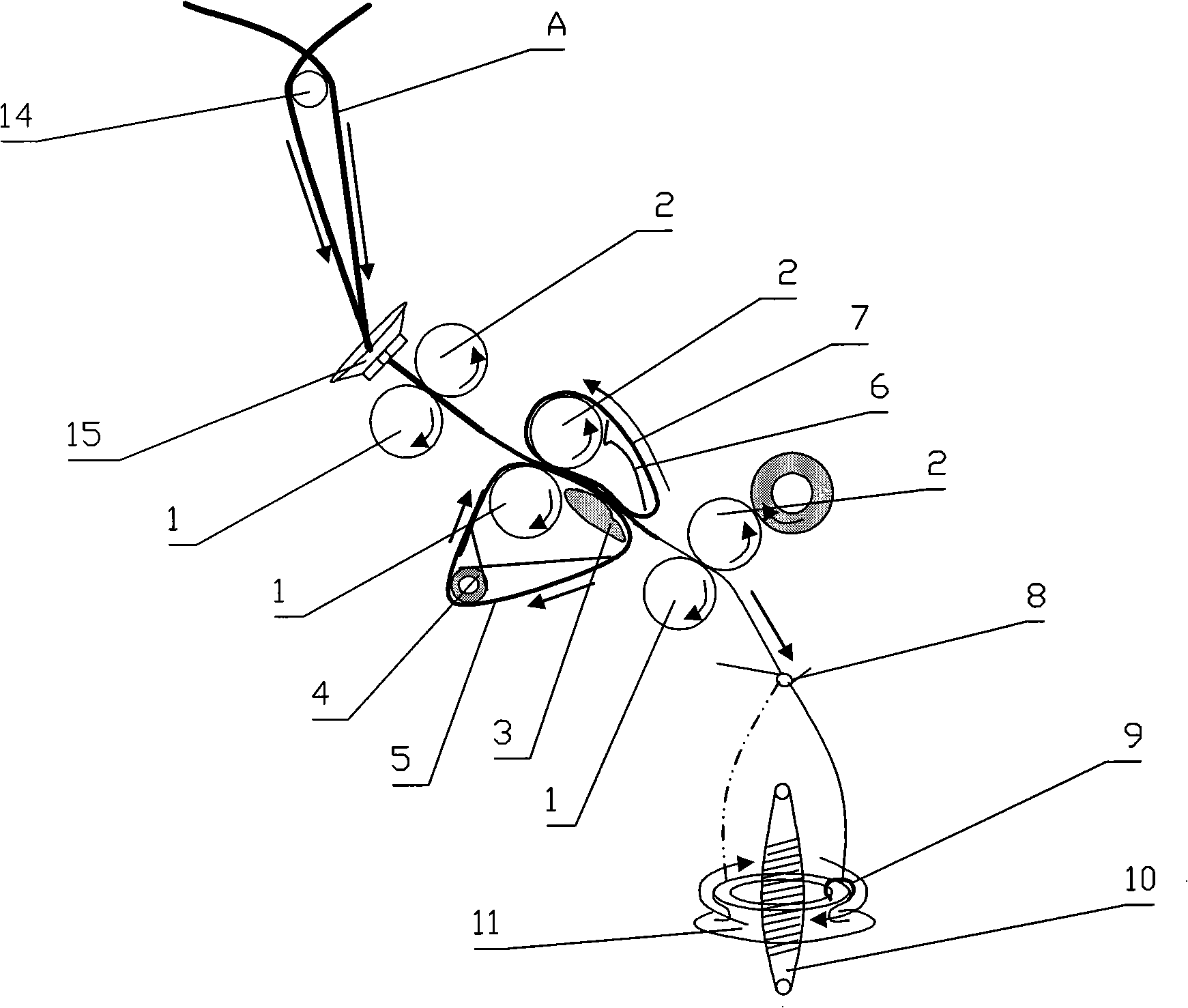

[0021] refer to figure 2 and image 3 , during Siro spinning, the two unwound rovings A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com