Deoxidizing and polishing one-bath process dyeing of polyester cotton knitted fabric

A technology of knitted fabric and bath method, which is applied in the field of deoxidizing, polishing, and one-bath dyeing of polyester-cotton knitted fabrics, which can solve the problems of time-consuming, poor treatment effect, and lengthy process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

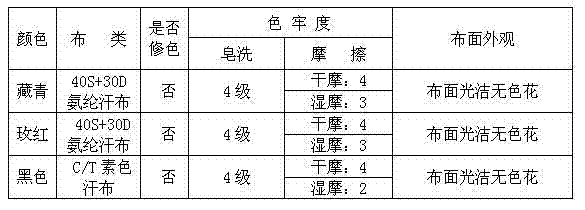

Examples

Embodiment 1

[0016] In this example, the samples to be treated are T / C (TERYLENCE / COTTON, polyester cotton cloth), CVC (chief value of cotton, textiles with a cotton content above 65%), T / R (POLYESTER / RAYON, polyester / cotton sticky) knitted fabrics. The sample to be treated is dyed according to the following process: alkaline dyeing and washing (398 process)--(reduction cleaning)--polishing, dyeing activity in the same bath treatment--post-treatment.

[0017] Among them, the one-bath method of oxygen removal and polishing dyeing is as follows: adjust the temperature to 40-60°C, adjust the pH value to 5-7, add polishing enzyme 988, and its addition amount is 1.5% (mass percentage), and add dye after 0-15 minutes , after 30 minutes, add sodium sulfate, add soda ash after 20 minutes, keep warm for 60 minutes, and the dyeing bath ratio is 1:5; sodium sulfate is added in 2 times, adding 1 / 3 of the total mass for the first time, and adding 1 / 3 of the total mass for the second time 2 / 3 of the to...

Embodiment 2

[0019] In this embodiment, the sample to be treated is rayon knitted fabric. Dye the sample to be treated according to the following process: Auxiliary 398 --- run for 15 minutes --- add dye (30 minutes) --- run for 15 minutes --- divide into 2 times to add starch powder (30 minutes ) --- run for 20 minutes --- add soda ash in 2 times --- heat preservation time --- post-processing --- cloth --- apply softener.

[0020] Among them, the one-bath method of oxygen removal and polishing dyeing is as follows: adjust the temperature to 40-60°C, adjust the pH value to 5-7, add polishing enzyme 988, the amount of which is 2% (mass percentage), and add dye after 0-15 minutes , after 30 minutes, add sodium sulfate, add soda ash after 20 minutes, keep warm for 60 minutes, and the dyeing bath ratio is 1:20; sodium sulfate is added in 2 times, adding 1 / 3 of the total mass for the first time, and adding 1 / 3 of the total mass for the second time 2 / 3 of the total mass; soda ash is added in 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com