Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Spinning process is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

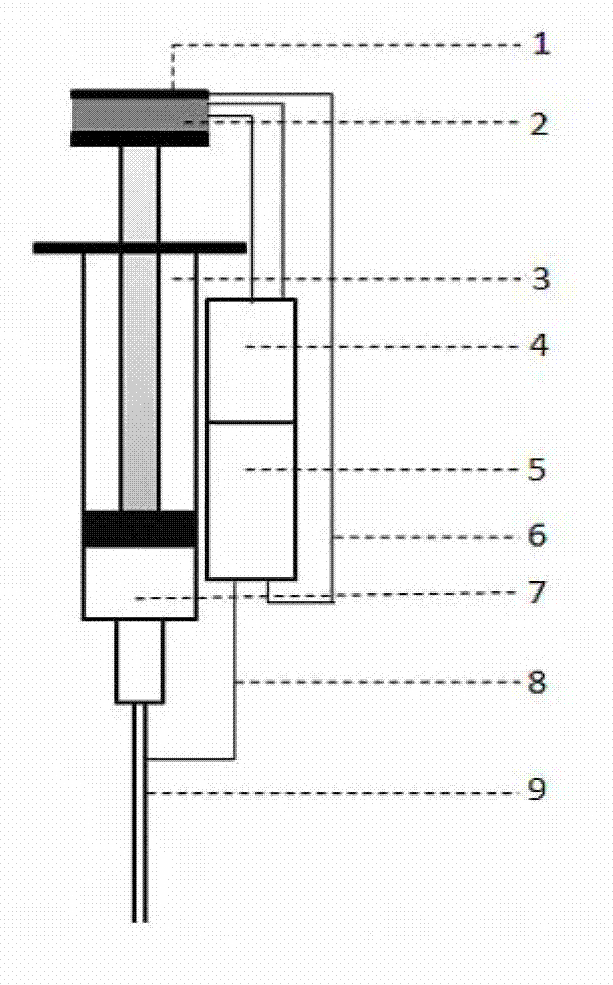

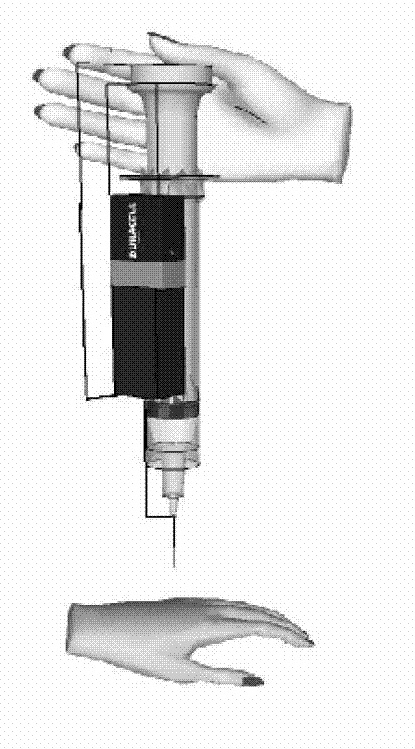

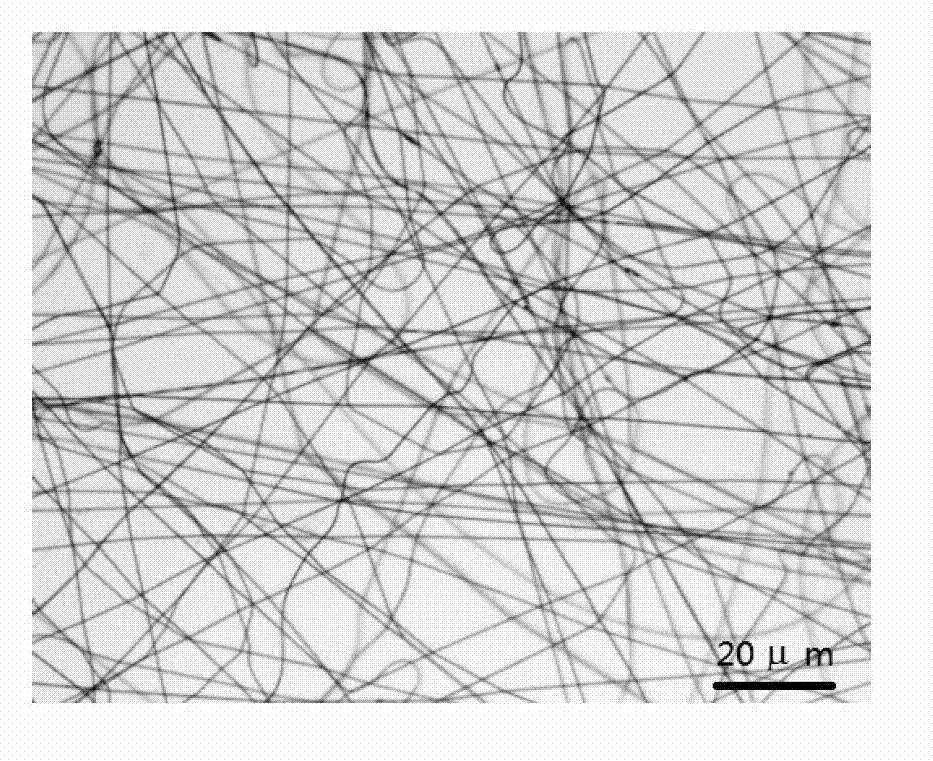

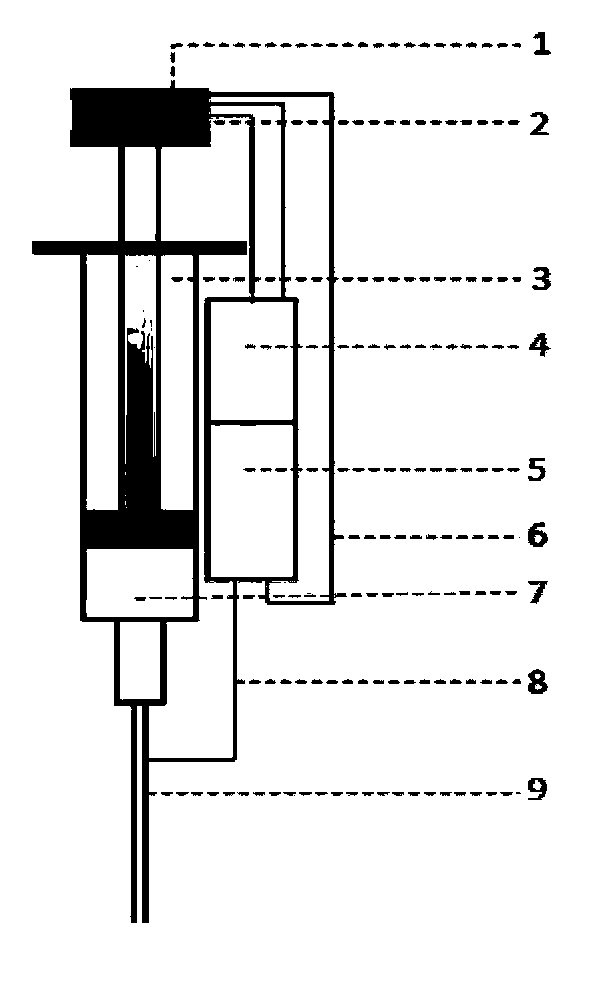

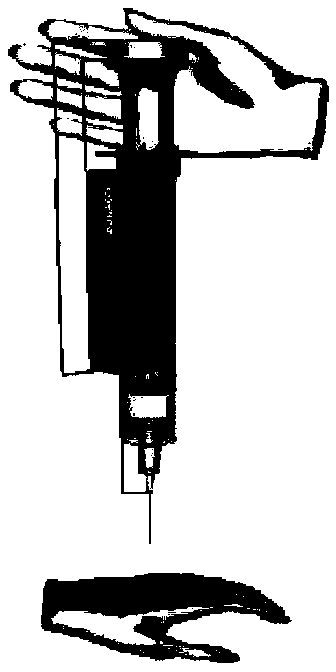

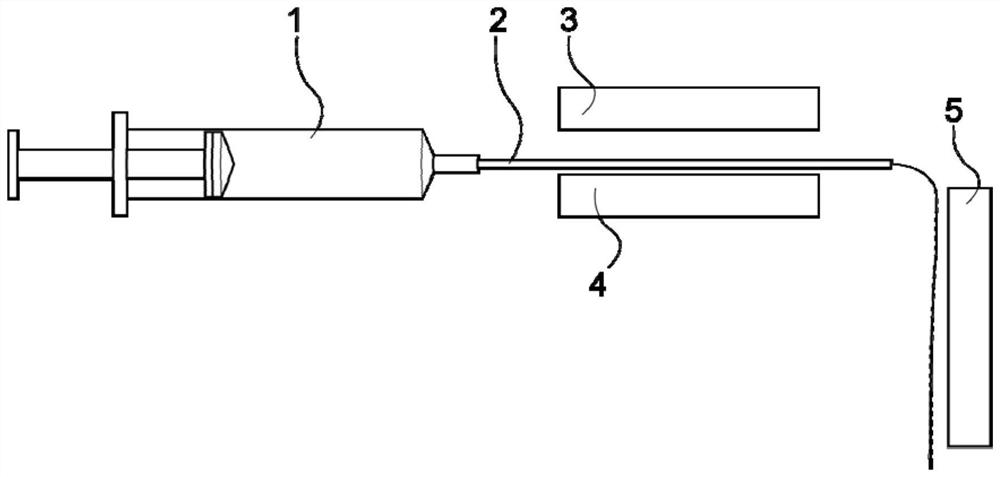

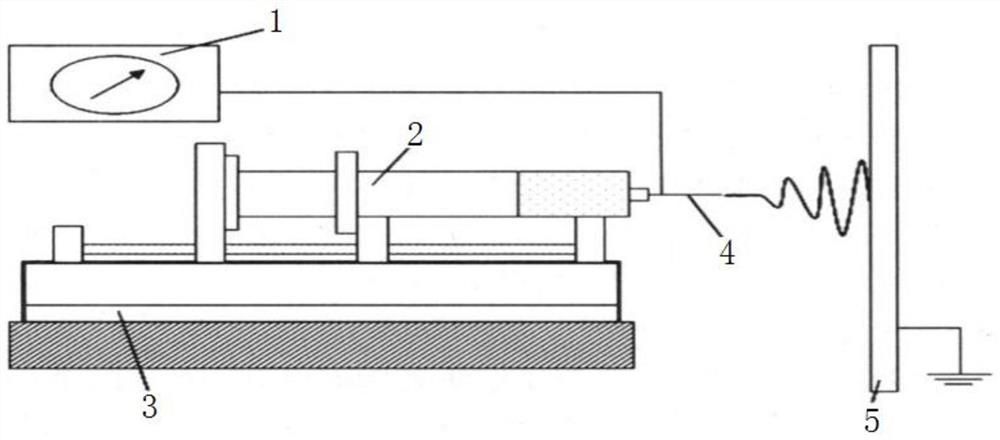

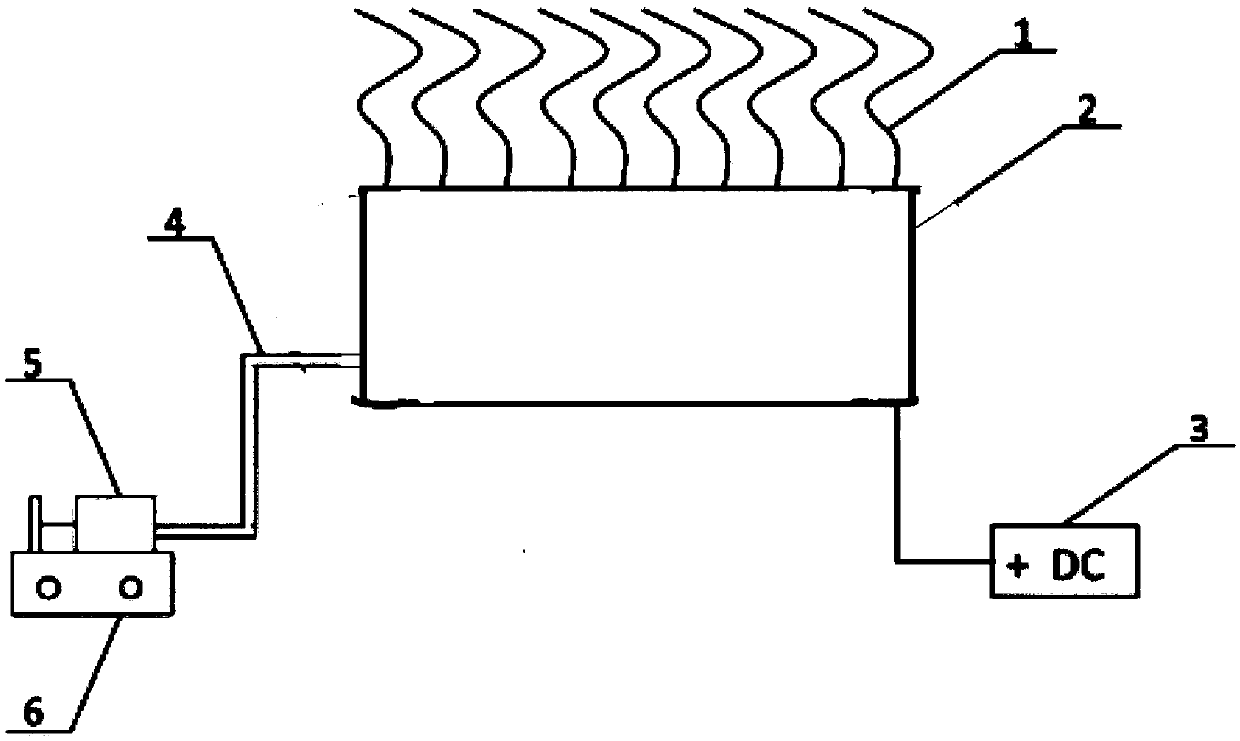

Portable handheld electrostatic spinning device

ActiveCN102776583AReduce fearTimely protectionFilament/thread formingEducational modelsElectricityElectrical battery

The invention belongs to the technical field of electrostatic spinning and relates to a portable handheld electrostatic spinning device. The top of a pushing rod of a medical syringe is provided with a pressure welding switch, a metal foil is arranged on the top side fixedly, a spinning solution is arranged in a front end inner cavity of the medical syringe, a square battery and a high-voltage direct-current inverter are arranged fixedly on the side wall of the syringe in a butt joint mode, and a stainless steel needle head which is used for spinning is arranged at the bottom end of the syringe in an inserting mode. A conventional medical syringe needle head structure and the syringe are combined and matched, the spinning solution is stored in the inner cavity of the medical syringe which is provided with the stainless steel needle head, the square battery provides a power supply for the high-voltage direct-current inverter, when the direct current voltage is inverted, the voltage in the unit of kilovolt, the positive pole of the high-voltage direct-current inverter is communicated electrically with the stainless steel needle head, and the negative pole of the high-voltage direct-current inverter is communicated electrically with the metal foils. The device is simple in overall structure, is convenient to carry, use and operate, applicable to occasions such as outdoor teaching and wounded rescue and high in economical value.

Owner:青岛中科凯尔科技有限公司

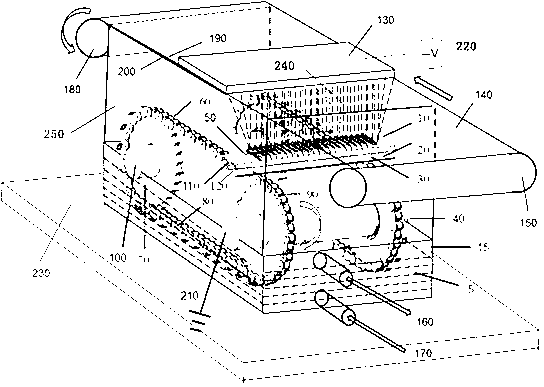

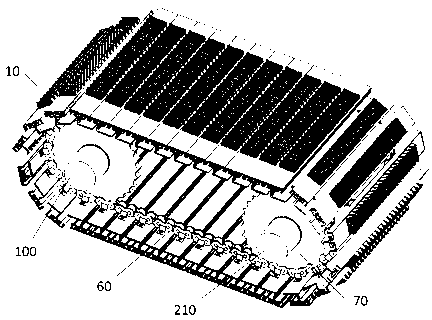

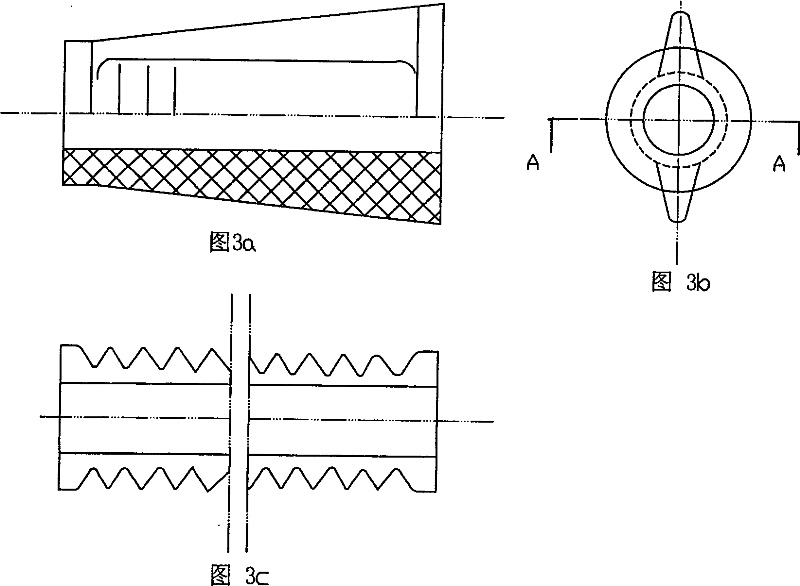

Tip-end type needle-free electrostatic spinning equipment

ActiveCN103255485AImprove uniformityTake advantage ofFilament/thread formingSpinningHigh-voltage direct current

The invention discloses tip-end type needle-free electrostatic spinning equipment which comprises a spinning solution storage box, base cloth, a spinning device and a negative-high-voltage direct-current power source, wherein the spinning device comprises a spinning box body, a needle plate, a chain, a negative electrode and a connecting device. The spinning box body is fixedly connected at the top end of the spinning solution storage box, and the chain is connected on the inner wall of the spinning box body. The connecting device is connected with a transmission device to achieve rotation of the chain, a lowermost link of the chain is submerged in spinning solution of the spinning solution storage box, and the needle plate is fixedly connected on the chain. The base cloth covers the top end of the spinning box body. The spinning solution storage box, the spinning box body and the base cloth form an enclosed spinning space. The negative electrode is attached to the top surface of the base cloth. The spinning device is earthed, the negative electrode is connected with the negative-high-voltage direct-current power source, and a high-voltage electrostatic field is formed between the negative electrode and metal card clothing. The tip-end type needle-free electrostatic spinning equipment can improve the yield and the uniformity of nanofiber products, the fineness of nanofiber manufactured through the tip-end type needle-free electrostatic spinning equipment is small, and the variation of the fineness is less.

Owner:JIANGSU FILTERTEX FILTER MATERIAL +1

Method of continuously preparing poly terephthaloyl-p-phenylene diamine fibre

InactiveCN1693543AShort defoaming timeImprove mixing uniformityFilament-forming treatmentMonocomponent polyolefin artificial filamentFiberViscosity

The invention discloses a method for continuously preparing p-phenylene terephthalamide (PPTA) fiber, including the steps of: (1) continuously adding 98-100% oil of vitriol and PPTA with specific logarithmic viscosity of 4.0-8.5 dl / g to an double spiral extruder, where the weight percent of PPTA is 14-24% and the mixing temperature is 50-100 deg.C; (2) fully mixing and entering in the other extruder, where the adjusting temperature is 50-100 deg.C and the staying time is 10-60 min, fully mixing, adjusting temperature and defoaming and then extruding them; (3) after measuring and filtering spinning solution, obtaining the invention by the routine steps, such as dry spraying-wet spinning. The advantages are short time for mixing materials, adjusting temperature and defoaming high mixing uniformity of materials able to implement continuous, stable filature in a short time, raising the production efficiency.

Owner:DONGHUA UNIV

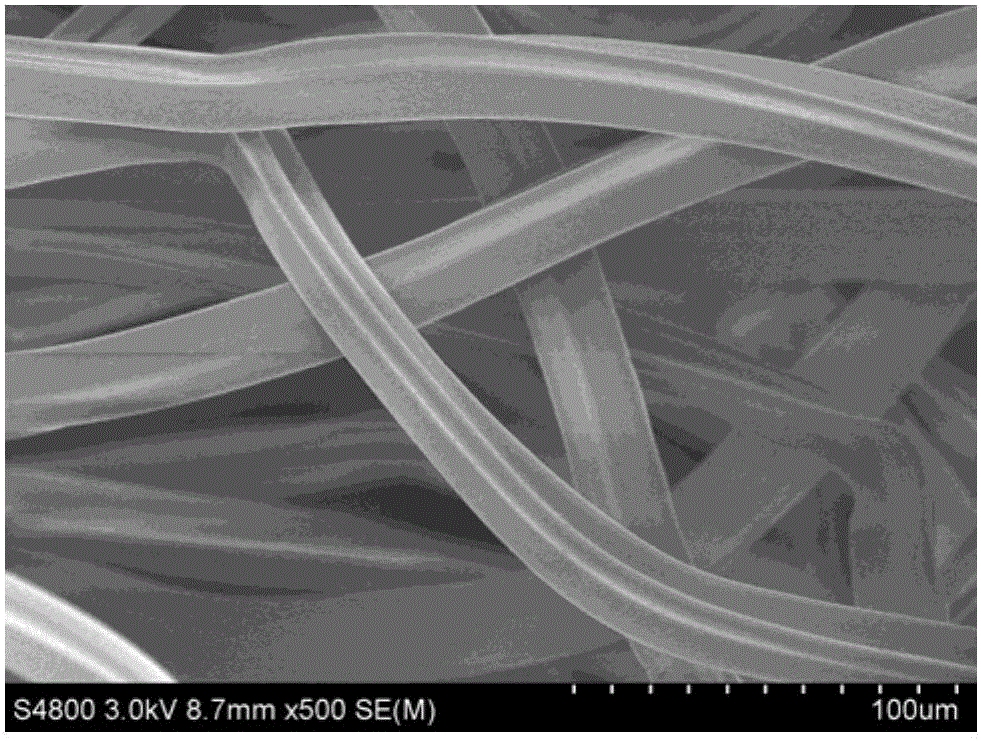

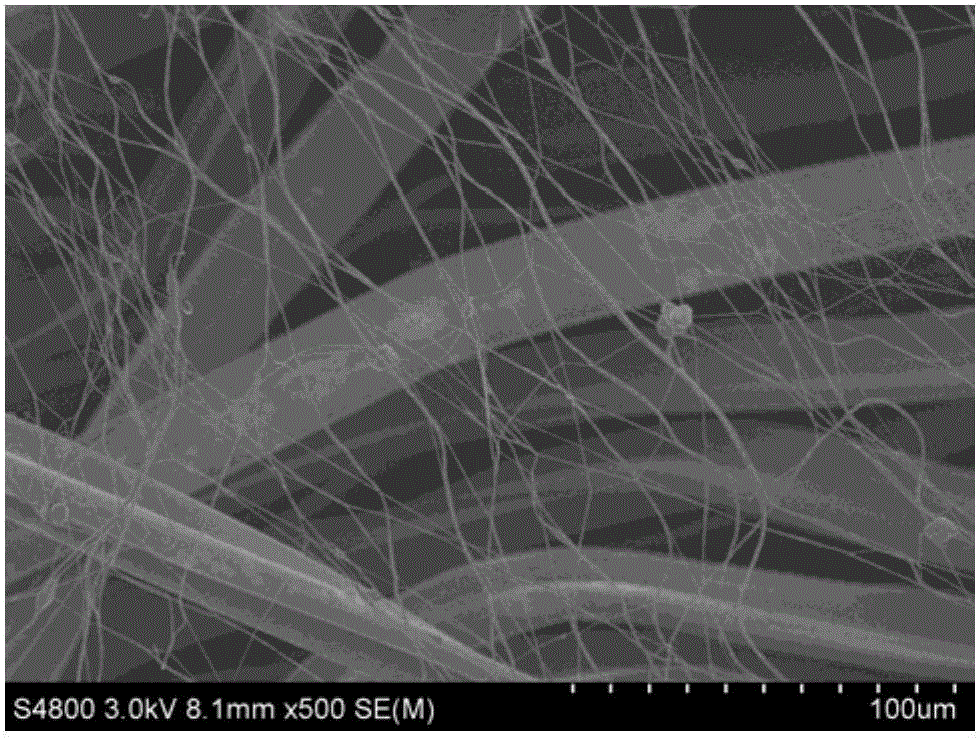

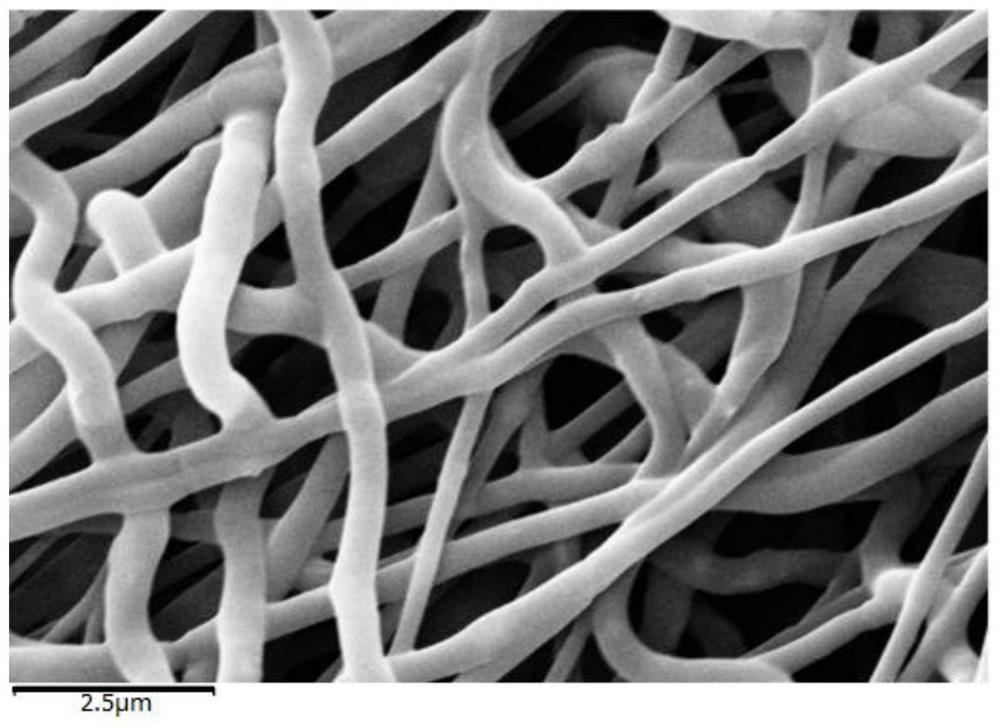

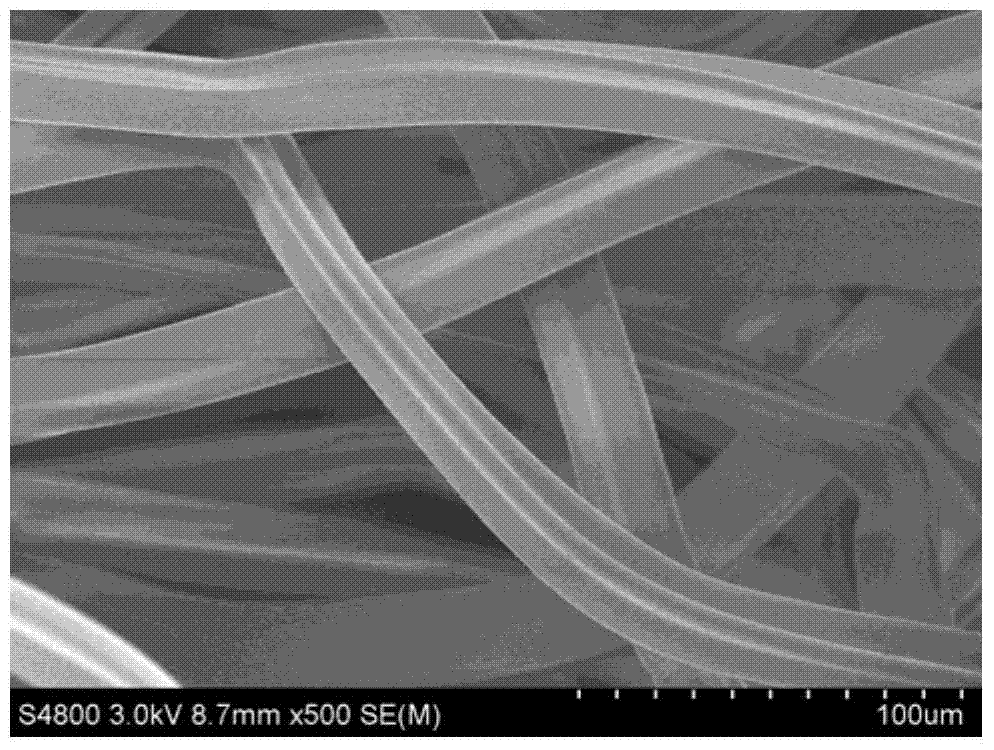

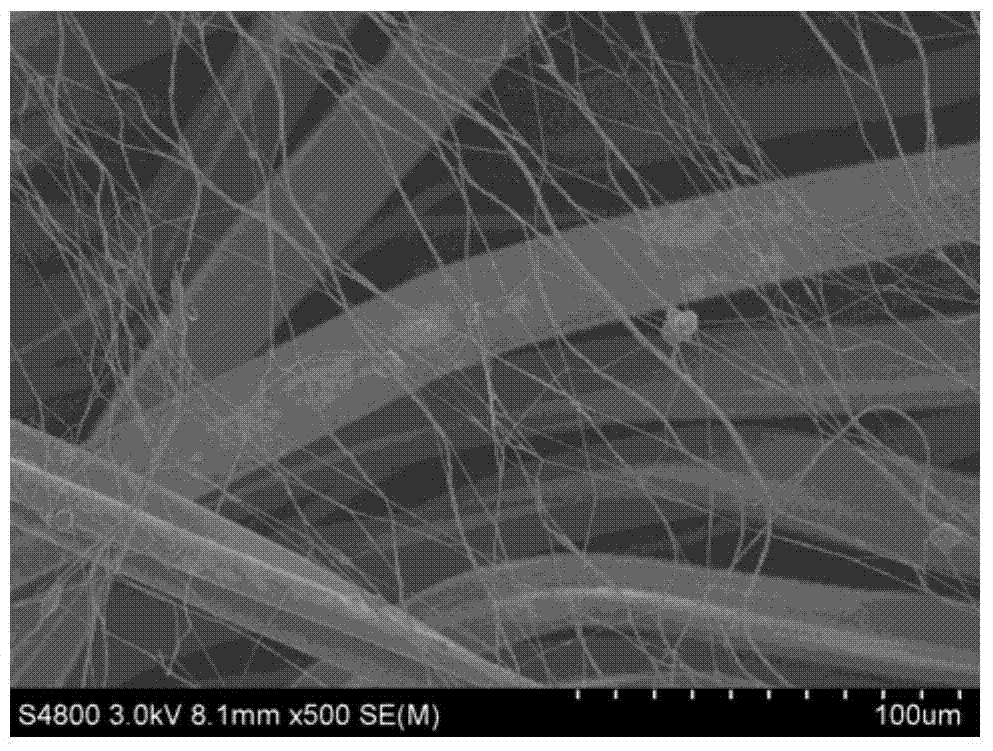

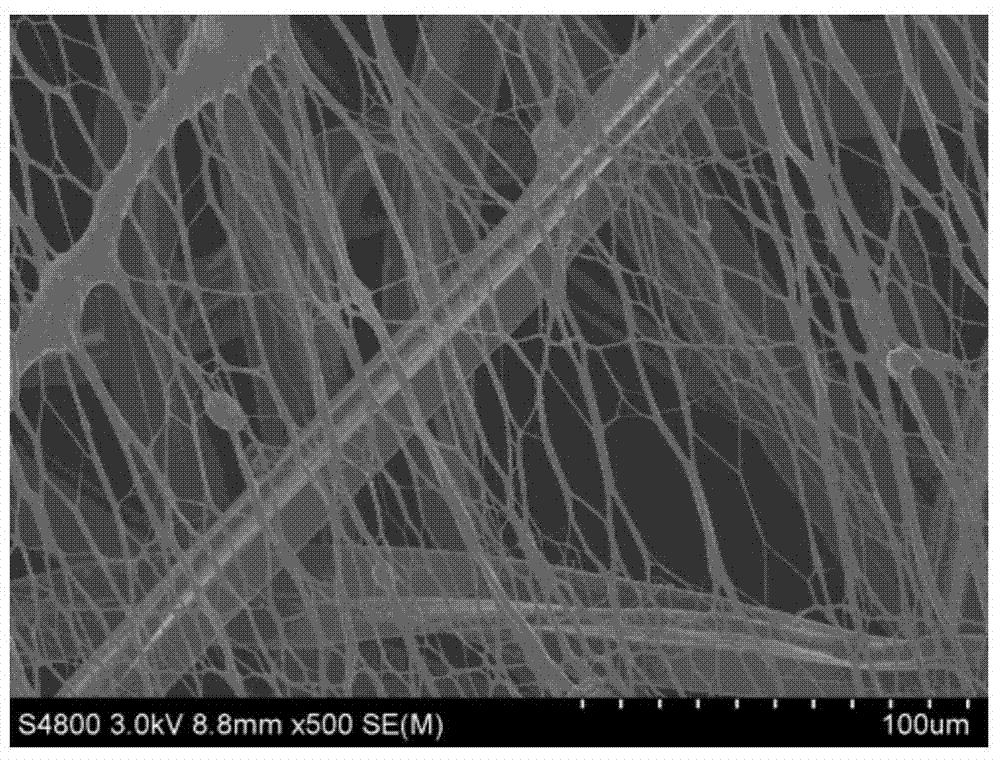

High interface adhesion strength nanofiber composite filament bundle and preparation method and application thereof

ActiveCN105088376AHigh viscosityHigh boiling pointTobacco smoke filtersArtificial filaments from cellulose derivativesCellulose diacetateCellulose acetate

The invention discloses a high interface adhesion strength nanofiber composite filament bundle and a preparation method and application thereof. The preparation method comprises the following steps: 1, preparing a spinning solution with polymer, additives and solvent, wherein the polymer comprises one or more ingredients out of cellulose diacetate, cellulose triacetate, hydroxyethyl cellulose, polyving akohol and polyving akohol, and the additives comprise one or more ingredients out of ethanediol, glycerol, pentaerythritol, diacetin, glycerol triacetate, glycerol trioleate, glycerol palmitate and glyceryl stearate; 2, taking a cigarette-used filament bundle as base materials, conducting electrostatic spinning on the spinning solution which is obtained in step 1, and obtaining the high interface adhesion strength nanofiber composite filament bundle. By means of the high interface adhesion strength nanofiber composite filament bundle, the phenol release amount and NNK release amount in mainstream smoke of a cigarette can be effectively reduced, the phenol release amount is reduced by 16-30%, and the NNK release amount is reduced by 12-36%.

Owner:CHINA TOBACCO ZHEJIANG IND

Production process for bamboo charcoal polyester staple fibre

InactiveCN102517686ARealize resource reuseReduce manufacturing costFilament forming substance formingArtificial filament heat treatmentPolyesterPolyethylene terephthalate glycol

The invention discloses a production process for a bamboo charcoal polyester staple fibre. In the production process, regenerative PET (Polyethylene Terephthalate) material is used as the material, and the finished product is acquired by pre-treating, rotary drum drying, melt spinning, cooling and forming, winding, drafting, curling, oil applying, thermosetting and cutting-off in sequence, wherein the rotary drum drying comprises the steps of firstly drying the regenerative PET material for 5.5h-6.5h and then adding bamboo charcoal master batches with the final mass fraction of 6%-8% and including bamboo charcoal with the mass fraction of 22%-27%; and the total drying time is 9.5h-10.5h; both the screw rod and the spinning beam of a screw extruder in the melt spinning step are at the temperature from 278 DEG C to 282 DEG C; cooling forming is realized through circular air blow, the temperature of the circular air is 22 DEG C to 26 DEG C, and the air velocity of the circular air is 4.0m / s-5.0m / s; the total draft multiple is 3.1-3.3 times; and the thermosetting temperature is 162 DEG C to 168 DEG C, and the thermosetting time is 13 minutes to 17 minutes. The production process can save the cost and is helpful for environmental protection; the produced product has a better smooth and comfortable hand feeling and moisture-absorption air permeability than those of a normal polyester staple fibre.

Owner:HANGZHOU BEST CHEM FIBER

Colored polyamide fiber and process for producing the same

ActiveCN101142348AExcellent fiber propertiesSpinning process is stableMonocomponent copolyamides artificial filamentConjugated synthetic polymer artificial filamentsHigh concentrationAliphatic hydrocarbon

Colored polyamide fibers which comprise a polyamide resin, a pigment, a coupling agent, and a compound represented by the following general formula (I): R'-CO-NH-R-NH-CO-R'' (I) (wherein R represents C1-4 alkylene; and R' and R'' each independently represents a C9-18 aliphatic hydrocarbon group). Even when a raw material composition containing the pigment in a high concentration is used, the colored polyamide fibers can be produced therefrom without causing bending or fiber breakage during melt spinning. The pigment has been evenly dispersed in the colored polyamide fibers. The fibers hence has a high color density and a high strength. The colored polyamide fibers are suitable for use in producing artificial leathers.

Owner:KURARAY CO LTD +1

Preparation process of fine-denier high-strength polyester fiber

InactiveCN109183164ASolve hair and broken endsStable productionSpinnerette packsMonocomponent polyesters artificial filamentDrawing ratioWool

The invention discloses a preparation process of a fine-denier high-strength polyester fiber, which includes the following steps: melting; metering and spinning; cooling and oiling; pre-interlacing; stretching and finalizing; main interlacing; and winding into a finished product. A 12-hole spinneret is used for spinning. A slow-cooling heating device is installed below the spinneret, and the temperature of the slow-cooling heating device is 8-12 DEG C higher than the surface temperature of the spinneret. Hot air equipment is used for cooling by means of circular blowing. Double oil nozzles areused for oiling, and the oiling rate is 0.85-0.95. Three pairs of rollers are used for draw-forming, and the drawing ratio is 1.75-1.85. The winding speed is 2450-2500m / min. Through the scheme, a stable spinning process is ensured, and the problem that fibers are prone to wool and broken ends is solved. Therefore, the production of the product is stable, the product is of high softness, and the fine-denier high-strength polyester fiber obtained achieves the effect of fine multifilament and can replace high-value products such as silk.

Owner:CHANGSHU POLYESTER

High shearing rate method for spinning poly-terephthaloyl p-phenylenediamine fibre

ActiveCN1752300AWell mixedStable mixFilament/thread formingMonocomponent polyamides artificial filamentFiberSlurry

The invented method includes the following steps: uniformly mixing PPTA and concentrated sulfuric acid whose concentration is greater than 99% in mixing cylinder, preparing mixed solution in which PPTA content is 14%-24%; making the prepared PPTA mixed solution pass through twin screw extruder, further dissolving to form liquid crystal spinning solution, defoaming, fully mixing and regulating temperature, applying high shear stress to the defoamed PPTA spinning slurry in extruder machine head, filtering and metering, adopting dry-jet wet-spinning process to obtain the invented PPTA fibre.

Owner:DONGHUA UNIV

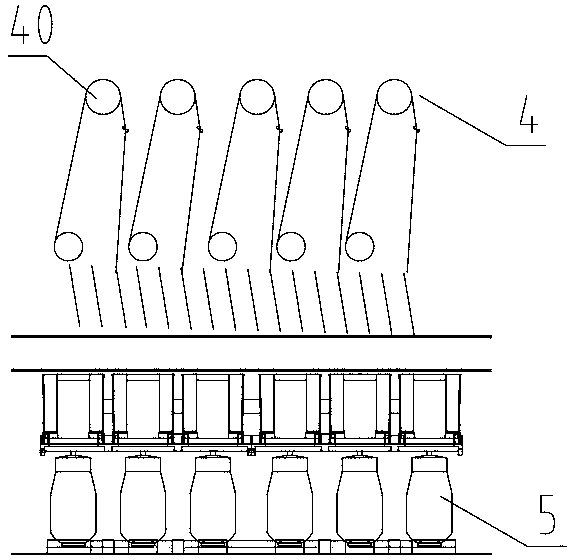

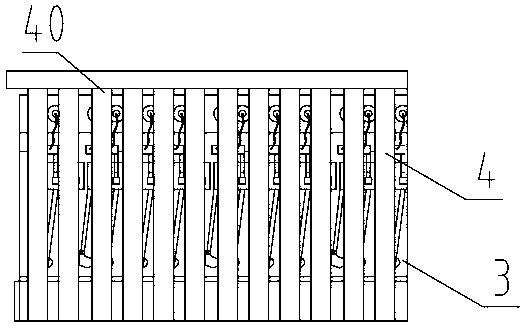

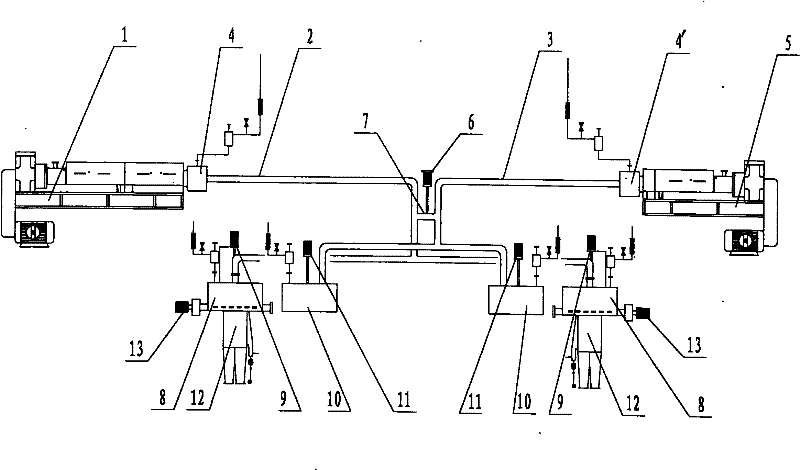

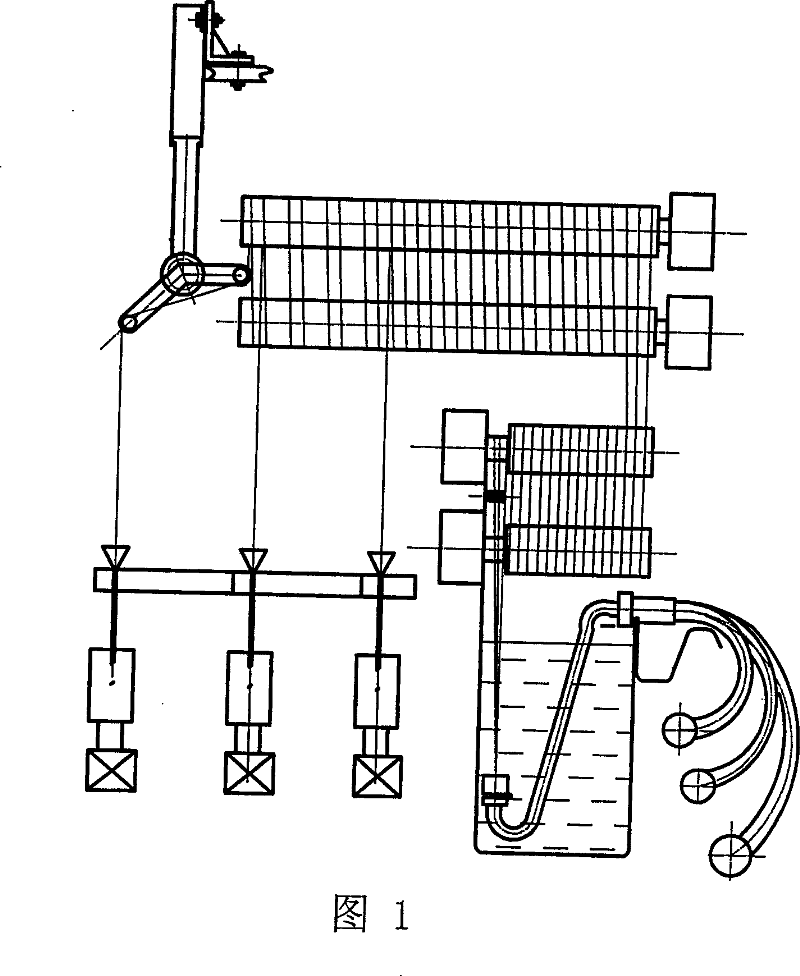

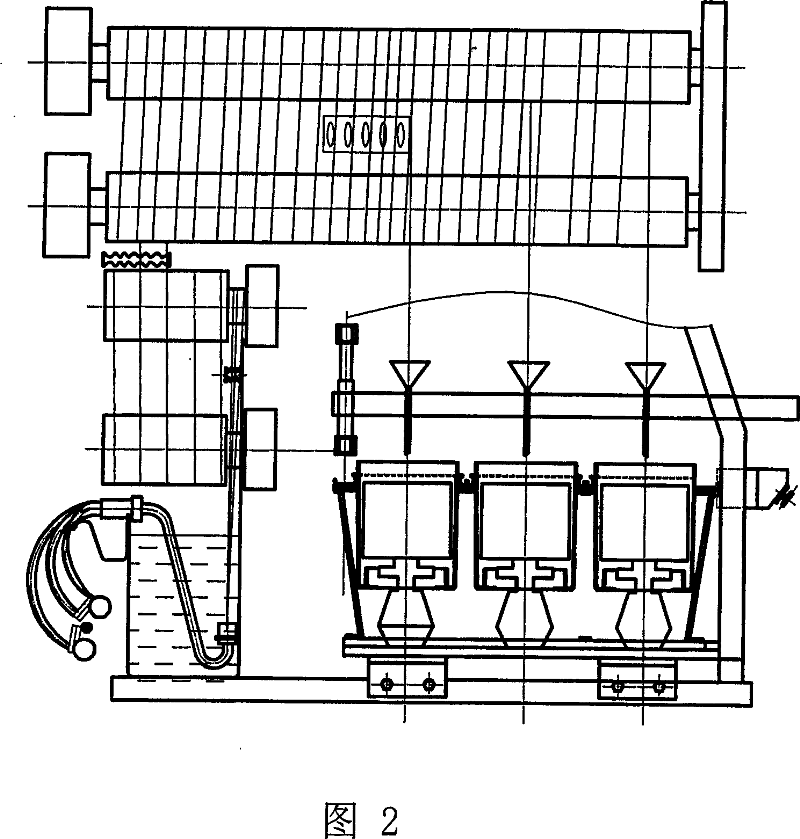

Novel semi-continuous high-speed spinning machine

ActiveCN103409825AEasy to operateControllableArtificial thread manufacturing machinesWet spinning methodsEngineeringSpin speed

The invention relates to a novel semi-continuous high-speed spinning machine which comprises a rack, a glue supply device, a filament strip forming device, a spinning device and a winding device. The spinning device comprises a spinning roller which is transversely arranged relative to the operating surface of a spinning face, and the two ends of the spinning roller are fixed on the rack. The novel semi-continuous high-speed spinning machine improves spinning speed, ensures that filament strips are sufficiently reacted, and then achieves the purposes of ensuring the quality of the filament strips, improving production efficiency and reducing spinning cost.

Owner:YIBIN HIEST FIBER +2

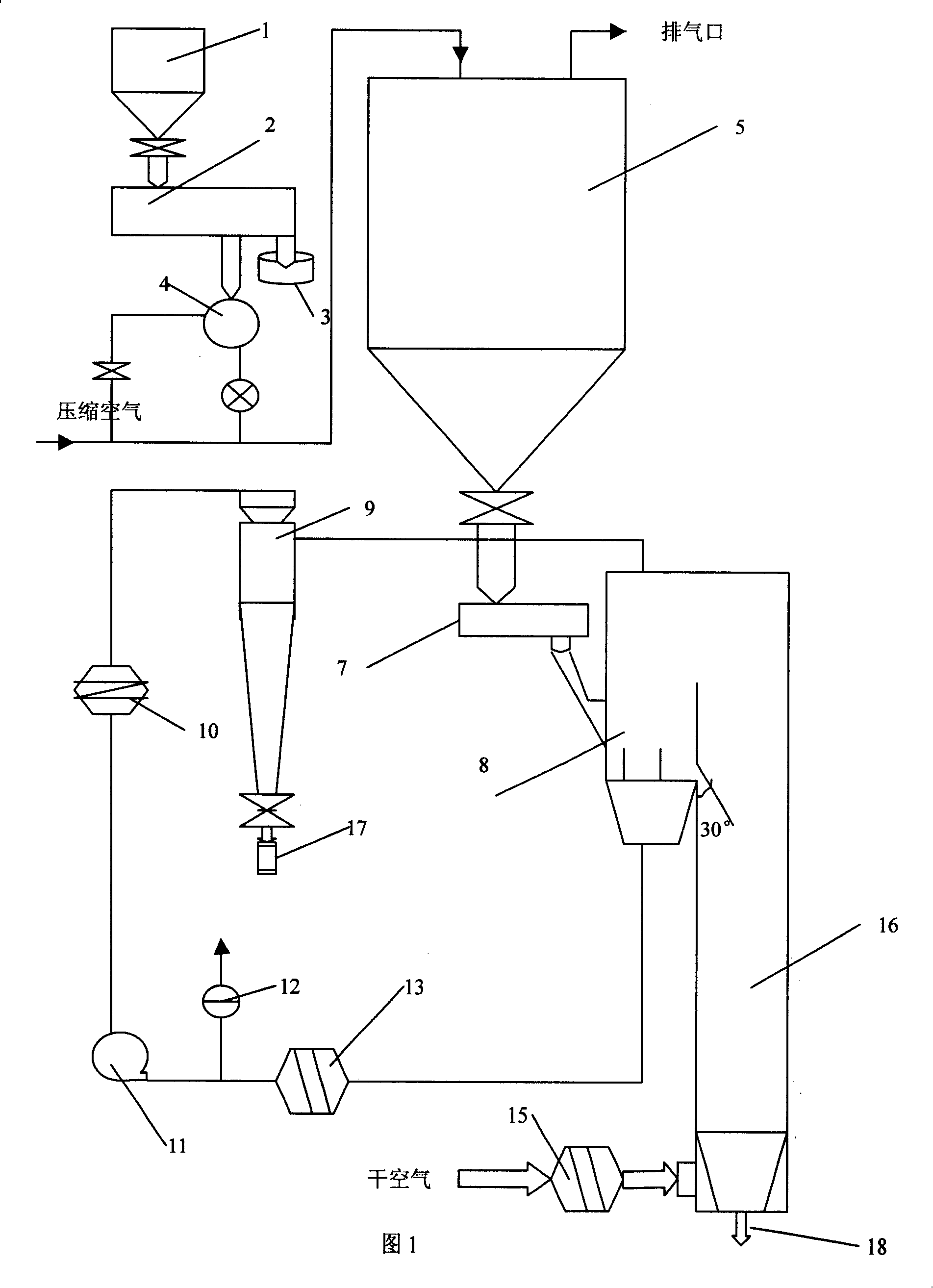

PTT slicing drying method for PTT/PET composite full drafting low-elasticity network thread

InactiveCN101210772AAvoid stickingAvoid damageSievingDrying solid materials with heatYarnFluidized bed

The invention relates to a method for drying a PTT slice of a PTT / PET composite full-tension low-elasticity interlaced yarn. The invention is characterized in that the PTT slice is dried by the following steps of: 1) sorting: the PTT slice is fed, in order, through a storage hopper, an oscillating screen, a pulse generator and another storage hopper; 2) pre-crystallization: the PTT slice is fed, in order, through a shaking feeder, a fluidized bed and a drying tower, and then kept in a fluidized bed pre-crystallizer for 5-15 minutes to allow the pre-crystallization to be finished; 3) drying: the PTT slice is dried with high-temperature dried air for 4-6 hours until the water content of the uniformly-crystallized PTT slice meets the standard. The inventive drying method ensures the uniform crystallization and normal color shade of the PTT dried slice and avoids the yellowing and deterioration problems. The water content of the slice is below 50ppm, which meets the technological requirements for drying PTT-POY pre-oriented yarns as well as PET composite spinning. The spinning of PTT dried slice is stable without filament drift.

Owner:JIANGSU ZHENYANG

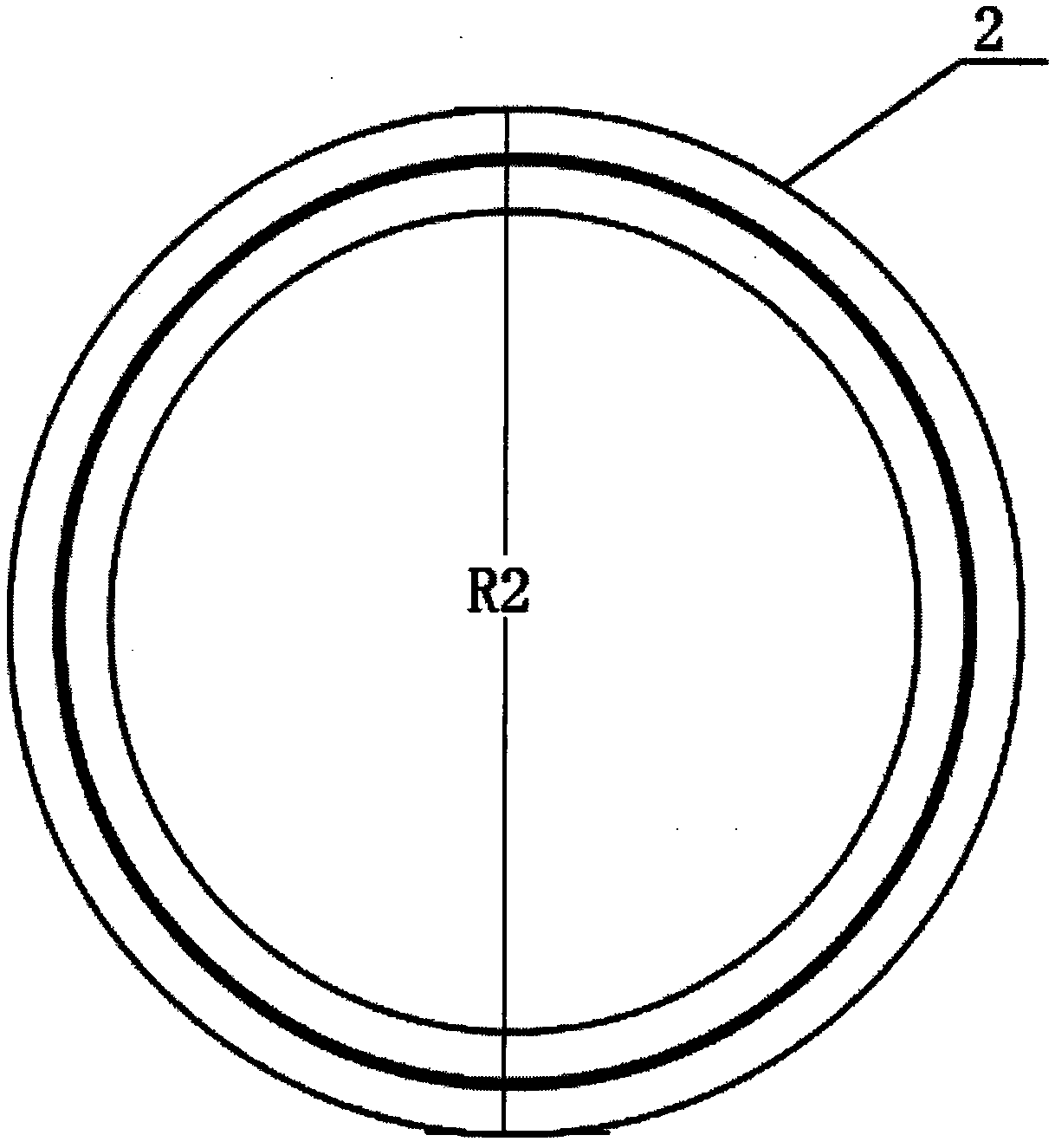

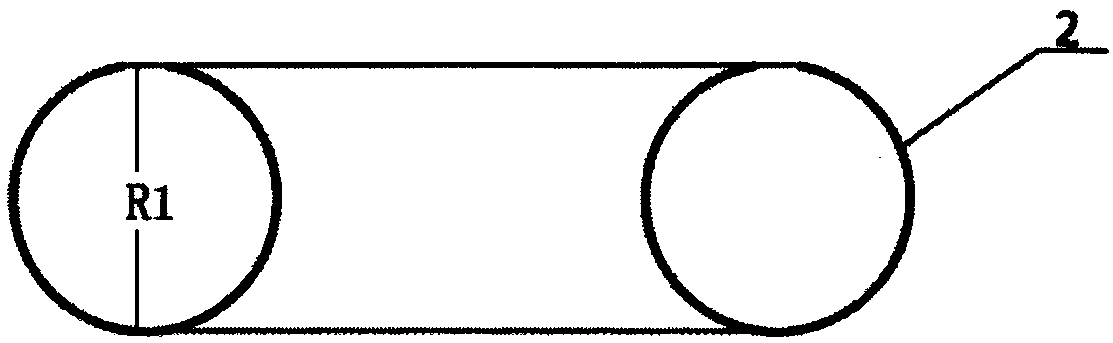

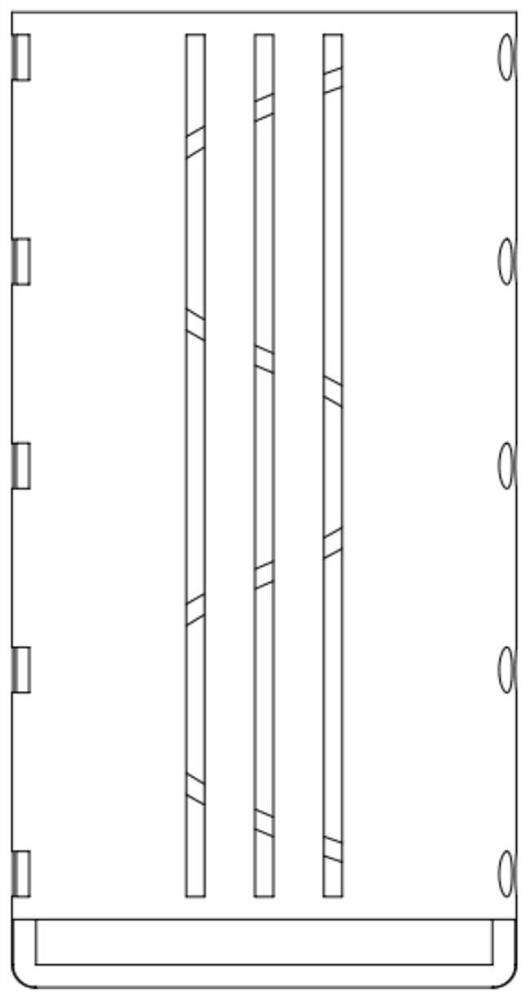

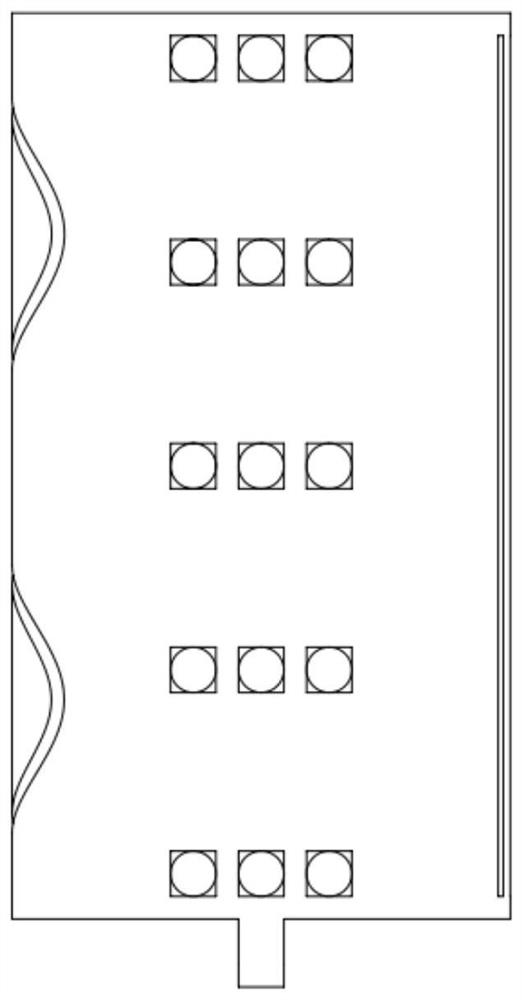

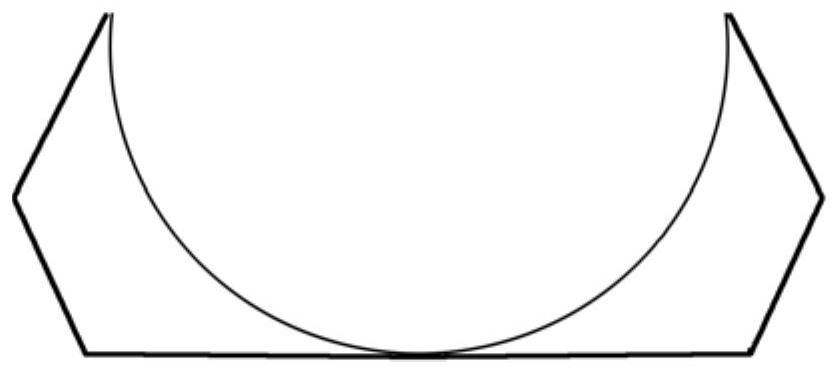

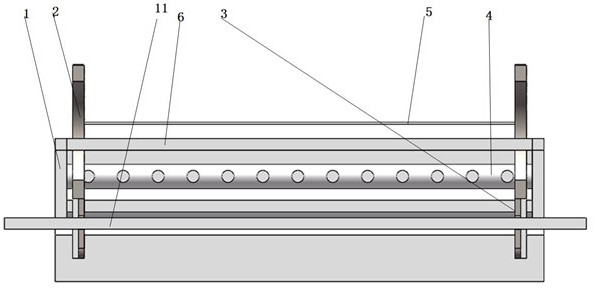

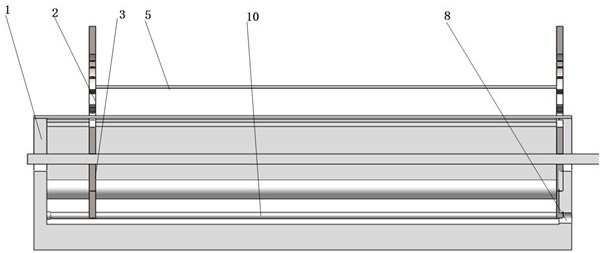

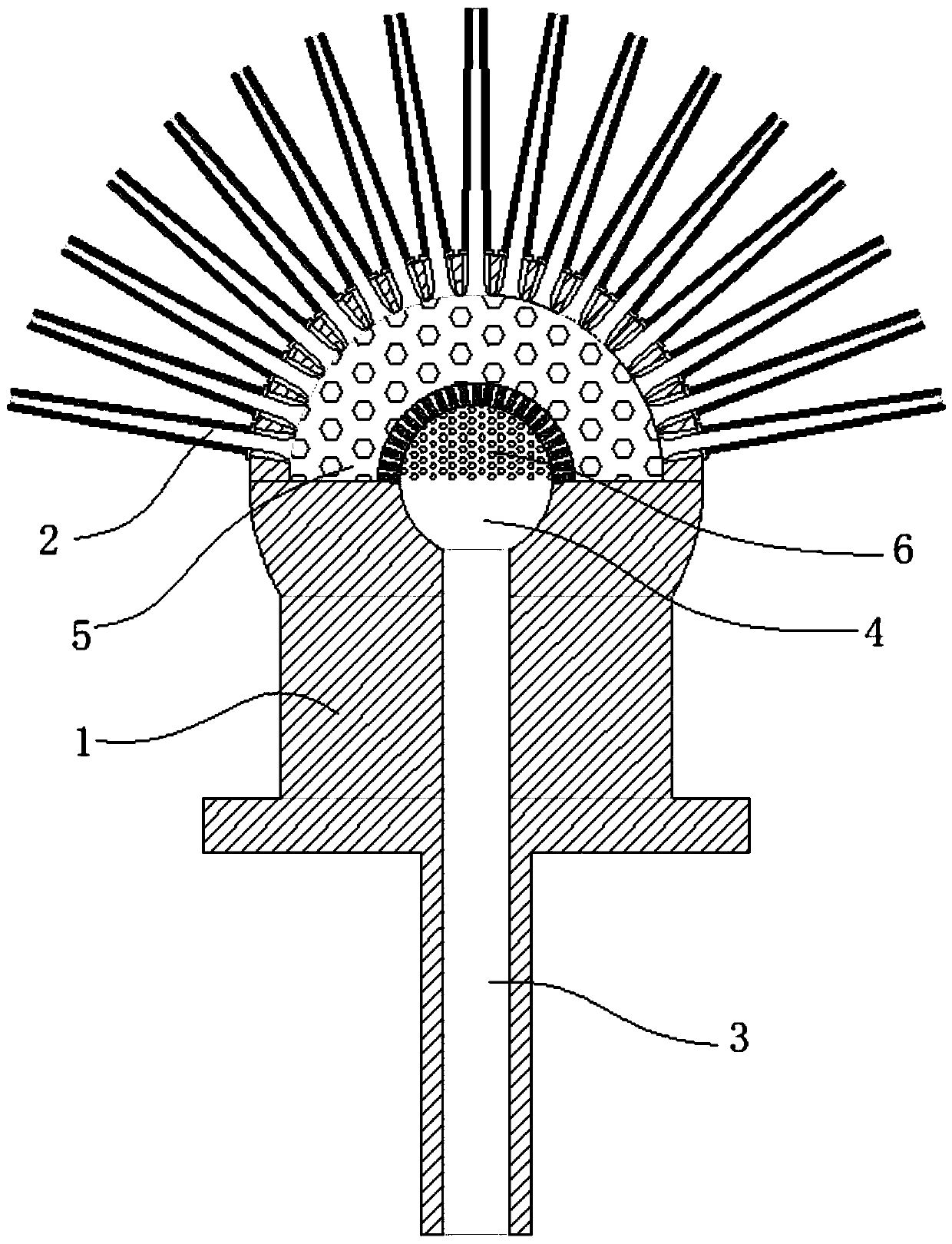

Annular electrostatic spinning device and electrostatic spinning method

The invention provides an annular electrostatic spinning device and an electrostatic spinning method. The annular electrostatic spinning device is characterized by comprising an annular spinneret anda solution supply device; the solution supply device is connected with the annular spinneret and is used for supplying spinning solution for the annular spinneret, the annular spinneret can be filledwith the spinning solution supplied by the solution supply device, a gap is reserved in the annular spinneret, the annular spinneret is connected with a high-voltage positive electrode, and a plurality of pieces of electrostatic spinning jet flow can be generated in the gap when voltages are higher than critical values. The annular electrostatic spinning device and the electrostatic spinning method have the advantages that the annular electrostatic spinning device is simple and is easy to clean and good in stability, and spray nozzles are difficult to block; the spinning efficiency can be obviously improved by the aid of the annular electrostatic spinning device and the electrostatic spinning method, and the yield of electrostatic-spun nano-fibers can be obviously increased by the aid of the annular electrostatic spinning device and the electrostatic spinning method.

Owner:DONGHUA UNIV

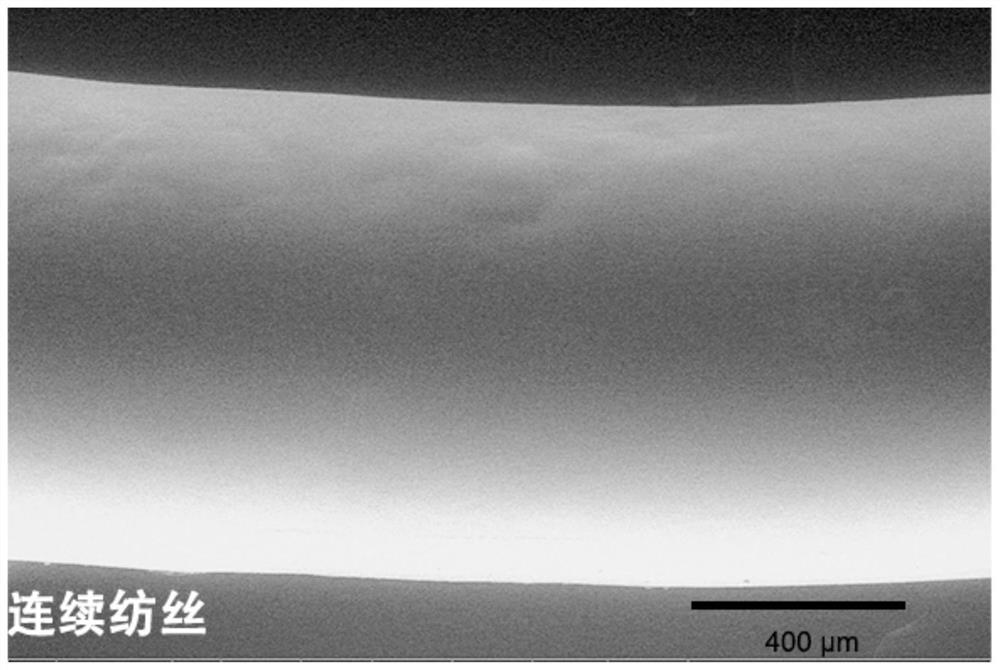

Chitosan filament and preparation method thereof

InactiveCN103409850ACompletely degradedSolve the problem of unstable and difficult to implement continuous productionSpinning solutions preparationArtifical filament manufactureEnvironmental resistanceHigh concentration

The invention relates to chitosan filaments and a preparation method thereof. According to the invention, chitosan is dissolved by using a green environment-friendly ionic liquid solvent; dissolving time and temperature are reasonably controlled, such that high-concentration spinning solution is prepared. With the method, continuous production can be carried out, such that that problems of difficulty for carrying out continuous productions due to low stability and poor stability of prior art are solved. According to the invention, during the chitosan filament preparation process, the chitosan is dissolved by using the ionic liquid solvent and the gradient temperature method, degradation is prevented during the chitosan heating process, spinning process is stable, the prepared chitosan fiber has high quality, and spinning yield is high. The chitosan filament provided by the invention has high mechanical strength which is higher than 2.5cN / dex and higher than chitosan fiber prepared by using an acidic solution. Therefore, the filament is suitable for the medical field, and has higher application value.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Process for producing modified PET/PTT elastic fiber

ActiveCN102127821AAdvanced and reasonable production technologySpinning process is stableArtificial filament physical treatmentFilament/thread formingElastic fibresYarn

The invention discloses a process for producing a modified polyethylene terephthalate / polytrimethylene terephthalate (PET / PTT) elastic fiber, relates to a process for producing a modified elastic fiber, and mainly aims to solve the problems of spinning instability and the like of a product produced by the conventional process. The method comprises the following steps of: tackifying PTT slices and PET slices in a ratio of 40:60; adding the PET slices into a screw extruder for extruding and melting, and heating in five areas; adding the PTT slices into the screw extruder for extruding and melting, and heating in three areas; and mixing a PET melt in a PET melt distributing pipe and PTT fed by a PTTa melt distributing pipe in a weight ratio of 90:10, producing by the conventional process to obtain a partially oriented yarn (POY) bobbin yarn semi-finished product, and showing elasticity by using a draw winder to obtain a draw textured yarn (DTY) finished product. The process has the advantage that: the modified PET / PTT elastic fiber which has spinning stability and high elastic recovery property can be produced.

Owner:辽宁际华新材料制造有限公司

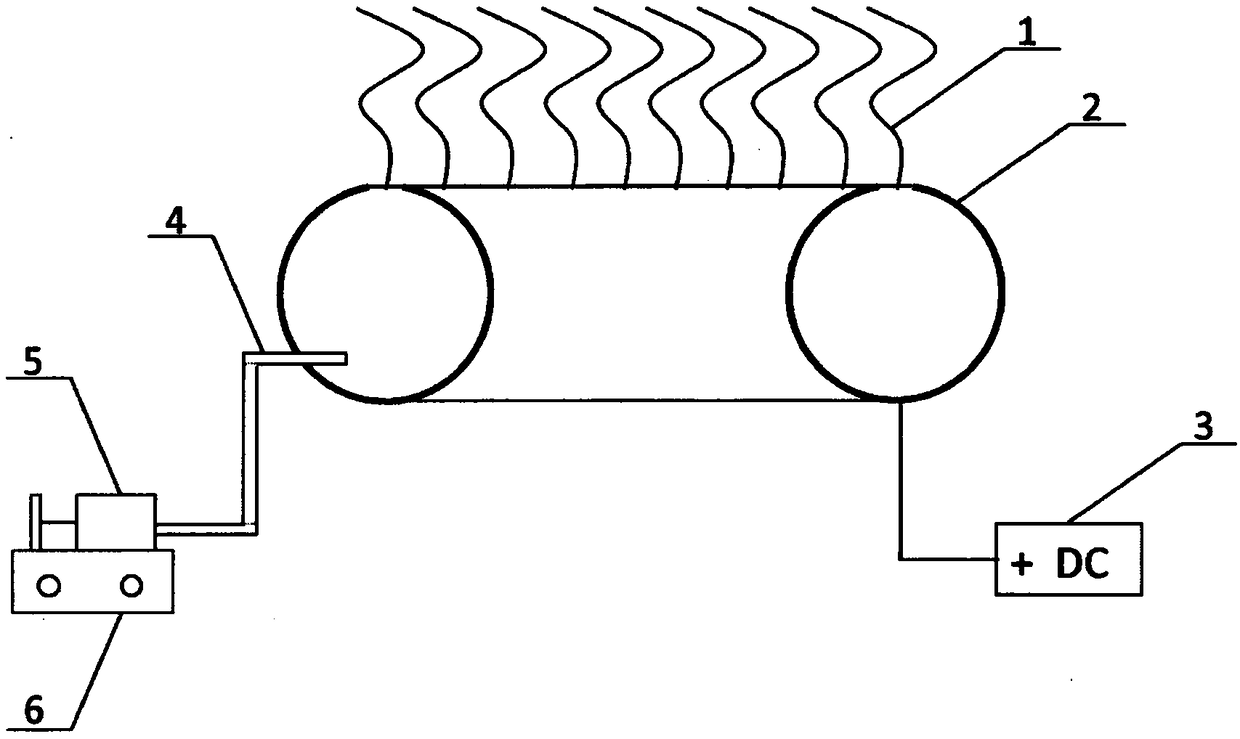

Portable handheld electrostatic spinning device

ActiveCN102776583BReduce fearTimely protectionFilament/thread formingEducational modelsElectricityMetal foil

The invention belongs to the technical field of electrostatic spinning and relates to a portable handheld electrostatic spinning device. The top of a pushing rod of a medical syringe is provided with a pressure welding switch, a metal foil is arranged on the top side fixedly, a spinning solution is arranged in a front end inner cavity of the medical syringe, a square battery and a high-voltage direct-current inverter are arranged fixedly on the side wall of the syringe in a butt joint mode, and a stainless steel needle head which is used for spinning is arranged at the bottom end of the syringe in an inserting mode. A conventional medical syringe needle head structure and the syringe are combined and matched, the spinning solution is stored in the inner cavity of the medical syringe which is provided with the stainless steel needle head, the square battery provides a power supply for the high-voltage direct-current inverter, when the direct current voltage is inverted, the voltage in the unit of kilovolt, the positive pole of the high-voltage direct-current inverter is communicated electrically with the stainless steel needle head, and the negative pole of the high-voltage direct-current inverter is communicated electrically with the metal foils. The device is simple in overall structure, is convenient to carry, use and operate, applicable to occasions such as outdoor teaching and wounded rescue and high in economical value.

Owner:青岛中科凯尔科技有限公司

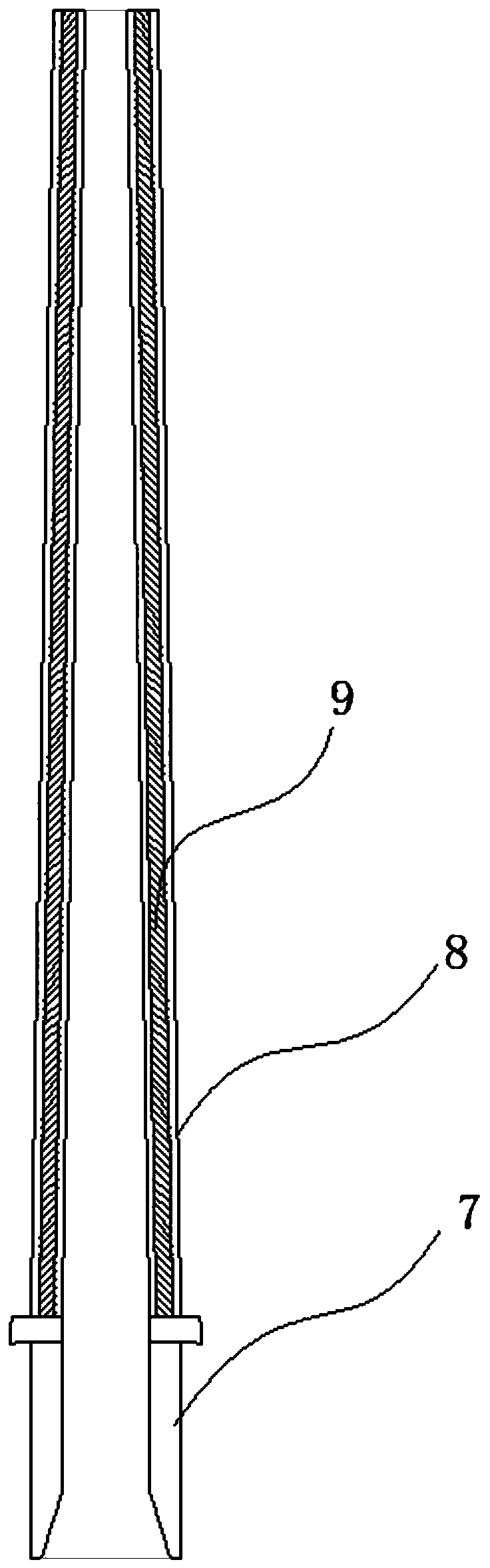

Preparation method of para-aramid low-denier fiber filament

ActiveCN106906525AIncreased tow strengthReduced risk of wire breakageSpinning solution filteringSpinning solution de-aeratingSulfuric acidFilament yarn

The invention relates to a preparation method of a para-aramid low-denier fiber filament, belongs to the technical field of chemical fiber spinning, and particularly relates to a preparation method of a para-aramid low-denier (25-100D) fiber filament. The problem of wire breaking needs to be solved in the spinning process of the para-aramid low-denier fiber filament to ensure the production stability and the tow performance stability. According to the preparation method of the para-aramid low-denier fiber filament, a selected spinneret cap is used for reducing the risk of extruded cross flow and doubling of a para spinning solution; an alkali liquor with proper concentration is used for washing primary tows, thereby quickly neutralizing sulfuric acid and improving the strength of the tows; and by adopting flat washing and drying modes, the risk of wire breaking in the washing and drying links is reduced. By using the method, the spinning process of the para-aramid low-denier filament is stable and easy to operate, and the obtained fiber is excellent in mechanical property and stable in quality.

Owner:TSINGHUA UNIV

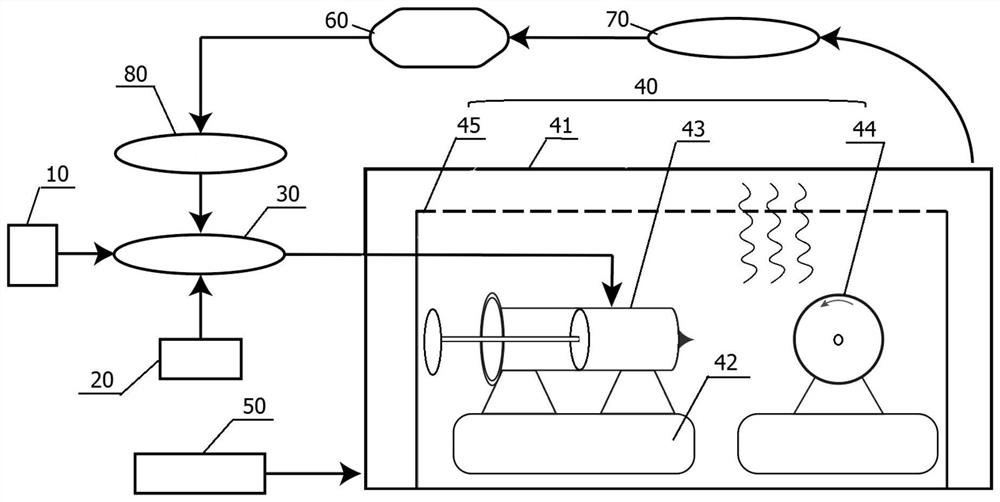

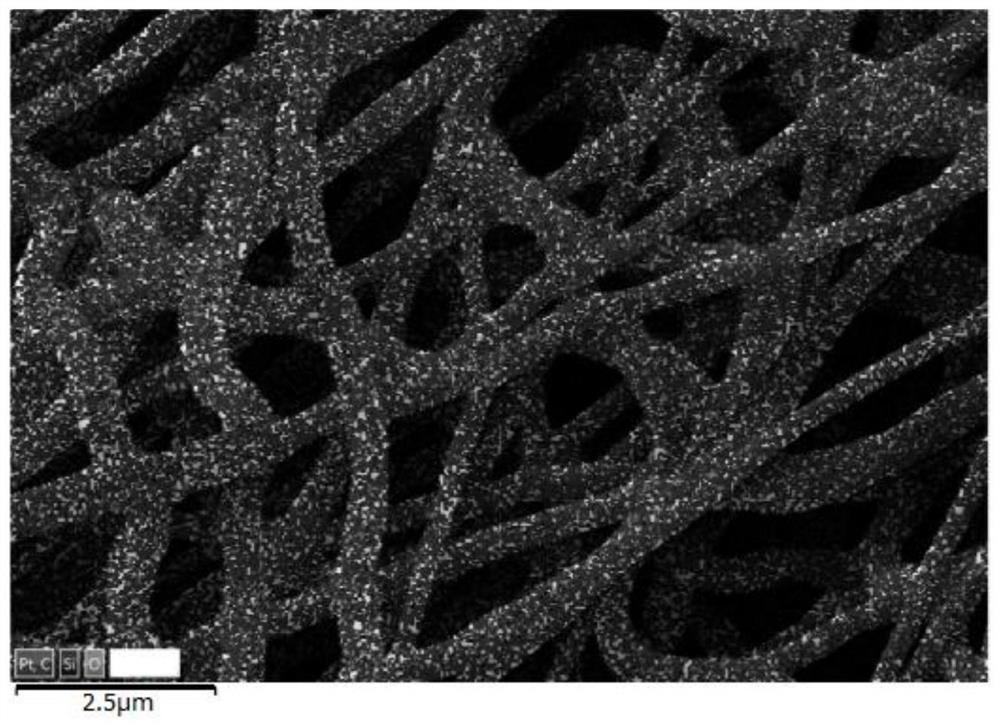

Preparation method and device of water-soluble polymer/inorganic nano-powder composite fiber, lithium ion battery negative electrode material and preparation method

The invention provides a preparation method and device of a water-soluble polymer / inorganic nano-powder composite fiber, a lithium ion battery negative electrode material and a preparation method. Thepreparation method comprises the following steps of S1, preparing precursor slurry of a water-soluble polymer and inorganic nano-powder by taking a mixed solvent of water and ethanol as a spinning solvent, wherein the average molecular weight of the water-soluble polymer is 58000 to 1300000; and S2, carrying out electrostatic spinning on the precursor slurry under the condition that the humidityis 30%-60% to obtain the water-soluble polymer / nano-powder composite fiber. By utilizing the preparation method, the problems of difficult spinning, high cost, poor environmental protection property and the like when the composite fiber for the lithium ion battery negative electrode material is prepared by utilizing solution electrostatic spinning in the prior art are effectively solved, the water-soluble polymer / inorganic nano-powder composite fiber with good morphology can be obtained, good stability in a heat treatment process is achieved, and the composite fiber is suitable for the lithiumion battery negative electrode material.

Owner:CHINA ENFI ENGINEERING CORPORATION

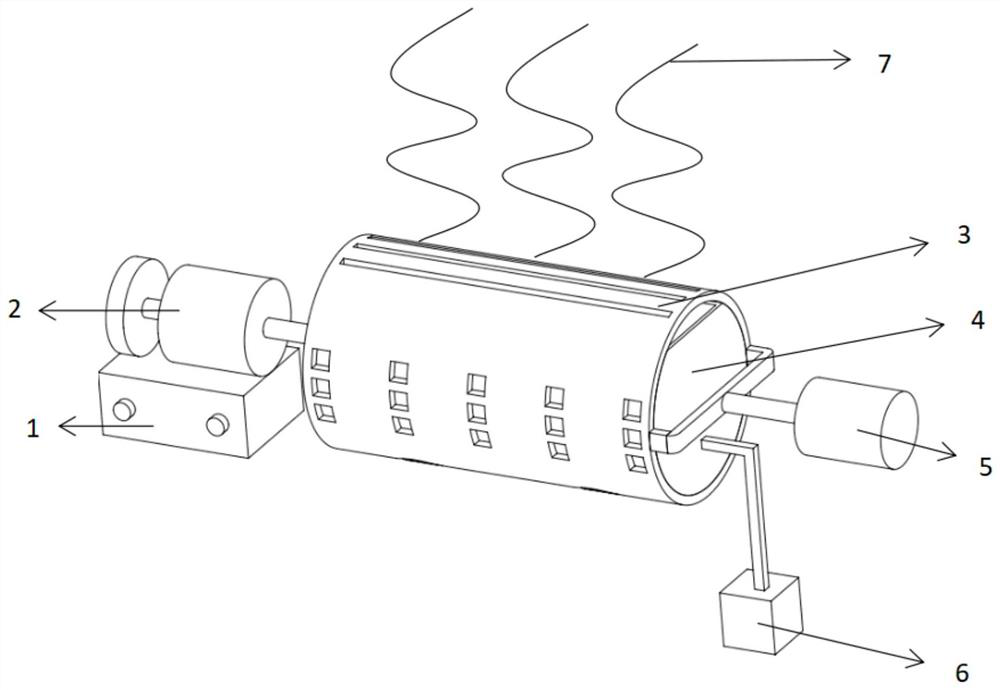

Rotary embedded electrostatic spinning device and spinning method

The invention discloses a rotary embedded electrostatic spinning device and a spinning method. The rotary embedded electrostatic spinning device comprises an outer hollow cylinder spinning nozzle, aninner hollow cylinder, an injector used for injecting spinning liquid into the inner hollow cylinder, a numerical control micro-injection pump used for controlling the injector, a high-voltage positive electrode connected with the inner hollow cylinder and the like. The spinning method comprises the steps that the spinning solution is injected into the inner hollow cylinder, when the spinning solution rises and the liquid level is higher than an opening in the top of the inner hollow cylinder, a servo motor is started to drive the outer hollow cylinder spinning nozzle to rotate the high-voltage positive electrode is opened and connected, voltage is increased, a plurality of electrostatic spinning jet flows is generated above the opening, and an electrostatic spinning process is started; and the electrostatic spinning jet flows are received through a collecting device. The spinning solution can form liquid films in different states on the openings in different forms, and then the jet flows with different fineness are generated, so that a nanofiber film with four or more diameter distributions and distinct levels can be prepared in one step under the condition without using various spinning solutions and without adjusting spinning parameters.

Owner:DONGHUA UNIV

Preparation process of dacron superfine fiber

InactiveCN108588867AEasily brokenSolve cohesionArtificial filament heat treatmentMelt spinning methodsFiberEngineering

The invention discloses a preparation process of dacron superfine fiber. The process comprises the following steps: (100) fusion; (200) metering and spinning, wherein the flow of a spinning solution subjected to the fusion is adjusted through a metering pump, and then a spinneret plate is used for erupting, spinning and forming to prepare fiber tows; a slow cooler is installed below the spinneretplate, and the slow cooler is used for slowly cooling the spinneret plate; (300) cooling and oiling; (400) pre-netting; (500) stretching and sizing; (600) main network; and (700) winding. By the mode,the process can guarantee the stable operation of spinning, the problems that broken filaments and broken ends appear easily in the fiber stretching and sizing process and dyeing performance is relatively poor are solved, and the products can be stably produced, and are high in level dyeing rate and excellent in quality.

Owner:CHANGSHU POLYESTER

Spinning method of gel fibers

ActiveCN111910268AEasy to separateReduce frictionSpinning solution filteringArtificial thread manufacturing machinesFiberPolymer science

The invention relates to a spinning method of gel fibers, and belongs to the technical field of high polymer materials. The method comprises the following steps of preparing a precursor solution fromlinear macromolecules, acrylamide, polyethylene glycol diacrylate, 2-Hydroxy-1-(4-(2-hydroxyethoxy)phenyl)-2-methylpropan-1-one and water, filling the precursor solution into an injection pump, injecting the precursor solution into a polytetrafluoroethylene tube through the injection pump, and performing primary ultraviolet irradiation polymerization in the polytetrafluoroethylene tube and secondary ultraviolet irradiation polymerization at an outlet of the polytetrafluoroethylene tube to obtain the gel fiber. According to the spinning method, the gel fibers are easily separated from the spinning tube wall by utilizing the lubricating layer formed by the linear polymer in the centers of the gel fibers and the spinning tube wall, besides, the friction force between the gel fibers and the spinning tube wall is reduced, and the stable spinning is promoted. Due to entanglement between linear macromolecules and a gel network, low-speed polymerization becomes possible, the compatibility of integratable functional groups is widened, and the method is high in operability, simple in equipment and easy to realize large-scale production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

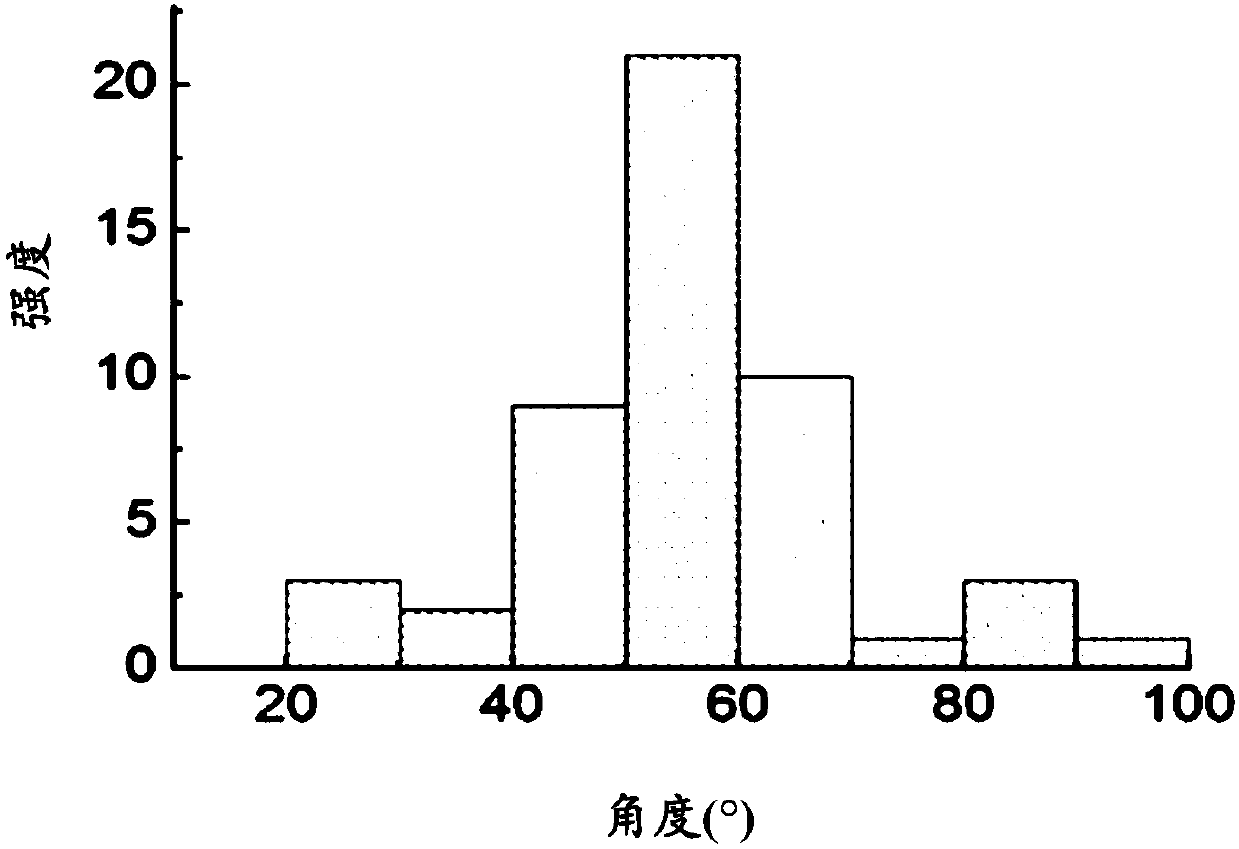

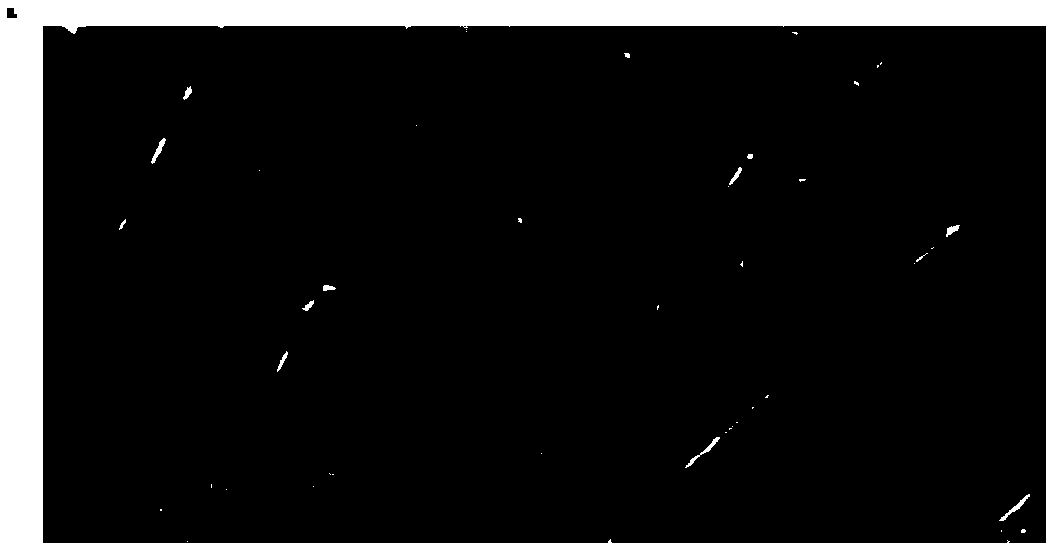

Orientation nanofiber and preparing method thereof

The invention discloses orientation nanofiber and a preparing method thereof. Through the combination of air current spinning and magnetic field force, the motion track of spinning solution jet flow is controlled, and producing the orientation nanofiber is achieved. A high pressure static electricity generating device is not needed, the orientation nanofiber is simple and economical, static electricity pollution and potential danger caused by high voltage static electricity are also avoided, the spinning process is safer and more stable, multiple strands of jet flow can be generated simultaneously, the spinning smoothness and production efficiency are drastically improved, and the preparing method is applicable to producing the orientation nanofiber in an industrialized mode.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

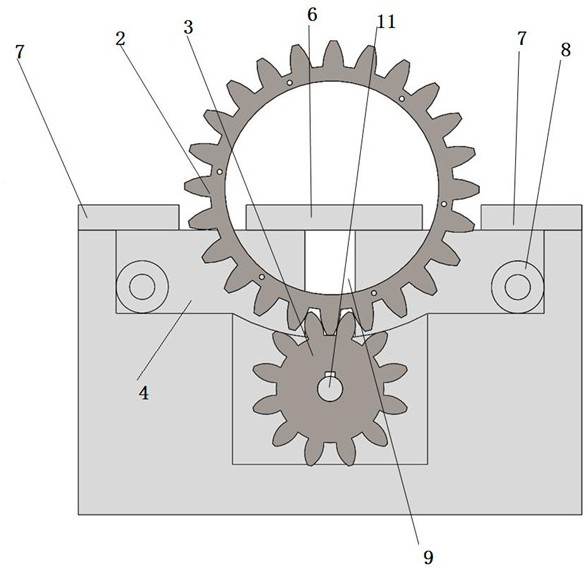

Rotary needleless spinning device

PendingCN112442742AReduce exposed areaReduce direct contactFilament/thread formingCircular discNeedle free

The invention belongs to the technical field of electrostatic spinning, and particularly relates to a rotary needleless spinning device which comprises a device body, wherein a hollow disc, a rotatinggear and a solution tank are arranged on the device body, an electrode wire is arranged on the hollow disc, the rotating gear can drive the hollow disc to rotate so as to drive the electrode wire onthe hollow disc to rotate, the solution tank is arranged below the hollow disc, and when the hollow disc rotates, one part of the lower part of the hollow disc is always positioned in the solution tank, so that the electrode wire on the hollow disc can pass through a solution in the solution tank, and part of the liquid is brought out when the electrode wire rotates out of a liquid level. According to the spinning device, the rotary electrode is adopted, manufacturing is convenient, the spinning field intensity of the electrode wire is uniform, and the stability of the physical or chemical property of the spinning solution in the spinning process can be guaranteed.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

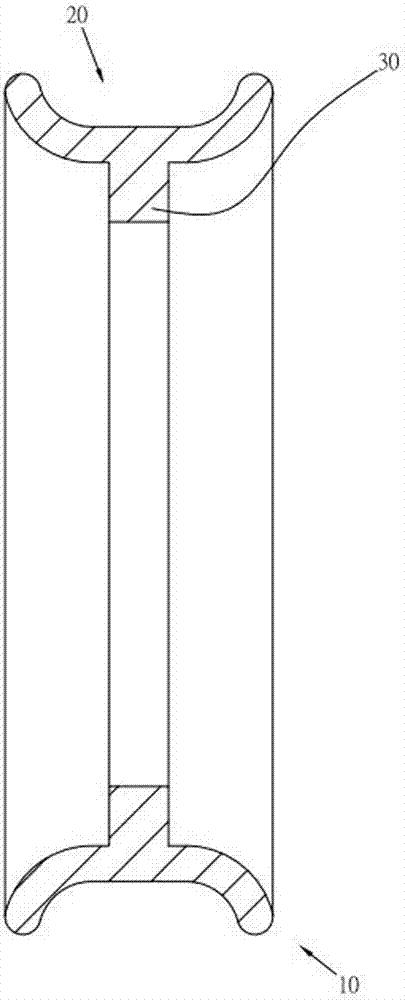

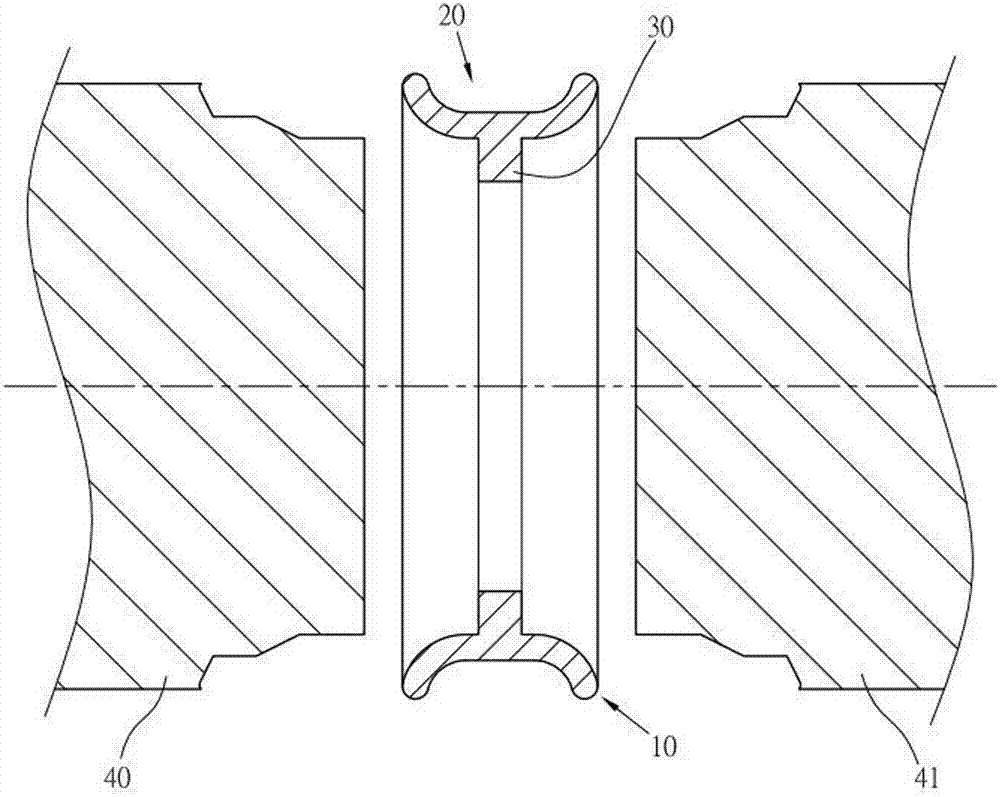

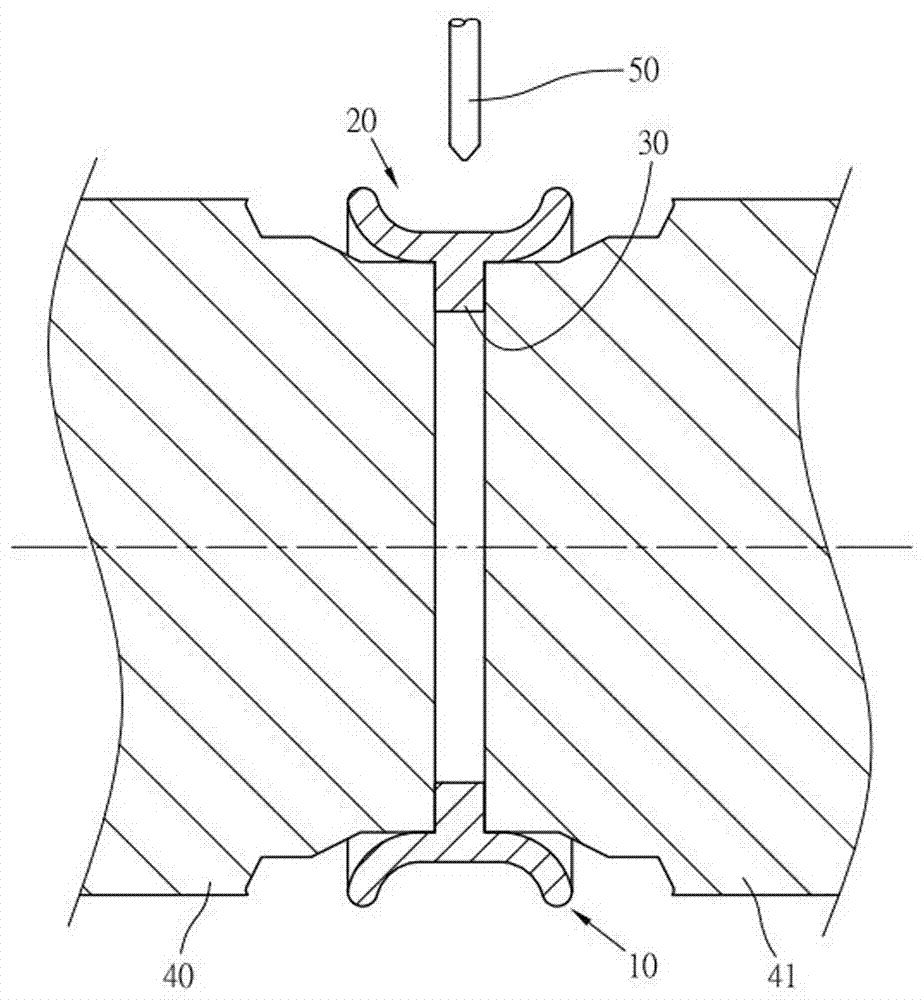

Wheel hub spinning manufacturing method

The invention discloses a wheel hub spinning manufacturing method. The method comprises the steps of (a) preparing an aluminum alloy material; (b) forging the aluminum alloy material into a wheel hub rough blank, the wheel hub rough blank is provided with a wheel rim and a rib part in an integrally formed mode, and the rib part is formed on the inner edge of the wheel rim; (c) the two sides of the wheel hub rough blank are clamped by two dies correspondingly; and (d) the two sides of the wheel rim of the wheel hub rough blank are spun by using a spinning device so as to form two rib arms in preset shapes, namely so as to form a wheel hub finished product. According to the method, by means of the parts, the wheel hub rough blank is provided with the wheel rim and the rib part which are in a Y shape in an integrally formed mode and is clamped by the dies, the two rib arms are formed on the two sides of the wheel rim in a spinning mode, the structure strength is high, and therefore the wheel hub forming can be diversified, the production efficiency can be improved, and the cost can be reduced.

Owner:D MAG KUNSHAN NEW MATERIAL TECH CO LTD

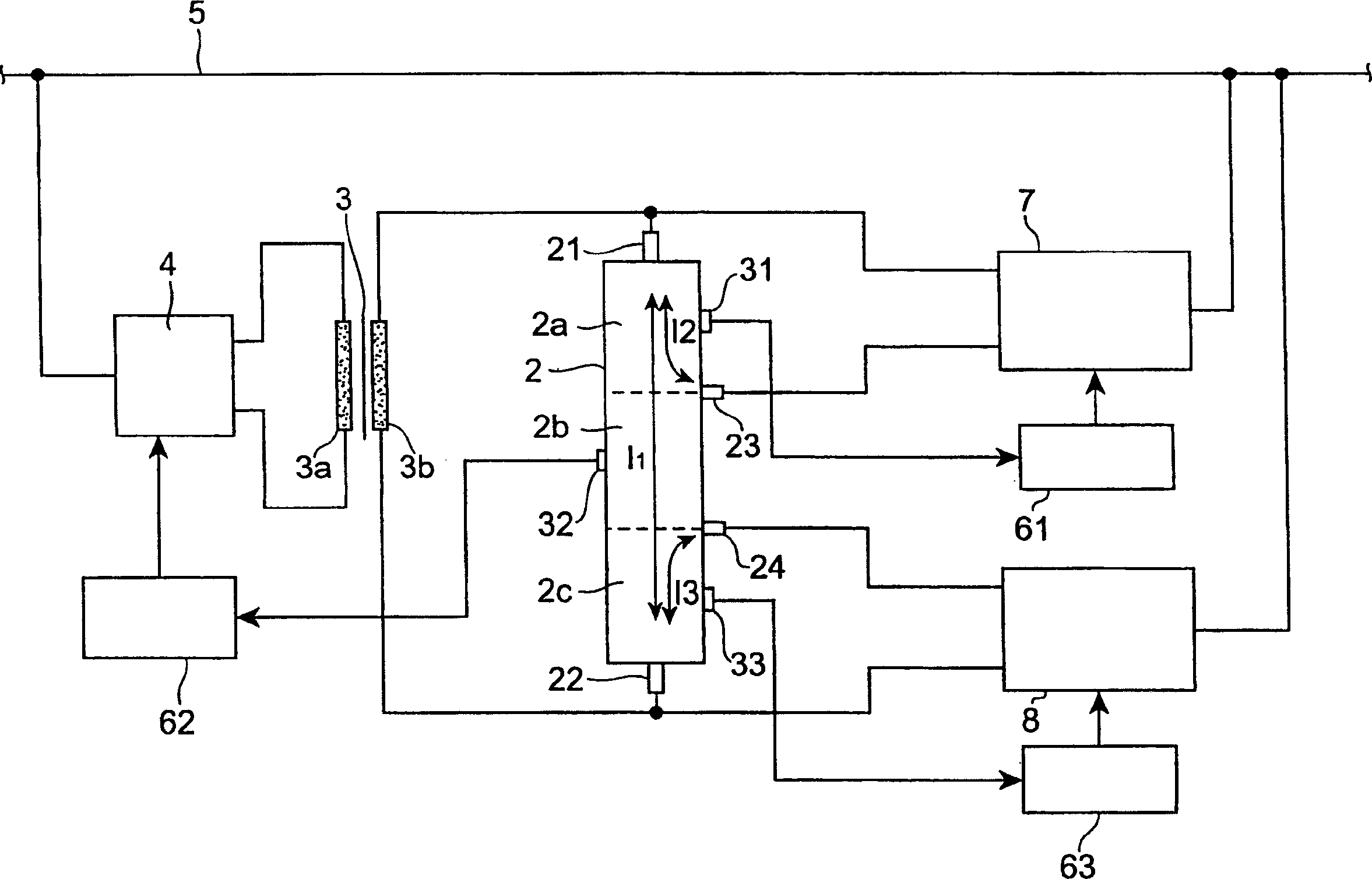

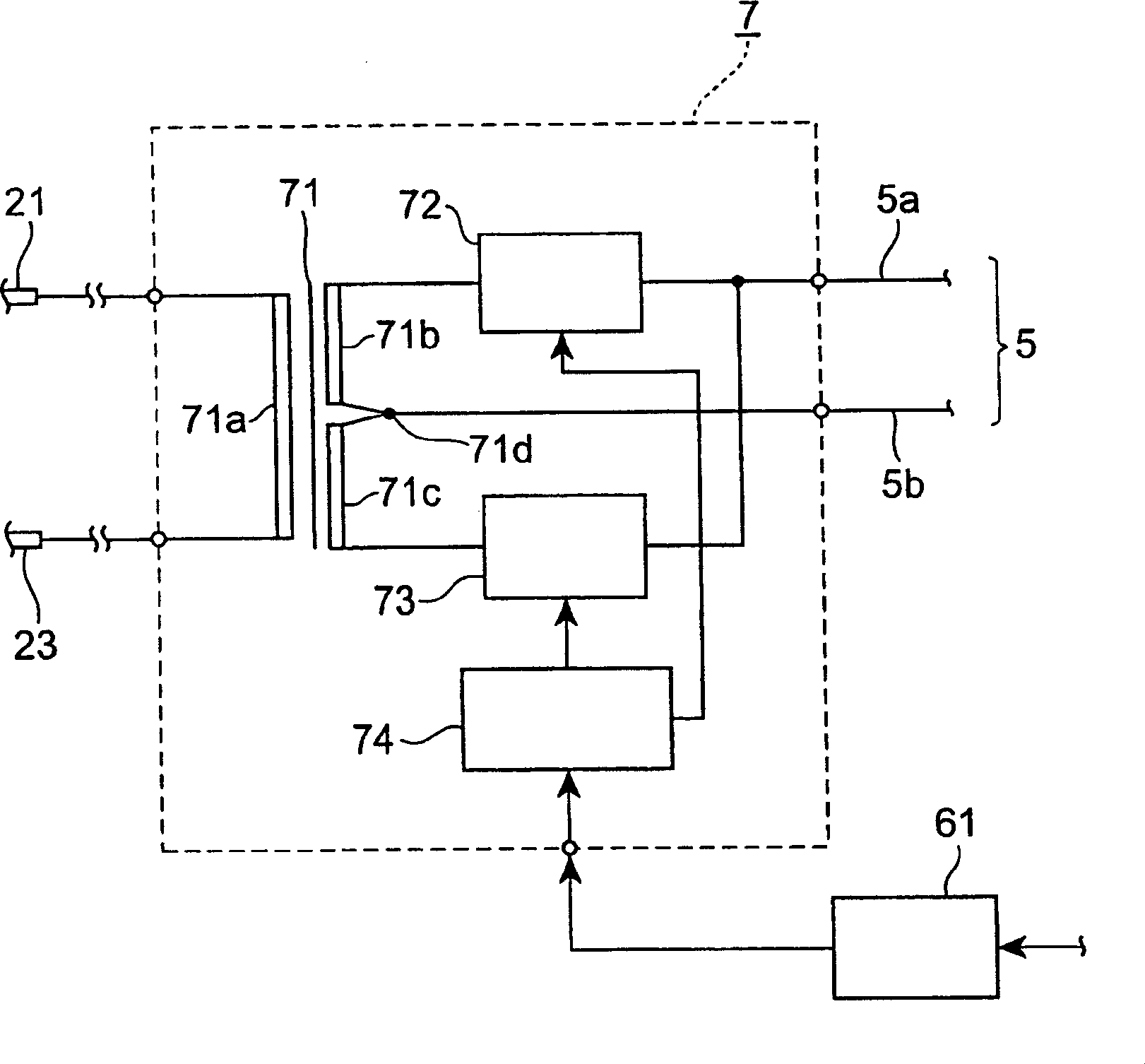

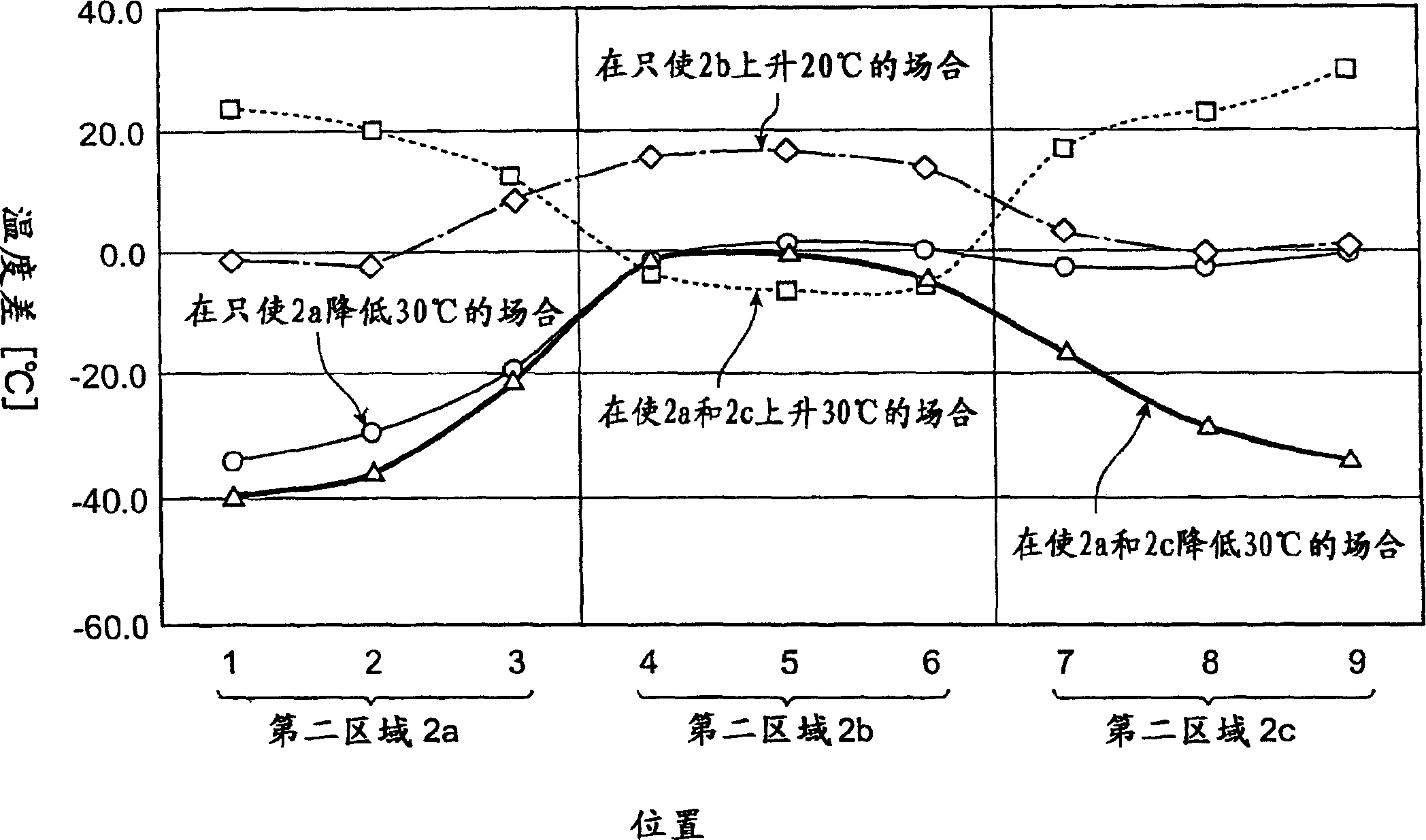

Bushing temp controller

InactiveCN1494517ASpinning process is stableHigh spinning efficiencyGlass making apparatusTemperature control using electric meansTemperature controlPower flow

A bushing temperature controller includes a transformer 3 which supplies a main current 11 to the bushing 2 for accommodating molten glass, and regulation current supply units 7 and 8 which are adapted to supply regulation currents I2 and I3 either in phase with the main current I1 or in phase inverted to the main current I1 to a portion of a region to which the transformer 3 applies the current. Thus, the temperature control of partial regions 2a and 2c in the region to which the current is applied can be performed in a wide temperature range.

Owner:NITTO BOSEIKI CO LTD

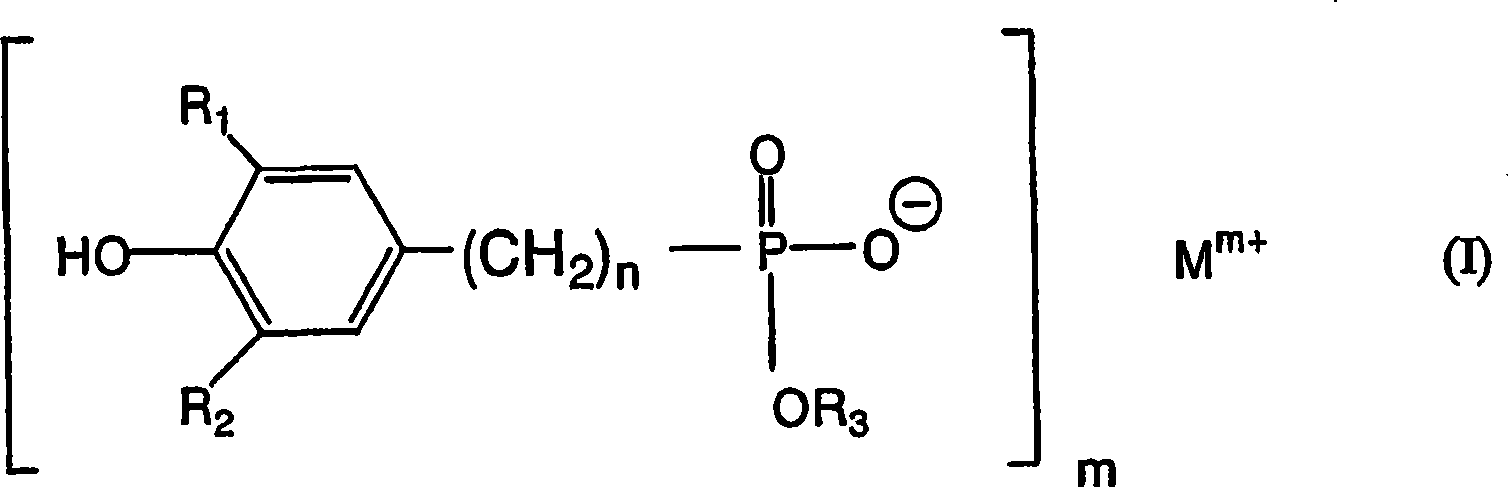

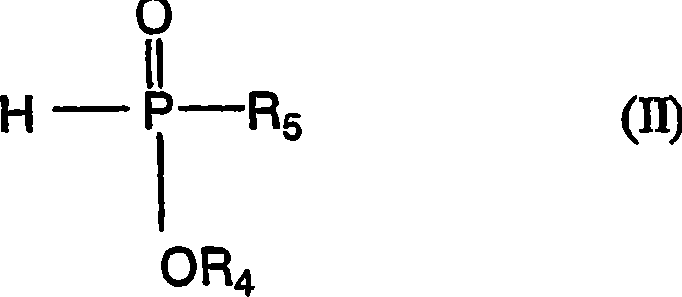

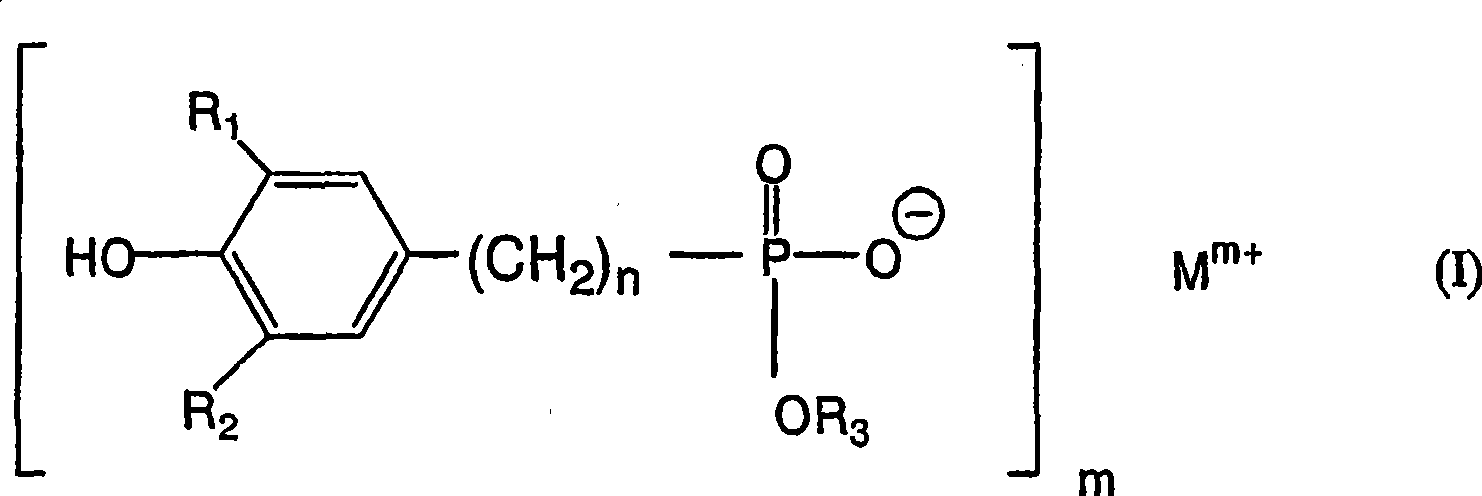

Polytrimethylene terephthalate

InactiveCN1984962AReduce contentReduce wire breakageMonocomponent polyesters artificial filamentAlkaline earth metalHydrogen

A polytrimethylene terephthalate which is reduced in cyclic dimer content and is less apt to generate cyclic dimmers during melt molding. The polytrimethylene terephthalate (A) consists mainly of trimethylene terephthalate units, has an intrinsic viscosity of 0.5-1.6 dL / g, and contains 0.01-0.5 wt.% compound represented by the following formula (I) or (II): (wherein R1, R2, and R3 are the same or different and each is a C1-10 hydrocarbon group; n is an integer of 1-5; and M is an alkali metal or alkaline earth metal, provided that when M is an alkali metal, then m is 1 and when M is an alkaline earth metal, then m is 2) (wherein R4 and R5 are the same or different and each is hydrogen or a C1-10 hydrocarbon group).

Owner:SOLOTEX CORP

Semi-continuous centrifugal spinning process

ActiveCN100354460CQuality improvementQuality assuranceArtificial filaments from viscoseWet spinning methodsCandleIngot

Owner:YIBIN GRACE

Preparation method of antibacterial UV resistant nonwoven cloth for surgery hole drape

InactiveCN108823671ASpinning process is stableGood antibacterial and anti-ultraviolet effectArtifical filament manufactureMonocomponent polyamides artificial filamentElectrospinningPolyamide

The invention discloses a preparation method of a UV resistant nonwoven cloth for a surgery hole drape. The preparation method comprises following steps: step one, mixing TiO2:(Al, Ce) powder, N,N-dimethyl acetamide, and zirconium beads, and grinding the mixture to prepare TiO2:(Al, Ce) dispersion liquid; step two, mixing polyamide and N,N-dimethyl acetamide, stirring, adding the TiO2:(Al, Ce) dispersion liquid, maintaining the temperature, and keeping on stirring to obtain a spinning solution; and step three, using the spinning solution to carry out electrostatic spinning to obtain TiO2:(Al,Ce) / polyamide nonwoven cloth, namely the UV resistant nonwoven cloth for a surgery hole drape. The prepared nonwoven cloth has a very good antibacterial and UV resistant performance.

Owner:HEFEI JIENUO MEDICAL PROD CO LTD

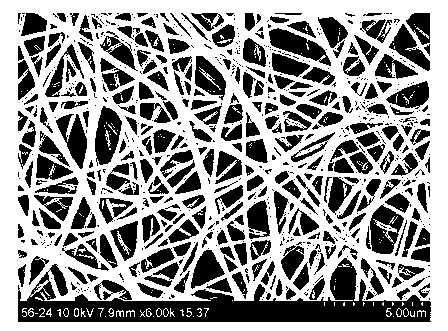

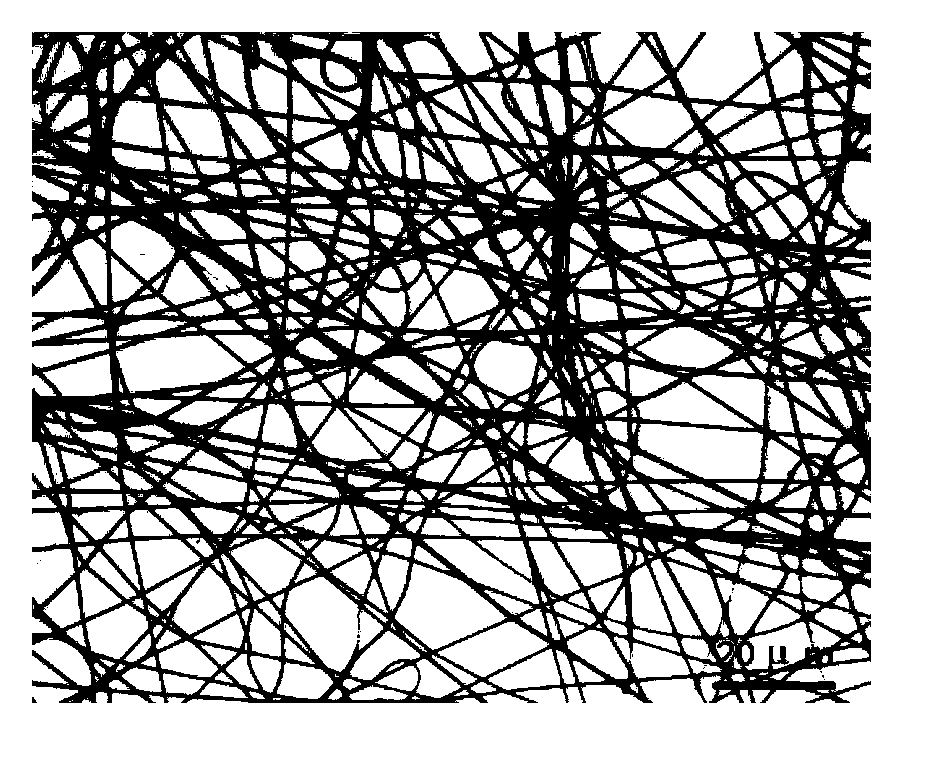

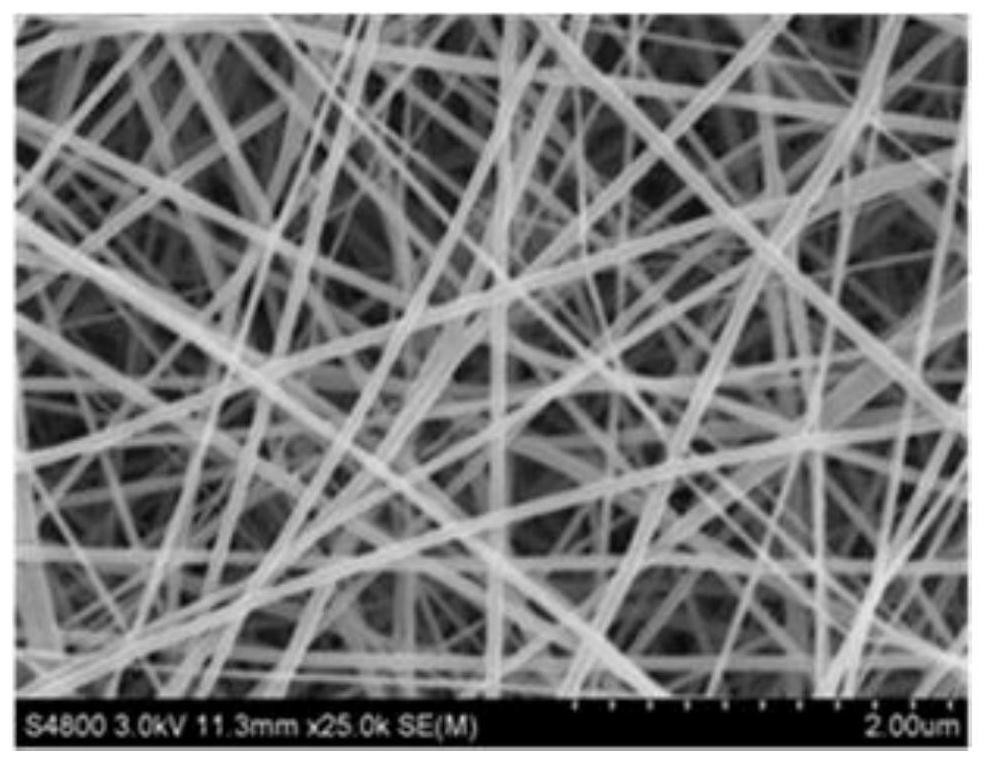

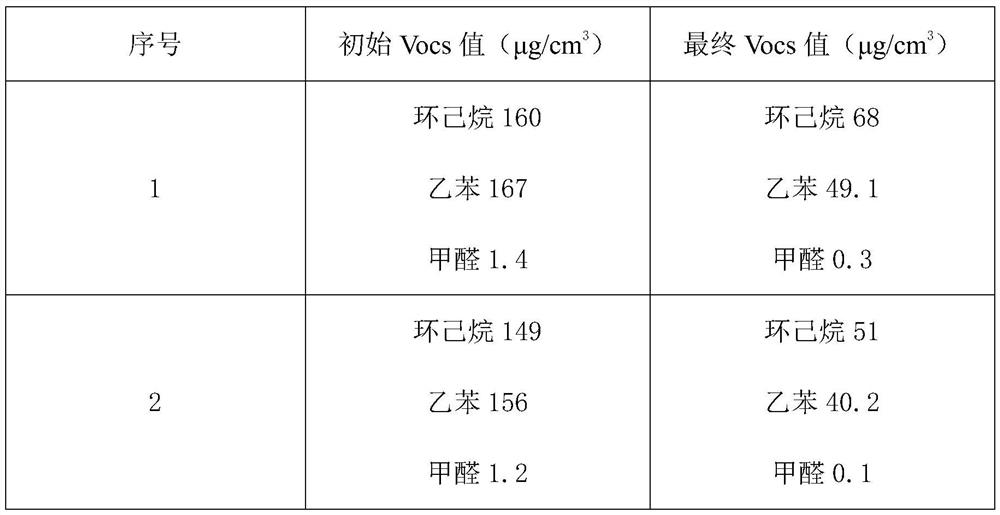

A kind of transparent pm2.5 filter film with photocatalysis and preparation method thereof

ActiveCN107754493BAvoid accessWith photocatalytic functionSemi-permeable membranesDispersed particle filtrationPolyamideNanofiber

The invention discloses a transparent PM2.5 filter membrane with photocatalysis and a preparation method thereof. The PM2.5 filter membrane is a composite nanofiber membrane with a sandwich-like structure, including polyacrylonitrile@TiO 2 and polyamide-6, the nanofiber diameter distribution of the composite nanofiber membrane is 60 to 100nm. The composite membrane is tightly cross-linked and has photocatalytic function, high transparency and efficient PM2.5 filtration performance. When used in anti-nano screen windows, it can not only effectively block outdoor PM2.5 from entering the room, but also effectively prevent outdoor PM2.5 from entering the room under the influence of sunlight. Photocatalyzes low-concentration harmful gases in the atmosphere while maintaining good lighting and ventilation effects.

Owner:SHAANXI UNIV OF SCI & TECH

Nanofiber composite tow with high interfacial adhesion strength and its preparation method and application

ActiveCN105088376BHigh viscosityHigh boiling pointTobacco smoke filtersArtificial filaments from cellulose derivativesCellulose diacetateGLYCERYL PALMITATE

Owner:CHINA TOBACCO ZHEJIANG IND

Polymer spinneret needle for electrospun nanofibers

InactiveCN110306245AIncrease productivityPressure is easy to controlFilament/thread formingElectrospun nanofiberNanofiber

The invention discloses a polymer spinneret needle for electrospun nanofibers. The polymer spinneret needle comprises a spinneret tube and detachable needle units, a spinneret duct, a spinneret distributor and a spinneret inner cavity are arranged in the spinneret tube, each needle unit comprises a connecting portion and a needle tube, the needle tube is a hose, and soft metal wires are embedded into the needle tube. The polymer spinneret needle is simple in principle and reasonable in design, spinning efficiency can be effectively improved, and spinning uniformity is improved. Moreover, the needle units can adjust spinneret directions along with change of positions, the number of the needle units is proper, stopping maintenance time is reduced, and nanofiber production efficiency is improved. Besides, polymer pressure in the spinneret inner cavity can be controlled, sharp spray of polymers and blockage of the needle are eliminated, and rapid and stable spinning is realized.

Owner:北京英鸿光大科技有限公司

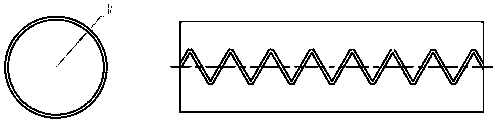

Rodlike electrospinning device and electrospinning method

InactiveCN109554771ASimple structureNarrow structureFilament/thread formingElectrospinningEngineering

The invention provides a rodlike electrospinning device and an electrospinning method. The rodlike electrospinning device is characterized by comprising a rodlike spinneret and a solution supply device which is connected with the rodlike spinneret to supply spinning solution to the rodlike spinneret, the spinning solution supplied by the solution supply device can be stored in the rodlike spinneret, and the rodlike spinneret is provided with a sawtoothed gap. The rodlike spinneret is connected with a high-voltage positive electrode, and when the voltage exceeds a critical value, various electrospinning jet flows can be generated in the sawtoothed gap. The rodlike electrospinning device is simple, the spinneret is less prone to blockage, jet flow interval uniformity, easiness in cleaning and high stability are realized, and spinning efficiency can be remarkably improved while electrospinning yield is greatly increased.

Owner:李瑞锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com