PTT slicing drying method for PTT/PET composite full drafting low-elasticity network thread

A low-elasticity network wire, drying method technology, applied in drying solid materials, chemical instruments and methods, heating to dry solid materials, etc. It is not easy to control and other problems to achieve the effect of reducing damage and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

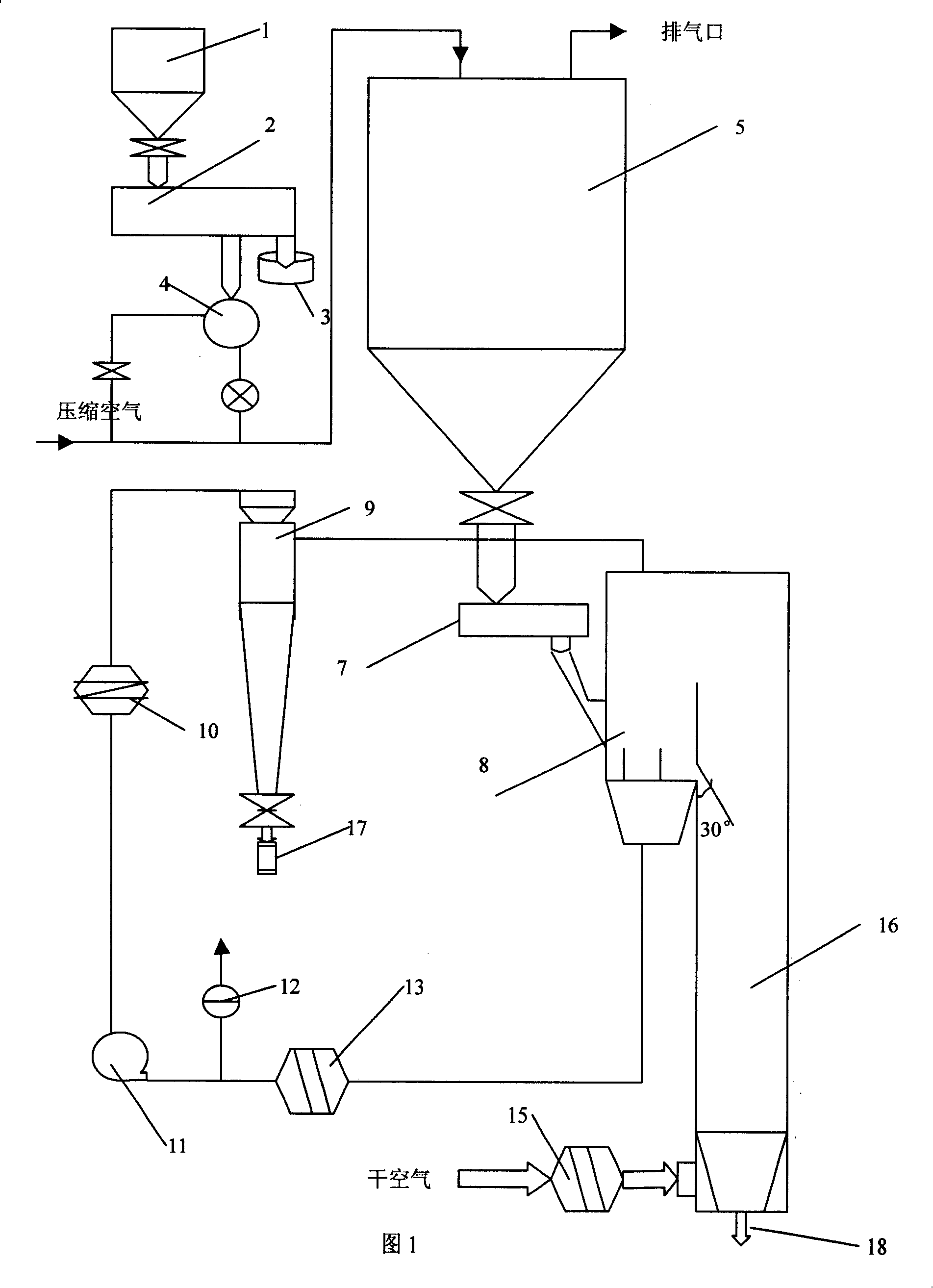

[0013] Describe the present invention in detail below in conjunction with accompanying drawing:

[0014] As shown in Figure 1, the PTT slice drying method in the PTT / PET composite full-drawing low-elastic network yarn, wherein: PET adopts the drying method when producing polyester-nylon composite yarn, and the PTT slice adopts the following drying method:

[0015] Step 1: Screening: Put the raw materials of PTT slices into the silo 1, turn on the control switch at the bottom of the silo 1, the raw materials of the PTT slices enter the vibrating screen 2 continuously, and the raw materials of the PTT slices that have been screened enter the pulse generator 4, and fail to pass The abnormal-shaped PTT slices of the sieve flow into the collection barrel 3; the PTT slice raw materials entering the pulse generator 4, under the joint action of the compressed air and the pulse generator 4, the PTT slice raw materials are sent to another silo 5;

[0016] The second step, pre-crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com