Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about "Spinning solution filtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

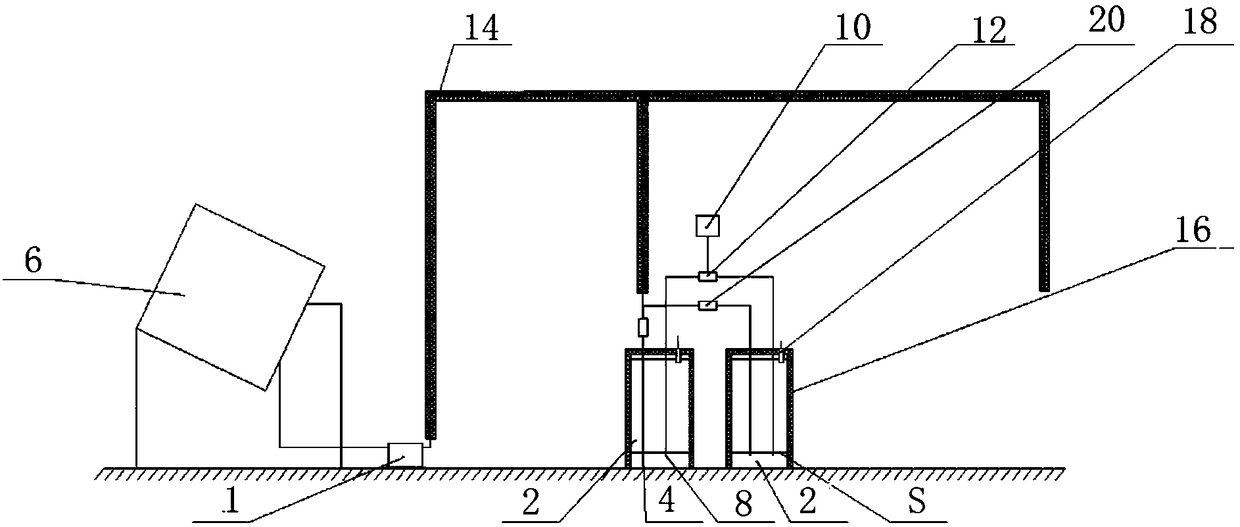

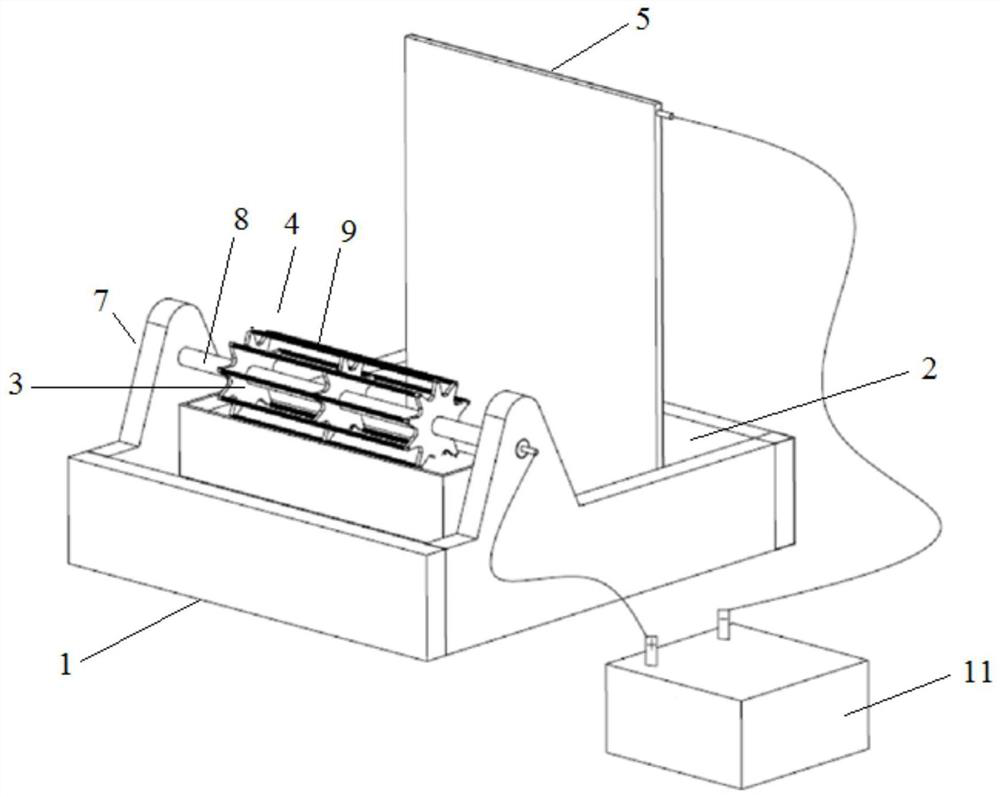

Electrospinning apparatus

InactiveUS20160083868A1Uniform qualitySimple manufacturing processSpinning solution filteringArtificial filament recoveryHigh volume manufacturingElectrospinning

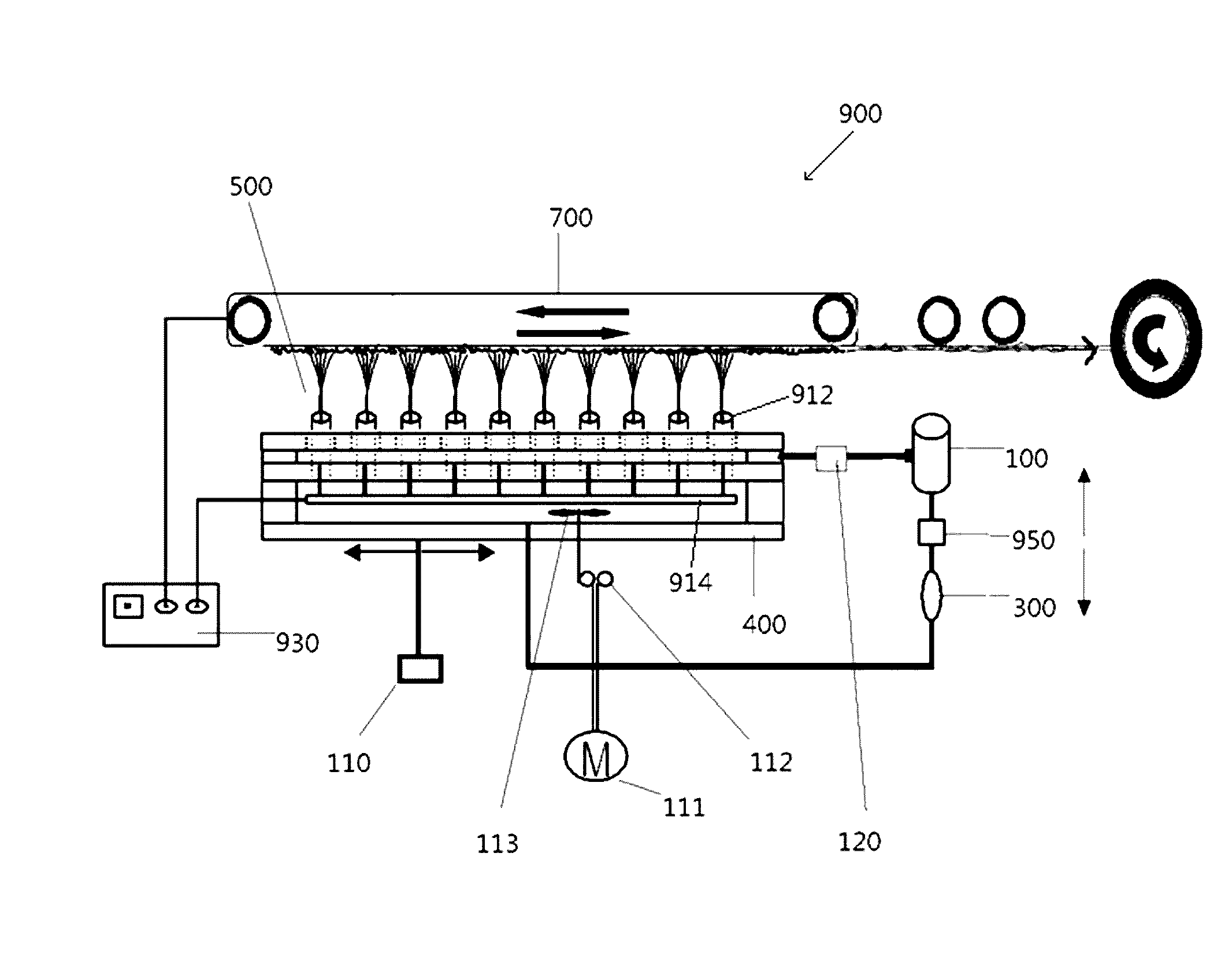

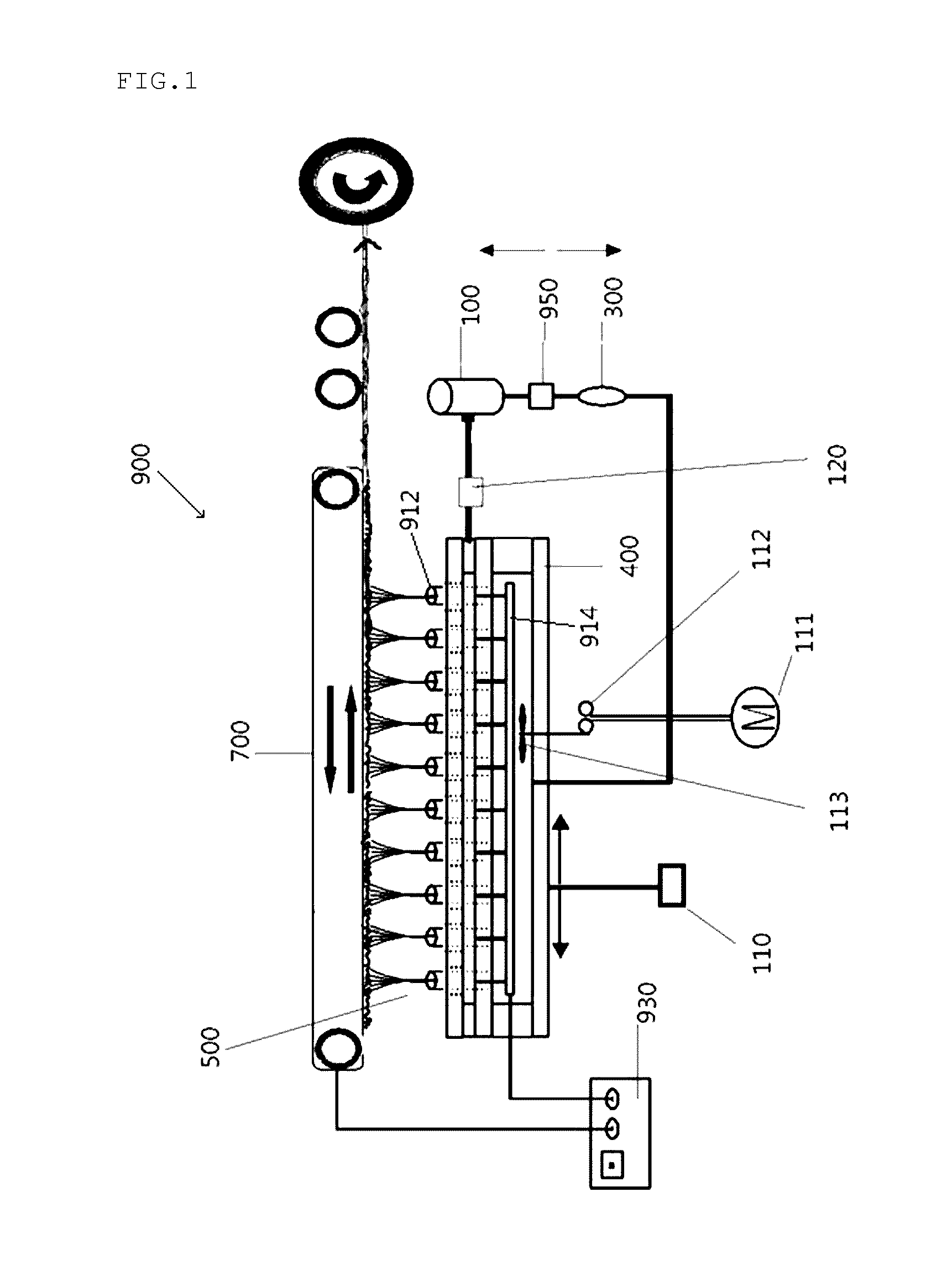

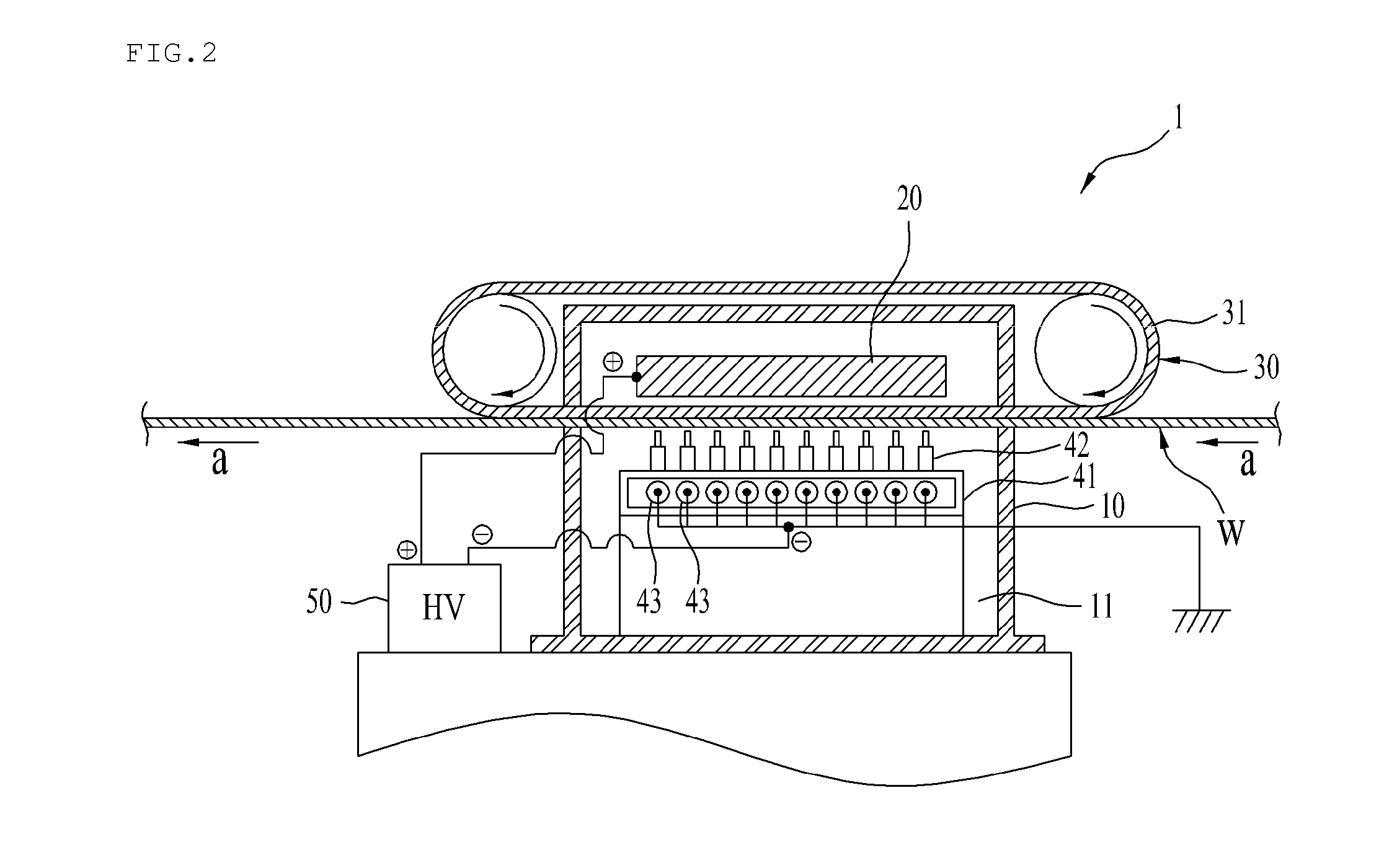

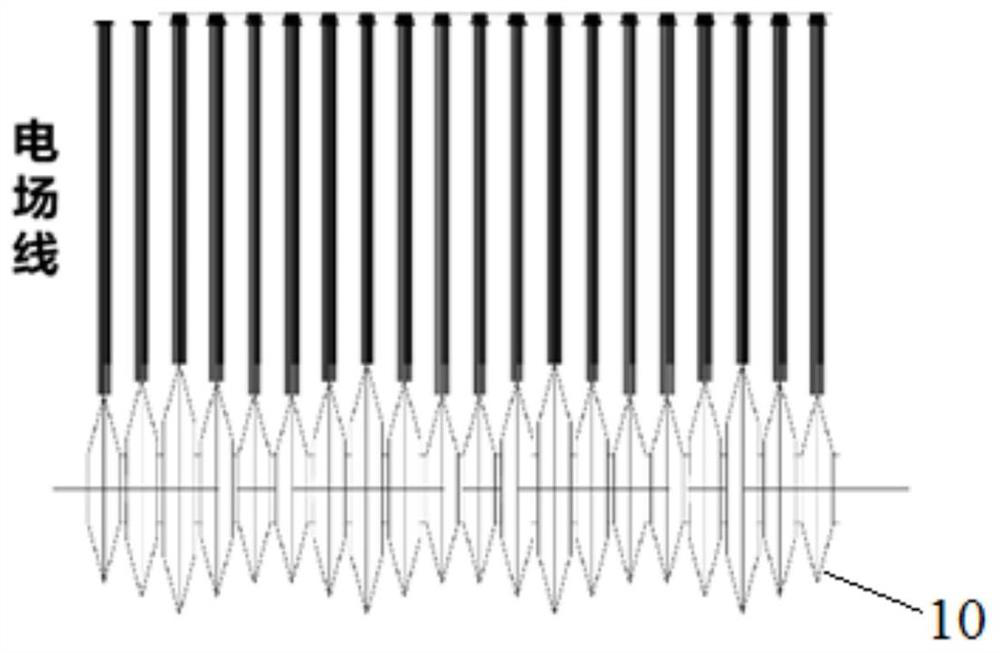

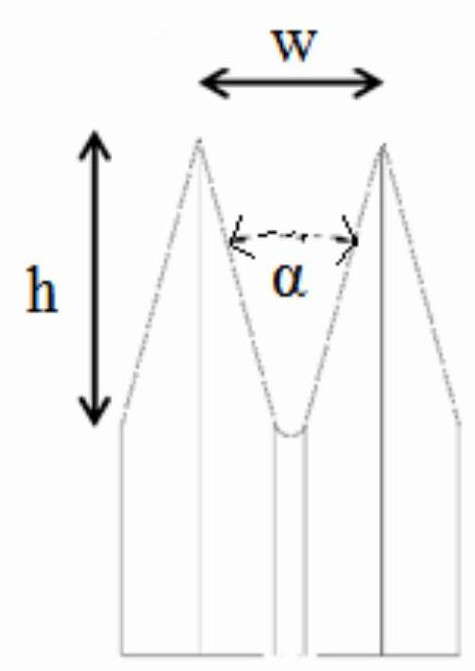

The present invention relates to an electrospinning apparatus, and the purpose of the present invention is to provide an electrospinning apparatus capable of producing nanofiber having various ingredients and thicknesses by controlling the temperature of at least one solution discharged from nozzles mounted on the tubular bodies of a nozzle block and thus controlling the viscosity of the solution which is electrospun; producing nanofiber having uniform quality without applying a density difference and a voltage difference by disposing the front end portions of the nozzles in a flare shape; and mass-producing nanofiber at a low cost as well as reducing the amount of the solution used by removing an overflow prevention system and using a metering pump alone or by using the metering pump and the overflow prevention system alternatively or in a hybrid manner.

Owner:FINETEX ENE

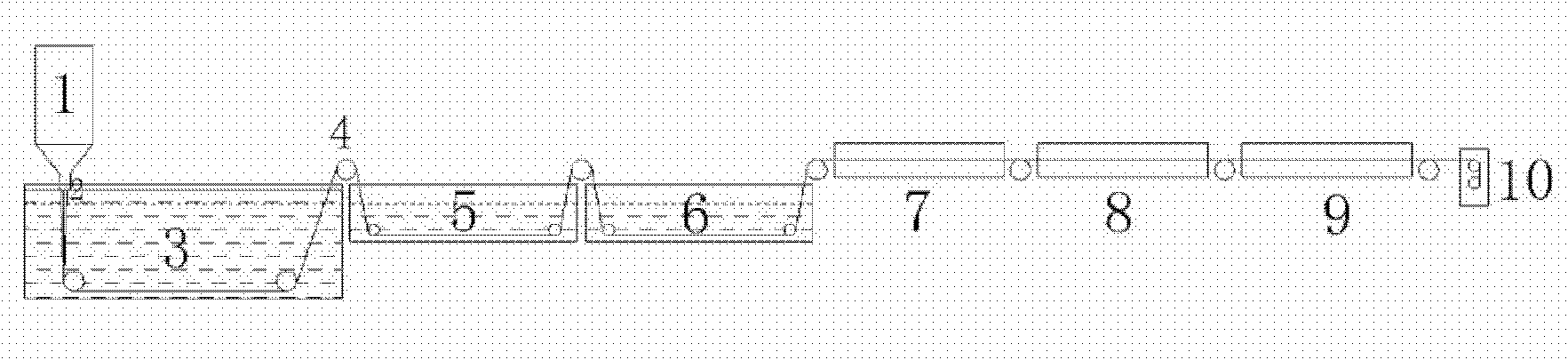

Method and equipment preparing viscose filament non-woven fabric through wet spinning technology

ActiveCN105401332AIncreased tangleOvercoming complexitySpinning solution filteringSpinning solution de-aeratingEngineeringWork in process

The invention discloses a method and equipment preparing viscose filament non-woven fabric through wet spinning technology; the method comprises the following steps: 1, spinning technology, spinning dope preparation; 2, spinning soup solidification reaction; 3, viscose formation; 4, washing; 5, drying: non-woven fabric formation technology; 6, lapping: uniformly scattering and lapping dried primary viscose fiber beams on a lapper web curtain, thus forming intersecting stacked filament fiber web; 7, spunlace reinforcement; 8, baking; 9, winding. The equipment comprises a wet spinning device and a non-woven fabric forming device; related steps in a conventional wet spinning technology can be omitted; semi-finish viscose filament can be directly used for non-woven fabric production; in the prior art, finished fiber filaments are secondarily used for non-woven fabric production; the novel method can break the conventional concept, can effectively save production cost, can reduce environment pollution in the production process, and can improve production efficiency.

Owner:QINGDAO UNIV

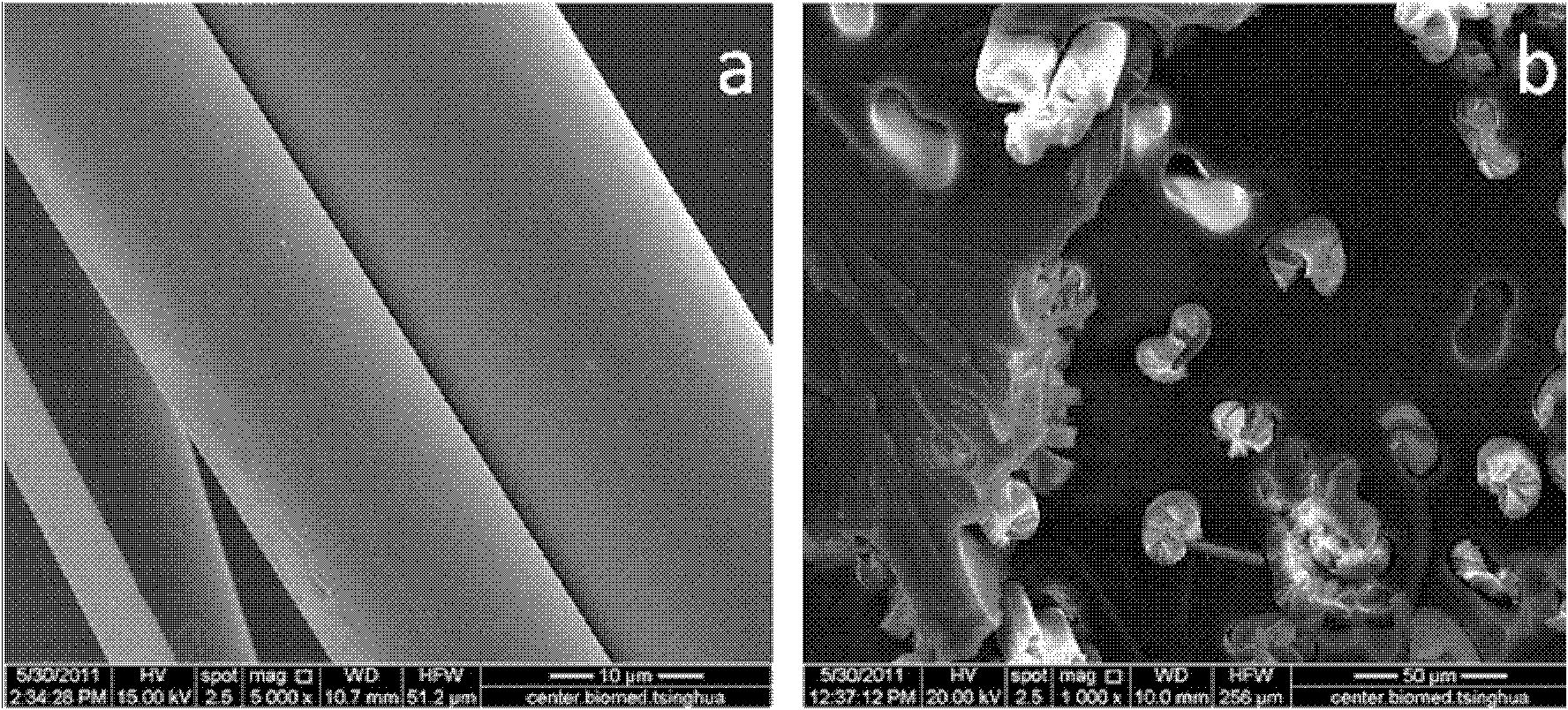

Method organic framework based on alginic acid electrospun fibers and preparation method thereof

InactiveCN107841879AUniform shapeArranged in an orderly mannerSpinning solution filteringNon-woven fabricsPolyethylene oxideMetal-organic framework

The invention discloses a metal organic framework based on alginic acid electrospun fibers and a preparation method thereof. The preparation method comprises the following steps: (1) electrospinning abase nanofiber membrane, namely taking a sodium alginate / polyethylene oxide nanofiber membrane obtained by adopting an electrospinning method as the base nanofiber membrane; and (2) growing MOFs crystals. The preparation method disclosed by the invention has the advantages that no high pressure or high temperature is required in a preparation process, preparation conditions are mild, production cost and potential safety hazard can be effectively reduced, the obtained metal organic framework is uniform in appearance and ordered in configuration, and yield is high, so that the preparation method disclosed by the invention is applicable to large-scale production and has a good application prospect.

Owner:QINGDAO AGRI UNIV

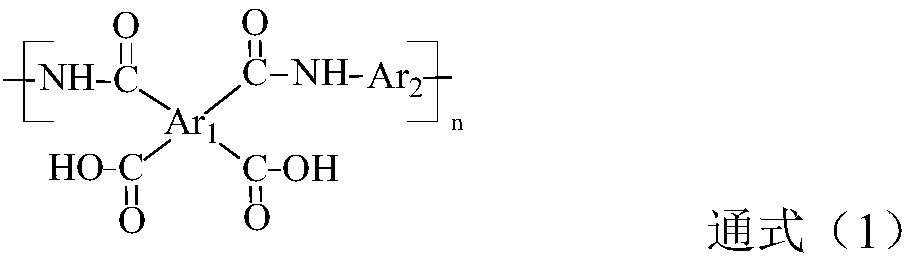

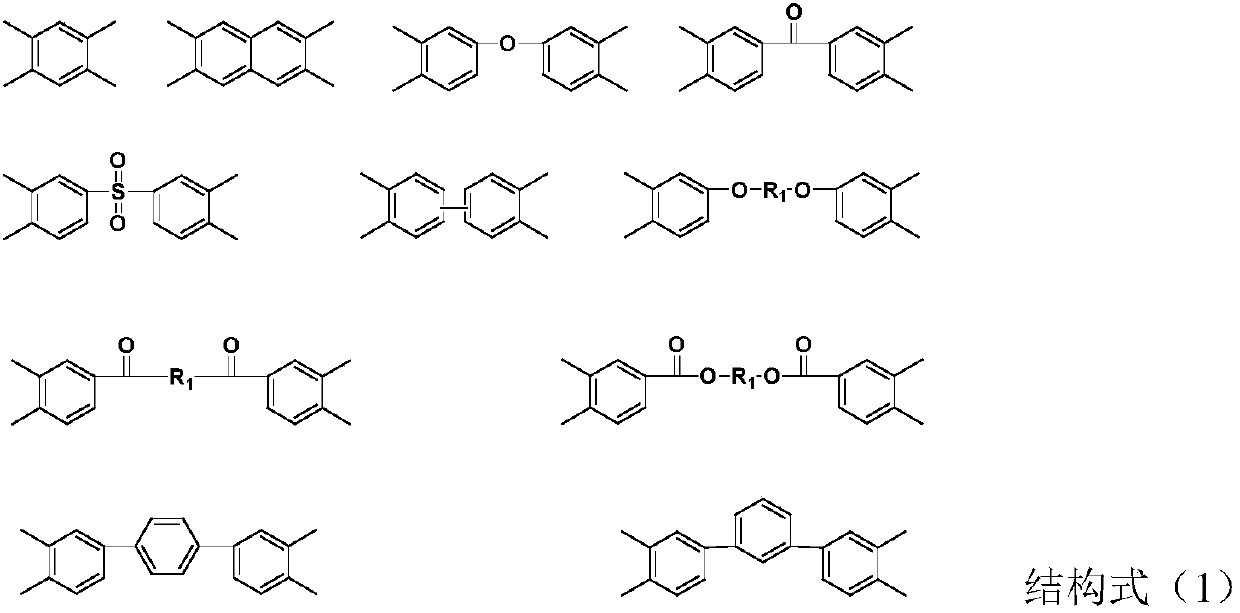

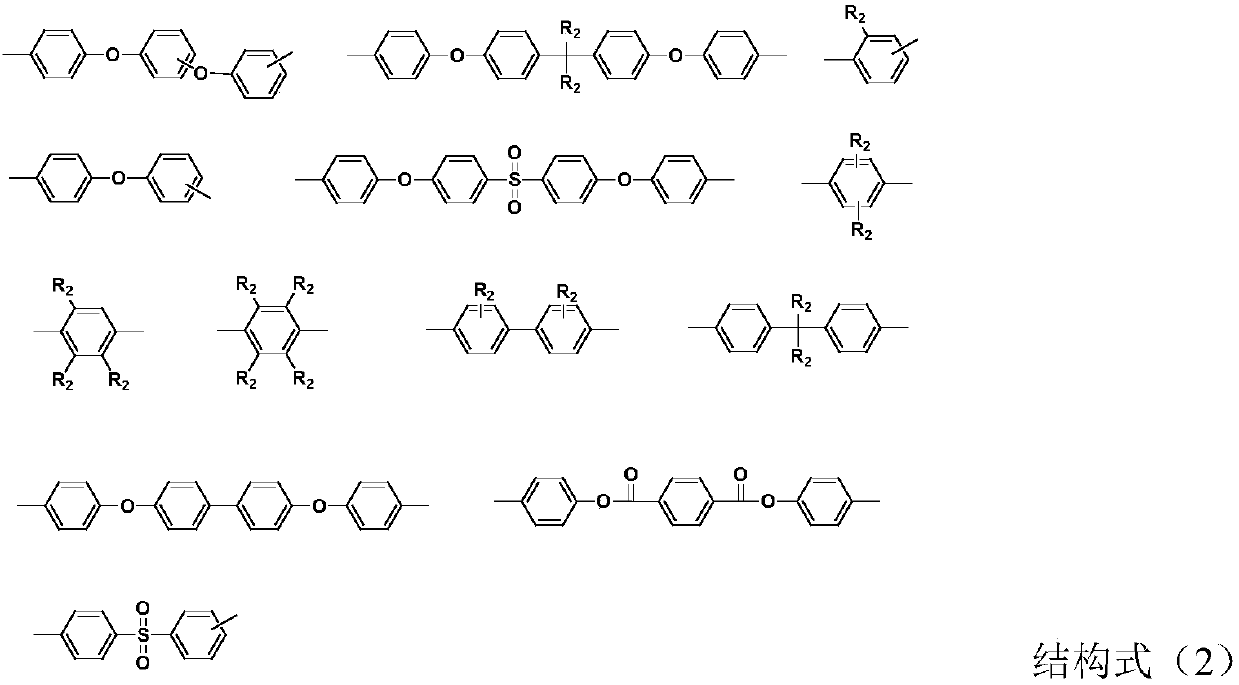

Polyimide fiber with kidney-shaped section and preparation method thereof

ActiveCN102560707AImprove production efficiencySimple preparation processSpinning solution filteringSpinning solution de-aeratingFiberConductor Coil

A polyimide fiber with kidney-shaped section and a preparation method thereof belong to the technical field of polyimide fibers. The preparation method includes: utilizing polyamide acid (PAA) solution synthesized by aromatic dianhydride and aromatic diamine to perform the wet spinning process by the aid of circular spinneret holes, adjusting spinning conditions including spinneret speed, composition, proportion and temperature of coagulating bath, the length of hydrazine and the like to obtain a PAA as-formed fiber with kidney-shaped section, then washing and drying the PAA as-formed fiber, cyclizing and drafting the same at high temperature stage by stage, and winding and the like, finally obtaining the polyimide (PI) fiber with the kidney-shaped section. The preparation method of the polyimide fiber with the kidney-shaped section has the advantages of simplicity in spinneret hole design and processing, easiness in control of spinning process, high preparation efficiency, low cost for raw materials, low energy consumption and the like and can be used for large-scale industrialized production.

Owner:BEIJING UNIV OF CHEM TECH

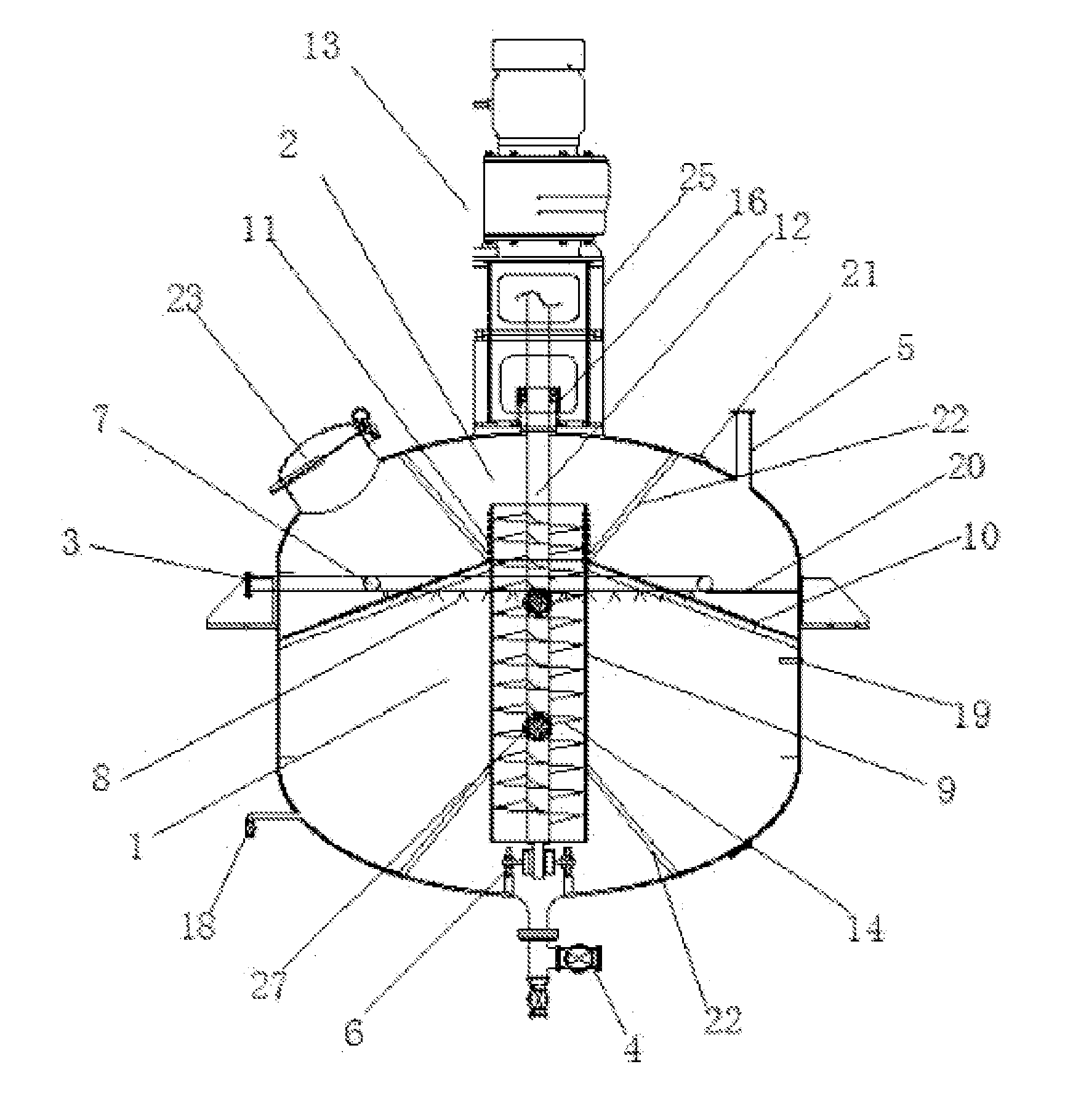

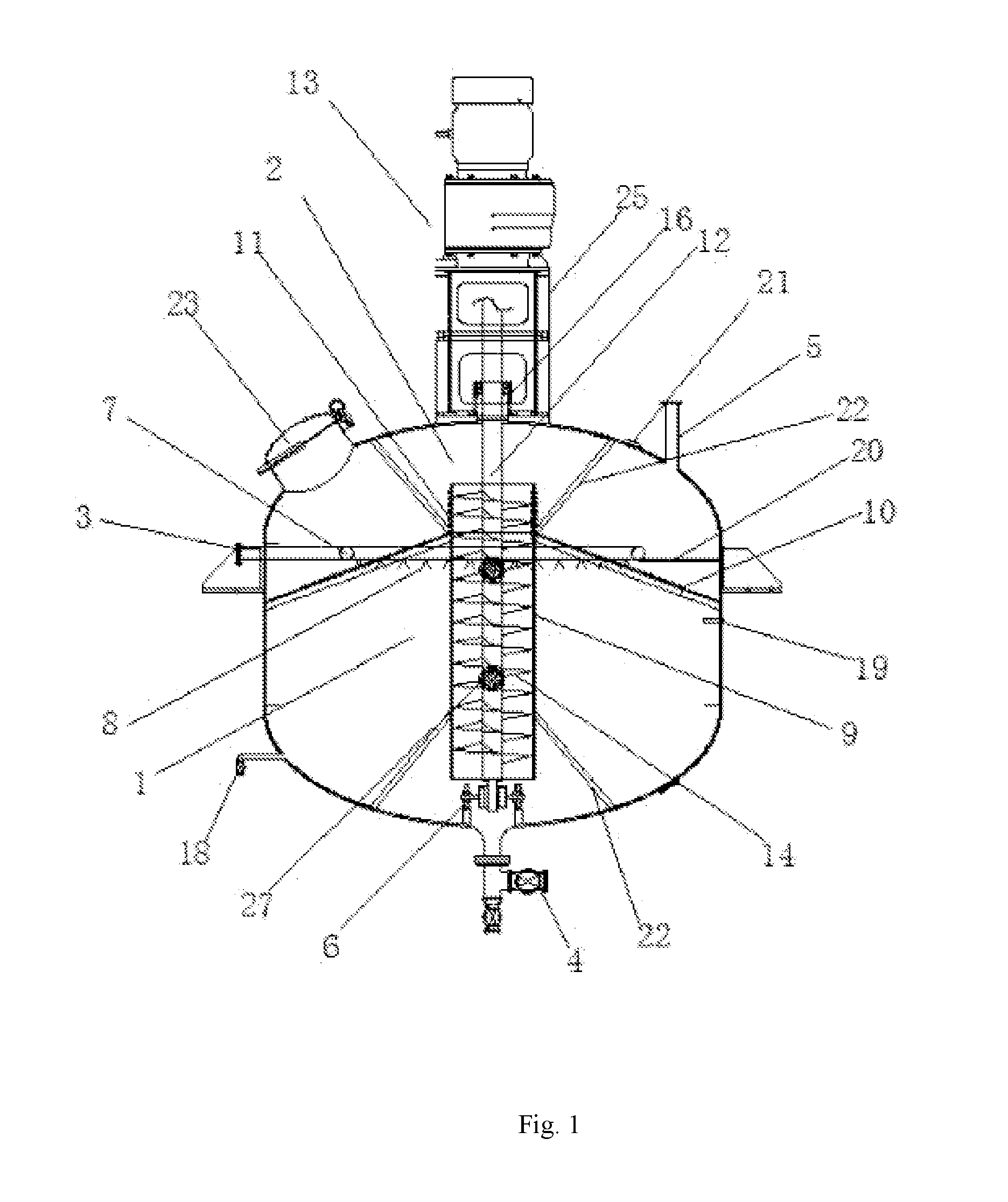

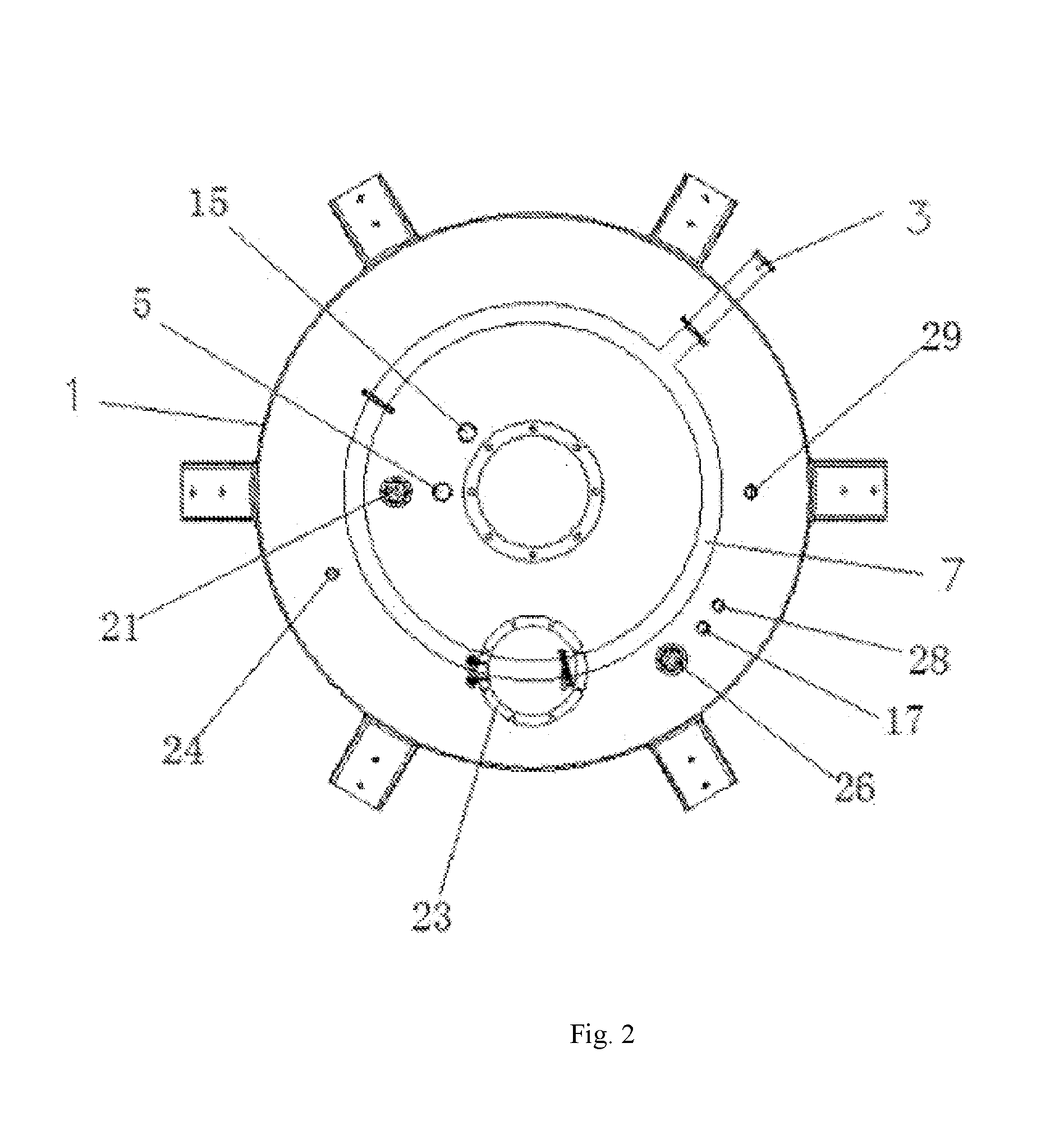

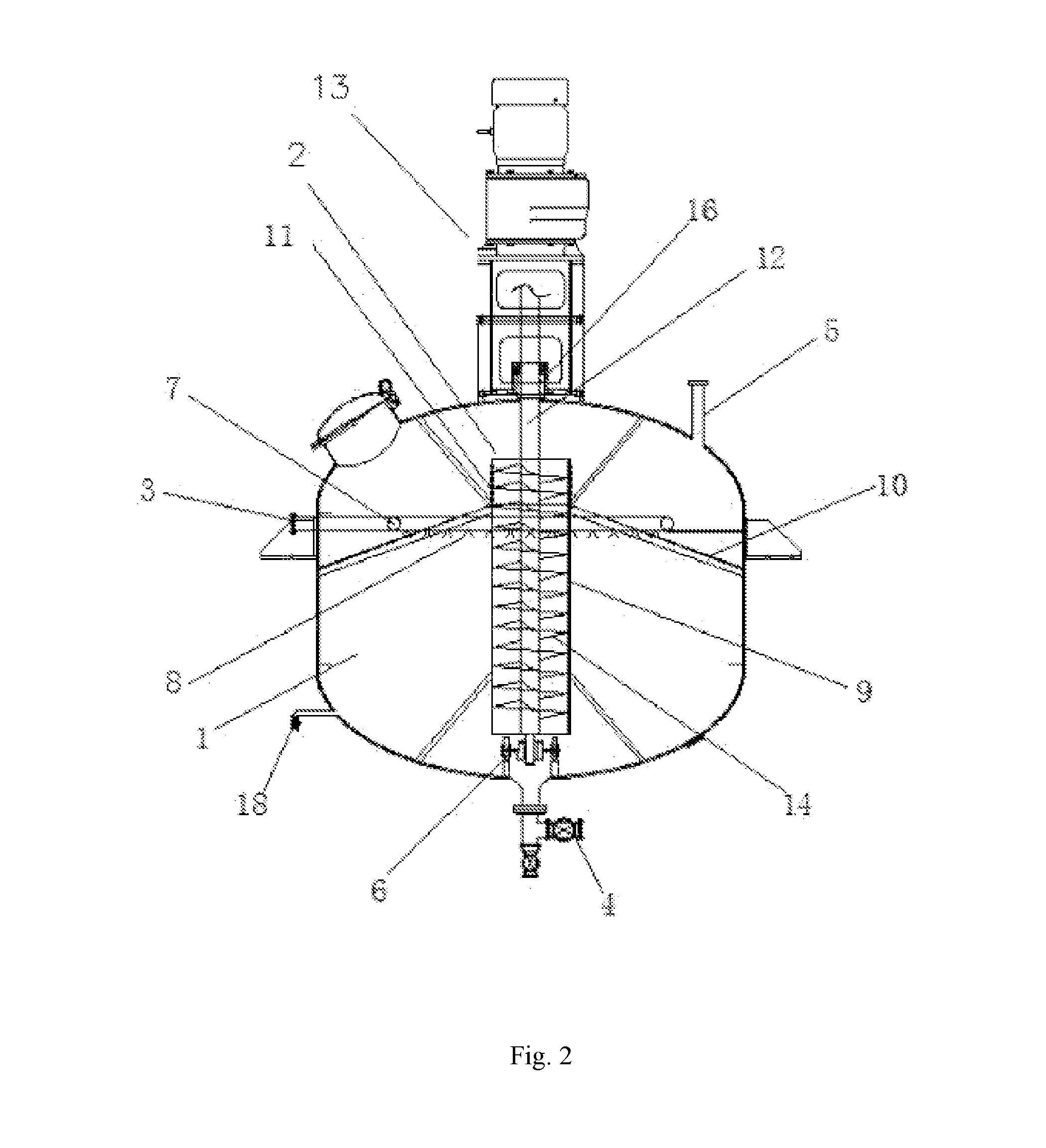

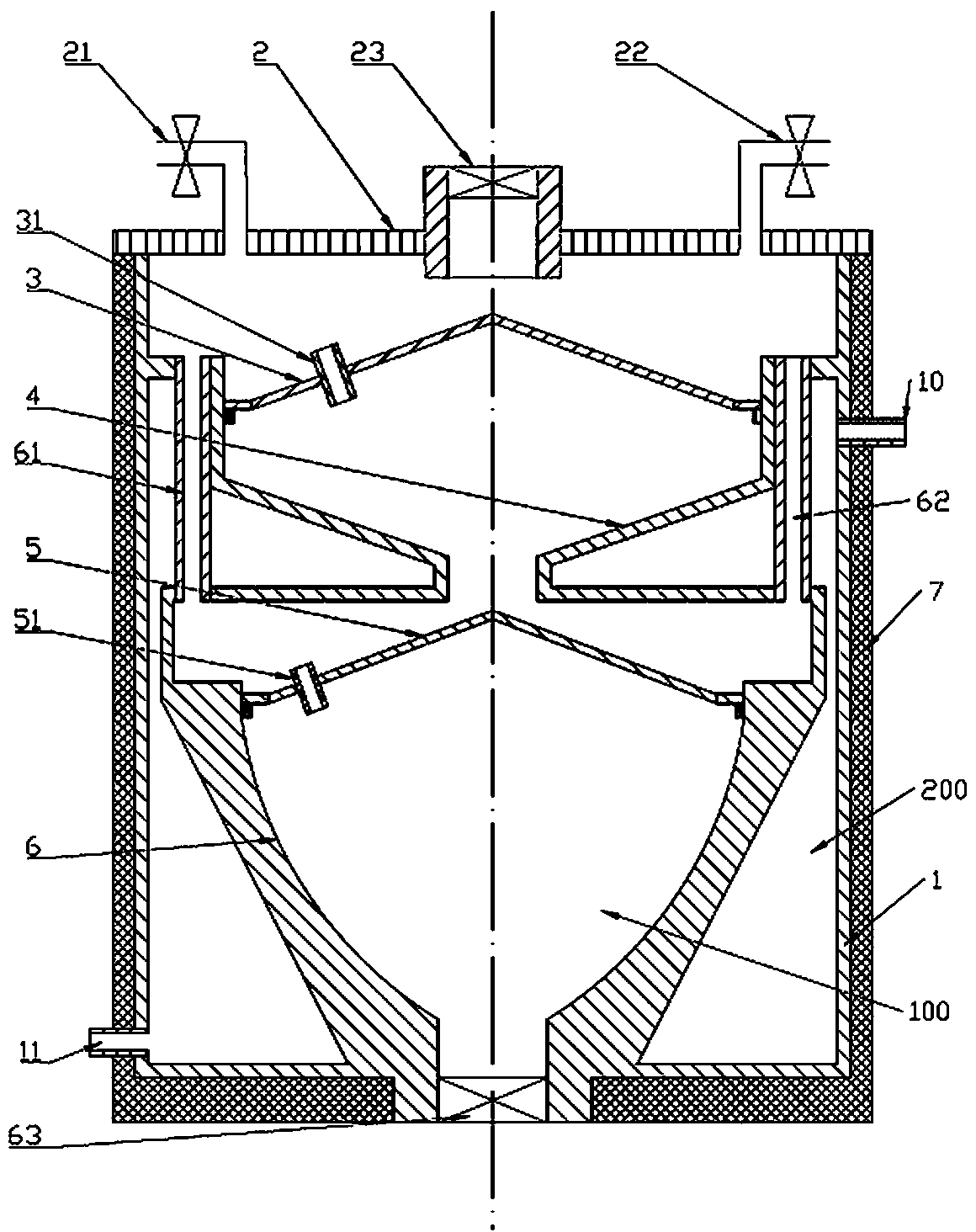

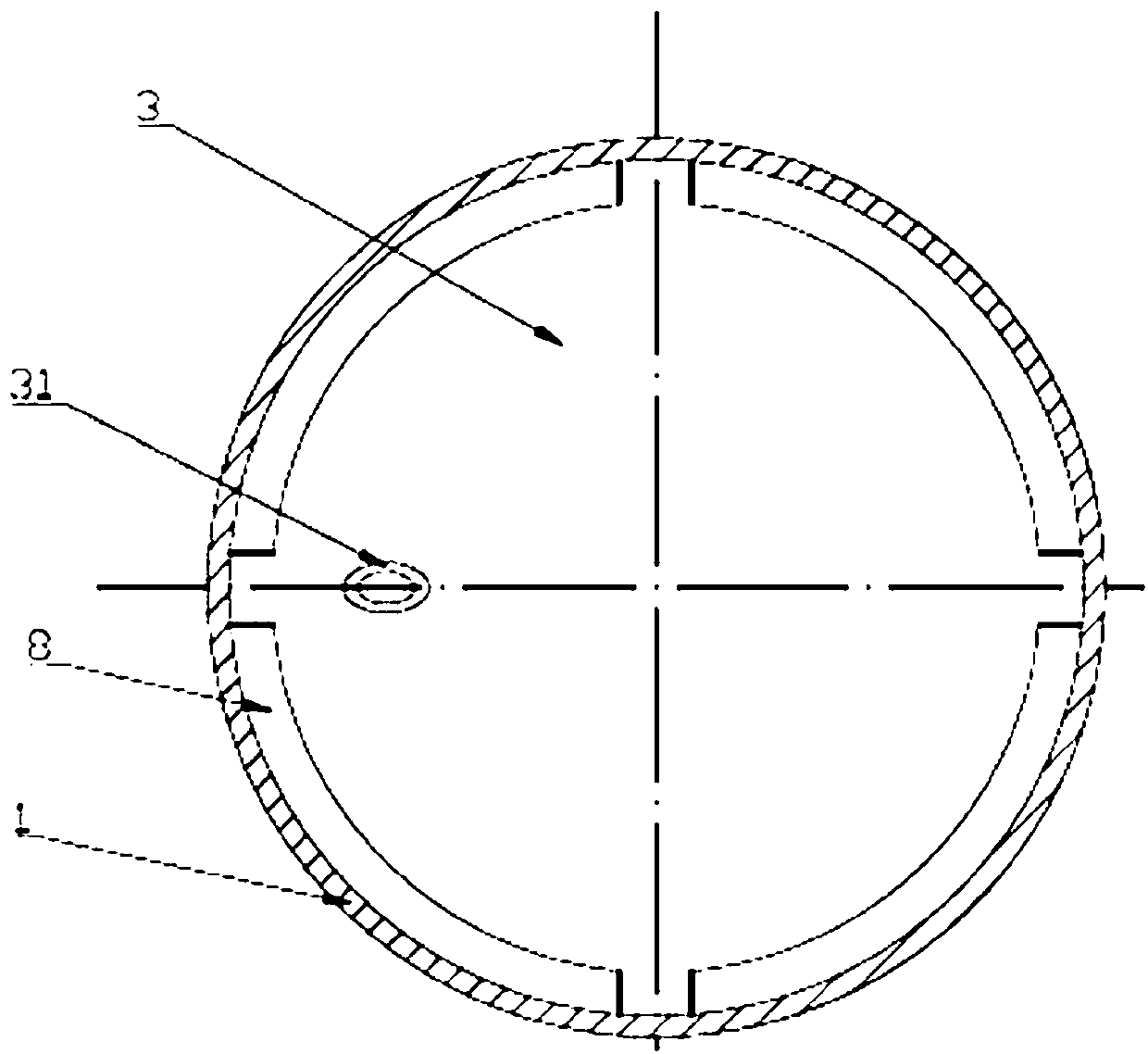

Defoaming apparatus for high-viscosity pure-chitosan spinning solution

InactiveUS20160193548A1Increase the areaHigh-efficiency high-qualitySpinning solution filteringTransportation and packagingPropellerEngineering

A degassing device for high-viscosity pure-chitosan spinning solutions having a reaction vessel and stirring device. A feed port and vacuum port are disposed at the upper part of the reaction vessel, an inner cylinder body is fixedly disposed in the center position of the reaction vessel which also has a discharge port, the upper cylinder opening of the inner cylinder body is closed and the lower cylinder opening is open, an umbrella-shaped dispersion plate is fixedly disposed at the periphery of the upper half part of the inner cylinder body, a gap is formed between the outer edge of the umbrella-shaped dispersion plate and the inner wall of the reaction vessel, and small liquid outlet holes are distributed on the part of the inner cylinder body above the umbrella-shaped dispersion plate. The stirring device has a stirring shaft with screw propeller and stirring power unit. The upper end of the stirring shaft is mounted to the stirring power unit, the stirring shaft passes through a mechanical sealing device and enters the reaction vessel with the lower end fixed on a seat-mounted bearing, the stirring shaft is superposed with the axial line of the inner cylinder body, and a gap is formed between the inner wall of the inner cylinder body and screw propeller.

Owner:HISMER BIO TECH

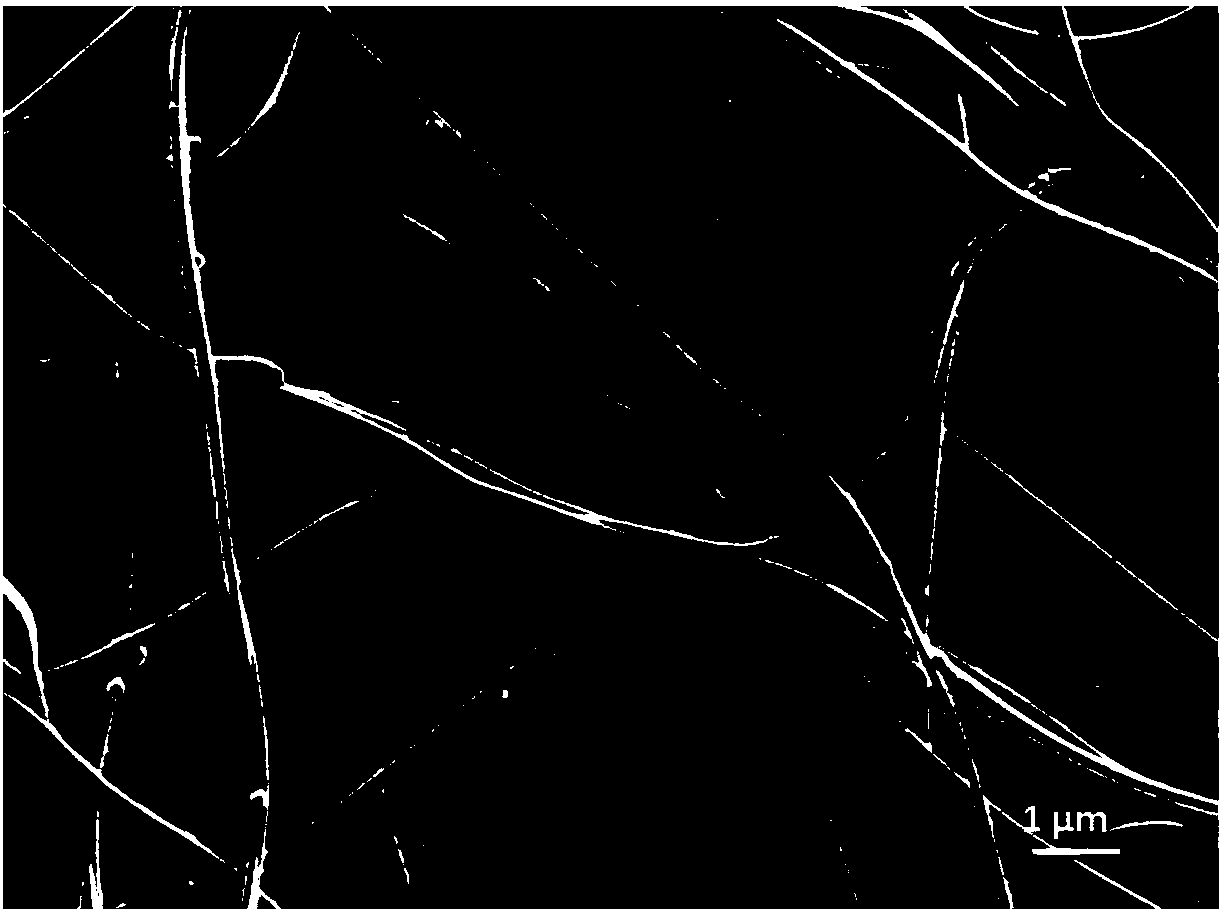

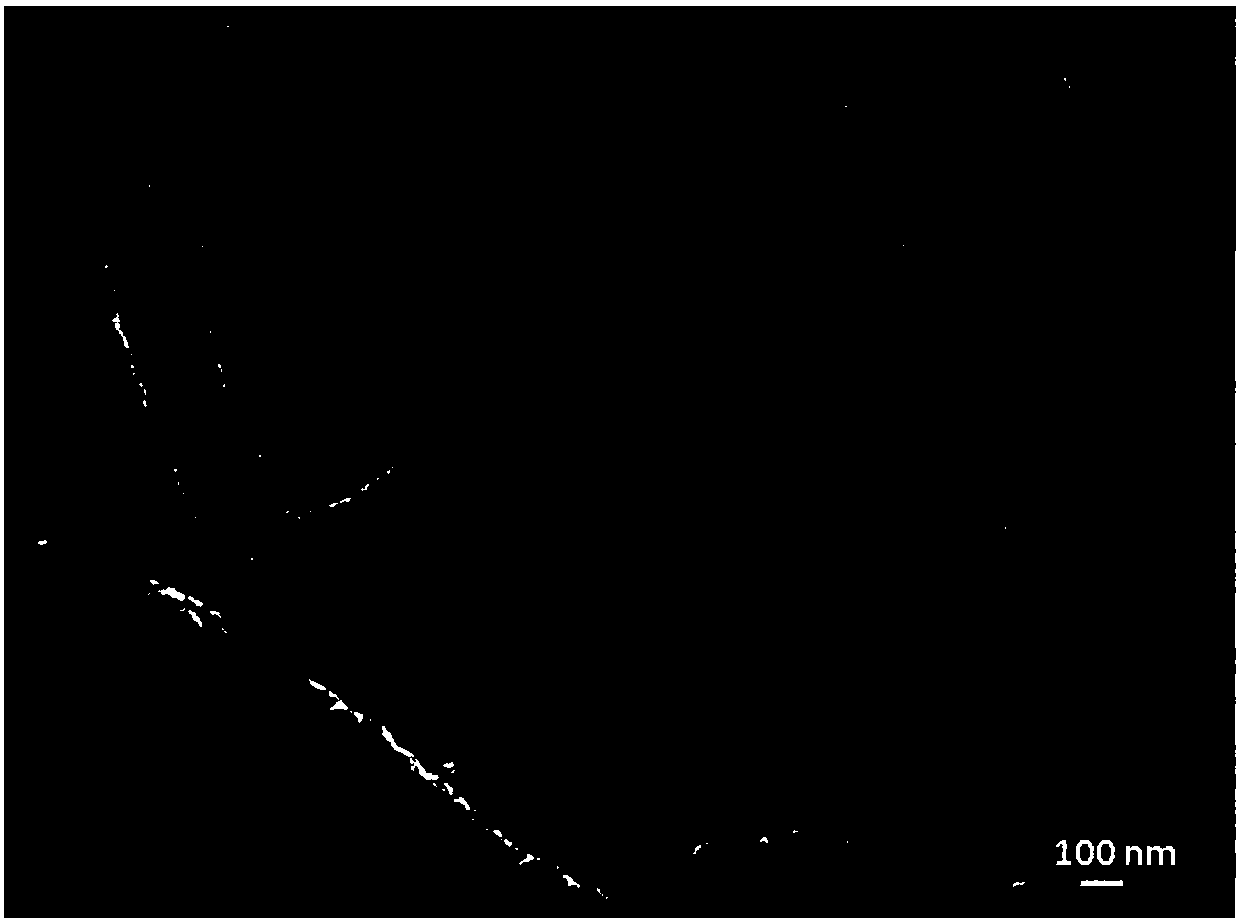

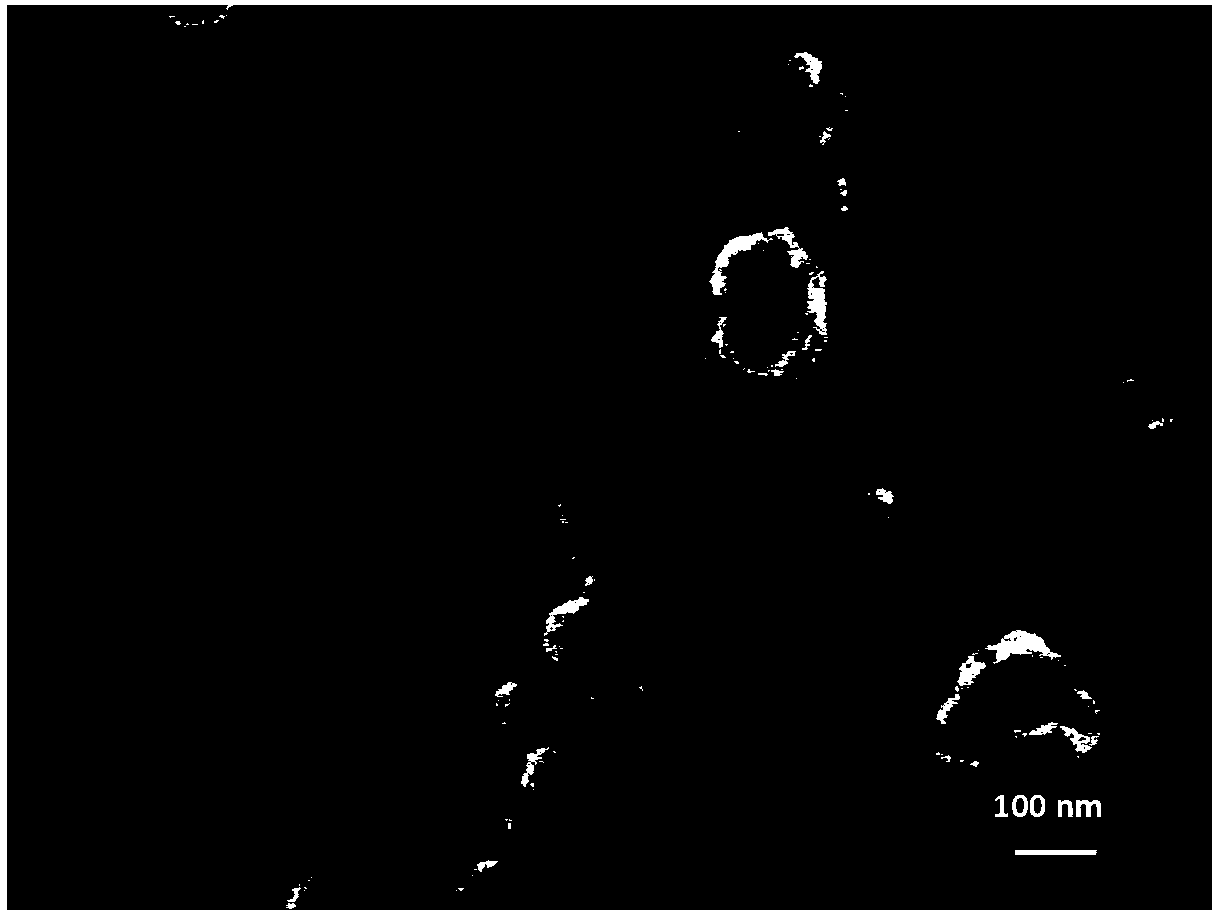

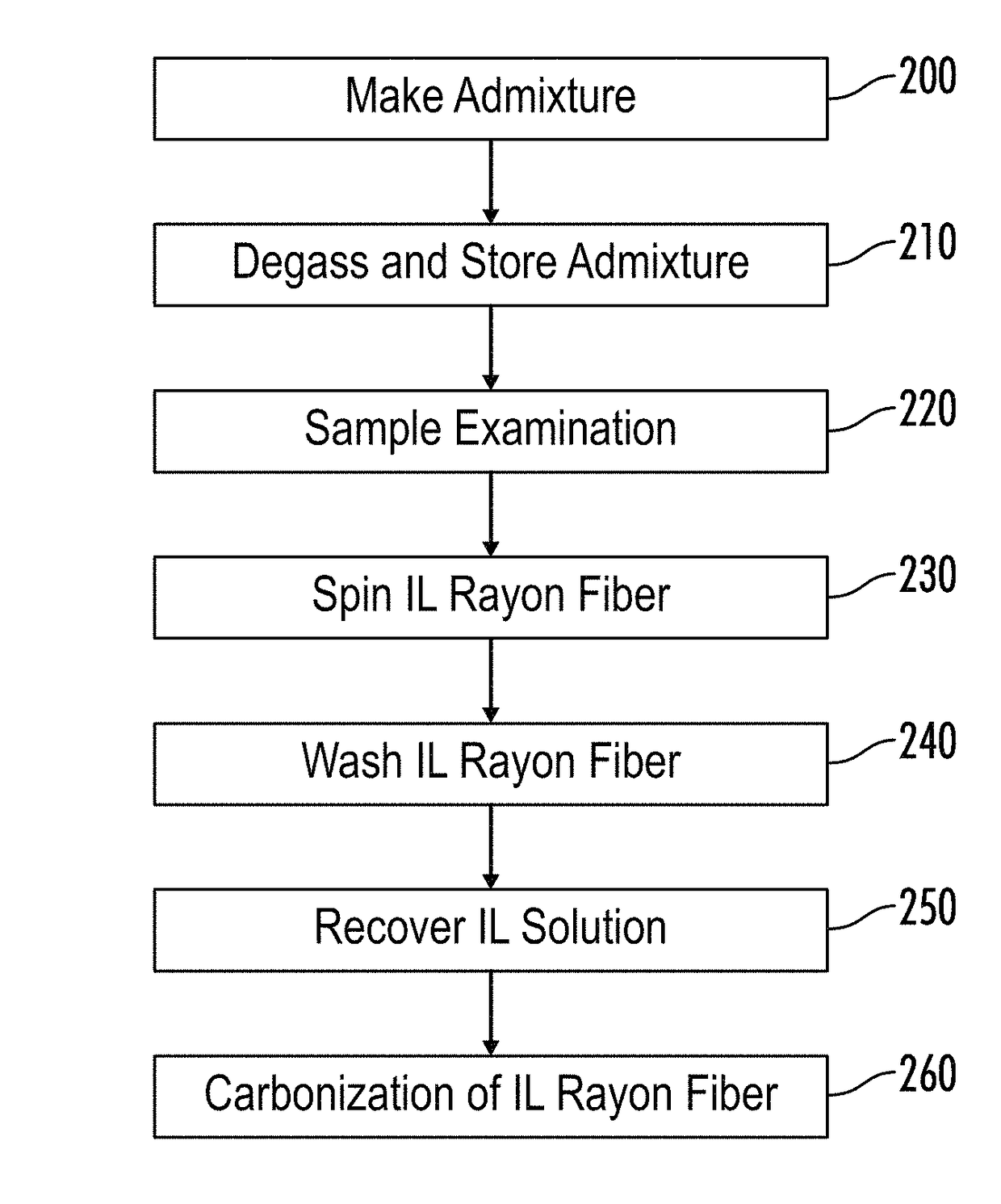

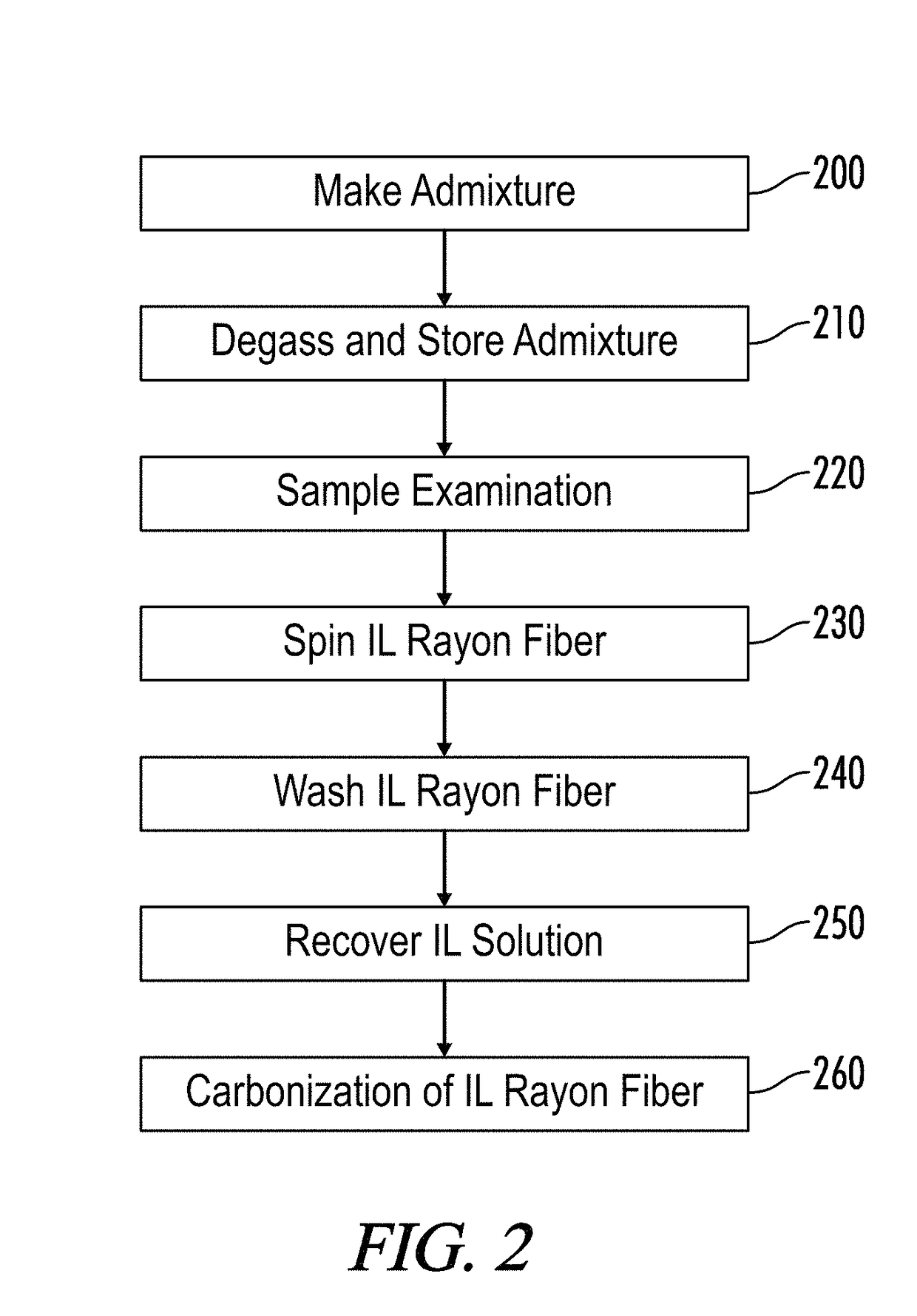

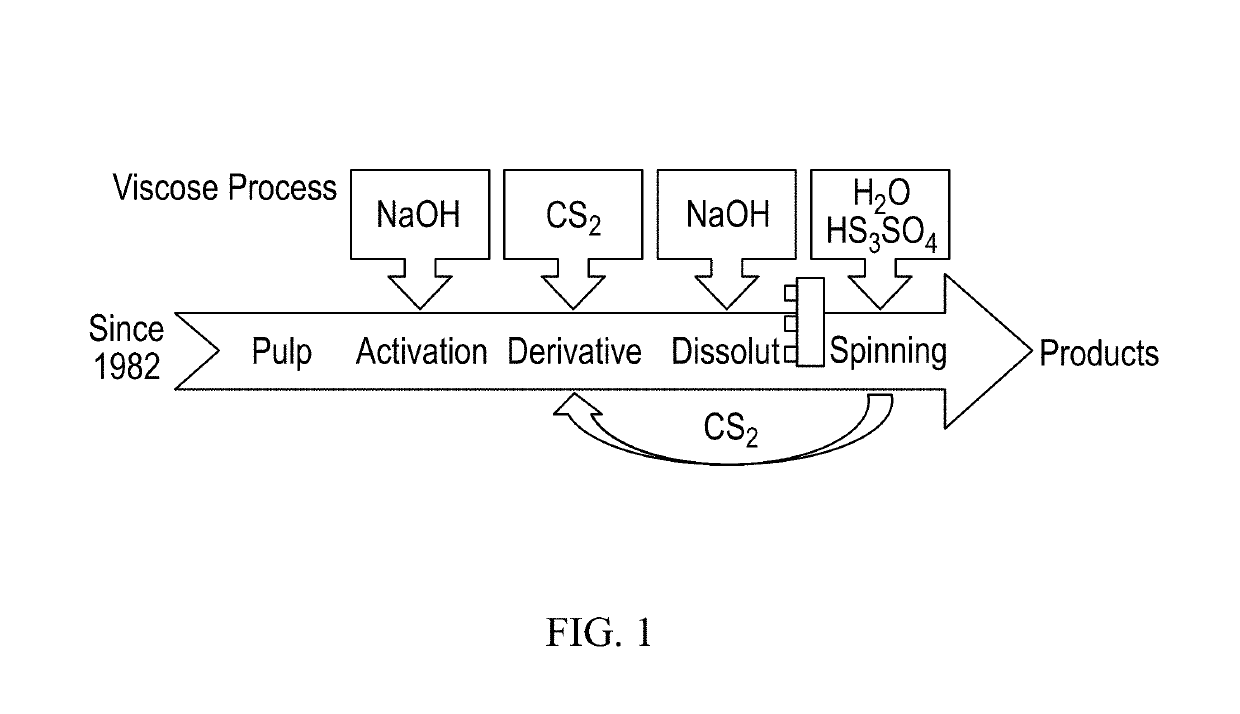

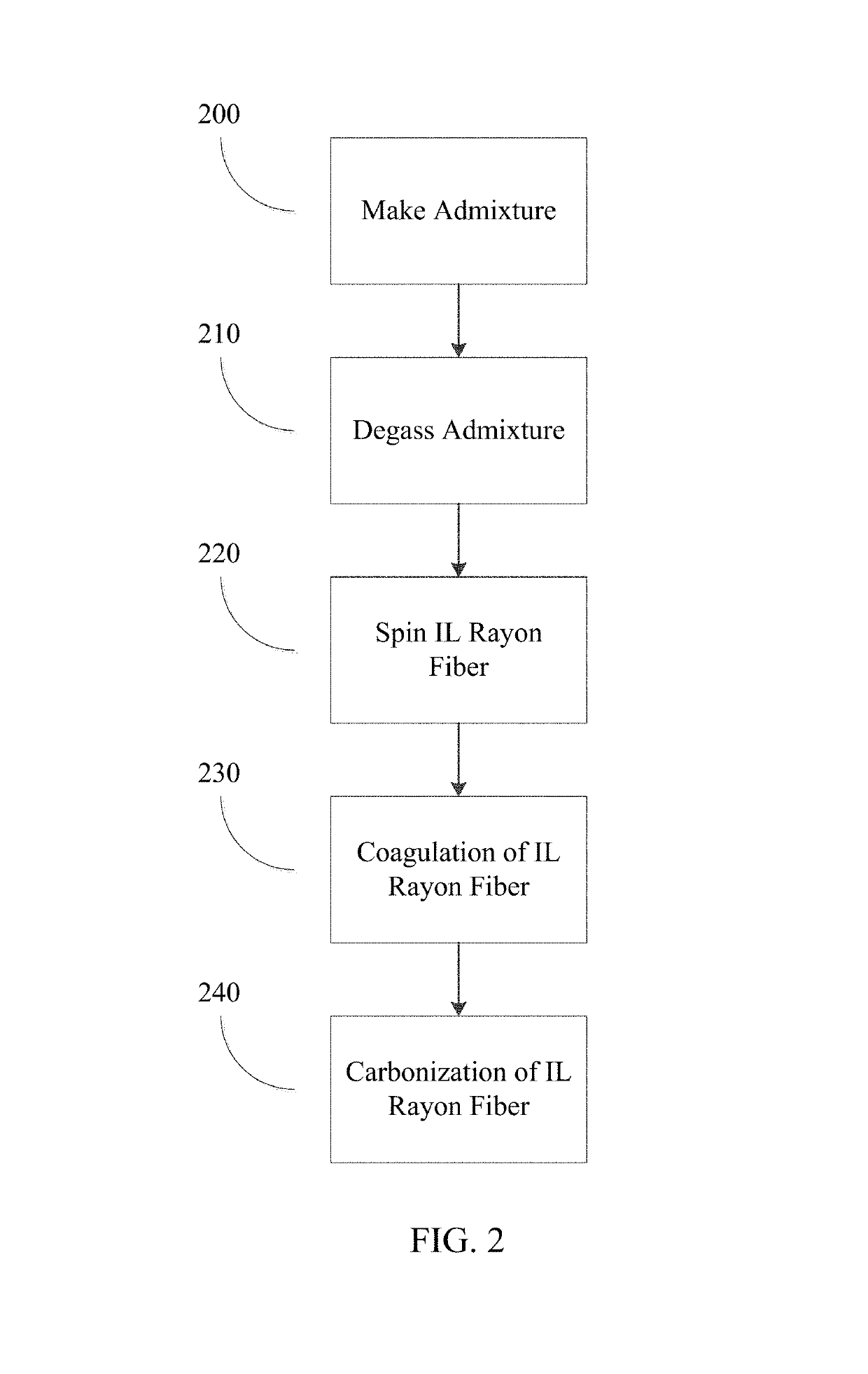

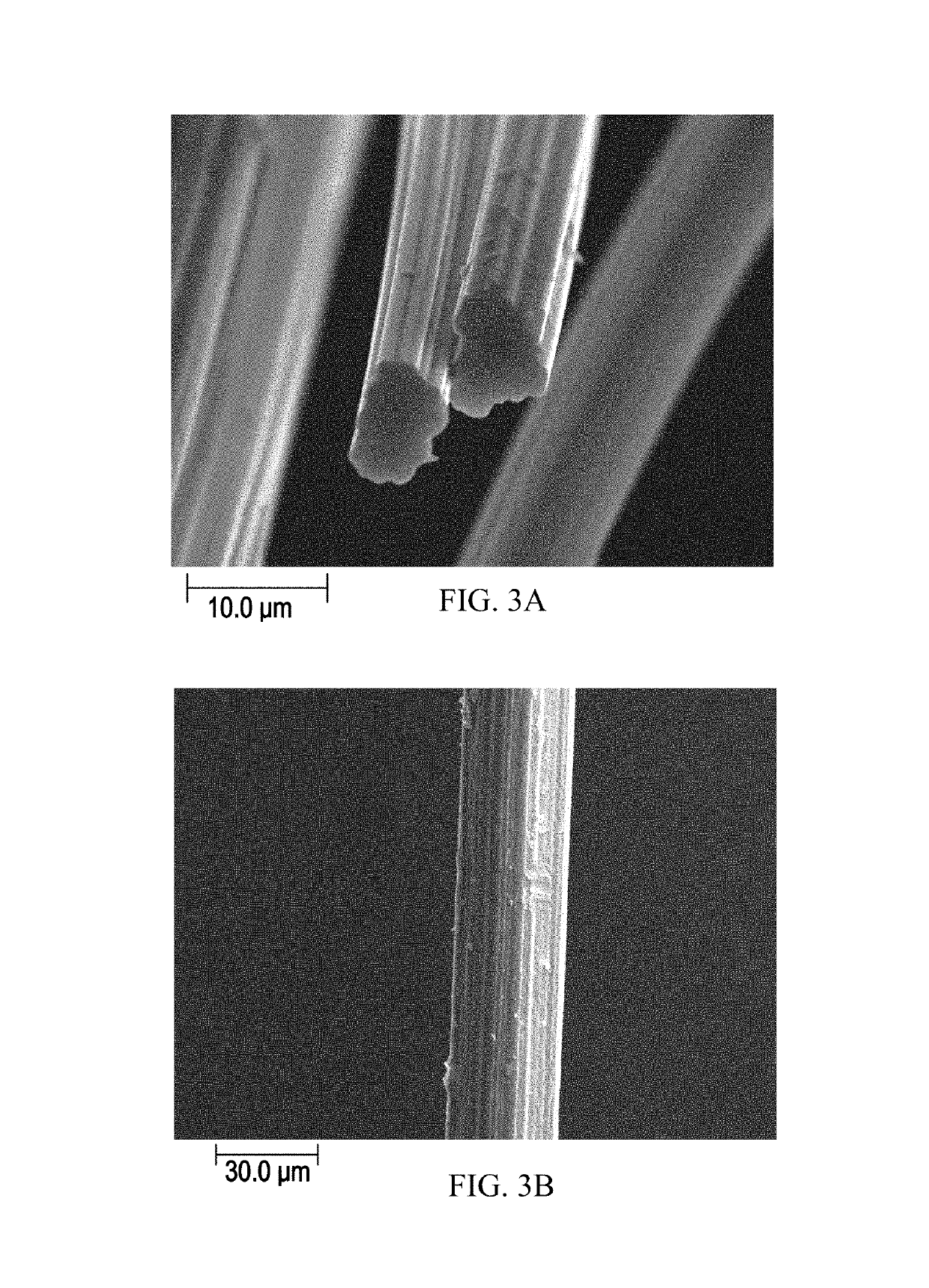

Methods and systems for making carbon fibers for high temperature applications

ActiveUS9695525B1Spinning solution filteringArtificial filaments from cellulose solutionsCelluloseCarbon fibers

The present invention relates to a method for the continuous production of low thermal conductivity endless filament yarns with a compact, homogeneous structural morphology. The presently disclosed methods utilize safe and recyclable ionic liquids (IL) to produce carbon fiber precursors from cellulose. The fibers are produced by the carbonization of cellulose carbon fiber precursors. The precursor fiber filaments have an increased tear resistance with simultaneously sufficient elongation, a round or crenulated cross-section, and homogeneous fiber morphology. The filament yarns exhibit performance characteristics similar to those produced from traditional viscous rayon. The resulting fibers are especially suited for aerospace applications in composite materials used at the limits of high temperatures, for instance in structures found in rocket nozzles or atmospheric reentry heat shields on spacecraft.

Owner:UNIVERSITY OF ALABAMA

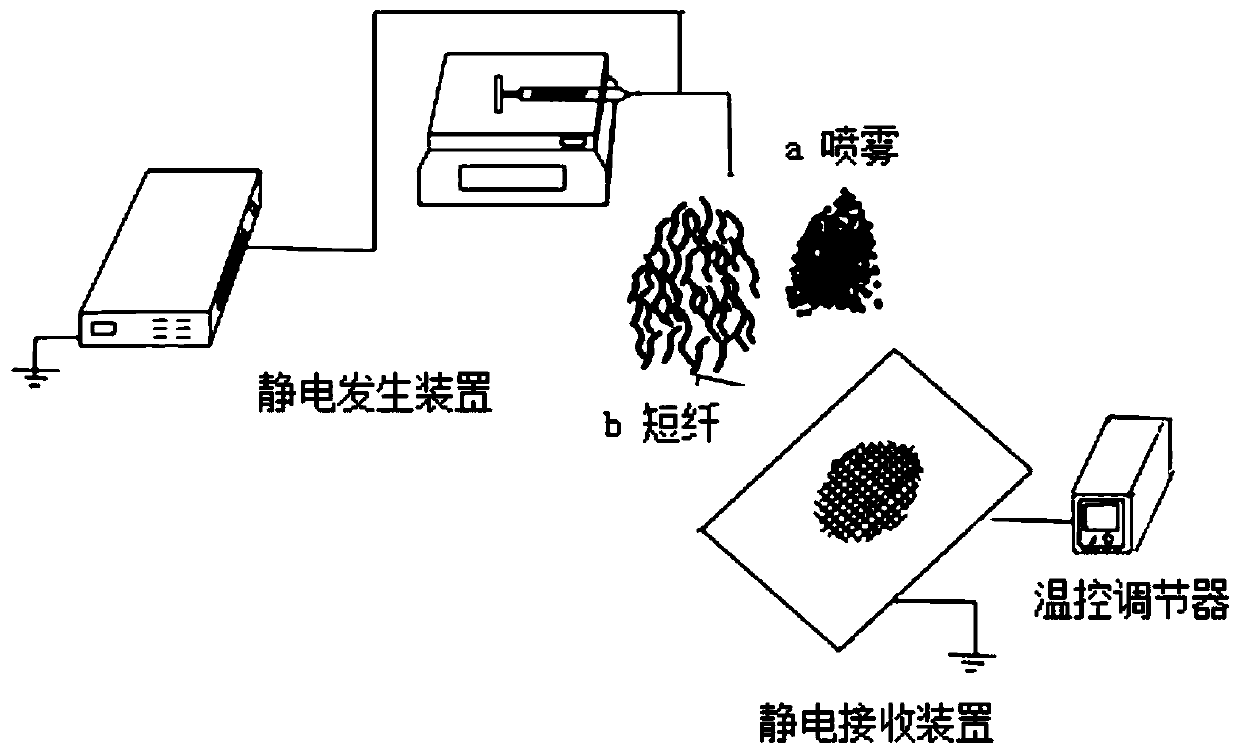

Solution spray type thermosetting electrospun composite membrane and preparation method and application thereof

InactiveCN110396770AEasy to operateImprove maneuverabilitySpinning solution filteringSpinning head liquid feederPorosityFiber

The invention belongs to the technical field of functional membrane materials, and particularly relates to a preparation method of a solution spray type thermosetting electrospun composite membrane. Apolymer, inorganic nanoparticles and an organic solvent are prepared into a spinning solution, and the membrane is formed by electrostatic spraying. By changing the proportion of the polymer to the solvent and the proportion of the inorganic nanoparticles to the polymer, the temperature of a receiving panel is adjusted so as to control the solid-liquid phase separation speed of membrane materials, and the regulation and control over the microstructure of the composite membrane are achieved. In the electrospinning process, the composite fibrous membrane can be directly woven; a mesh membrane is formed through melting-collapse and re-jointing of the fibrous membrane; or the membrane materials are sprayed out in the form of droplets to form the membrane, and the above two or three forms canbe combined. According to the prepared composite membrane, different polymers and inorganic nanoparticles can be replaced, and the prepared composite membrane has the advantages that the nanoparticlesare uniformly distributed, the specific surface area is large and the porosity is high; moreover, the prepared composite membrane has adsorption capacity and has a good application prospect in gas filtration and water treatment.

Owner:CHANGZHOU UNIV

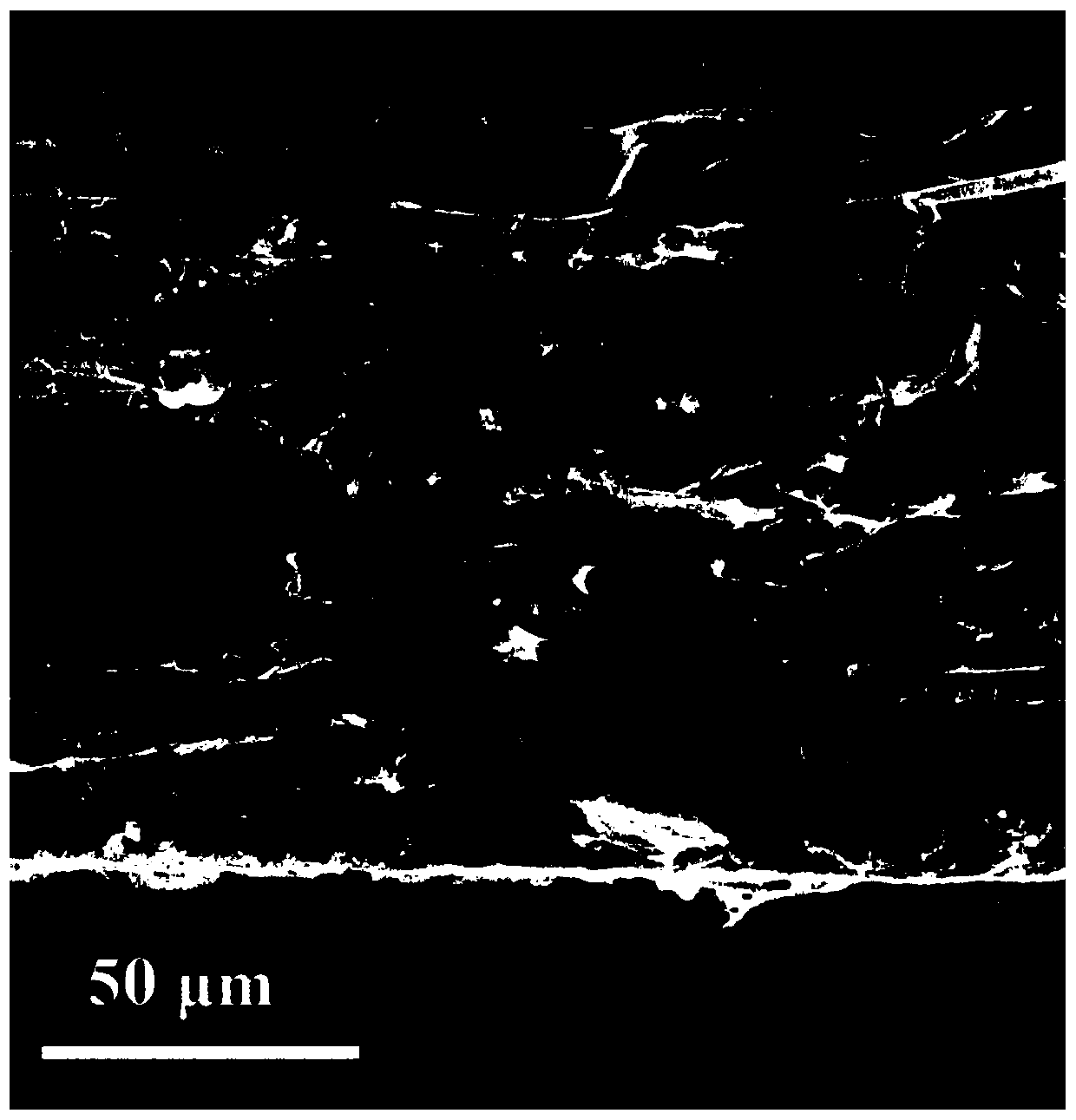

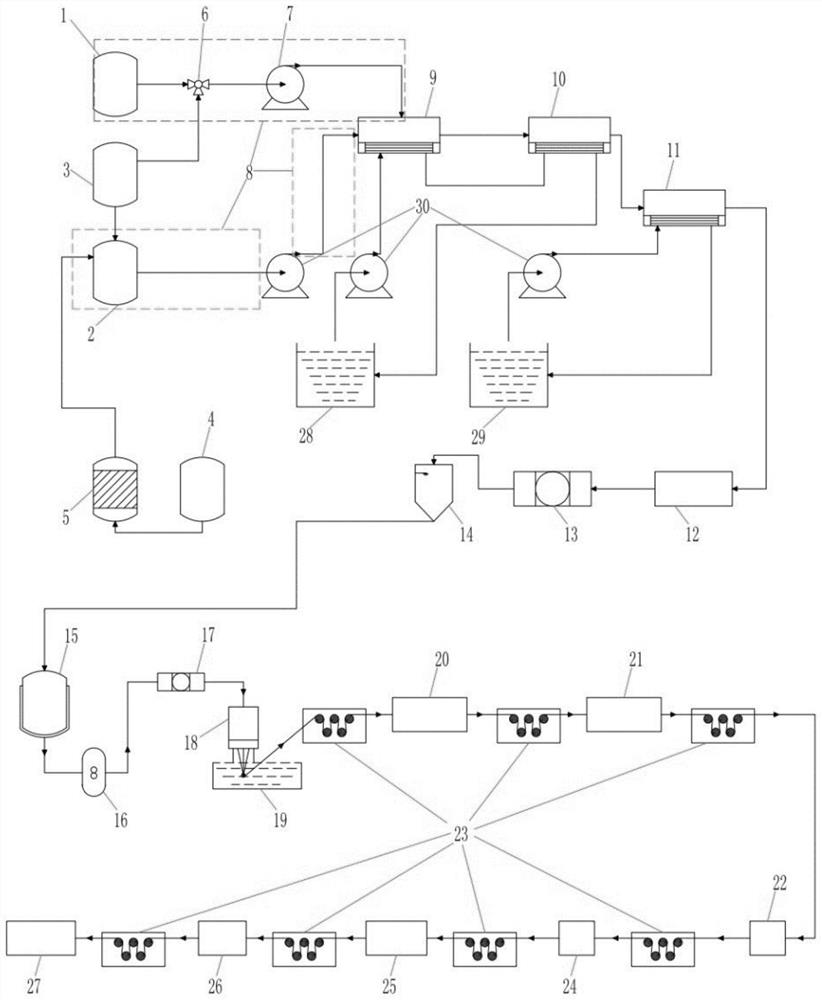

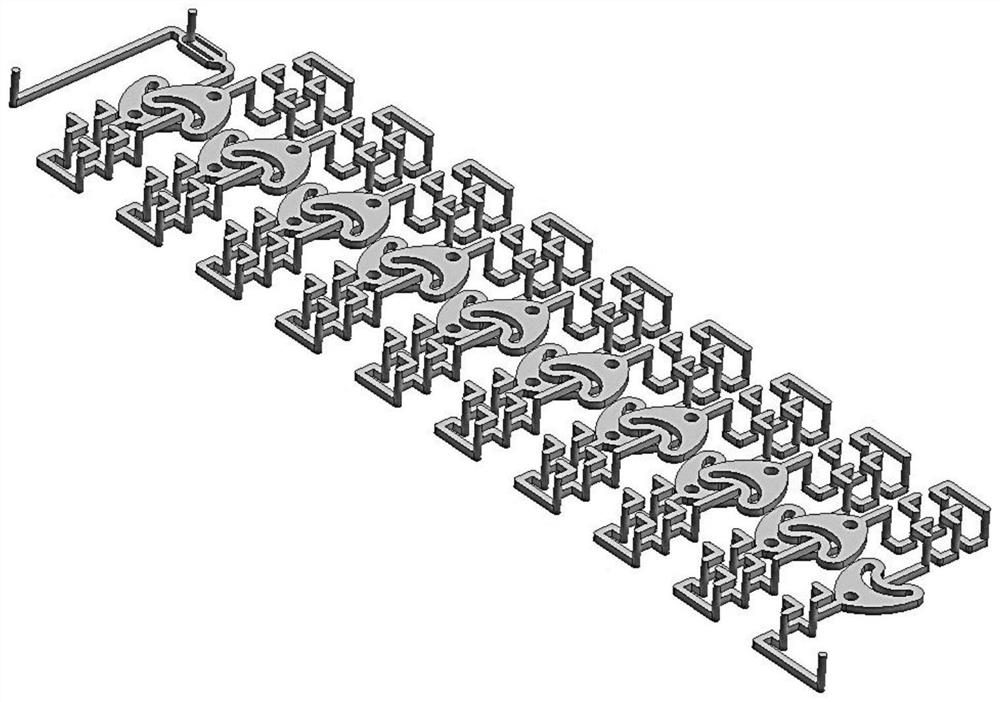

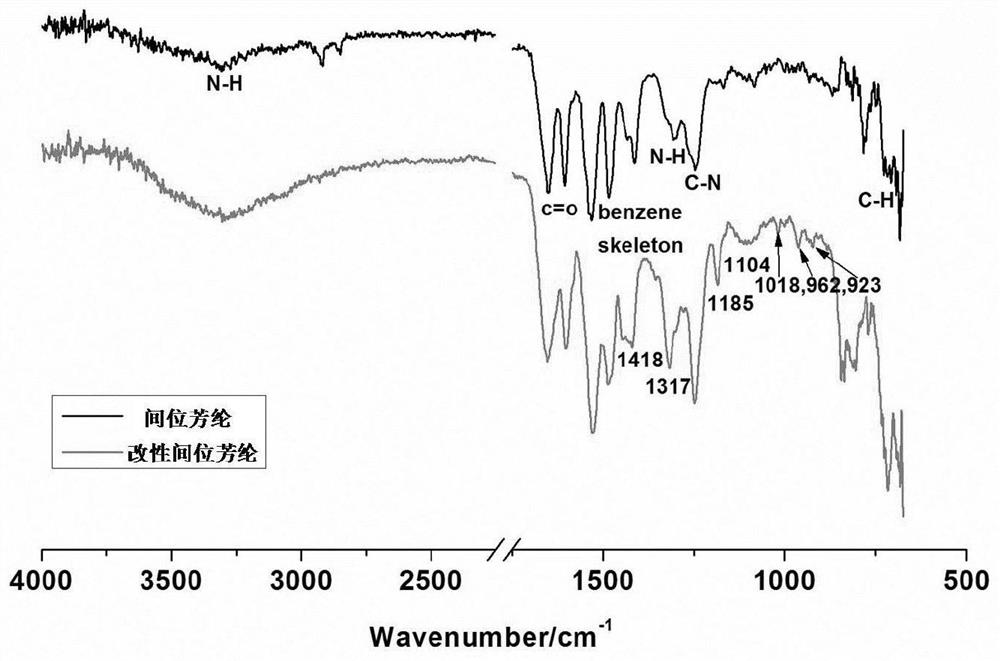

Method and device for preparing modified meta-aramid fiber through continuous polymerization-dry-wet spinning

ActiveCN113774509AImprove spinnabilityHigh molecular weightFlow mixersTransportation and packagingMicroreactorPolymer science

The invention discloses a method and a device for preparing modified meta-aramid fiber through continuous polymerization-dry-wet spinning. The method comprises the following steps that (1), a DMAc mixed solution of m-phenylenediamine and a copolymerized diamine monomer is prepared by using a cosolvent; (2), the isophthaloyl dichloride melt is mixed with a DMAc mixed solution of m-phenylenediamine and a copolymerized diamine monomer, and pre-polycondensation and polycondensation are carried out to obtain a modified meta-aramid resin solution; and (3), auxiliaries are added into the modified meta-aramid resin solution, filtering, defoaming, and spinning are carried out by a dry-wet method to obtain modified meta-aramid fibers. A pre-polymerization system of the continuous polymerization-dry-wet spinning device comprises a micro-mixer and a micro-reactor which are connected in sequence, and a micro-channel of the micro-reactor is designed to be heart-shaped; and the polycondensation system is a multi-stage microscrew combination. The problems in the preparation process of the meta-position aramid fiber are comprehensively solved, the obtained product is complete in structure, excellent in performance, stable and controllable, and continuous and efficient production can be achieved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

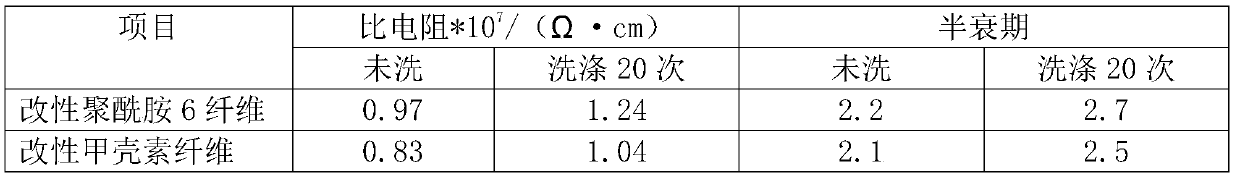

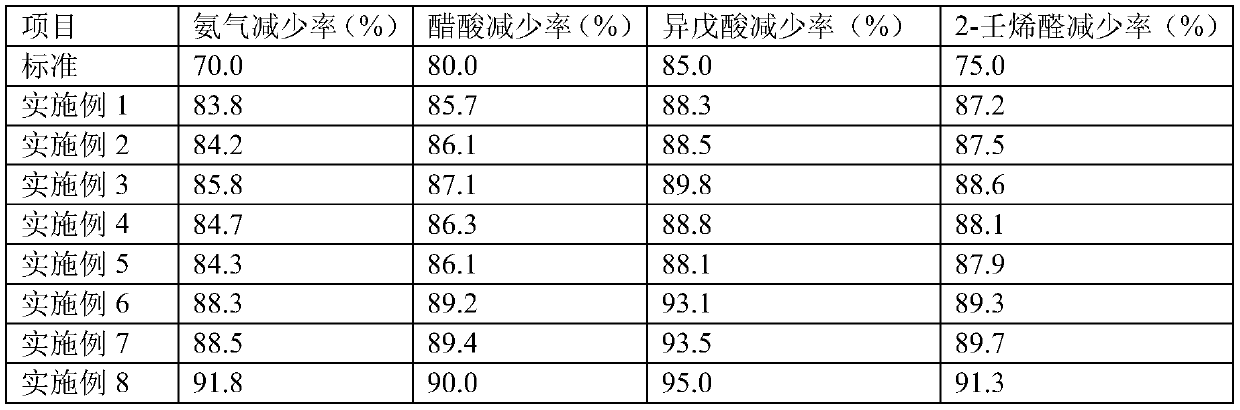

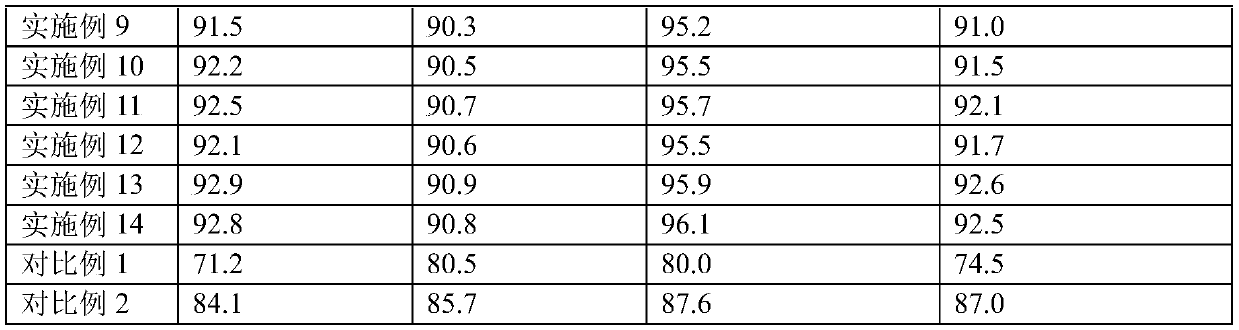

Antibacterial and antistatic garment fabric

InactiveCN111501162AImprove securityImprove antibacterial and antistatic abilitySpinning solution filteringElectroconductive/antistatic filament manufacturePolymer scienceAnti bacterial

The invention relates to antibacterial and antistatic garment fabric and belongs to the technical field of garment fabric. The antibacterial and antistatic garment fabric comprises the following components including, by weight, 15-25 parts of chitin fiber, 18-22 parts of chitosan fiber, 35-45 parts of tea fiber, 20-25 parts of folium isatidis viscose, 30-40 parts of modified polyamide 6 fiber and120-160 parts of antibacterial agents. According to the antibacterial and antistatic garment fabric, the effect of improving the antibacterial and antistatic performance of the garment fabric is achieved.

Owner:NINGBO ZHONGDI SHOES

Baffle plate type spandex defoaming apparatus

InactiveCN105463591AFlow levelingNo aggregationSpinning solution filteringEngineeringMechanical engineering

Owner:YANTAI TAYHO ADVANCED MATERIALS

Preparing method of polyimide fiber

InactiveCN106149087ASpinning solution filteringArtificial filament heat treatmentFiberPolymer science

The invention discloses a preparing method of polyimide fiber. The preparing method includes the following steps that three raw materials including 2-(4-aminophenyl)-5-aminobenzimidazole (BIA), p-phenylenediamine (p-PDA) and 3,3',4,4'-biphenyl tetramethyl anhydride (BPDA) are used for preparing BPDA / (p-PDA / BIA)(BPB) system ternary polymerization polyamide acid; bubble removal is carried out on the prepared ternary polymerization polyamide acid, and two-step method wet spinning is adopted to prepare polyamide acid fiber; imidization is carried out on the polyamide acid fiber at the temperature of 450-500 DEG C for intramolecular dehydration; rolling and aftertreatment are carried out finally. The prepared polyimide fiber is excellent in mechanical performance and surface performance, and the method is simple and environmentally friendly.

Owner:高海燕

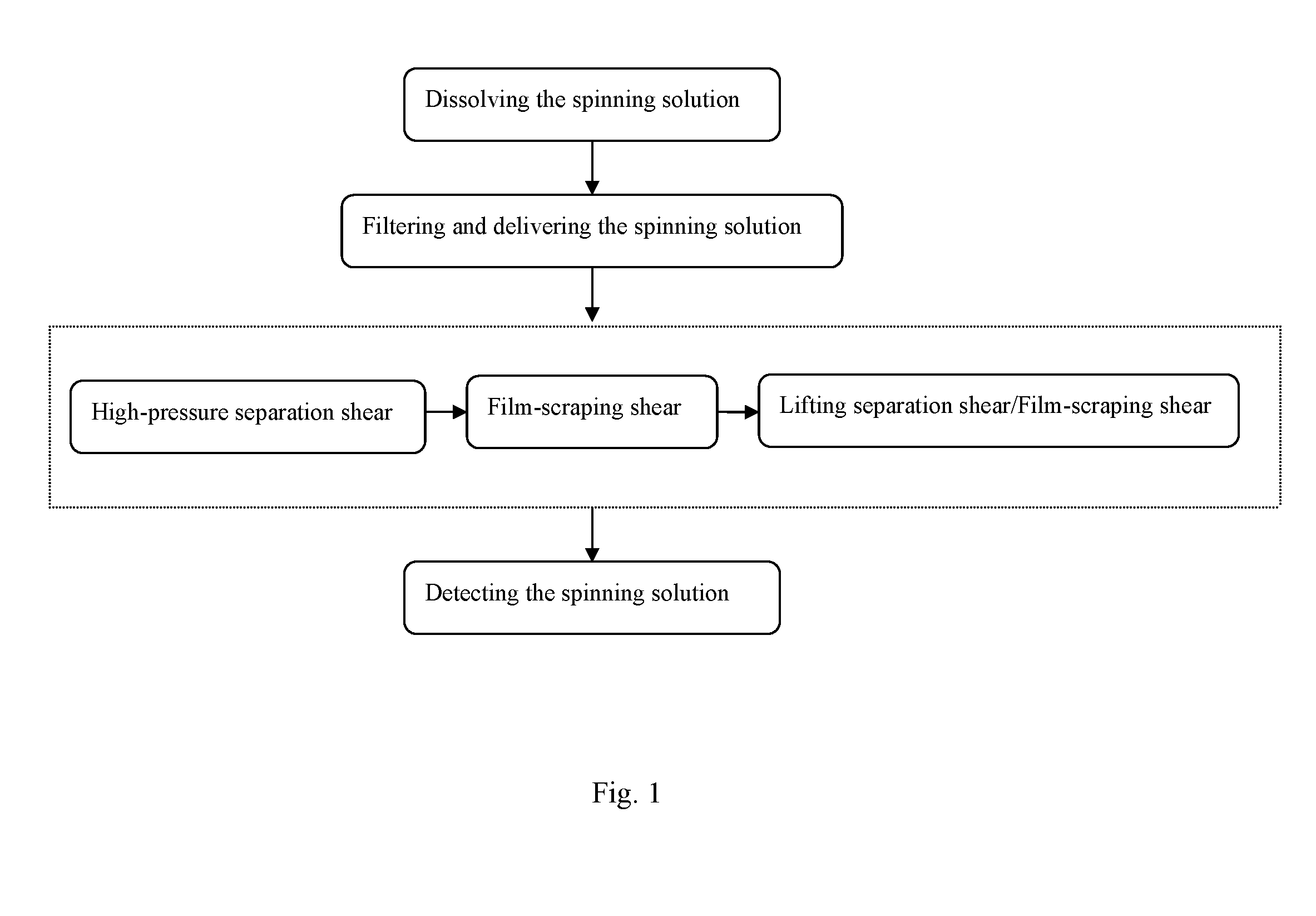

Composite defoaming method for high-viscosity pure chitosan spinning solution

ActiveUS20160214035A1Increase the areaHigh-efficiency high-quality degassing operationSpinning solution filteringRotary stirring mixersPolymer scienceSpinning

A combined degassing method for a high-viscosity pure-chitosan spinning solution, including: step 1, thoroughly dissolving the spinning solution in a dissolution vessel for subsequent use, the viscosity reaching 450,000-500,000 mpa·s; step 2, delivering the spinning solution in step 1 to the feed port of a degassing vessel from the dissolution vessel after filtration; step 3, in the degassing vessel, under the conditions of vacuumizing and maintaining the inner pressure of the degassing vessel to be 500-3,000 Pa, performing continuous treatment by a combined degassing process integrating separation, film-scraping, lifting and shear; and step 4, sampling at a sampling port for the detection of degassing degree, finishing the degassing operation if the detection result is eligible, otherwise repeating step (3) until the detection result is eligible. This method has high degassing efficiency and good degassing effect, and is applicable to spinning solutions of a wide range of viscosity.

Owner:HISMER BIO TECH

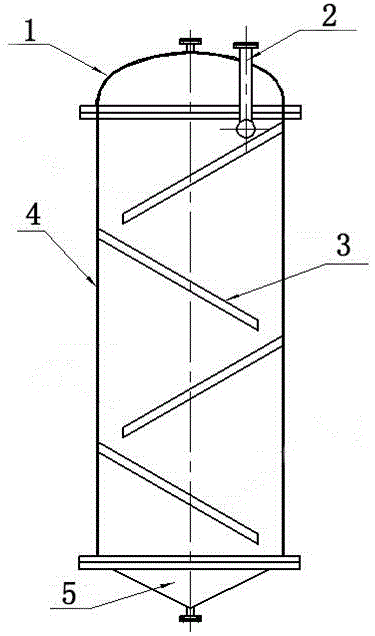

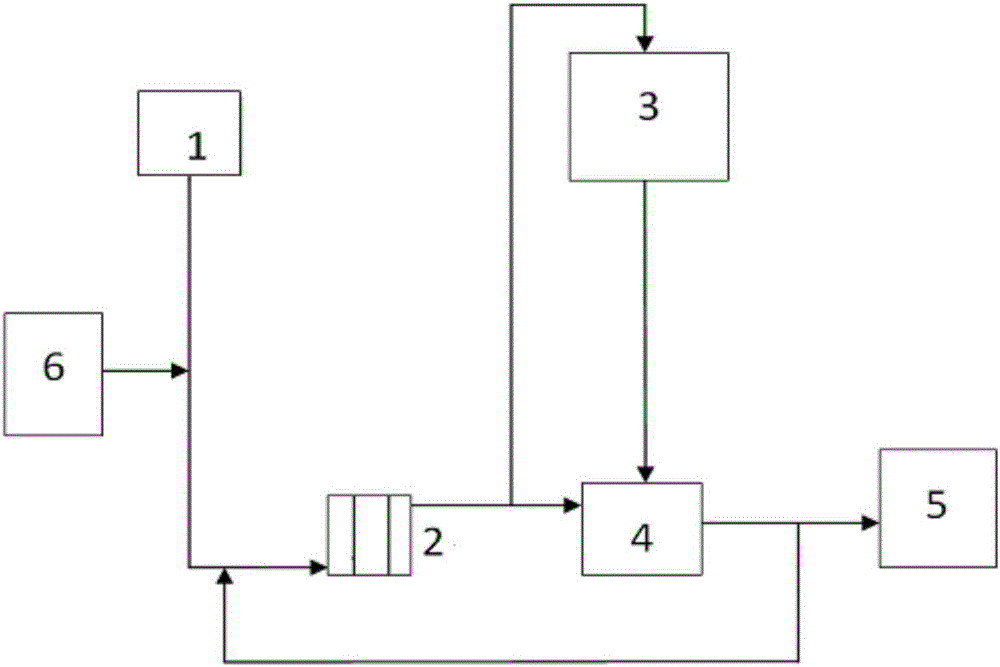

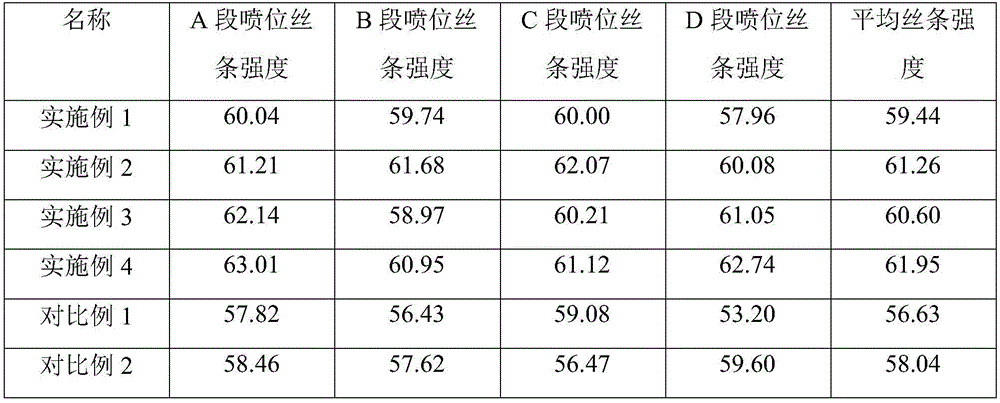

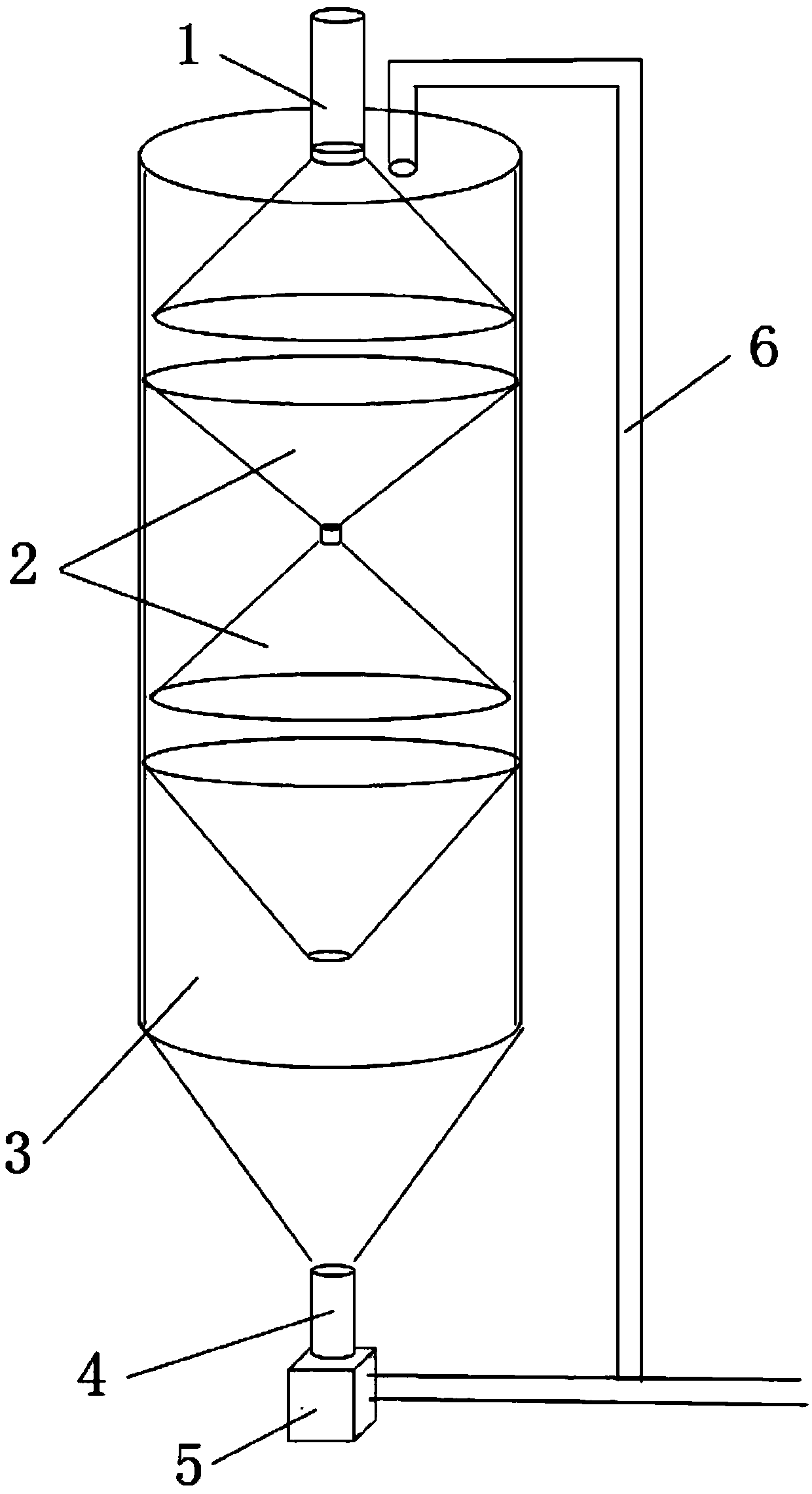

System and method for reducing carbon fiber spinning stoste bubbles

ActiveCN106087077AExtended stayIntensity fluctuation range is smallSpinning solution filteringCarbon fibersEngineering

The invention relates to a system and a method for reducing carbon fiber spinning stoste bubbles, and belongs to the field of methods for treating carbon fiber spinning stoste. The system comprises a demonomerisation and defoaming tower and a spinning unit, wherein the demonomerisation and defoaming tower comprises a secondary demonomerisation and defoaming tower and a tertiary demonomerisation and defoaming tower; a buffering tank is arranged between the secondary demonomerisation and defoaming tower and the tertiary demonomerisation and defoaming tower; the spinning unit is arranged behind the tertiary demonomerisation and defoaming tower; spinning stoste enters the buffering tank after being defoamed by the secondary demonomerisation and defoaming tower, and an initiator in the spinning stoste is decomposed in the buffering tank; the obtained spinning stoste enters the tertiary demonomerisation and defoaming tower for treatment. According to the method, the buffering tank is additionally arranged between the secondary demonomerisation process and the tertiary demonomerisation process, so that the initiator can be fully decomposed, and then the spinning stoste is defoamed through the tertiary demonomerisation and defoaming tower. After the method is used, the quantity of broken silks from a spinning nozzle is obviously reduced, and the tensile strength of raw silks is also enhanced.

Owner:兰州蓝星纤维有限公司

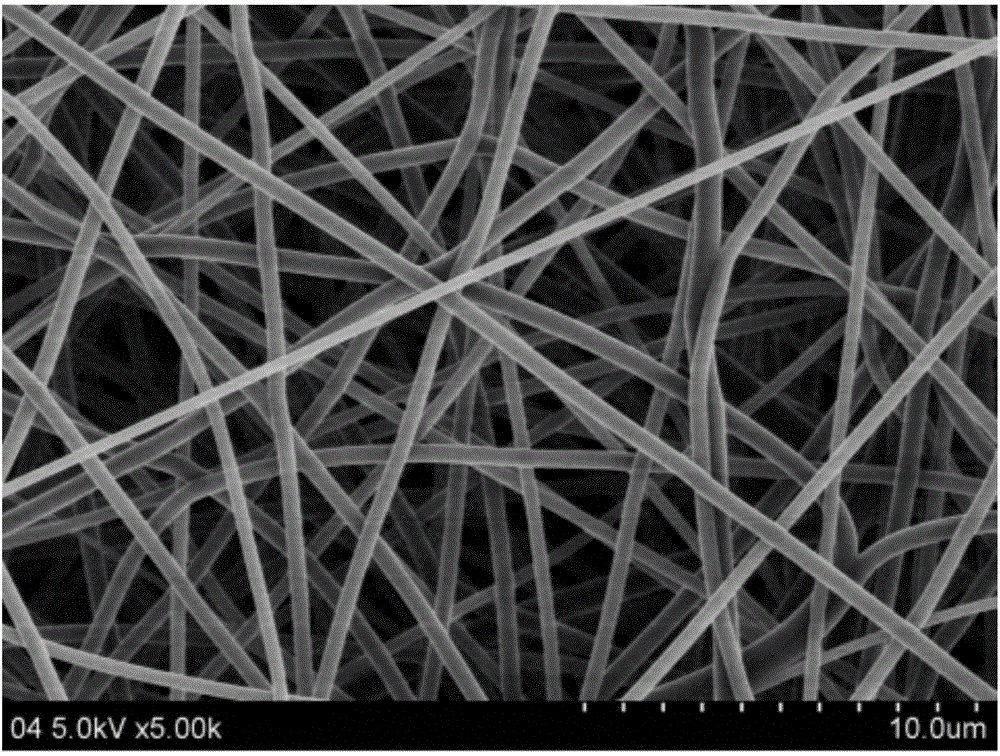

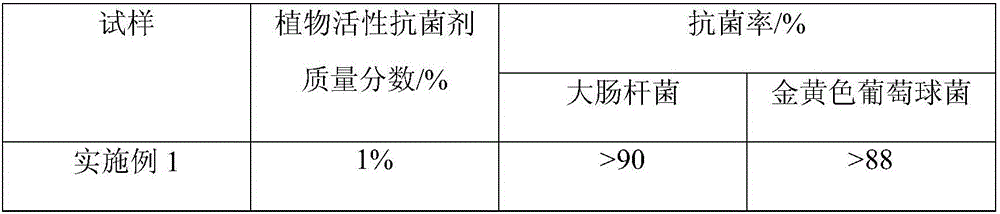

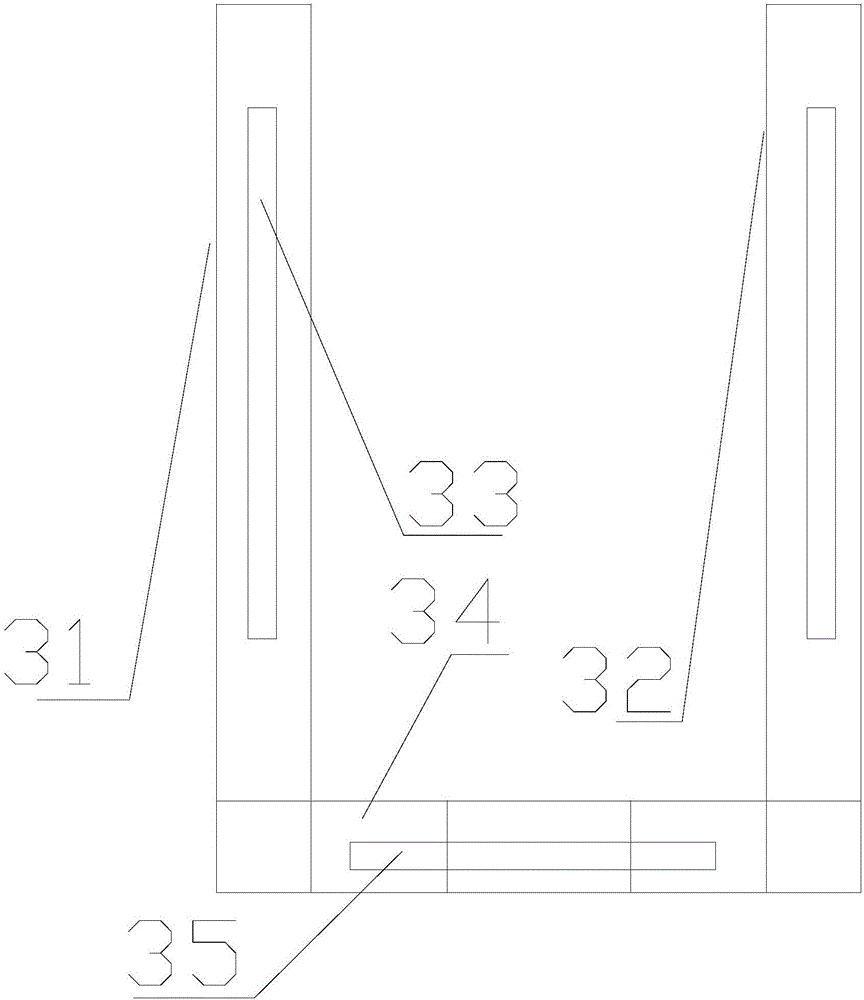

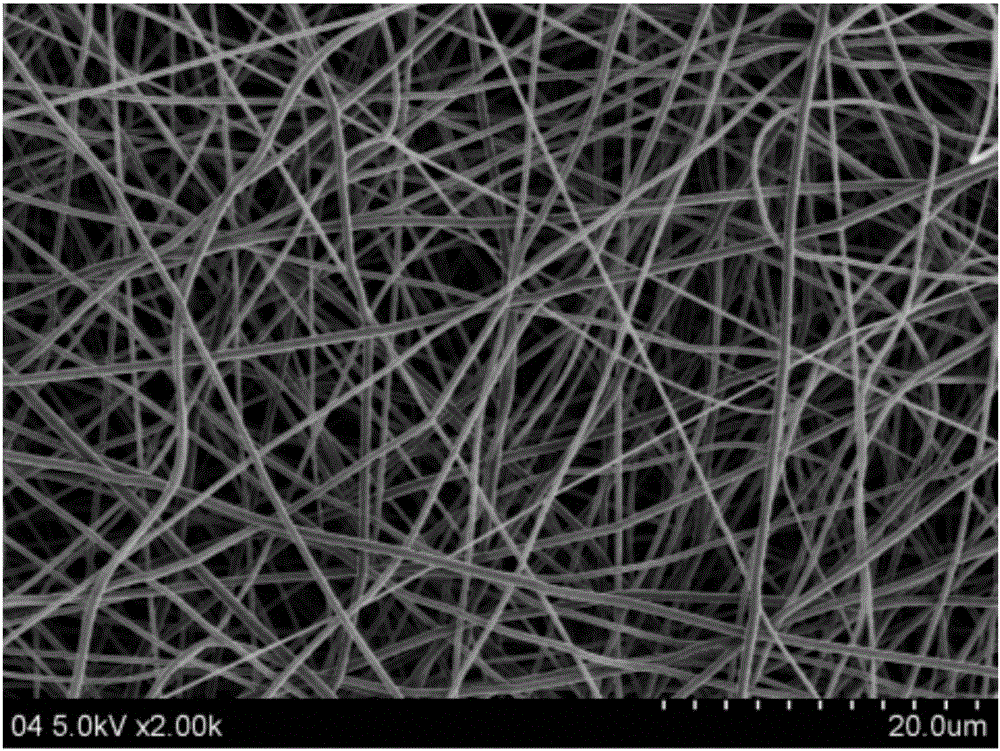

Method for preparing dandelion phenol activity antibacterial agent and chitosan composite nanofiber felt

InactiveCN105696196AReduce dosageEasy to makeSpinning solution filteringFilament/thread formingComposite nanofibersWound dressing

The invention relates to a method for preparing dandelion phenol activity antibacterial agent and chitosan composite nanofiber felt. The method comprises the steps of dissolving chitosan in formic acid solution, and performing stirring to obtain chitosan solution; adding a dandelion phenol activity antibacterial agent extracted from plants, performing stirring and ultrasonic degassing to obtain dandelion phenol activity antibacterial agent / chitosan solution; and performing electrostatic spinning to obtain the felt. The method is simple and practical and is apt to industrialization; the obtained plant activity antibacterial agent and chitosan composite nanofiber felt can be used for the fields such as wound dressing, is excellent is antibacterial effect and has wide application prospects.

Owner:DONGHUA UNIV +1

Method for preparing polytetrafluoroethylene superfine fiber and electrostatic spinning device thereof

ActiveCN106192052AHigh strengthEliminate post-processing stepsSpinning solution filteringElectro-spinningFiberElectrospinning

The invention provides a method for manufacturing a polytetrafluoroethylene superfine fiber and an electrostatic spinning device thereof. The method comprises the steps of dissolving polytetrafluoroethylene in N-methyl pyrrolidone, adding graphene, performing ultrasonic dispersion evenly, and obtaining spinning solution; after the spinning solution is defoamed, performing electrostatic spinning at a spinning speed of 3.0-5.0 ml / h and a spinning voltage of 20-25 kV in the presence of ionic wind, and obtaining the polytetrafluoroethylene superfine fiber. The method has the advantages that ions are generated around the position of a pinhole of a needle through the weak ionic wind, the ions neutralize part of electric charges on the jet flow surface, so that the jet flow stability and whipping controllability are enhanced, and not only can instable whipping of jet flow be avoided, but also over-distance orderly output of cellosilk can be performed.

Owner:江苏金由新材料有限公司

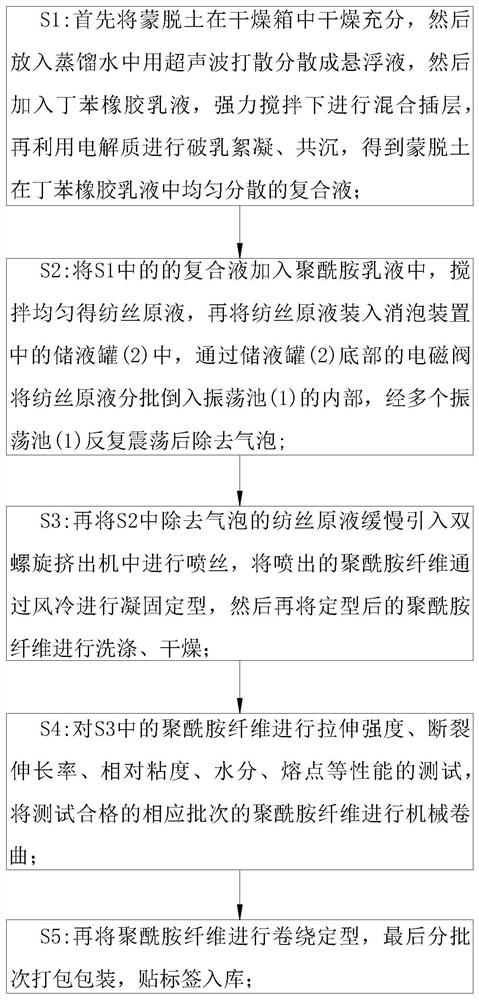

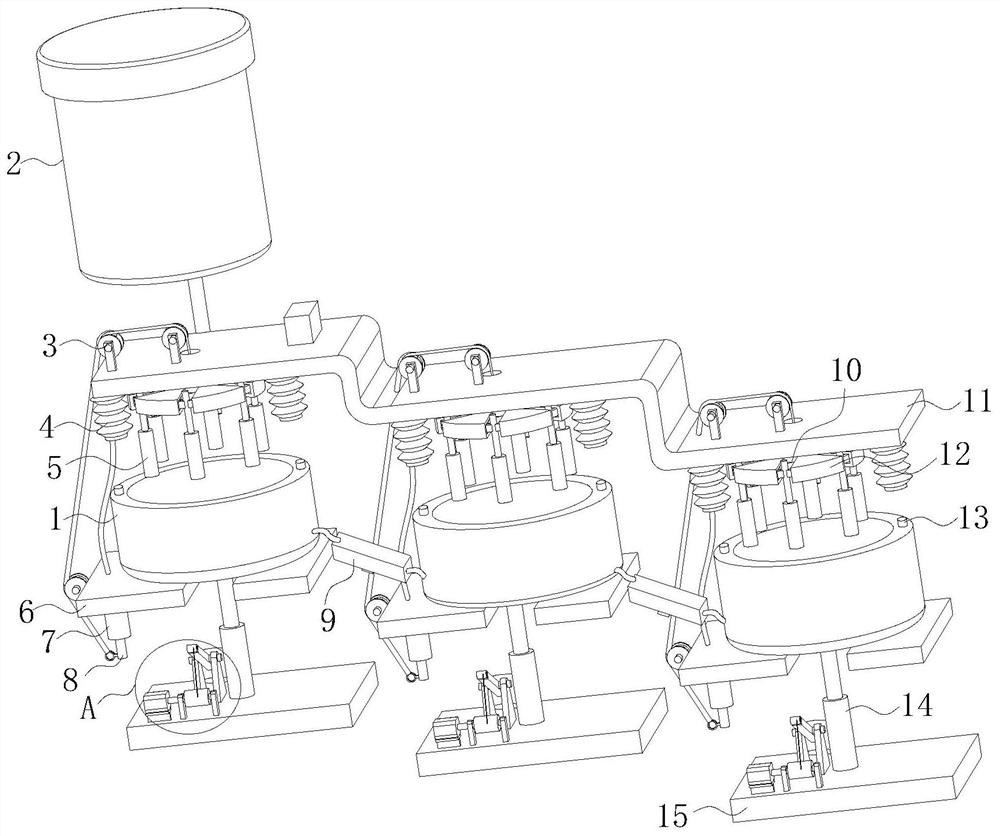

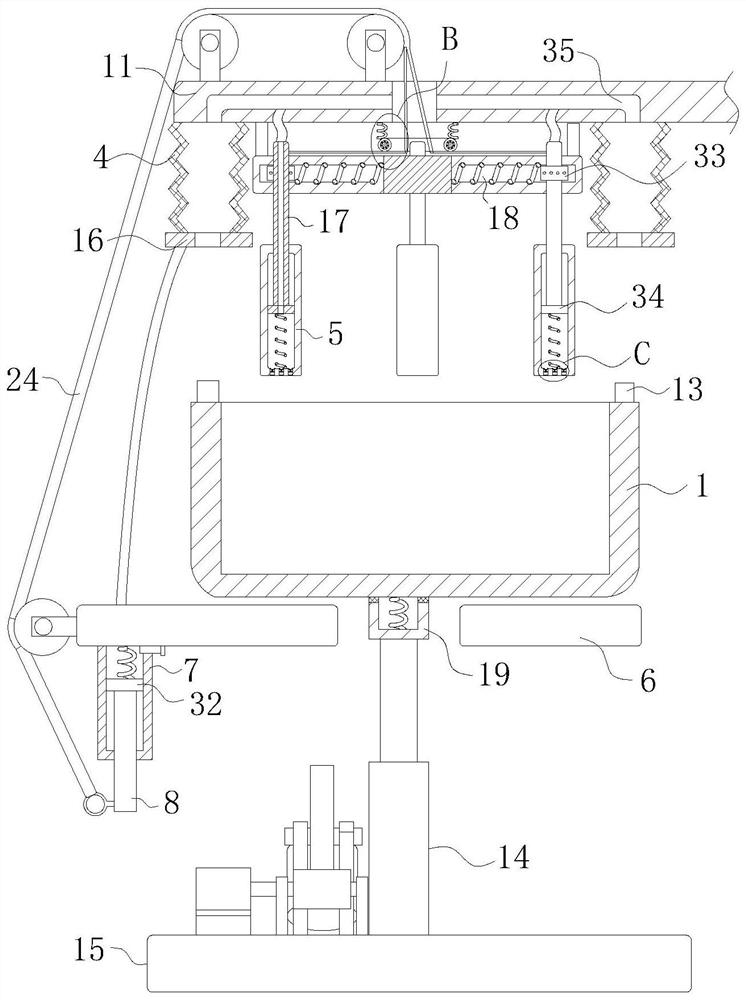

Polyamide fiber

InactiveCN111893594AEasy to moveConducive to blastingSpinning solution filteringSpinning solution de-aeratingPolymer scienceSpinning

The invention belongs to the technical field of polyamide fibers and specifically relates to a polyamide fiber. A preparation process of the polyamide fiber comprises the following steps of S1, sufficiently drying montmorillonite in a drying box first; and then putting the montmorillonite into distilled water to be scattered and dispersed by using ultrasonic waves to obtain a suspension liquid; and then adding butadiene styrene rubber emulsion to the suspension liquid; carrying out mixed intercalation on an obtained mixture during strong stirring; and carrying out demulsification flocculationand coprecipitation by using electrolyte to obtain complex liquid in which the montmorillonite is uniformly dispersed in the butadiene styrene rubber emulsion. According to the polyamide fiber, by adding a spinning solution in a solution storage tank to vibration ponds in batches, bubbles in the spinning solution can be eliminated in a vibrating manner through up-and-down vibrating of the vibration ponds; as multiple groups of vibrating ponds are arranged, the spinning solution in the same batch is vibrated for multiple times by using the multiple vibration ponds so that the bubble eliminatingefficiency can be greatly enhanced; and as inserting and tamping rods are arranged at the tops of the vibration ponds, the spinning solution can collide with the inserting and tamping rods in a contacting manner in the upwardly moving process of the vibration ponds so that the bubbles in the spinning solution can be broken up.

Owner:李卓

Beauty maintaining and young keeping sea cucumber cellulose fiber and making method thereof

ActiveCN107268097AEliminates hyperpigmentationStay flexibleAntibacterial agentsCosmetic preparationsWrinkle skinSlurry

The invention provides a beauty maintaining and young keeping sea cucumber cellulose fiber. The dry fracture strength is not less than 2.8 cN / dtex, the wet fracture strength is not less than 2.1 cN / dtex, the sea cucumber collagen content is not less than 2%, the dry breaking elongation is 12-14%, and the wet breaking elongation is 17-19%. The invention also provides a making method of the beauty maintaining and young keeping sea cucumber cellulose fiber. The method comprises a step of preparation of a sea cucumber slurry, and the sea cucumber slurry preparation step comprises desalting, pulping, chemical water treatment and heating. An under product made of the beauty maintaining and young keeping sea cucumber cellulose fiber can repair human face tissues, and collagens contained in the fiber can make skins keep elastic, prevent and reduce wrinkles and eliminate face pigment deposition, so the fiber is a good raw material for making face masks, breast masks and wet wipes.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Defoaming device and defoaming method for aramid fiber III spinning solution

InactiveCN109537066AGuaranteed stabilityEvenly dispersedSpinning solution filteringEngineeringStatic mode

The invention discloses a defoaming device and a defoaming method for an aramid fiber III spinning solution. The defoaming device comprises a defoaming tank and a circulatory system arranged on the outside of the defoaming tank, wherein a spinning solution feeding opening and a vacuum pump are arranged at the top of the defoaming tank; a discharging opening with a spinning solution delivery pump is formed in the bottom of the defoaming tank; the circulatory system is connected with the discharging opening and the spinning solution feeding opening; a multistage umbrella plate device for defoaming is arranged in the defoaming tank. According to the defoaming device disclosed by the invention, by adopting the multistage umbrella plate device, a high viscosity aramid fiber III spinning solution enters the multi-stage umbrella plate device in the defoaming tank through the feeding opening, the defoaming efficiency of a static mode in the prior art is improved and the structure of the defoaming tank is simplified. The device has the advantages of simple structure, low cost and small occupied area. When the device is used for a defoaming process, the number of the obtained minute bubbleswith the diameter below 0.03 mm is smaller than 5 and the loss amount of solvents in the defoaming process is smaller than 0.5 percent.

Owner:四川辉腾科技股份有限公司

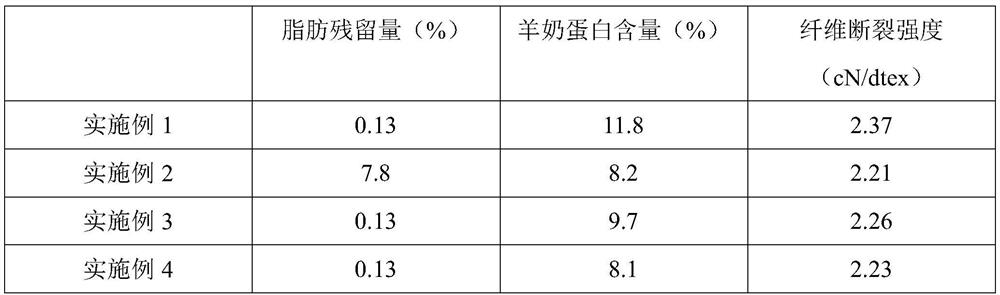

Goat milk protein fibers and preparation method thereof

InactiveCN112760726APerfect method stepsImprove product qualitySpinning solution filteringConjugated cellulose/protein artificial filamentsViscoseEngineering

The invention discloses a preparation method of goat milk protein fibers, and solves the problems of poor degreasing effect and poor quality. The preparation method comprises the following steps of 1, taking goat milk, adding a nonionic surfactant, stirring, removing an upper-layer substance, adding ethanol, keeping the temperature for 0.5-1.0 h, removing the upper-layer substance, heating until boiling, filtering and drying to obtain goat milk protein powder; 2, dissolving goat milk protein powder in a sodium hydroxide solution, filtering, adding a cyclodextrine solution, dissolving step by step, stirring and mixing to obtain a goat milk protein solution; 3, quantitatively adding a cross-linking agent into the goat milk protein solution, carrying out defoaming treatment, mixing the goat milk protein mixed solution with viscose according to a ratio, and carrying out defoaming; 4, carrying out two-bath wet spinning on the mixed solution to obtain viscose trickles; 5, enabling the viscose trickles to be coagulated and formed through a coagulating bath, and obtaining fiber tows through a solidifying bath; 6, enabling the fiber tows to be subjected to aftertreatment, and obtaining the goat milk protein fibers. The method has the advantages of improving the degreasing effect and the fiber quality and the like.

Owner:YIBIN SPARK NEW FIBER CO LTD

Flexible fiber having flame retardancy and preparation method thereof

ActiveCN106609401ABiodegradableSoft textureSpinning solution filteringFlame-proof filament manufactureCellulose fiberCellulose pulp

The invention relates to a flexible fiber having flame retardancy and a preparation method thereof. The flexible fiber is prepared from 1.5 to 2.5 parts by weight of a cellulose pulp plate, 17 to 19 parts by weight of an ionic liquid, 1.5 to 2 parts by weight of amino silicone oil and 19 to 21 parts by weight of hydroxyl silicone oil. The preparation method comprises putting the cellulose pulp plate in the ionic liquid to obtain a cellulose solution, adding the amino silicone oil into the cellulose solution to obtain a blended spinning liquid, carrying out ultrasonic treatment and standing to remove bubbles, carrying out spinning through a dry-jet wet spinning technology, collecting fibers, soaking the fibers in deionized water, carrying out drying, dipping the fibers in the hydroxyl silicone oil for surface coating and carrying out drying. The preparation method has simple processes. The prepared fiber is soft, has flame retardant effects and provides broad prospects for the application of cellulose fiber products.

Owner:BEIJING FORESTRY UNIVERSITY

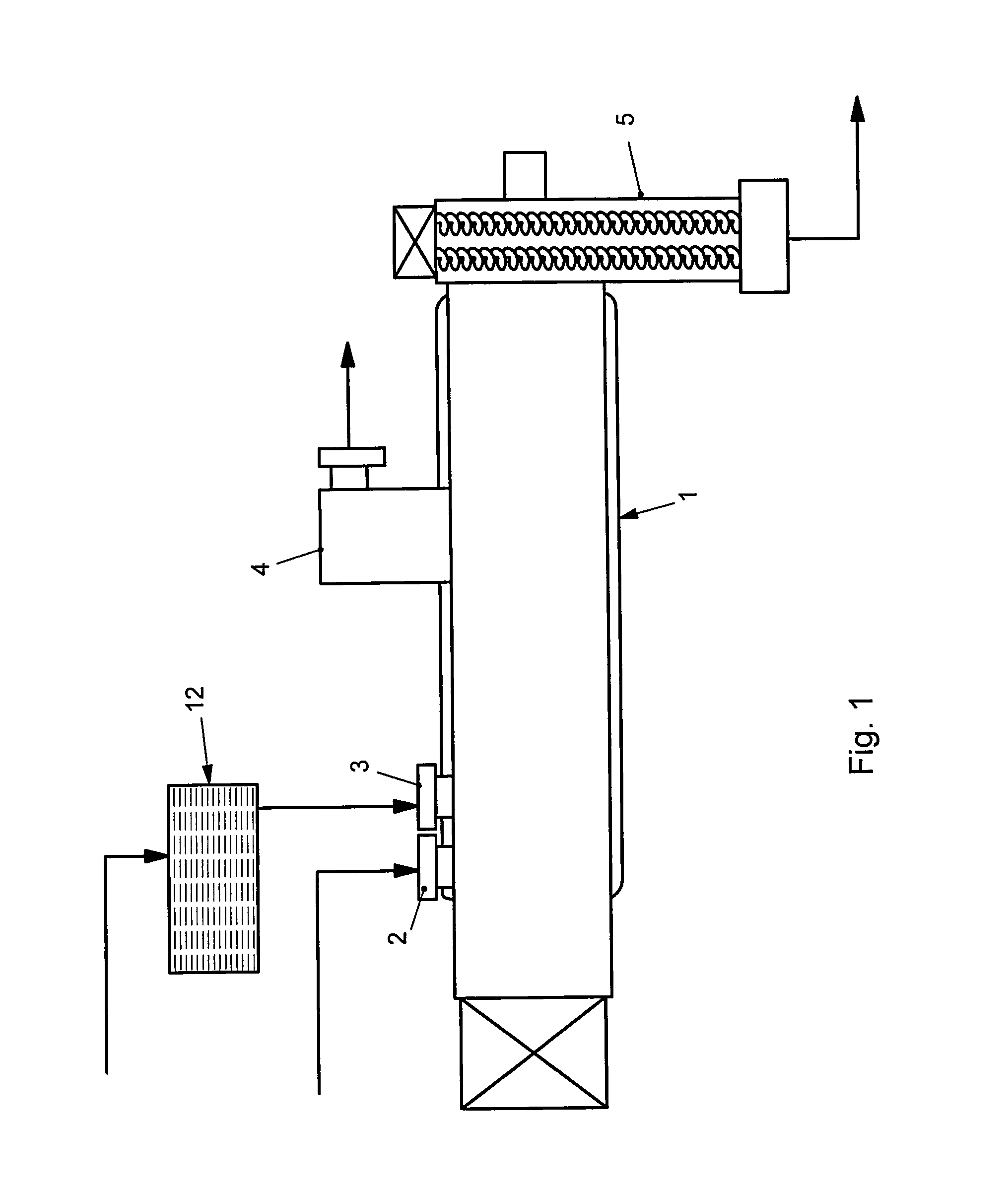

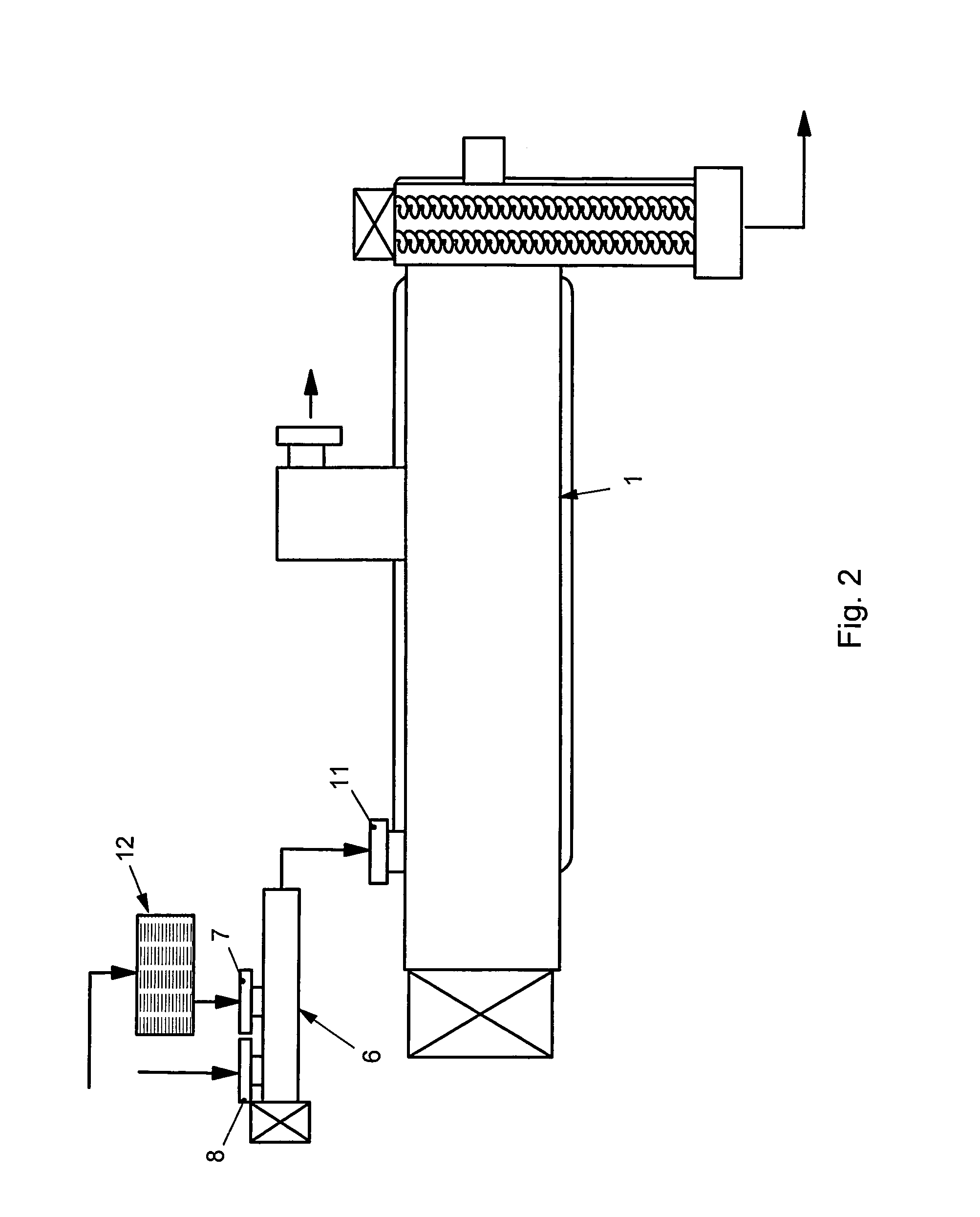

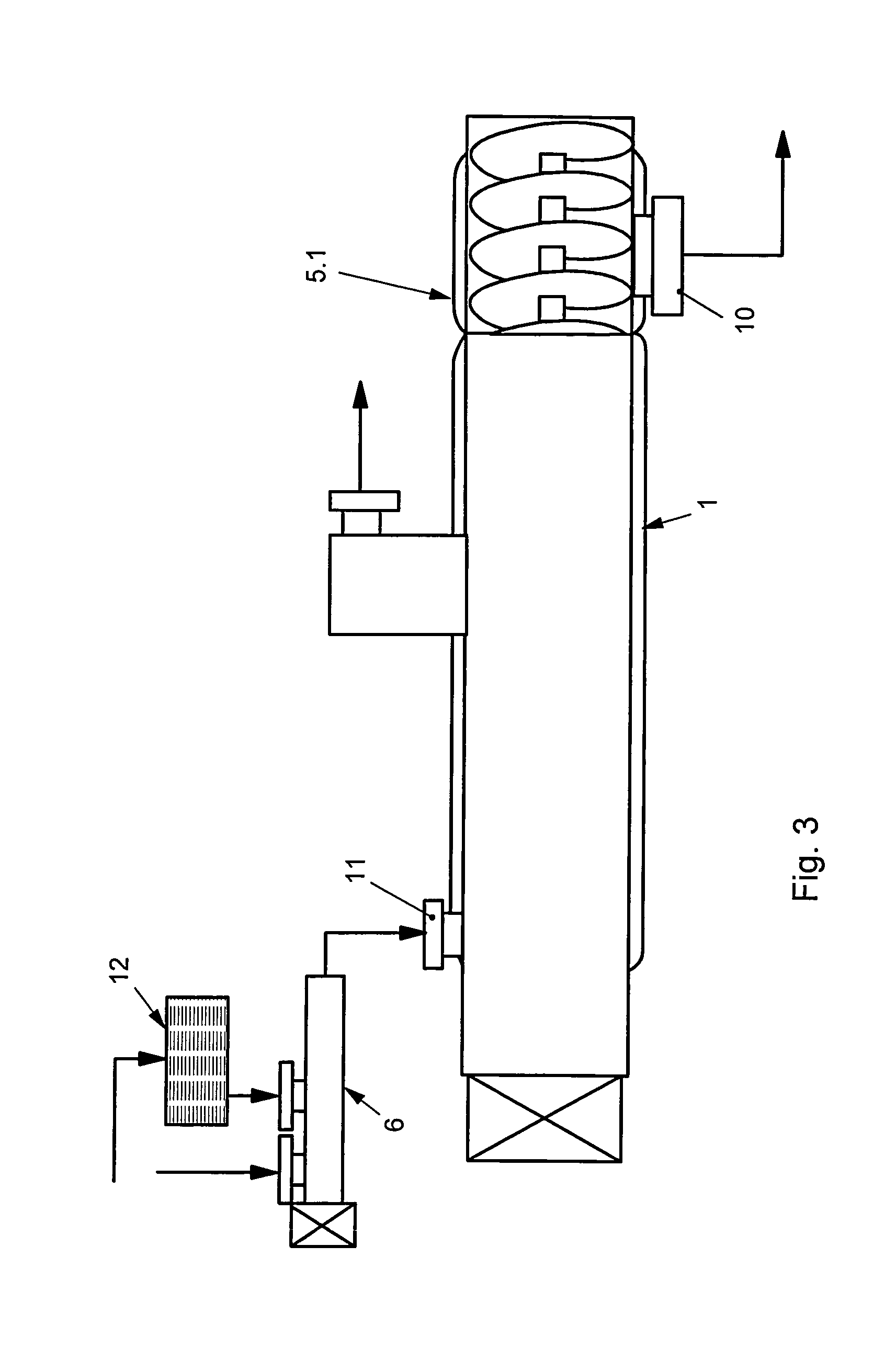

Method and system for producing a spinning solution for producing a polymer fiber

ActiveUS8129460B2Significantly simplerLess costlySpinning solution filteringLiquid degasificationPolymer sciencePolyamide

A method for producing a spinning solution for producing a polymer fiber, particularly a p-aramid fiber, the polymer being blended with a solvent, mixed, melted, homogenized, and degassed and then discharged, liquid sulfuric acid being used as the solvent and at least the mixing, homogenization, and degassing taking place in a preferably continuously operated single or double cell reactor (1).

Owner:LIST TECHNOLOGY AG

Method for utilizing low intermediate phase content asphalt stock to perform continuous spinning to prepare high-quality intermediate phase asphalt precursor fiber

ActiveCN107488876AIncrease profitImprove qualitySpinning solution filteringFilament forming substance formingFiberMetering pump

The invention relates to a method for efficiently utilizing low intermediate phase content asphalt to perform direct spinning to prepare high-quality intermediate phase asphalt precursor fiber. According to the method, the low intermediate phase content asphalt is adopted as a raw material, and the method comprises the steps: (1) determining the specific content of an intermediate phase; (2) adding the asphalt to a stirring tank, pressurizing with inert gas, and performing stirring and heating, to fully melt the asphalt; (3) after the asphalt is fully melted, stopping stirring and standing, so as to sink the intermediate phase of the asphalt to the lower portion of melt; (4) depressurizing and vacuumizing to remove bubbles in the molten asphalt; (5) cooling the molten asphalt to a spinning temperature, pressurizing with an inert gas, and switching on a valve to cause the asphalt on the lower portion to enter a spinning machine through a metering pump for spinning, and stopping spinning when the weight of the spun asphalt precursor fiber is lower than or equal to the weight of the intermediate phase in the raw material. According to the method, the utilization rate of the asphalt with the low intermediate phase content can be greatly improved, and the intermediate phase preparation cost and the cost of high-performance pitch-based carbon fiber are reduced.

Owner:上海高强高模新材料科技有限公司

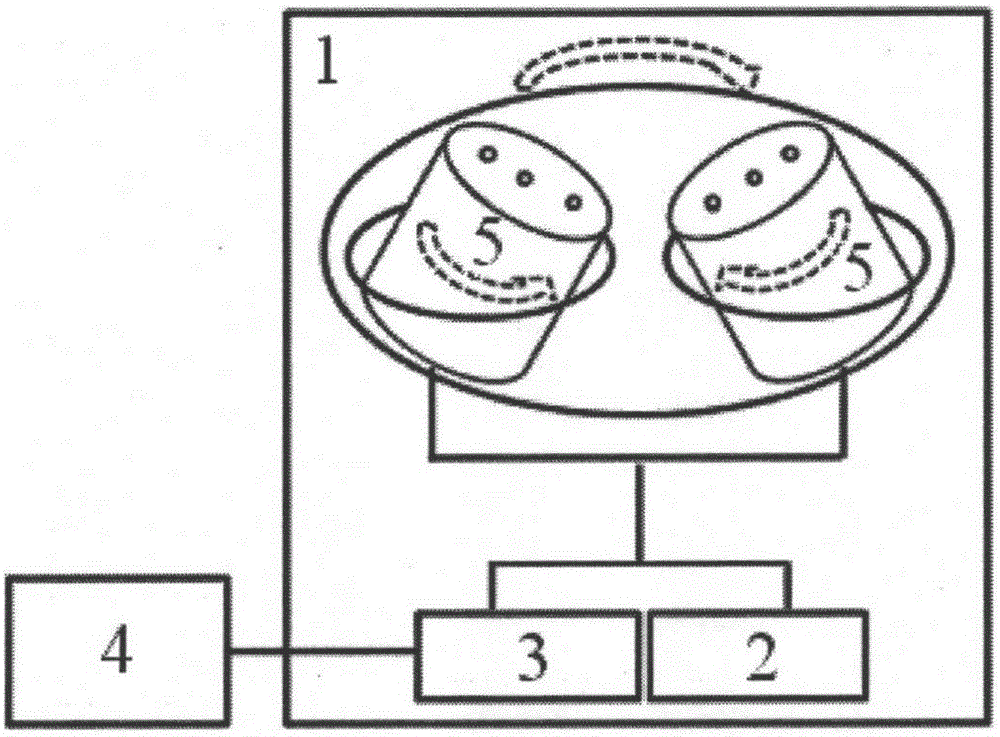

Equipment and method for non-contact dissolution and deaeration of high-concentration and high-viscosity spinning solution

InactiveCN106222761AEfficient SolubilityEfficient defoamingSpinning solution filteringSpinning solutions preparationHigh concentrationTemperature control

The invention discloses a piece of equipment and a method for non-contact dissolution and deaeration of a high-concentration and high-viscosity spinning solution. The equipment for the dissolution and deaeration comprises a gear assembly, wherein a material cup is disposed on the gear assembly; and the material cup is connected to a temperature control device and a pressure control device respectively. The method for the dissolution and deaeration comprises the steps that a polymer and a solvent are directly added into the material cup, the temperature control device is started, the gear assembly is started, revolution and rotation of the material cup are conducted, temperature and rotation speeds are adjusted, and the spinning solution is obtained after the dissolution of the polymer and the solvent; and the pressure control device is then started, the temperature and the rotation speeds are adjusted, and the transparent and clear spinning solution is obtained after the deaeration of the spinning solution. According to the invention, raw materials are dissolved firstly under a zero vacuum degree or a low vacuum degree to prepare the spinning solution; and then, the deaeration of the spinning solution is conducted under a high vacuum degree, and the dissolution and the deaeration of the spinning solution can be completed in the same equipment. In this way, integration of the efficient dissolution and the efficient deaeration of the spinning solution can be achieved; and efficiency of the dissolution and the deaeration can be increased.

Owner:DONGHUA UNIV +1

Preparation method of polyimide nanofiber

ActiveCN109666979AGood diameter uniformityImprove spinning efficiencySpinning solution filteringSpinning solution de-aeratingOrganic solventElectrospinning

The invention relates to a preparation method of polyimide nanofiber, and mainly aims to solve the problems of poor diameter uniformity of the polyimide nanofiber and tendency to form beads in electrostatic spinning due to wide molecular weight distribution and large quantity of gel particles during preparation of the polyimide nanofiber with a two-step process in the prior art. The preparation method of the polyimide nanofiber comprises the following steps: dissolving X mole of diamine in an organic solvent, and adding Y mole of dianhydride for reacting to obtain a prepolymer solution 1; dissolving Z mole of diamine in an organic solvent, adding K mole of dianhydride for reacting to obtain a prepolymer solution 2; adding the prepolymer solution 2 into the prepolymer solution 1 to obtain apolyamide acid solution; deaerating and filtering the polyamide acid solution, and performing electrostatic spinning and amination to obtain uniform polyimide nanofiber. By adopting the preparation method, the problems are well solved. The preparation method can be applied to the continuous production of the polyimide nanofiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Viscosity homogenizing/bubble removing integrated device and method for preceramic polymer spinning melt

ActiveCN110158161AAchieve uniform temperature and uniform viscosityImprove performanceSpinning solution filteringSpinning head liquid feederEngineeringMetering pump

The invention relates to a viscosity homogenizing / bubble removing integrated device and method for a preceramic polymer spinning melt. The device comprises a bubble removing kettle and is characterized in that the upper portion of the bubble removing kettle or a kettle upper cover is provided with a feeding metering pump, the bottom of the bubble removing kettle is provided with a spinning metering pump, a first umbrella-shaped guide face, a second umbrella-shaped guide face, a third umbrella-shaped guide face and a fourth guide and temperature homogenizing arc face are sequentially arranged in the inner cavity of the bubble removing kettle from top to bottom, the joint of the first umbrella-shaped guide face and the inner wall of the bubble removing kettle is provided with a first overflow seam, and the joint of the second umbrella-shaped guide face and the inner wall of the bubble removing kettle is provided with a second overflow seam. The method uses the viscosity homogenizing / bubble removing integrated device to perform viscosity homogenizing and bubble removing. The viscosity homogenizing / bubble removing integrated device and method has the advantages that bubbles in the spinning melt can be completely removed while melt temperature and viscosity homogenizing can be achieved, bubble removing efficiency and melt viscosity uniformity are increased, the breaking and deformation of thin spinning flow and fiber breakage during spinning can be avoided, original fiber defects can be reduced, and the performance of the finished-product ceramic fibers can be increased.

Owner:NAT UNIV OF DEFENSE TECH

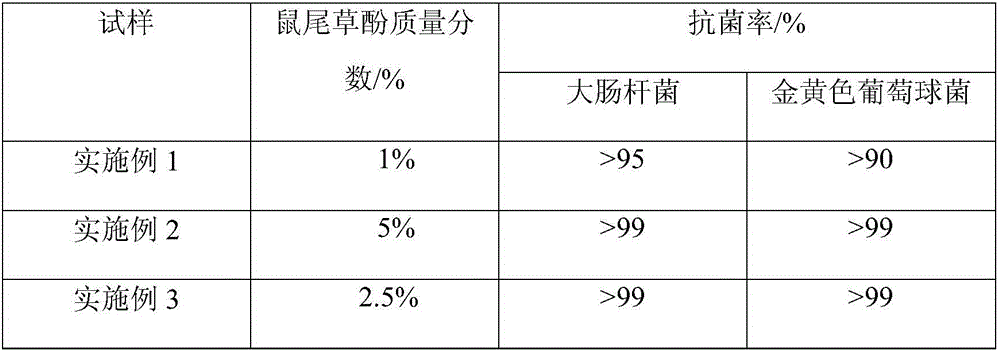

Preparation method of carnosol and chitosan composite nanometer fiber mat

InactiveCN105696195ASimple methodEasy to industrializeSpinning solution filteringOrganic chemistryFiberComposite nanofibers

The invention relates to a preparation method of carnosol and chitosan composite nanofiber felt, comprising: dissolving chitosan in formic acid solution and stirring to obtain chitosan solution; mixing carnosol and chitosan The solution is mixed, stirred, and ultrasonically degassed to obtain a carnosol / chitosan solution, which is then electrostatically spun. The method of the invention is simple and easy to implement, and is easy to be industrialized, and the obtained carnosol composite nanofiber mat can be used in fields such as wound dressings, has excellent antibacterial effect, and has broad application prospects.

Owner:DONGHUA UNIV +1

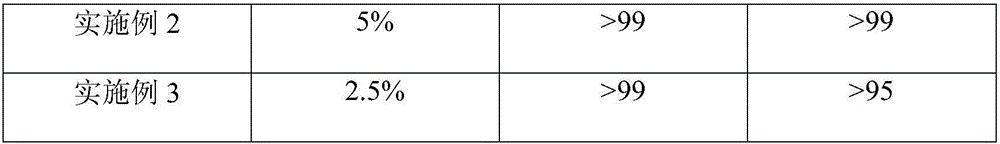

Off-line coating feeding system

PendingCN108103590AGuaranteed purityQuality assuranceSpinning solution filteringSpinning head liquid feederAgricultural engineeringCoating

The invention discloses an off-line coating feeding system which comprises a coating pot group and a heating component. The coating pot group is provided with at least two coating pots, each coating pot is connected with a coating storage pot through a feeding pipe with a pump and connected with a coating die holder through a discharging pipe, and a feeding switching unit selects one coating pot to feed coatings into the coating die holder. The heating component is used for heating the coating storage pots, the feeding pipes, the discharging pipes and the coating pots. According to the coatingfeeding system, before entering the coating die holders, the coatings are sequentially subjected to heating in the coating storage pots, pipeline heating and heating in the coating pots, particularly, the coatings are heated in a zero pressure standing environment in the coating pots, bubbles in the heated coatings float upwards (to liquid level or above the liquid level), expand and fracture andare discharged to the outside of the coating pots, so that the bubbles entrained in the coatings are removed, the purity of the coatings entering the coating die holder is ensured, and optical fiberquality is guaranteed.

Owner:江苏南方光纤科技有限公司

The defoaming method of polyacrylonitrile stock solution

ActiveCN104562226BReduce the presence of air bubblesImprove uniformitySpinning solution filteringCarbon fibersVacuum pump

The invention relates to a defoaming method for preparing a polyacrylonitrile stock solution, and aims at solving the problems that a stock solution in the prior art is not uniform, and an upper layer easily generates gel, or is even dried and hardened. According to the technical scheme, the defoaming method for preparing the polyacrylonitrile stock solution comprises the following steps: (a) starting a heating device, heating a defoaming kettle, starting a vacuum pump, vacuumizing the defoaming kettle, slowly conveying the polyacrylonitrile stock solution to the defoaming kettle from a demonomerisation kettle while vacuumizing, closing the vacuum pump after the polyacrylonitrile stock solution completely enters the defoaming kettle, introducing gas to the defoaming kettle, pressurizing and defoaming; (b) after pressurizing and defoaming are finished, starting the vacuum pump, vacuumizing the defoaming kettle, defoaming in vacuum, so as to obtain the final polyacrylonitrile stock solution, and the problems are relatively well solved; the defoaming method can be applied to industrial production of a carbon fiber precursor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods for making carbon fibers for high temperature applications

ActiveUS10260171B1Increase temperatureReduce the temperatureSpinning solution filteringArtificial filaments from cellulose solutionsCelluloseCarbon fibers

The present invention relates to a method for the continuous production of low thermal conductivity endless filament yarns with a compact, homogeneous structural morphology. The presently disclosed methods utilize safe and recyclable ionic liquids to produce carbon fiber precursors from cellulose. The fibers are produced by the carbonization of cellulose carbon fiber precursors. The precursor fiber filaments have an increased tear resistance with simultaneously sufficient elongation, a round or crenulated cross-section, and homogeneous fiber morphology. The filament yarns exhibit performance characteristics similar to those produced from traditional viscose rayon. The resulting fibers are especially suited for aerospace applications in composite materials used at the limits of high temperatures, for instance in structures found in rocket nozzles or atmospheric reentry heat shields on spacecraft.

Owner:UNIVERSITY OF ALABAMA

Preparation method of guar gum nanofiber

ActiveCN113061997ALarge specific surface areaBroad application spaceSpinning solution filteringFilament/thread formingPolymer scienceSpinning

The invention discloses a preparation method of guar gum nanofiber. The method comprises a step of spinning a guar gum spinning solution through electrostatic spinning, wherein the guar gum spinning solution is prepared by mixing a cationic surfactant, guar gum and water according to the weight ratio of (0.1-0.5): (0.5-4): (90-99). By adding a proper amount of the cationic surfactant into the guar gum solution, the surface tension of the guar gum solution is regulated and controlled, the chain entanglement degree of the guar gum solution is optimized, and the conformation of the guar gum solution is improved, so that the spinnability of guar gum electrostatic spinning is improved. The invention further provides an improved needleless electrostatic spinning device. By means of the device, the spinning efficiency and spinning quality of the guar gum spinning solution can be improved. The guar gum nanofiber prepared by the method has the diameter of 100 nm or below, relatively high dispersion and relatively high strength and rebound resilience.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com