Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

215 results about "Fiber morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber Morphology. FFF produces very straight fiber while maintaining precise control of the diameter, with the ability to vary diameter as fibers grow. Diameter control can be applied to the entire set of fibers, to random subsets, and down to individual fibers. Fiber diameters can range from 15 to 100 microns.

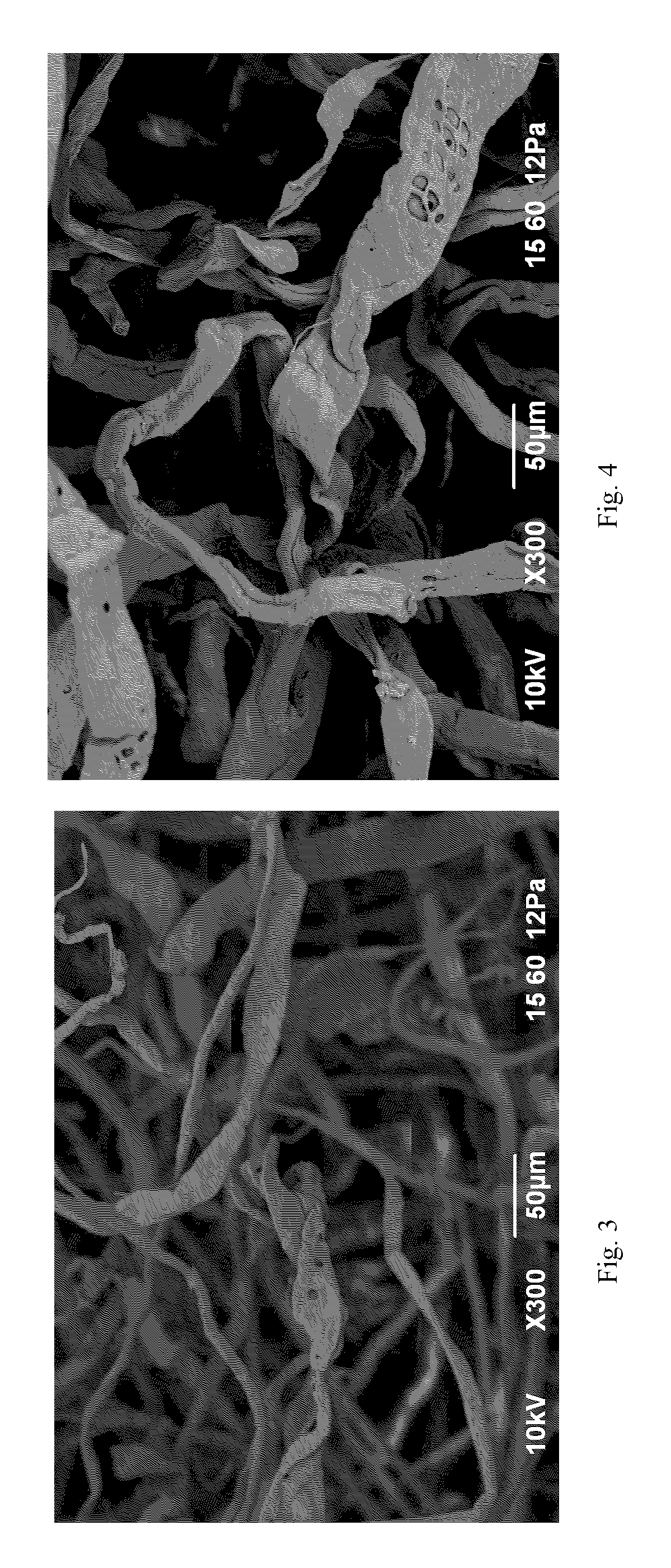

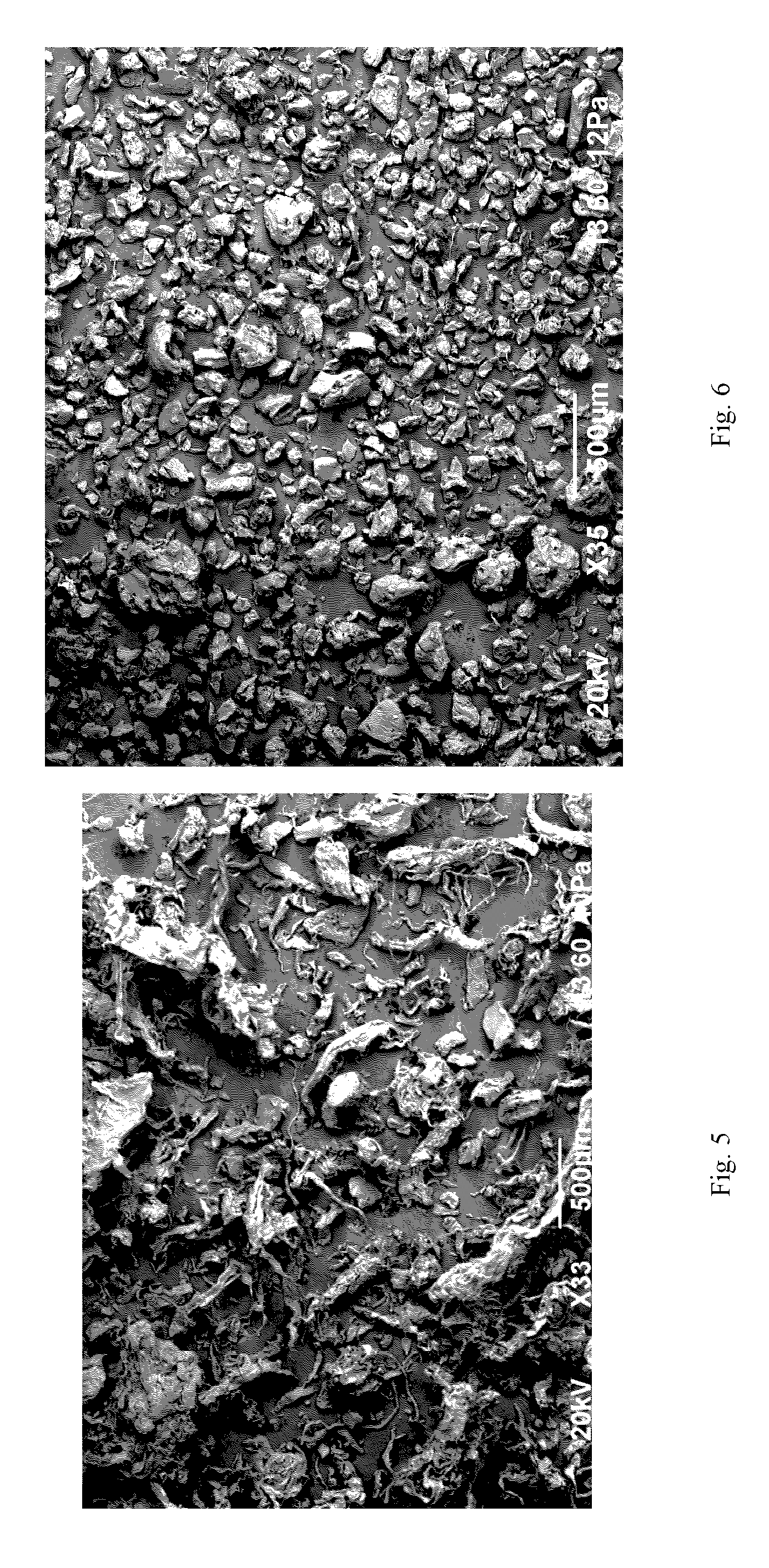

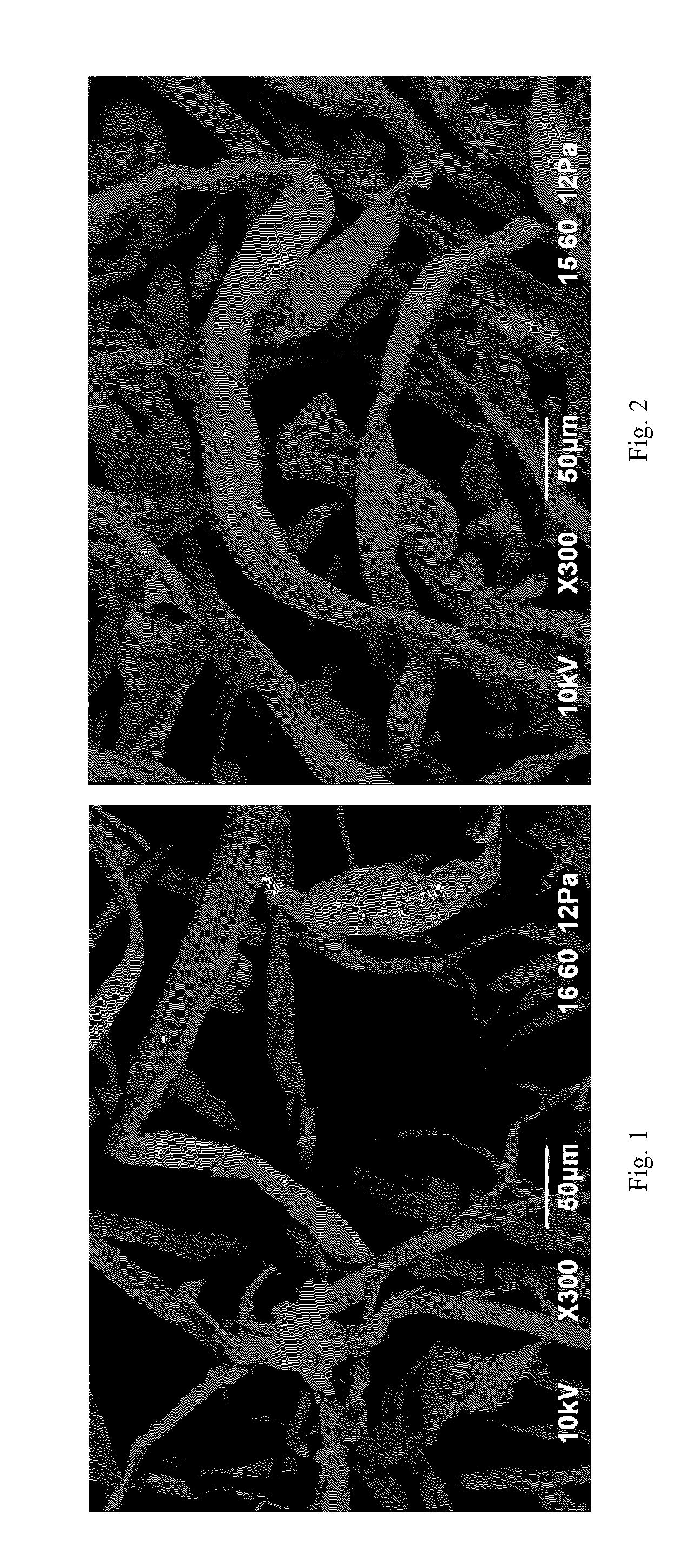

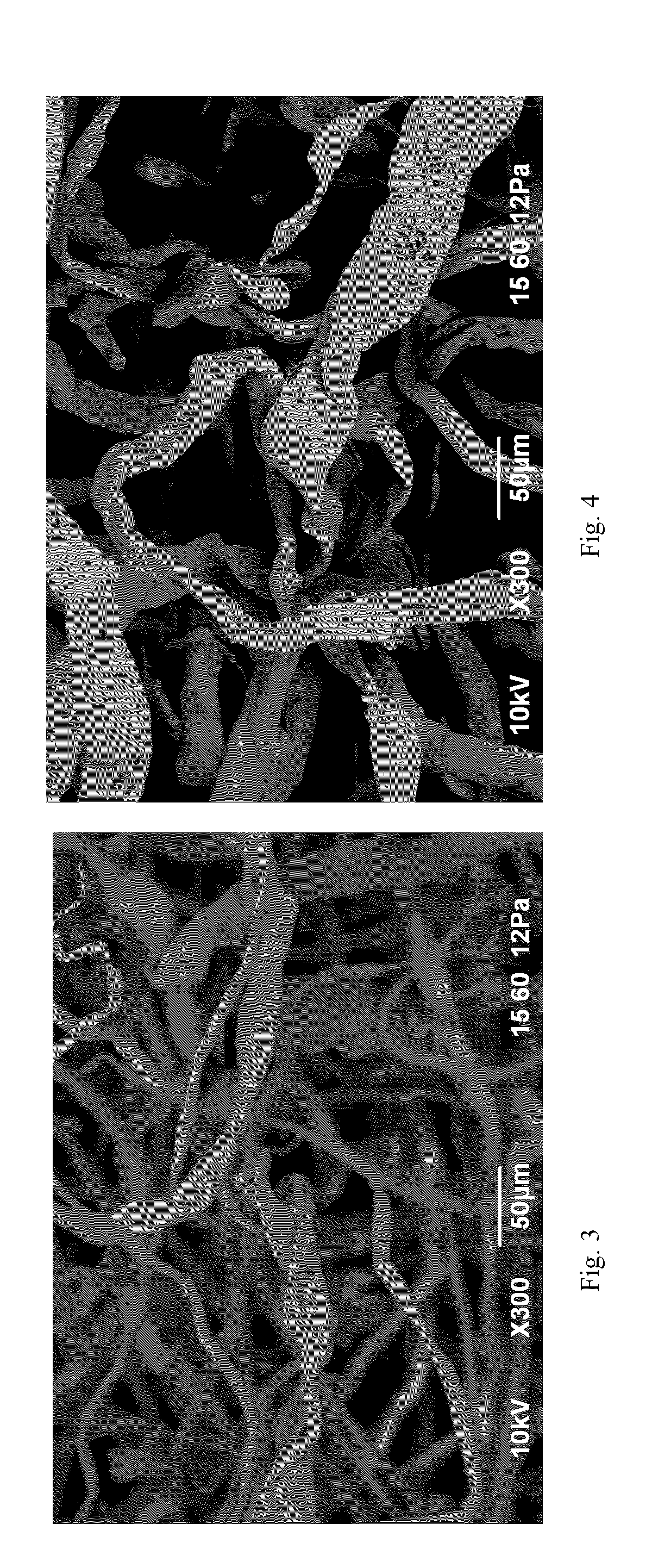

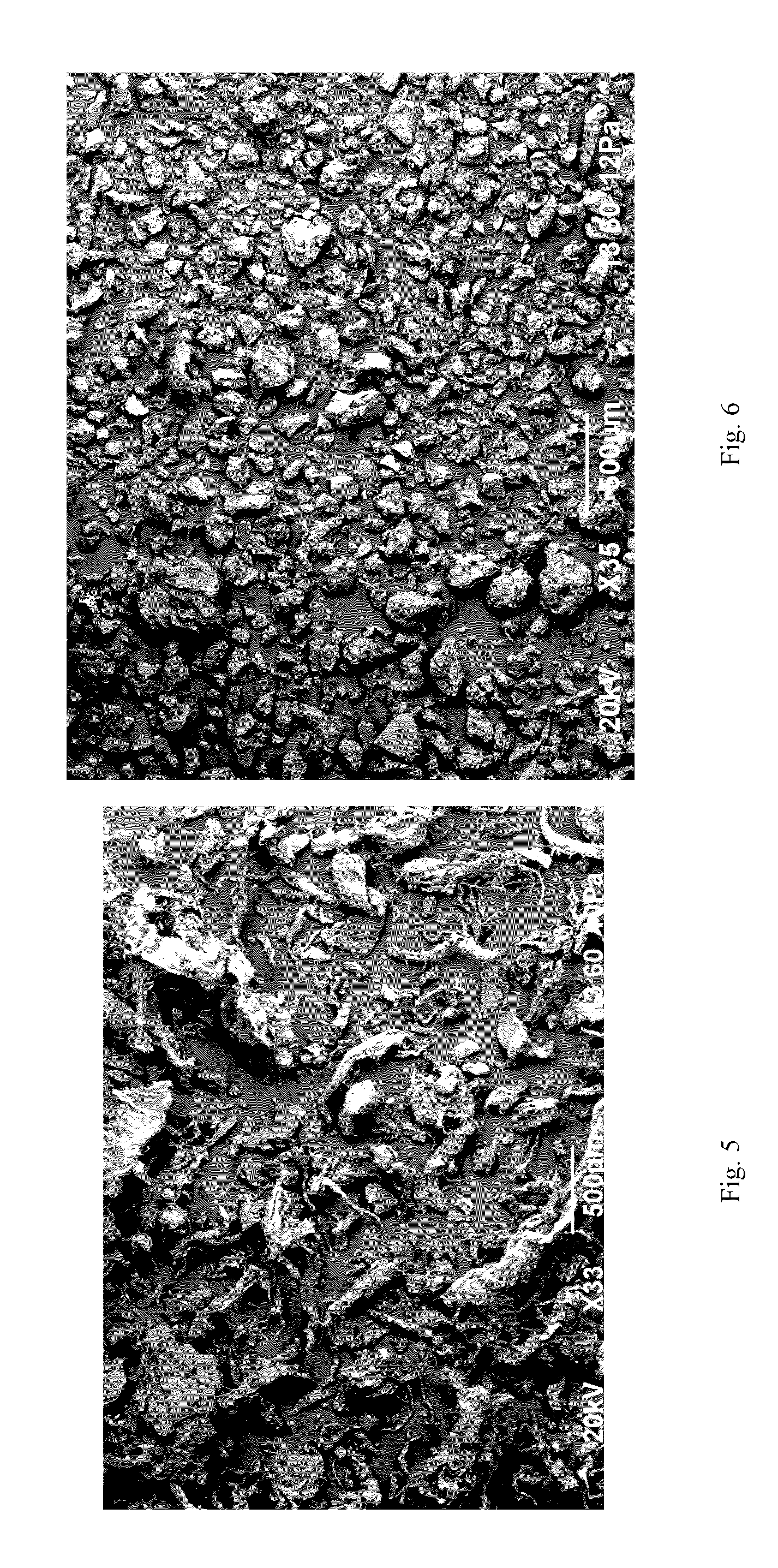

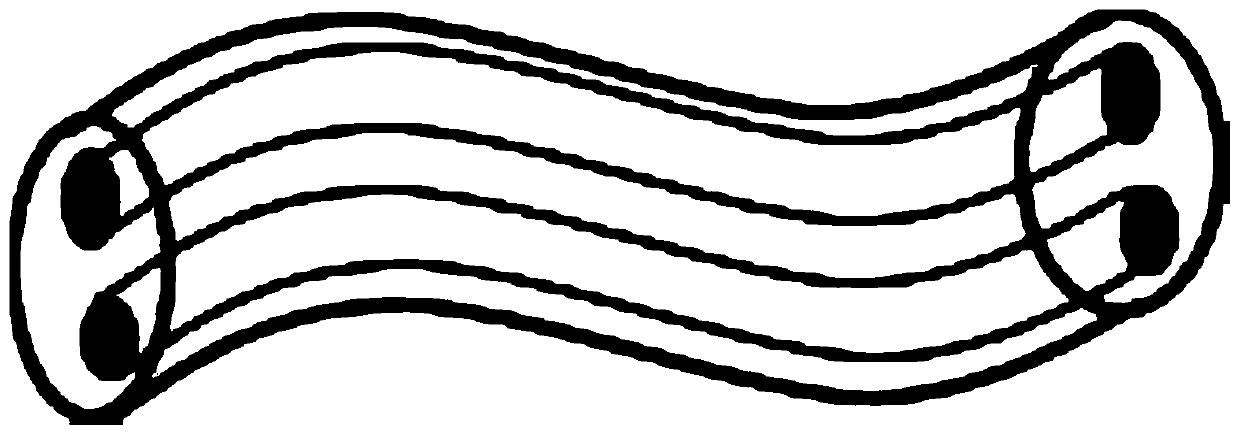

Wood pulp fiber morphology modifications through thermal drying

InactiveUS6837970B2High degreeIncreased formationPulp properties modificationPaper/cardboardFiberCross linker

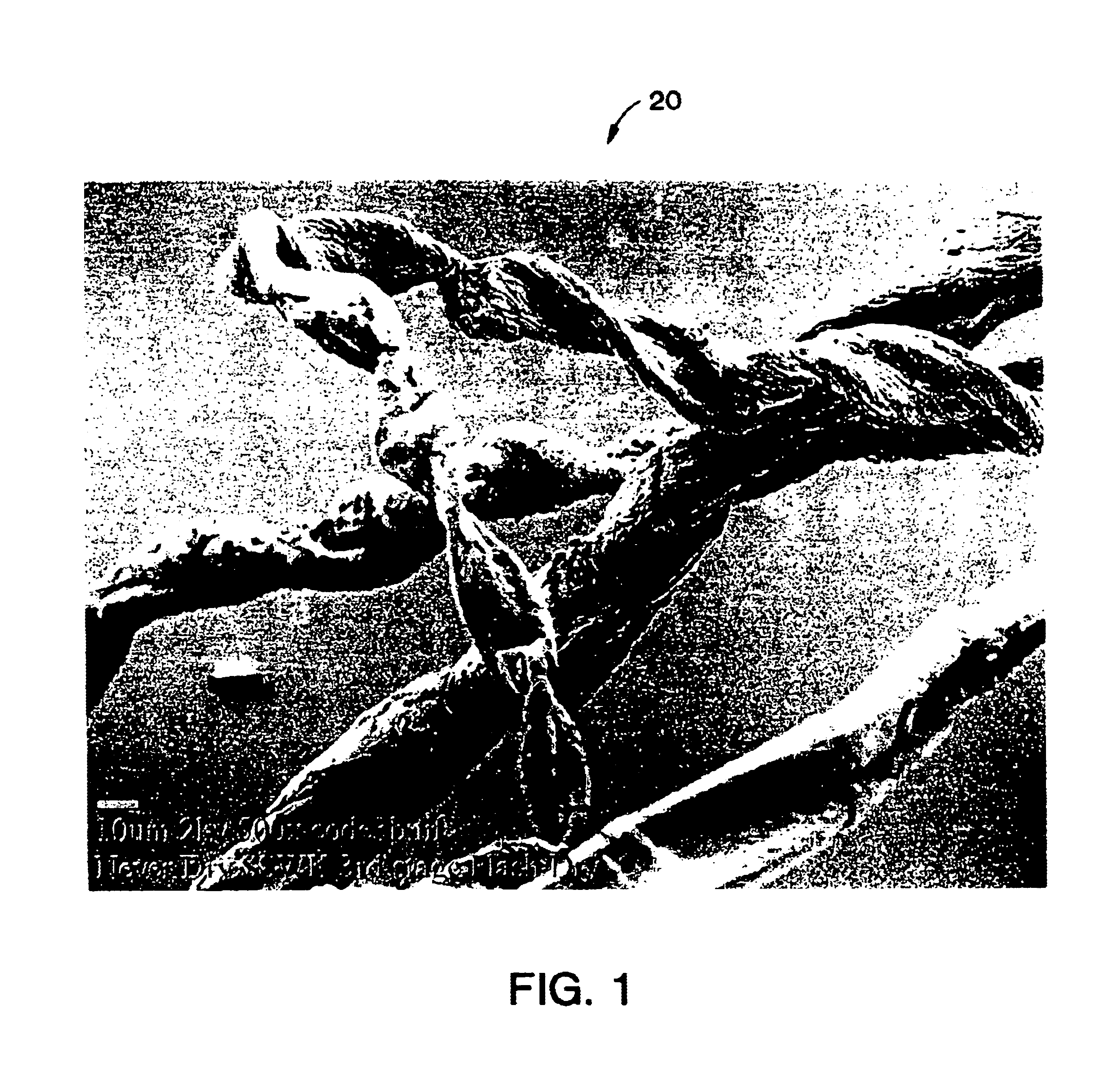

A method of modifying a two-dimensional, flat fiber morphology of a never-been-dried wood pulp into a three-dimensional twisted fiber morphology without the aid of a chemical cross-linker. The method includes the steps of treating a never-been-dried wood pulp fiber slurry with a drying aid and thermally drying the wood pulp fiber slurry. The method may alternatively, or additionally, include the steps of spray drying a wood pulp fiber slurry and / or a slurry of a hydrophilic material, and flash drying the spray dried wood pulp fiber slurry and / or slurry of hydrophilic material.

Owner:KIMBERLY-CLARK WORLDWIDE INC

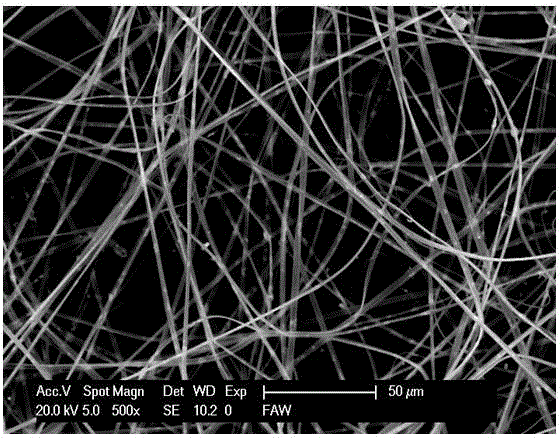

Nonwoven fiber materials

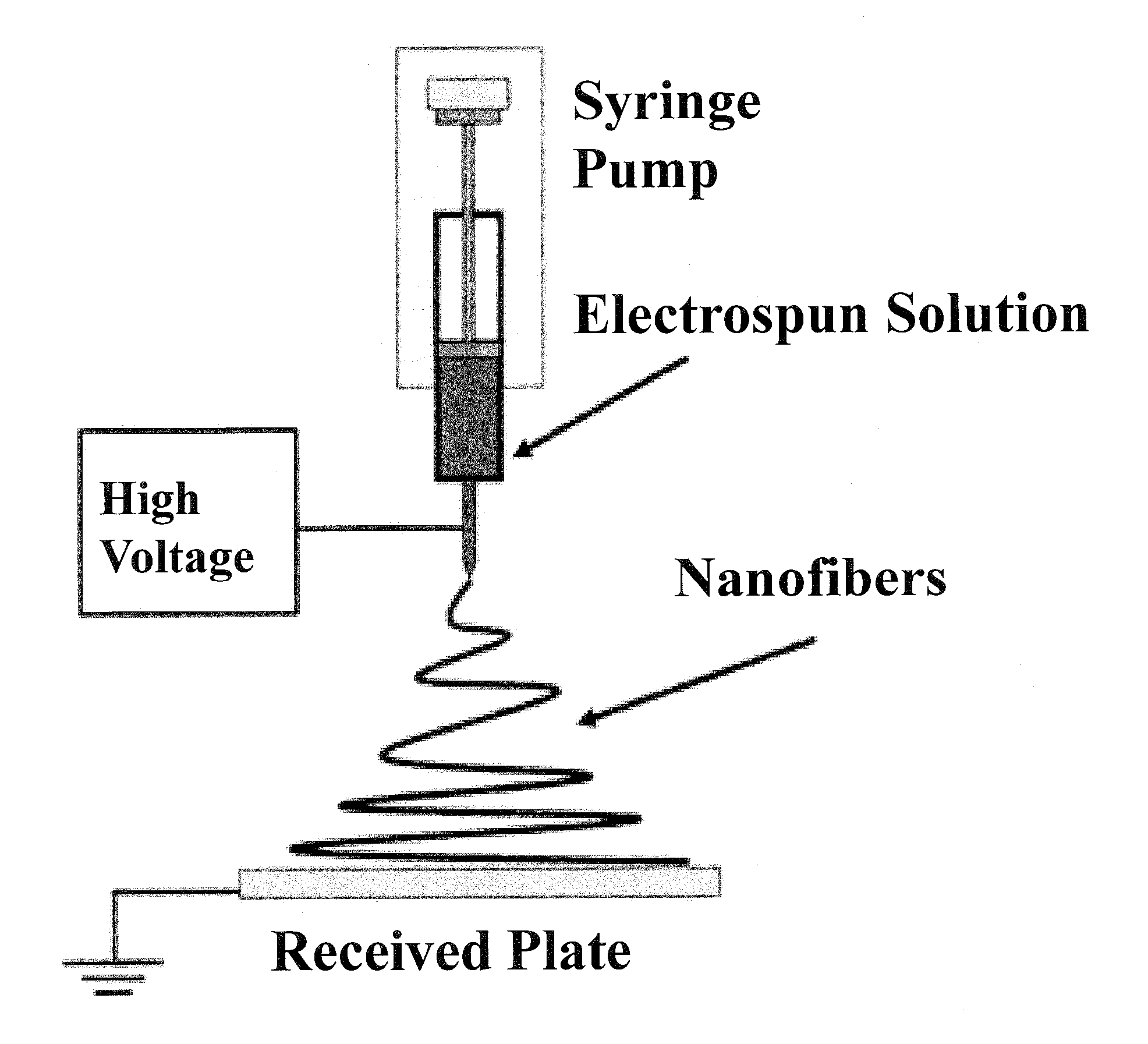

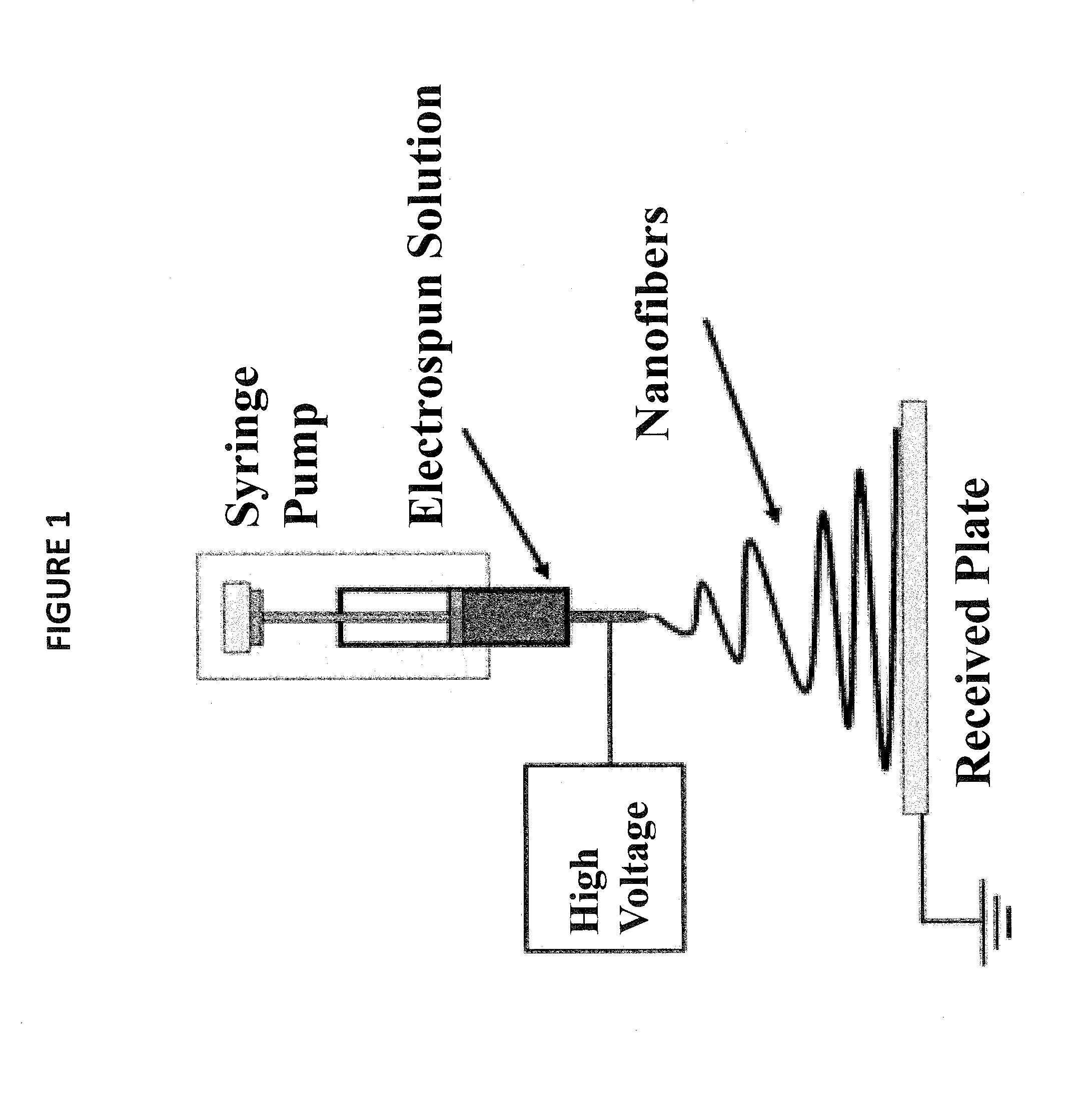

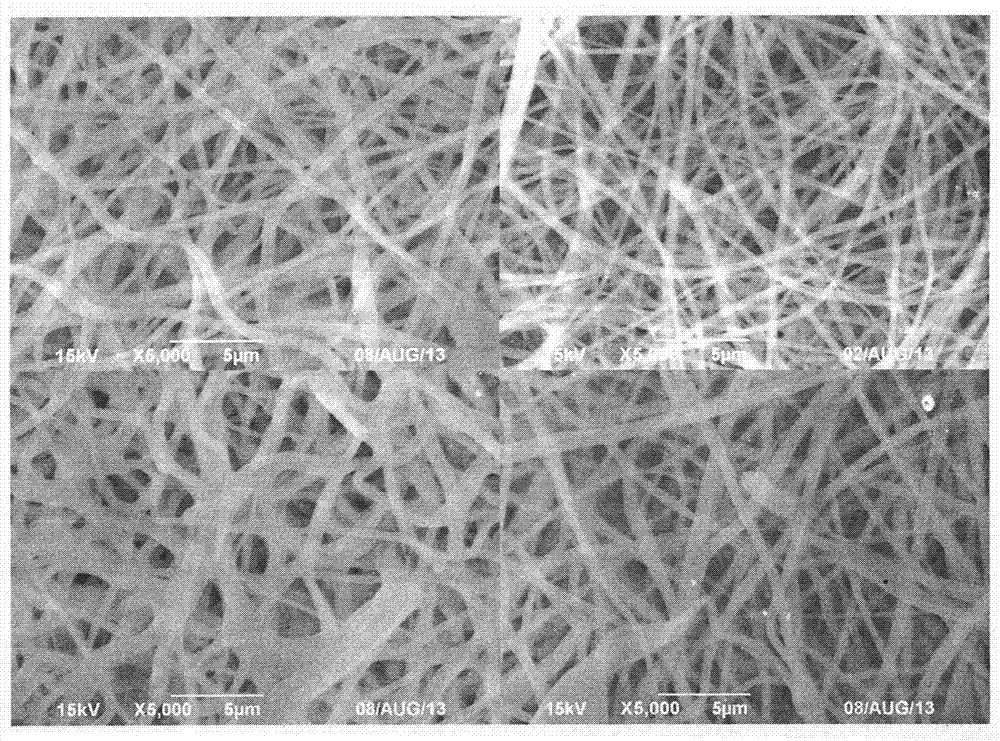

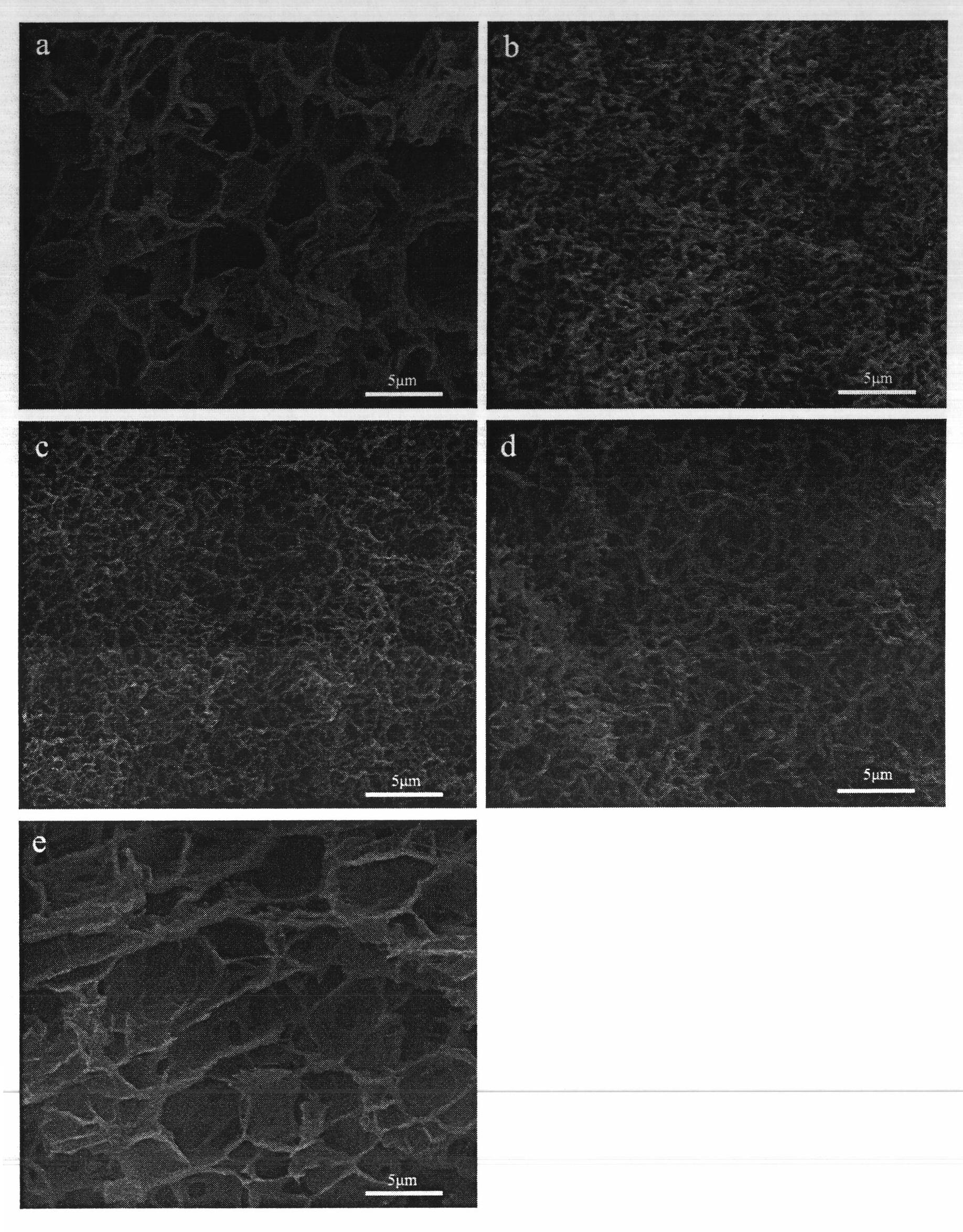

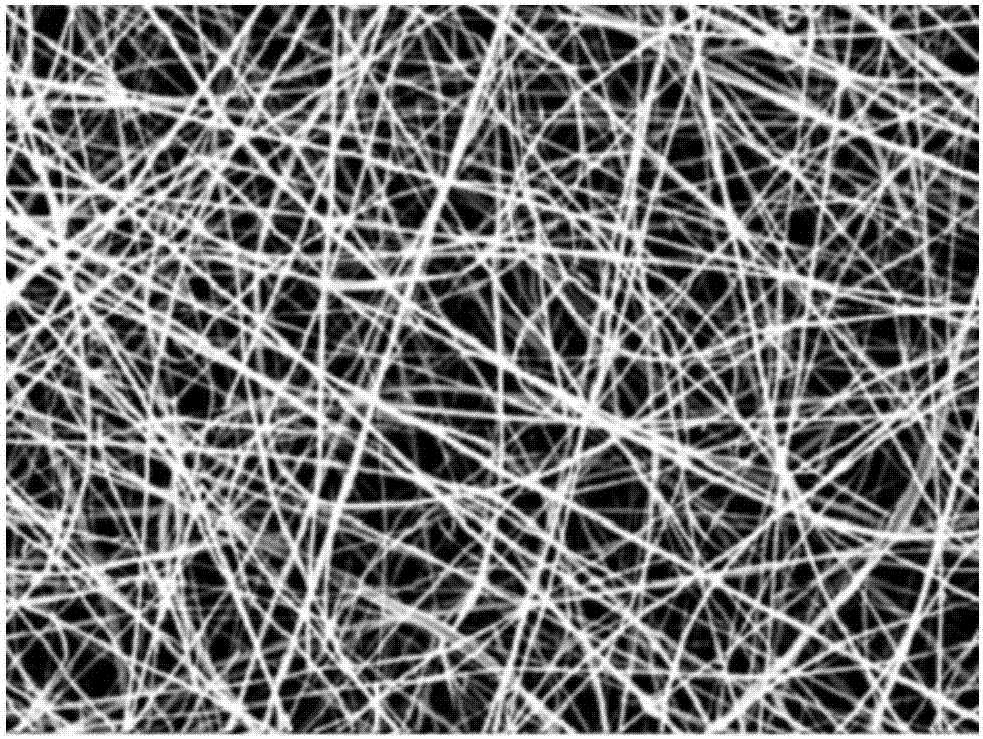

The present invention provides electrospun fibrous materials with various potential applications in the healthcare industry. Unique fiber morphologies are provided, which can allow the fibrous materials to exhibit a range of desirable properties. The electrospun fibrous materials are advantageously biocompatible and may be tailored for certain specific applications, e.g., by the incorporation of one or more therapeutic agents. Exemplary materials described herein can be employed in controlled, localized drug delivery, tissue engineering, and wound healing applications.

Owner:NORTH CAROLINA STATE UNIV

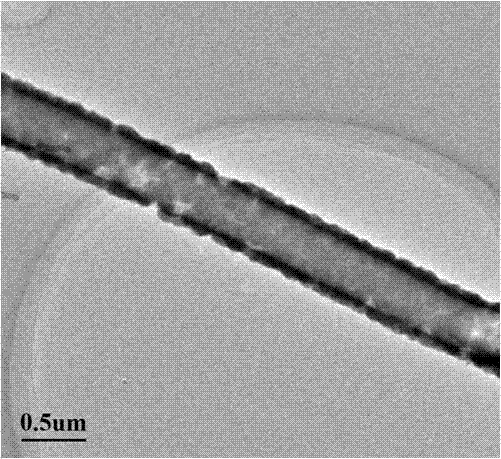

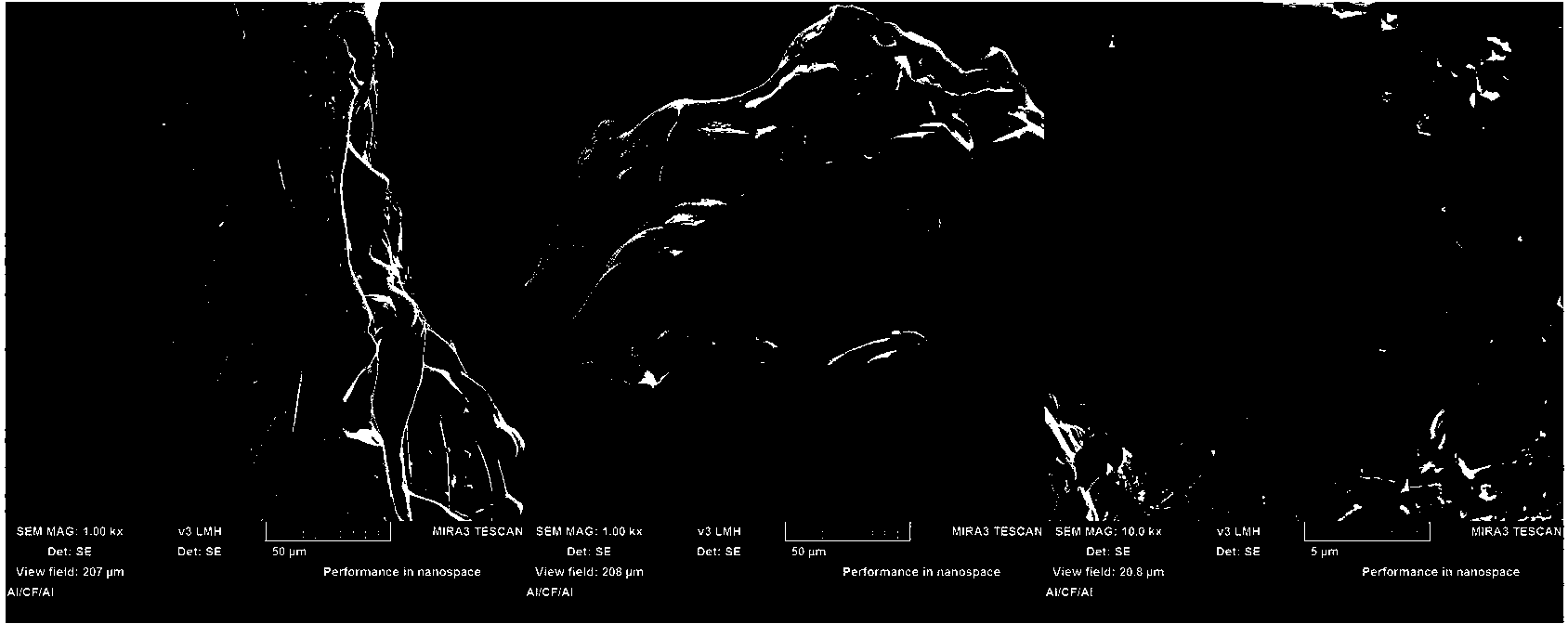

Lithium ferric manganese phosphate as cathode material of nanometer fibrous lithium ion battery and preparation method of lithium ferric manganese phosphate

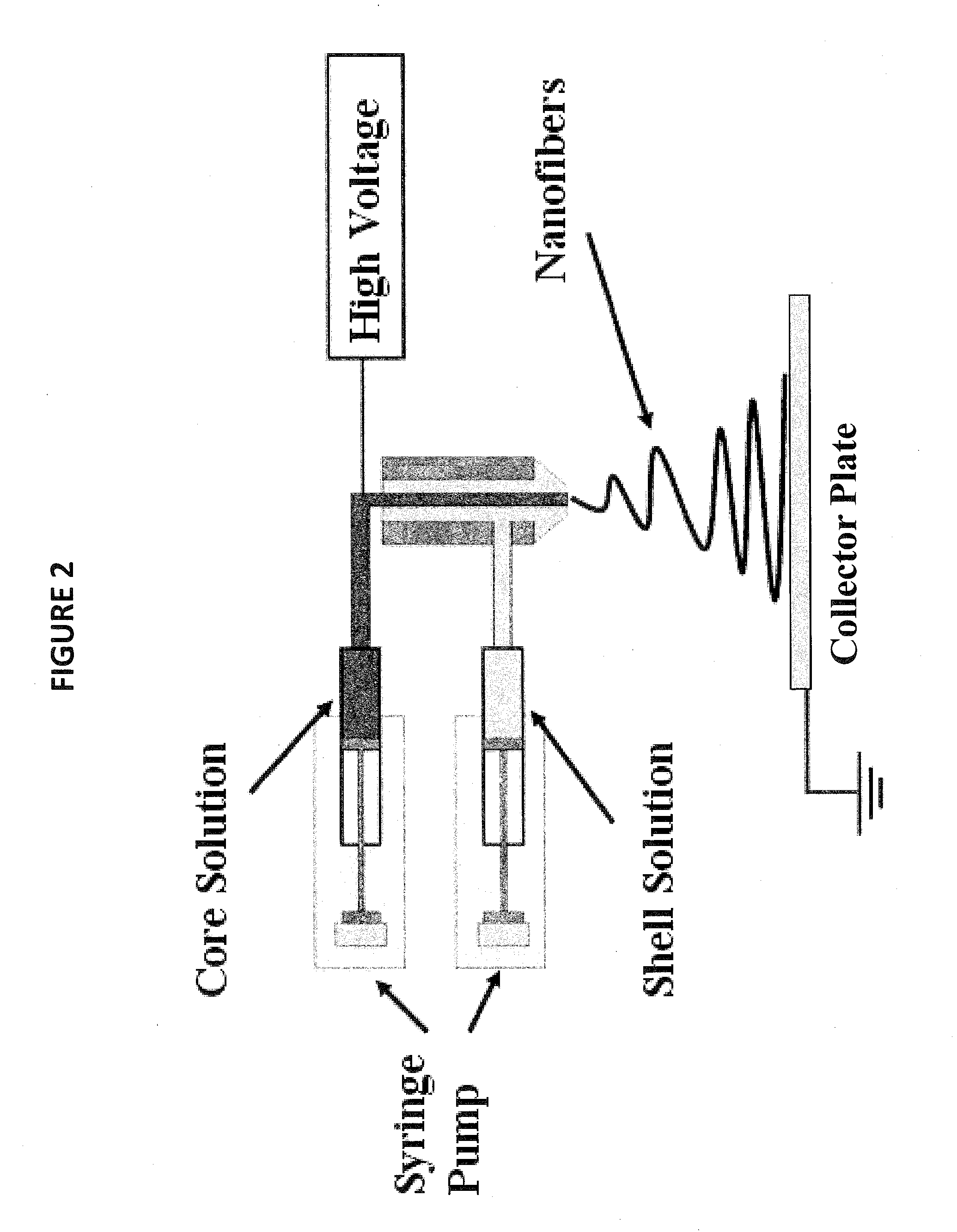

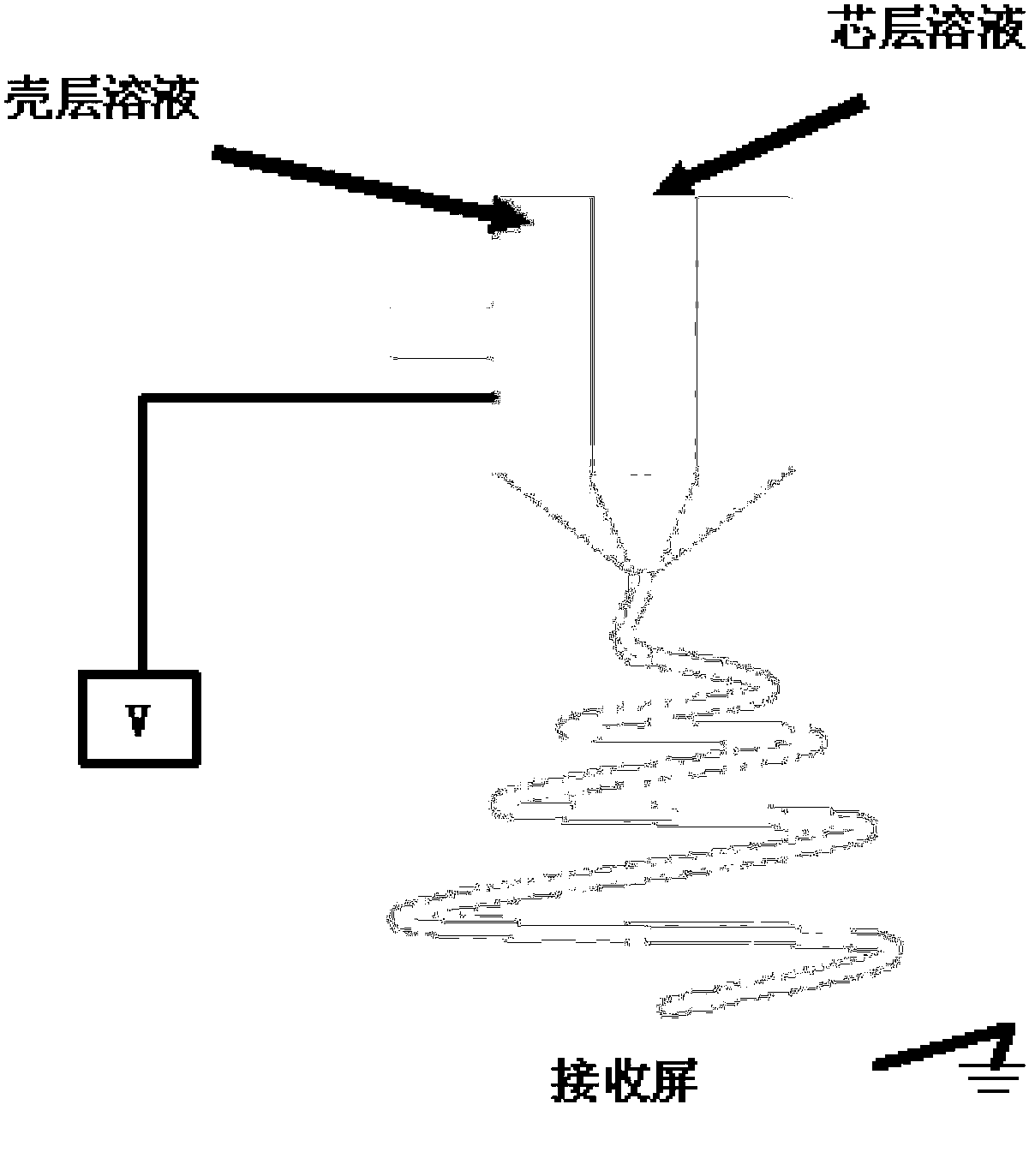

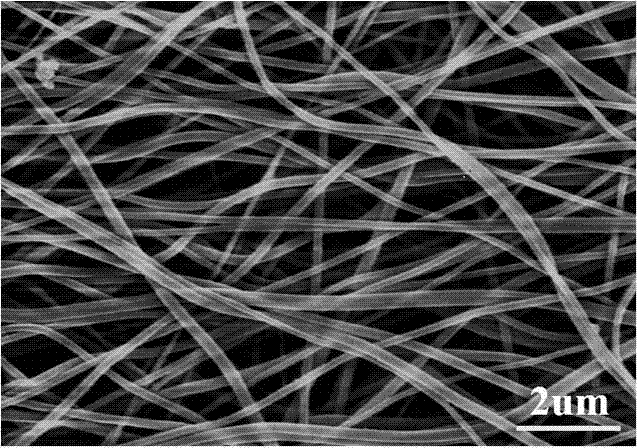

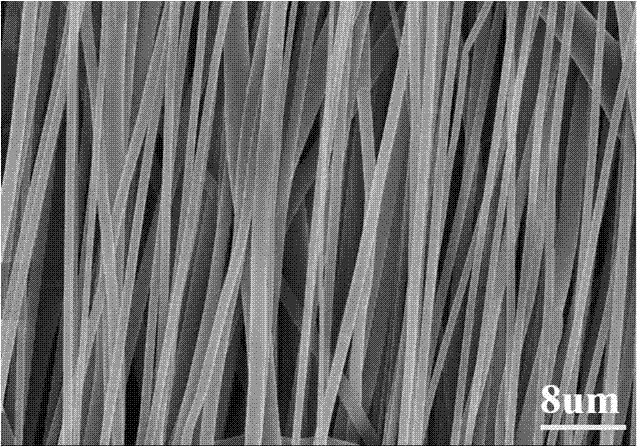

The invention relates to lithium ferric manganese phosphate as a cathode material of a novel nanometer fibrous lithium ion battery. The lithium ferric manganese phosphate is prepared according to the following steps that iron source compounds, manganese source compounds, phosphorus source compounds, lithium source compounds and macromolecular polymers are used as raw materials, the manganese source compounds easily eroded by electrolyte are dispersed in core layer solution, the more stable iron source compounds are dispersed in case layer solution, and an electrostatic spinning method is adopted. The method for preparing composite materials has the advantages that on one hand, a voltage platform of lithium ion positive electrode materials can be improved, and the specific capacity density and the specific power density of the materials can be greatly improved; and on the other hand, because manganese elements are wrapped in a material core layer, the defects that in the existing preparation technology of the cathode material of the manganese-element-containing lithium ion battery, manganese elements are easily dissolved by electrolyte, the structure is not stable enough, the collapse is easily caused, and the volume attenuation is caused are overcome, and meanwhile, because of the nanometer fiber morphology character, the specific capacity and specific power density and the multiplying power circulation performance of the materials are greatly improved.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

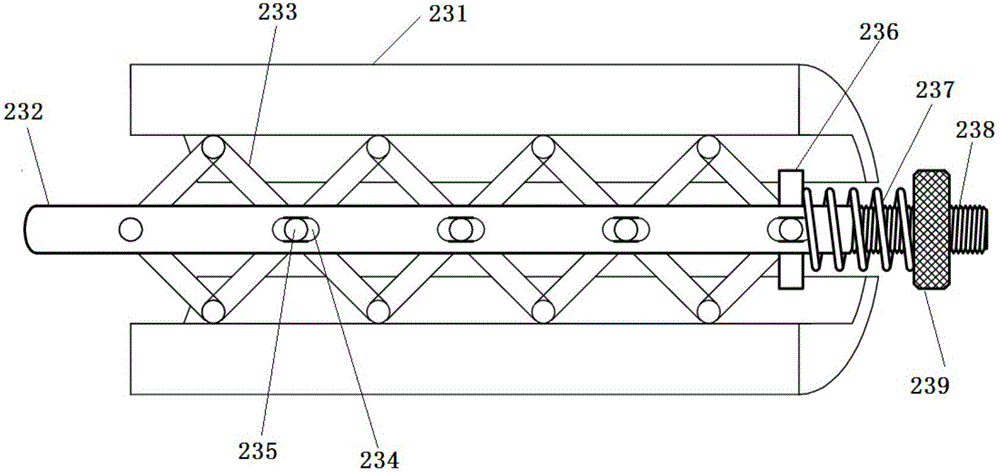

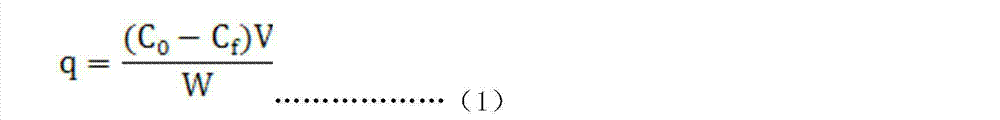

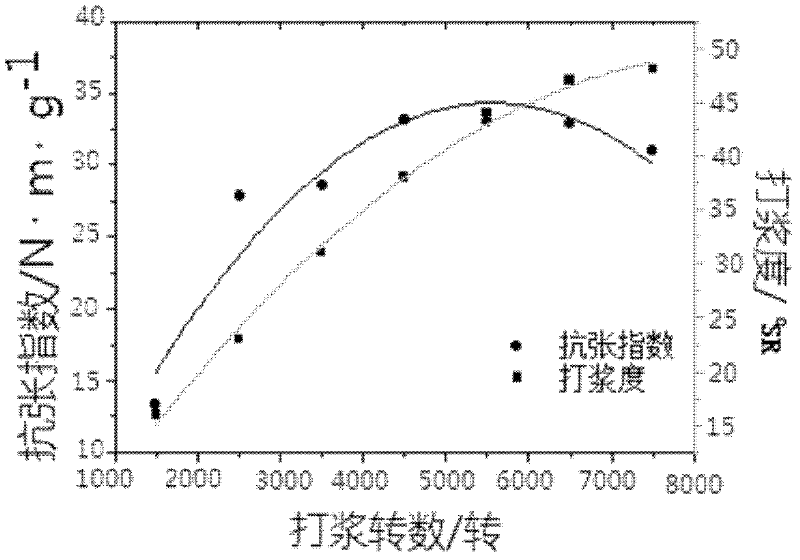

Method for preparing reconstituted tobacco paper base made from tobacco stems

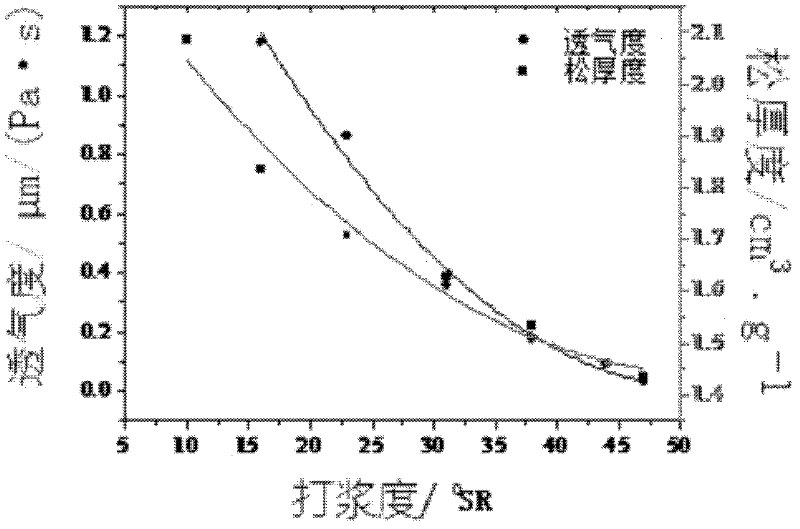

The invention discloses a method for preparing reconstituted tobacco paper base made from tobacco stems, wherein the reconstituted tobacco paper base is prepared through taking the tobacco stems as a raw material and adopting a papermaking method and the preparing method comprises the steps of impregnation, defibrination, pulping, sheet making and drying of the tobacco stems. According to the invention, a technical scheme capable of optimizing the comprehensive property of the reconstituted tobacco paper base made from the tobacco stems is provided, which comprises treatment conditions of key processes of the impregnation, the defibrination, the pulping and the like; and a technical mean capable of improving the fiber morphology of the tobacco stems and the physical property of paper pulp is obtained. Showed by results, contents of water-soluble sugar, total plant alkaloid, chlorine and total nitrogen in the tobacco stems are decreased to varying degrees and the holocellulose content is relatively increased by 12.4% after the impregnation and extraction in the technical scheme provided by the invention are adopted; the fiber length of the obtained tobacco stem pulp is longest and the bulk of the finished paper is highest through selecting different types of refining plates and different defibrination gaps; and the tensile index, the tear index, the bulk, the air permeability and the burst index of a paper base product are appropriate and the good quality of reconstituted tobacco is guaranteed through combining the design of the beating degree of the tobacco stem pulp and the technical condition of the sheet making.

Owner:CHINA TOBACCO GUANGDONG IND +1

Nerve tissue engineering electric conduction nano-fiber tubular stent and preparation method thereof

The present invention relates to a nerve tissue engineering electric conduction nano-fiber tubular stent and a preparation method thereof. The nerve tissue engineering electric conduction nano-fiber tubular stent comprises an electric conduction nano-fiber tube and an electric conduction hydrogel filling material, wherein the electric conduction nano-fiber tube is formed by compounding an inner layer and an outer layer, the inner layer is an electric conduction nano-fiber film arranged in a parallel manner and oriented along the axial direction of the catheter, the outer layer is a non-electric conduction non-woven arrangement nano-fiber film, and the filling material is formed by compounding a natural macromolecular hydrogel and growth factor-loading electric conduction nano-tubes. According to the present invention, the catheter stent material can provide the multifunctional bionic microenvironment for nerve tissue engineering, has good biocompatibility, and can provide nutrients for nerve repair, wherein the two-dimensionally oriented fiber morphology can promote the differentiation and growth of nerve cells, and with the adding of the electric conduction material, the differentiation degree of nerve cells can be further improved, the cell proliferation can be promoted, and the conditions required by nerve regeneration can be well met.

Owner:BEIJING UNIV OF CHEM TECH +1

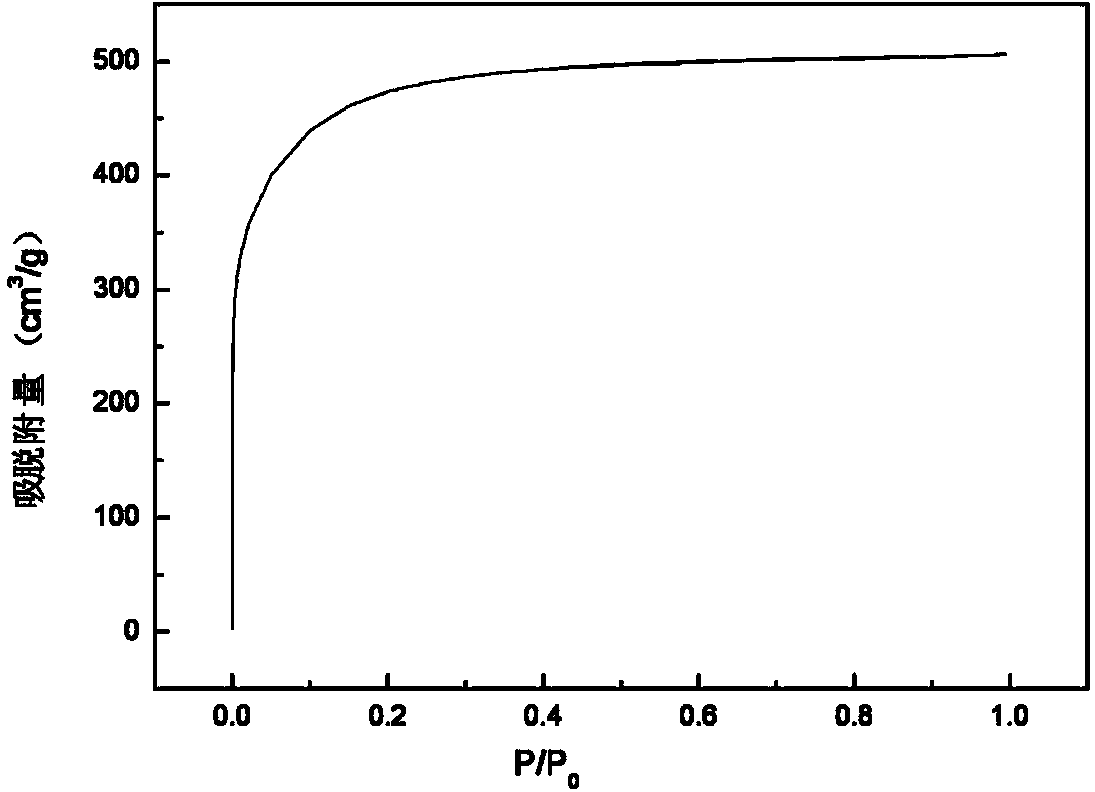

Preparation of lignin nano-carbon fibers for supercapacitor

InactiveCN107956001AWide variety of sourcesLow priceHybrid capacitor electrodesFibre chemical featuresCapacitanceFiber

The invention discloses a preparation method of lignin nano-carbon fibers for a supercapacitor. Lignin which is extensive in sources, regenerative, high in carbon content and low in price is used as acarbon source, and a polymer which has high molecular weight is used as a spin finish aid. Nano initially spun fibers are prepared by an electrospinning technology, and are subjected to processes ofpre-oxidation, carbonization and the like to obtain nano-carbon fibers. The obtained carbon fibers can form a film directly, and the film can be directly tailored into an electrode of a capacitor. Themethod has the advantages of simplicity in process, high maneuverability, extensive sources, low price and the like. The obtained nano-carbon fibers are continuous fibers, the fiber morphology is good, and the capacitance characteristics are good.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing porous functional carbon fiber cluster from waste cotton textiles

The invention relates to a method for preparing a porous functional carbon fiber cluster from waste cotton textiles. The method comprises the following steps of sequentially carrying out immersion treatment on waste cotton textiles with a KH-550 solution, an ammonium chloride solution and a zinc chloride solution, firstly pre-oxidizing at 150-300 DEG C and then isolating from the air, heating up to 350-950 DEG C and carrying out carbonization treatment to convert the textiles into the porous functional carbon fiber cluster of which the surface contains functional groups. The carbon fiber cluster prepared by the method disclosed by the invention has the advantages of stable surface physical and chemical properties and can maintain the advantages of fiber morphology as well as has highly active functional groups and holes. The carbon fiber cluster can be used as an adsorbent material to achieve high-value recycling of waste cotton textiles.

Owner:TAIYUAN UNIV OF TECH

Preparation method of constant-hydrophilic graft-modified chlorinated polymer micro/nano fiber film

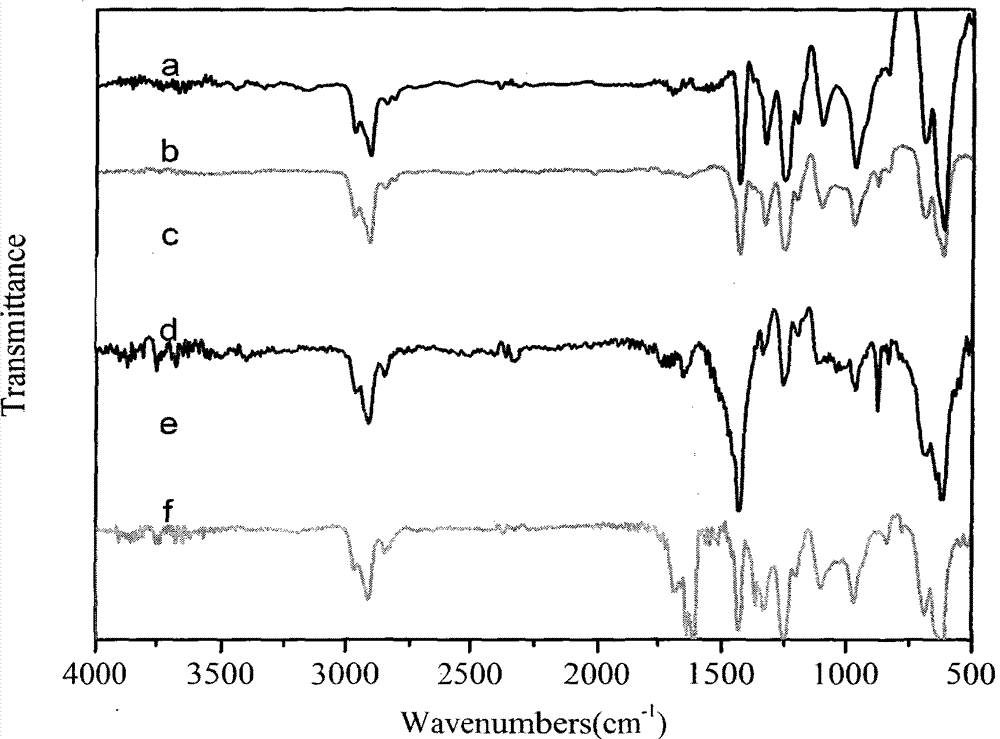

ActiveCN103924384AStructural damage is smallLow application costFibre treatmentNon-woven fabricsFiberHydrophilic monomer

The invention provides a preparation method of a constant-hydrophilic graft-modified chlorinated polymer micro / nano fiber film, and relates to electric-spinning preparation and surface modification of the chlorinated polymer micro / nano fiber film. According to the method for preparing the chlorinated polymer micro / nano fiber film through electrospinning and surface graft polymerization hydrophilic modification, the problems that pressure drop is large, flux is small and the film is prone to contamination during a water system is treated through hydrophobic film material can be solved on the basis of less damages to the film structure. The method includes performing mild dehydrochlorination on chlorinated polymer resin during reflux under the condition of alkaline catalysis, preparing spinning solution, utilizing a self-made electrospinning device, adjusting spinning process parameters, obtaining the micro / nano fiber film with uniform fiber morphology and good mechanical property, then performing surface modification by the method of hydrophilic monomer surface grafting polymerization initiated by azodiisobutyronitrile, and obtaining the chlorinated polymer micro / nano fiber film with high hydrophilicity. The film can be applied to efficient frame-type filtering films.

Owner:SHIHEZI UNIVERSITY

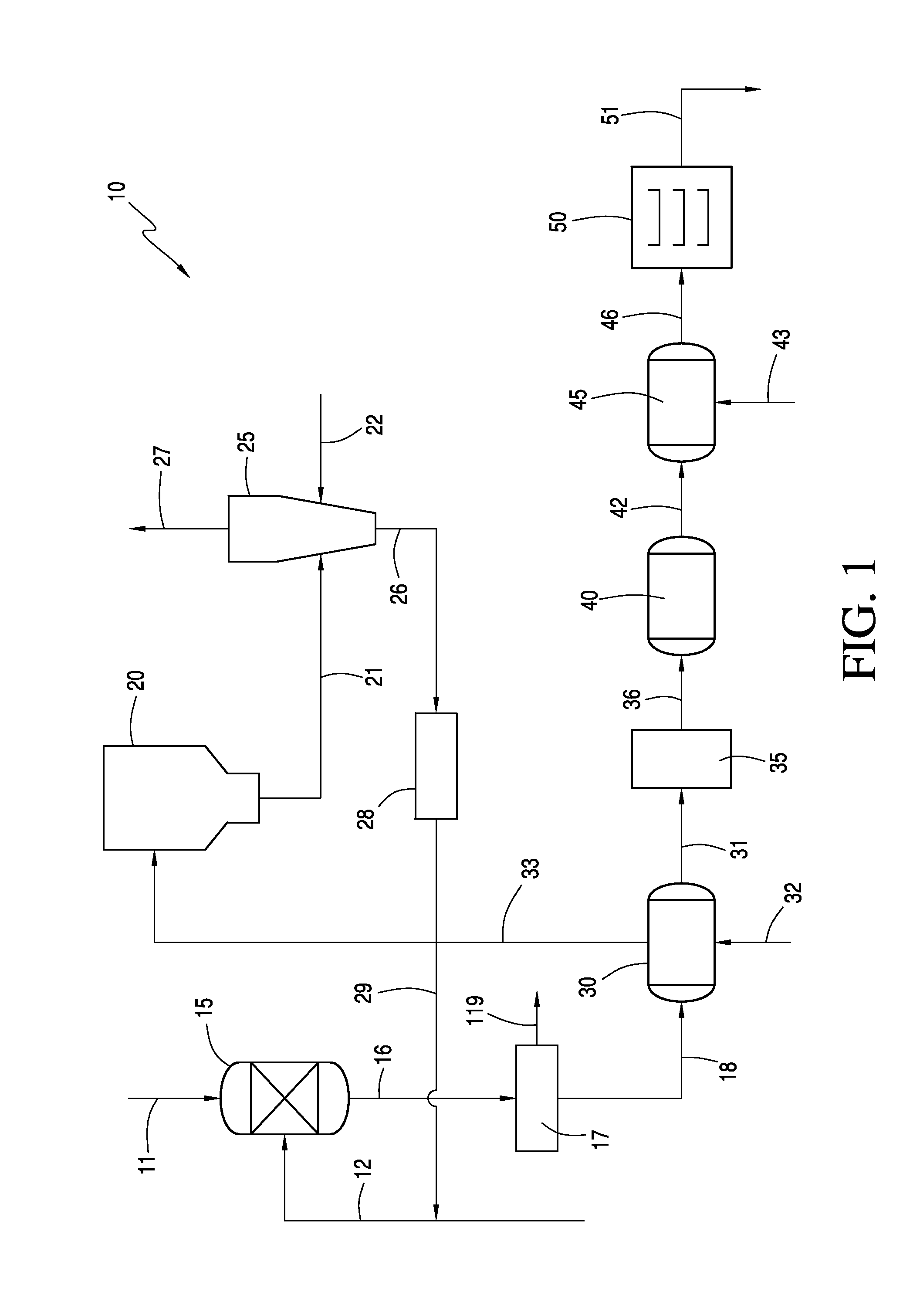

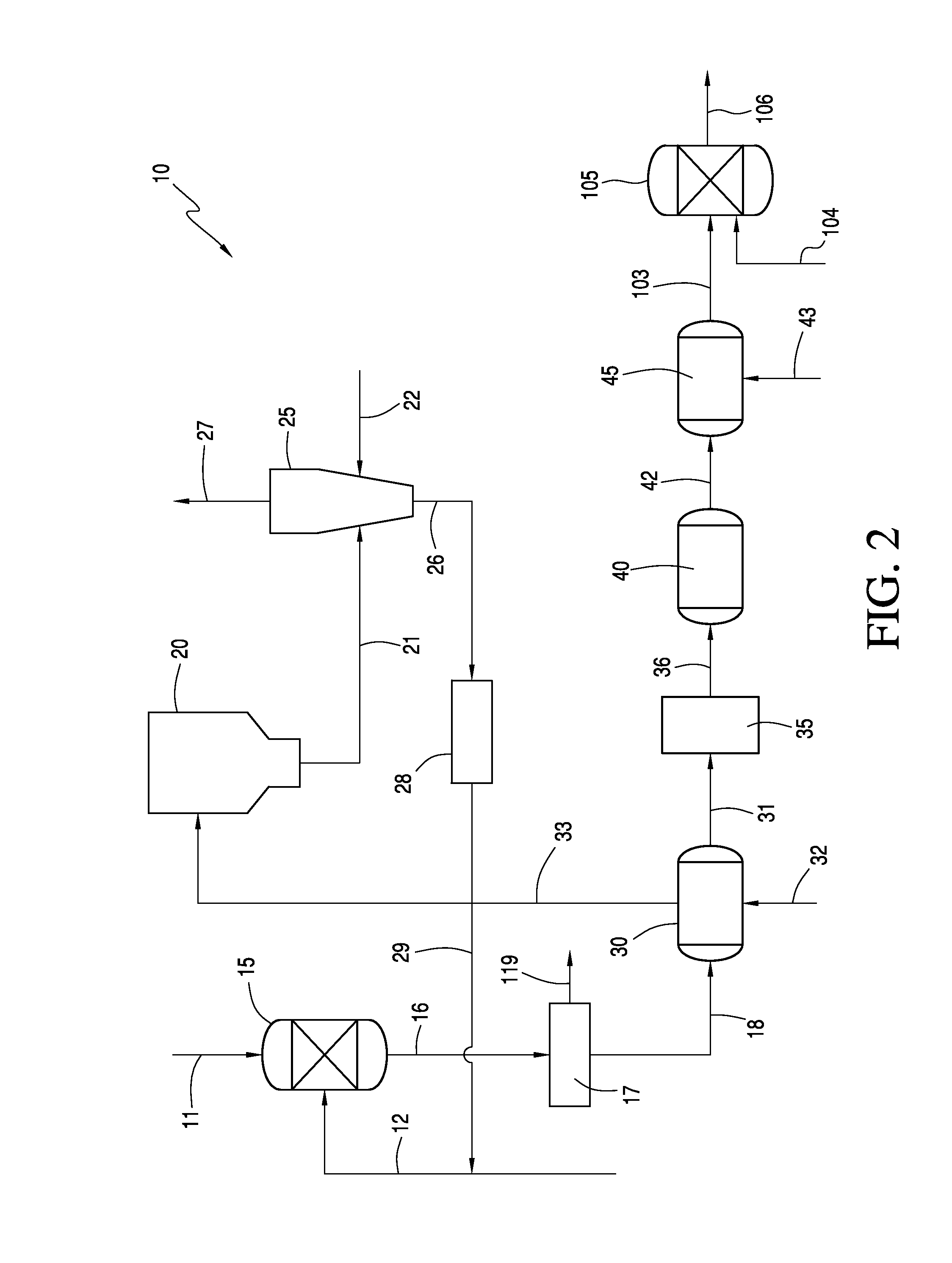

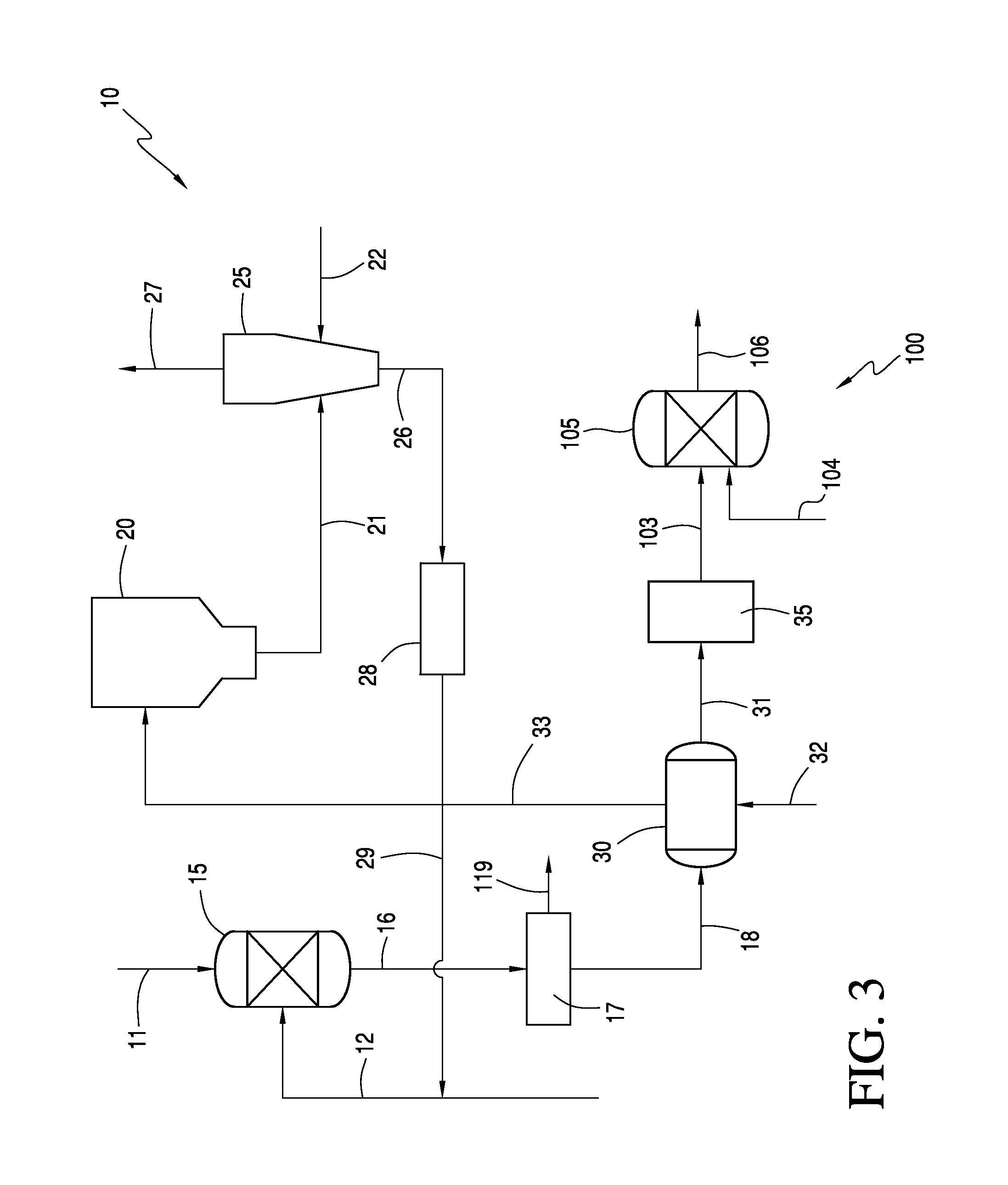

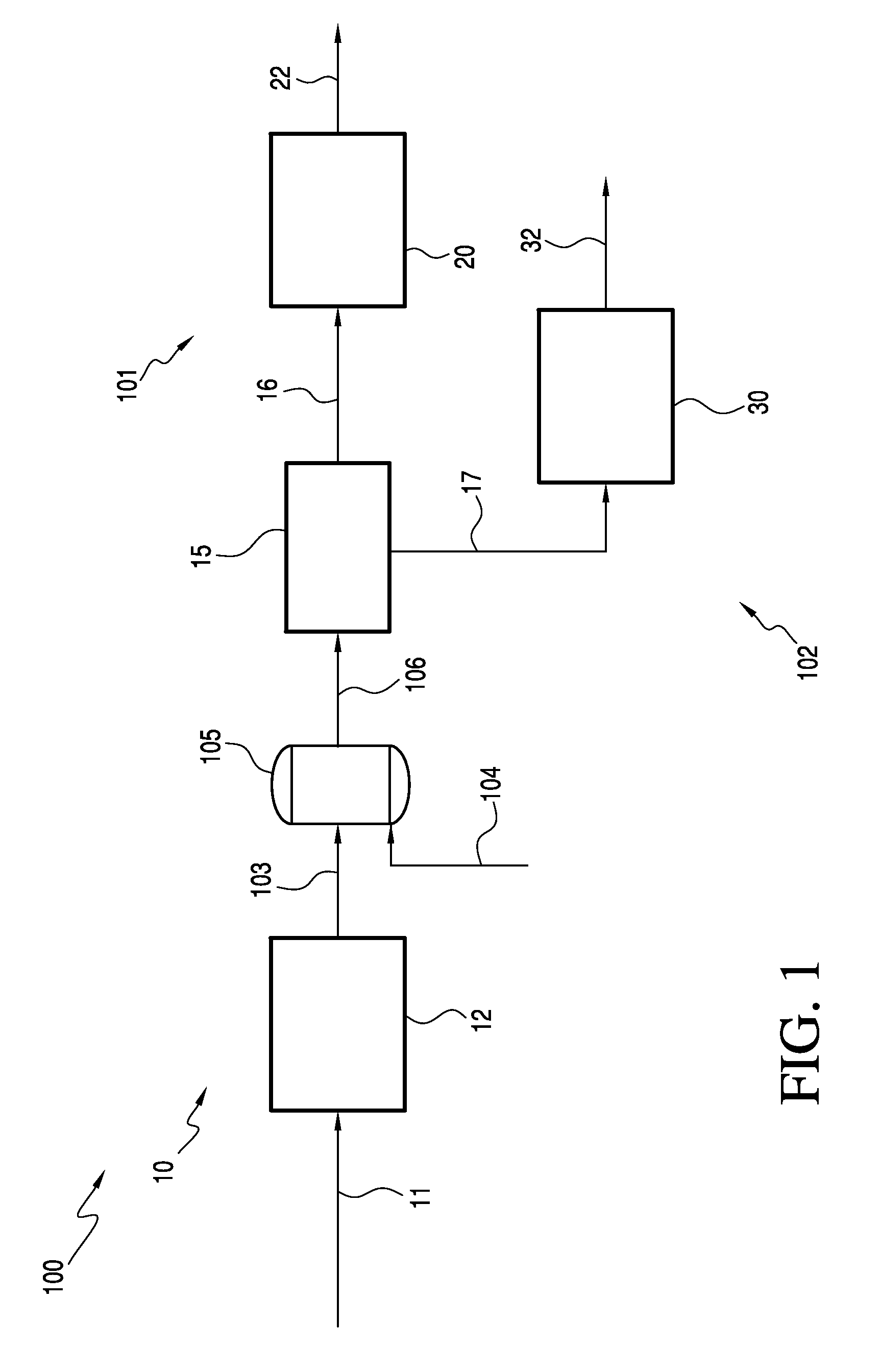

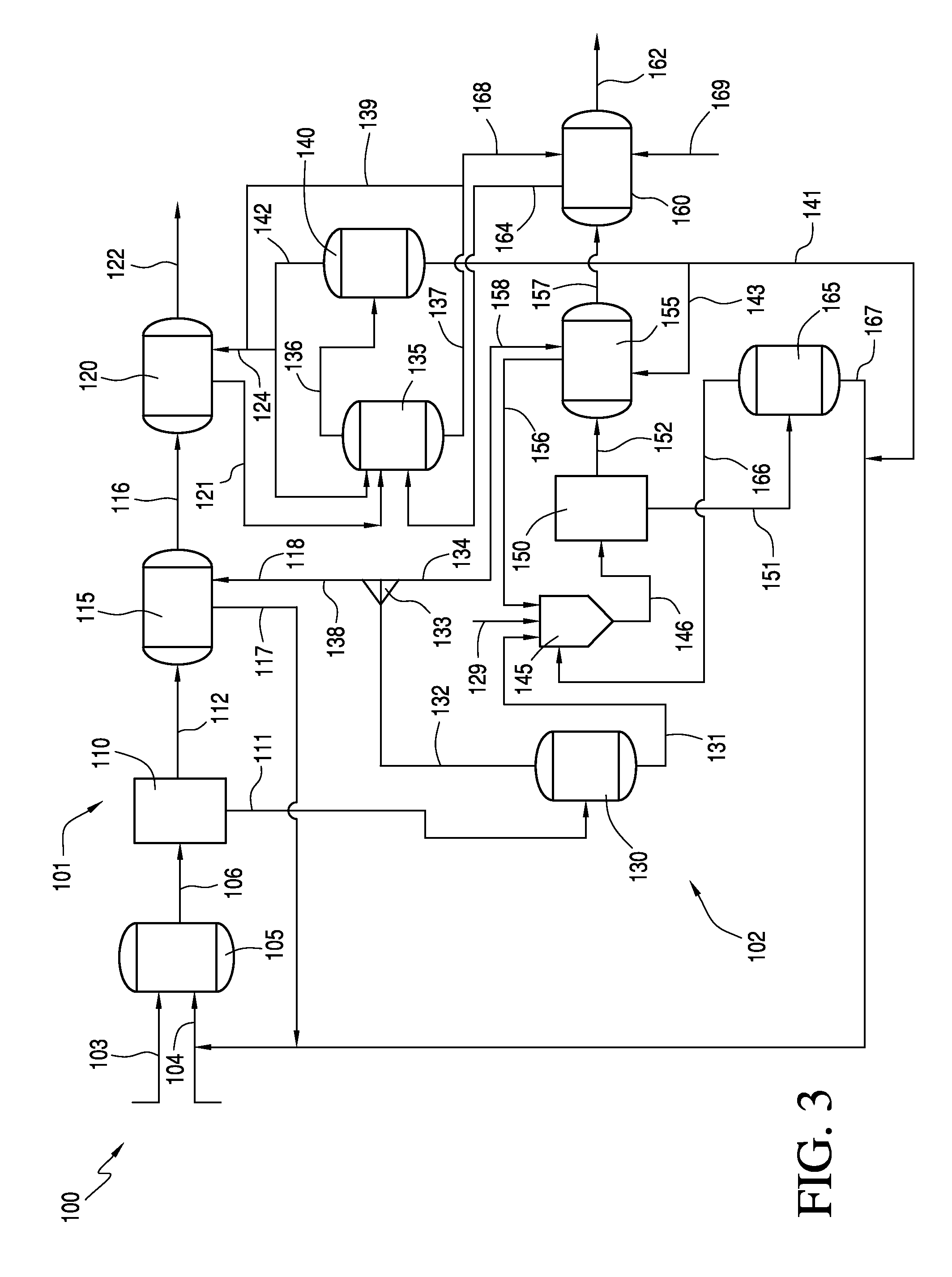

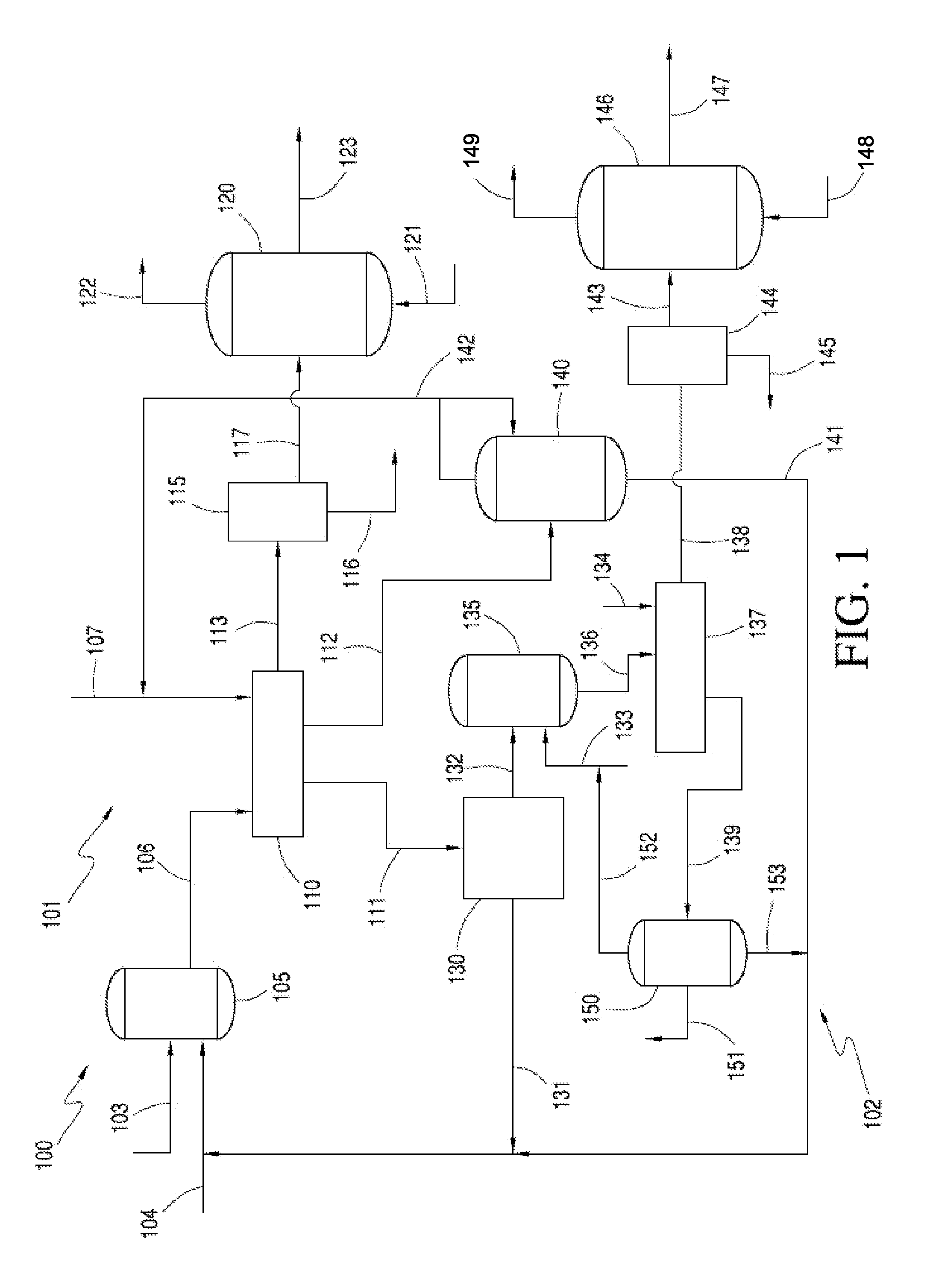

Integrated Processes for Purifying a Cellulosic Material

InactiveUS20140326422A1Pulp properties modificationWashing/displacing pulp-treating liquorsCellulose fiberHemicellulose

A process for converting a starting material to a purified pulp material, comprising removing lignin from a starting material to form a wet pulp comprising at least 5 wt. % water, extracting hemicellulose from the wet pulp with an extractant, and separating the extracted hemicellulose from the extraction mixture to form a cellulosic product comprising less hemicellulose than the wet pulp. The extractant comprises a cellulose solvent and a co-solvent. The cellulosic product advantageously retains its cellulosic fiber morphology. The process involves separating and recovering hemicellulose and separating and recycling various process streams employed in the process.

Owner:CELANESE ACETATE LLC

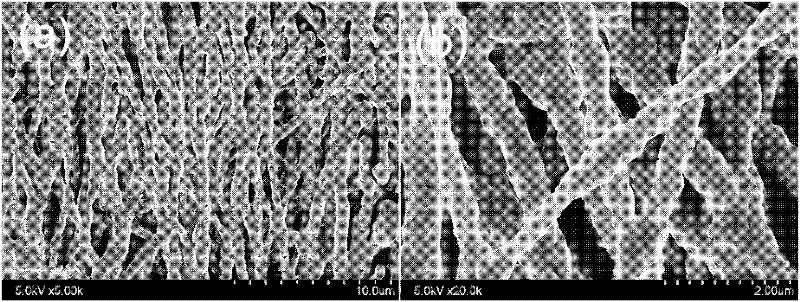

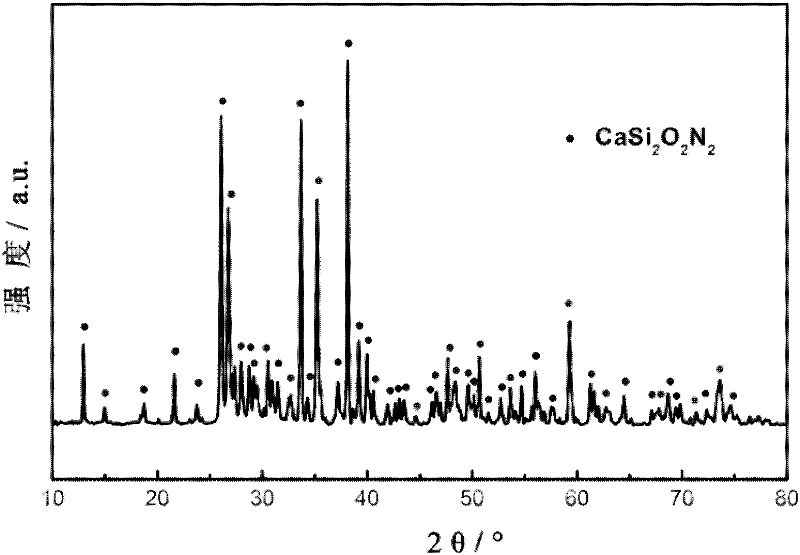

Preparation method for CaSi2O2N2:Eu<2+> fluorescence nano-fiber

InactiveCN102358963AGood fiber shapeSimple methodFilament/thread formingArtificial filament heat treatmentFluorescenceSolvent

The present invention relates to a preparation method for CaSi2O2N2:Eu<2+> fluorescence nano-fiber. The method comprises the following steps: (1) dissolving calcium nitrate and europium nitrate in a mixed solvent comprising alcohol and water; adding tetraethyl orthosilicate while stirring; adding polyvinylpyrrolidone after stirring; continuously stirring to obtain a spinning liquid; (2) pouring the spinning liquid into a syringe, carrying out electrostatic spinning to collect a layer of uniform white fiber on receiving aluminum foil; (3) placing the white fiber into a high-temperature tubularatmosphere furnace to carry out a heat treatment; finally carrying out cooling along with the furnace to obtain the CaSi2O2N2:Eu<2+> fluorescence nano-fiber. The method of the present invention has characteristics of simpleness, low nitridation temperature and short time. The prepared CaSi2O2N2:Eu<2+> phosphor has good fiber morphology so as to contribute to improvement of the luminescent property and the later package in the LED, and has a good application prospect.

Owner:DONGHUA UNIV

Preparation method of aerogel based on double network structure design

InactiveCN108192153AImprove the defects of easy collapse and insufficient mechanical strengthRetain structureConjugated synthetic polymer artificial filamentsFiberFreeze-drying

The invention discloses a preparation method of an aerogel based on a double network structure design. The method comprises the steps that a sodium alginate is added by a one-step or two-step method by radical polymerization to form a gel solution of a polyacrylamide chemical cross-linking network interpenetrating sodium alginate structure, gel is extruded into a coagulation bath to form microspheres or fiber and other forms, at the same time, calcium alginate ion cross-linking is formed through ion exchange, and finally a double-network structure hydrogel interlocking chemical cross-linking and ion cross-linking is formed. After washing with water and freeze-drying, finally an aerogel is obtained. The aerogel exhibits a microscopic multi-layered pore structure with large pore nested mesopores and micropores. According to the preparation method of the aerogel based on the double network structure design, the sodium alginate and acrylamide are utilized to prepare the composite aerogel,the application of an aerogel material in actual production is expanded, and moreover theerogel material has outstanding characteristics of economy, environmental protection, biocompatibility, degradation and the like compared with other aerogel materials, not only can be processed into microspheres, massive structure, but also can directly be processed into fiber morphology.

Owner:DALIAN POLYTECHNIC UNIVERSITY +1

Processes for pretreating and purifying a cellulosic material

A process for treating a cellulosic material comprising pretreating the cellulosic material and then extracting the cellulosic material with an extractant to selectively extract hemicellulose therefrom and separating the extracted hemicellulose to form a cellulosic product comprising less hemicellulose than the cellulosic material. The extractant comprises a cellulose solvent and a co-solvent. The cellulosic product advantageously retains its cellulosic fiber morphology. The processes involve separating and recovering the hemicellulose and separating and recycling various process streams employed in the process.

Owner:CELANESE ACETATE LLC

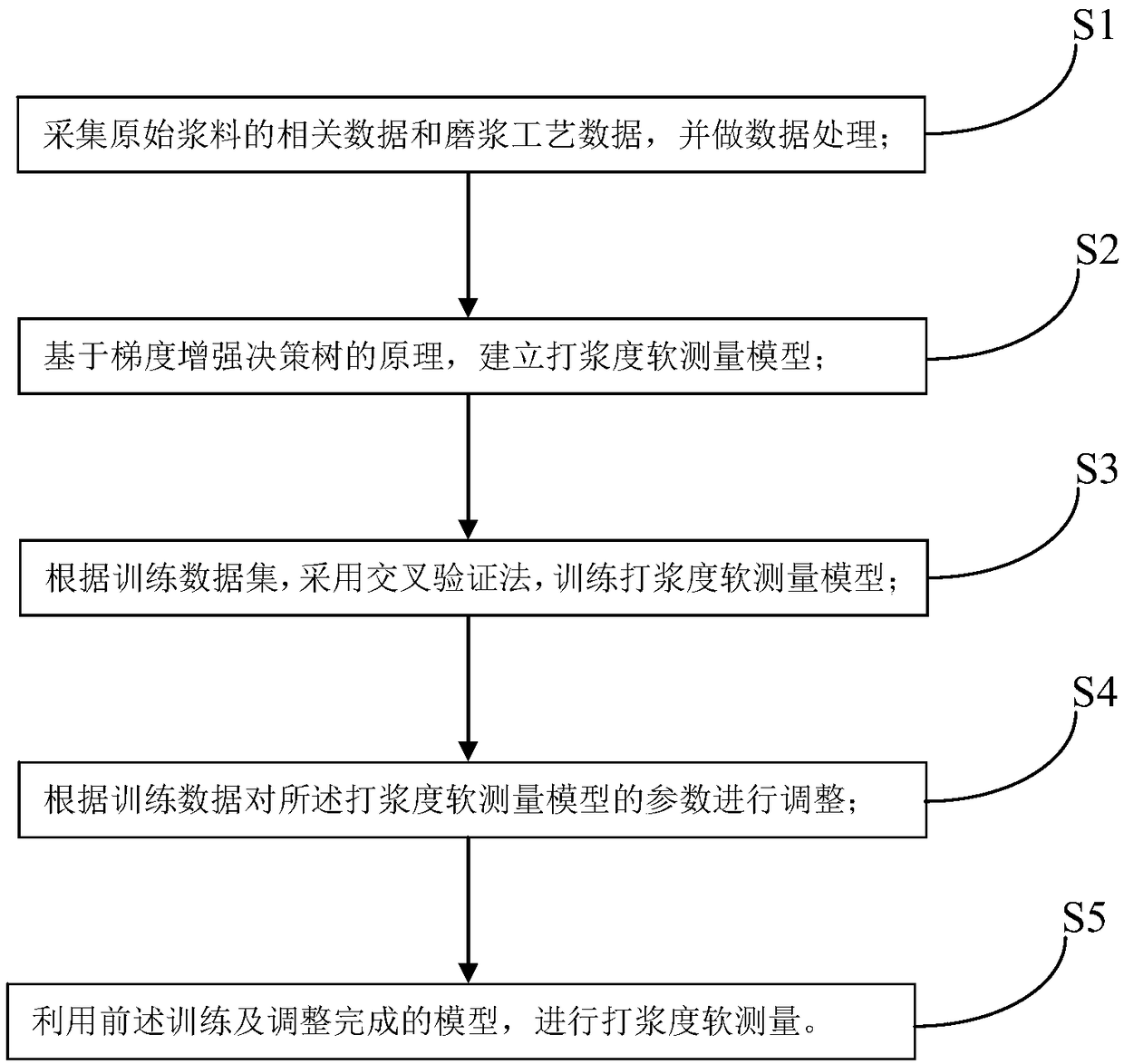

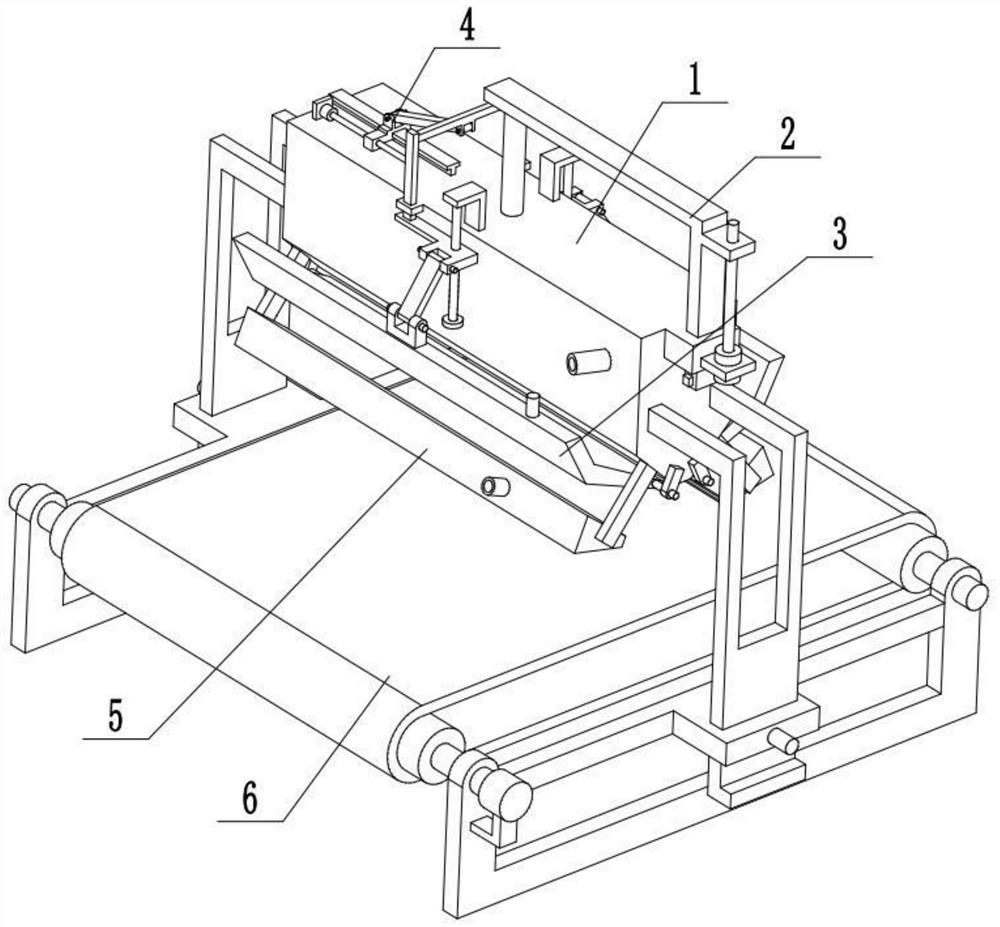

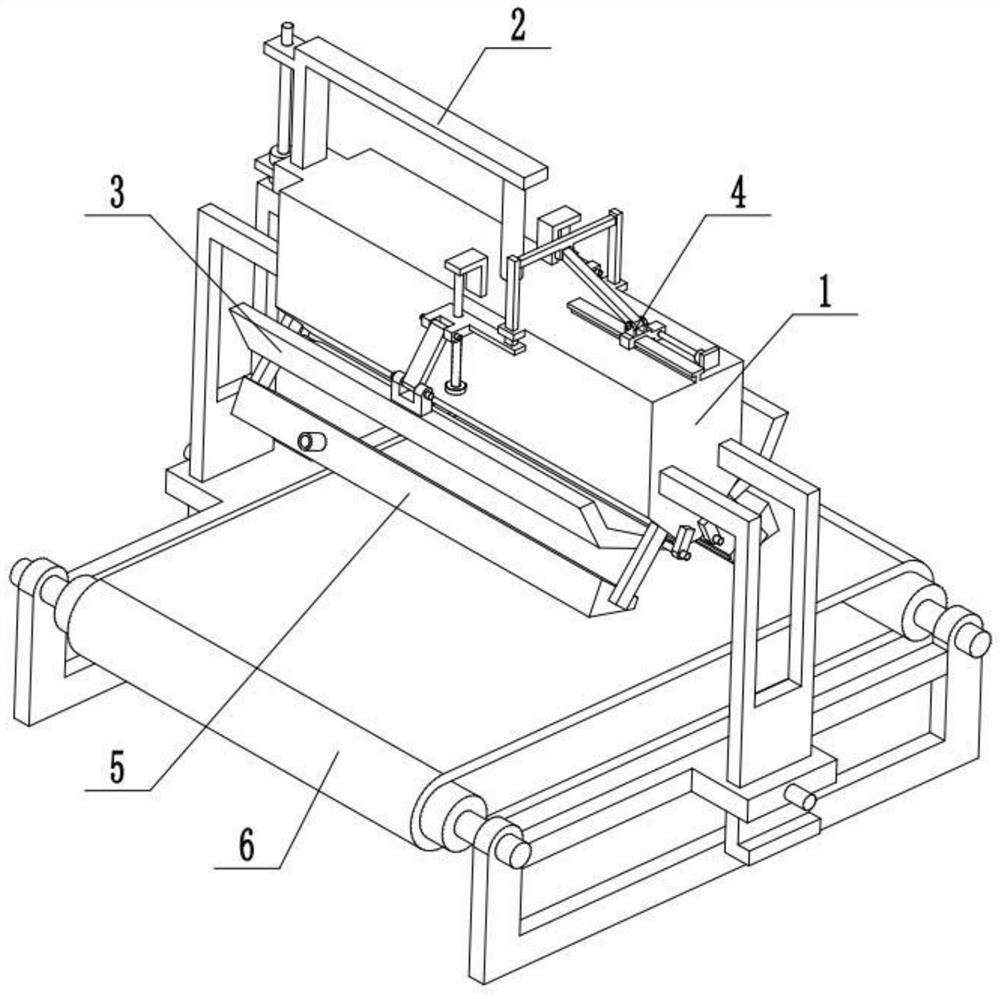

Soft measurement method for beating degree of papermaking process based on gradient enhanced regression tree

ActiveCN109440515AFully express the effect of freenessSolve the problem of missing value handlingPulp beating methodsFiberData set

The invention discloses a soft measurement method for the beating degree of the papermaking process based on a gradient enhanced regression tree. The method comprises the following steps of S1, collecting fiber morphology data of an original slurry and initial pulping degree data, collecting the refining process data, and conducting data processing; S2, based on the principle of gradient enhancedregression tree, establishing a soft measurement model of the beating degree; S3, using a cross-validation method according to the training data set, and training the soft measurement model of the beating degree; S4, adjusting the parameters of the soft measurement model of the beating degree according to the training data set; S5, using the aforementioned training and the adjusted model to conduct the soft measurement of the beating degree on a sample to be tested; the method is based on the gradient enhanced regression tree, the soft measurement model of the beating degree is established, the model is convenient and highly precise, and the method has strong generalization ability and good prospects for popularization and application.

Owner:广州博依特智能信息科技有限公司

Methods for removing hemicellulose

A method for treating a cellulosic material comprising extracting the cellulosic material with an extractant to selectively extract hemicellulose therein and separating the extracted hemicellulose to form a cellulosic product comprising less hemicellulose than the cellulosic material. The extractant comprises an amine oxide and a non-solvent. The cellulosic product retains the cellulosic fiber morphology.

Owner:CELANESE INT CORP

A polyvinyl alcohol/collagen/quaternized chitosan electrospun composite fiber film and a preparing method thereof

PendingCN107693835AAntibacterial and anti-inflammatoryRapid hemostasisSurgical adhesivesConjugated cellulose/protein artificial filamentsFiberPolymer science

The invention relates to a polyvinyl alcohol / collagen / quaternized chitosan electrospun composite fiber film and a preparing method thereof, and belongs to the field of medical devices. The method includes firstly evaluating morphology of spinning fibers through adjusting a mass ratio between polyvinyl alcohol and collagen and concentrations so as to determine that the optimum ratio between the polyvinyl alcohol and the collagen is 80:20, and that the optimum concentration is 8%; and then when the concentration of added quaternized chitosan is 5%, preparing the composite fiber film by an electrospinning technique. The composite fiber film is simple and convenient to prepare, has good flexibility and mechanical properties, can rapidly stop bleeding, and can form a protective fiber felt layeron wound surfaces to promote wound healing and prevent bacterial infection, thus healing skin wounds. The composite fiber film also has a bleeding arresting function, a wound healing function, antibacterial and anti-inflammation functions, and the like, is suitable for use as a bleeding arresting material, a wound healing material, and a medical device material, and has a good application prospect.

Owner:BINZHOU MEDICAL COLLEGE

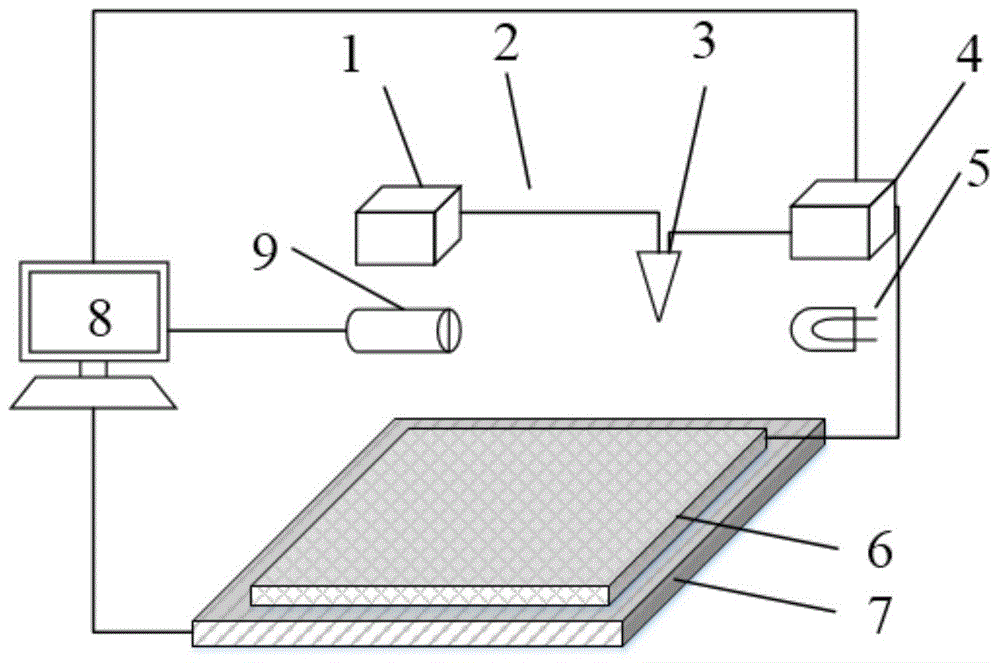

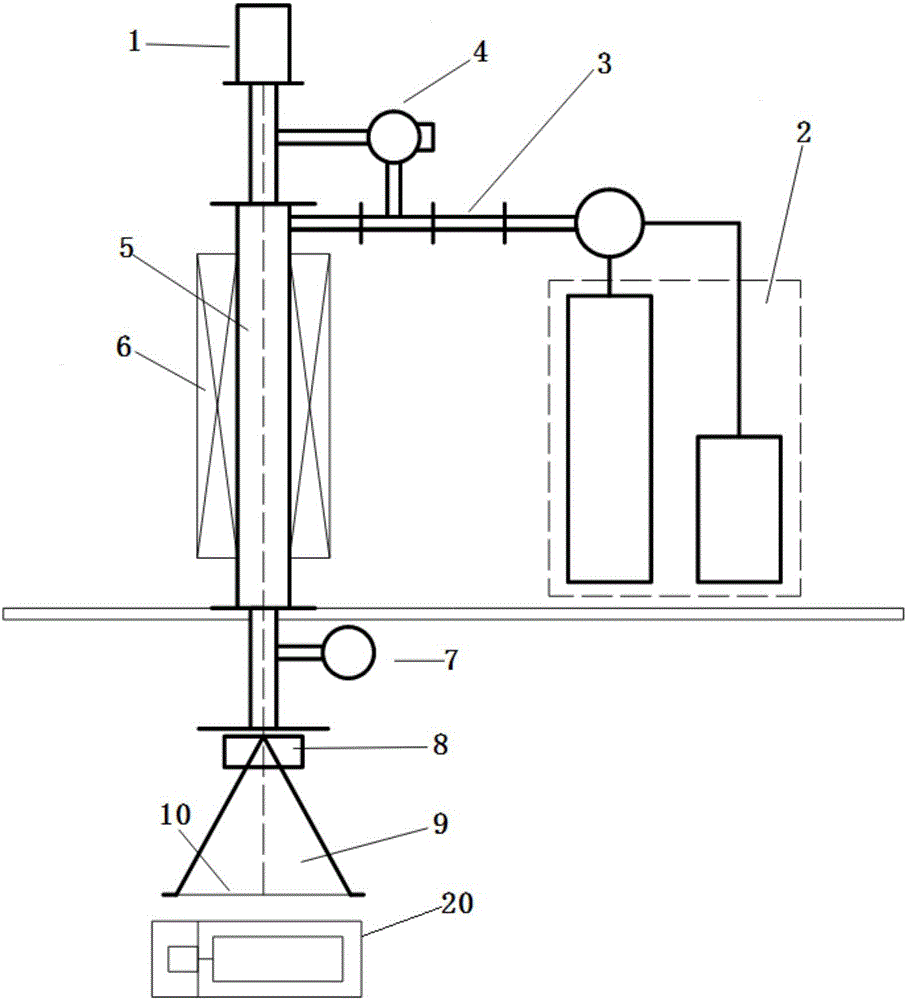

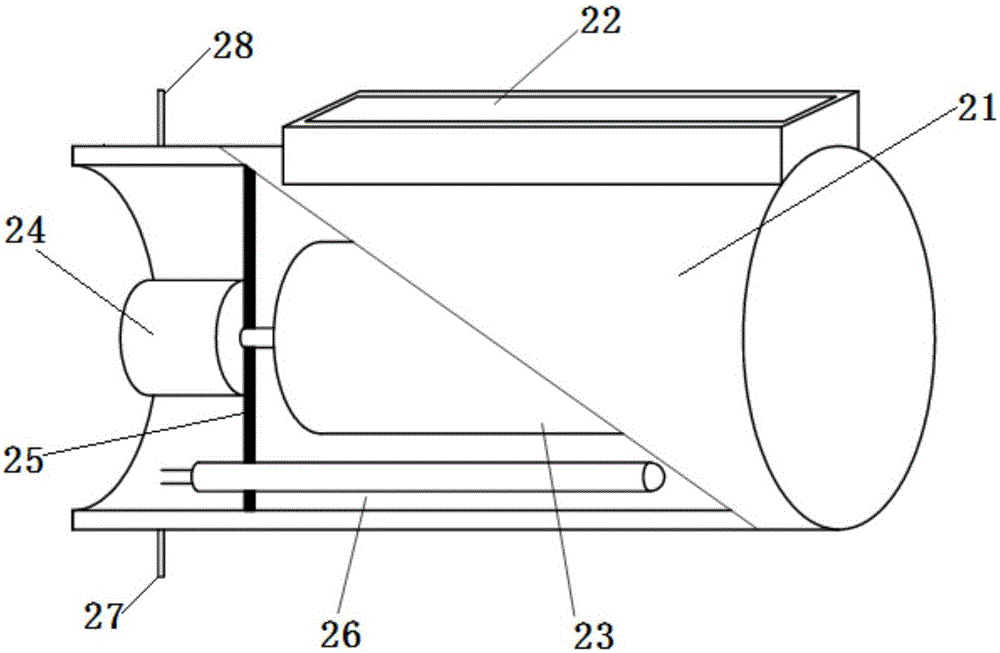

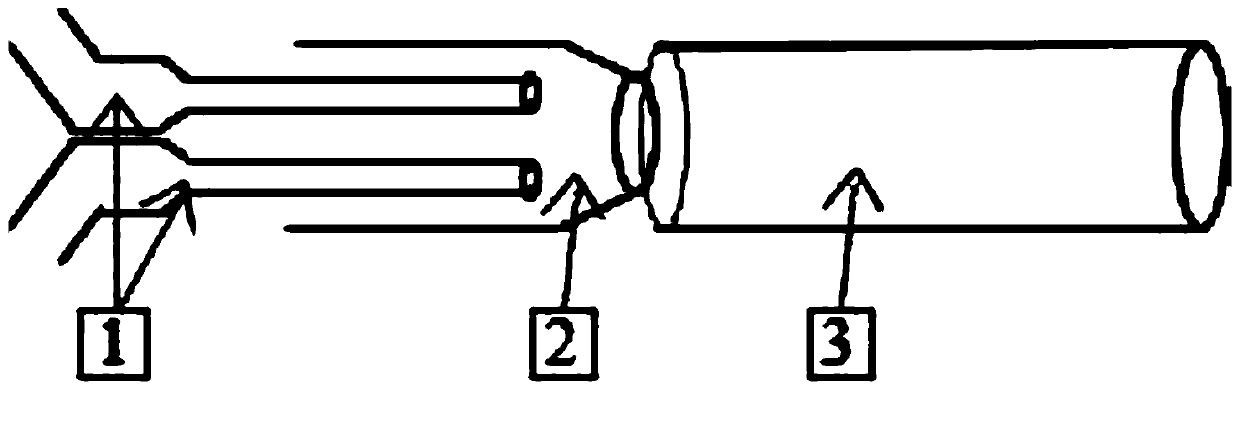

Device for generating micro/nano-fibers with controllable waveforms

InactiveCN103993369AExclude the effect of depositionEasy to controlNew-spun product collectionFilament/thread formingFiberSpinning

The invention provides a device for generating micro / nano-fibers with controllable waveforms. The device comprises a precision injection pump, a precision injection pump feed mechanism guide rail, an injector push rod, an injector, an electrostatic spinning sprayer, auxiliary electrodes, a controllable power supply, a motion platform, a collector, a high-voltage direct-current power supply, a control system and a power lead screw, wherein the injector is installed on the precision injection pump, the precision injection pump controls the feed rate of a solution inside the injector through an injector push mechanism, the electrostatic spinning sprayer is installed at the tail end of the injector and used for forming an electrostatic spinning environment, the collector is installed on the motion platform and used for collecting fibers and providing a spinning environment, and the motion platform is used for providing the motion speed and direction of a collecting board in a near field direct writing mode. According to the device, electric fields between the two auxiliary electrodes change, the stress of jet flow in air also changes in the spinning process, so that the deposited track of the jet flow also changes, and the shape and the size of the deposited fibers can be controlled by controlling output signals of the controllable power supply.

Owner:GUANGDONG UNIV OF TECH

Processes for Purifying a Cellulosic Material

InactiveUS20140326421A1Reduced hemicellulose contentHigh solid contentPulp properties modificationWashing/displacing pulp-treating liquorsCellulose fiberHemicellulose

A process for treating a cellulosic material comprising extracting the cellulosic material with an extractant to selectively extract hemicellulose therefrom and separating the extracted hemicellulose to form a cellulosic product comprising less hemicellulose than the cellulosic material. The extractant comprises a cellulose solvent and a co-solvent. The cellulosic product advantageously retains its cellulosic fiber morphology. The processes involve separating and recovering the hemicellulose and separating and recycling various process streams employed in the process.

Owner:ACETATE INT LLC

PHBV (Poly (HydroxyButyrate-hydroxyValerate)) nano fiber support material as well as preparation method and application thereof

The invention discloses a PHBV (Poly (HydroxyButyrate-hydroxyValerate)) nano fiber support material, a preparation method and application thereof. The preparation method comprises the following steps of: (1) dissolving PHBV powder with the molecular weight of 3*105 in an organic solvent to compound a solution with the concentration of 7.5%, and then stirring for 3-5 hours in a water bath at 50 DEG C by using magnetic force; (2) after fully dissolving the PHBV, hermetically placing the solution; (3) after the solution fully forms hydrogel, taking the hydrogel out, adding acetone for replacing the organic solvent, and then replacing the acetone by using deionized water; and (4) and freezing and drying the PHBV hydrogel to obtain the PHBV nano fiber support material. The PHBV nano fiber support material has the advantages of low cost, simple preparation process, good biocompatibility, high porosity and controllable support structure and fiber morphology; and because the morphological structure of the PHBV nano fiber support material is similar to that of an extracellular matrix in cartilaginous tissue cells of a human body, the PHBV nano fiber support material can promote the adhesion, the propagation and the differentiation of cartilaginous cells and is very suitable for restoring and reconstructing cartilaginous tissues.

Owner:SOUTH CHINA UNIV OF TECH

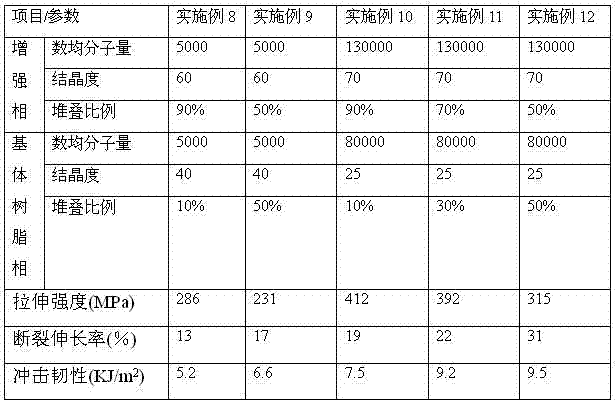

Self-reinforced bionic material and manufacture method thereof

The invention discloses a self-reinforced bionic material, comprising a reinforced phase prepared from a biodegradable polymer A with high molecular weight and high crystallinity, and a matrix resin phase prepared from a biodegradable polymer B with molecular weight and crystallinity lower than those of the biodegradable polymer A; the reinforced phase and the matrix resin phase are stacked by a guide die; and the stacking percentage of the reinforced phase is 30-90%, and the stacking percentage of the matrix resin phase is 5-60%. The invention also provides a manufacturing method of the self-reinforced bionic material. The invention employs ultrasonic transient heating and interface mechanism with controllable strength to solve a problem for keeping melting fiber morphology when the difference of melting temperature between matrix and the reinforced phase is small; and fiber distribution gradient is constructed to prepare a biodegradable self-reinforced biomimetic material with bamboo imitation structure, high strength and high toughness.

Owner:GUANGZHOU MEDICAL UNIV

Methods for extracting hemicellulose from a cellulosic material

InactiveUS20140048221A1Less hemicelluloseWashing/displacing pulp-treating liquorsPulping with organic compoundsNon solventAcetic acid

A method for treating a cellulosic material comprises extracting the cellulosic material with an extractant to selectively extract hemicellulose therein and separating the extracted hemicellulose to form a cellulosic product comprising less hemicellulose than the cellulose-containing material. The extractant comprises an ionic liquid and a non-solvent comprising acetic acid. The cellulosic product retains the cellulosic fiber morphology.

Owner:CELANESE INT CORP

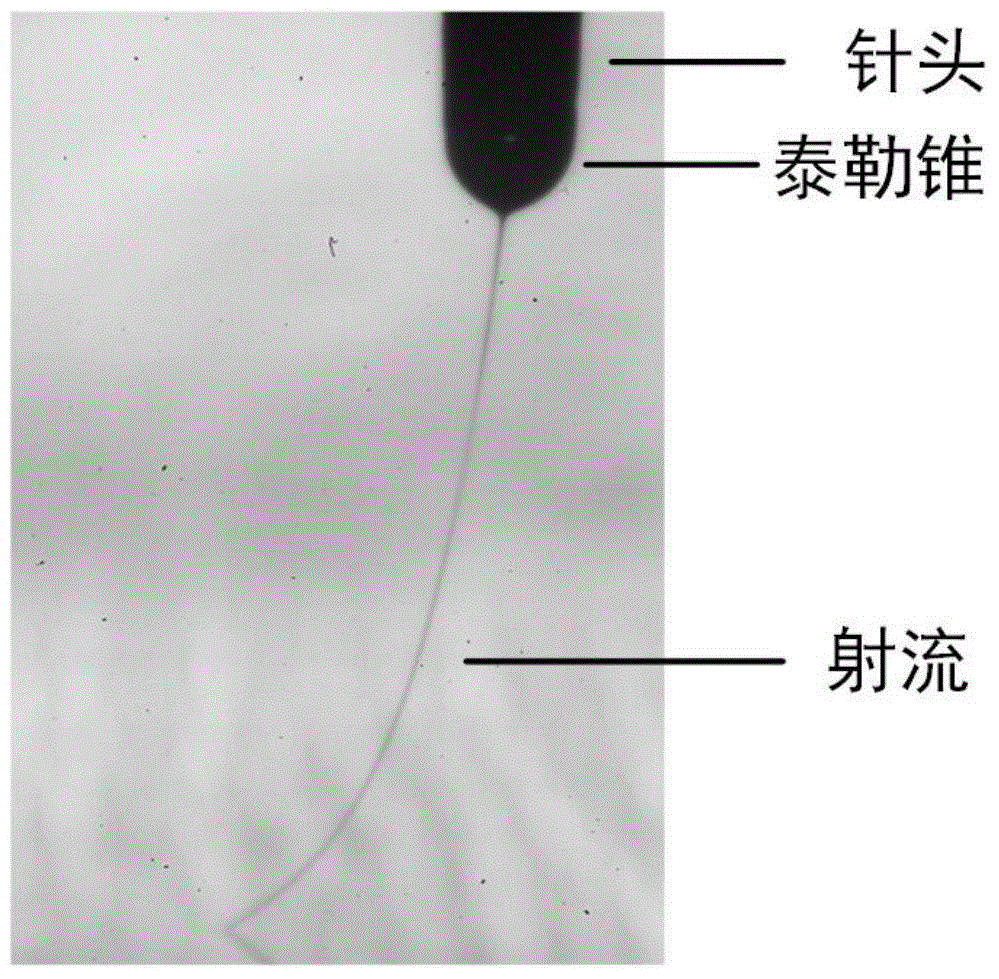

Closed-loop control method for electrospining direct writing technology

InactiveCN104309338AEffective removal of interferenceEliminate distractionsSpinning head liquid feederFilament manufactureFiberLoop control

The invention discloses a closed-loop control method for electrospining direct writing technology, according to the fluid change at actual spraying time, the liquid at the nozzle is divided into taylor cone and jet flow for control, the high speed camera is used for detecting the form, the end information is directly fed back to the controller for adjusting and controlling the substrate movement speed and spraying voltage impacting the jet flow and taylor cone, having closed-loop control to the electrospining direct writing technology, controlling the fiber morphology and diameter and preparing high precision array pattern.

Owner:HUAZHONG UNIV OF SCI & TECH

Methods for removing hemicellulose

InactiveUS20140048223A1Suitable characteristicWashing/displacing pulp-treating liquorsPulping with organic compoundsNon solventCellulose fiber

A method for treating a cellulosic material comprising extracting the cellulosic material with an extractant to selectively extract hemicellulose therein and separating the extracted hemicellulose to form a cellulosic product comprising less hemicellulose than the cellulosic material. The extractant comprises an amine oxide and a non-solvent. The cellulosic product retains the cellulosic fiber morphology.

Owner:CELANESE INT CORP

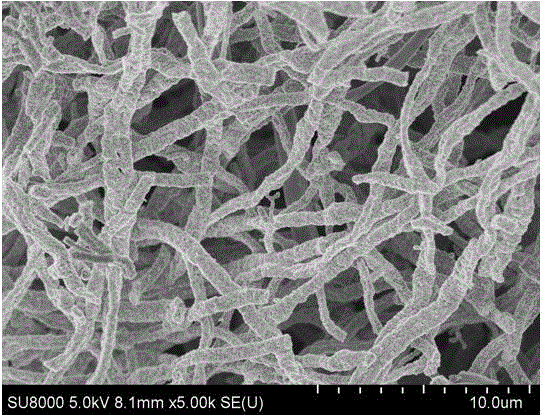

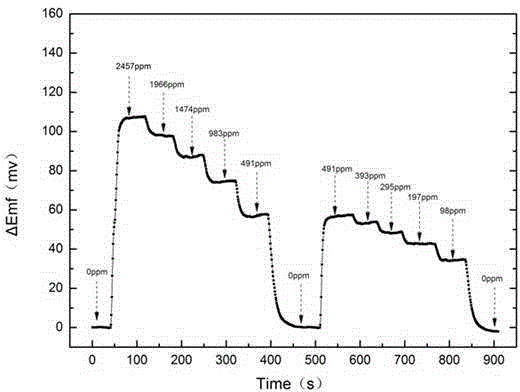

Method for preparing NiO fiber material for NOX detection

InactiveCN104532403AReduce usageLow costInorganic material artificial filamentsMaterial analysis by electric/magnetic meansFiberNickel salt

The invention relates to a method for preparing a NiO fiber material for NOX detection. The material is characterized by being prepared from NiO with the nano fiber morphology. The method specifically comprises the following steps: dissolving soluble nickel salt in a proper amount of solvent, stirring to dissolve the nickel salt at the room temperature, adding PVP into a solution, thereby obtaining a precursor solution; putting the precursor solution into electrostatic spinning equipment, performing electrostatic spinning, calcining PVP composite nano fiber, and naturally cooling to be the room temperature, thereby obtaining the NiO nano fiber material after calcining. The material is low in cost and easy in preparation and has good response property to NOX gas concentration change.

Owner:CHINA FIRST AUTOMOBILE

Method and device for preparing BN fiber through electron beam irradiation crosslinking

ActiveCN106757530AHigh crystallinityExcellent dielectric propertiesPhysical treatmentFibre chemical featuresElectricityCarbonization

The invention discloses a method and a device for preparing a BN fiber through electron beam irradiation crosslinking. The method comprises the following steps: (1) taking an organic polyborazine precursor as a raw material and performing melt spinning, thus obtaining a proto fiber; (2) irradiating the proto fiber with electron beam, thus obtaining BN non-melting fiber through electron beam irradiation crosslinking; (3) heating the beam treated in the last step, causing the residual free radical to further react to lose activity; (4) performing inorganic and ceramic treatment on the non-melting fiber, thus obtaining the BN fiber. According to the invention, a new non-melting treating technique is applied to the BN fiber; the proto fiber obtained after the treatment according to the technique can maintain the fiber morphology in the subsequent treatment processes, such as, low-temperature de-carbonization and high-temperature nitridation; the solid BN fiber with excellent crystallinity and dielectric property can be obtained; the mechanical property of the BN fiber can be greatly improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method and application of electrostatic spinning modified membrane adsorption material

The invention discloses a preparation method and application of an electrostatic spinning modified membrane adsorption material. A nanofiber membrane is prepared by adopting an electrostatic spinning instrument and is processed by a low-temperature plasma device, so that the electrostatic spinning nanofiber membrane is modified to obtain the electrostatic spinning modified membrane adsorption material. The PET (polyethylene glycol terephthalate) nanofiber membrane with uniform fiber morphology is prepared by adopting the electrostatic spinning instrument and then is subjected to surface modification by adopting the low-temperature plasma processing device in a plasma processing method combining gas phase and liquid phase, thus obtaining the PET nanofiber membrane with excellent hydrophilic performance. The modified membrane is applied to adsorption of heavy metal ions Cu (II). The electrostatic spinning modified membrane adsorption material can adsorb Cu (II) efficiently and rapidly.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of tobacco sheet paper base by cabo

ActiveCN102640980AOptimization of beating processAccurately reflect the actual lengthTobacco preparationFiberPaper based

The invention discloses a preparation method of tobacco sheet paper base by cabo. The tobacco sheet paper base is prepapred by taking the cabo as raw material and adopting a paper making method. The preparation method comprises the steps of dipping the cabo, grinding, beating, making sheet and drying the cabo. The beating concentration is 10%, the gap between a beating roller and a beating room is 0.2mm, and the beating pressure is 3.33N / mm; and the beating revolution is 1500-2500, and the bearing degree is 20-30 degrees SR. According to the preparation method, the optimal process condition of the beating steps is determined, the technical scheme for the comprehensive performances that the tobacco sheet paper base is prepared by utilizing the cabo again is optimized, the proper design and technical conditions of the beating degree of the cabo is determined, the excellent fiber shape and the excellent physical performance of pulp are obtained, the tensile indexes, tearing indexes, bulk, air permeability and burst indexes of the paper base product are proper, and the good quality of the tobacco which is prepared again can be ensured.

Owner:CHINA TOBACCO GUANGDONG IND +1

Hydrophobic melt-blown fabric preparation method

InactiveCN111648042AChange the receiving distanceImprove bulkNew-spun product collectionMelt spinning methodsPolymer sciencePolymer chemistry

The invention relates to a technical field of melt-blown fabric production, and more specifically, discloses a hydrophobic melt-blown fabric preparation method. The hydrophobic melt-blown fabric preparation method comprises the following steps: step 1, stock solution adding: adding raw material solution, and spraying out the raw material solution; step 2, drafting: drafting the raw material solution with high temperature to form a superfine fiber; step 3, cooling: adhering the superfine fiber sprayed out through own adhesive action, making the superfine fiber sprayed out form a melt-blown fabric through a cooling air flow; step 4, transporting: transporting the melt-blown fabric to next work station; step 5, angle adjustment: adjusting angle of the high temperature air flow, and obtainingthe melt-blown fabric with good fiber morphology. In the hydrophobic melt-blown fabric preparation method above, a hydrophobic melt-blown fabric preparation apparatus is also related; the hydrophobicmelt-blown fabric preparation apparatus comprises a melt-blown die head component, an extrusion discharging apparatus, a high temperature air flow generator component, an angle adjustment apparatus, acooling air flow generator and a receiving apparatus, wherein the belt-blown die head component is arranged on the receiving apparatus.

Owner:烟台舒朗医疗科技有限公司

Preparation method and application of bionic multi-component fiber

ActiveCN111485296AImprove mechanical propertiesGood electrical propertiesElectroconductive/antistatic filament manufactureHybrid capacitorsFiberSpinning

The invention relates to a preparation method and application of a bionic multi-component fiber. The bionic multi-component fiber comprises an outer shell layer and a multi-inner-core layer. The outershell layer is composed of a biological material excellent in mechanical performance. The multi-inner-core layer is composed of a biological material excellent in electrical performance, so that thetensile property and electrical property of the bionic multi-component fiber are guaranteed; the tensile property and electrical property of the bionic multi-component fiber are precisely adjusted bycontrolling the number of inner cores and the thickness proportion of a shell and the inner cores; and the shell and the multi-inner-core layer are prepared through a multi-component microfluidic technology. The multi-component fiber has good mechanical performance and electrical performance, and the preparation method for microfluidic spinning has the advantages of being low in cost, convenient to assemble and control, safe, reliable and capable of precisely controlling the fiber morphology. The application of the prepared bionic multi-component fiber on the aspect of flexible electronics isprovided, the bionic multi-component fiber has good electrical performance, shows good flexibility and cyclicity, and is high in applicability.

Owner:NANJING DRUM TOWER HOSPITAL

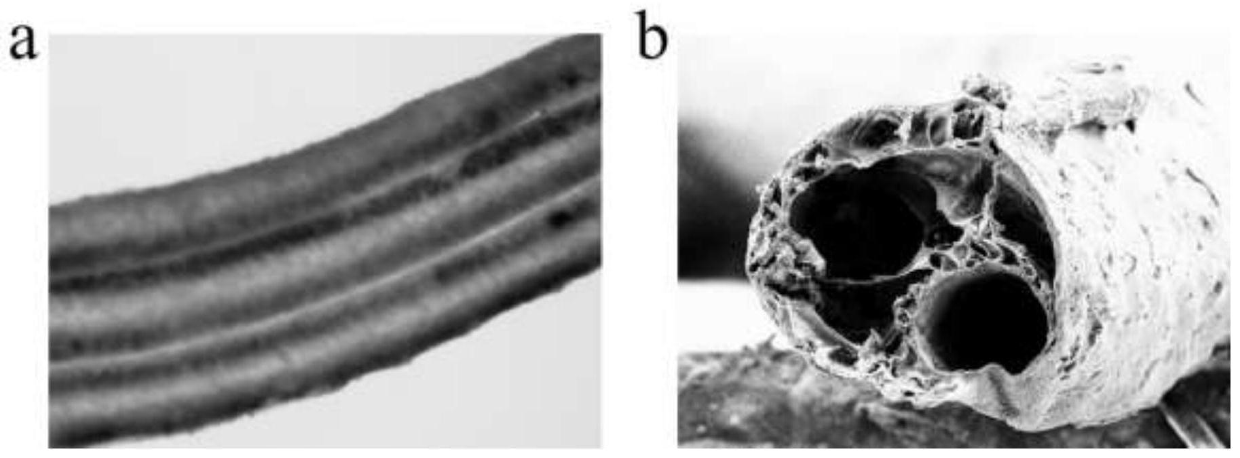

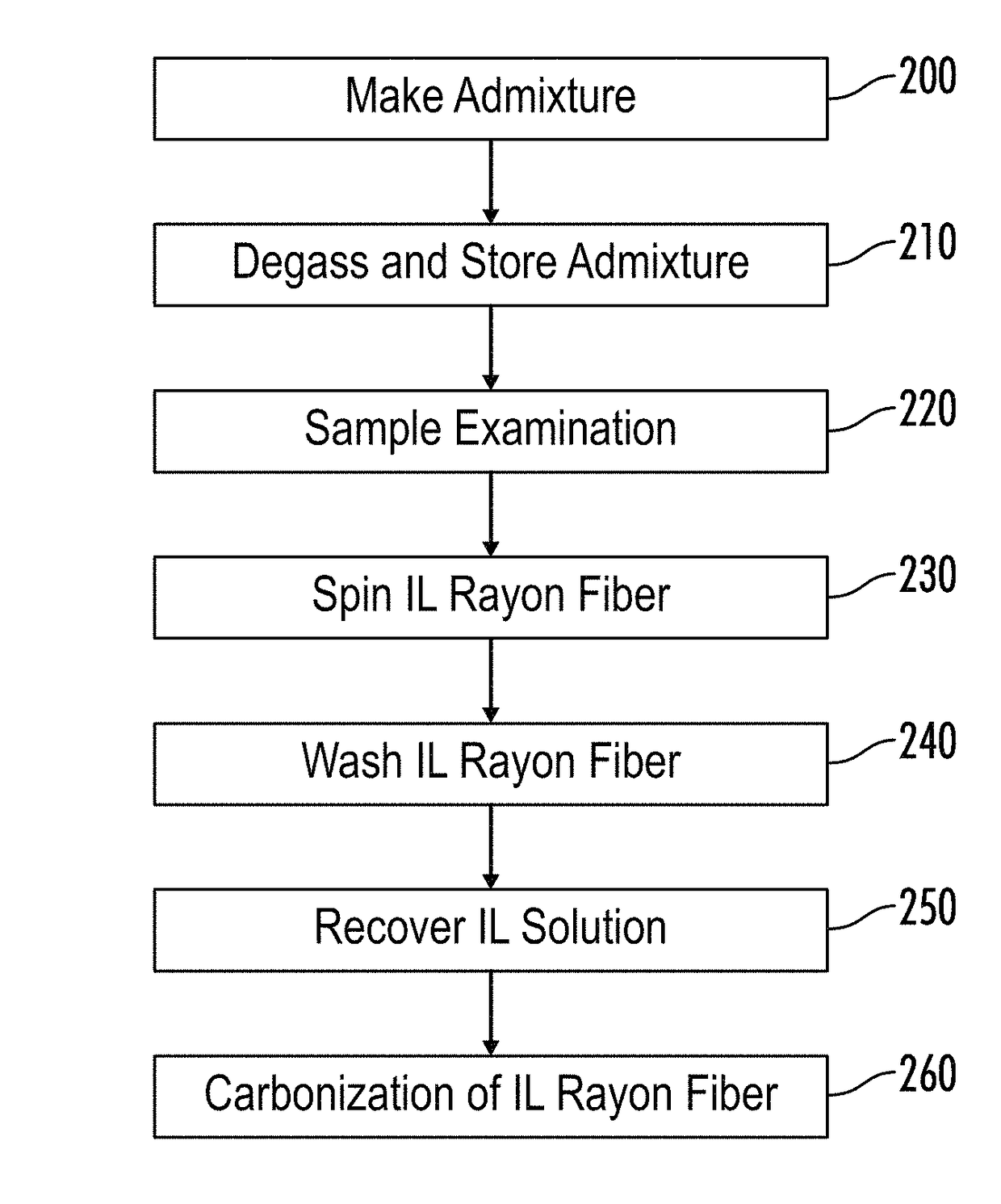

Methods and systems for making carbon fibers for high temperature applications

ActiveUS9695525B1Spinning solution filteringArtificial filaments from cellulose solutionsCelluloseCarbon fibers

The present invention relates to a method for the continuous production of low thermal conductivity endless filament yarns with a compact, homogeneous structural morphology. The presently disclosed methods utilize safe and recyclable ionic liquids (IL) to produce carbon fiber precursors from cellulose. The fibers are produced by the carbonization of cellulose carbon fiber precursors. The precursor fiber filaments have an increased tear resistance with simultaneously sufficient elongation, a round or crenulated cross-section, and homogeneous fiber morphology. The filament yarns exhibit performance characteristics similar to those produced from traditional viscous rayon. The resulting fibers are especially suited for aerospace applications in composite materials used at the limits of high temperatures, for instance in structures found in rocket nozzles or atmospheric reentry heat shields on spacecraft.

Owner:UNIVERSITY OF ALABAMA

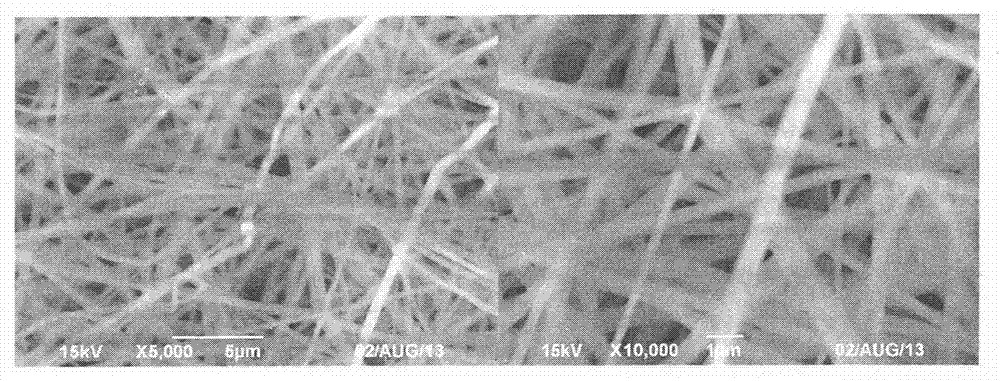

Submicron/nanometer anaerobic silicon carbide fiber felt and preparation method thereof

ActiveCN107988712AImprove high temperature resistanceAvoid introducingElectro-spinningMonocomponent synthetic polymer artificial filamentOrganic solventOxygen

The invention discloses submicron / nanometer anaerobic silicon carbide fiber felt and a preparation method thereof. The preparation method includes the steps of providing a spinning solution containinghigh-molecular-weight polycarbosilane with the Mw greater than 8000, a spinning-assisting polymer and an organic solvent which are uniformly mixed, performing electrospinning with the spinning solution to obtain precursor fiber felt, and performing heating pyrolysis treatment on the precursor fiber felt in a protective atmosphere to obtain the submicron / nanometer anaerobic silicon carbide fiber felt. According to the preparation method, soluble and infusible high-molecular-weight polycarbosilane is adopted to prepare the submicron / nanometer anaerobic silicon carbide fiber felt, and as high-molecular-weight polycarbosilane does not need air infusibility treatment in the heating process, it is avoided that oxygen is introduced into the submicron / nanometer anaerobic silicon carbide fiber felt; besides, after the silicon carbide fiber felt is treated at the temperature reaching 1600 DEG C in an inert atmosphere, the mass decrement is smaller than 2wt%, and the complete fiber morphology can still be maintained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com