Method for preparing NiO fiber material for NOX detection

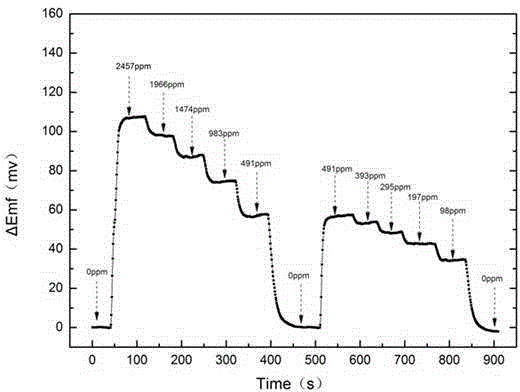

A fiber material and nanofiber technology, applied in the field of sensors, can solve the problems of difficult to meet the commercialization needs of NOX sensors, easy poisoning, weak signal, etc., and achieve high practical value, large specific surface area, and low material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

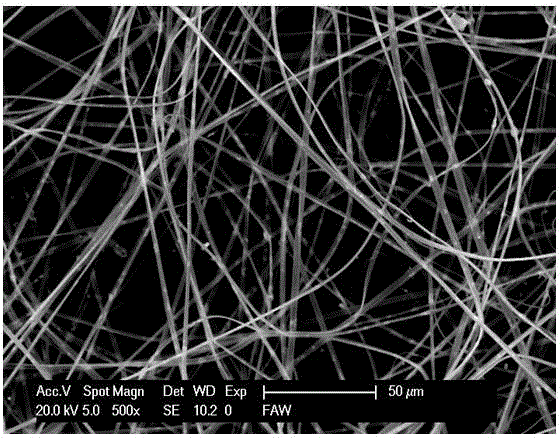

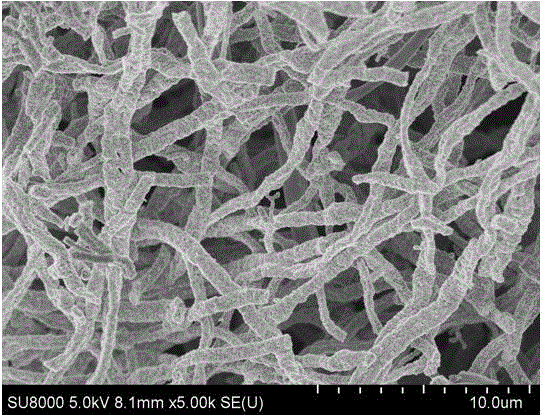

[0027] Such as Figure 1-3 As shown, weigh 1 g of nickel acetate and place it in a beaker, add 100 g of absolute ethanol, stir at room temperature to dissolve it, and stir for 2 hours; then add 5 g of PVP, and continue stirring for 12 hours to obtain a precursor solution. Put the precursor solution in the electrospinning equipment, apply a high voltage of 15kV to the end of the capillary containing the solution, use aluminum foil as a receiving plate, apply a high voltage of -1kV to the aluminum foil, adjust the receiving distance to 15cm, start spinning, and obtain PVP after 5 hours Composite nanofiber membrane. Remove the film, place it in a high-temperature sintering furnace, raise the temperature to 200°C at a heating rate of 2°C / min, keep the temperature constant for 2 hours, then raise the temperature to 500°C at a heating rate of 10°C / min, keep the temperature at a constant temperature for 4 hours, and then cool to room temperature with the furnace . Obtain NiO nanofi...

Embodiment 2

[0029] Weigh 5g of nickel acetate and place it in a beaker, add 100g of absolute ethanol, stir to dissolve at room temperature for 4h; then add 10g of PVP, continue stirring for 10h to obtain a precursor solution. Put the precursor solution in the electrospinning equipment, apply a high voltage of 20kV to the end of the capillary containing the solution, use aluminum foil as a receiving plate, apply a high voltage of -1kV to the aluminum foil, adjust the receiving distance to 20cm, start spinning, and obtain a composite after 4 hours nanofibrous membrane. Remove the film, place it in a high-temperature sintering furnace, raise the temperature to 300°C at a heating rate of 5°C / min, keep the temperature constant for 2 hours, then raise the temperature to 600°C at a heating rate of 15°C / min, keep the temperature at a constant temperature for 3 hours, and then cool to room temperature with the furnace . Obtain NiO nanofiber material.

Embodiment 3

[0031] Weigh 8g of nickel acetate and place it in a beaker, add 100g of absolute ethanol, stir to dissolve at room temperature for 3h; then add 15g of PVP, continue stirring for 15h to obtain a precursor solution. Put the precursor solution in the electrospinning equipment, apply a high voltage of 20kV to the end of the capillary containing the solution, use aluminum foil as a receiving plate, apply a high voltage of -1kV to the aluminum foil, adjust the receiving distance to 30cm, start spinning, and obtain a composite after 6 hours nanofibrous membrane. Remove the film, place it in a high-temperature sintering furnace, raise the temperature to 400°C at a heating rate of 7°C / min, keep the temperature constant for 2 hours, then raise the temperature to 800°C at a heating rate of 20°C / min, keep the temperature at a constant temperature for 4 hours, and then cool to room temperature with the furnace . Obtain NiO nanofiber material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com