Nerve tissue engineering electric conduction nano-fiber tubular stent and preparation method thereof

A nerve tissue and fiber tube technology is applied in the fields of conductive nanofiber tubular scaffolds, nerve conduits for nerve repair and their preparation, new tissue engineering filling materials and preparation fields, and achieves the promotion of proliferation and differentiation, excellent conductivity, and high packing density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

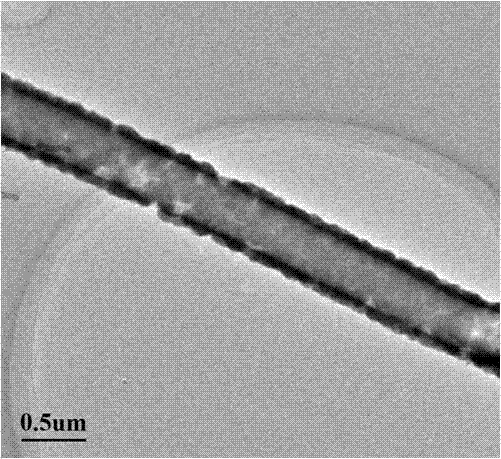

[0037] (1) Dissolve 4 g of PY and 10 g of DBSA in 100 ml of deionized water, place in an ice bath, and add 10 ml of pre-cooled APS aqueous solution [20% (w / v)] dropwise under mechanical stirring , Initiate PY polymerization in PY / DBSA solution under mechanical stirring, control the reaction temperature at 0°C, add excess methanol after 8h to terminate the reaction, collect the black precipitate by centrifugation, wash with deionized water, methanol, acetone, respectively, until liquid Become colorless and transparent. The black solid product was dissolved in chloroform, filtered to remove the insoluble matter, and the solvent was removed by rotary evaporation to prepare soluble PPY.

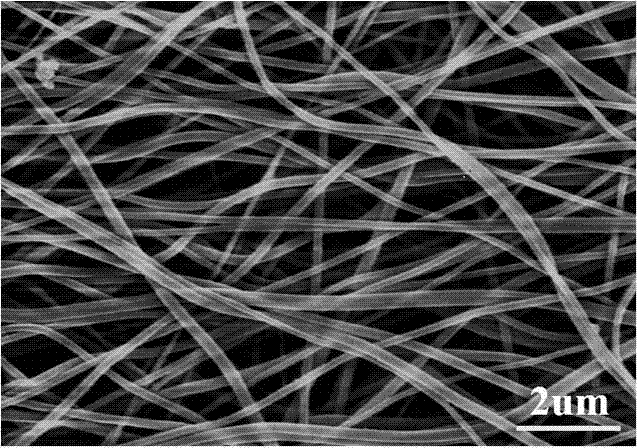

[0038] (2) Dissolve 2 g PLGA7525 (lactide content 75 mol%, molecular weight 100,000) in 5.5 ml chloroform, dissolve 0.2 g PPY prepared in step (1) in 5.5 ml DMF, and mix the two in equal proportions to obtain the mass A mixed solution with a concentration of 20% by volume, with a metal drum rota...

Embodiment 2

[0046] Adopt the same method as Example 1 to prepare the conductive fiber tubular support filled with conductive hydrogel, except the outer biodegradable polyester non-woven fiber membrane of the tubular support, adopt poly-L-lactic acid (PLLA, molecular weight) whose degradation rate is slower than PLGA7525 100,000), thereby obtaining a NGF-loaded conductive fiber tubular scaffold for nerve tissue engineering with a certain degradation gradient from the inside to the outside of the fiber tube wall.

[0047] Step (4) is operated as follows, and other operating steps are the same as in Example 1:

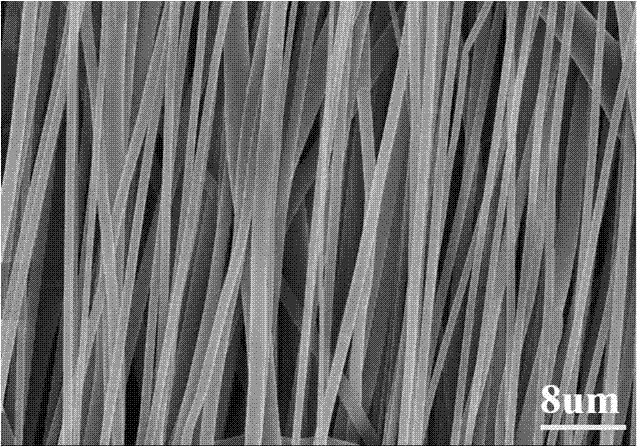

[0048] Dissolve 1 g of PLLA in 10 ml of trifluoroethanol to obtain a viscous solution with a mass volume percentage concentration of 10%. The aluminum foil fixed with parallel fiber membrane A is used as the receiving device, and the fibers are directly piled up on it by electrospinning and arranged randomly The double-layer spun fiber membrane C was obtained from the PLLA fiber memb...

Embodiment 3

[0050] The conductive fiber tubular scaffold filled with conductive hydrogel was prepared by the same method as in Example 1, except that the growth factor aqueous solution configured in step (7) was a solution containing both NGF and bFGF, thus obtaining a Conductive fiber tubular scaffolds for neural tissue engineering with growth factors that promote nerve regeneration.

[0051] Step (7) is operated as follows, and other operating steps are the same as in Example 1:

[0052] The conductive PPY nanotubes prepared in step (6) are treated by the method of modifying the dopamine aqueous solution in step (3), fully ground after drying and sterilized by ultraviolet light. Dissolve 0.01 mg NGF and 0.01 mg bFGF in 10 ml deionized water at the same time, filter and sterilize, disperse and impregnate 0.1 g PPY nanotubes in the NGF aqueous solution after sterilizing, and load the two via the adsorption of nanotubes. a growth factor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com