Preparation method of constant-hydrophilic graft-modified chlorinated polymer micro/nano fiber film

A technology of grafting modification and nanofibers, which can be used in fiber processing, textiles, papermaking, non-woven fabrics, etc., and can solve problems such as difficult grafting reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

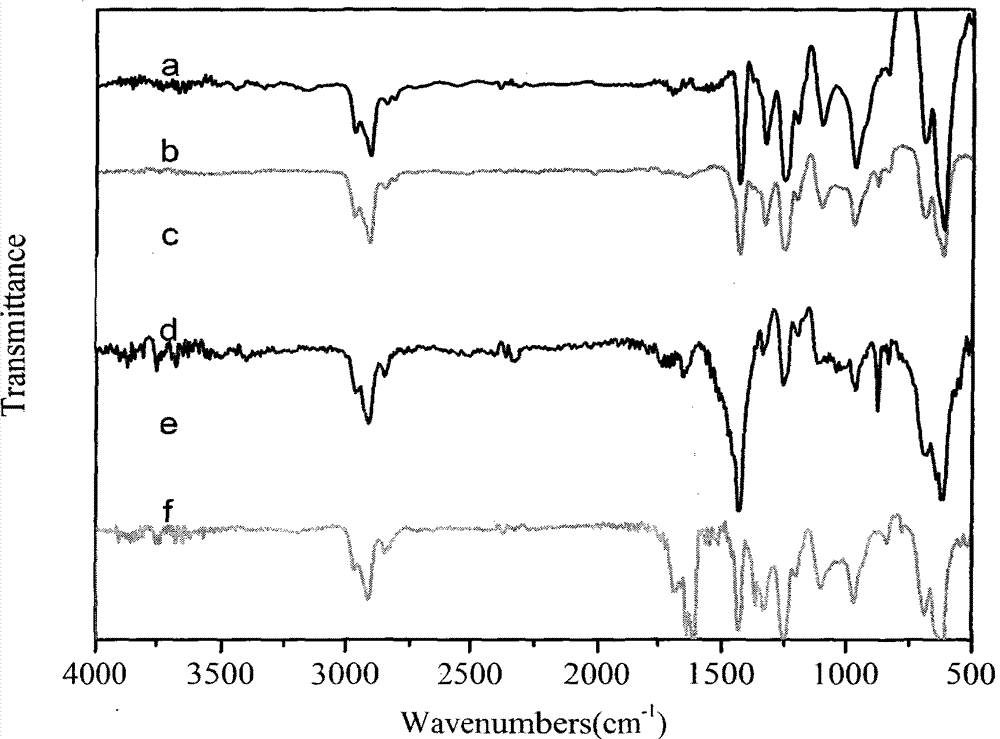

[0023] 1. PVC dehydrochlorination treatment

[0024] Add 15.00g of SG7 type PVC resin and 10wt% NaOH solution of 10 times the mass (150.00g) into a 250mL three-necked bottle, set up a reflux device, heat to the set temperature (102°C), boil and reflux for 2h, and cool to At room temperature, vacuum filter, wash with a large amount of distilled water until all residues are removed, then transfer the product to a jar and vacuum dry to constant weight to obtain a reddish dehydrochlorinated polyvinyl chloride resin (DPVC).

[0025] 2. Preparation of spinning solution

[0026] Weigh 1.30g of DPVC resin and dissolve it in 10.00g of THF / DMF mixed solvent, wherein the mixing mass ratio of THF and DMF is 40 / 60, place it in a rotary air bath constant temperature oscillator at 25°C for 24h, fully dissolve and mix evenly, and then ultrasonically eliminate Bubble.

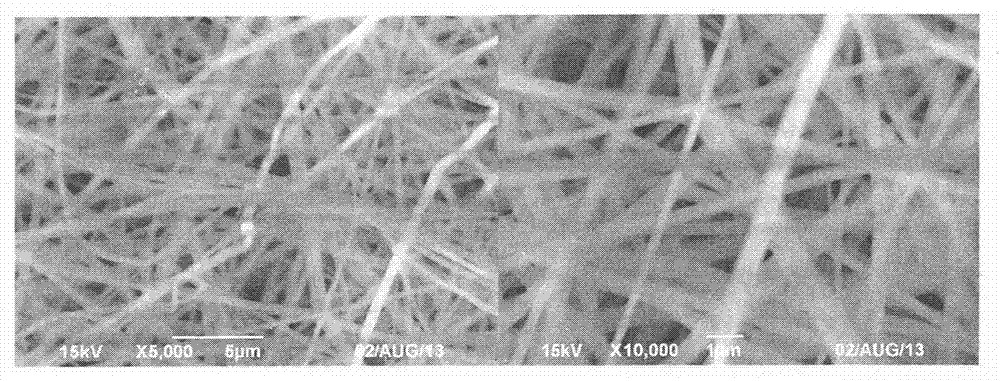

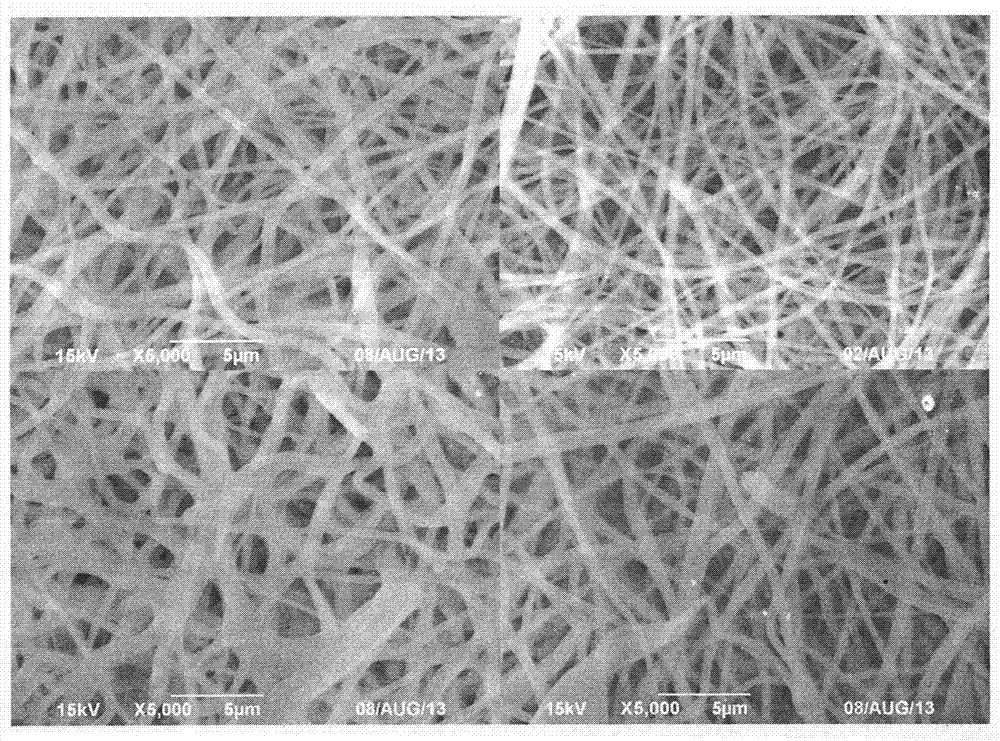

[0027] 3. Preparation of DPVC nanofiber membrane by electrospinning

[0028] Use a 10mL disposable sterile syringe to abso...

Embodiment 2

[0034] 1. PVC dehydrochlorination treatment

[0035] Add 15.00g of SG7 type polyvinyl chloride (PVC) resin and 10wt% NaOH solution of 10 times the mass (150.00g) into a 250mL three-necked bottle, set up a reflux device, heat to the set temperature (102°C), boil and reflux for 2h, After the reaction, cool to room temperature, vacuum filter, wash with a large amount of distilled water until all residues are removed, then transfer the product to a jar and vacuum dry to constant weight to obtain reddish DPVC.

[0036] 2. Preparation of spinning solution

[0037] Weigh 1.30g of DPVC resin and dissolve it in 10.00g of THF / DMF mixed solvent, wherein the mixing mass ratio of THF and DMF is 50 / 50, place it in a rotary air bath constant temperature shaker at 25°C for 24h, fully dissolve and mix evenly, and then sonicate defoaming.

[0038] 3. Preparation of DPVC nanofiber membrane by electrospinning

[0039] Use a 10mL disposable sterile syringe to absorb the above prepared spinning ...

Embodiment 3

[0045] 1. PVC dehydrochlorination treatment

[0046] Add 15.00g of SG7 type PVC resin and 10wt% NaOH solution of 10 times the mass (150.00g) into a 250mL three-necked bottle, set up a reflux device, heat to the set temperature (102°C), boil and reflux for 2h, and cool to At room temperature, vacuum filter, wash with a large amount of distilled water until all residues are removed, then transfer the product to a jar and vacuum dry to constant weight to obtain reddish DPVC.

[0047] 2. Preparation of spinning solution

[0048] Weigh 1.30g of DPVC resin and dissolve it in 10.00g of THF / DMF mixed solvent, wherein the mixing mass ratio of THF and DMF is 60 / 40, place it in a rotary air bath constant temperature shaker at 25°C for 24h, fully dissolve and mix evenly, and then ultrasonically eliminate Bubble.

[0049] 3. Preparation of DPVC nanofiber membrane by electrospinning

[0050] Use a 10mL disposable sterile syringe to absorb the above prepared spinning solution, clamp it on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com