Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about "Carbon fluorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium rate and high rate batteries

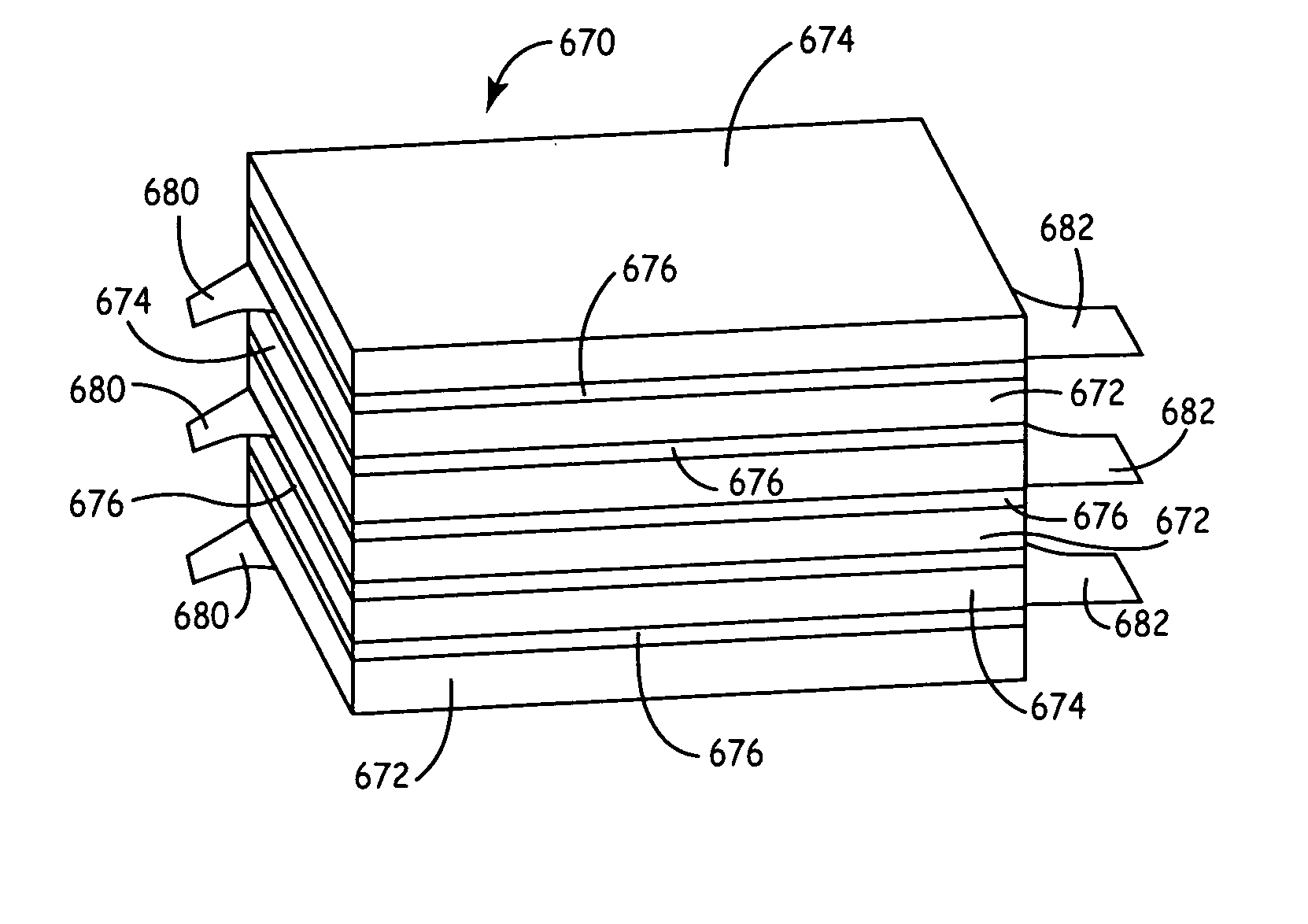

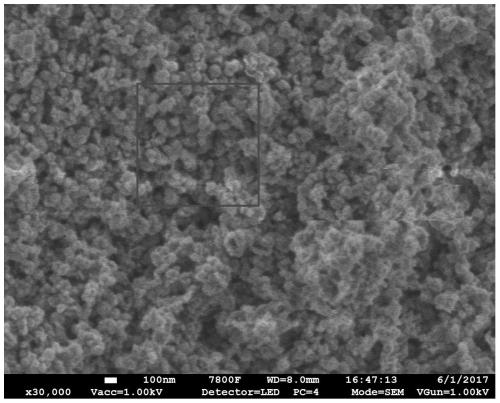

Improved submicron carbon fluoride has increased graphite content and can also have improved uniformity. The increased graphite content and / or uniformity can result in improved battery performance, for example with respect to specific capacity. Desirable battery structures provide for use with implantable medical devices. Suitable batteries can be used for high rate, medium rate, low rate or a combination of rate applications.

Owner:GREATBATCH TECH ADVANCED RES LAB

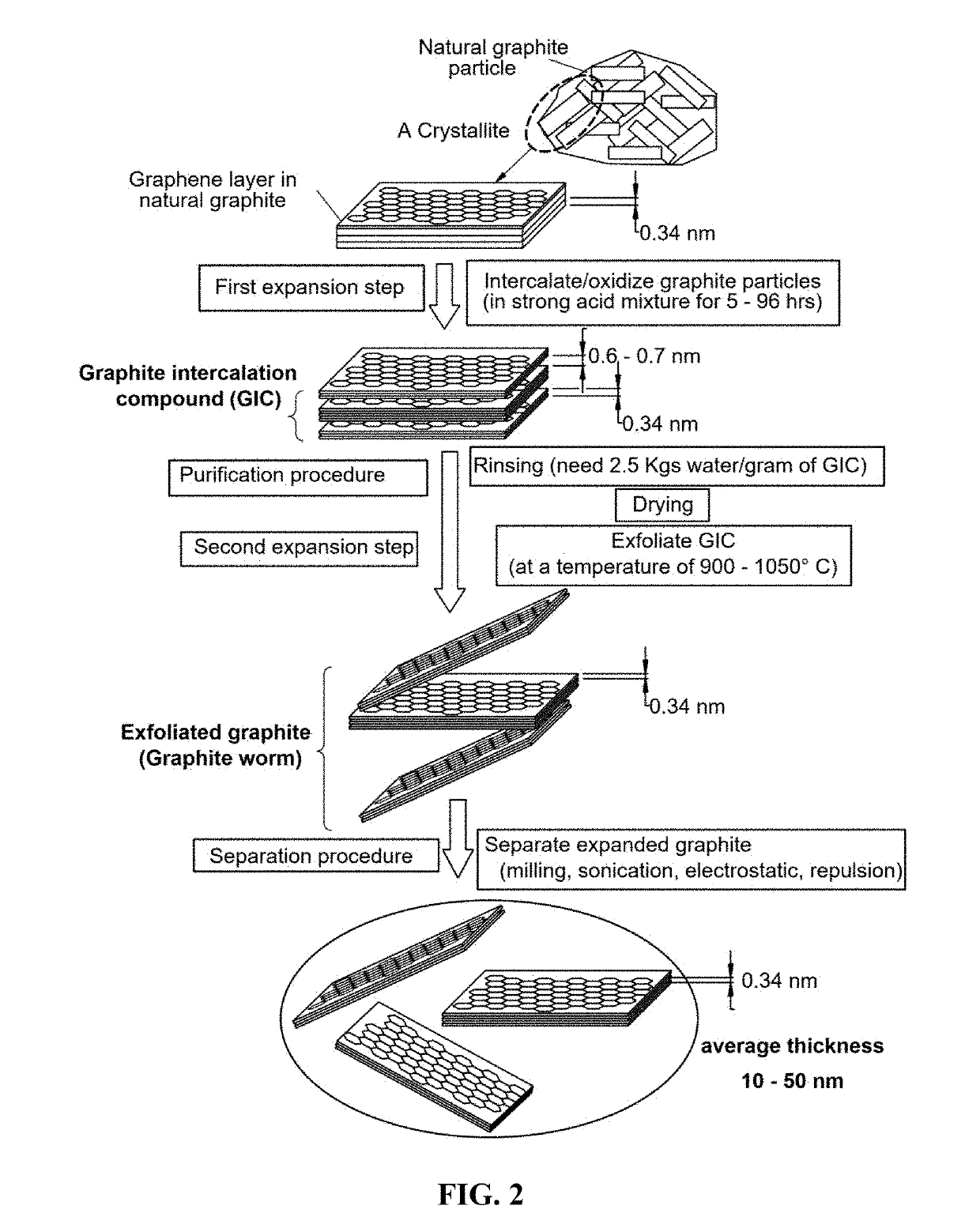

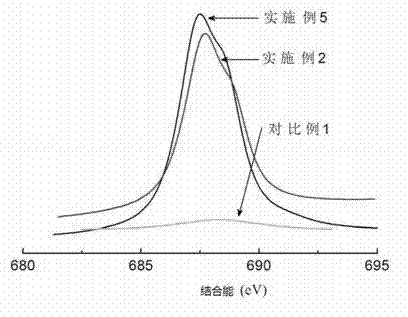

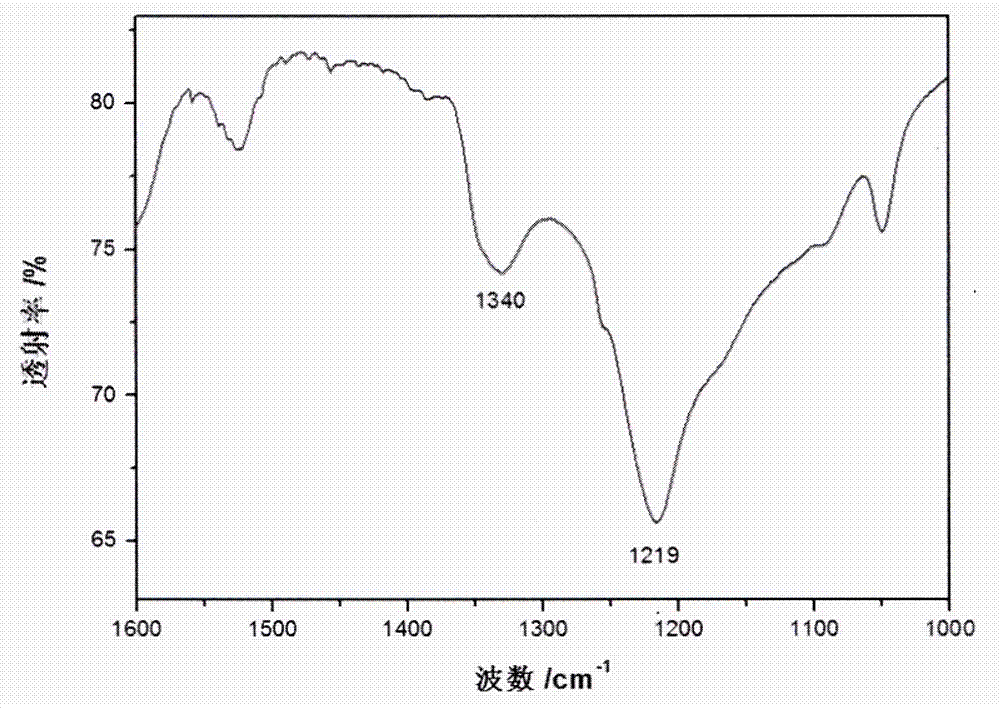

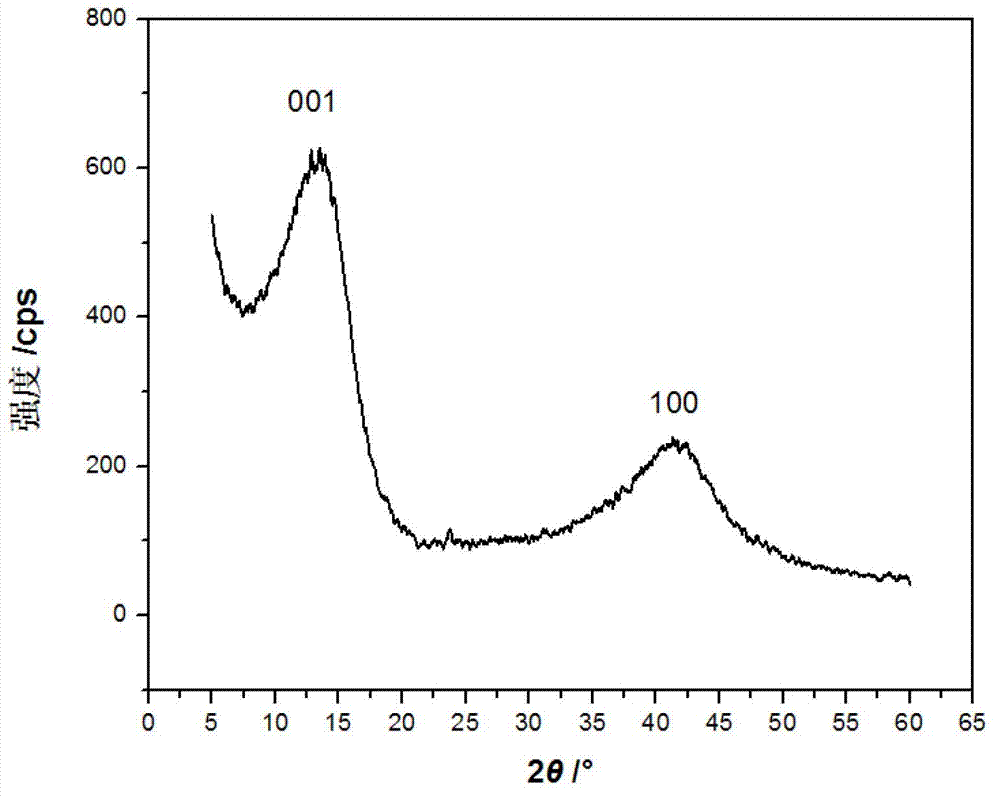

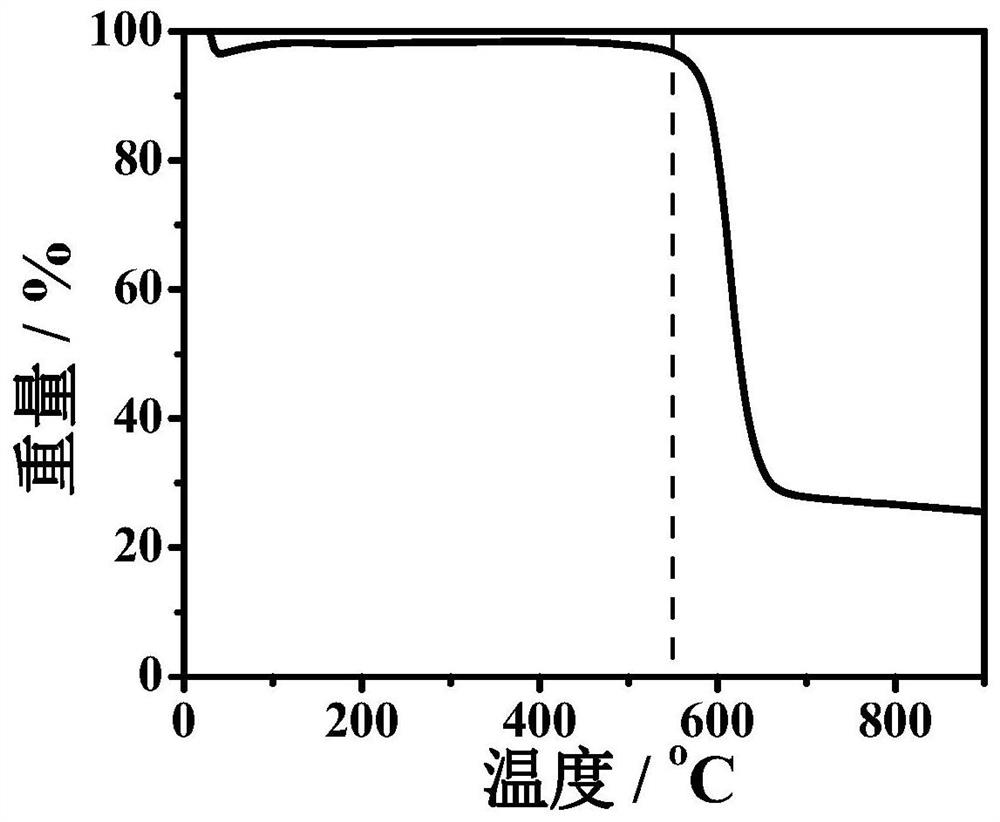

High-fluoride-content graphite fluoride and preparation method thereof

ActiveCN103420352AEasy to spreadFully contactedGrapheneCarbon fluoridesHigh fluorideReaction temperature

The invention discloses high-fluoride-content graphite fluoride and a preparation method thereof. The method comprises the following steps: preparing aqueous dispersion liquid of graphite oxide with a conventional improved Hummers method, then freezing the aqueous dispersion liquid of graphite oxide in liquid nitrogen to be completely frozen into solid, and freezing and drying to obtain cellular graphite oxide; under a mixed atmosphere of inert gas and fluoride, warming the cellular graphite oxide for fluoridation, and cooling to room temperature. The fluoride content of the prepared high-fluoride-content graphite fluoride is 55-70 percent, fluorine atoms are bonded with carbon atoms in a covalent bond mode, weightlessness peak temperature is larger than 470 DEG C, the heat stability is good, and the resistance is larger than 1012 omega. The prepared graphite fluoride has the advantages of high fluoride content, good heat resistance of fluorine-containing groups, low cost, simple process, lower reaction temperature, high safety and energy saving, is suitable for mass production, and has a better application prospect.

Owner:SICHUAN UNIV

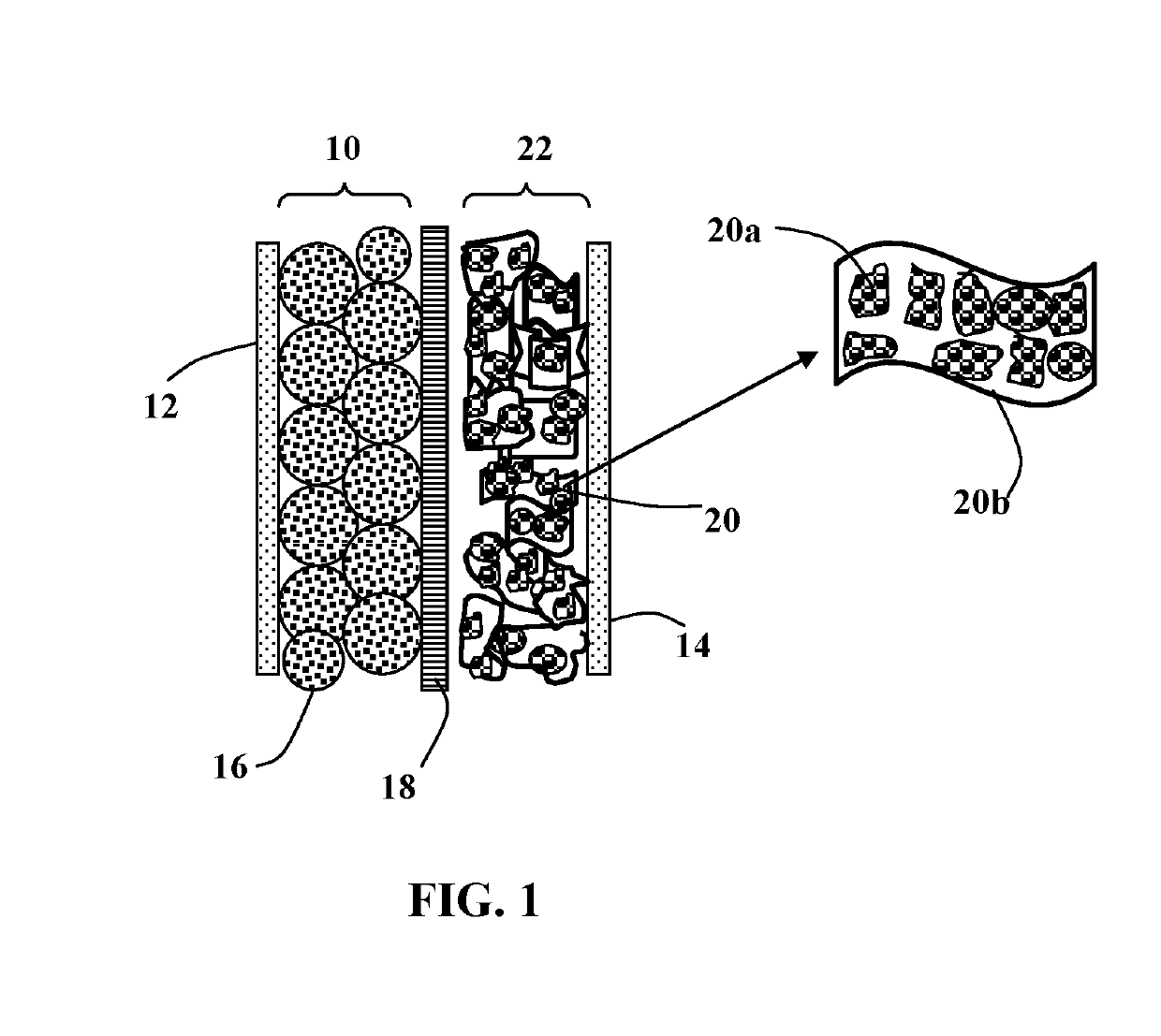

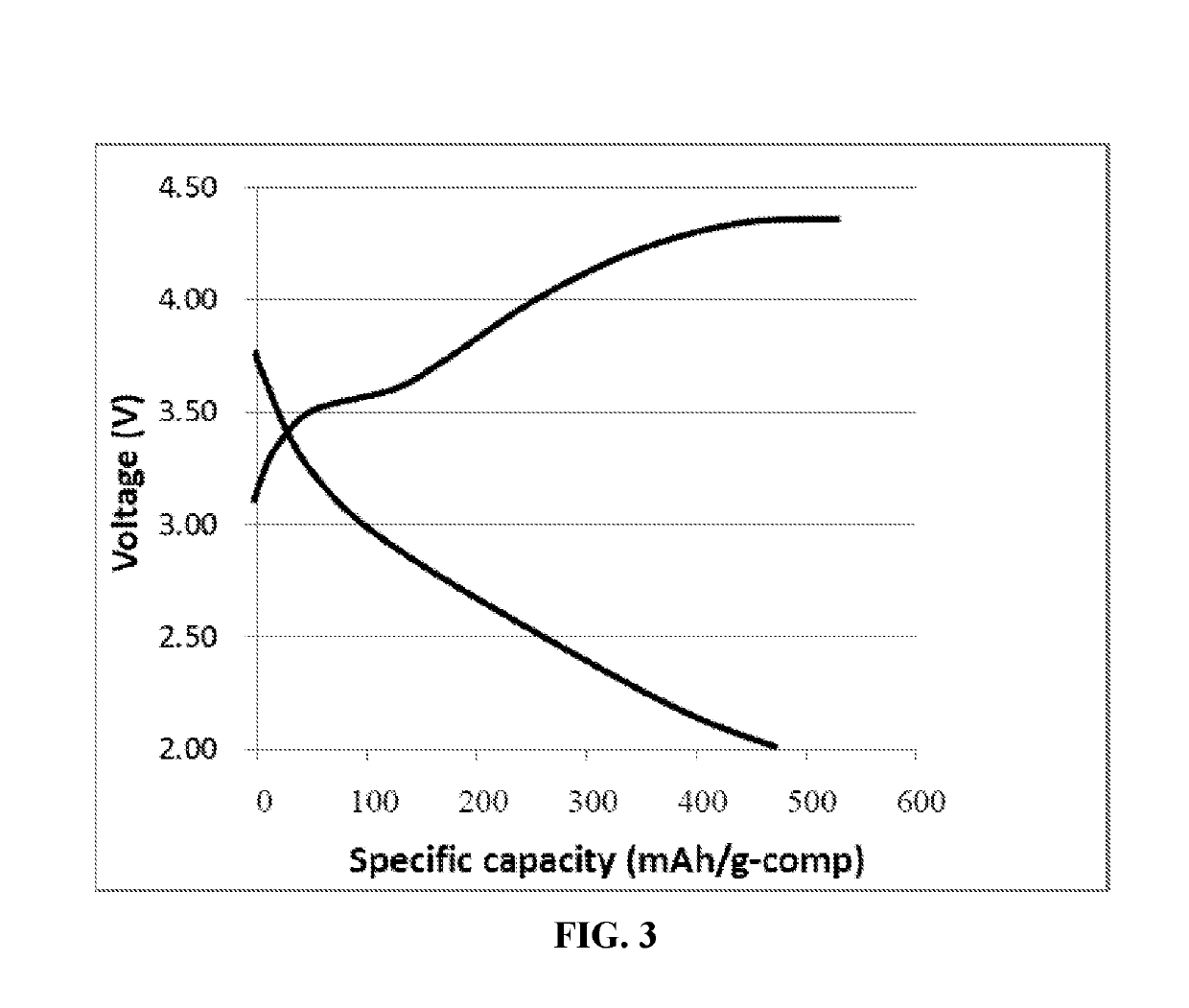

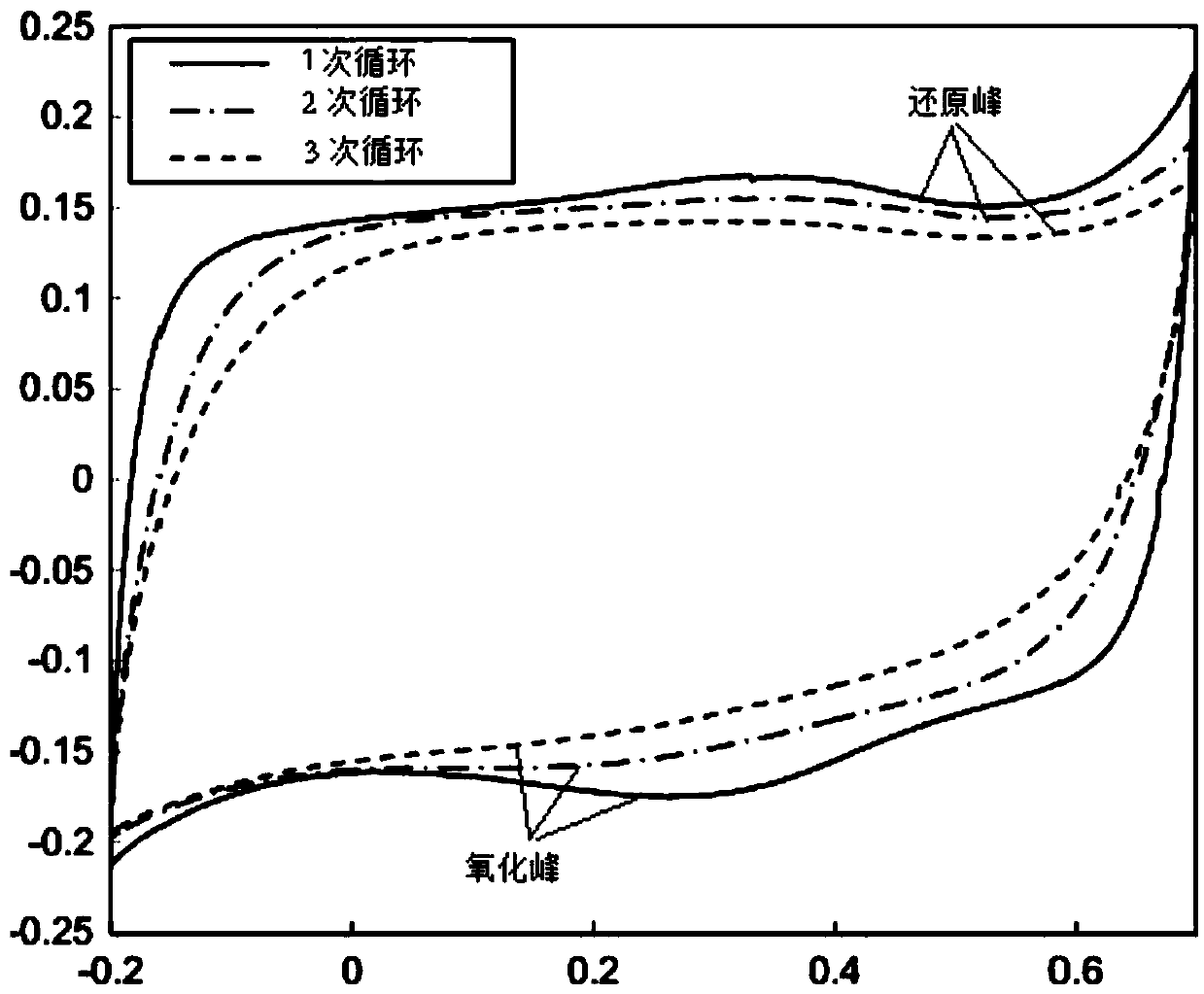

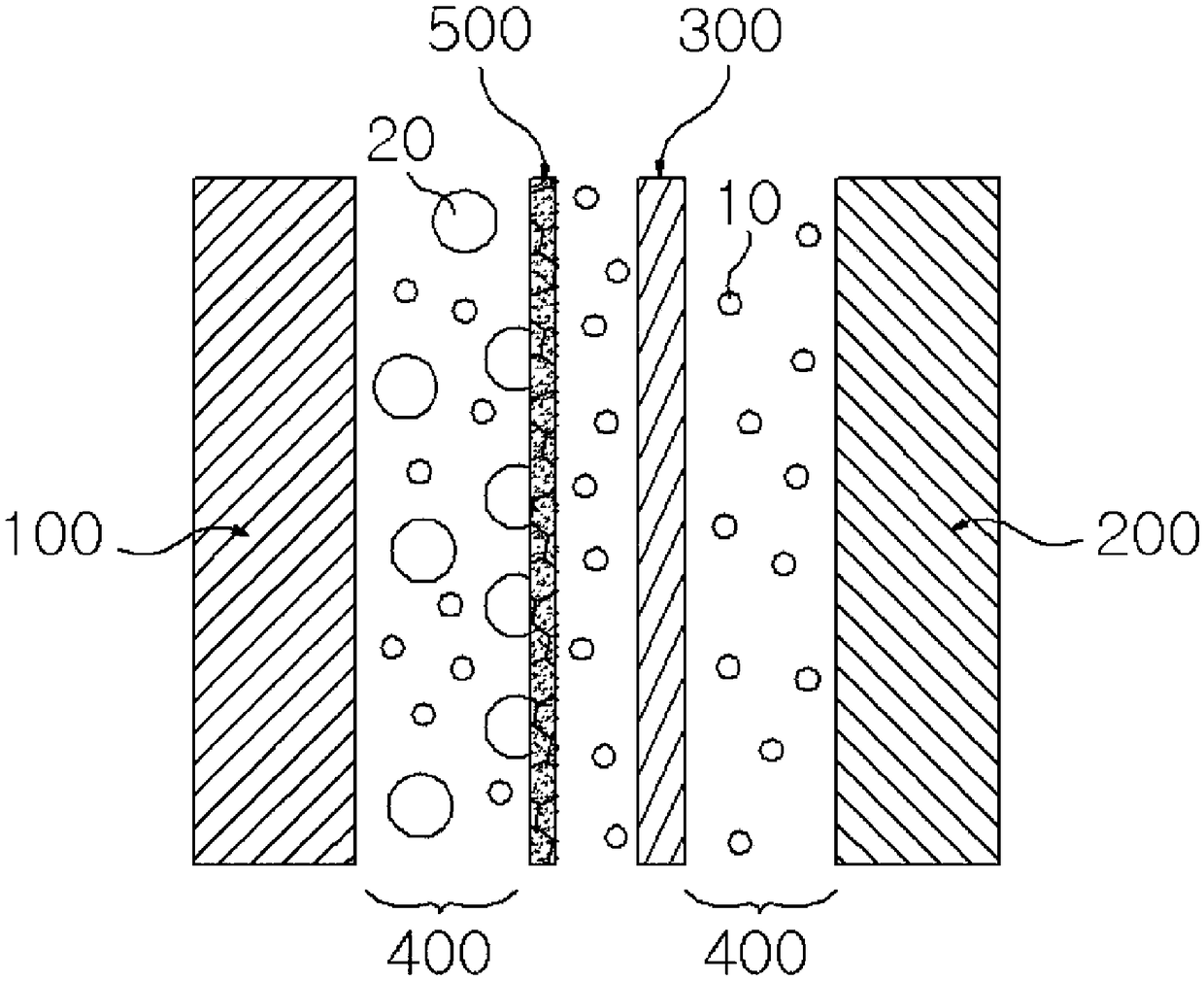

Lithium ion-based internal hybrid electrochemical energy storage cell

ActiveUS20190108948A1Great fabricationImprove responseMaterial nanotechnologyFuel and secondary cellsFiberCapacitance

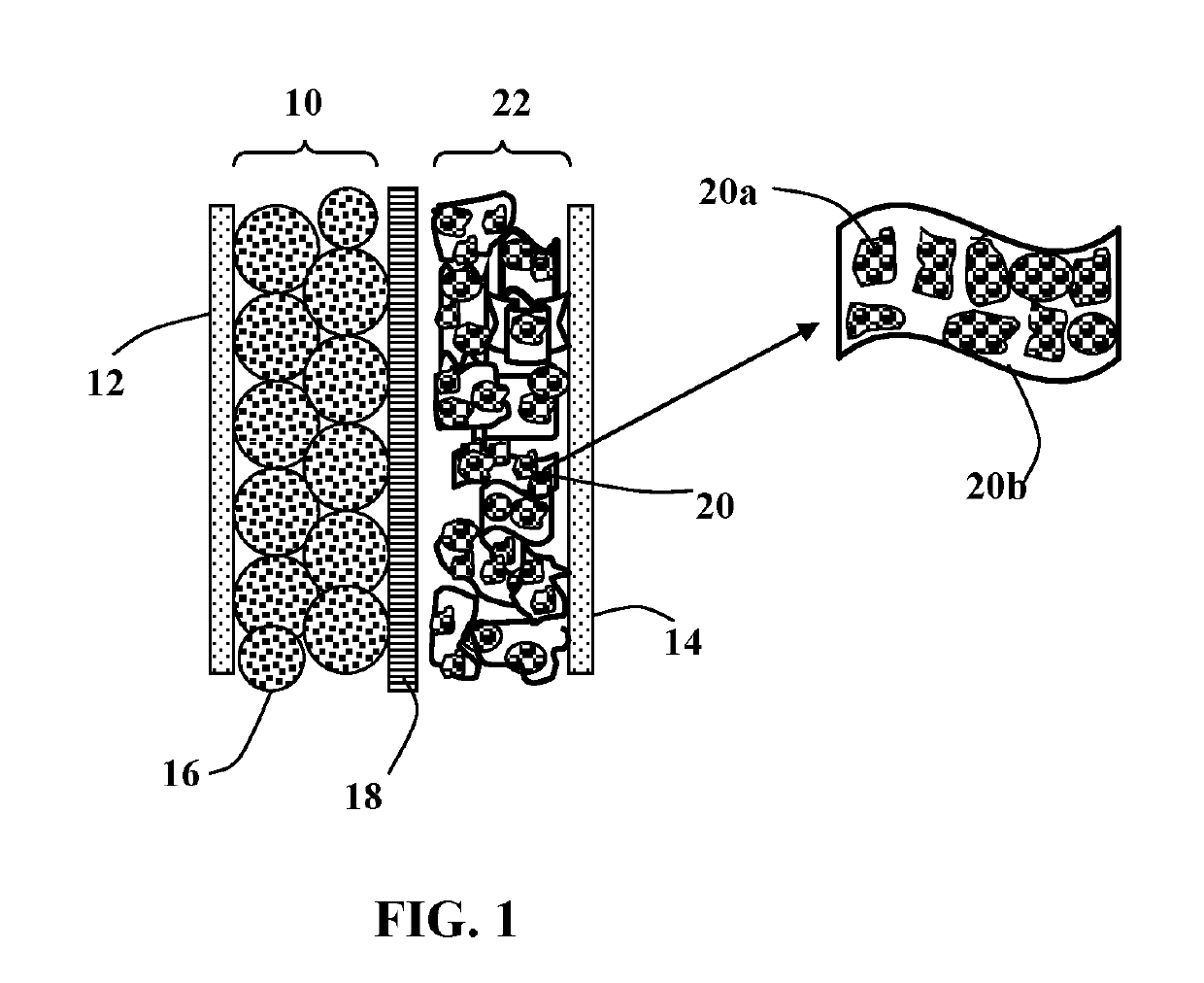

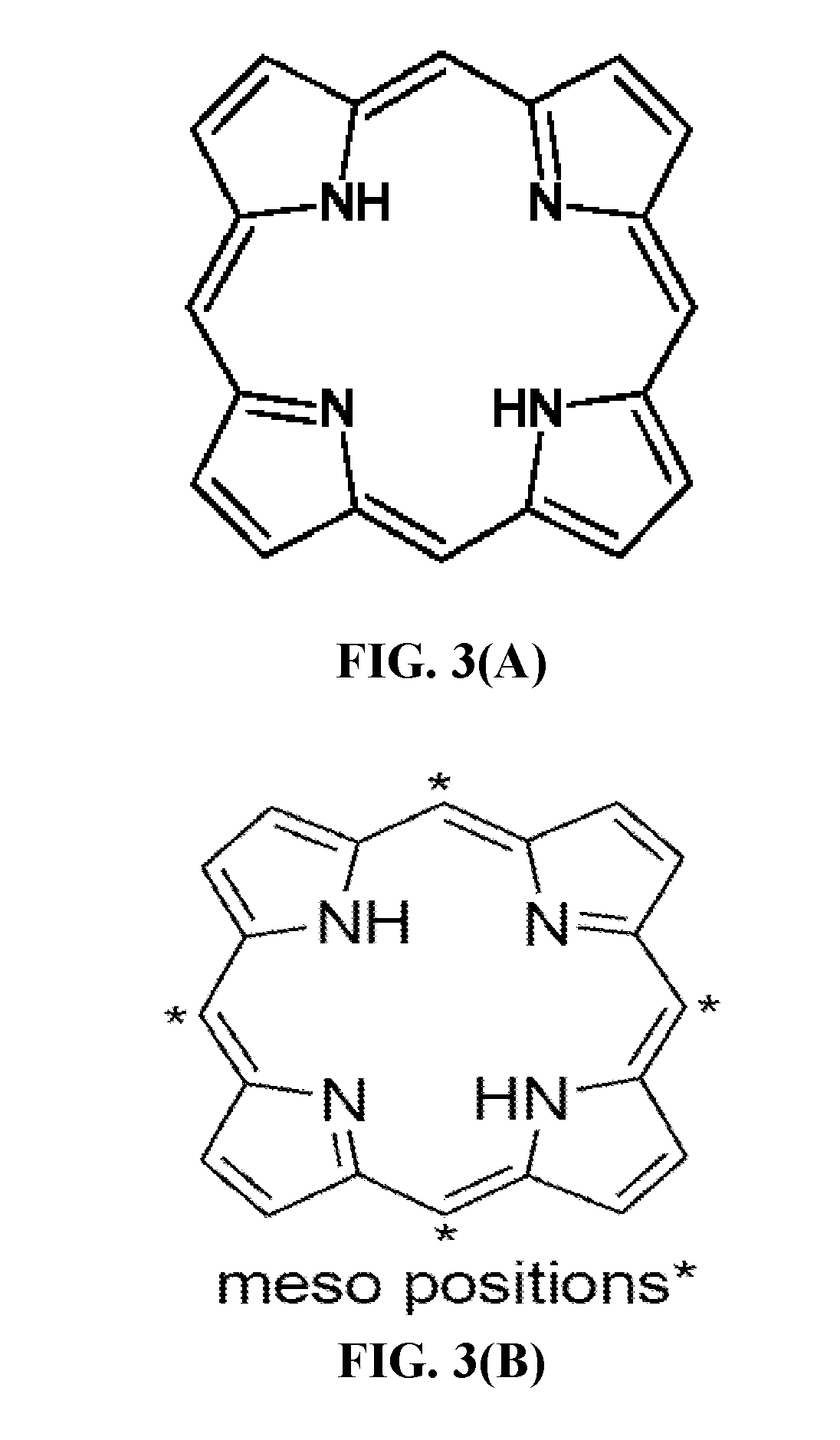

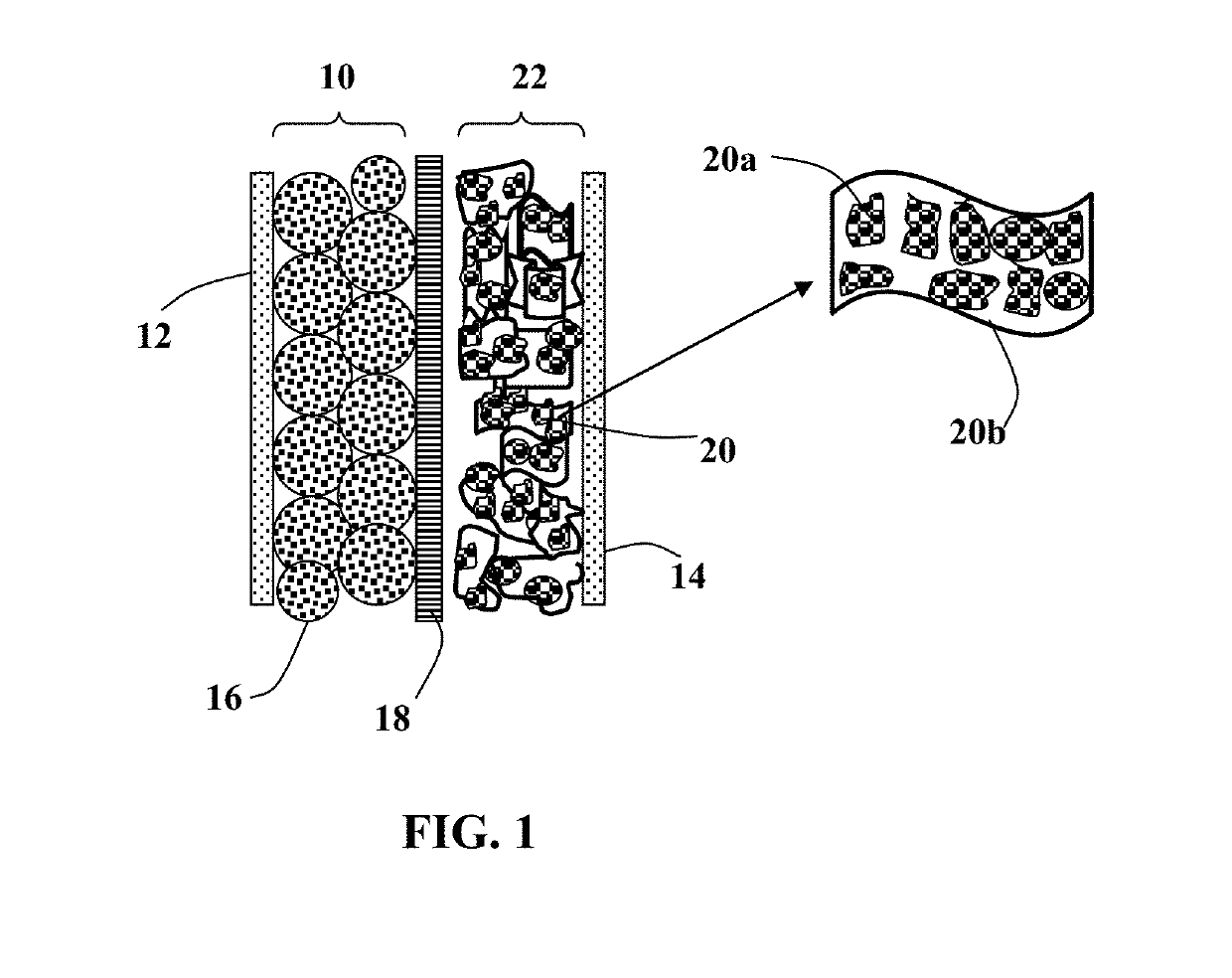

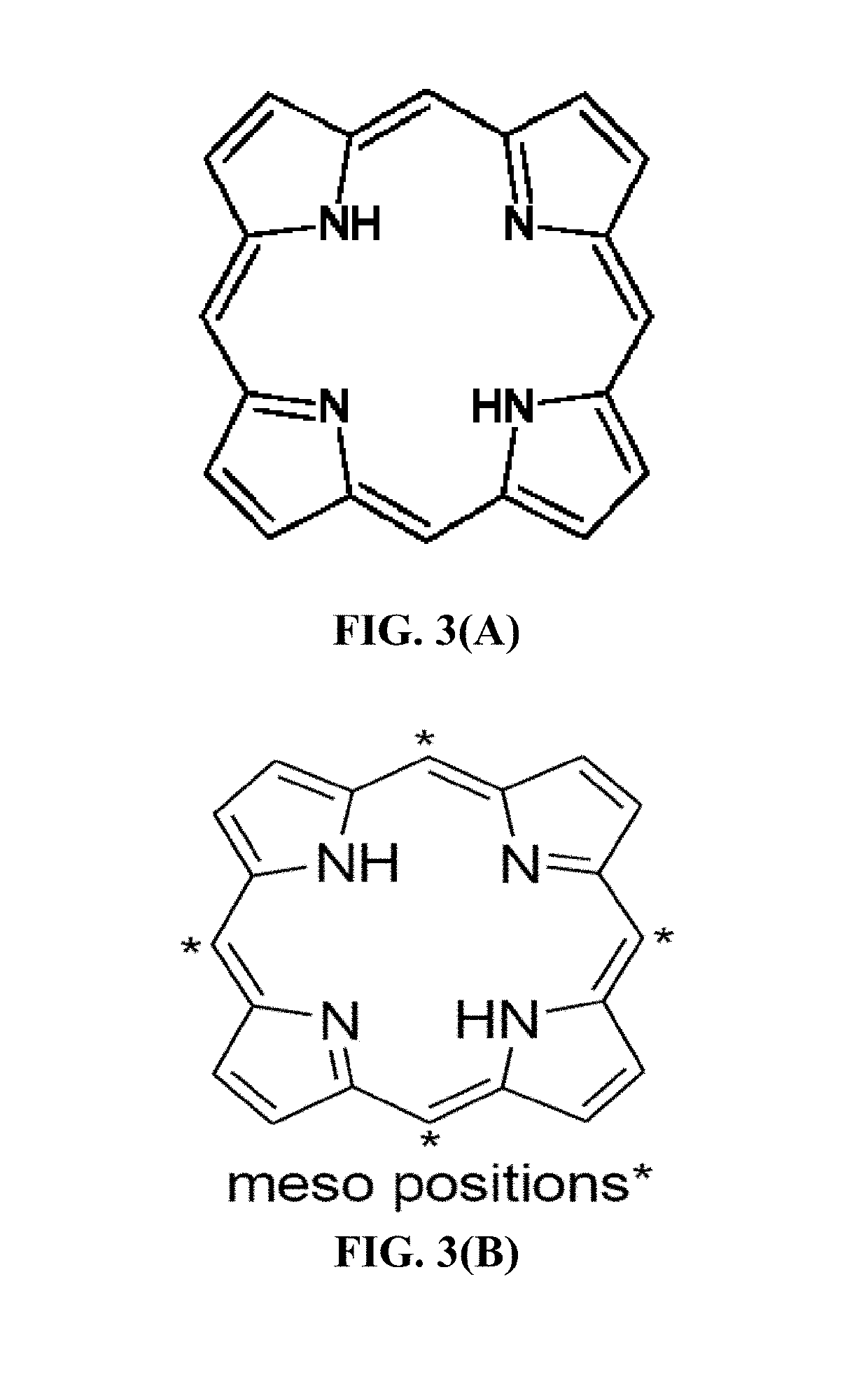

Provided is an internal hybrid electrochemical cell comprising: (A) a pseudocapacitance cathode comprising a cathode active material that contains a conductive carbon material and a porphyrin compound, wherein the porphyrin compound is bonded to or supported by the carbon material to form a redox pair for pseudocapacitance, wherein the carbon material is selected from activated carbon, activated carbon black, expanded graphite flakes, exfoliated graphite worms, carbon nanotube, carbon nanofiber, carbon fiber, a combination thereof; (B) a battery-like anode comprising lithium metal, lithium metal alloy, or a prelithiated anode active material (e.g. prelithiated Si, SiO, Sn, SnO2, etc.), and (C) a lithium-containing electrolyte in physical contact with the anode and the cathode; wherein the cathode active material has a specific surface area no less than 100 m2 / g which is in direct physical contact with the electrolyte.

Owner:NANOTEK INSTR GRP LLC

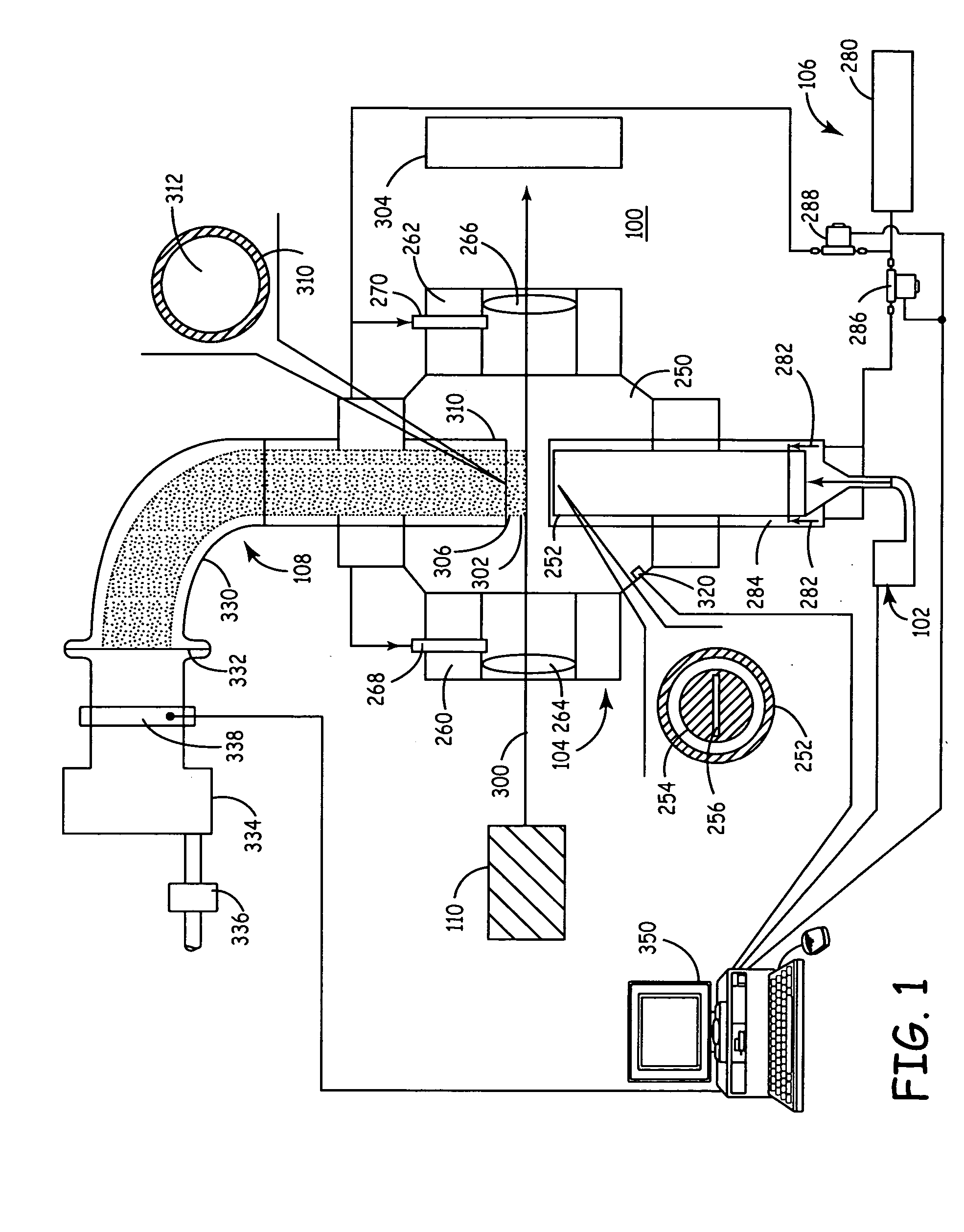

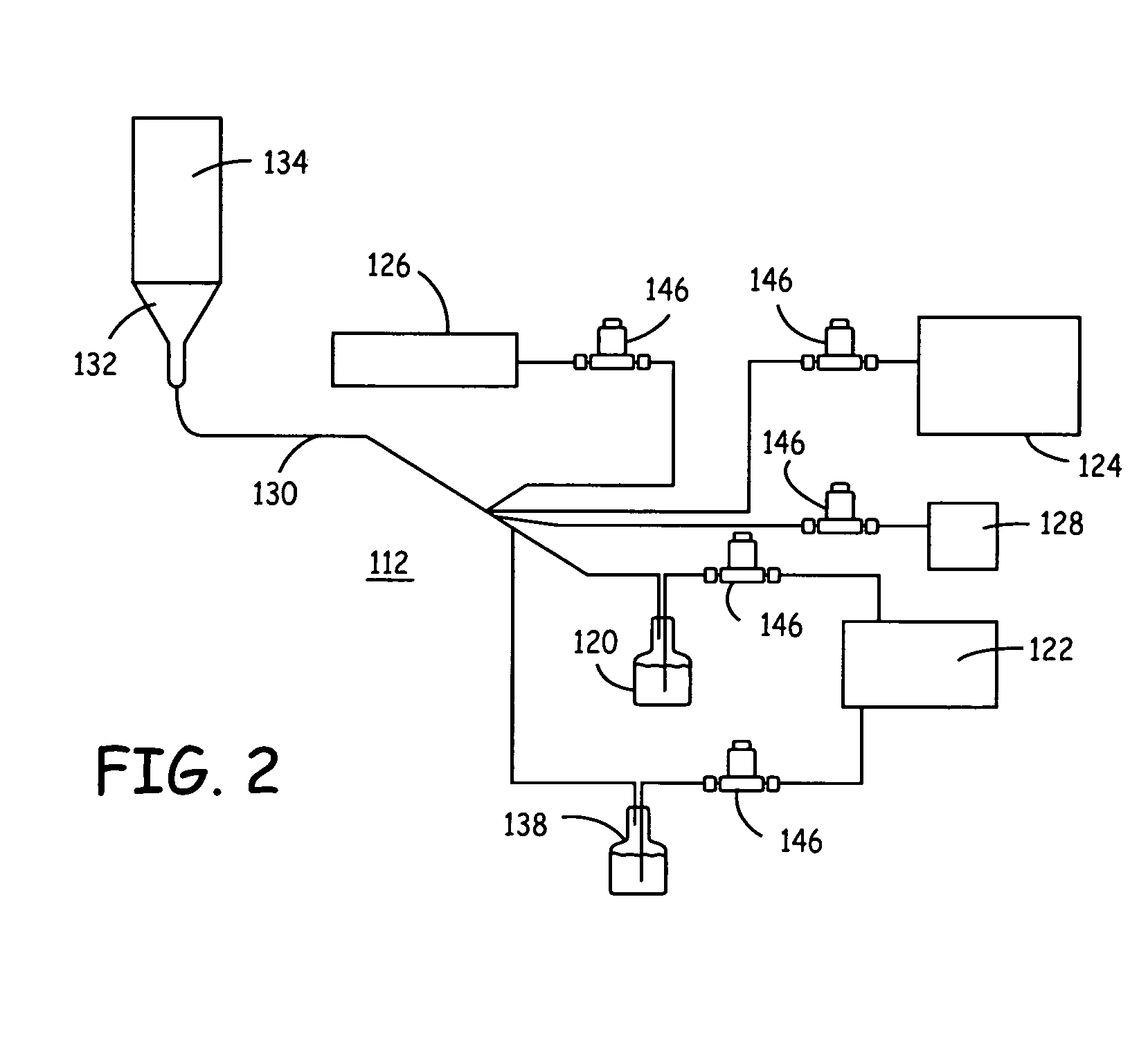

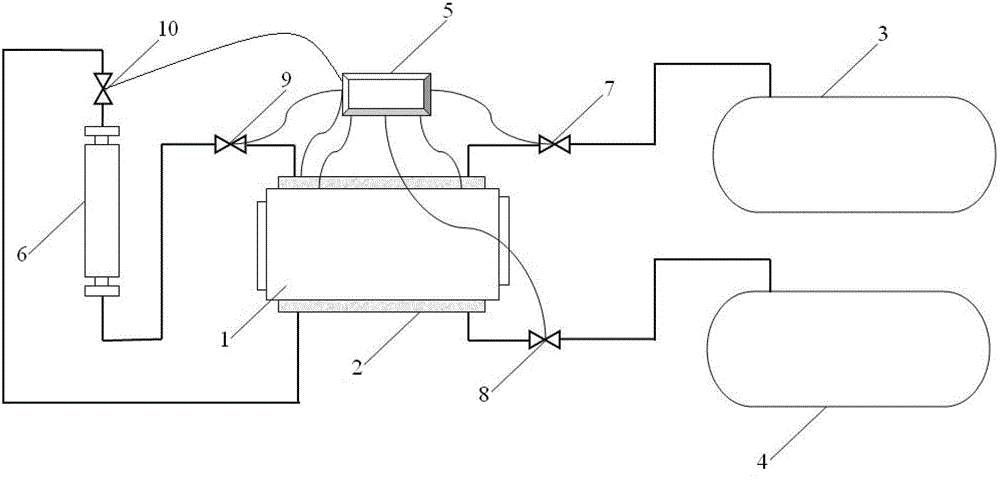

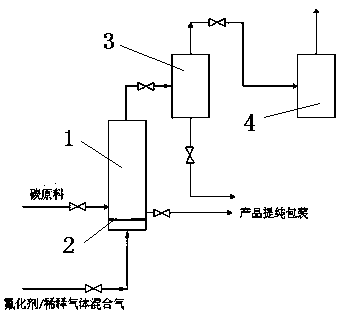

Method for preparing carbon monofluoride or fluorocarbon through inner circulation of fluorine

InactiveCN103332669ALow costReduce manufacturing costCarbon fluoridesCarbon monofluorideHigh concentration

The invention provides a method for preparing carbon monofluoride or fluorocarbon through inner circulation of fluorine. The method comprises the following steps of: (1) firstly passivating a reaction system, and then loading the pretreated graphite or carbon material into a reaction kettle with a cycling passage; (2) adding argon or nitrogen into the reaction kettle, adding fluorine to obtain the fluorine nitrogen or fluorine argon mixed gas; (3) heating the reaction kettle, setting and maintaining a reaction temperature and reaction pressure, and stopping the heating after the reaction is carried out for 1 to 70h under the inner circulation working condition; and (4) taking out the carbon monofluoride or fluorocarbon when the reaction kettle is cooled to the room temperature. The invention also provides a synthesizing device for preparing the carbon monofluoride or fluorocarbon through the inner circulation of the fluorine. The carbon monofluoride or fluorocarbon is synthesized by adopting the fluorine nitrogen mixed gas with high concentration of fluorine, the passivated reaction system, automatic control of a remote computer and a novel fluorine inner circulation process. The cost is low, the safety is high, the yield is high, and the fluorine-carbon ratio of a product is precisely controlled.

Owner:HUBEI ZHUOXI FLUOROCHEM

Internal hybrid electrochemical energy storage cell having both high power and high energy density

ActiveUS20190103232A1Great fabricationImprove responseMaterial nanotechnologyMultiple fixed capacitorsMetallic lithiumCapacitance

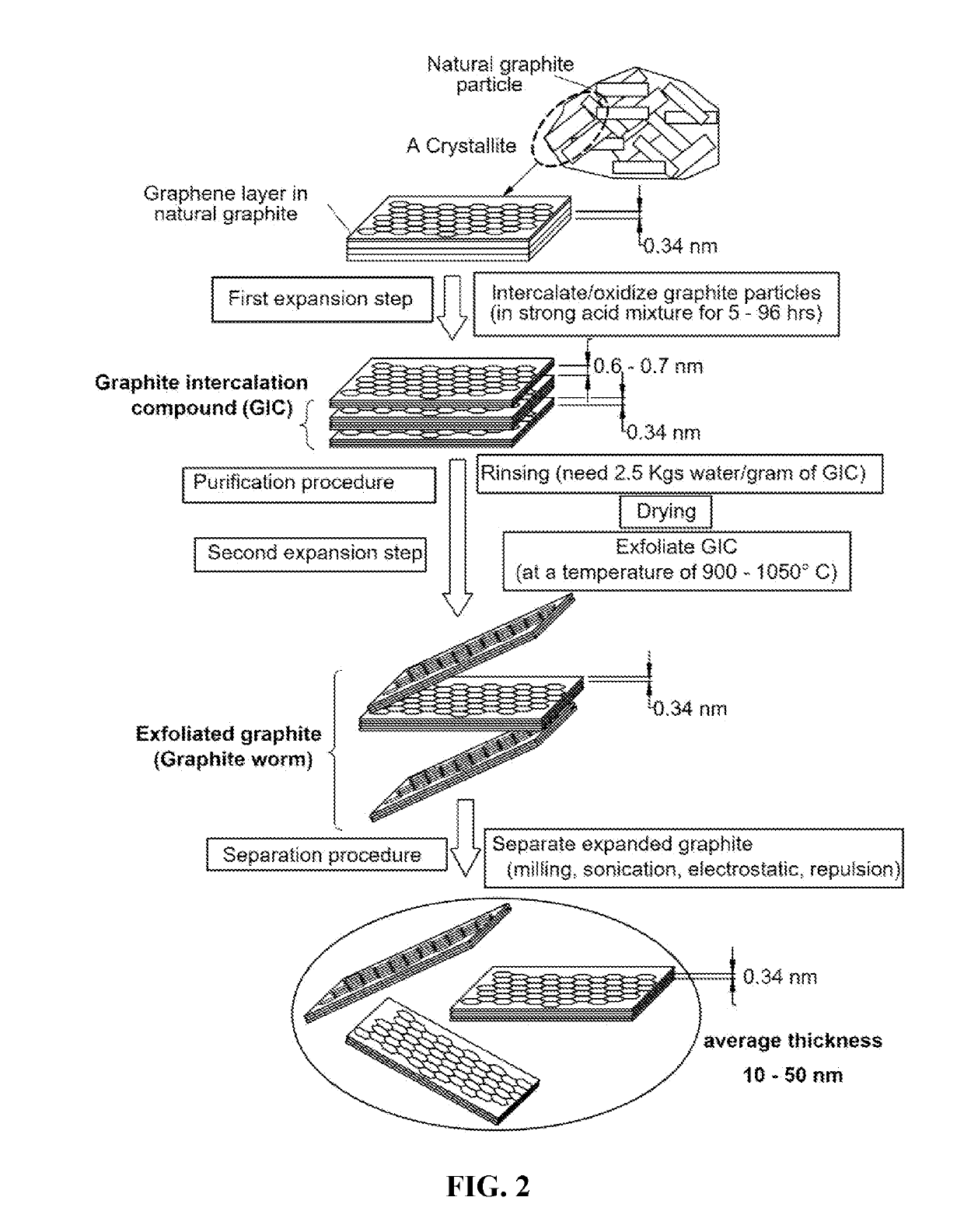

Provided is an internal hybrid electrochemical cell comprising: (A) a pseudocapacitance cathode comprising a cathode active material that contains both graphene sheets and a porphyrin complex, wherein said porphyrin complex is bonded to or supported by primary surfaces of said graphene sheets to form a redox pair for pseudocapacitance; (B) a battery-like anode comprising lithium metal, lithium metal alloy, or a prelithiated anode active material (e.g. prelithiated Si, SiO, Sn, SnO2, etc.), and (C) a lithium-containing electrolyte in physical contact with the anode and the cathode; wherein the cathode active material has a specific surface area no less than 100 m2 / g which is in direct physical contact with the electrolyte.

Owner:NANOTEK INSTR GRP LLC

Internal hybrid electrochemical energy storage cell

PendingUS20190103231A1Not conducive to fabricationImprove responseNitrogen compoundsCapacitor and primary/secondary cellsCapacitanceElectrical battery

Provided is an internal hybrid electrochemical cell comprising: (A) a pseudocapacitance cathode comprising both graphene sheets and a 2D inorganic material, in a form of nanodiscs, nanoplatelets, or nanosheets that are bonded to or supported by primary surfaces (not the edges) of the graphene sheets and the 2D inorganic material and graphene sheets form a redox pair for pseudocapacitance; (B) a battery-like anode comprising a prelithiated anode active material (e.g. prelithiated Si, SiO, Sn, SnO2, etc.), and (C) a lithium-containing electrolyte in physical contact with the anode and the cathode; wherein the cathode active material has a specific surface area no less than 100 m2 / g which is in direct physical contact with the electrolyte.

Owner:NANOTEK INSTR GRP LLC

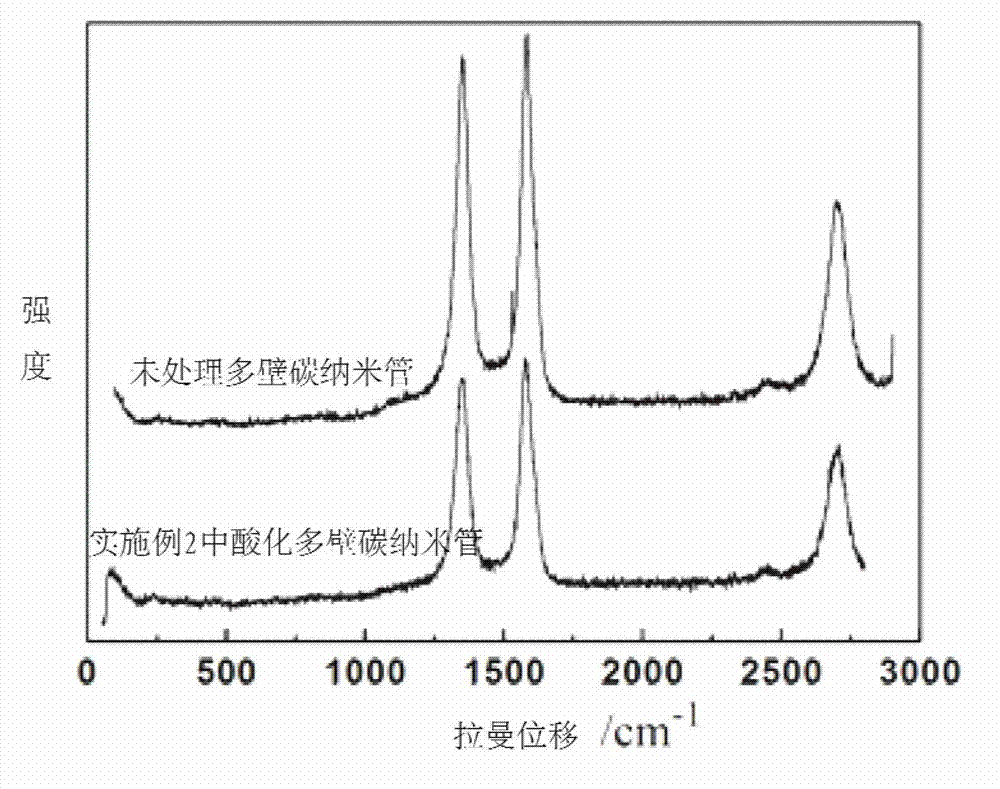

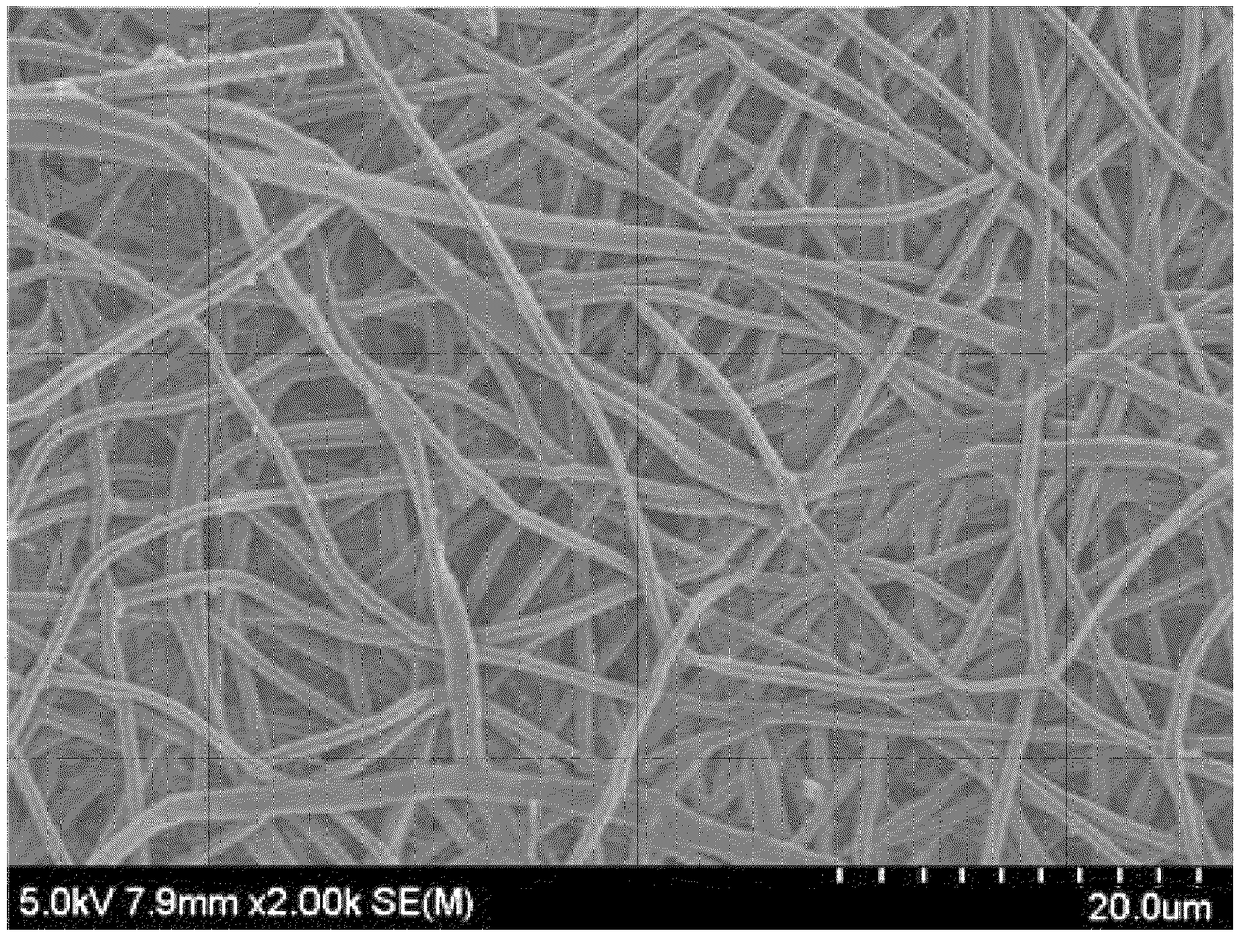

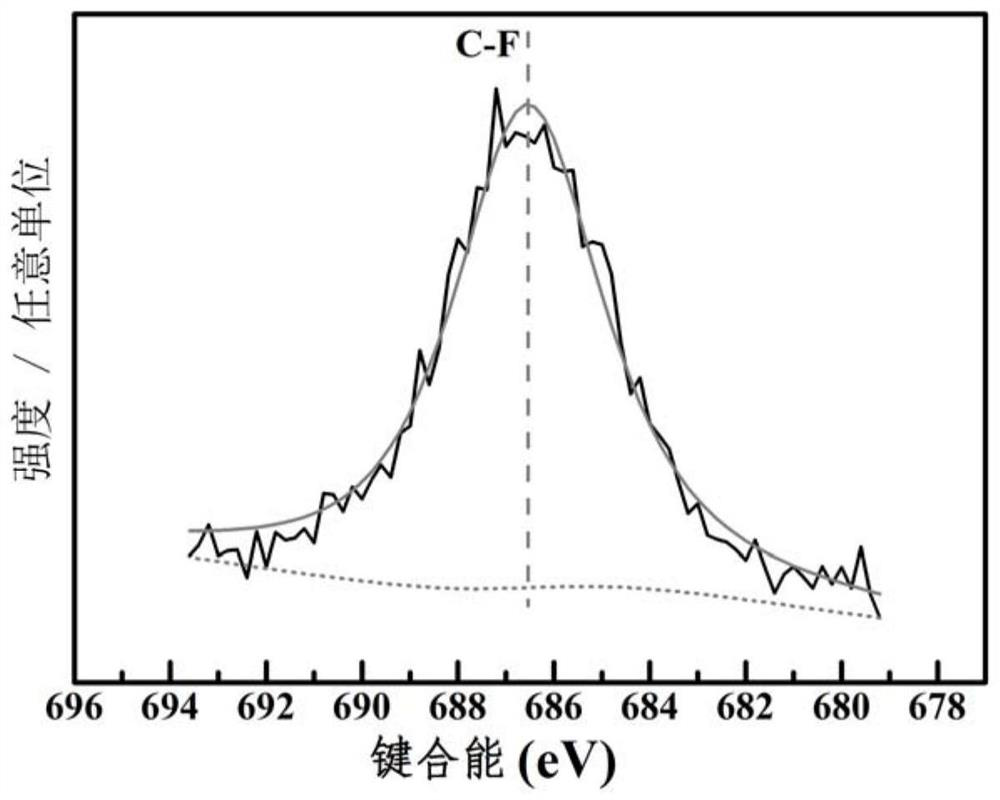

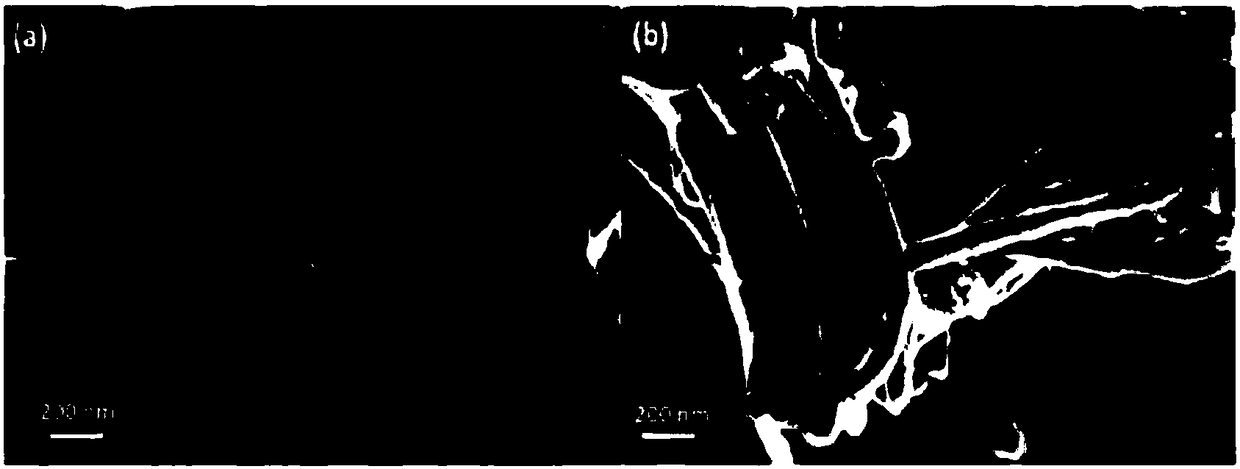

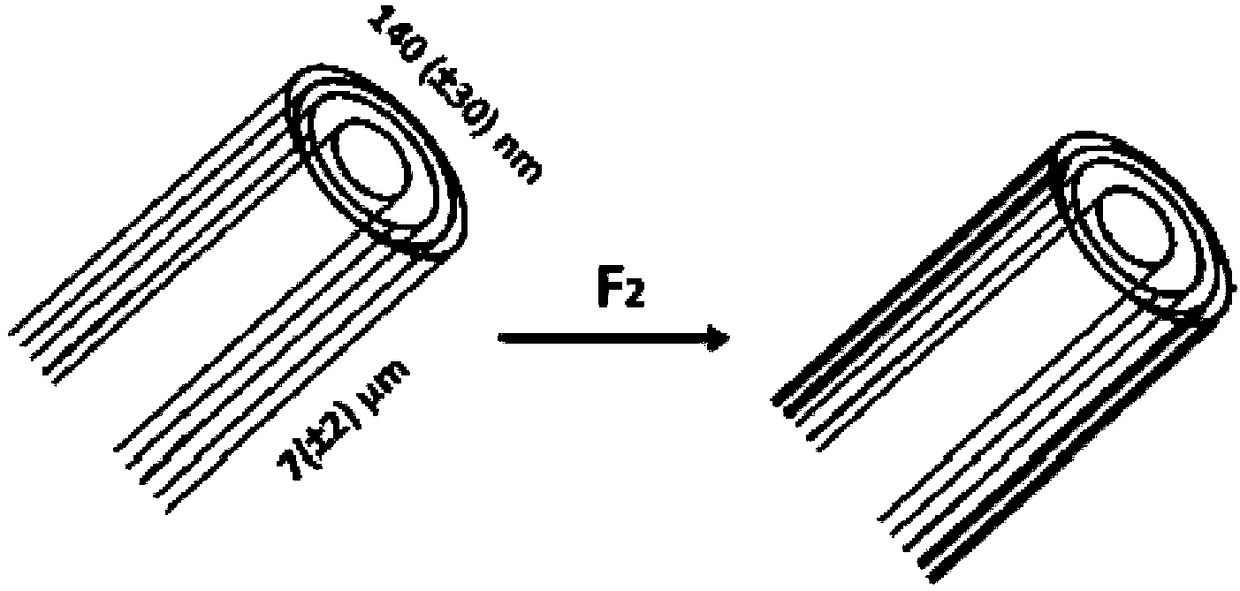

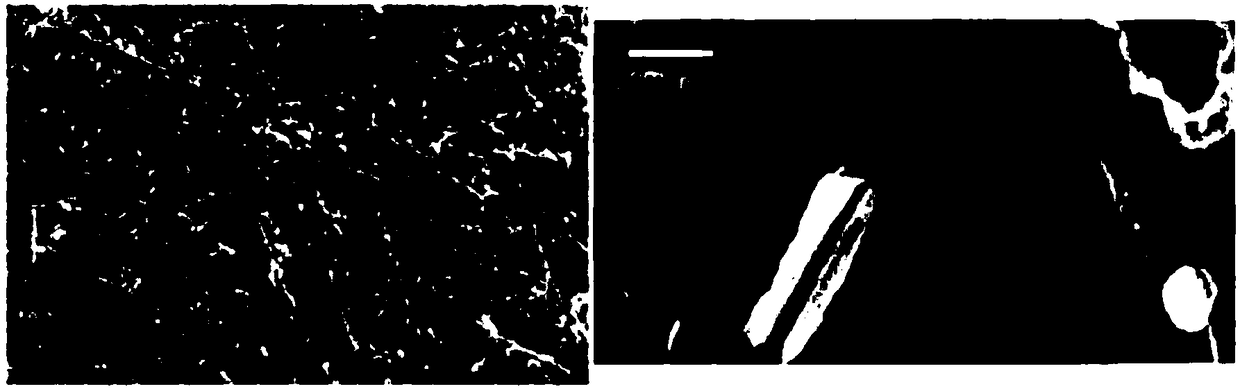

Carbon nano-tube with fluorine-containing surface and preparation method thereof

ActiveCN102730664AImprove heat resistanceEasy generationMaterial nanotechnologyCarbon fluoridesReaction temperatureStrong acids

The invention discloses a carbon nano-tube with a fluorine-containing surface, wherein the surface of the carbon nano-tube is of a carbon-fluorine covalent bond structure, the content of fluorine in the surface is 4-14%, and the decrease rate of the content of the fluorine is smaller than 5% after a produced fluorocarbon nano-tube is treated for 1 hour under a vacuum condition at 350 DEG C. The preparation method of the carbon nano-tube comprises the following steps of: firstly treating the carbon nano-tube by utilizing strong acid, secondly placing the carbon nano-tube in a vacuum reactor, charging fluorine / inert gas mixture with fluorine partial pressure of 10-100KPa in nitrogen atmosphere under room temperature to react for 0.5-4 hours at 150-300 DEG C, and cooling down to be the room temperature to obtain the carbon nano-tube. The fluorocarbon nano-tube prepared by the preparation method disclosed by the invention has the advantages of high fluorine content, low reaction temperature, high safety, energy conservation, and simple process, a fluorine-containing group of the surface of the treated prepared fluorocarbon nano-tube has good heat resistance and lower cost, and the fluorocarbon nano-tube is suitable for large-batch production and has stronger application prospect.

Owner:SICHUAN UNIV

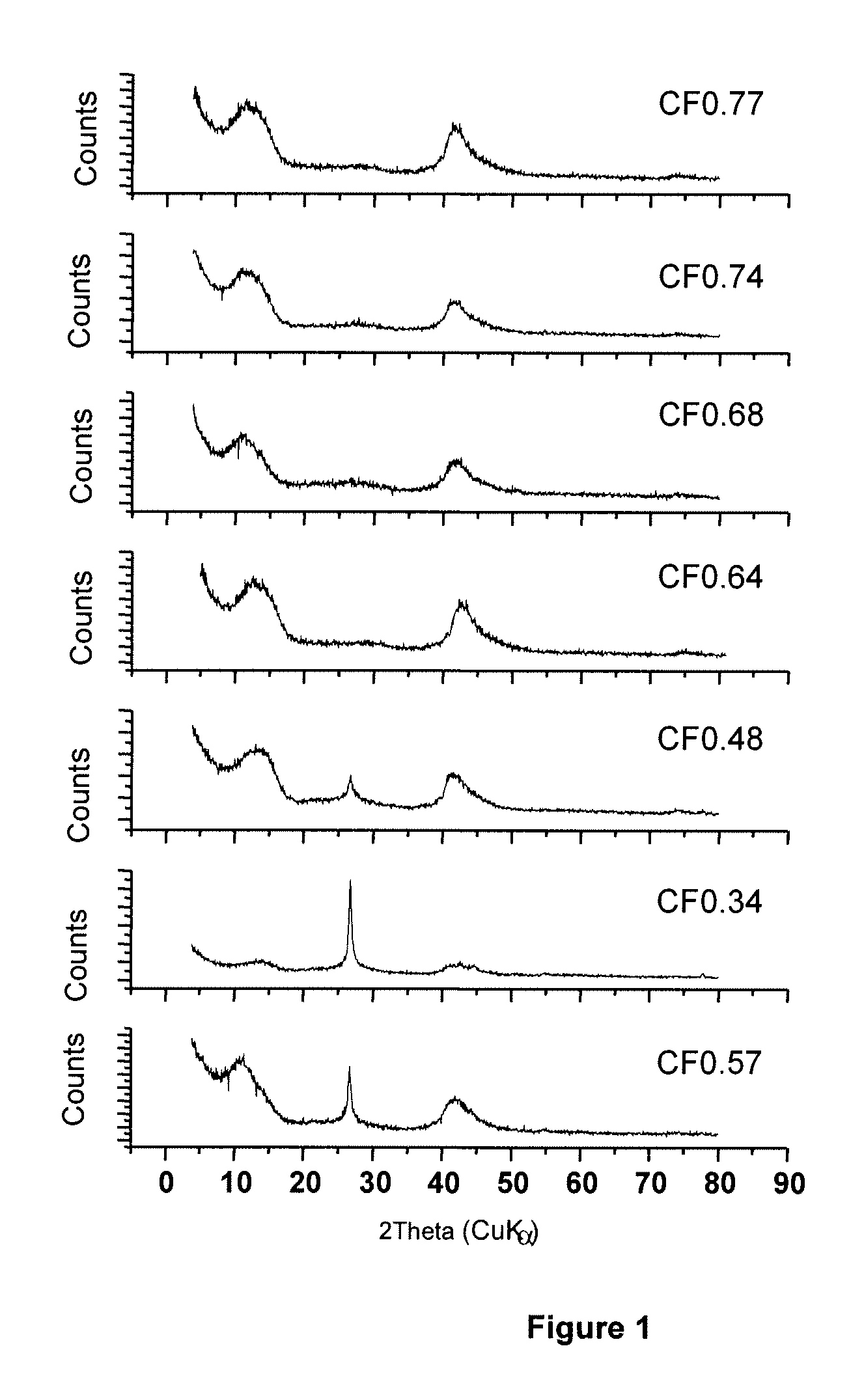

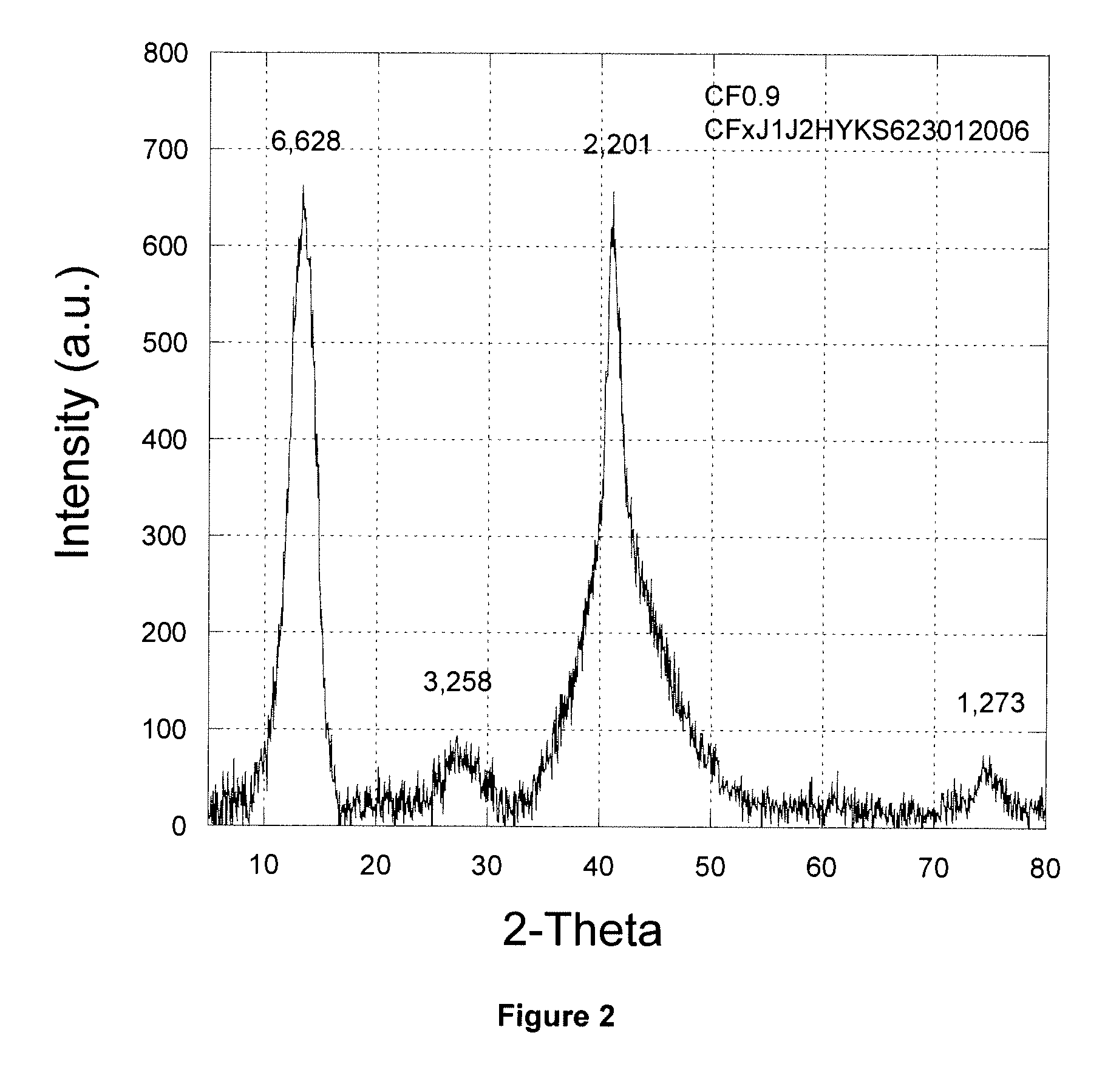

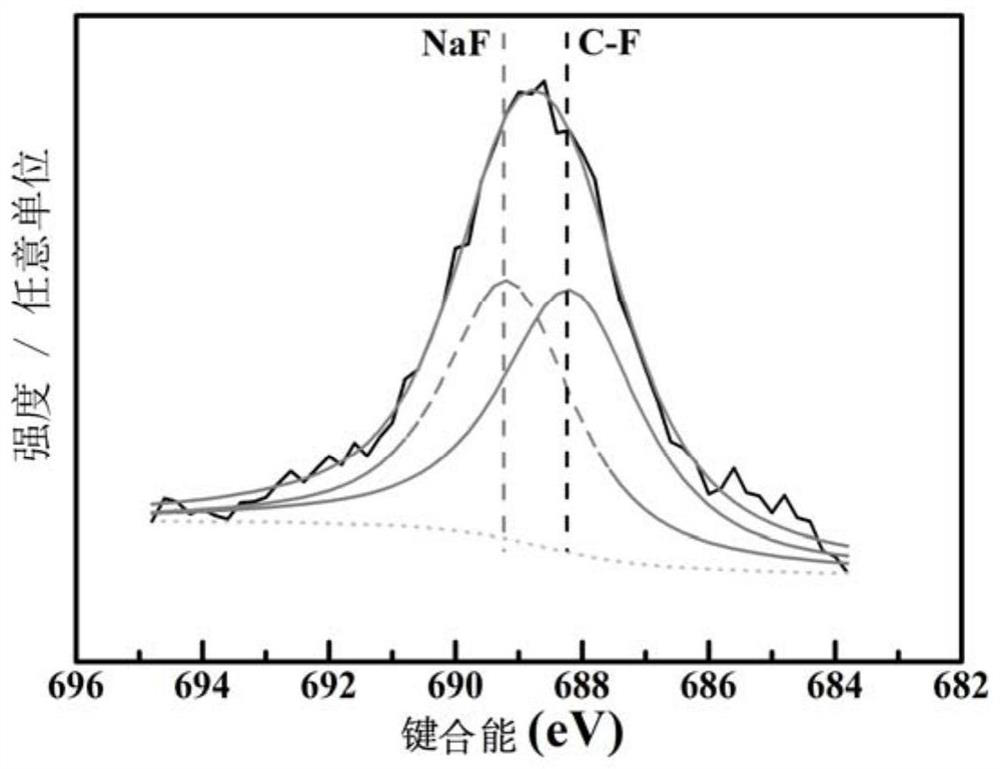

Electrochemistry of carbon subfluorides

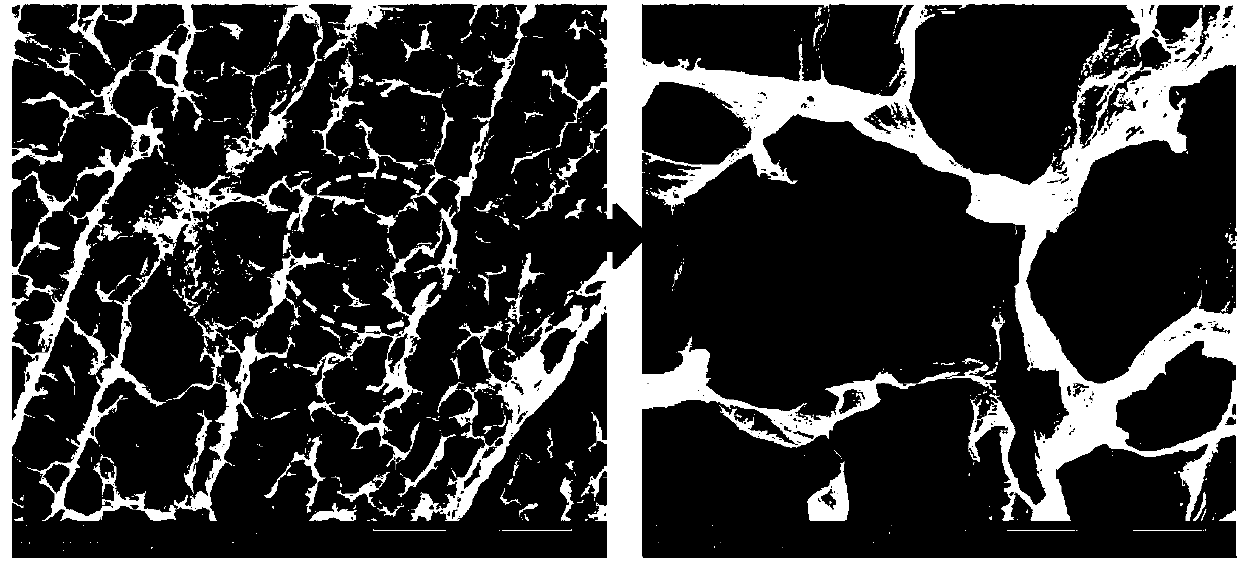

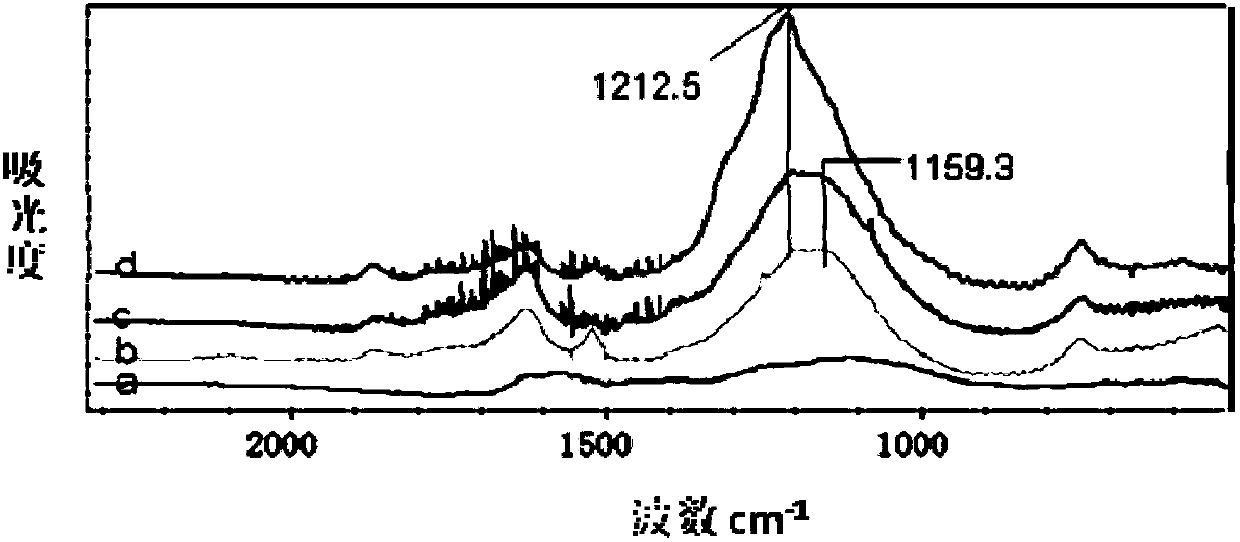

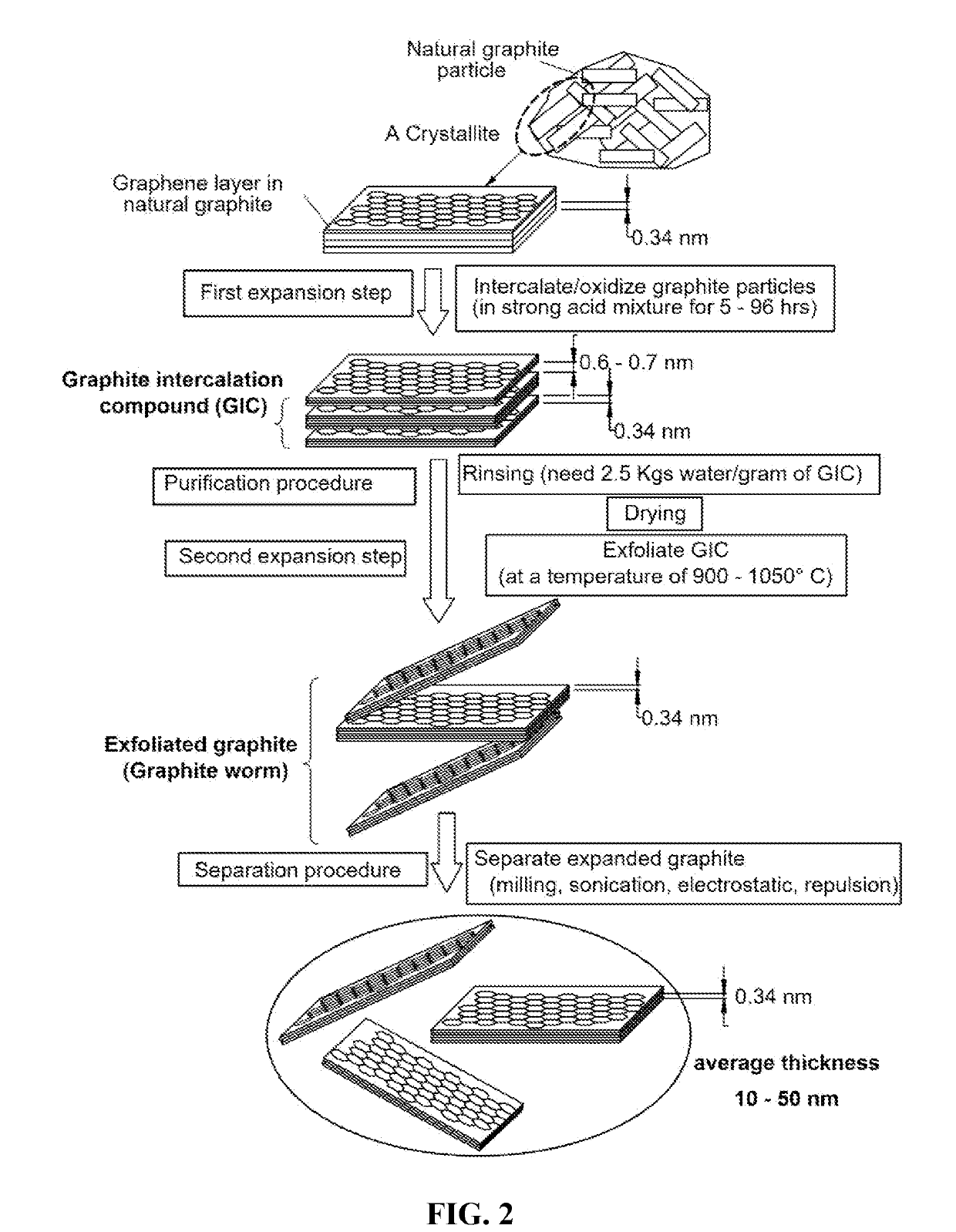

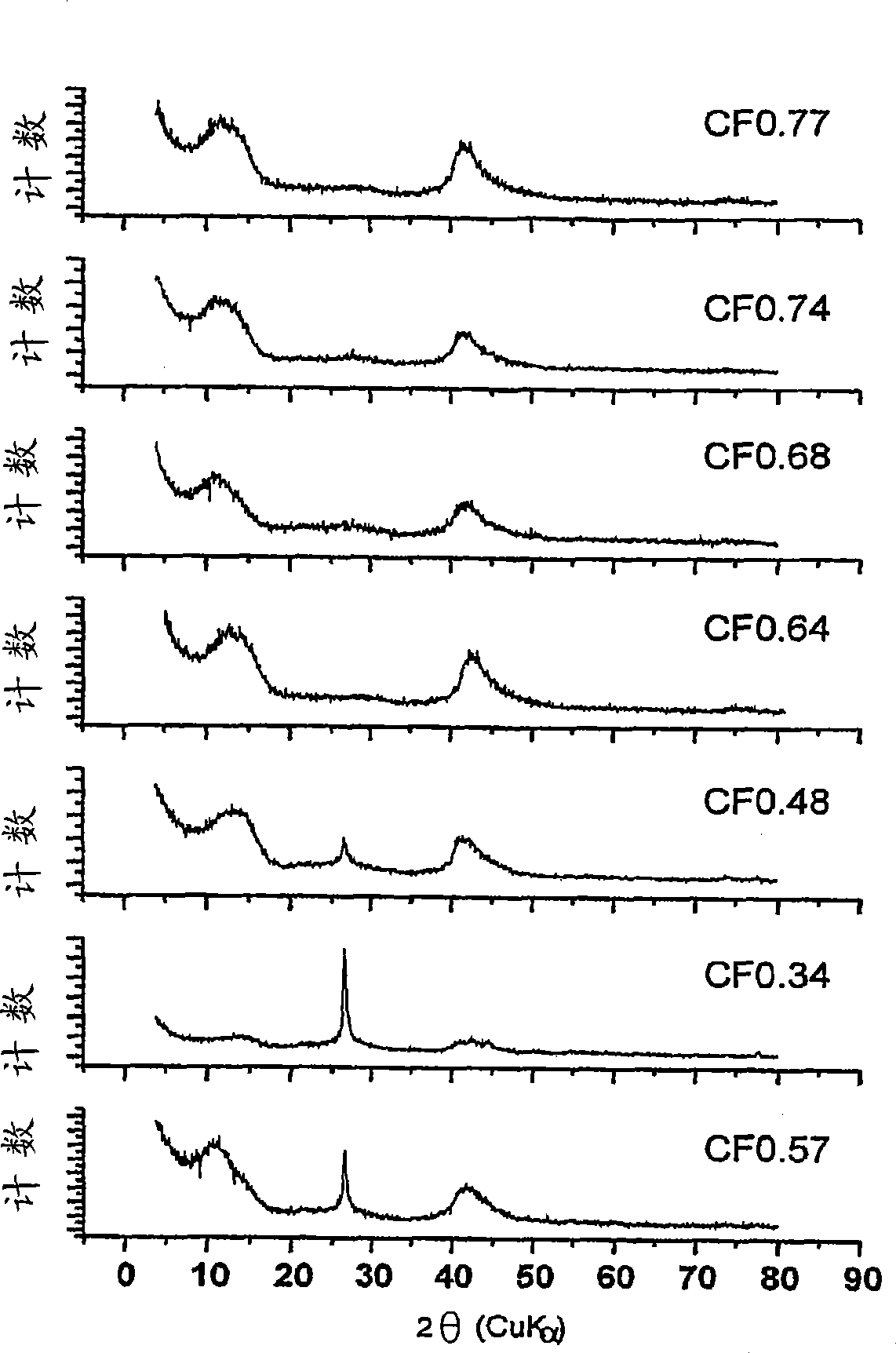

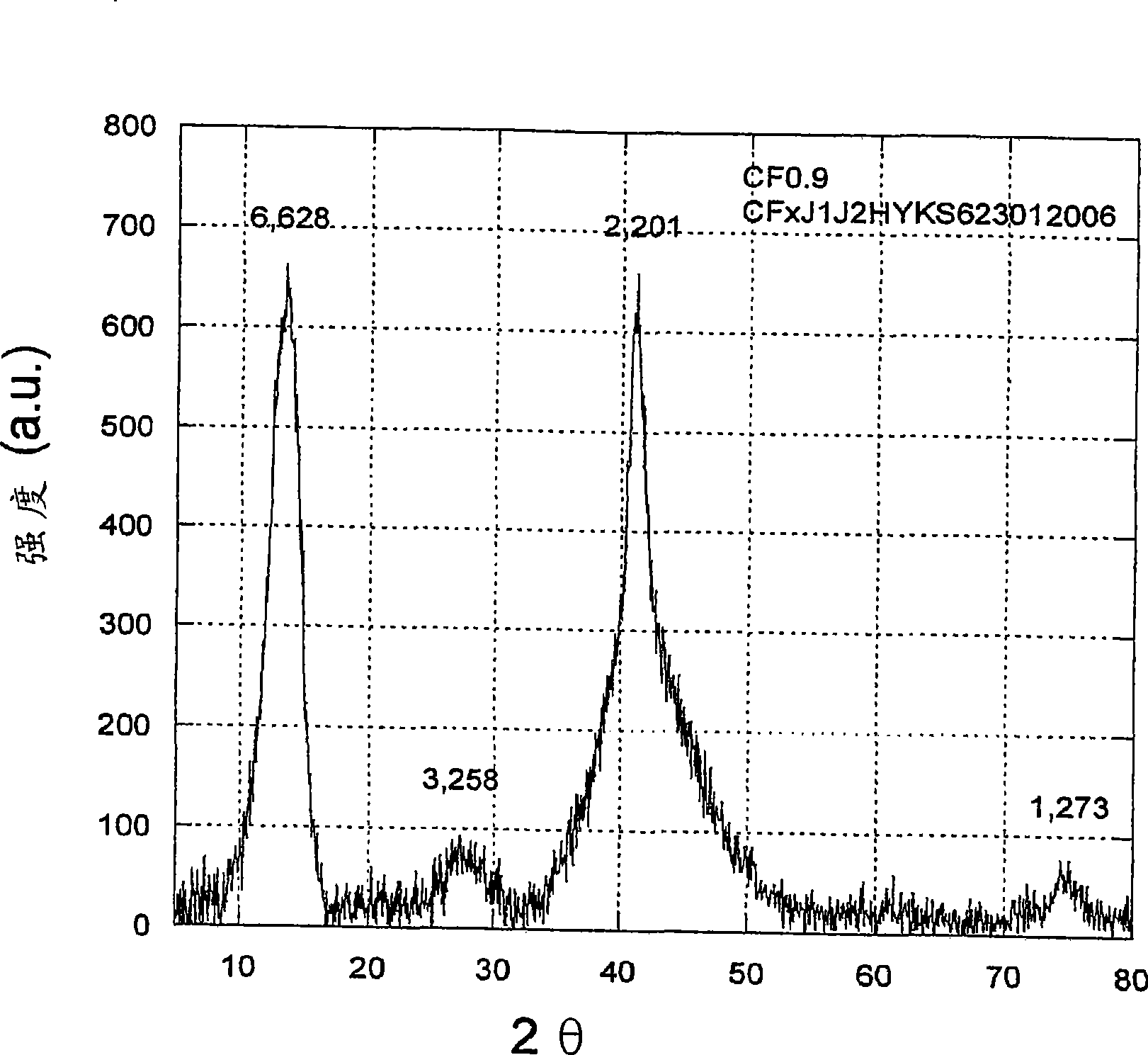

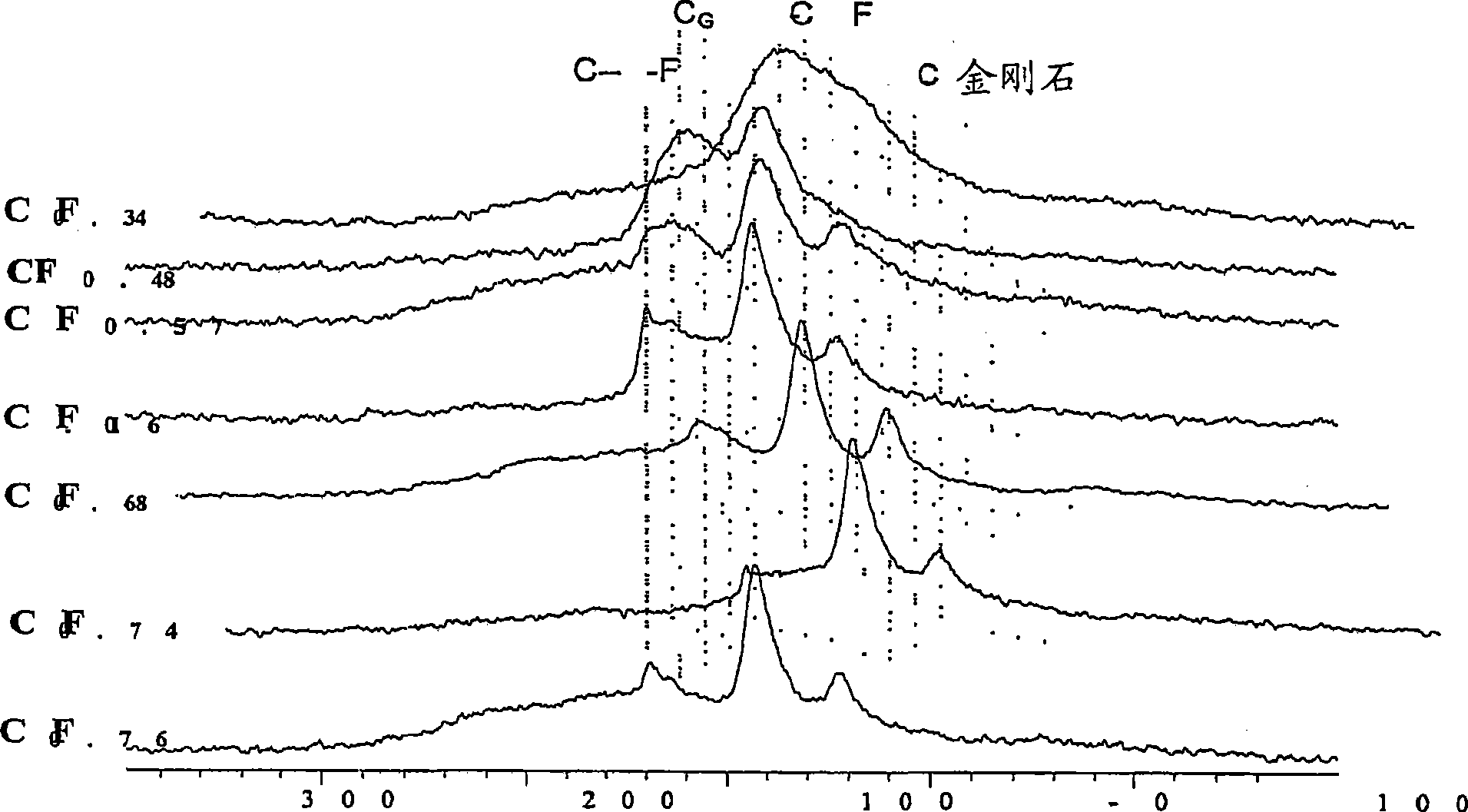

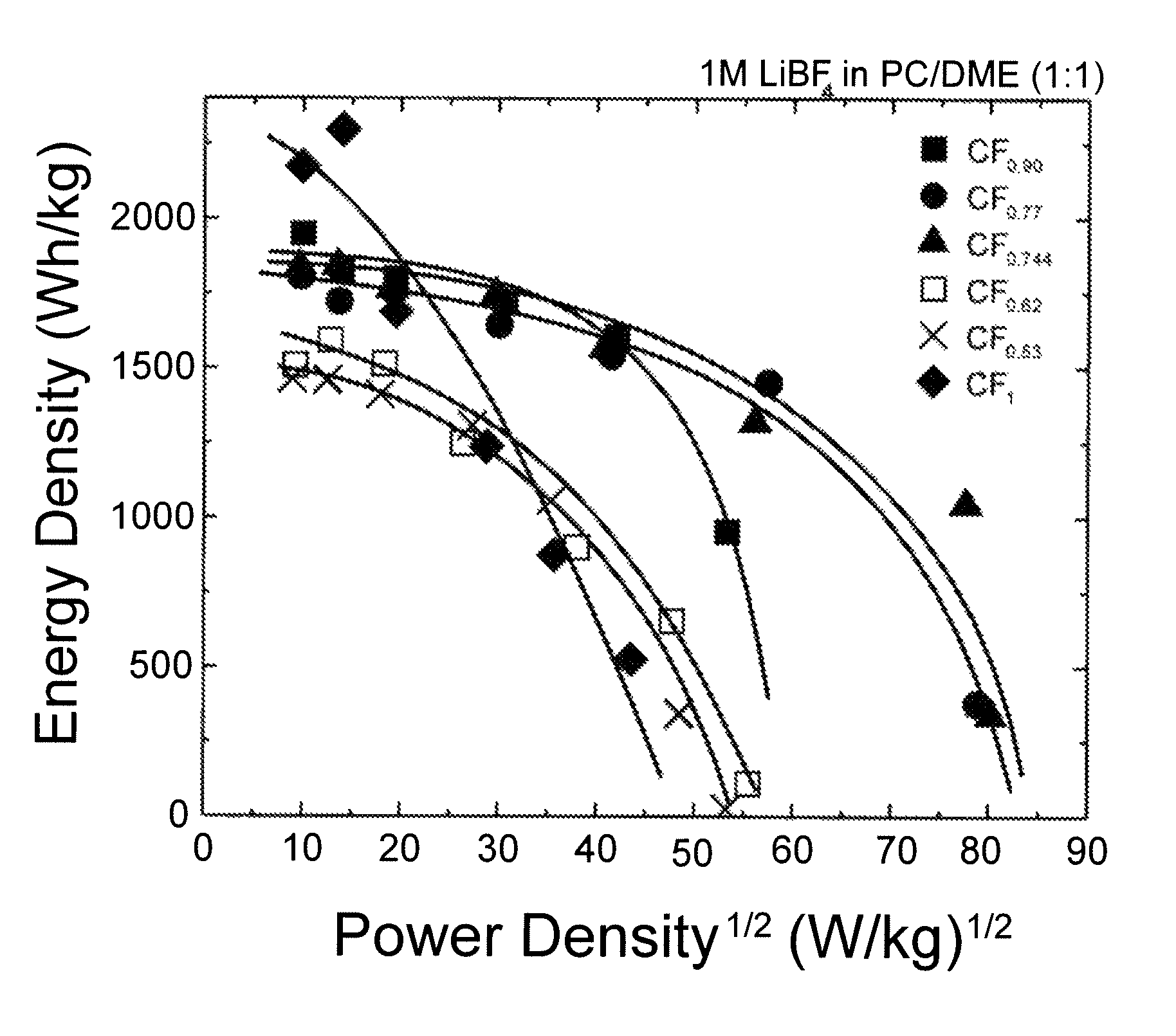

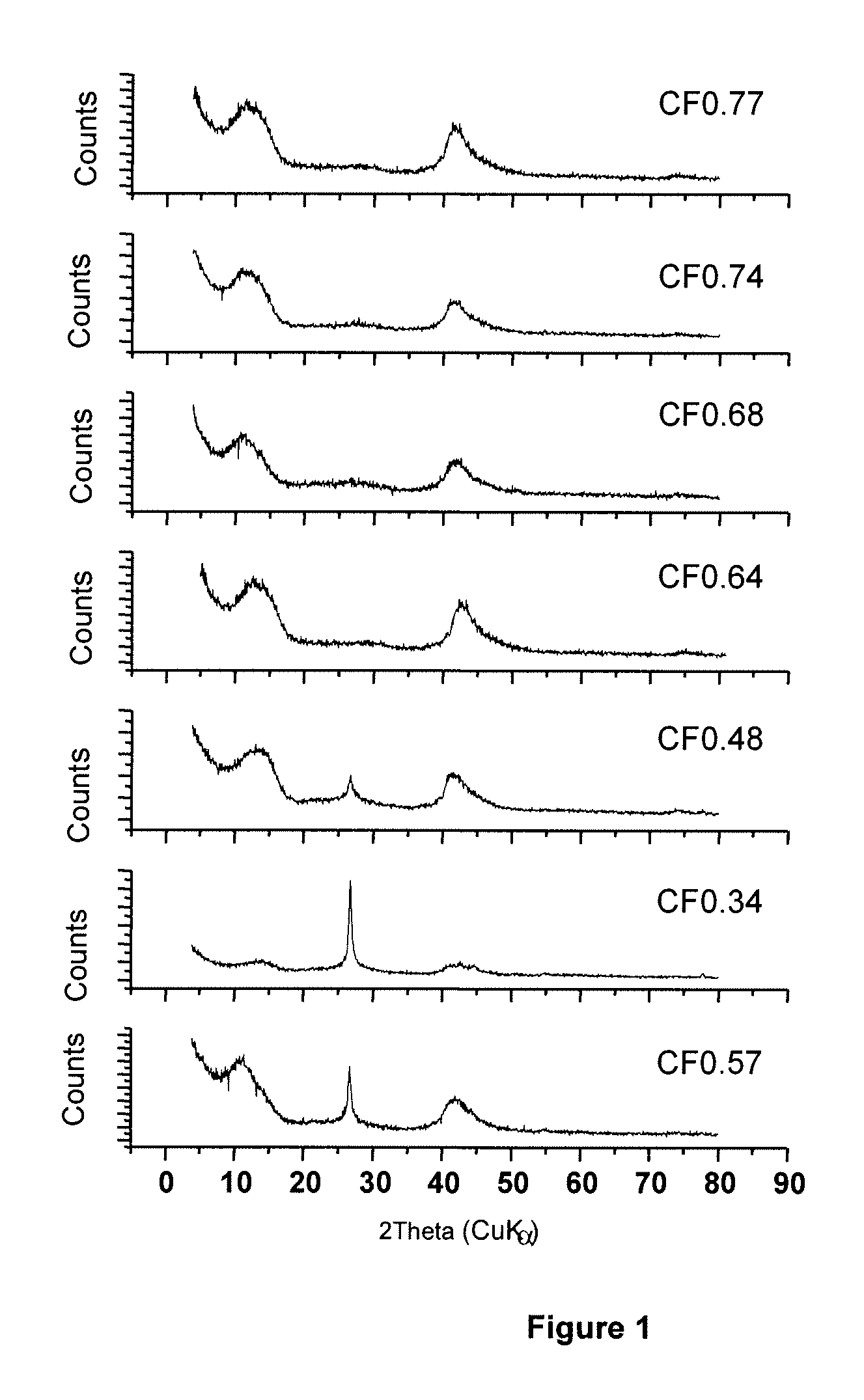

ActiveUS20070231697A1Improve cathode performanceImprove battery performanceNon-aqueous electrolyte cellsElectrode carriers/collectorsChemical compositionHigh rate

Subfluorinated carbonaceous materials obtained through direct fluorination of graphite or coke particles are provided. One set of subfluorinated carbonaceous materials has an average chemical composition CFx in which 0.63<x≦0.95, 0.66<x≦0.95 or 0.7<x≦0.95. The subfluorinated carbonaceous materials are capable of electrochemical performance superior to commercial CF at relatively high rates of discharge.

Owner:CALIFORNIA INST OF TECH +2

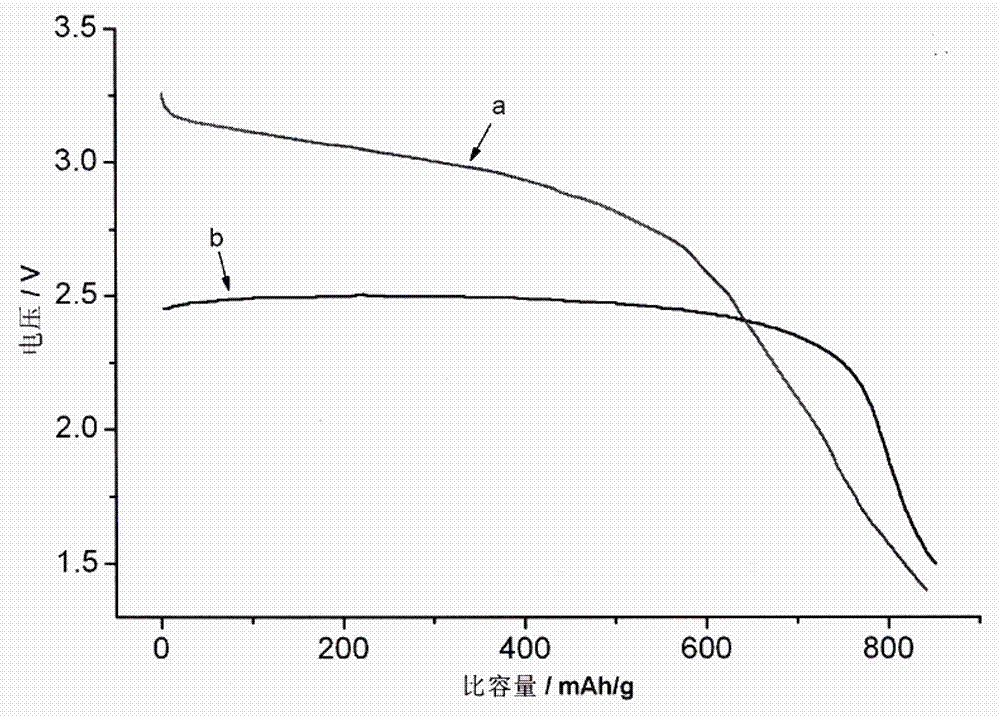

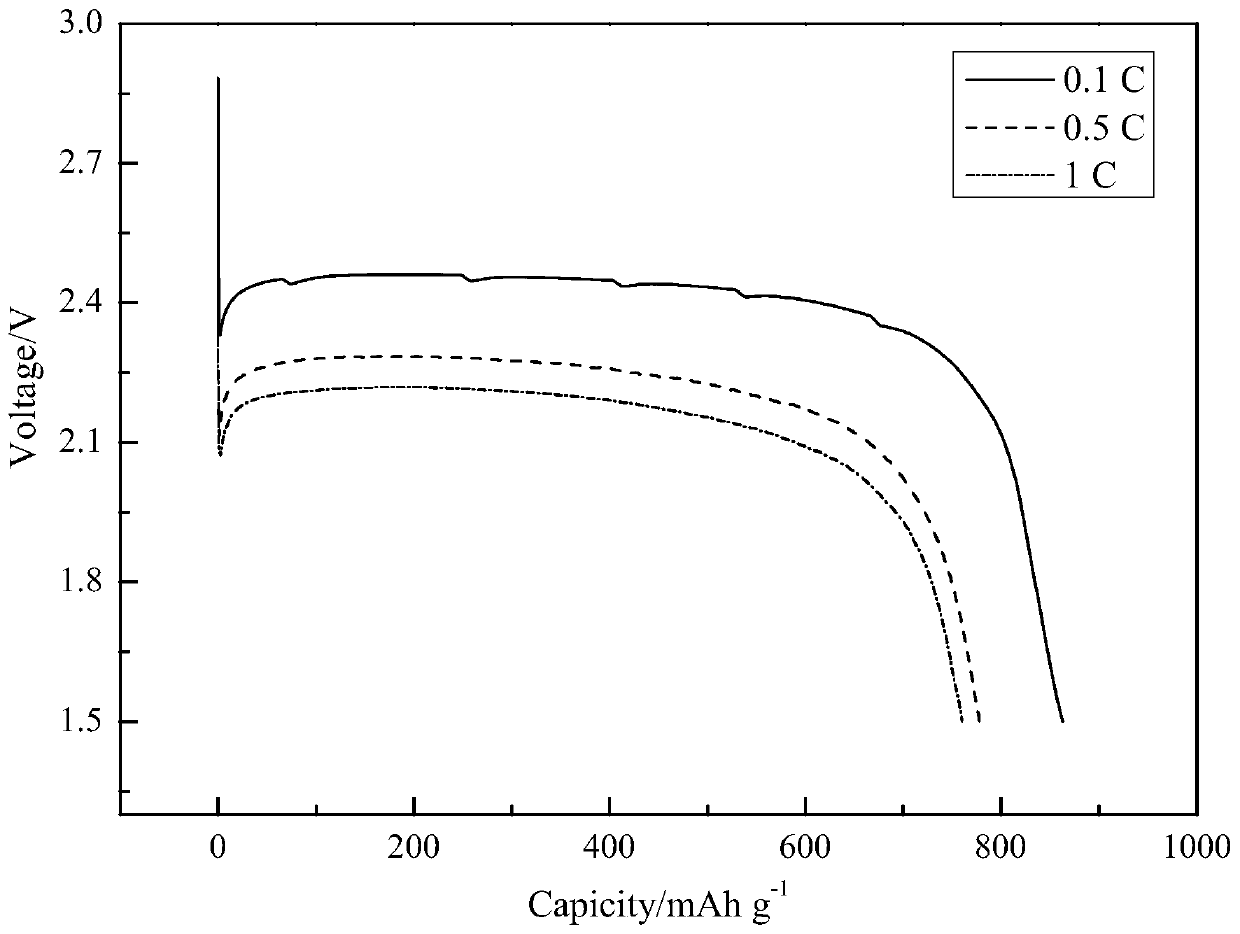

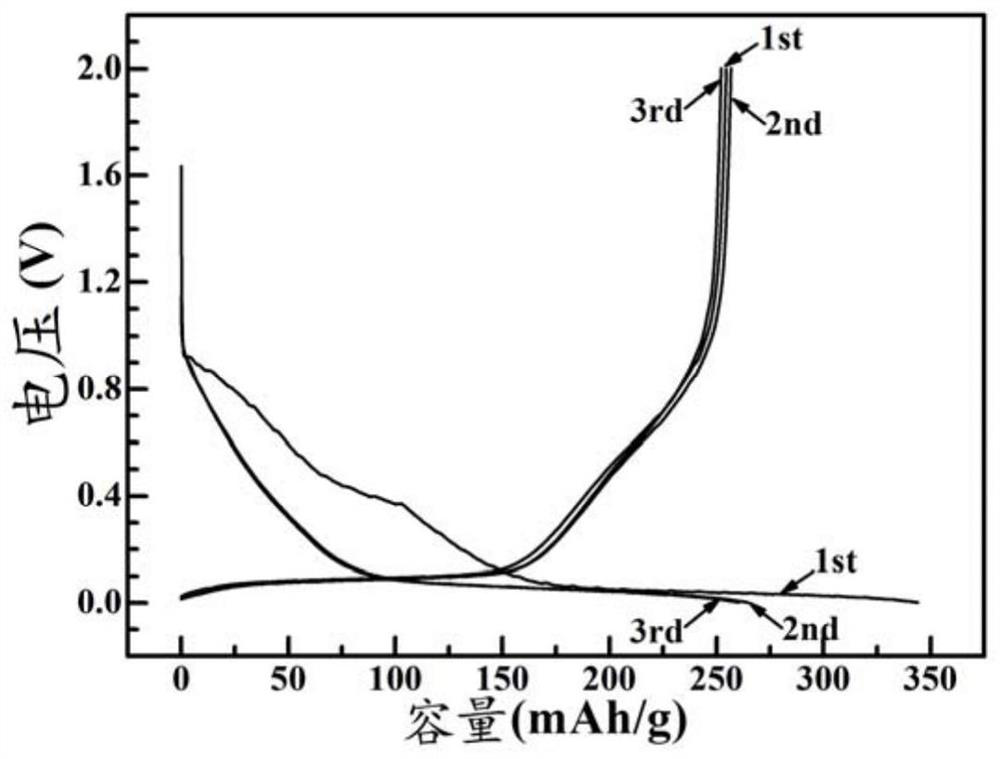

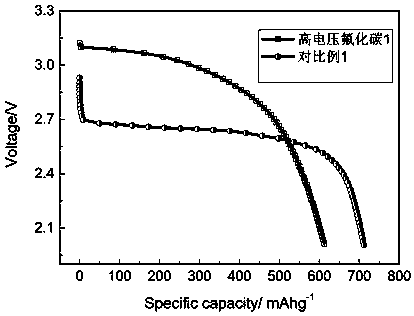

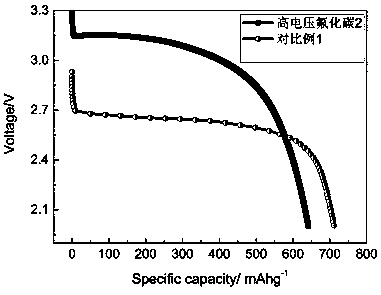

Carbon fluoride and application thereof

ActiveCN102730663AEasy to prepareEasy to operateCell electrodesCarbon fluoridesReaction temperatureGraphite

The invention discloses carbon fluoride prepared by carrying out heating reaction of bamboo charcoal and a fluorination reagent in a closed container. A preparation method of carbon fluoride is characterized by heating bamboo charcoal and the fluorination reagent in the closed container for 1-20 h to obtain carbon fluoride, wherein the fluorination reagent is NF3, and the reaction temperature of the heating reaction is 300-600 DEG C. In addition, the invention further discloses an application of the carbon fluoride in being used as a lithium primary cell cathode material. The preparation method of the carbon fluoride has the advantages of simple process, high specific capacity and good safety. A lithium primary cell prepared by using the carbon fluoride provided by the invention has high working voltage platform, the discharge voltage of lithium-carbon fluoride is raised to 3.0V which is higher than the discharge voltage being 2.5V of lithium-graphite fluoride, thus the energy storage capacity of the lithium primary cell can be raised by about 20%.

Owner:NORTHWEST INST OF NUCLEAR TECH

Preparation method of high-performance fluorinated peanut shell hard carbon electrode material

InactiveCN110880599AIncrease capacityLow costCell electrodesSecondary cellsCarbon monofluorideHigh energy

The invention discloses a preparation method of a high-performance fluorinated peanut shell hard carbon electrode material. The method comprises the following steps of pulverizing peanut shells, and cleaning the peanut shells with deionized water once to remove the water-soluble impurities; soaking the peanut shells in a KOH solution, activating, drying, carrying out high-temperature pyrolysis for4-6 hours under the protection of inert gas, and after the pyrolysis is finished, cooling to room temperature so as to obtain a pyrolytic carbon material; washing the pyrolytic carbon material to beneutral, drying, grinding the pyrolytic carbon material into powder, fluorinating the pyrolytic carbon material obtained in the step 4 by adopting a gas-phase fluorination method, wherein the fluorination gas is mixed gas of fluorine gas and nitrogen gas; keeping the fluorination temperature at 200-300 DEG C for 3-5 hours, and cooling to obtain a carbon fluoride material; uniformly mixing the carbon fluoride material with carbon black and a binder in proportion, uniformly coating an aluminum foil with an NMP, and drying to obtain the high-performance fluorinated peanut shell hard carbon electrode material. The high-energy-density carbon fluoride material can be obtained and used for a lithium primary battery, and the specific capacity of a battery can be remarkably improved.

Owner:TIANJIN UNIV

Electrochemistry of carbon subfluorides

Subfluorinated carbonaceous materials obtained through direct fluorination of graphite or coke particles are provided. One set of subfluorinated carbonaceous materials has an average chemical composition CFx in which 0.63 < x <= 0.95, 0.66 < x <= 0.95 or 0.7 < x <= 0.95. The subfluorinated carbonaceous materials are capable of electrochemical performance superior to commercial CF at relatively high rates of discharge.

Owner:CALIFORNIA INST OF TECH +2

Method for industrially producing carbon fluoride materials

PendingCN108529589ARealize industrial scale productionIncrease profitCarbon fluoridesChemical/physical processesSynthesis methodsLithium-ion battery

The invention discloses a method for industrially producing carbon fluoride materials. A carbon raw material is in sufficient contact with a fluorinating agent for a reaction in a fluidized bed, and the carbon fluoride materials with different fluoride contents are generated; after purification and drying, carbon fluoride material products with different fluoride contents are obtained, wherein thefluoride contents are within the range of 3-66%. Compared with a synthesis method in the prior art, the production method can achieve industrial scale production of the carbon fluoride materials, andbesides, the production method is simple in technology process, high in reaction efficiency, low in production cost and uniform in product quality. The obtained carbon fluoride material products aremainly applied to anode materials of lithium ion batteries, high-end solid lubricant materials, filler of high-end coatings, oil absorption materials and the like.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

Purification method of battery-grade graphite fluoride

InactiveCN102602908AEffective dissolutionEasy to cleanCarbon fluoridesHydrogen fluorideHydrofluoric acid

The invention discloses a purification method of ultrasound assisted HF (hydrogen fluoride) washing battery-grade graphite fluoride. The method comprises the following concrete steps of: mixing common graphite fluoride and 20% hydrofluoric acid uniformly; cleaning for 30-60 minutes under ultrasound assistance, and dissolving impurities fully; and then leaching the system above, placing a filter cake in a heat furnace of 150-200 DEG C and drying, thereby obtaining graphite fluoride meeting the battery-grade requirement. The purification method of ultrasound assisted HF washing battery-grade graphite fluoride provided by the invention is not only simple and convenient in process, is low in cost, but also is wide in application range, and is favor of industrial production.

Owner:SHANGHAI SCI BIO PHARMA

Fluorinated graphene material as well as preparation method and application thereof

The invention discloses a fluorinated graphene material as well as a preparation method and an application thereof, and belongs to the field of new materials. The preparation method comprises the following steps: mixing a graphene oxide solution with HF acid for reflux stirring reaction at 20-80 DEG C to obtain a mixed system; performing hydrothermal reaction on the mixed system obtained in the step 1 to obtain suspension; removing excess HF from the suspension and performing drying to obtain fluorinated graphene. According to the preparation method, a solvent is pollution-free, a fluorinationreagent is a cheap and easily available HF solution, a small quantity of the reagent is used, and the overall process is low in difficulty, low in pollution and energy consumption; the obtained fluorinated graphene material comprises 2-8 layers of sheets and is thinner; with application of AlH3 or Al powder coated with the fluorinated graphene material prepared with the method in propulsion, sensitivity of AlH3 in propellant application can be reduced, and combustion efficiency of Al powder is improved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

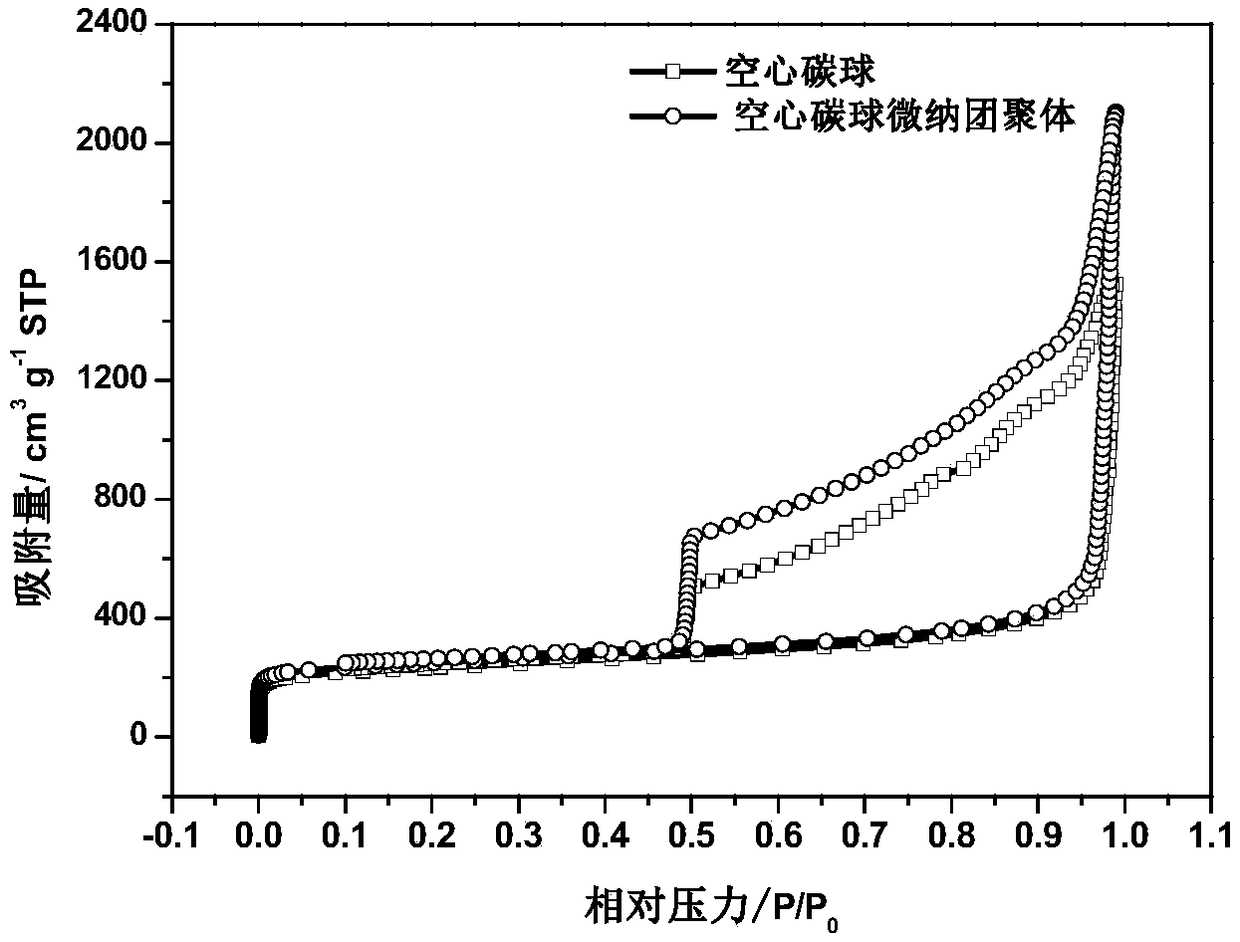

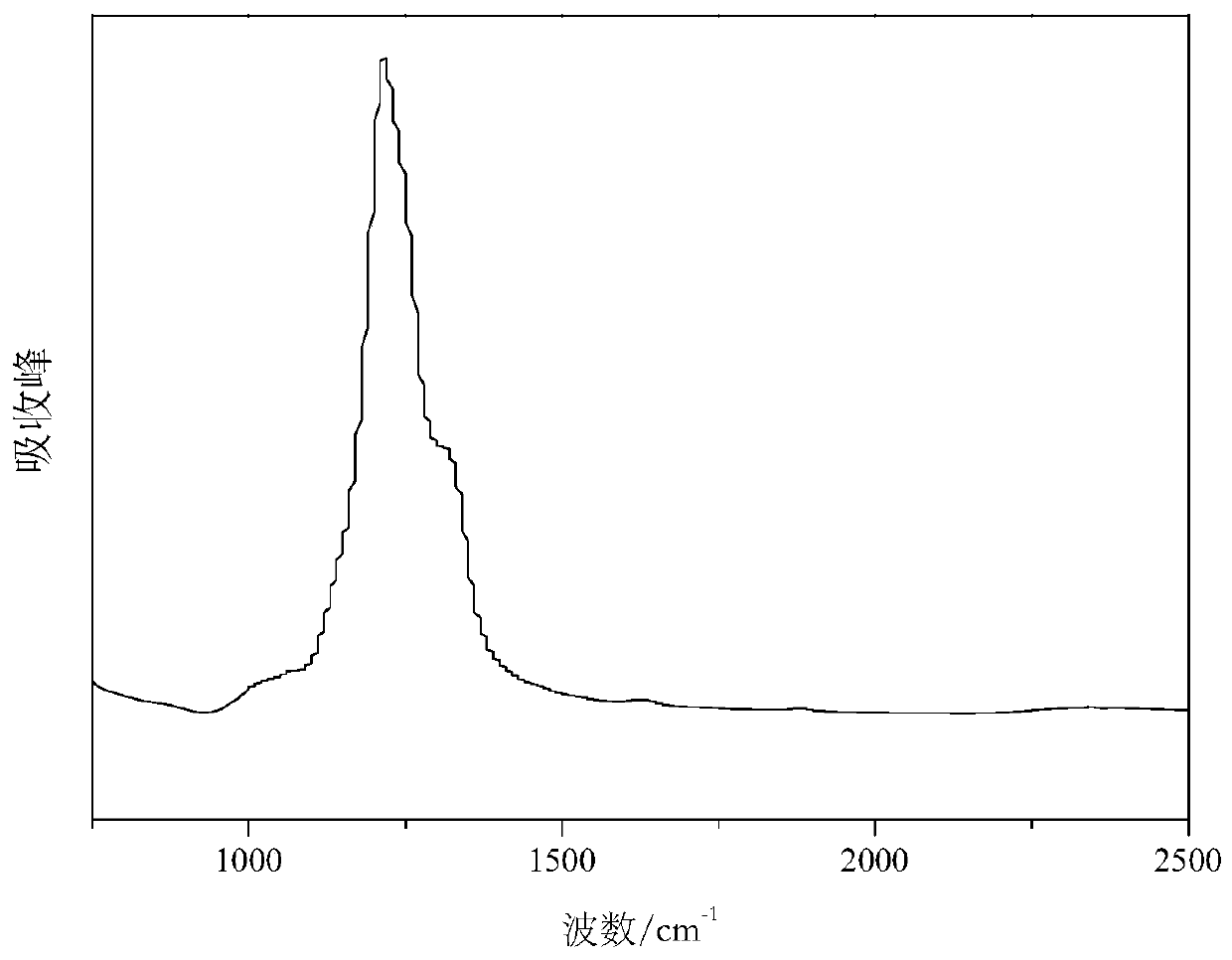

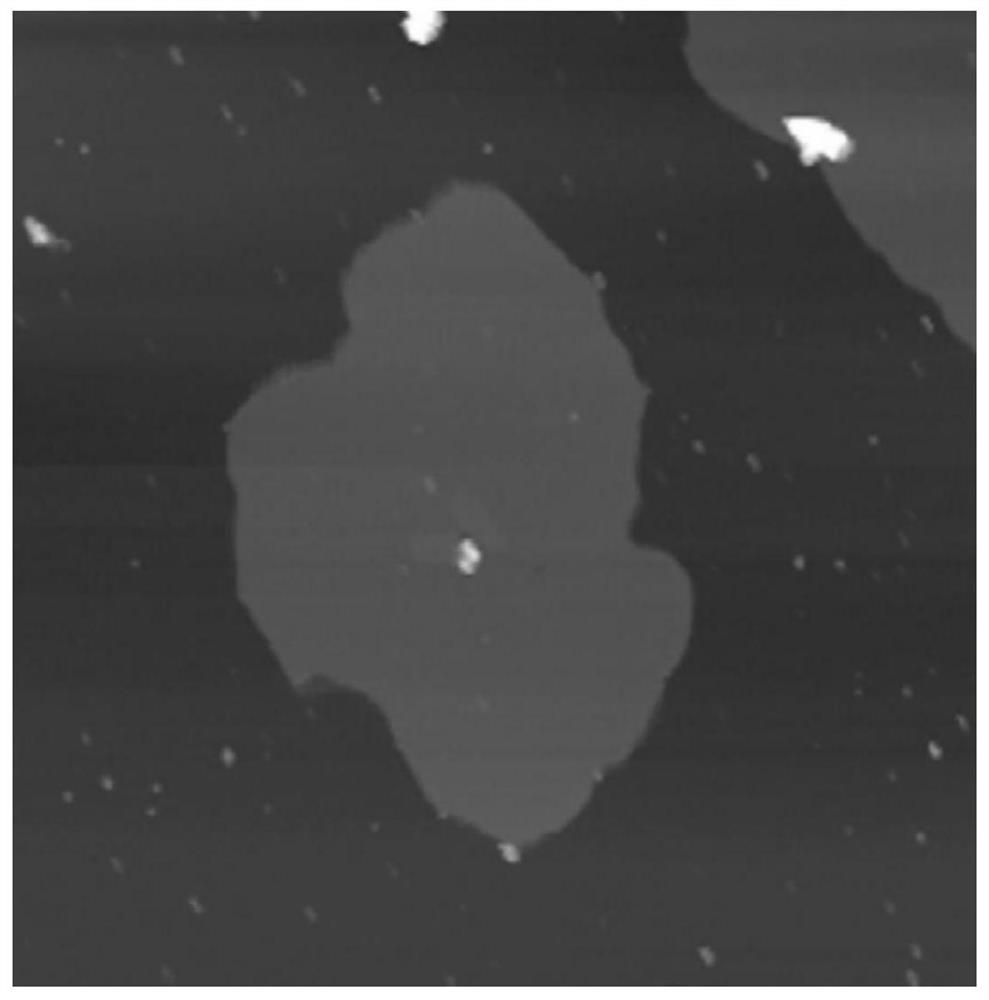

Preparation method and application of hollow carbon sphere micro-nano agglomerate/sulfur composite material

ActiveCN108640102AEvenly dispersedImprove conductivityCell electrodesSulfur compoundsMicro nanoHydrofluoric acid

A preparation method of a hollow carbon sphere micro-nano agglomerate / sulfur composite material comprises the following steps: a) uniformly dispersing organic material-coated inorganic nano-spheres inwater or a water and alcohol solvent to obtain a mixed solution; b) completely dissolving a certain mass of an aqueous binder in water, adding the obtained aqueous solution to the mixed solution under stirring, and carrying out heating drying to evaporate away the solvent in order to obtain a nano-hollow carbon sphere micro-nano structure precursor; c) carrying out high-temperature sintering in an inert atmosphere or a hydrogen-containing reduction atmosphere to obtain nano-hollow carbon sphere micro-nano structure precursor carbide; d) placing the nano-hollow carbon sphere micro-nano structure precursor carbide in an aqueous hydrofluoric acid solution or a hot aqueous sodium hydroxide solution to etch away the above inorganic material in the nano-hollow carbon spheres, and washing and drying the obtained carbide to obtain a nano-hollow carbon sphere micro-nano agglomerate; and e) mixing the nano-hollow carbon sphere micro-nano agglomerate with a certain mass of sulfur powder, uniformly grinding the obtained mixture, placing the ground mixture in an oven full of N2, heating the ground mixture to 155 DEG C, keeping the temperature for 6-24 h, and cooling the obtained material to obtain the product.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing carbon fluorine material

InactiveCN109775685AImprove securityReduce manufacturing costCell electrodesCarbon fluoridesMaterials preparationElectrochemistry

The invention relates to a method for preparing a carbon fluorine material and belongs to the field of lithium battery material preparation. According to the method, a specific carbon source is selected to react with a fluorine source, the fluorination temperature is low, the fluorination time is short, and the reaction is implemented at normal pressure, so that the safety of a fluorination process is improved, and the preparation cost of the carbon fluorine material is lowered; in addition, carbon fluorine prepared according to the method has a high fluorine-carbon ratio, that is, as high as0.8-1.2, and has good electrochemical properties.

Owner:PERIC SPECIAL GASES CO LTD

Preparation method of fluorinated graphene material with adjustable fluorine content

ActiveCN111620326ALow equipment requirementsLower requirementGrapheneCarbon fluoridesHydrogen fluorideOrganic solvent

The invention provides a preparation method of a fluorinated graphene material with adjustable fluorine content, which comprises the following steps: (1) uniformly mixing a mixed metal salt with graphite fluoride by grinding or ball milling, wherein the mixed metal salt is two or three of NaCl, CaCl2, LiCl, BaCl2 and ZnCl2, the melting point of the mixed metal salt is lower than 550 DEG C, and themass ratio of the mixed metal salt to the graphite fluoride is 4: 1 to 1: 1; (2) putting the mixed product into a tubular furnace, and reacting at 550 DEG C for a period of time; and (3) carrying outultrasonic stripping on the reaction product in a mixed solution of an organic solvent and hydrogen fluoride, centrifugally separating out an upper-layer solution, carrying out suction filtration andwashing, and carrying out vacuum drying to obtain the fluorinated graphene. The synthesis method disclosed by the invention is low in equipment requirement, simple in technological process, strong inoperability and easy to amplify.

Owner:FUJIAN JIANGXIA UNIV

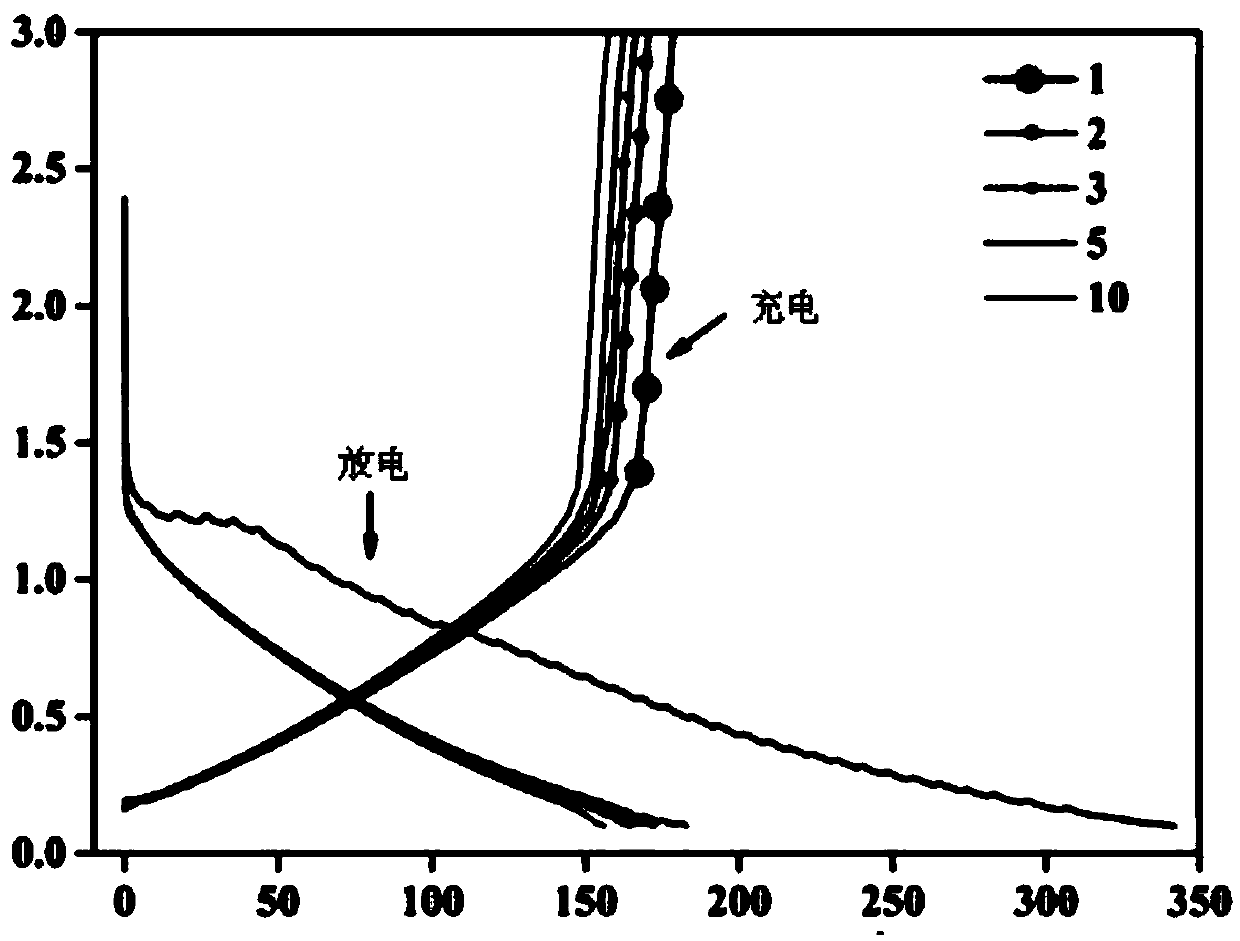

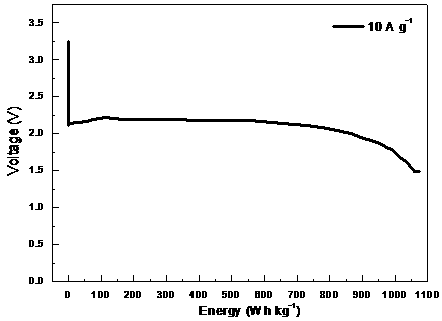

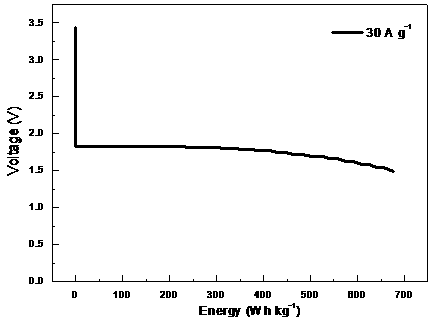

Preparation method and application of carbon fluoride material

ActiveCN111170302AHigh specific powerIncrease specific energyCell electrodesNon-aqueous electrolyte cellsCarbon monofluorideElectrical battery

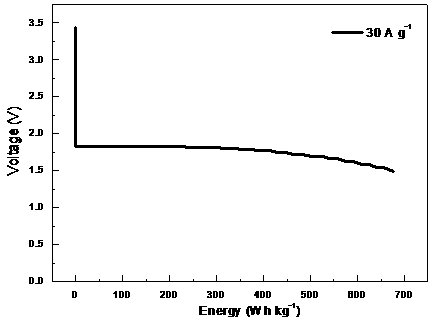

The invention discloses a preparation method of a carbon fluoride material, which comprises the following steps: S1, weighing 70-98 wt% of a hard carbon raw material and 2-30 wt% of a soft carbon rawmaterial, mixing in a solvent, uniformly stirring, and sintering in a protective atmosphere at 1500-2800 DEG C for 1-24 hours to obtain a pretreated material; S2, grinding the pretreated material obtained in the step S1 to prepare a powdery product; and S3, putting the powdery product obtained in the step S2 into fluorination equipment, introducing fluorination gas, keeping the pressure at 90-120kPa, and reacting at 350-450 DEG C for 8-16 hours to obtain the carbon fluoride material. The carbon fluoride material prepared by the invention has high specific power and high specific energy, can realize discharge under the current of 30 A / g, has the specific energy of more than 550 Wh / kg and the specific power of more than 45000 W / kg, and can be applied to a lithium carbon fluoride battery positive electrode material.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

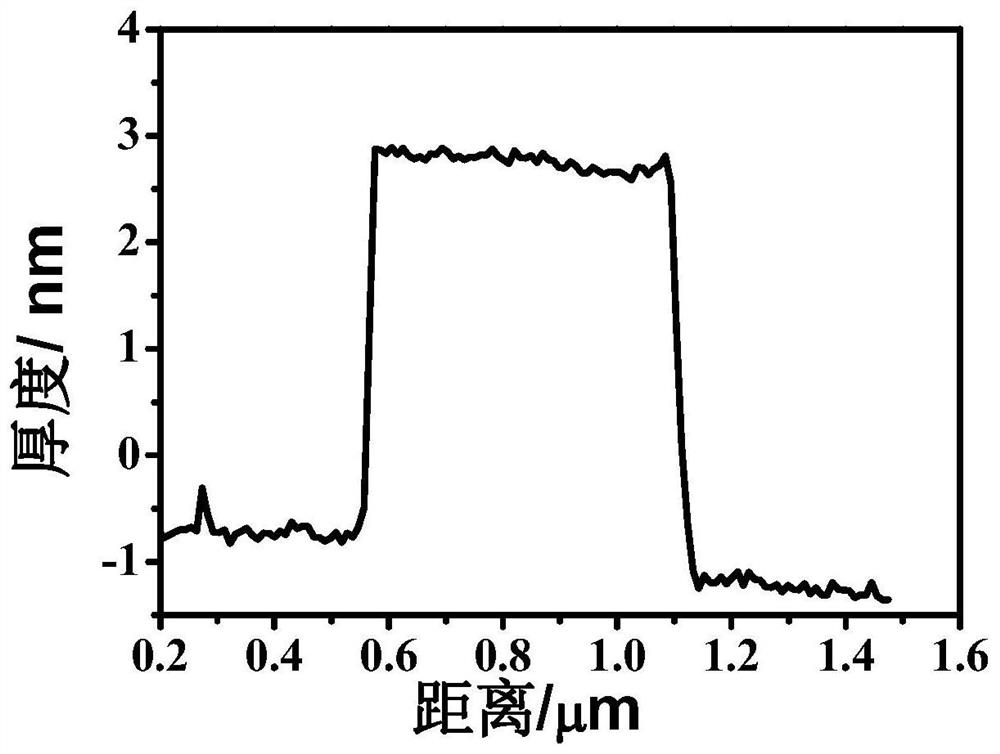

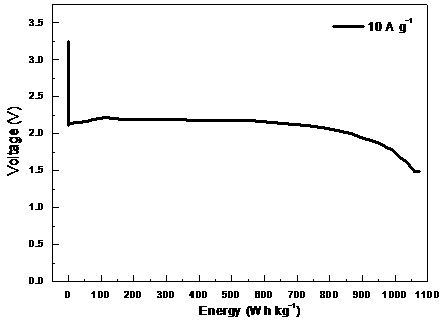

Preparation method and application of carbon fluoride material

ActiveCN111170303AHigh specific powerIncrease specific energyCell electrodesCarbon fluoridesCarbon monofluorideElectrical battery

The invention discloses a preparation method of a carbon fluoride material, which comprises the following steps: S1, weighing 70-98 wt% of a soft carbon raw material and 2-30 wt% of a graphite carbonmaterial, mixing in a solvent, uniformly stirring, and sintering in a protective atmosphere at 300-1500 DEG C for 1-24 hours to obtain a pretreated material; S2, grinding the pretreated material obtained in the step S1 to prepare a powdery product; and S3, putting the powdery product obtained in the step S2 into fluorination equipment, introducing fluorination gas, keeping the pressure at 90-120 kPa, and reacting at 350-450 DEG C for 8-16 hours to obtain the carbon fluoride material. The carbon fluoride material prepared by the invention has high specific power and high specific energy, can realize discharge under the current of 10 A / g, has the specific energy of more than 850 Wh / kg and the specific power of more than 17000 W / kg, and can be applied to a positive electrode material of a lithium carbon fluoride battery.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

Method for preparing fluorinated graphene dispersion liquid on large scale

InactiveCN110950331AImprove hydrophobicityReduce manufacturing costGrapheneCarbon fluoridesGraphiteGraphene

The invention discloses a method for preparing fluorinated graphene dispersion liquid on a large scale. The method comprises the following steps of carrying out hydrothermal reaction on graphite fluoride and ionic liquid, and carrying out centrifugal collection to obtain the fluorinated graphene dispersion liquid. The hydrophobicity of the fluorinated graphene is improved by utilizing the ionic liquid, so that the fluorinated graphene can be stripped in water; the prepared fluorinated graphene dispersion liquid can be stably dispersed for a long time, single-layer or few-layer fluorinated graphene can be obtained, meanwhile, the process is simple and convenient and environment-friendly, the production cost is low, and the large-batch preparation can be achieved.

Owner:SHAANXI UNIV OF SCI & TECH

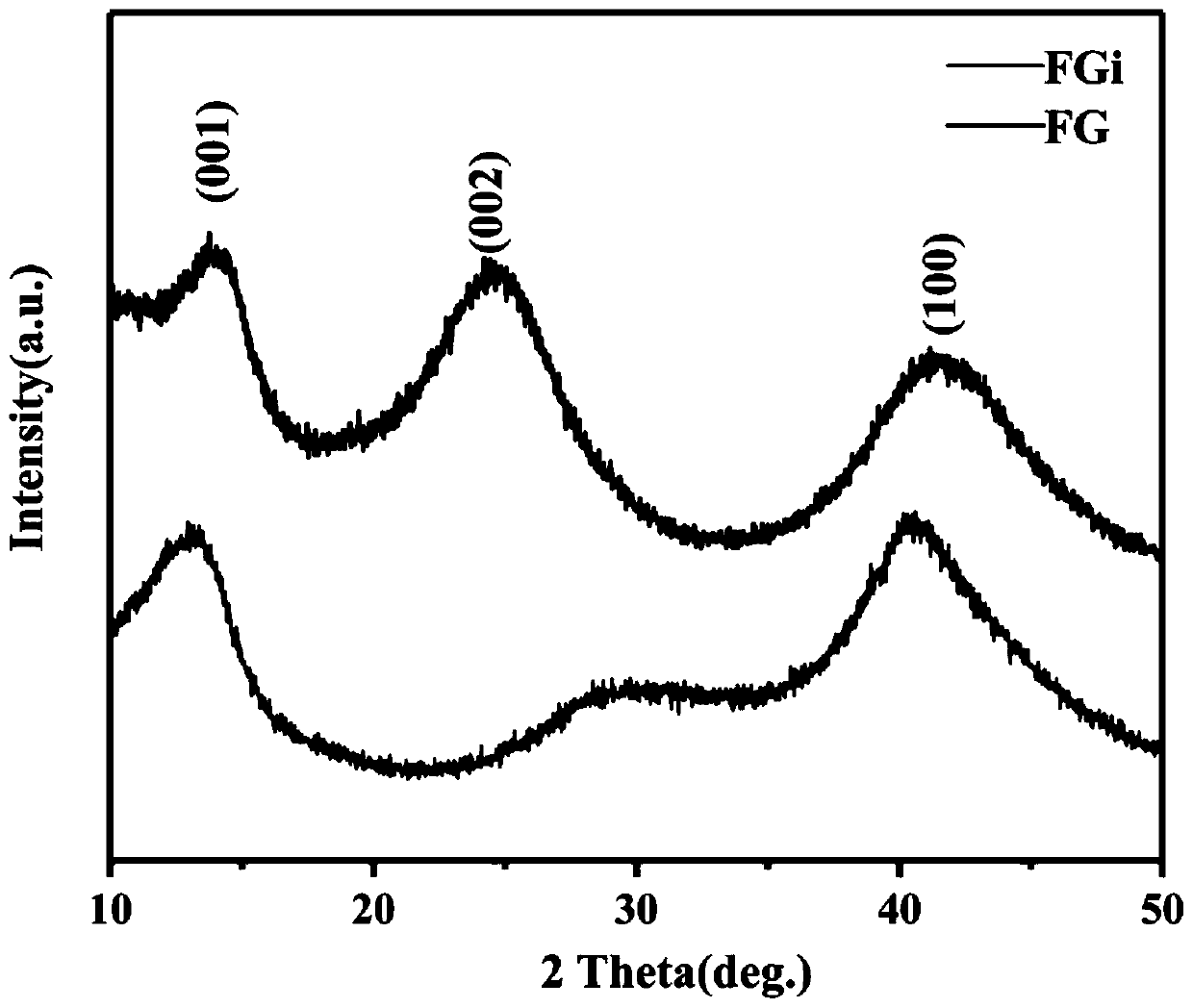

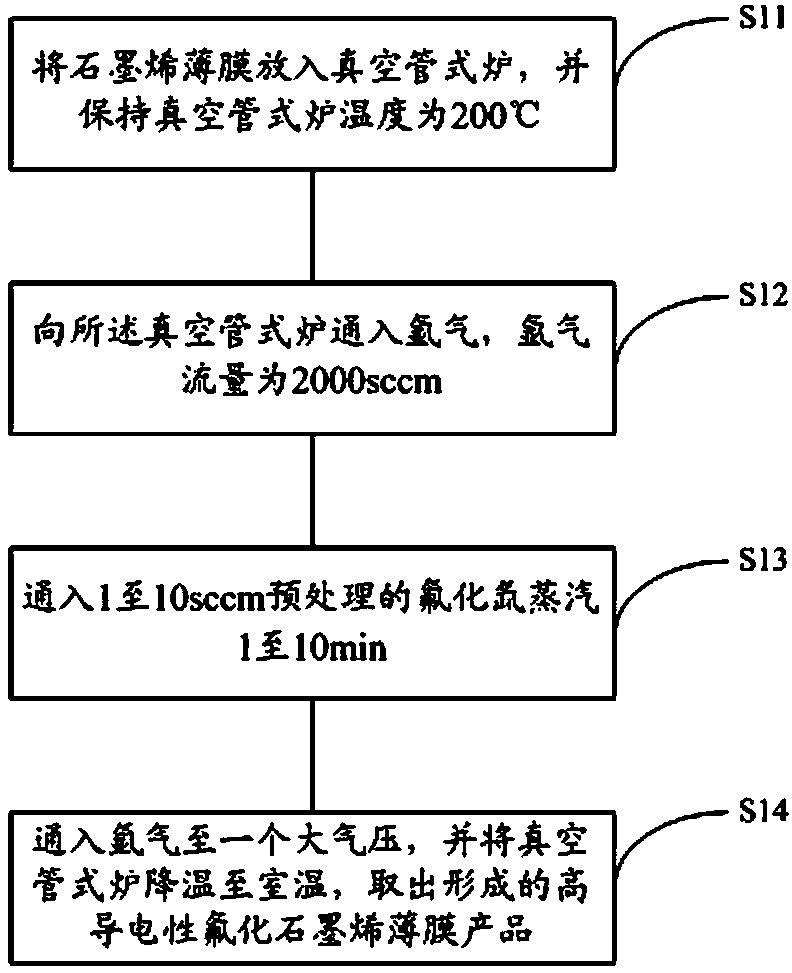

Preparation method of high conductive fluorinated graphene film

The invention discloses a preparation method of a high conductive fluorinated graphene film. The method comprises the steps of: placing a graphene film into a vacuum tube furnace, and maintaining the temperature of the vacuum tube furnace at 200DEG C; introducing argon at a flow rate of 2000sccm into the vacuum tube furnace; introducing pretreated fluorinated xenon steam at a flow rate of 1-10sccm for 1-10min; introducing argon to an atmospheric pressure, cooling the vacuum tube furnace to room temperature, taking out a formed high conductive fluorinated graphene film product. According to the preparation method provided in the invention, the graphene film is placed in the vacuum tube furnace and its temperature is preserved at 200DEG C; argon is introduced into the vacuum tube furnace to serve as a protective atmosphere; then, pretreated fluorinated xenon steam is introduced for certain time to react with the graphene film; and argon is introduced to an atmospheric pressure, the vacuum tube furnace is cooled to room temperature, and finally the formed high conductive fluorinated graphene film product is taken out.

Owner:厦门烯成石墨烯科技有限公司

Chemically modified carbonaceous materials made by the defluorination of graphite fluoride and process therefor

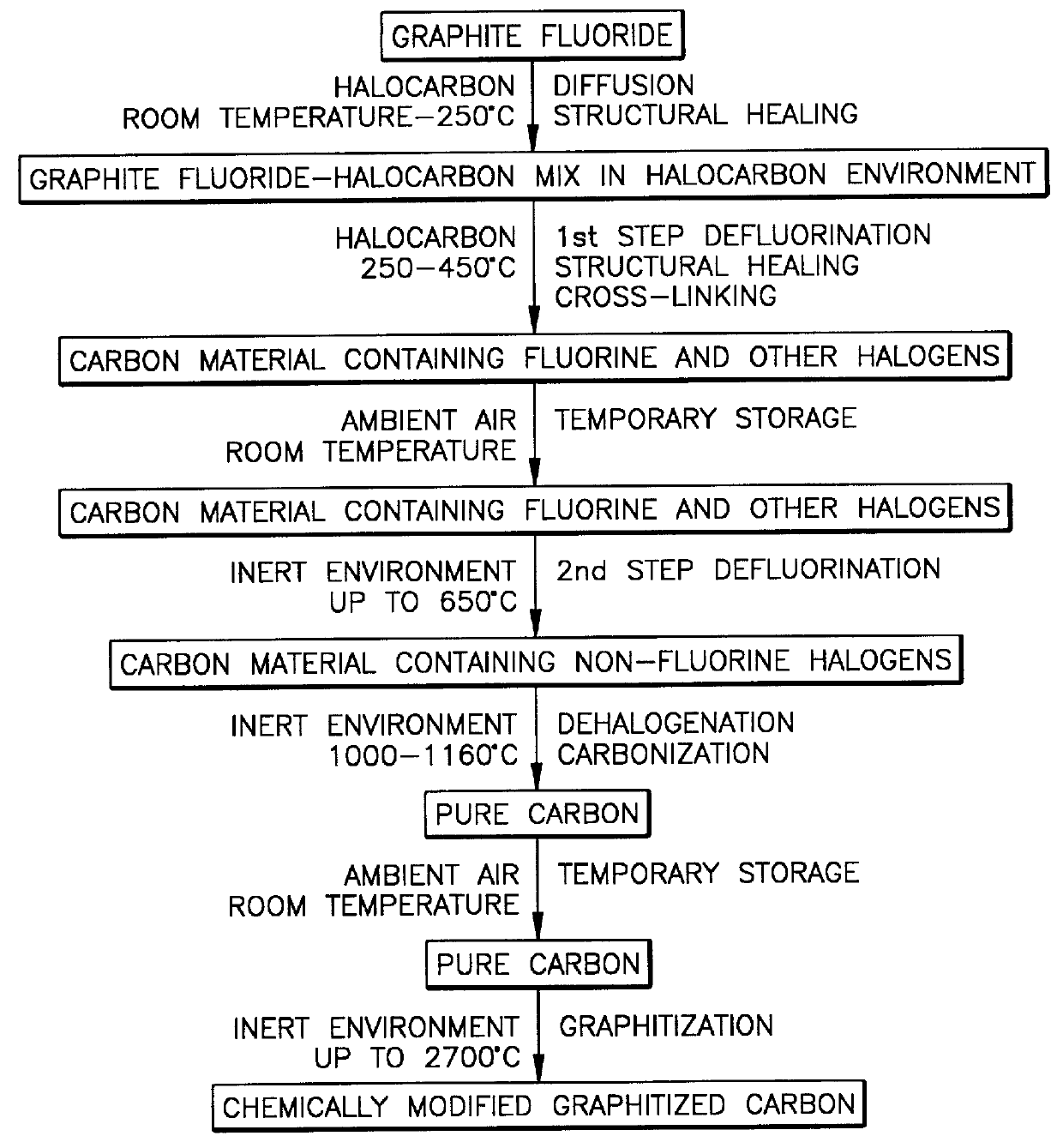

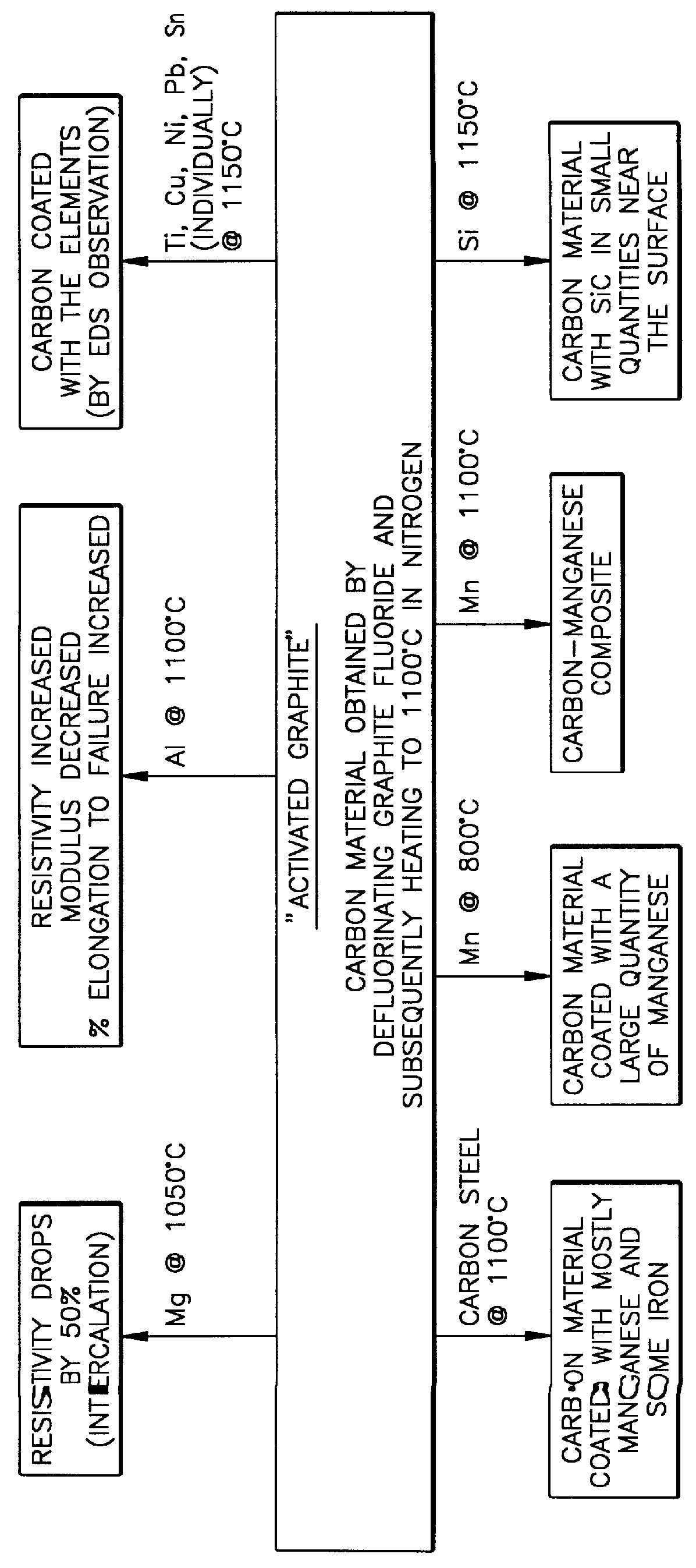

InactiveUS6036934AHigh modulusLow costSolid state diffusion coatingCarbon preparation/purificationLamellar crystalsSulfur

A method of making chemically modified carbon-based materials for engineering purposes from a precursor containing graphite fluoride by using halocarbons or elemental sulfur as chemical agents that diffuse into the lamellar crystal structure of the graphite fluoride and permit defluoridation at a controlled rate upon heating, to produce graphite fluoride-free intermediate carbon material and, upon further heating to form a chemically modified non-graphitized carbon.

Owner:HUNG CHING CHEH

Carbon-based fiber sheet and lithium-sulfur battery including same

PendingCN108602674AIncrease capacityImprove life characteristicsCell electrodesElectro-spinningLithium–sulfur batteryLithium sulfur

The present invention relates to a carbon-based fiber sheet and a lithium-sulfur battery including the same. According to the present invention, a carbon-based fiber sheet for a lithium-sulfur batteryis doped with highly concentrated nitrogen so as to perform roles of adsorbing lithium polysulfide eluted from a cathode during charging or discharging and of preventing the diffusion thereof, such that a shuttle reaction is suppressed, thereby enabling capacity and lifespan characteristics of a lithium-sulfur battery to improve.

Owner:LG ENERGY SOLUTION LTD

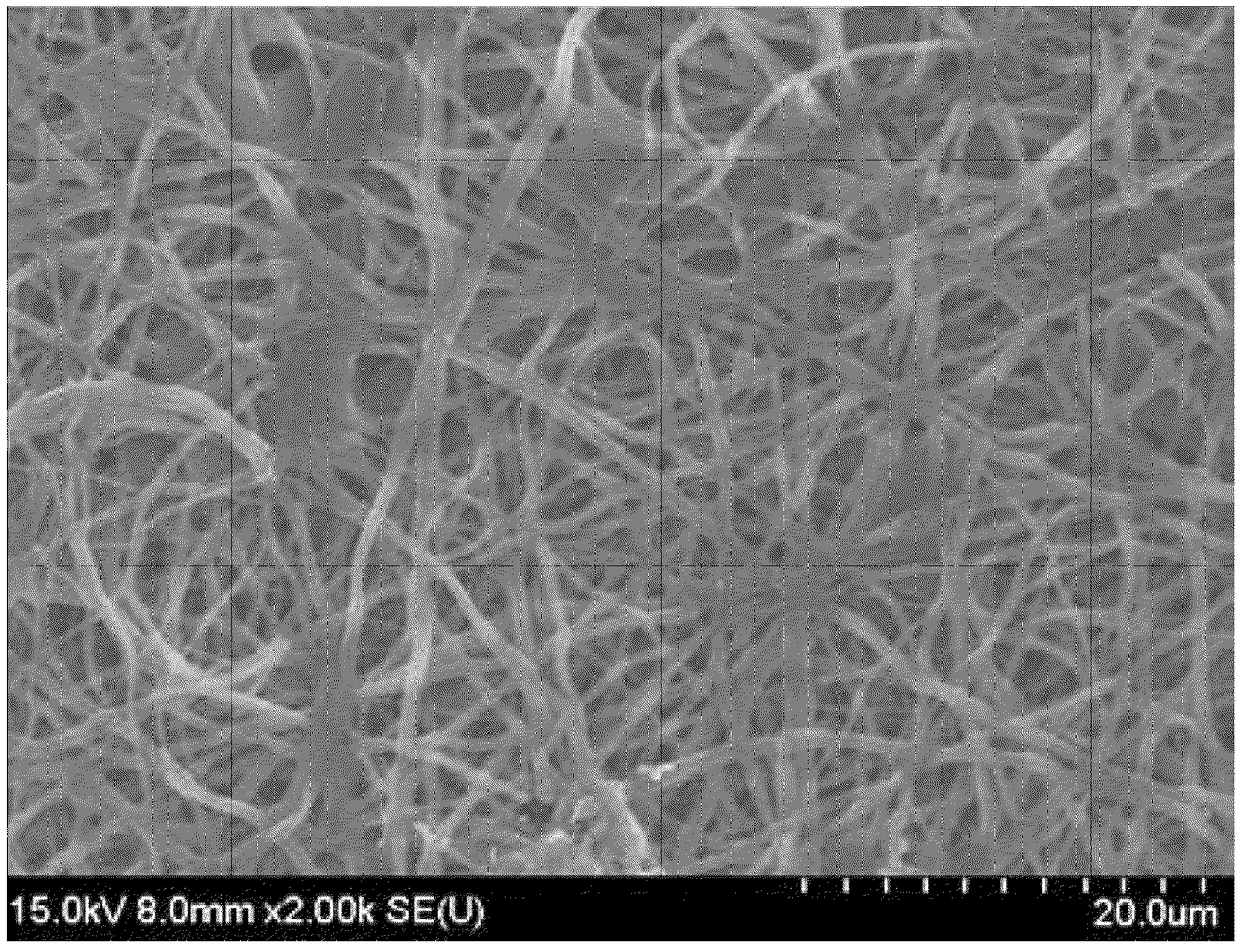

Hard carbon composite material, and preparation method and application thereof

ActiveCN112002881AShort cycleReduce energy consumptionSecondary cellsNegative electrodesCarbon compositesCarbon monofluoride

The invention discloses a hard carbon composite material, and a preparation method and application thereof. The composite carbon material disclosed by the invention is of a core-shell structure, consists of a hard carbon material of an inner core and carbon fluoride of an outer shell, and is prepared from commercial hard carbon and a fluorine-containing polymer through simple heat treatment. Whenthe hard carbon composite material is used for the negative electrode of a sodium-ion battery, optimal balance of capacity, coulombic efficiency and cycle life can be realized. The hard carbon composite material is prepared from cheap raw materials by the simple method, and is low in energy consumption, low in cost, short in period and beneficial to large-scale production.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +3

Method for producing a lithium battery material, materials and lithium battery

InactiveCN108473310AImprove electrochemical performanceCell electrodesOrganic electrolyte cellsElectrical batteryEngineering

The invention relates to a method for producing a lithium battery material with improved electrochemical characteristics, to materials that can be produced by the method according to the invention, toan electrode comprising a material according to the invention, to a battery, especially a lithium battery, comprising a material according to the invention, and to devices comprising a lithium battery according to the invention. The invention is particularly applicable to the production of lithium batteries.

Owner:UNIV CLERMONT AUVERGNE +1

Electrochemistry of carbon subfluorides

ActiveUS8232007B2Improve cathode performanceHigh rateNon-aqueous electrolyte cellsElectrode carriers/collectorsHigh rateChemical composition

Subfluorinated carbonaceous materials obtained through direct fluorination of graphite or coke particles are provided. One set of subfluorinated carbonaceous materials has an average chemical composition CFx in which 0.63<x≦0.95, 0.66<x≦0.95 or 0.7<x≦0.95. The subfluorinated carbonaceous materials are capable of electrochemical performance superior to commercial CF at relatively high rates of discharge.

Owner:CALIFORNIA INST OF TECH +2

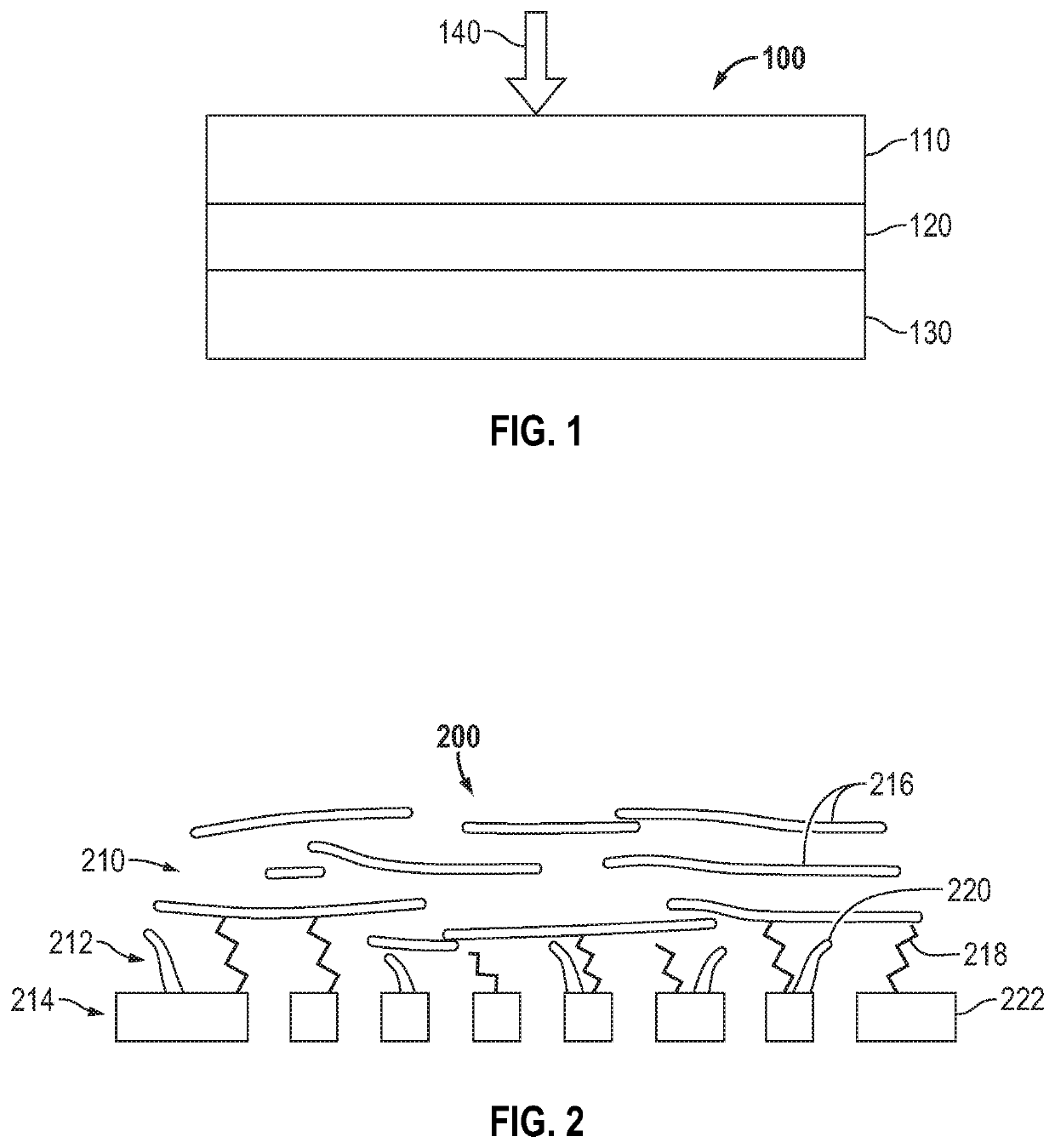

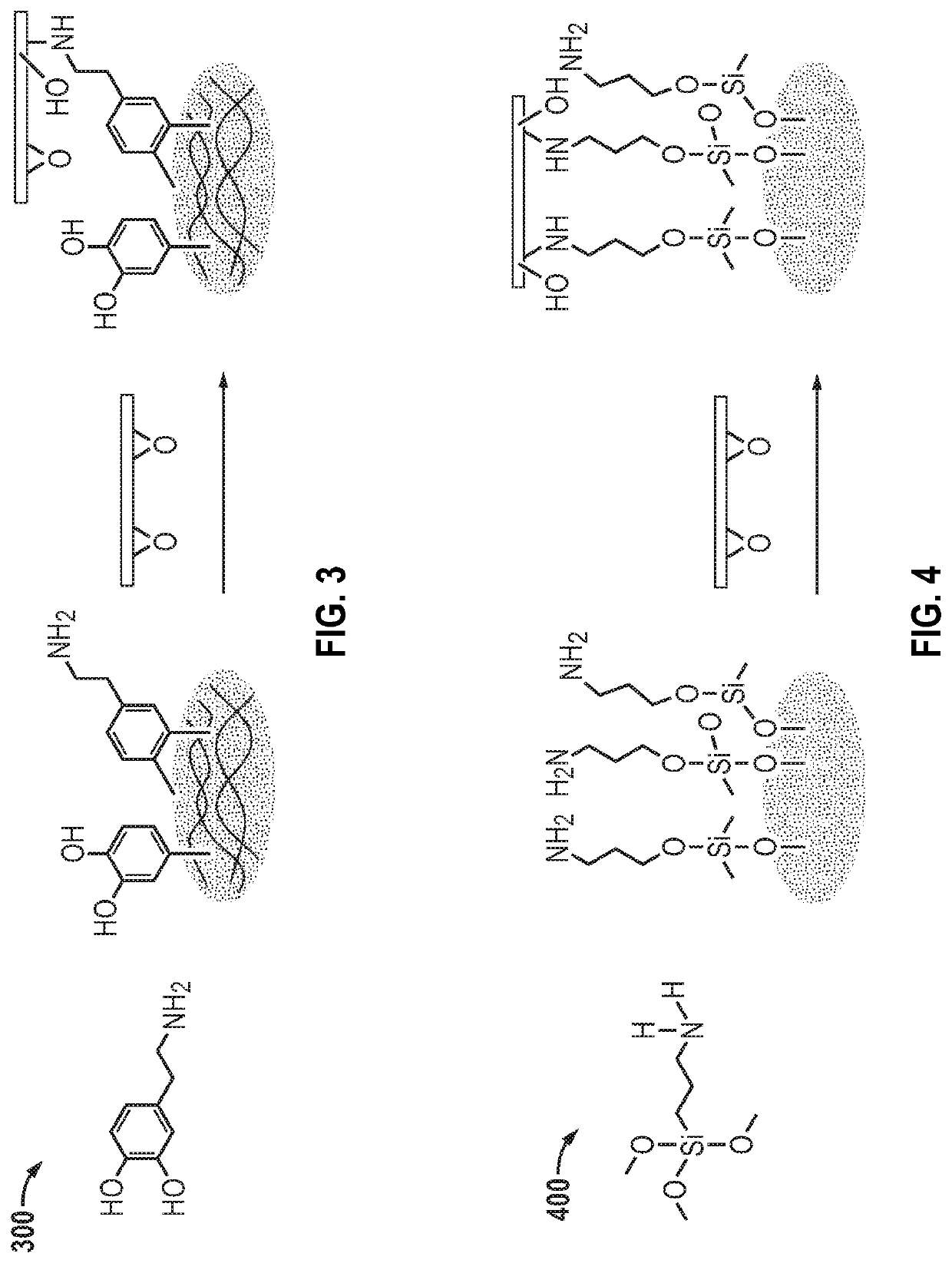

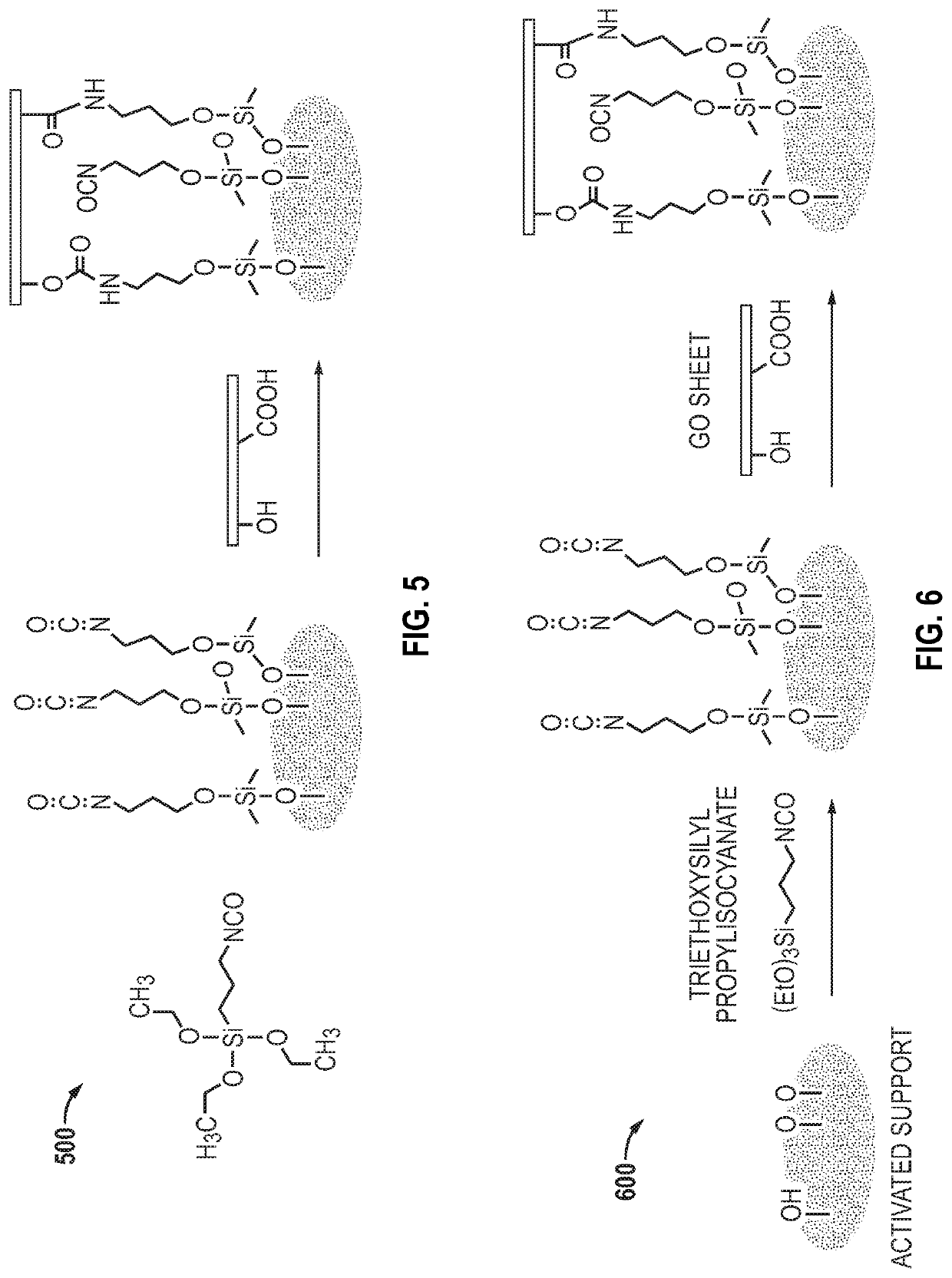

Filtration membranes

A membrane assembly is provided. The membrane assembly includes a non-metallic, porous substrate. A graphene oxide membrane is formed over the non-metallic, porous substrate. A chemical linker interface covalently binds the graphene oxide membrane to the non-metallic, porous substrate.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Macroscopic-quantity preparation method of fluorinated graphene

The invention provides a macroscopic-quantity preparation method of fluorinated grapheme. According to the preparation method, with cheap fluorinated graphite as a raw material, after treatment by a cationic surfactant and an organic intercalator and ultrasonic stripping, single-layer or few-layer fluorinated grapheme can be obtained. According to the preparation method, a technology is simple, the reaction is mild, control is easy, the raw material is cheap and easy to obtain, and the yield is high; the preparation method is applicable to large-scale macroscopic-quantity industrial production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

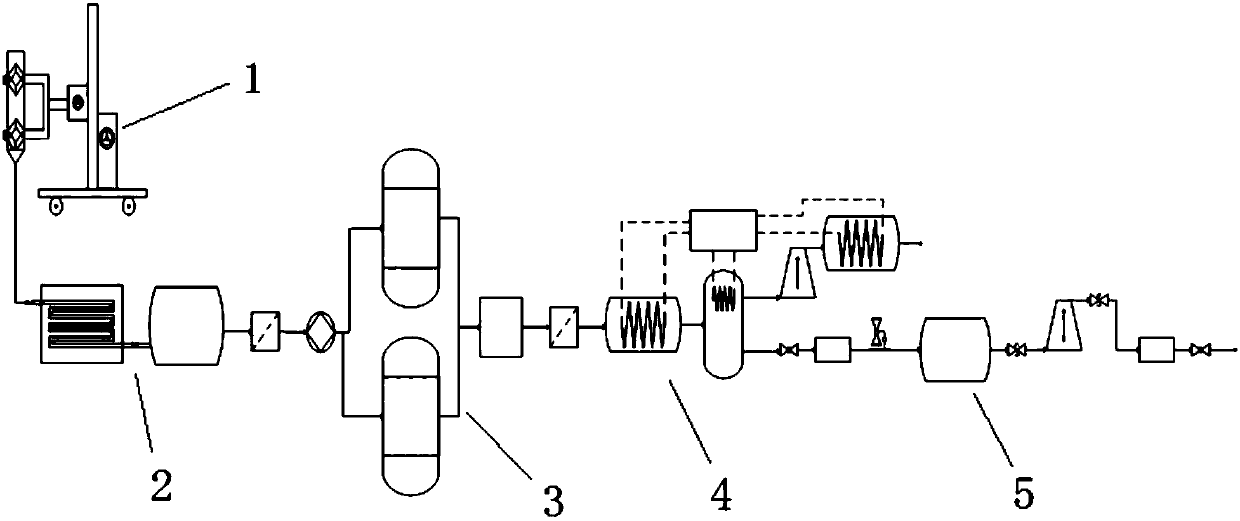

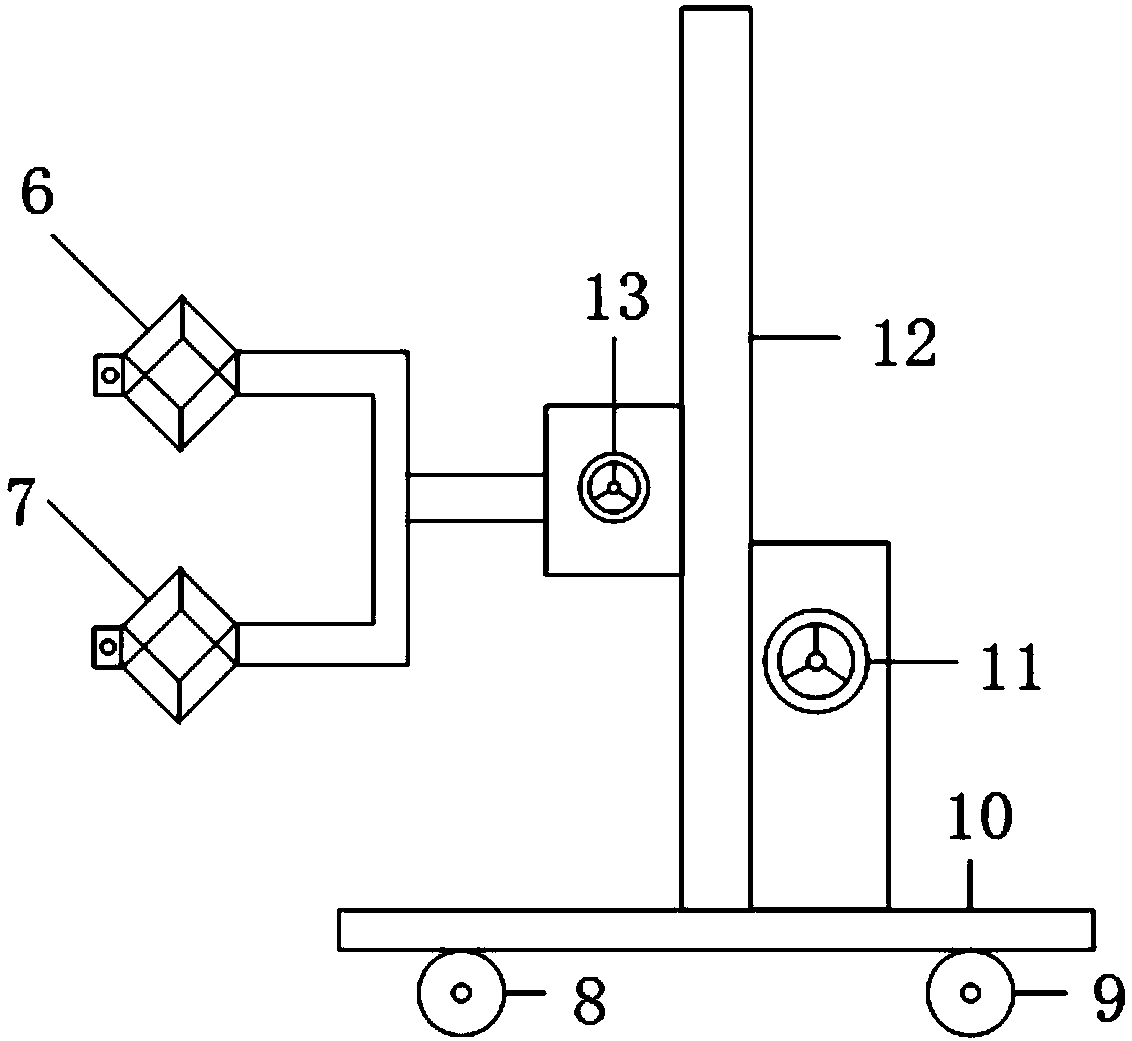

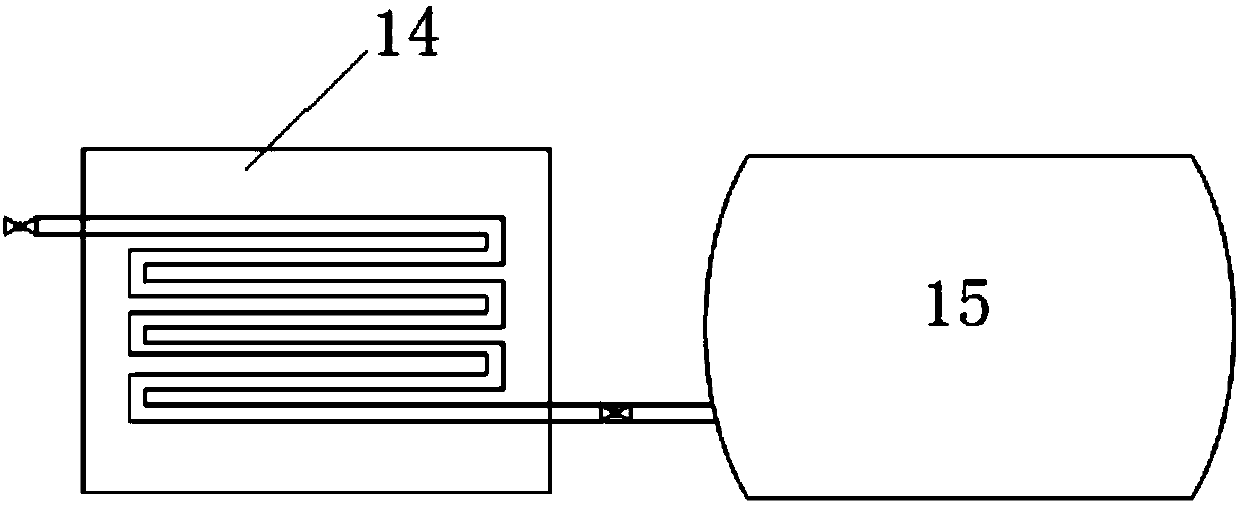

Separation system and separation method for sulfur hexafluoride and carbon tetrafluoride

PendingCN107715493ASolve the problem of no flowFacilitate the process of primary purification by adsorption treatmentProductsGas treatmentSulfur hexafluorideProcess engineering

The invention discloses a separation system and a separation method for sulfur hexafluoride and carbon tetrafluoride. The separation system comprises a reversing unit, a buffering unit, a treatment unit and a cryogenic separation unit, wherein the reversing unit is a reversing device, and is used for clamping a steel bottle and rotating the steel bottle to reverse the steel bottle such that a liquefied mixture in the steel bottle can flow out successfully; the buffering unit comprises an evaporator and a first buffering tank; an inlet of the evaporator is connected with an outlet of the steelbottle; an outlet of the evaporator is connected with an inlet of the first buffering tank; the treatment unit comprises an adsorption tower; an inlet of the adsorption tower is connected with an outlet of the first buffering tank to adsorb and remove impurities from the mixture; the cryogenic separation unit comprises a heat exchanger and a low temperature rectifying tower; an outlet of the adsorption tower is connected with a hot medium inlet of the heat exchanger; a cold medium outlet of the heat exchanger is connected with an inlet of the low temperature rectifying tower.

Owner:ELECTRIC POWER RES INST OF EAST INNER MONGOLIA ELECTRIC POWER +3

Method for preparing fluorocarbon material on large scale

PendingCN110395713AHigh voltageHigh Specific Power CharacteristicsNon-aqueous electrolyte cellsPositive electrodesHigh voltageRaw material

The invention discloses a method for preparing fluorocarbon material on a large scale, belongs to the technical field of fluorocarbon. The method comprises that following steps: S1, preparing nano carbon material, putting carbohydrate as raw material into a tube furnace, introducing an inert gas, and heating the carbohydrate to 400-700 DEG C under the protection of an inert gas atmosphere; performing heat preservation for 1-2 h, then quenching to room temperature to obtain the nano carbon material with defective structure; S2: fluorinating the nano carbon material with defective structure prepared in the step S1, putting the nano carbon material with defective structure prepared in the step S1 into a fluorination device, introducing a fluorine-containing gas, contacting the fluorine-containing gas with the nano carbon material with defective structure prepared in the step S1, maintaining the pressure of 100-200 KPa, and reacting for 11-13 hours at 300-600 DEG C, stoping heating, and S3, cooling down to obtain material. The large-scale preparation method of the fluorocarbon material of the present invention can prepare the fluorocarbon material with high voltage and high specific power characteristics and improve the power performance of the lithium battery.

Owner:厦门弗能科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com