Method for preparing carbon monofluoride or fluorocarbon through inner circulation of fluorine

A technology of fluorinated graphite or carbon fluoride, which is applied in the direction of fluorinated carbon, can solve the problems of low fluorocarbon ratio, poor safety, and poor quality, and achieve the effects of lower temperature, higher safety, and lower pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

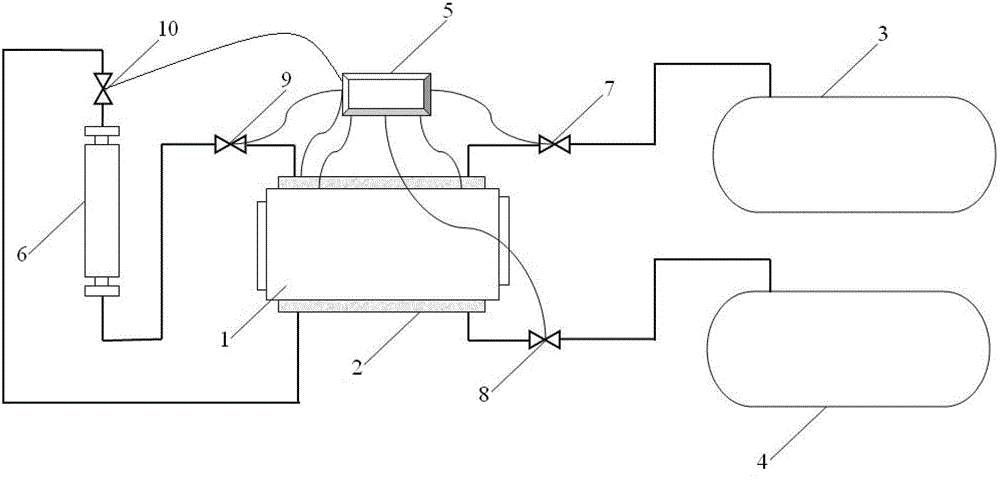

Method used

Image

Examples

Embodiment 1

[0036] Dry the graphite powder at 110°C for 24 hours and put it into the reaction kettle, feed high-purity nitrogen and high-purity fluorine gas to make the concentration of fluorine gas 50%, keep the reaction temperature at 400°C, and the reaction pressure at 0.05MPa. Lasts 30 hours. The fluorocarbon ratio of the product is 0.61, and the yield is 94%.

Embodiment 2

[0038] Dry 5 kg of graphene at 110°C for 36 hours and put it into the reactor, feed high-purity nitrogen and high-purity fluorine gas to make the concentration of fluorine gas 60%, keep the reaction temperature at 450°C, and the reaction pressure at 0.05MPa , the reaction lasted for 40 hours. The fluorocarbon ratio of the product was 0.72, and 5.1 kg of fluorinated graphite was obtained.

Embodiment 3

[0040] Dry the graphite powder at 110°C for 40 hours and put it into the reaction kettle, feed high-purity nitrogen and high-purity fluorine gas to make the concentration of fluorine gas 80%, keep the reaction temperature at 450°C, and the reaction pressure at 0.05MPa. Lasts 40 hours. The fluorocarbon ratio of the product is 0.8, and the yield is 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com