Hard carbon composite material, and preparation method and application thereof

A composite material and hard carbon technology, applied in the preparation/purification of carbon, fluorinated carbon, negative electrode, etc., can solve the problems of difficult formation of protective film on the surface of hard carbon, unfavorable battery cycle, high initial irreversible capacity, etc., to achieve cycle Optimizing the balance of life, realizing the effect of capacity and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

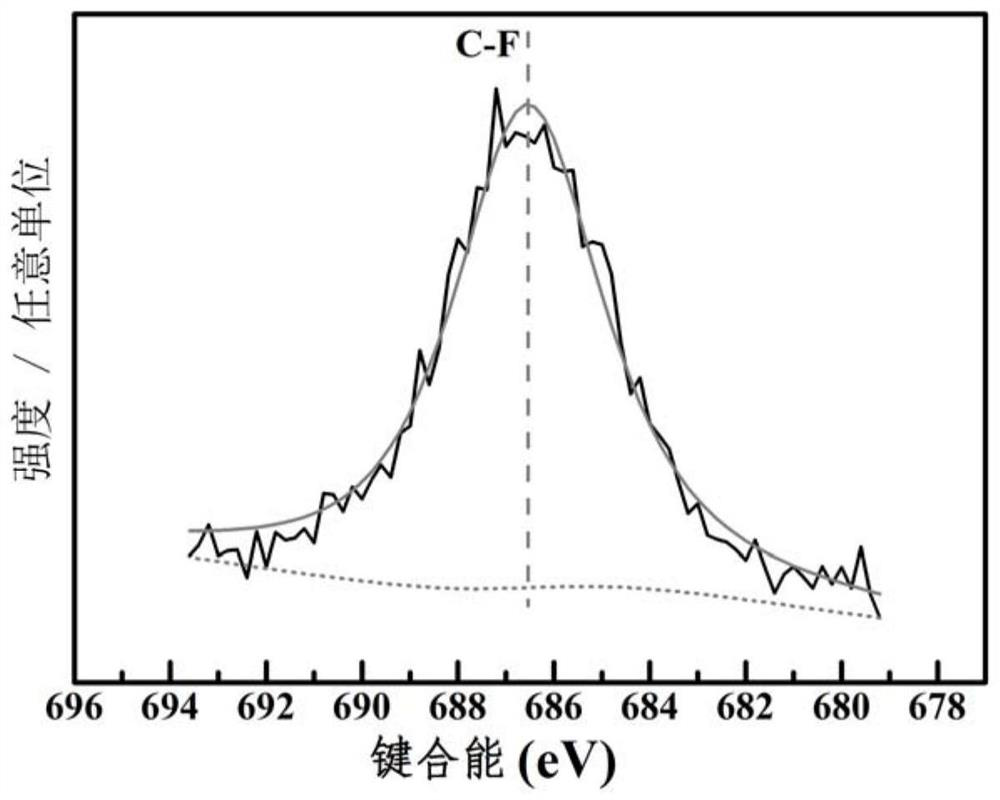

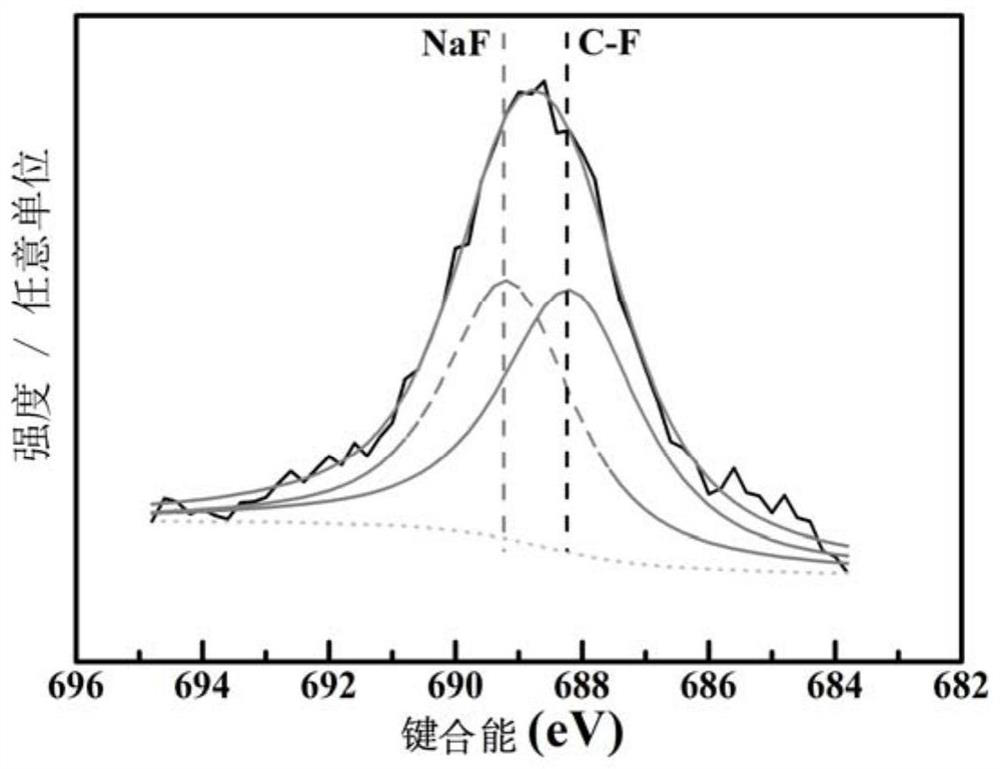

[0038] 1g of commercial hard carbon was heat-treated at 1400°C for 3 hours in an argon atmosphere; the heat-treated hard carbon and 2 grams of polyvinylidene fluoride were separately placed in two magnetic boats, and then the magnetic boat was placed in a heat treatment furnace, and then placed in a In an argon atmosphere, heat treatment was performed at 400° C. for 3 hours to obtain a hard carbon composite material. The product is analyzed by XPS, and the surface contains carbon fluoride, see figure 1 .

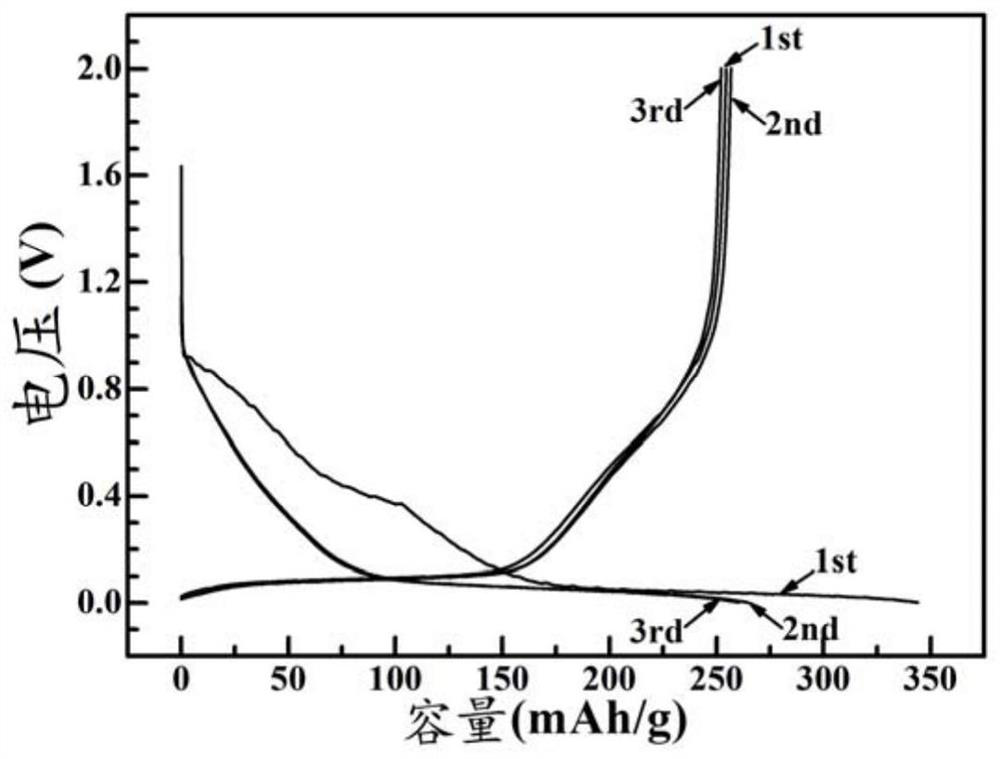

[0039] The hard carbon composite material prepared in this embodiment is used as the working electrode, the metal sodium is used as the counter electrode, the glass fiber membrane is used as the separator, and NaPF 6 The propylene carbonate (PC) / ethyl methyl carbonate (EMC) solution is used as the electrolyte, and the charge and discharge test is carried out. The charge and discharge curve is as follows figure 2 shown. Constant current charge and discharge test (current ...

Embodiment 2

[0043] 1g of commercial hard carbon was heat-treated at 1200°C for 4 hours in an argon atmosphere; the heat-treated hard carbon and 1 gram of polytetrafluoroethylene were separately placed in two magnetic boats, and then the magnetic boat was placed in a heat treatment furnace, and then placed in a In an argon atmosphere, heat treatment was performed at 450° C. for 2 hours to obtain a hard carbon composite material.

Embodiment 3

[0045] 1g of commercial hard carbon was heat-treated at 1500°C for 2 hours in an argon atmosphere; the heat-treated hard carbon and 1 gram of polyperfluoroethylene propylene were placed in two magnetic boats, and then the magnetic boat was placed in a heat treatment furnace. Then, heat treatment was performed at 500° C. for 1 hour in an argon atmosphere to obtain a hard carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com