Halogen-free filling flame-retardant nylon 6 composite material and preparation method thereof

A technology of flame-retardant nylon and composite materials, applied in the field of polymer flame-retardant materials preparation, can solve the problems of unpublished GWFI test and mechanical properties, non-environmentally friendly flame-retardant of flame-retardant filled nylon, unstable GWFI test, etc., and achieve excellent results Dimensional stability, enhanced flame retardancy, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

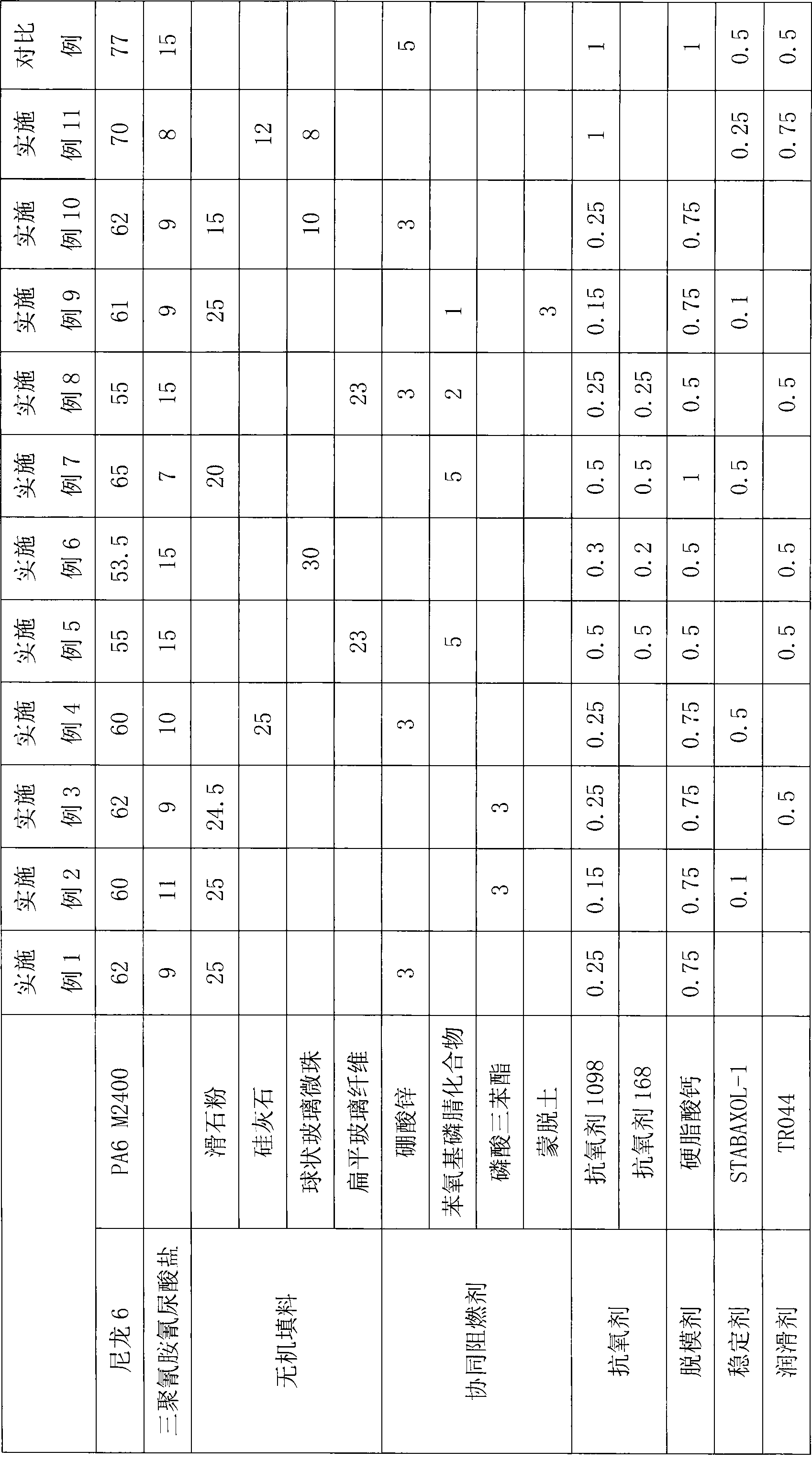

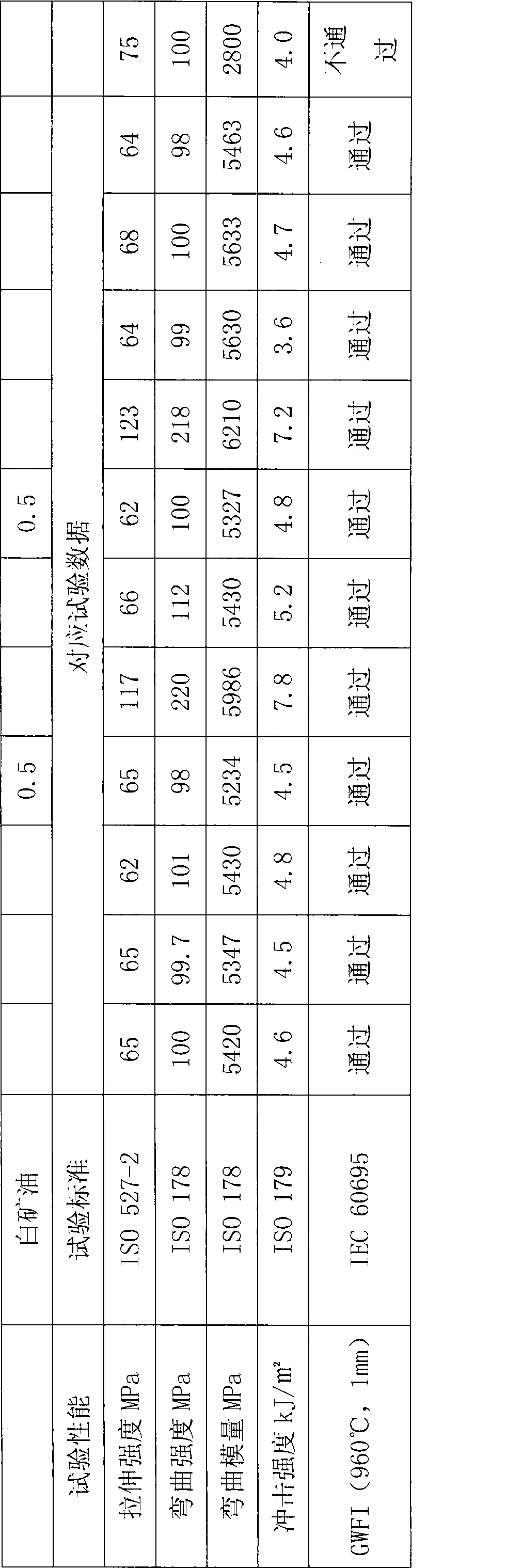

Embodiment 1-11

[0032] Among the raw materials used in Examples 1-11, nylon 6 is PA6M2400 (produced by Xinhui Meida); melamine cyanurate is a commercially available powder (produced by Sichuan Fine Chemical); Limestone is acicular silica lime with an aspect ratio of 15-20:1; the average diameter of spherical glass microspheres is about 15 μm; the size ratio of the main cross-sectional axis to the secondary cross-sectional axis of flat glass fibers is 2, and the length is 2 - 3 mm chopped fibers. The montmorillonite is sodium montmorillonite DK5 produced by Zhejiang Fenghong Clay Chemical; the zinc borate is ZB-2335 produced by Zibo Xubei Chemical; the phenoxy polyphosphazene is KP-735NA produced by Zibo Lanyin Chemical; Phenyl ester is produced by Changzhou Ke'an Chemical; the stabilizer is polycarbodiimide, which adopts STABAXOL-1 produced by German Rheinland Chemical; the antioxidant is N, N'-bis-(3-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionyl) hexamethylenediamine (Irganox 1098 of C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com