Carbon-based fiber sheet and lithium-sulfur battery including same

A carbon-based fiber and lithium-sulfur battery technology, applied in lithium batteries, batteries, fiber treatment, etc., can solve problems such as lithium metal negative electrode corrosion, achieve the effects of inhibiting diffusion, improving capacity and life characteristics, and preventing diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] The carbon-based fiber sheet prepared in the above preparation example was used to prepare a lithium-sulfur battery.

[0129] First, a positive electrode mixture composed of 80% by weight of sulfur / carbon composite, 10% by weight of carbon black as a conductive material, and 10% by weight of PVDF (binder) was added to the solvent NMP (N-methyl-2- Pyrrolidone) to prepare positive electrode slurry. The positive electrode slurry was coated on an aluminum current collector with a thickness of 20 μm and dried to prepare a positive electrode for a lithium-sulfur battery with a thickness of 150 μm.

[0130] A lithium foil with a thickness of about 150 μm was used as the negative electrode, and a polyethylene with a thickness of 20 μm was used as the separator.

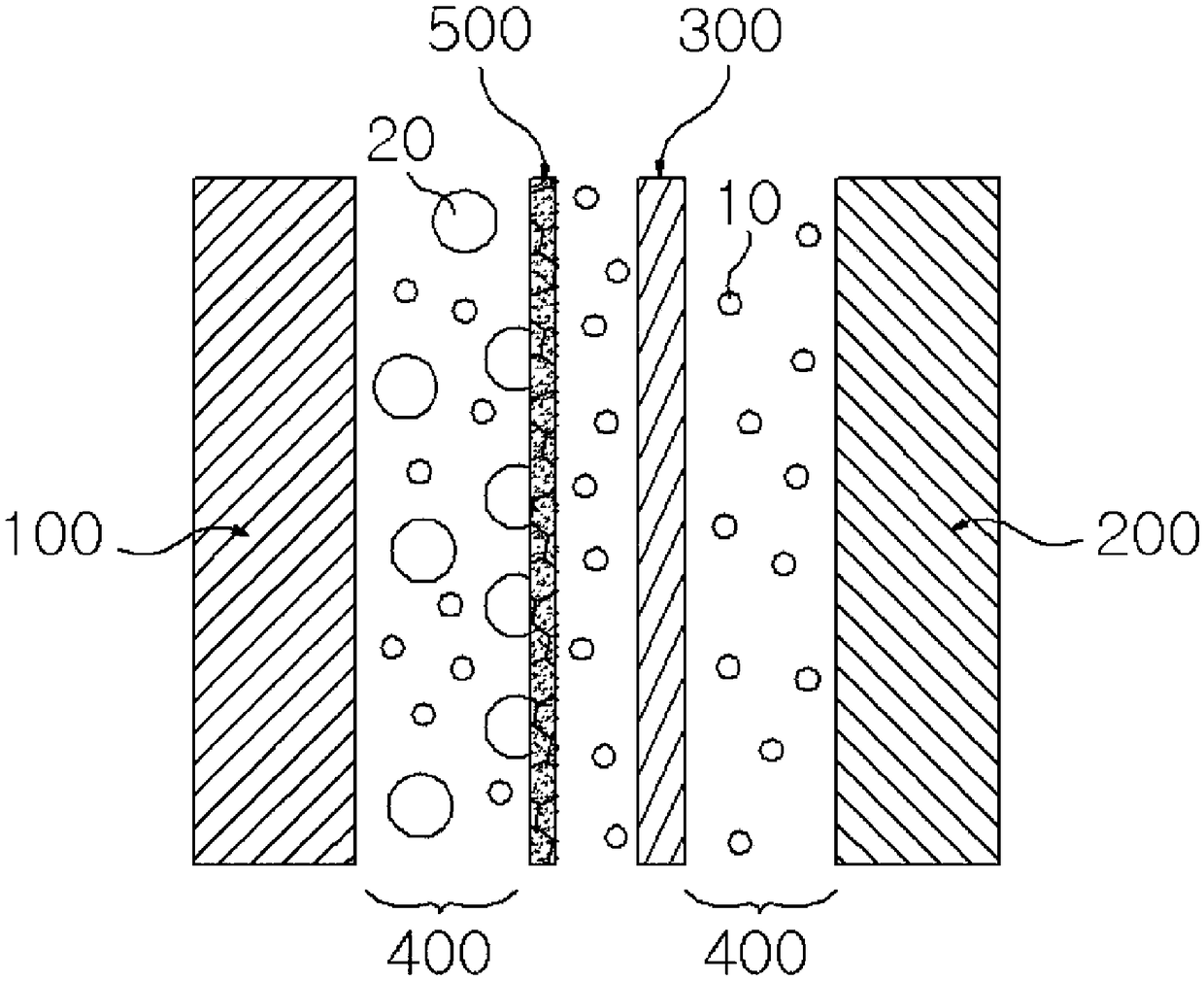

[0131] After stacking in the order of positive electrode, carbon-based fiber sheet, separator and negative electrode, inject dimethoxyethane, dioxolane and diglyme (volume ratio 14:65:21) as electrolyte Mixed solvent (1M Li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com