Preparation method and application of carbon fluoride material

A technology of fluorinated carbon and carbon materials, applied in the field of electrochemical energy storage of power supply technology, to achieve the effect of high specific power and high specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

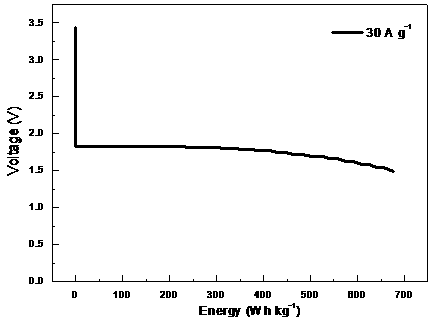

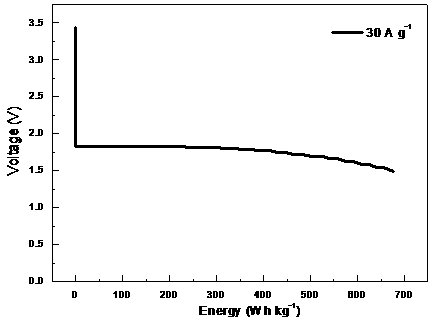

Image

Examples

Embodiment 1

[0022] A preparation method of carbon fluoride material, comprising the steps of:

[0023] Step 1: According to the mass ratio of soft carbon raw material non-graphitized mesocarbon microspheres and graphene materials as 98%: 2%, mix non-graphitized mesocarbon microspheres and graphene materials in methyl methacrylate , stirred evenly, and then sintered in a protective atmosphere at 900 °C for 12 hours to obtain a pretreated material.

[0024] Step 2: Grinding the pretreated product obtained in step 1 until the particle size reaches below 60 microns, passing through 200 mesh, 400 mesh, and 800 mesh sieve successively to obtain a powdery product.

[0025] Step 3: Put the powder material obtained in Step 2 into the fluorination equipment, pass in the fluorination gas NF3, keep the pressure at 120KPa, and react at 450°C for 12 hours to obtain a graphene carbon in the bulk phase with a fluorocarbon ratio of 0.8 Fluorinated carbon material.

[0026] The fluorinated carbon materia...

Embodiment 2

[0029] A preparation method of carbon fluoride material, comprising the steps of:

[0030] Step 1: According to the mass ratio of soft carbon raw material non-graphitized mesocarbon microspheres and graphene materials as 70%:30%, mix non-graphitized mesocarbon microspheres and graphene materials in methyl methacrylate , stirred evenly, and then sintered in a protective atmosphere at 300 °C for 24 hours to obtain a pretreated material.

[0031] Step 2: Grinding the pretreated product obtained in step 1 until the particle size reaches below 60 microns, passing through 200 mesh, 400 mesh, and 800 mesh sieve successively to obtain a powdery product.

[0032] Step 3: Put the powder material obtained in Step 2 into the fluorination equipment, pass in the fluorination gas NF3, keep the pressure at 90KPa, and react at 350°C for 24 hours to obtain a graphene carbon in the bulk phase with a fluorocarbon ratio of 0.7 Fluorinated carbon material.

[0033] The fluorinated carbon material...

Embodiment 3

[0035] A preparation method of carbon fluoride material, comprising the steps of:

[0036] Step 1: According to the mass ratio of soft carbon raw material non-graphitized mesocarbon microspheres and graphene materials as 85%:15%, mix non-graphitized mesocarbon microspheres and graphene materials in methyl methacrylate , stirred evenly, and then sintered in a protective atmosphere at 1500°C for 3 hours to obtain a pretreated material.

[0037] Step 2: Grinding the pretreated product obtained in step 1 until the particle size reaches below 60 microns, passing through 200 mesh, 400 mesh, and 800 mesh sieve successively to obtain a powdery product.

[0038] Step 3: Put the powder material obtained in Step 2 into the fluorination equipment, pass in the fluorination gas NF3, keep the pressure at 100KPa, and react at 400°C for 10 hours to obtain graphene carbon in the bulk phase with a fluorocarbon ratio of 0.75 Fluorinated carbon material.

[0039] The fluorinated carbon material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific power | aaaaa | aaaaa |

| Specific energy | aaaaa | aaaaa |

| Specific power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com