Fluorinated graphene material as well as preparation method and application thereof

A technology of fluorinated graphene and fossils, applied in the direction of graphene, chemical instruments and methods, carbon fluoride, etc., can solve the problems of small size, high price, thick slices, etc., and achieve low energy consumption, small pollution, and process The effect of low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

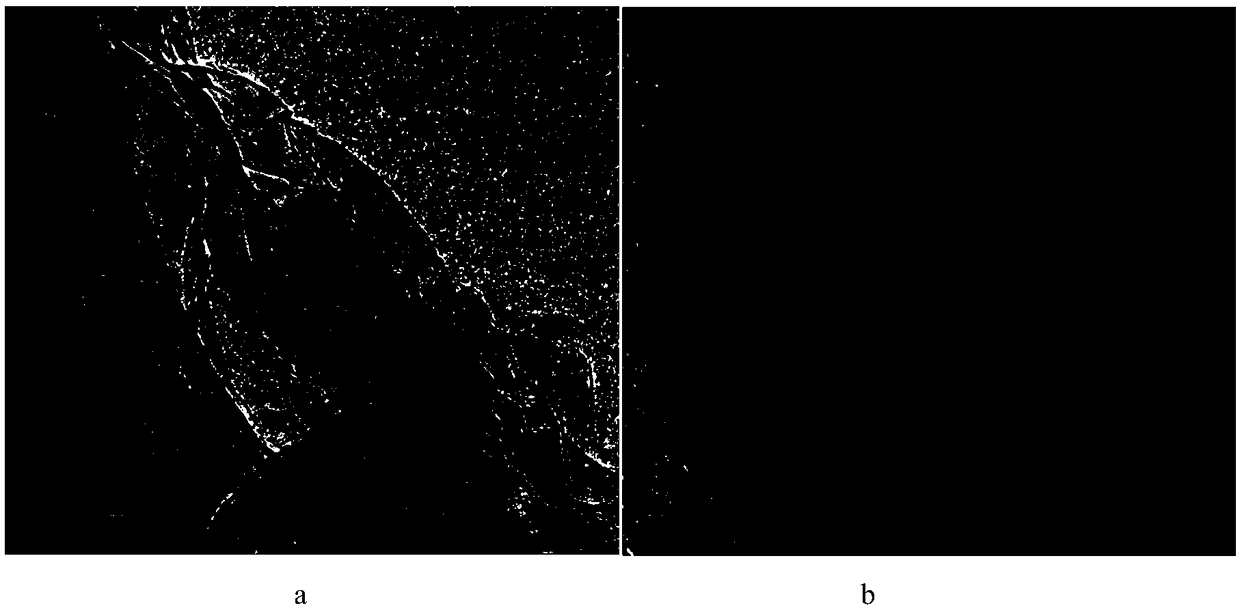

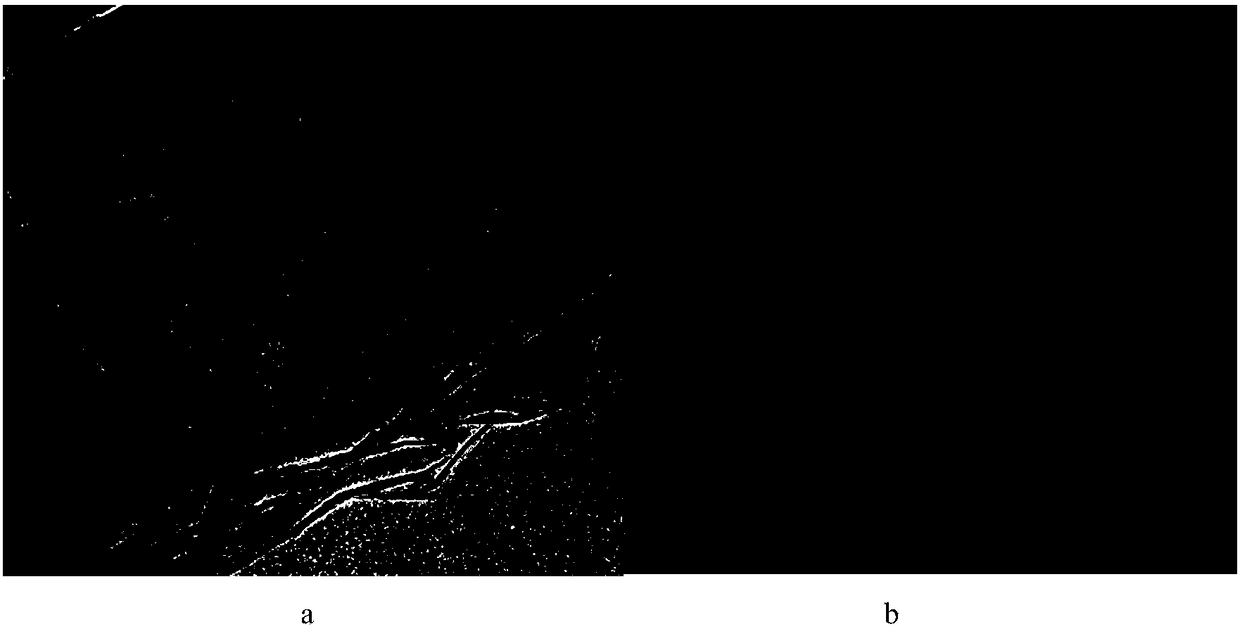

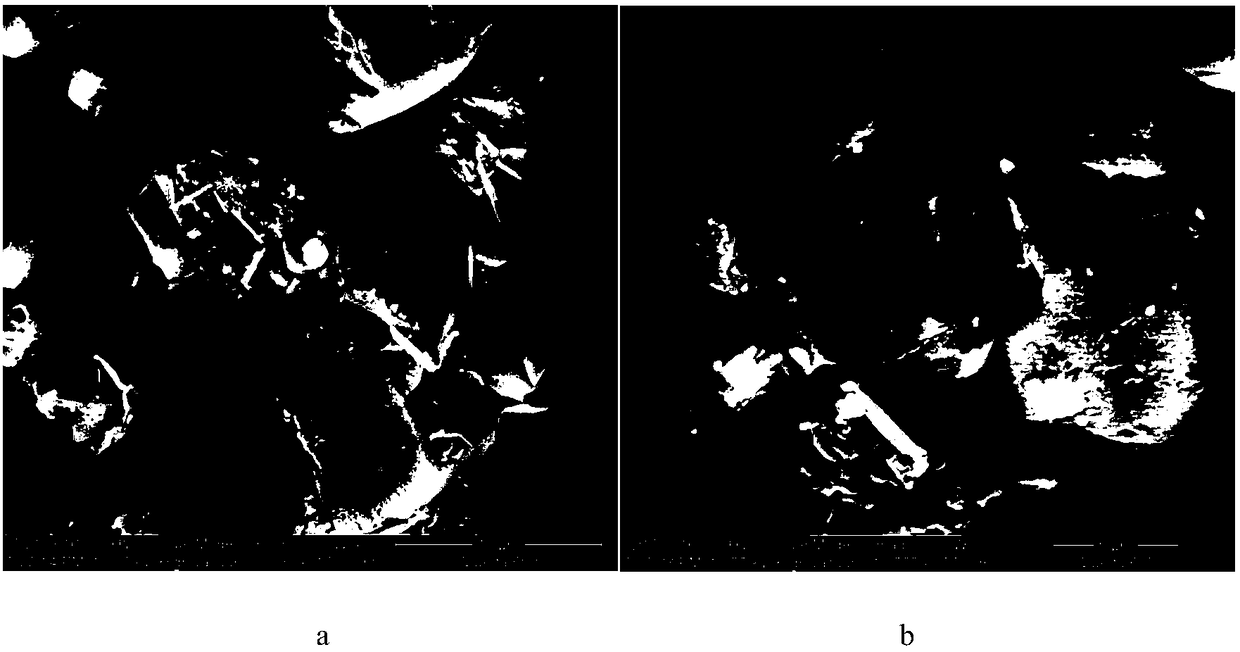

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a kind of preparation method of fluorinated graphene material, comprises the following steps:

[0032] Step 1. Mix the graphene oxide solution with HF acid, and carry out reflux and stirring reaction at 20°C-80°C to obtain a mixed system;

[0033] Wherein, the graphene oxide solution may be a commercial graphene oxide solution or a graphene oxide solution prepared from commercial highly active graphene powder, which is not limited in the present invention; the preferred oxygen content of the graphene oxide is 30wt% -60wt%;

[0034] The concentration of the graphene oxide solution is preferably 0.5mg / mL-5mg / mL, the mass concentration of the HF acid is preferably 20%-40%, and the volume ratio of the graphene oxide solution to the HF acid is preferably 1:0.0125-0.25 ; At this time, the proportion of raw materials used is in line with atomic economy, and the fluorinated graphene product sheet is relatively thin.

[0035] Fo...

Embodiment 1

[0048] Step 1: Add 30mL of graphene oxide (oxygen content 40%) aqueous solution with a concentration of 2mg / mL to 1.5mL of HF acid with a concentration of 30wt%. The reaction was carried out for 24 hours to obtain a mixed system. During the reaction, magnetic stirring was performed, and the rotational speed of the magnet was 300 r / min.

[0049] Step 2: Transfer the mixed system obtained from the reaction to a 50mL reactor, raise the temperature to 120°C at a rate of 3°C / min, and maintain it for 8h. After the reaction is completed, cool naturally to room temperature to obtain a suspension.

[0050] Step 3: Use a Buchner funnel to suction-filter the suspension obtained in step 2. After the suction filtration, add water to the filter residue to wash and suction-filter again until the pH value of the cleaned filtrate is neutral. The filter cake was dispersed with a small amount of water, transferred to a watch glass, and placed in a freeze dryer for freeze-drying for 30 hours. Th...

Embodiment 2

[0053] Step 1: Add 60mL of graphene oxide aqueous solution (oxygen content 60%) with a concentration of 2mg / mL to 3mL of HF acid with a concentration of 40wt%. After reacting for 24 hours, a mixed system was obtained. During the reaction, magnetic stirring was performed, and the rotational speed of the magnet was 500 r / min.

[0054] Step 2: Transfer the mixed system obtained from the reaction to a 100mL reactor, raise the temperature to 120°C at a rate of 3°C / min, and maintain it for 8h. After the reaction is completed, naturally cool to room temperature to obtain a suspension.

[0055] Step 3: Put the suspension obtained in step 2 into a centrifuge for centrifugation, remove the supernatant, continue to add deionized water to wash the precipitate and centrifuge, repeat several times until the pH value of the supernatant is neutral, and the lower precipitate is transferred Put it into a beaker and put it into a vacuum oven at 80°C to dry it for 24h. The obtained sample was a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Content | aaaaa | aaaaa |

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com