High-fluoride-content graphite fluoride and preparation method thereof

A technology of fluorinated graphene and graphene, applied in the direction of graphene, fluorinated carbon, nano-carbon, etc., can solve the problems of fluorinated graphene with high fluorine content, low thermal stability, cumbersome process, etc., and achieve Increased fluorination degree, improved thermal stability, and easy diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

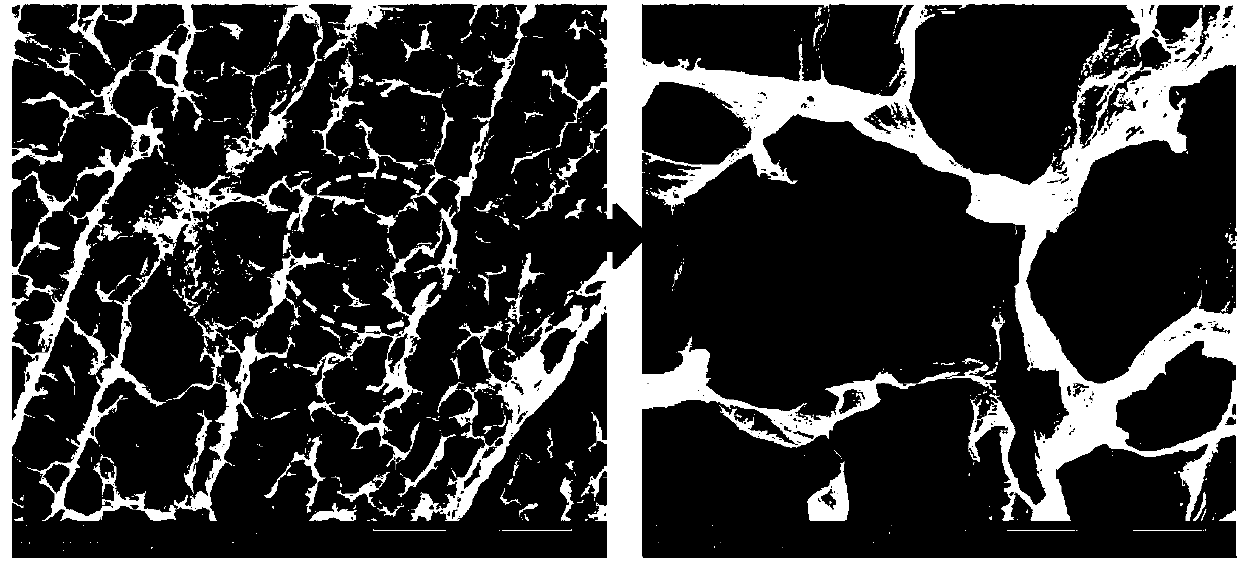

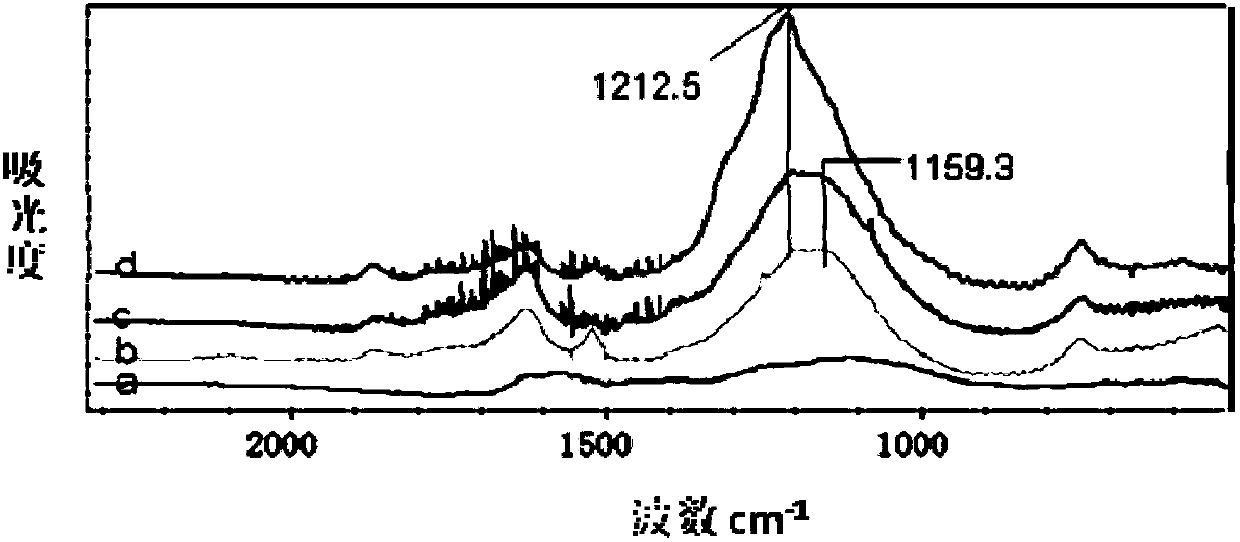

[0036] Freeze the prepared graphene oxide aqueous dispersion in liquid nitrogen for 100s and then dry it with a freeze dryer to a water content of 1% to obtain honeycomb graphene oxide; place the graphene oxide in a closed vacuum reactor , replace the air in the reactor with nitrogen three times, then vacuumize, then fill with fluorine and nitrogen, and control the initial partial pressure of fluorine in the reactor to 3 KPa, and then raise the temperature to 200°C at a heating rate of 1°C / min And keep warm for 30 minutes, wait for the reactor to cool down to room temperature naturally, take out the fluorinated graphene.

[0037] It is measured that the massfraction of fluorine element in this graphene is 56%, and the massfraction of carbon element is 44%.

Embodiment 2

[0039] The prepared aqueous dispersion of graphene oxide was frozen in liquid nitrogen for 300s and then dried to a water content of 1% with a lyophilizer to obtain honeycomb graphene oxide; the graphene oxide was placed in a closed vacuum reactor , replace the air in the reactor with nitrogen three times, then vacuumize, then fill with fluorine and nitrogen, and control the initial partial pressure of fluorine in the reactor to 30 KPa, and then raise the temperature to 250°C at a heating rate of 5°C / min And keep warm for 10 minutes, wait for the reactor to cool down to room temperature naturally, take out the fluorinated graphene.

[0040] It is measured that the mass fraction of fluorine element in this graphene is 55%, and the mass fraction of carbon element is 45%.

Embodiment 3

[0042] The prepared graphene oxide aqueous dispersion was frozen in liquid nitrogen for 200s and then dried to a water content of 2% with a lyophilizer to obtain honeycomb graphene oxide; the graphene oxide was placed in a closed vacuum reactor , replace the air in the reactor with nitrogen for three times, then evacuate, then fill with fluorine, nitrogen and argon, and control the initial partial pressure of fluorine in the reactor to 50 KPa, then raise the temperature at a rate of 5 °C / min to 200°C and keep it warm for 120 minutes. After the reactor is naturally cooled to room temperature, the fluorinated graphene is taken out.

[0043] It is measured that the mass fraction of fluorine in the graphene is 64%, and the mass fraction of carbon is 36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com