Preparation method of fluorinated graphene material with adjustable fluorine content

A technology of fluorinated graphene and fluorinated graphite, applied in graphene, chemical instruments and methods, carbon fluoride, etc., can solve problems such as inability to achieve large-scale preparation and application limitations, and achieve low equipment requirements and wide application prospects. , the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention relates to a preparation method of fluorinated graphene material with adjustable fluorine content, characterized in that: the steps of the method are as follows:

[0029] (1) uniformly mixing the mixed metal salt and graphite fluoride, the mixing method can be grinding or ball milling;

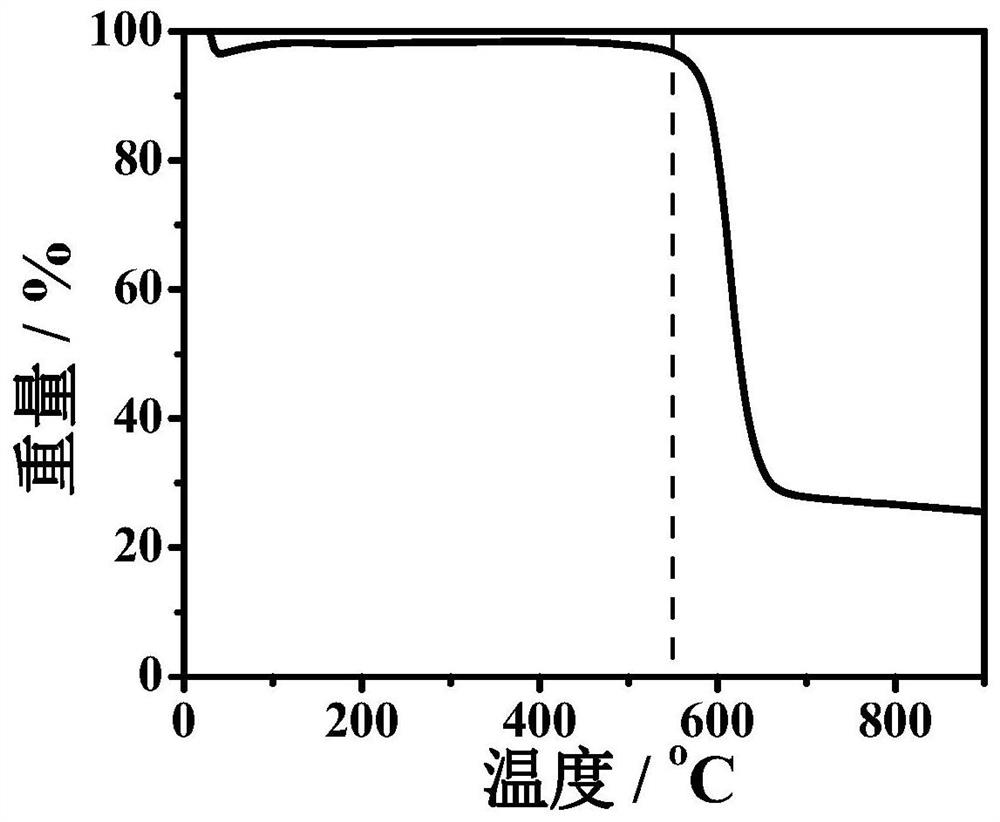

[0030] (2) The mixed product is placed in a tube furnace at 550° C. for a period of time;

[0031] (3) Ultrasonic stripping is performed on the reaction product in a mixed solution of an organic solvent and hydrogen fluoride, the upper layer solution is separated by centrifugation, washed by suction filtration, and vacuum-dried to obtain fluorinated graphene.

[0032] The mixed metal salt in step (1) is NaCl, CaCl 2 , LiCl, BaCl 2 and ZnCl 2 Two or three of the mixed metal salts have a melting point lower than 550°C. The mass ratio of the mixed metal salt to graphite fluoride is 4:1-1:1. In step (1), if the mixing method is grinding, the grinding time is 30-12...

Embodiment 1

[0040] Weigh 1.169g of sodium chloride, 2.415g of anhydrous calcium chloride (the molar ratio of the two is 1:1.088), and 1.792g of graphite fluoride, mix them together, and grind them with a mortar for 60 minutes. Put the ground solid into a tube furnace, heat up to 550°C at a rate of 10°C per minute, and heat for 2 hours.

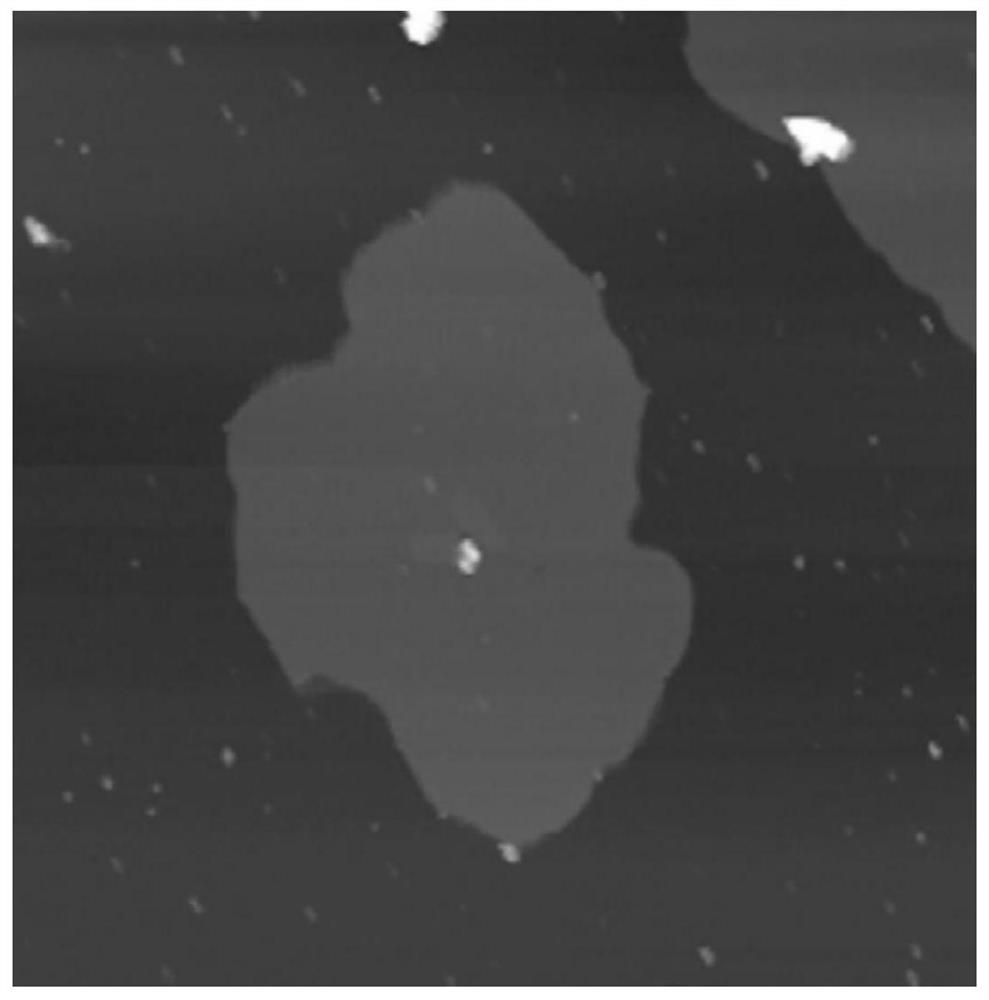

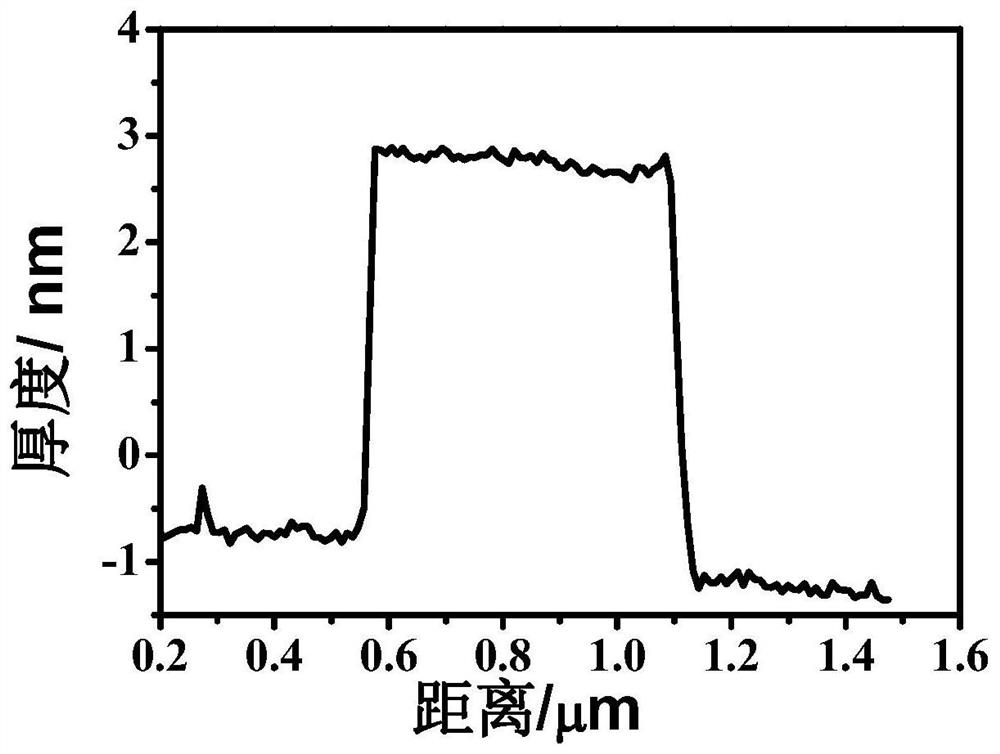

[0041] After the reaction, the solid was taken out, dispersed into 100 mL of N-methylpyrrolidone, added with 5 g of hydrogen fluoride solution, and ultrasonically stripped for 120 minutes. The resulting solution was centrifuged at 1000 rpm for 10 minutes, and the supernatant was collected. The supernatant was suction-filtered, washed three times with N-methylpyrrolidone, absolute ethanol, and water respectively, and the solid product was collected and vacuum-dried at 60°C for 12 hours to obtain 1.428 g of the final sample fluorinated graphene.

Embodiment 2

[0043] Weigh 1.272g of lithium chloride, 1.793g of anhydrous calcium chloride (the molar ratio of the two is 1.857:1), and 1.184g of fluorinated graphite, mix them together, and use an oil-sealed planetary ball mill to mill at 500rpm for 60 minutes. Put the ball-milled solid into a tube furnace, and raise the temperature to 550°C at a speed of 10°C per minute, and the heating time is 1, 2, 5, and 10 hours respectively.

[0044] After the reaction, the solid was taken out, dispersed into 100 mL of N-methylpyrrolidone, added with 10 g of hydrogen fluoride solution, and ultrasonically stripped for 180 minutes. The resulting solution was centrifuged at 1000 rpm for 10 minutes, and the supernatant was collected. Suction filter the supernatant, wash three times with N-methylpyrrolidone, absolute ethanol, and water respectively, collect the solid product, and dry it in vacuum at 70°C for 12 hours, and the heating time is 1, 2, 5, and 10 hours to obtain the final sample The masses of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com