Multilayer silicon nitride antireflection film of crystalline silicon solar cell and preparation method of multilayer silicon nitride antireflection film

A solar cell, silicon nitride reduction technology, applied in coatings, circuits, electrical components, etc., can solve the problems of low anti-reflection effect, poor passivation effect, etc., achieve low equipment requirements, reduce reflectivity, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

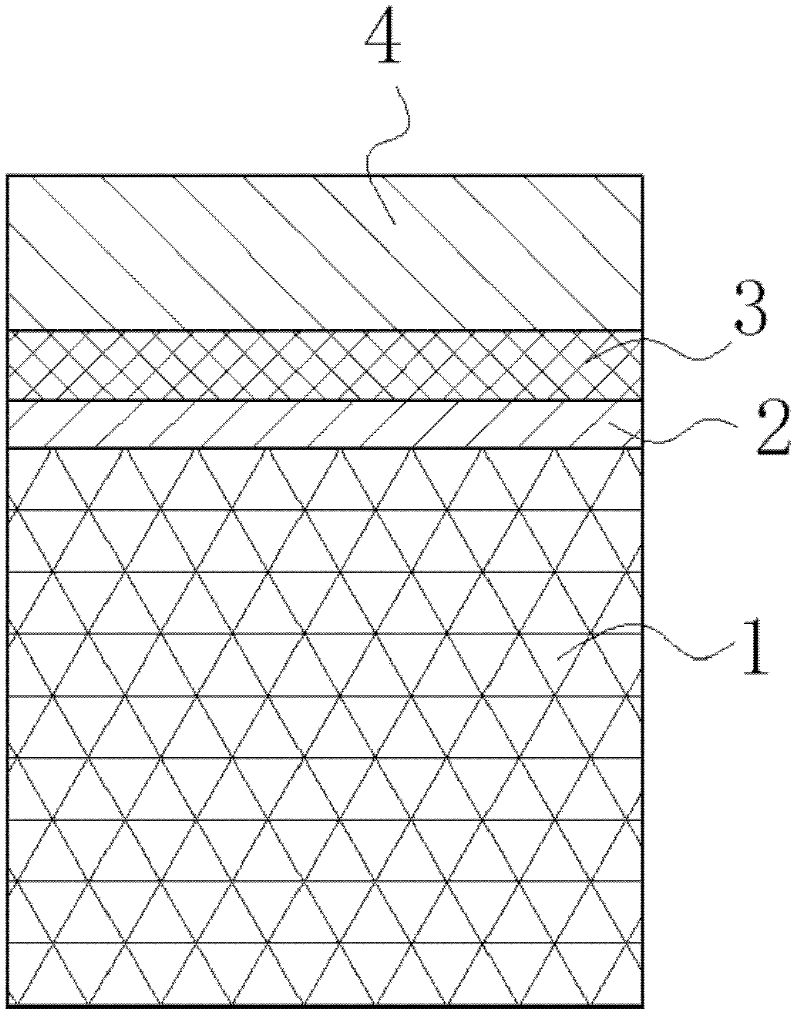

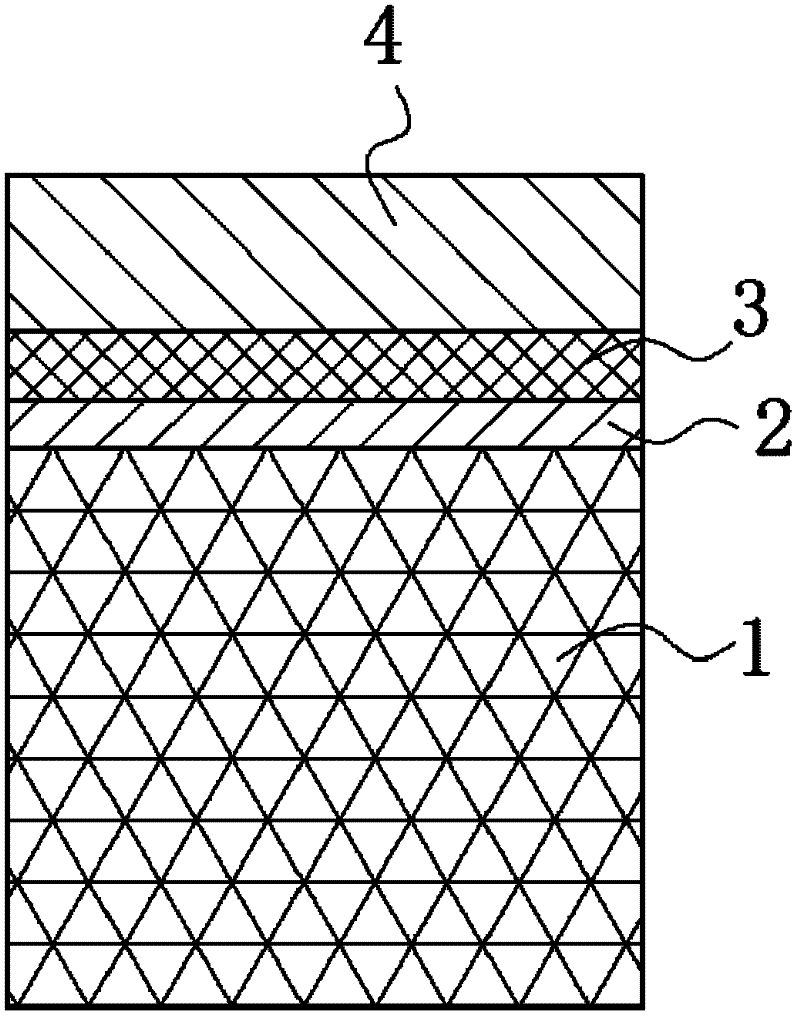

[0031] A kind of multilayer silicon nitride anti-reflection film for crystalline silicon solar cells, such as figure 1 As shown, a dense silicon nitride film 2 , an intermediate silicon nitride film 3 and a loose silicon nitride film 4 are sequentially deposited on the surface of a silicon wafer 1 . The dense layer silicon nitride film 2 has a refractive index of 2.15-2.35 and a thickness of 5-10 nm; the intermediate layer silicon nitride film 3 has a refractive index of 2.0-2.2 and a thickness of 20-30 nm; the loose layer The silicon nitride film 4 has a refractive index of 1.85-2.05 and a thickness of 40-60 nm.

[0032] In this example, if figure 1 As shown, the dense layer silicon nitride film 2 is the lowermost layer, the loose layer silicon nitride film 4 is the uppermost layer, the dense layer silicon nitride film 2, the middle layer silicon nitride film 3 and the loose layer The silicon nitride thin film 4 is constituted according to the law from bottom to top, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com