Hydrocracking catalyst for maximum production of low-solidifying point diesel oil and preparation method and application thereof

A technology of catalyst and diesel oil, which is applied in the field of hydrocracking catalyst for the largest production of low-point diesel oil and its preparation and application, and achieves the effects of low preparation cost, low freezing point, and strong isomerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

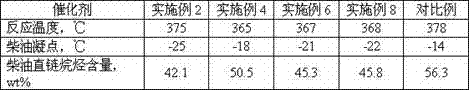

Examples

Embodiment 1

[0028] (1) Mix alumina powder, modified USY molecular sieve and modified β zeolite powder evenly, then add acid solution, fully roll and shape, then dry and roast to obtain the catalyst carrier;

[0029] (2) impregnating the catalyst carrier obtained in step (1) with an impregnating solution containing active metal components, then drying and calcining to obtain a hydrocracking catalyst. Catalyst properties are listed in Table 1.

[0030] Step (1) The preparation steps of the modified USY molecular sieve are as follows: the silica / alumina molar ratio is 20, the specific surface area is 760m 2 / g of hydrogen-type USY molecular sieve was added to 0.55mol / L tetraethylammonium hydroxide solution, the mass ratio of the amount of USY molecular sieve added to the solution was 1:10, and then treated at 70°C for 1.5 hours, and finally Wash until the pH value is less than 10 to obtain the modified USY molecular sieve. The modified USY molecular sieve has the following properties after...

Embodiment 2

[0033] (1) Mix alumina powder, modified USY molecular sieve and modified β zeolite powder evenly, then add acid solution, fully roll and shape, then dry and roast to obtain the catalyst carrier;

[0034] (2) impregnating the catalyst carrier obtained in step (1) with an impregnating solution containing active metal components, then drying and calcining to obtain a hydrocracking catalyst. Catalyst properties are listed in Table 1.

[0035] Step (1) The preparation steps of the modified USY molecular sieve are as follows: the silica / alumina molar ratio is 33, the specific surface area is 820m 2 / g of hydrogen-type USY molecular sieve is added to 0.60mol / L tetrapropyl ammonium hydroxide solution, the mass ratio of the amount of USY molecular sieve added to the solution is 1:15, and then treated at 80°C for 1.0 hour, and finally Wash until the pH value is less than 10 to obtain the modified USY molecular sieve. The modified USY molecular sieve has the following properties after ...

Embodiment 3

[0038] (1) Mix alumina powder, modified USY molecular sieve and modified β zeolite powder evenly, then add acid solution, fully roll and shape, then dry and roast to obtain the catalyst carrier;

[0039] (2) impregnating the catalyst carrier obtained in step (1) with an impregnating solution containing active metal components, then drying and calcining to obtain a hydrocracking catalyst. Catalyst properties are listed in Table 1.

[0040] Step (1) The preparation steps of the modified USY molecular sieve are as follows: the silica / alumina molar ratio is 16, the specific surface area is 735m 2 / g of hydrogen-type USY molecular sieve is added to the 0.23mol / L tetrabutylammonium hydroxide solution, the mass ratio of the amount of USY molecular sieve added to the solution is 1:16, then treated at 60°C for 2.0 hours, and finally washed to If the pH value is less than 10, the modified USY molecular sieve is obtained. The modified USY molecular sieve has the following properties af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com