Hydrophobic melt-blown fabric preparation method

A melt-blown fabric and hydrophobic technology, which is applied in the direction of melt spinning, non-woven fabrics, and clustering of newly extruded filaments. The effect of loft and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

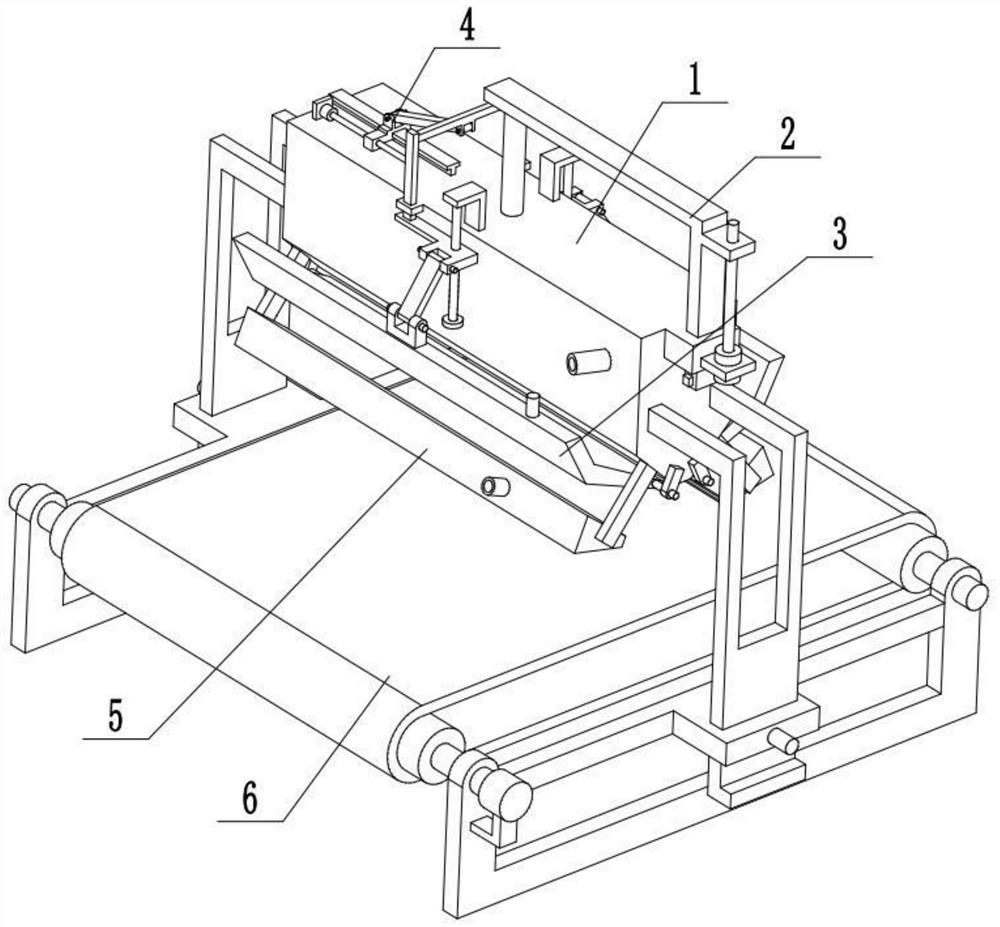

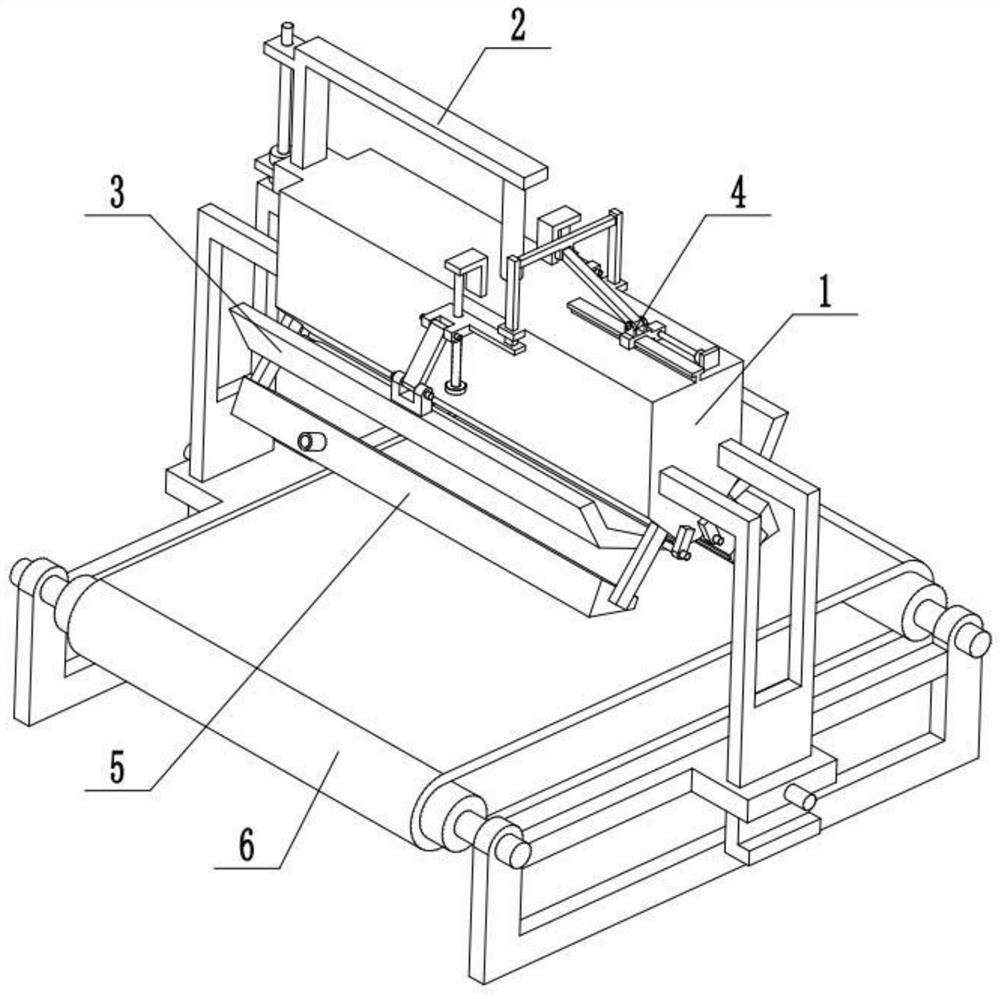

[0033] Combine below Figure 1-9 To illustrate this embodiment, a method for preparing a hydrophobic melt-blown cloth comprises the following steps:

[0034] Step 1, stock solution addition: add raw material solution, and the raw material solution is sprayed out;

[0035] Step 2, drafting: high-temperature airflow drafts the raw material solution to form ultrafine fibers;

[0036] Step 3. Cooling: the ejected ultrafine fibers are bonded under the action of self-bonding, and the cooling airflow makes the ejected ultrafine fibers form a melt-blown cloth;

[0037] Step 4, transportation: the melt blown cloth is transported to the next station;

[0038] Step 5. Adjust the angle: adjust the angle of the high-temperature airflow to obtain a melt-blown cloth with good fiber shape;

[0039] The method for preparing hydrophobic melt-blown cloth also relates to a preparation device for hydrophobic melt-blown cloth;

[0040]The hydrophobic melt-blown cloth preparation device includes...

specific Embodiment approach 2

[0042] Combine below Figure 1-9 To illustrate this embodiment, the meltblown die head assembly 1 includes a nozzle 1-1, a liquid inlet pipe 1-2 with a control valve, a side carriage 1-3, a sliding sleeve 1-4, a T-shaped bar 1- 5. The side fixing sleeve 1-6 and the injection port 1-7; the liquid inlet pipe 1-2 is fixedly connected to and communicated with the nozzle 1-1, and the two ends of the nozzle 1-1 are respectively fixedly connected to a side carriage 1-3 , the two side sliding frames 1-3 are all connected with the receiving device 6, the sliding sleeve 1-4 and the T-shaped bar 1-5 are fixedly connected to the front and rear ends of the liquid inlet pipe 1-2 respectively, and the two side fixing sleeves 1 -6 is symmetrically and fixedly connected to the left and right ends of the nozzle 1-1, and the extruding device 2 is connected with the nozzle 1-1 to cooperate with the high-temperature air flow generator assembly 3, which is symmetrically arranged at the lower end of...

specific Embodiment approach 3

[0044] Combine below Figure 1-9 To illustrate this embodiment, the extrusion discharge device 2 includes a first motor 2-1, a screw 2-2, an L-shaped frame 2-3, a telescopic rod 2-4 and an extrusion plate 2-5; the first motor 2-1 is fixed on the nozzle 1-1 through the motor frame, the output shaft of the first motor 2-1 is connected to the screw rod 2-2 through a coupling, and the front end of the L-shaped frame 2-3 is connected to the screw rod 2-2 through thread fit. 2, the two ends of the telescopic rod 2-4 are respectively fixedly connected to the L-shaped frame 2-3 and the extruding plate 2-5, and the telescopic rod 2-4 is sealed and slidably connected to the upper end of the nozzle 1-1, and the extruding plate 2- 5 is connected by sliding fit inside the nozzle 1-1, and the liquid inlet pipe 1-2 is located at the lower end of the extruding plate 2-5. The first motor 2-1 starts to drive the extrusion plate 2-5 to move downward through the screw rod 2-2, L-shaped frame 2-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com