Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

478results about How to "Improve bulk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

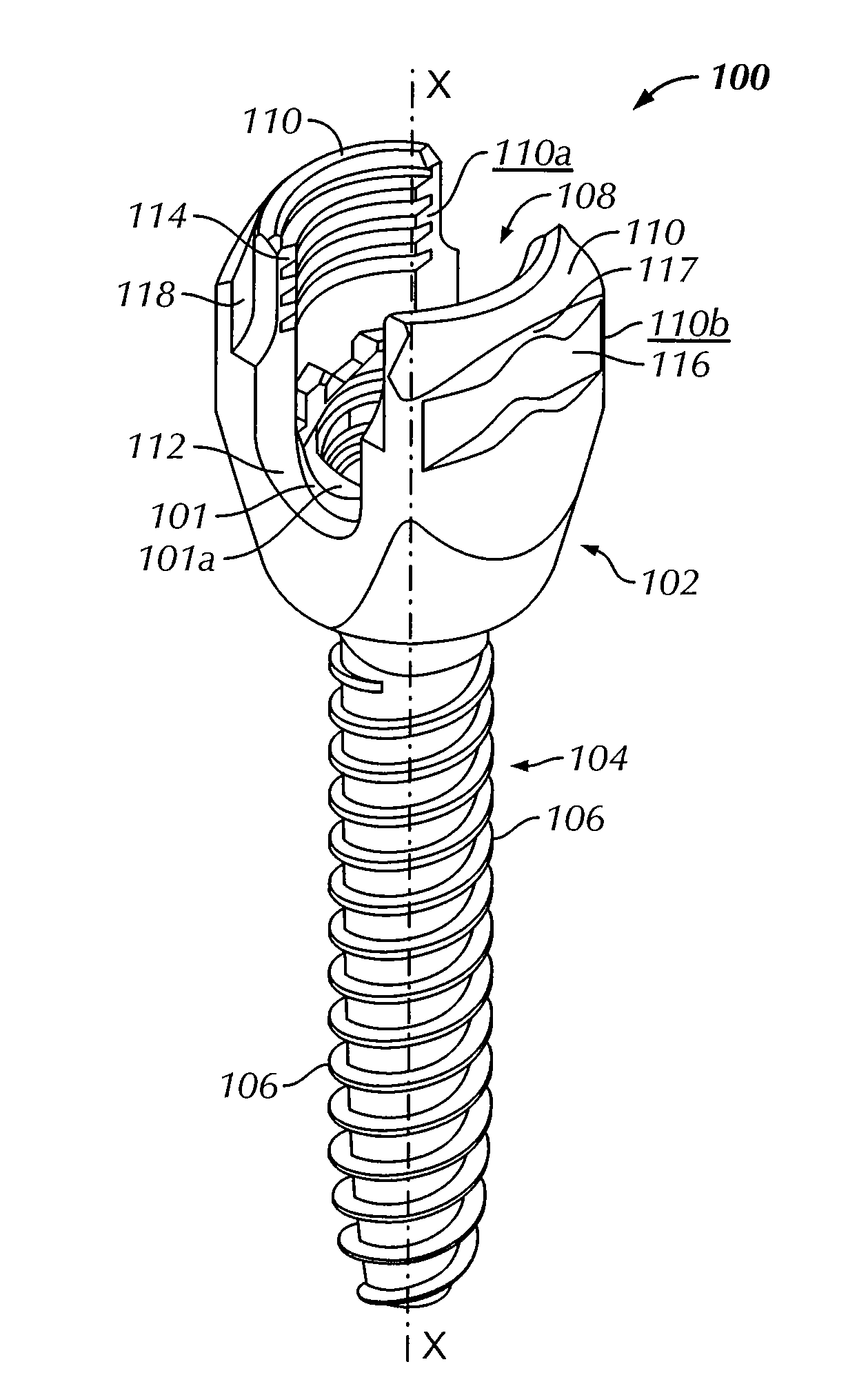

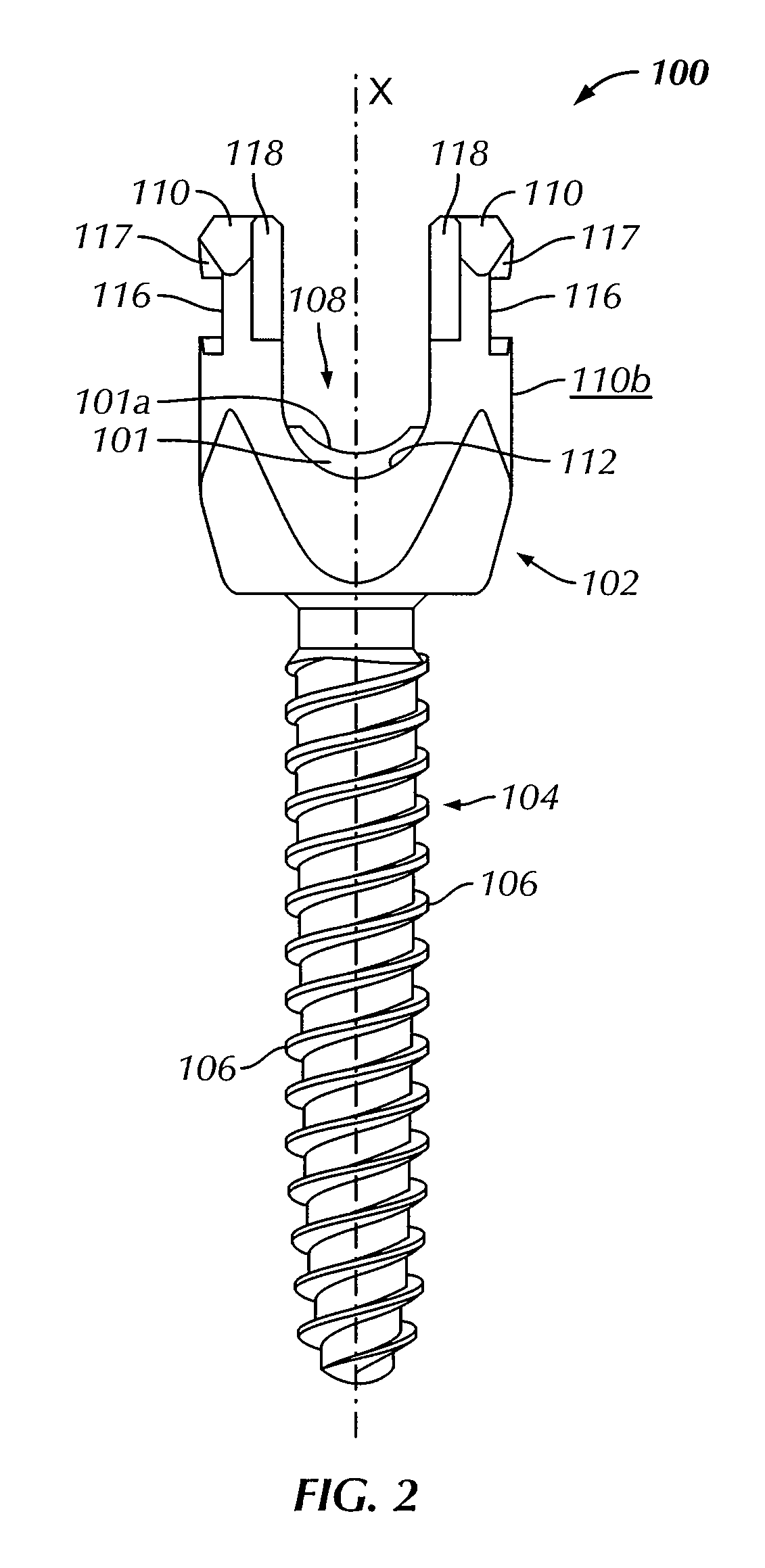

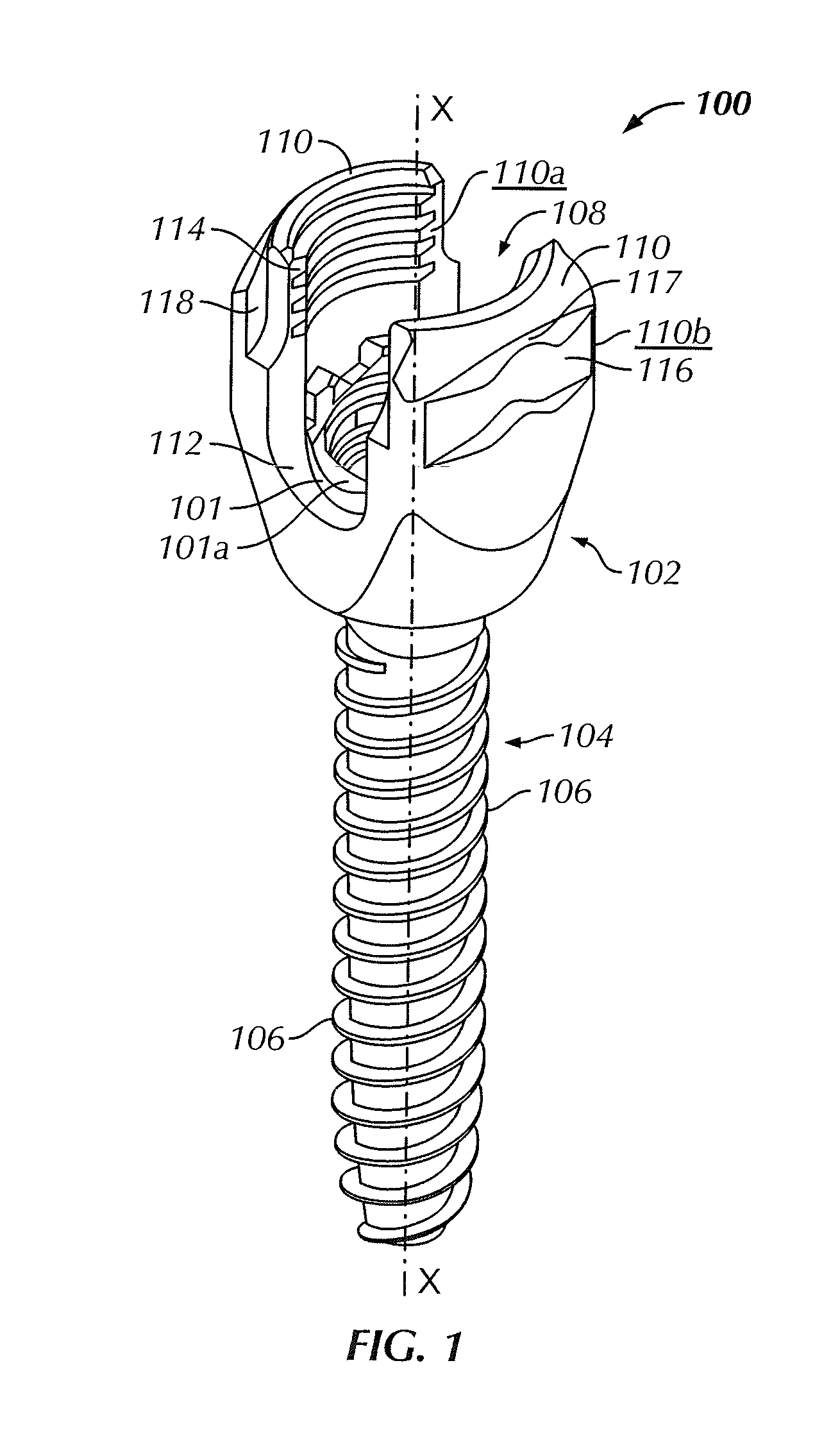

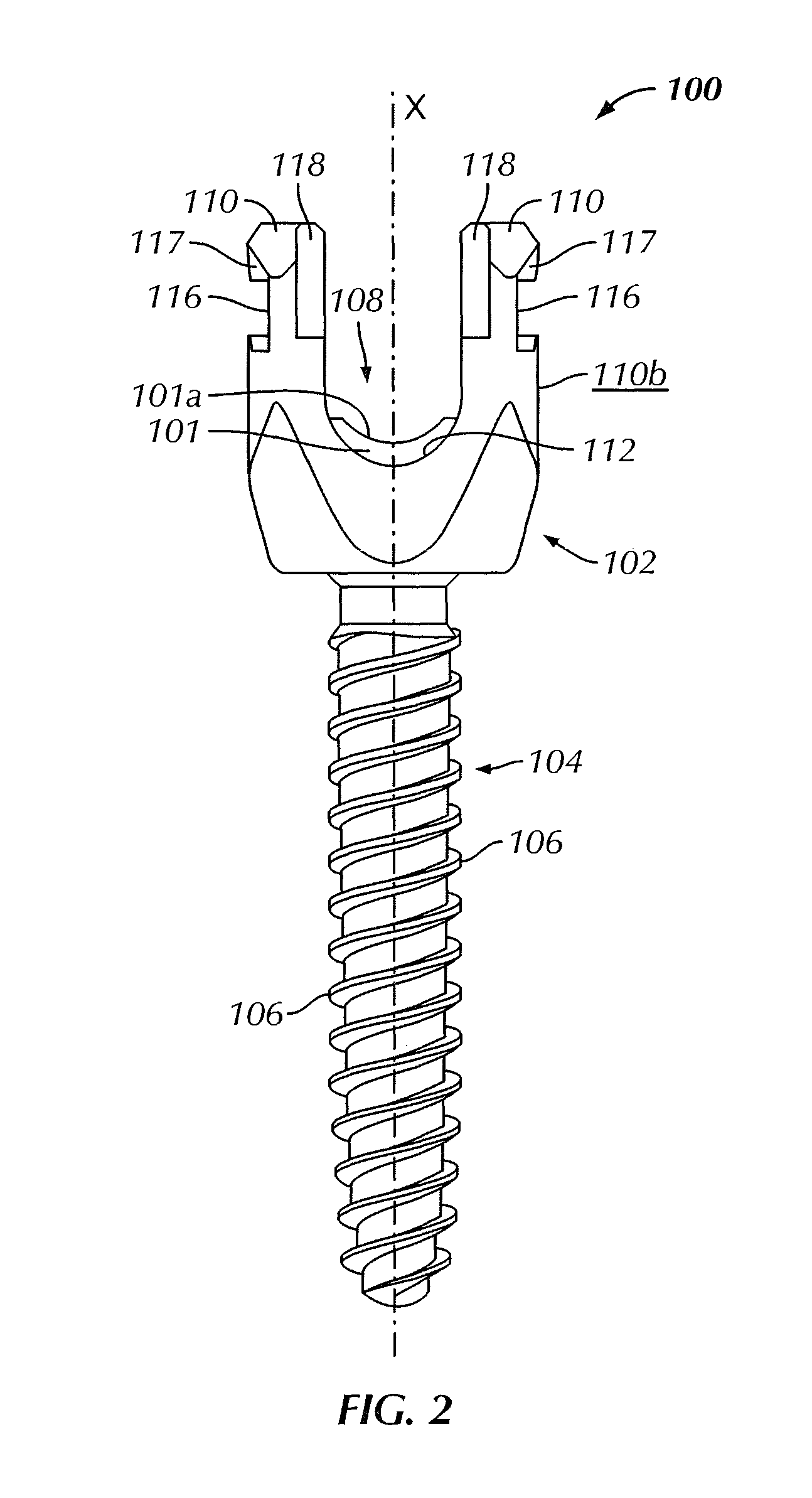

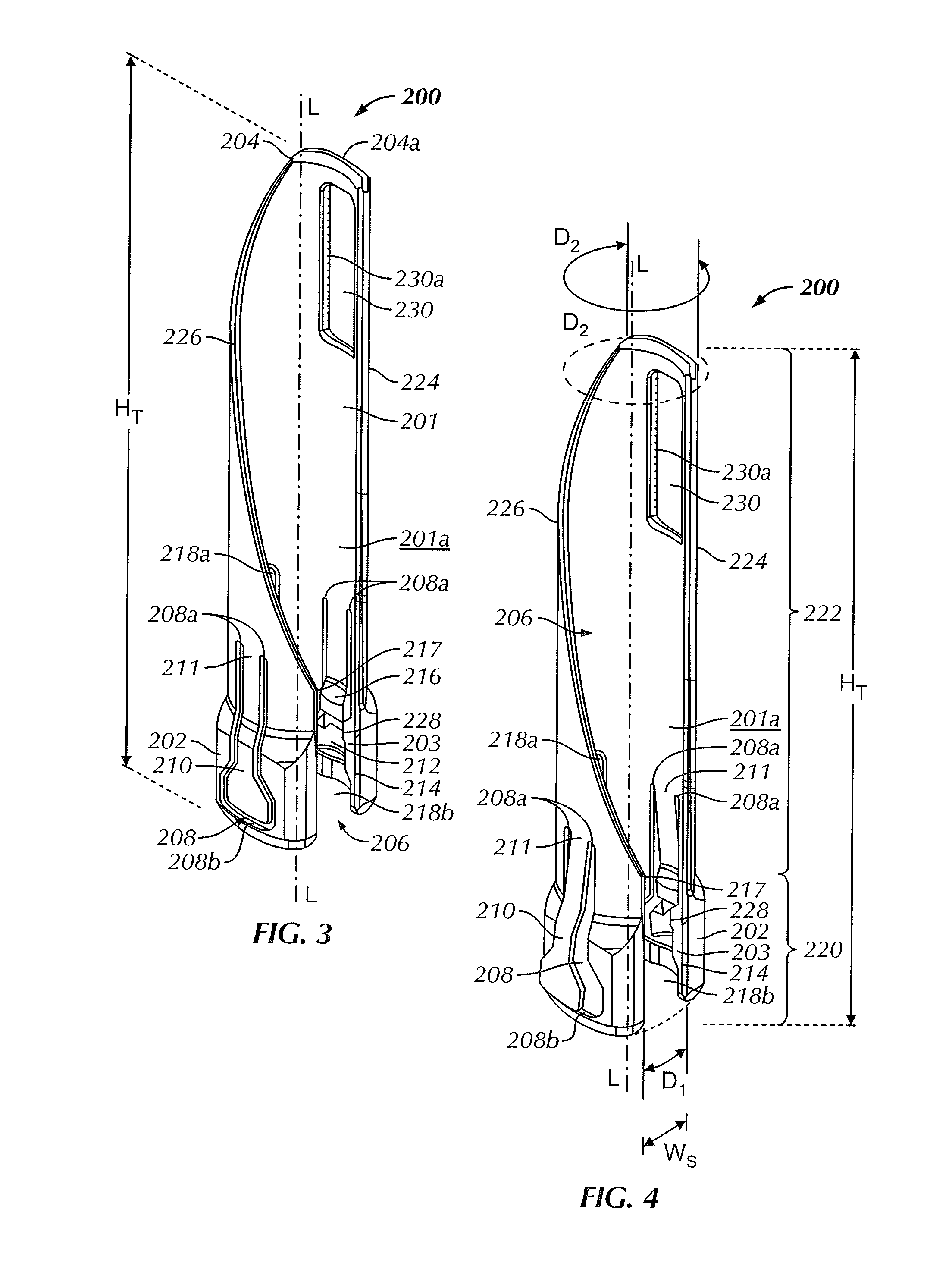

Minimally invasive instrument set, devices and related methods

ActiveUS20110263945A1Improve fluoroscopic visualizationMaximum line-of-sight potentialSuture equipmentsInternal osteosythesisDrive shaftSurgery

A minimally invasive system includes a bone screw and a tissue retractor having distal and proximal end portions and a partial pathway therebetween. The tissue retractor is removably couplable to the bone screw. An instrument has distal and proximal end portions and a hollow cavity and is removably couplable to the tissue retractor. A drive shaft has a diameter less than a diameter of the hollow cavity and is rotatable with respect to the instrument. A counter-torque handle has gripping and an interlock end portions with an instrument interface releasably positioned within the hollow cavity at the proximal end portion thereof and rotatably fixed thereto in an assembled configuration. The interlock end portion also includes an open-ended slot having a width greater than the drive shaft diameter such that the counter-torque handle is movable to and from the assembled configuration while the drive shaft is within the hollow cavity.

Owner:DEPUY SYNTHES PROD INC

Wiper containing a controlled-release anti-microbial agent

InactiveUS6916480B2Controlled release rateGood flexibilityHeavy metal active ingredientsBiocideControlled releaseSimple Organic Compounds

A wiper having a controlled release anti-microbial agent therein for providing anti-microbial cleansing of surfaces is provided. The wiper is formed from an absorbent base web to which an anti-microbial formulation is adhered. The formulation includes an anti-microbial agent that is capable of being controllably released from the wiper. In some embodiments, a polymer mixture may be employed to control the rate of release of the anti-microbial agent. Various anti-microbial agents, such as metal ions and organic compounds may be employed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

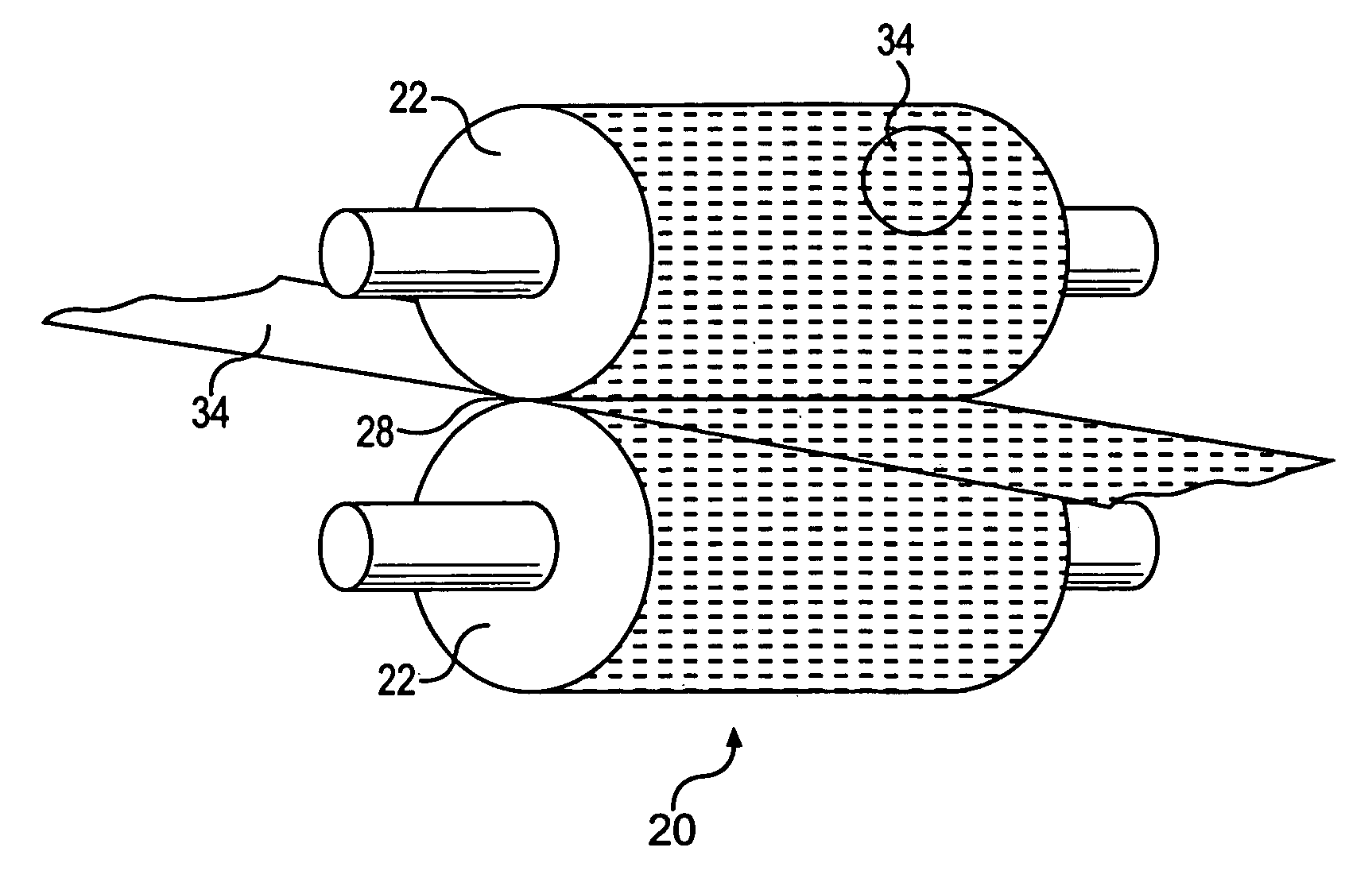

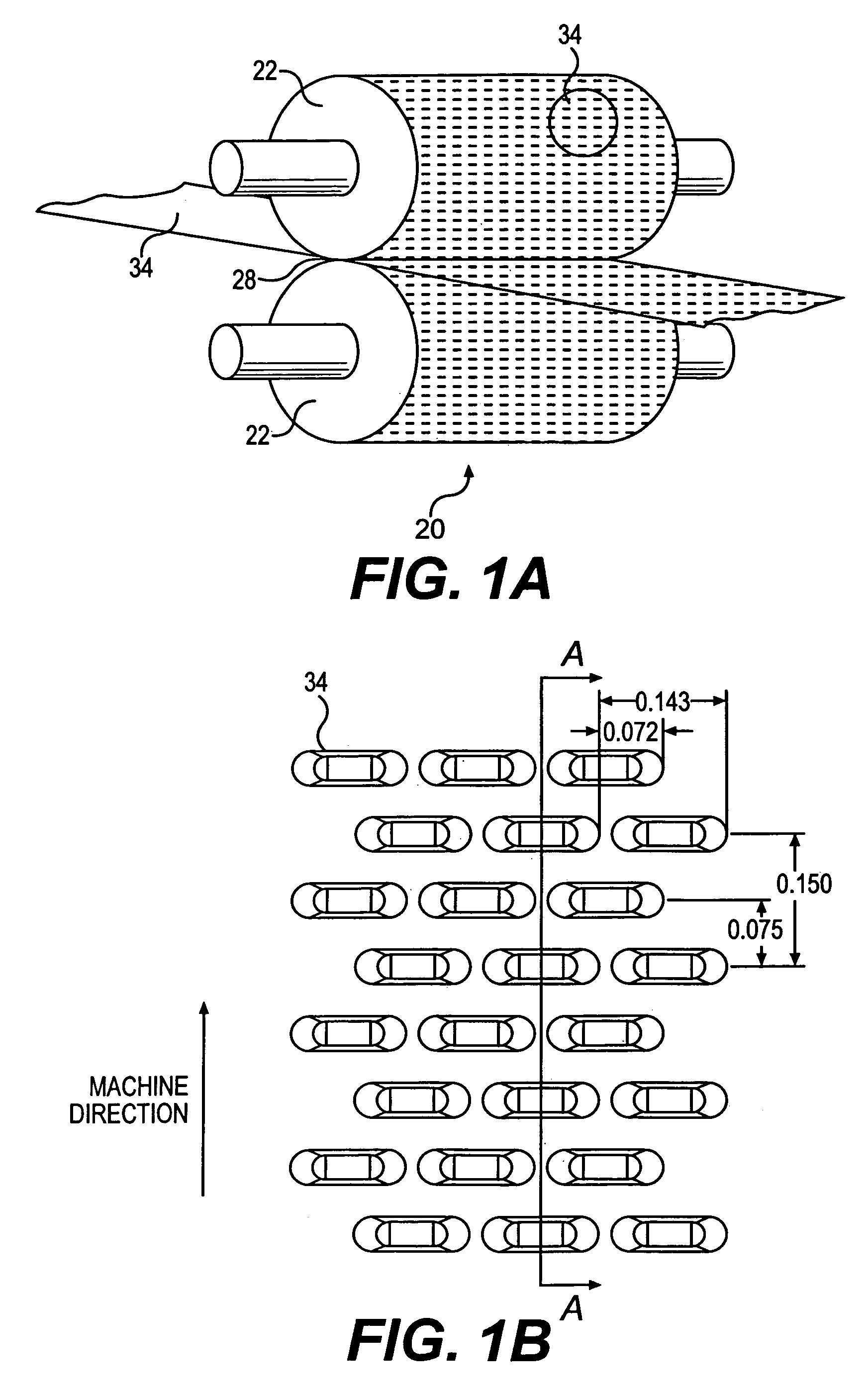

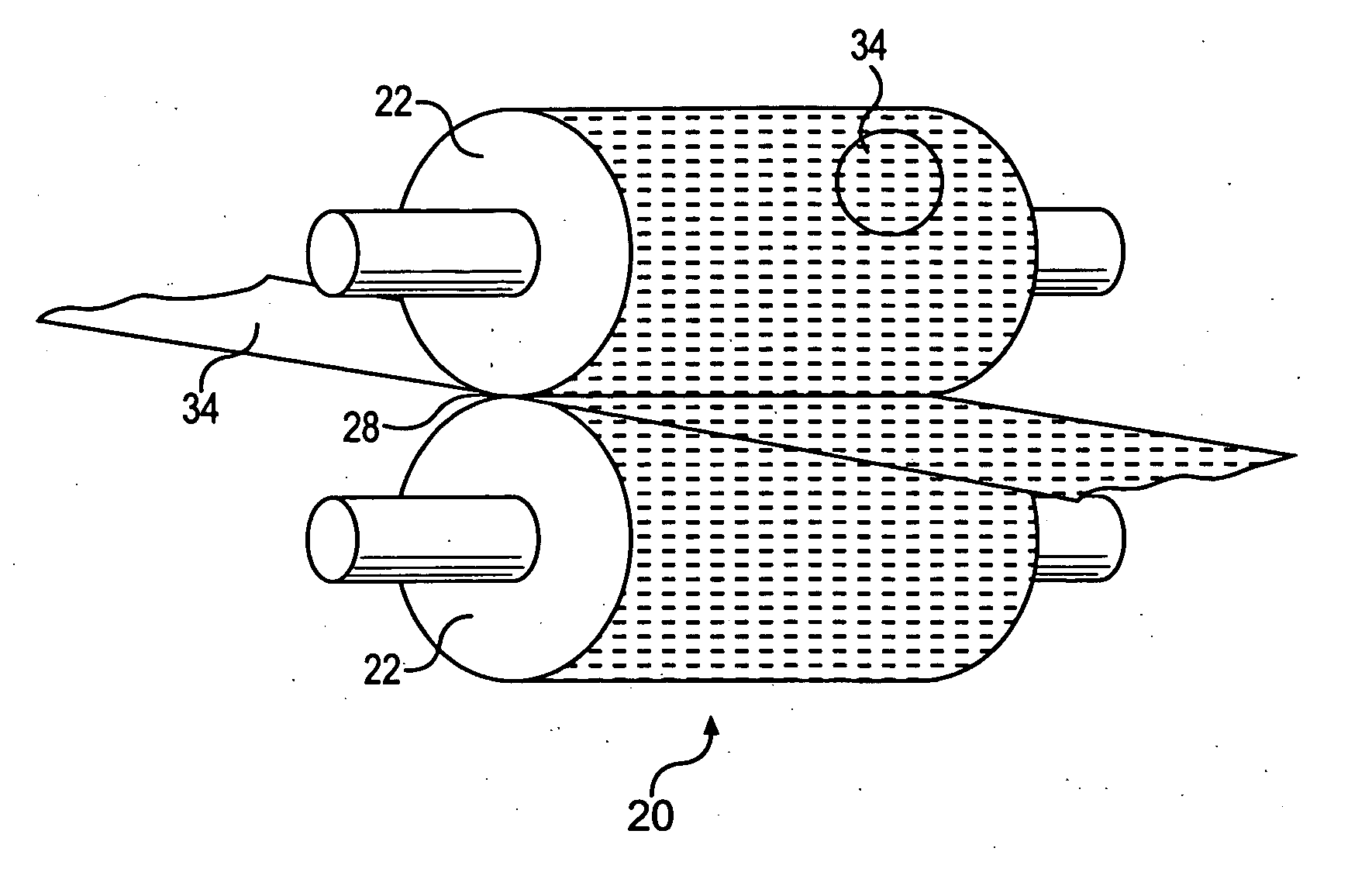

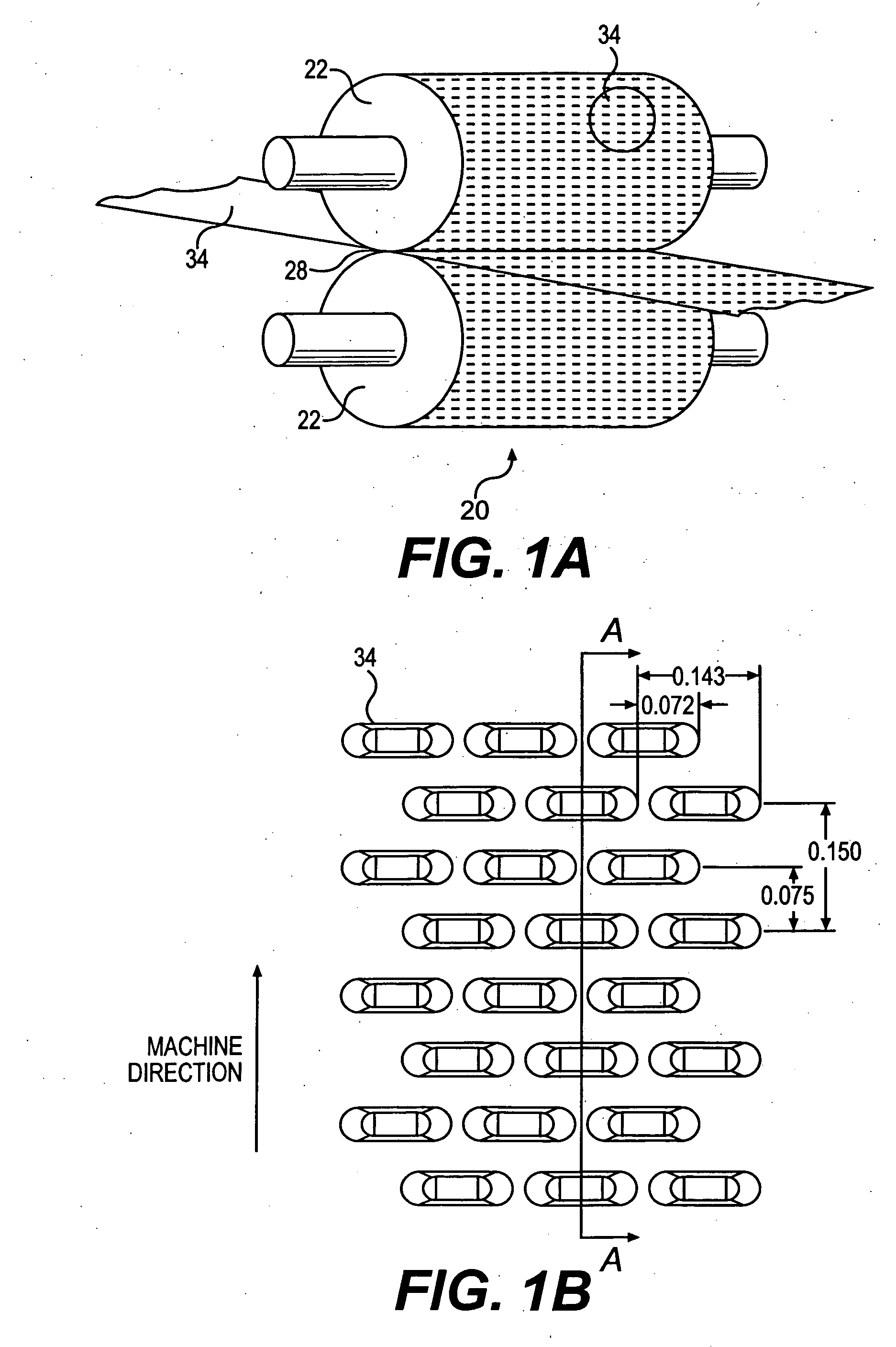

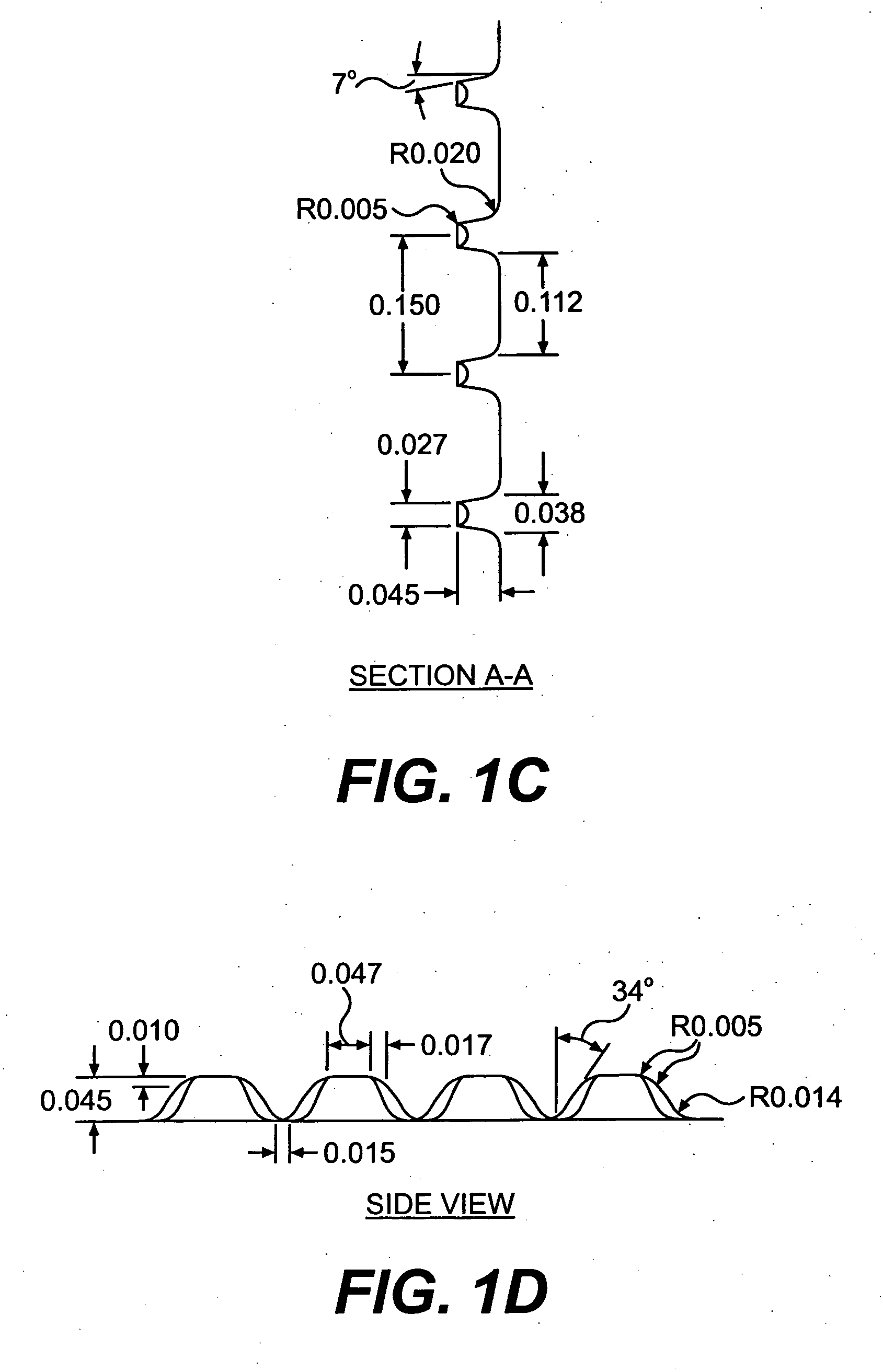

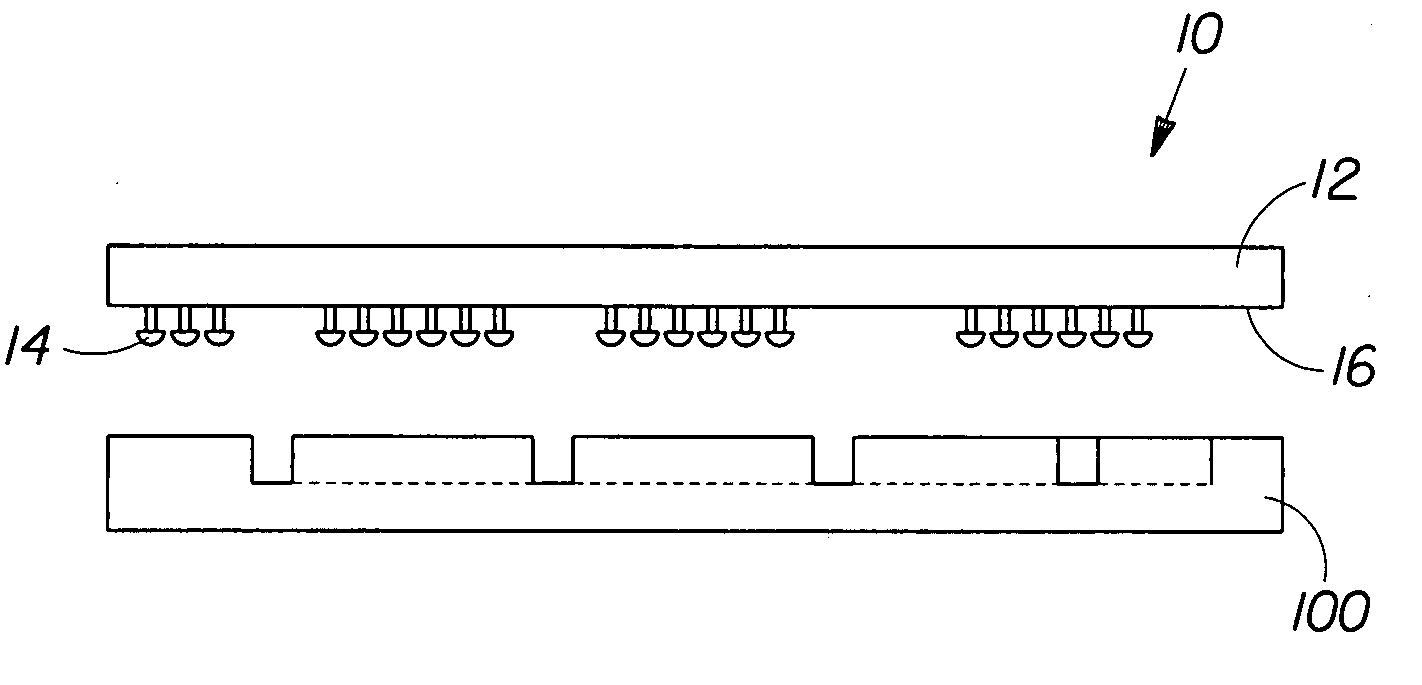

Apparatus and method for degrading a web in the machine direction while preserving cross-machine direction strength

InactiveUS7326322B2Prevent degradationIncrease flexibilityNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringUltimate tensile strength

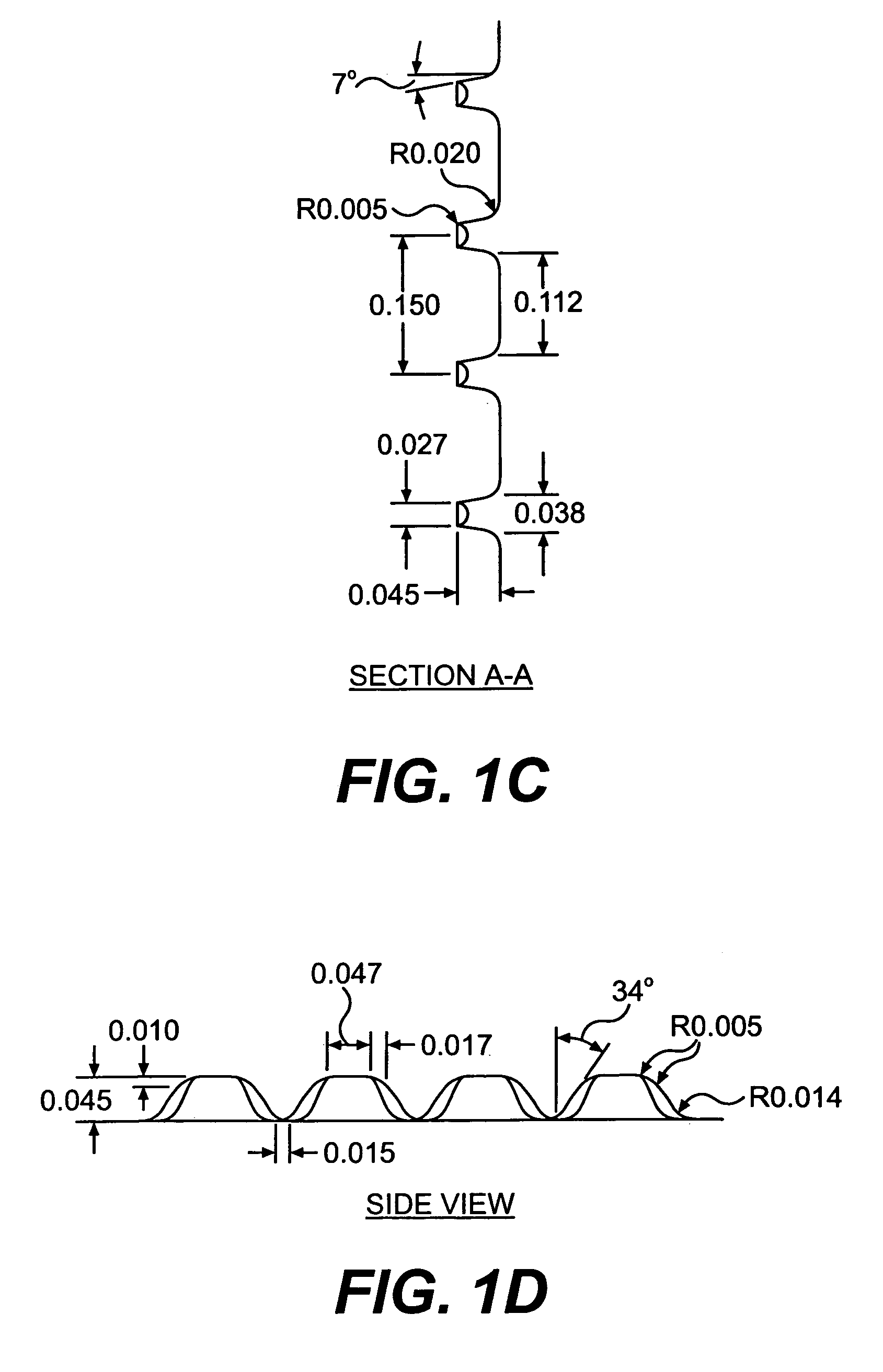

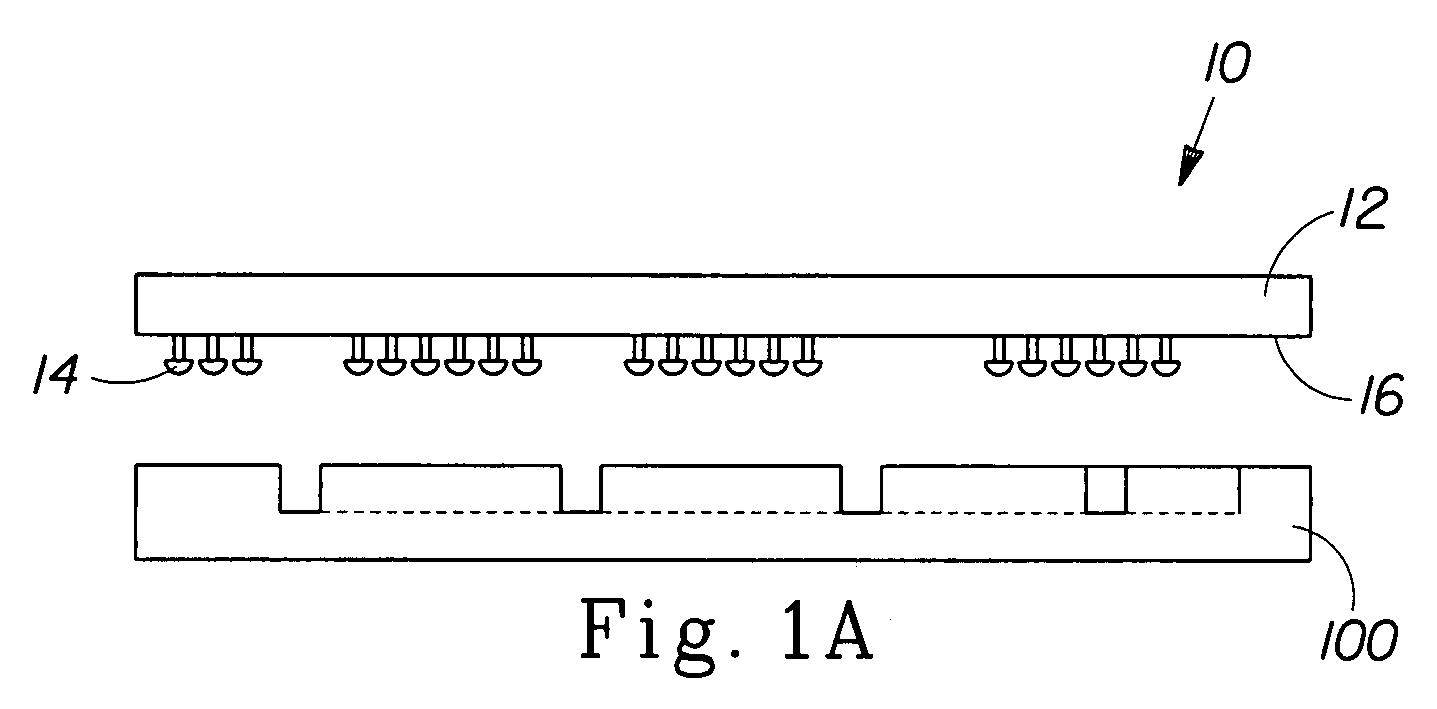

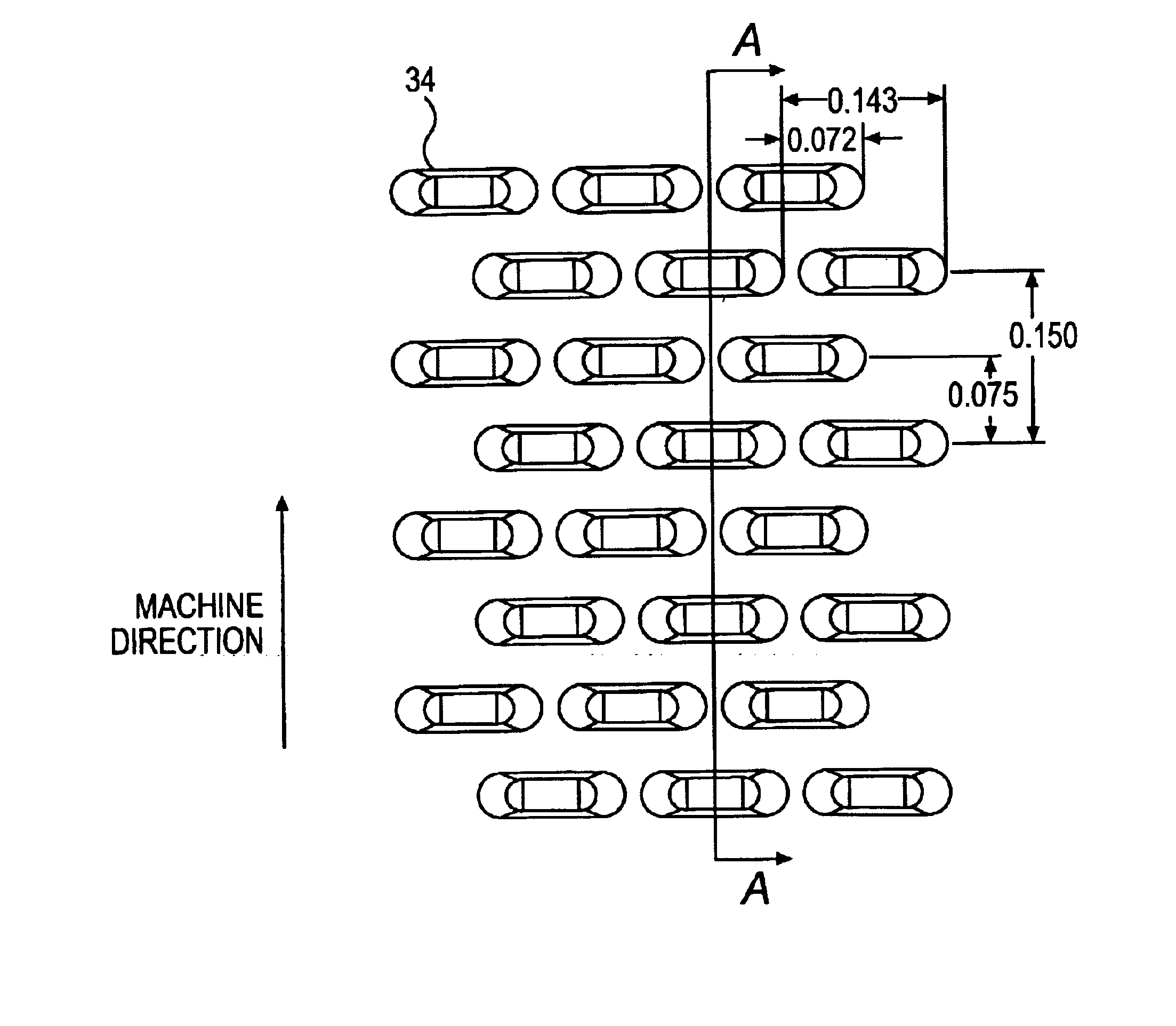

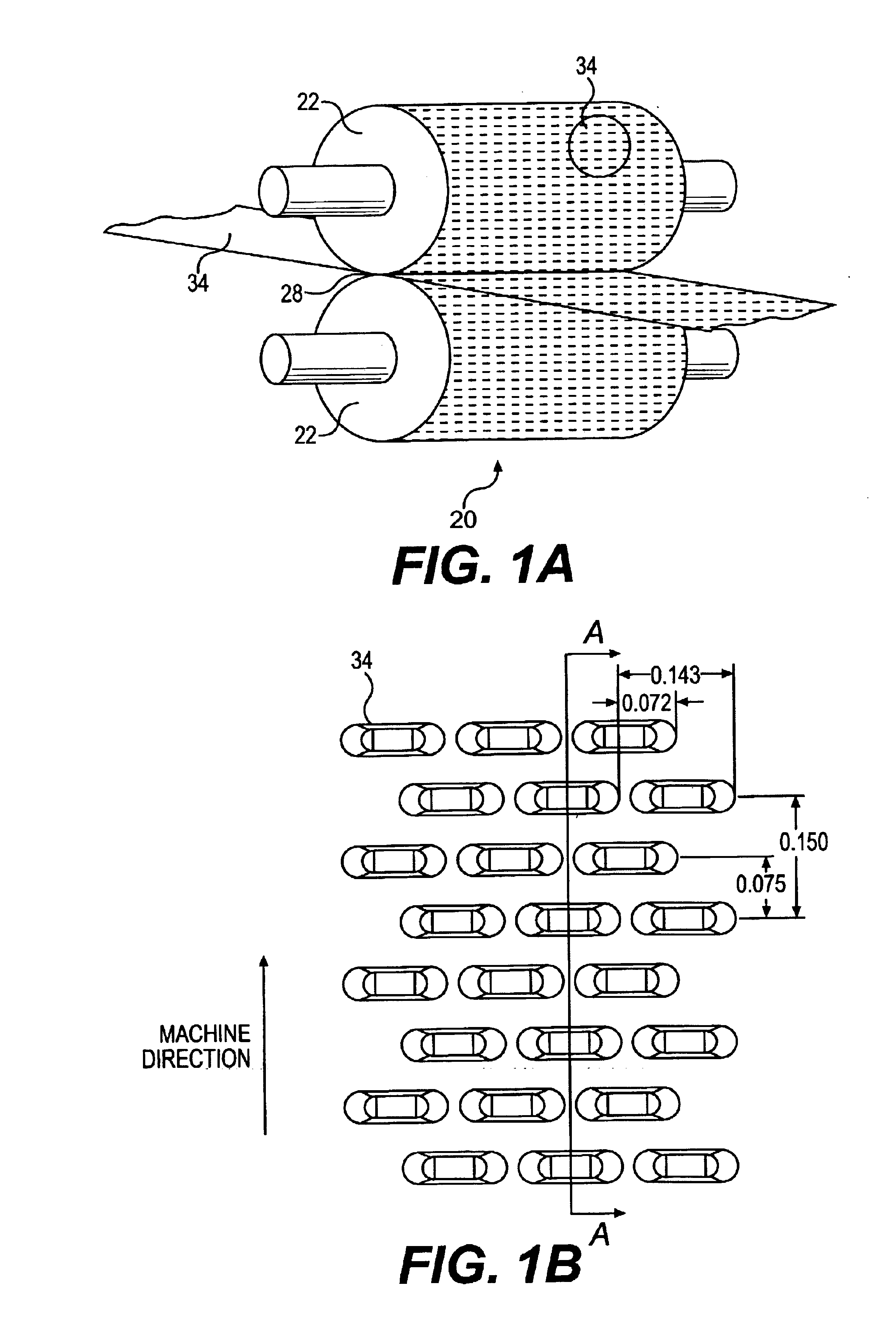

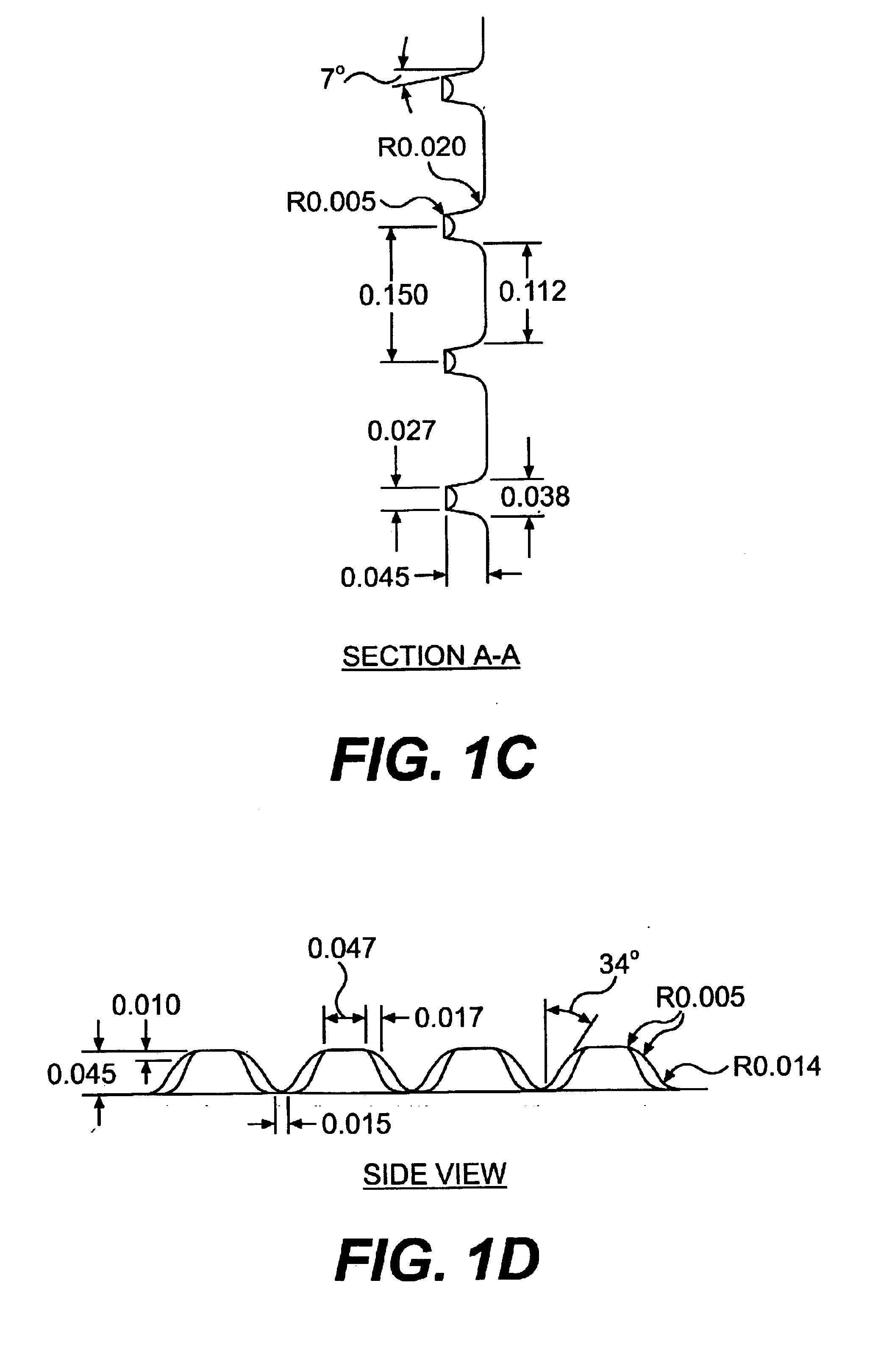

An embossing system is provided for embossing a web having a first embossing roll having embossing elements and a second embossing roll having embossing elements, wherein at least a portion of the embossing elements of the first and second embossing rolls are substantially oriented in the cross-machine direction. The embossing roll may be crowned, may have alignment means, and may be provided with precision gearing.

Owner:GPCP IP HLDG LLC

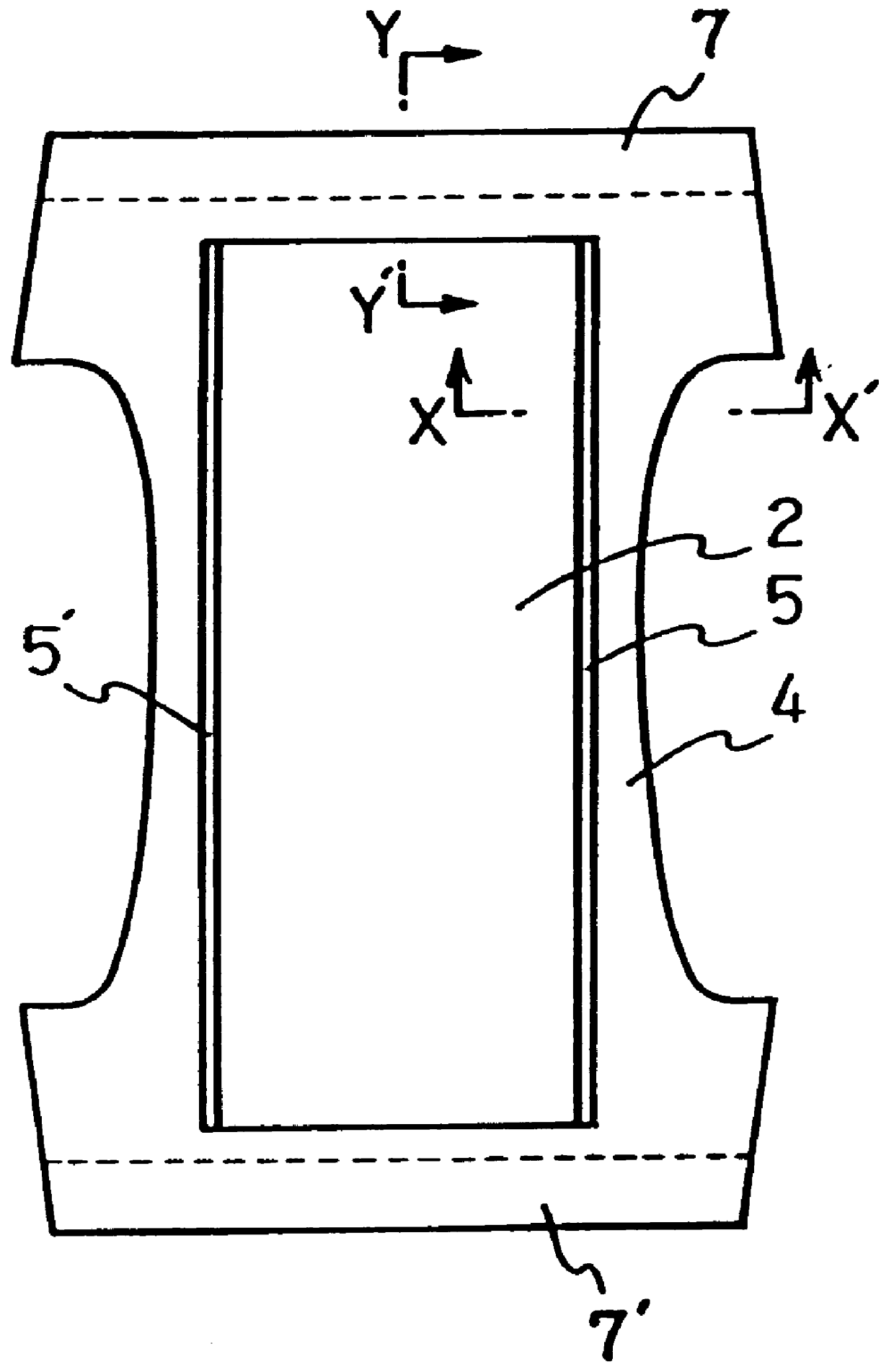

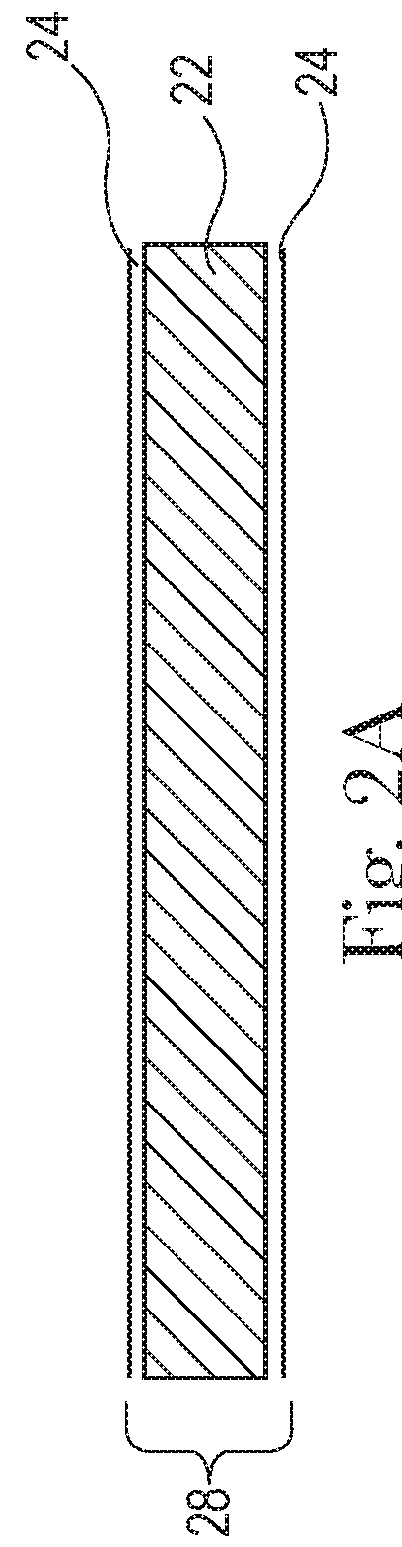

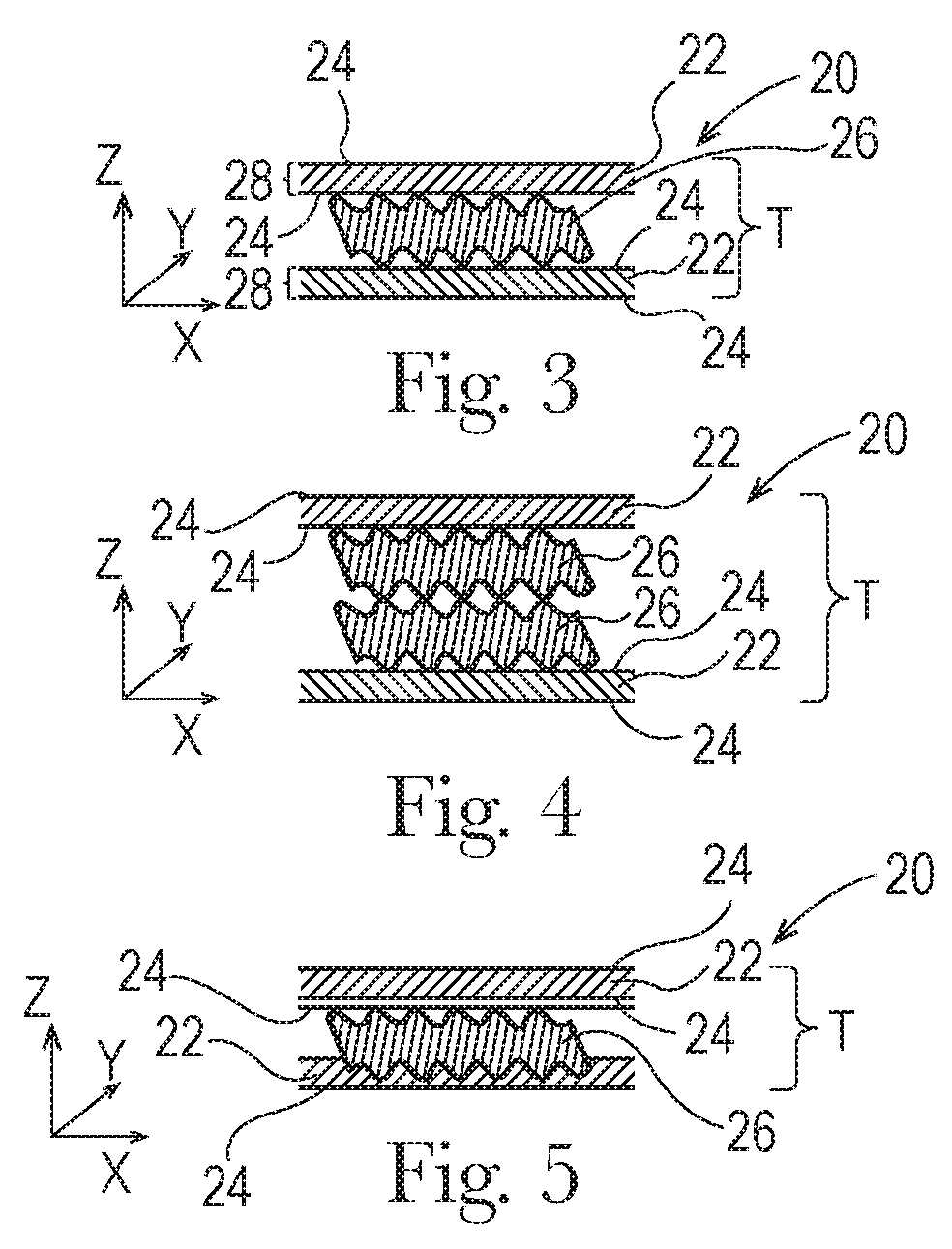

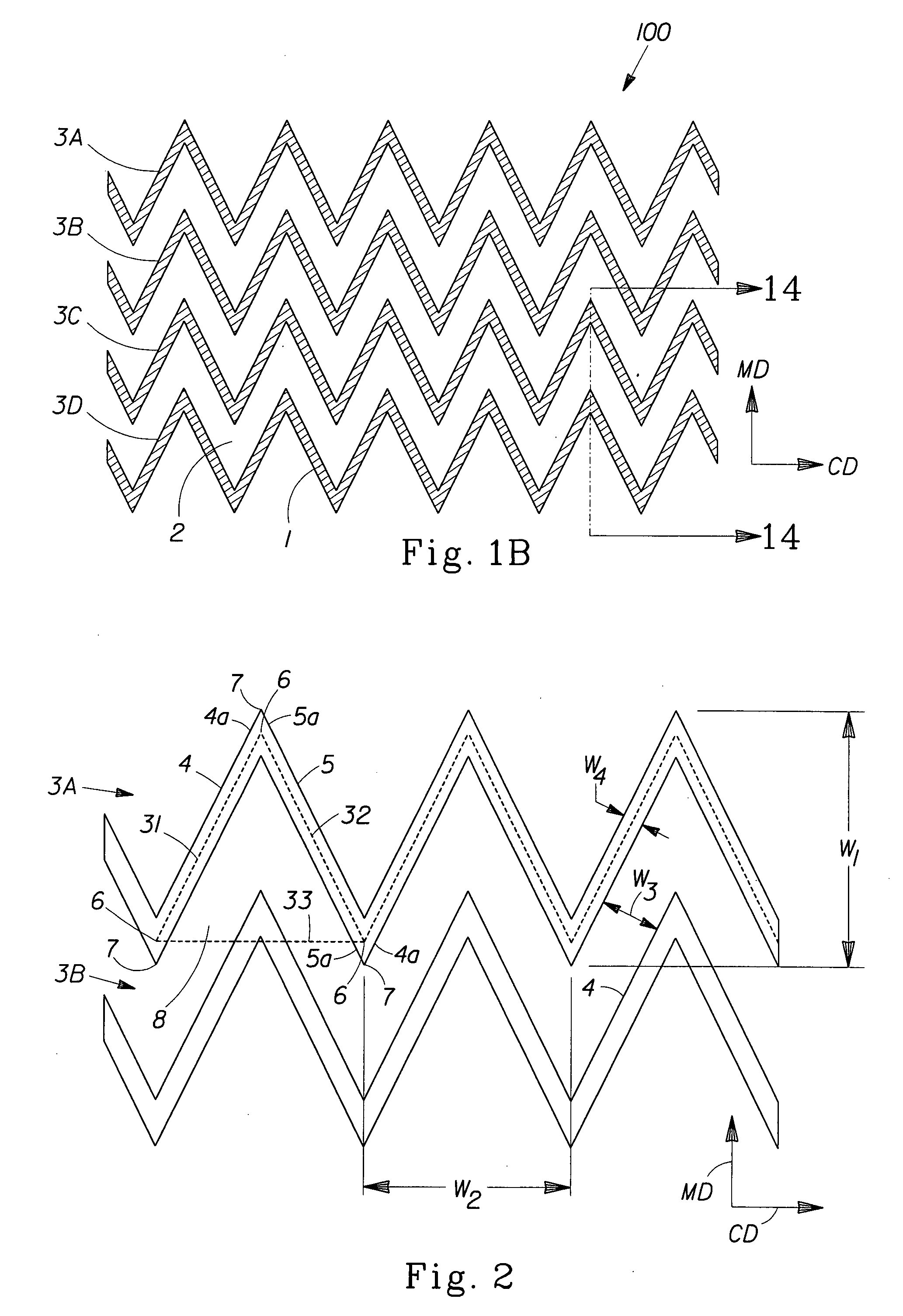

Nonwoven fabric for a female component of a fastening system

InactiveUS7789870B2High bonding strengthHigh mechanical strengthLayered productsBaby linensEngineeringNonwoven fabric

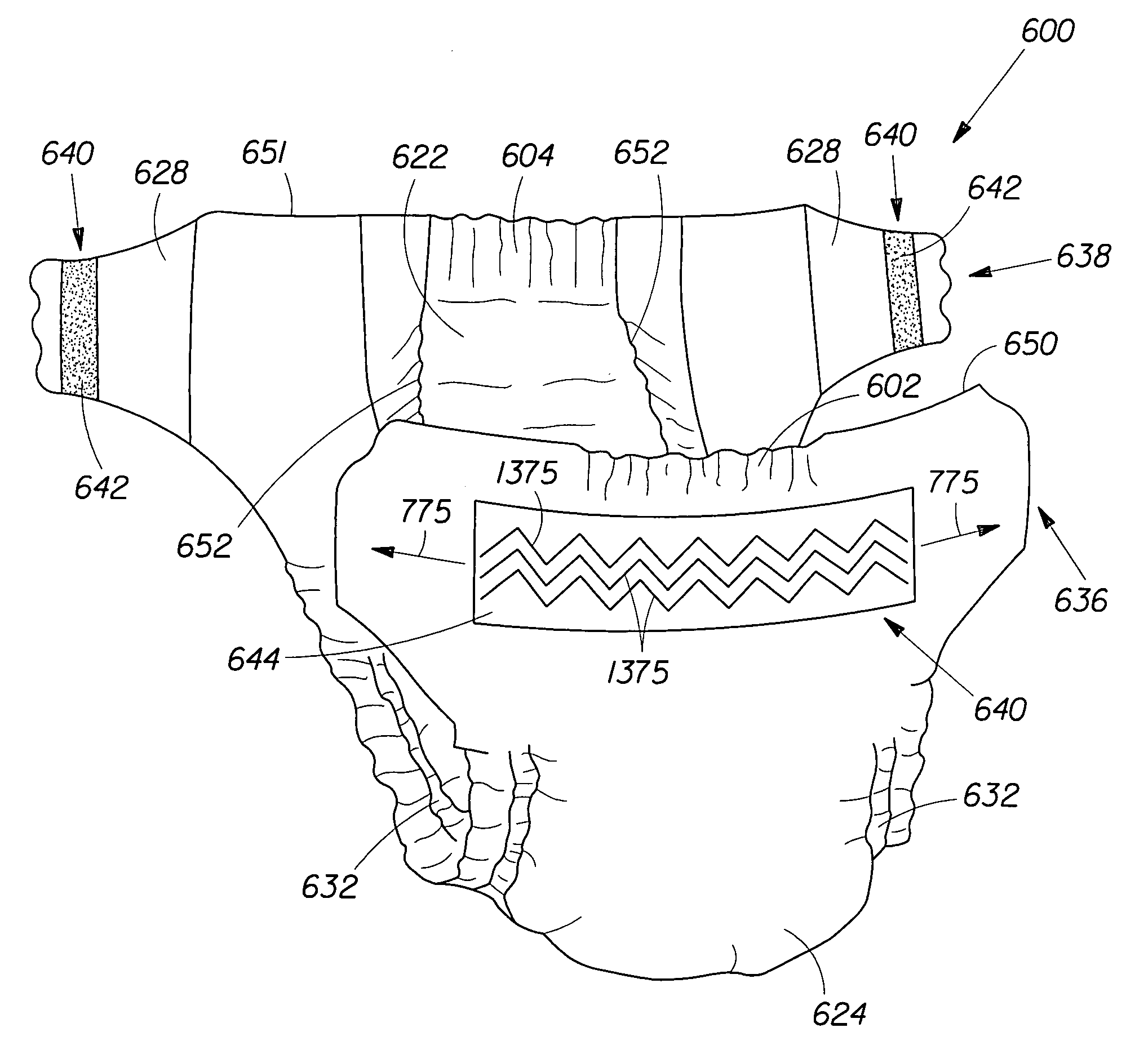

A fastening system includes an engaging component and a receiving component. The engaging component has a plurality of engaging elements capable of engaging the receiving component. The receiving component includes a nonwoven fabric having composite fibers, an embossed section, and a non-embossed section. The composite fibers are bonded together in the embossed sections. The composite fibers include a first propylene polymer and a second propylene polymer, wherein the first and second propylene polymers extend continually in a longitudinal direction and are arranged such that the second propylene polymer is associated with the first propylene polymer such that the composite fiber forms a crimp therein. The embossed sections have a plurality of zigzag unit patterns arranged in a machine direction which have a ratio of W1 / W2 in the range of about 0.5 to about 2.0.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatus and method for degrading a web in the machine direction while preserving cross-machine direction strength

InactiveUS6887349B2Reducing tensile ratioPrevent degradationNon-fibrous pulp additionNatural cellulose pulp/paperUltimate tensile strengthMechanical engineering

An embossing system is provided for embossing a web having a first embossing roll having embossing elements and a second embossing roll having embossing elements, wherein at least a portion of the embossing elements of the first and second embossing rolls are substantially oriented in the cross-machine direction. The embossing roll may be crowned, may have alignment means, and may be provided with precision gearing.

Owner:GPCP IP HLDG LLC

Thermal protection flocculus and manufacturing method thereof

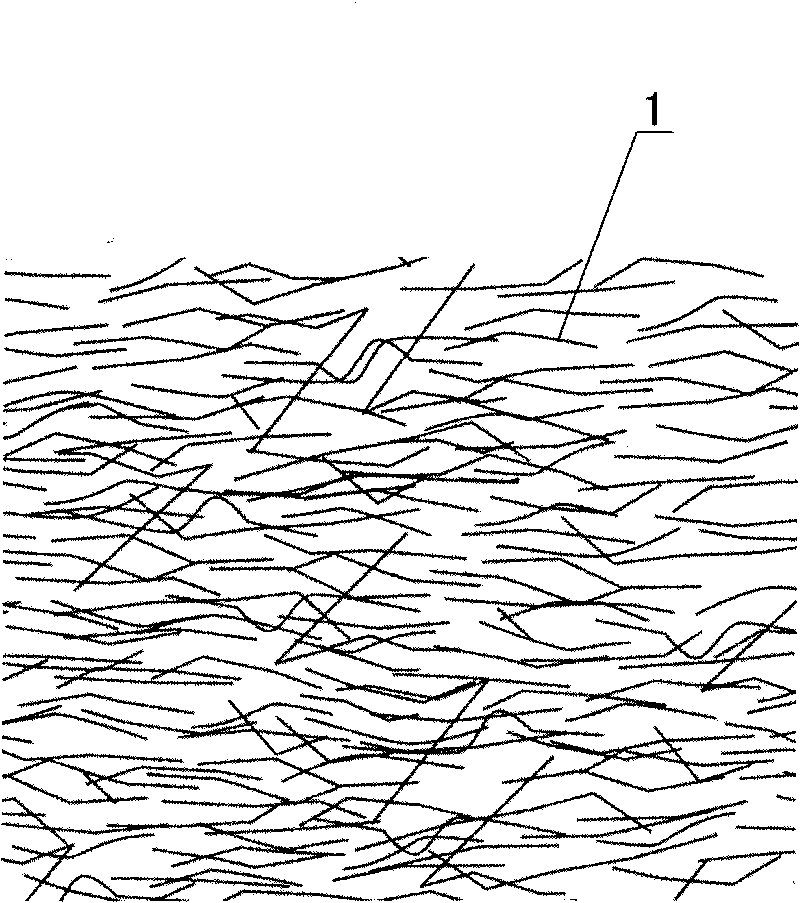

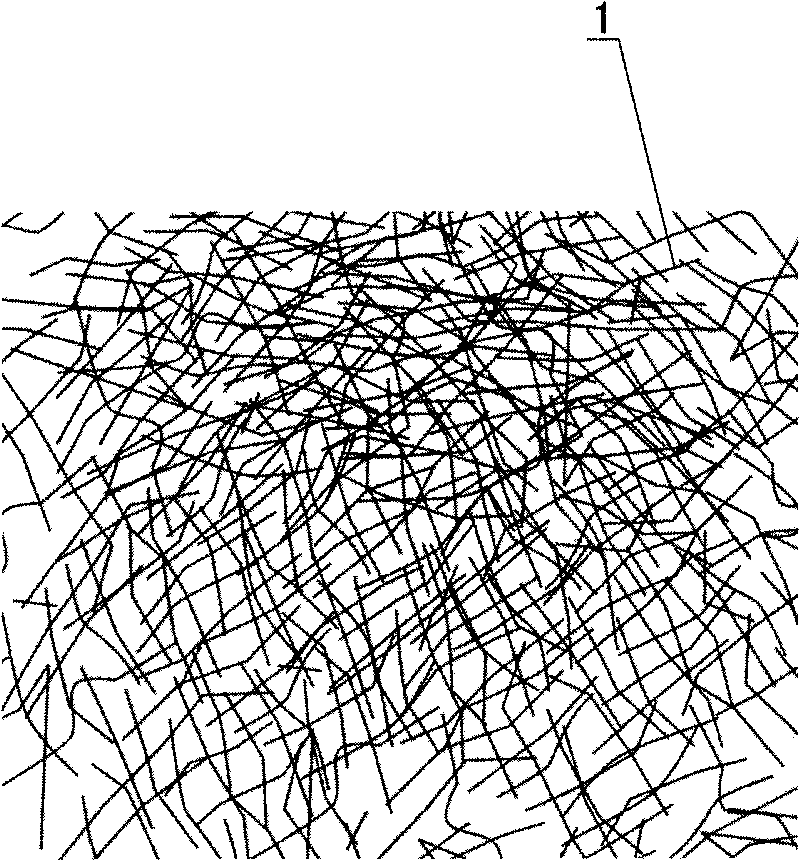

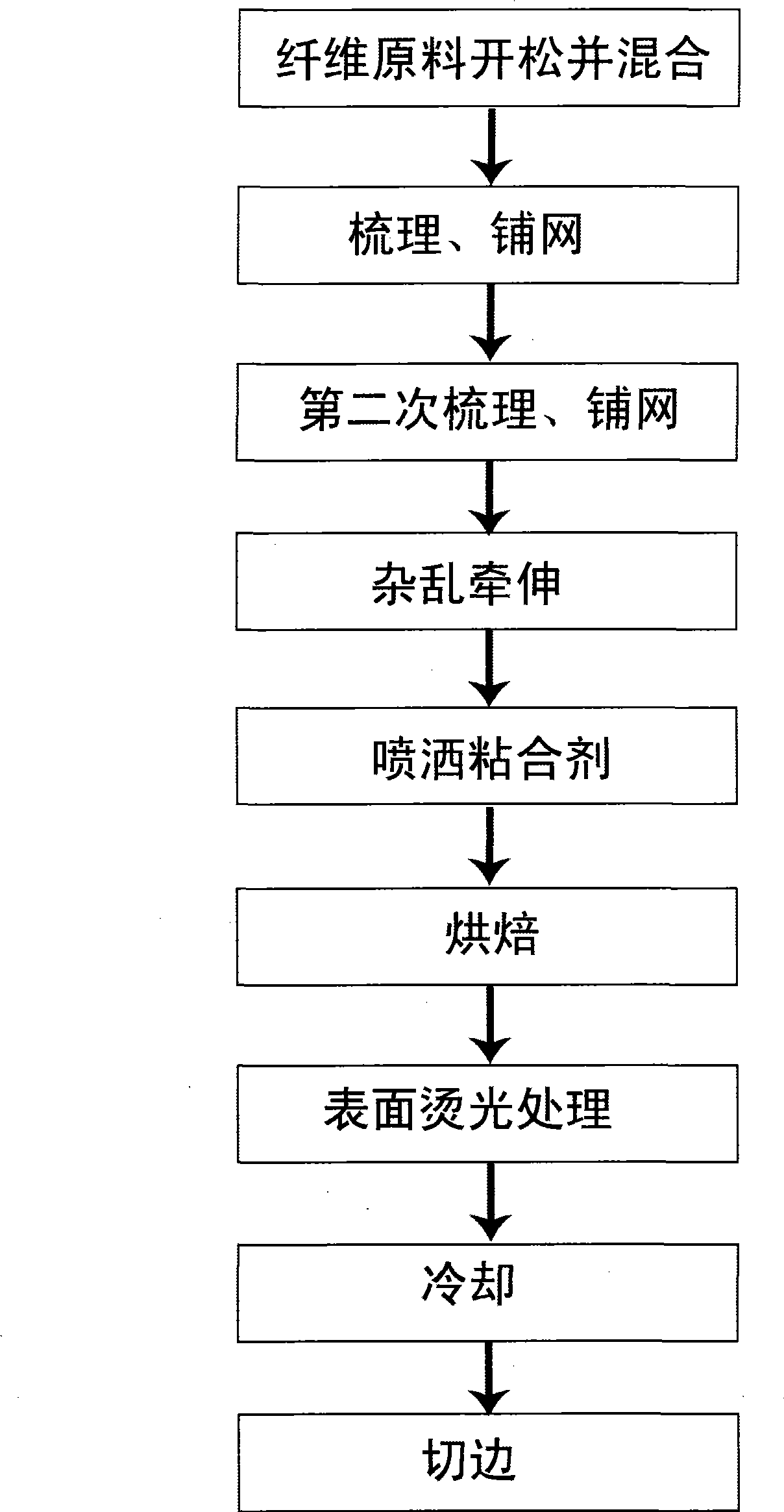

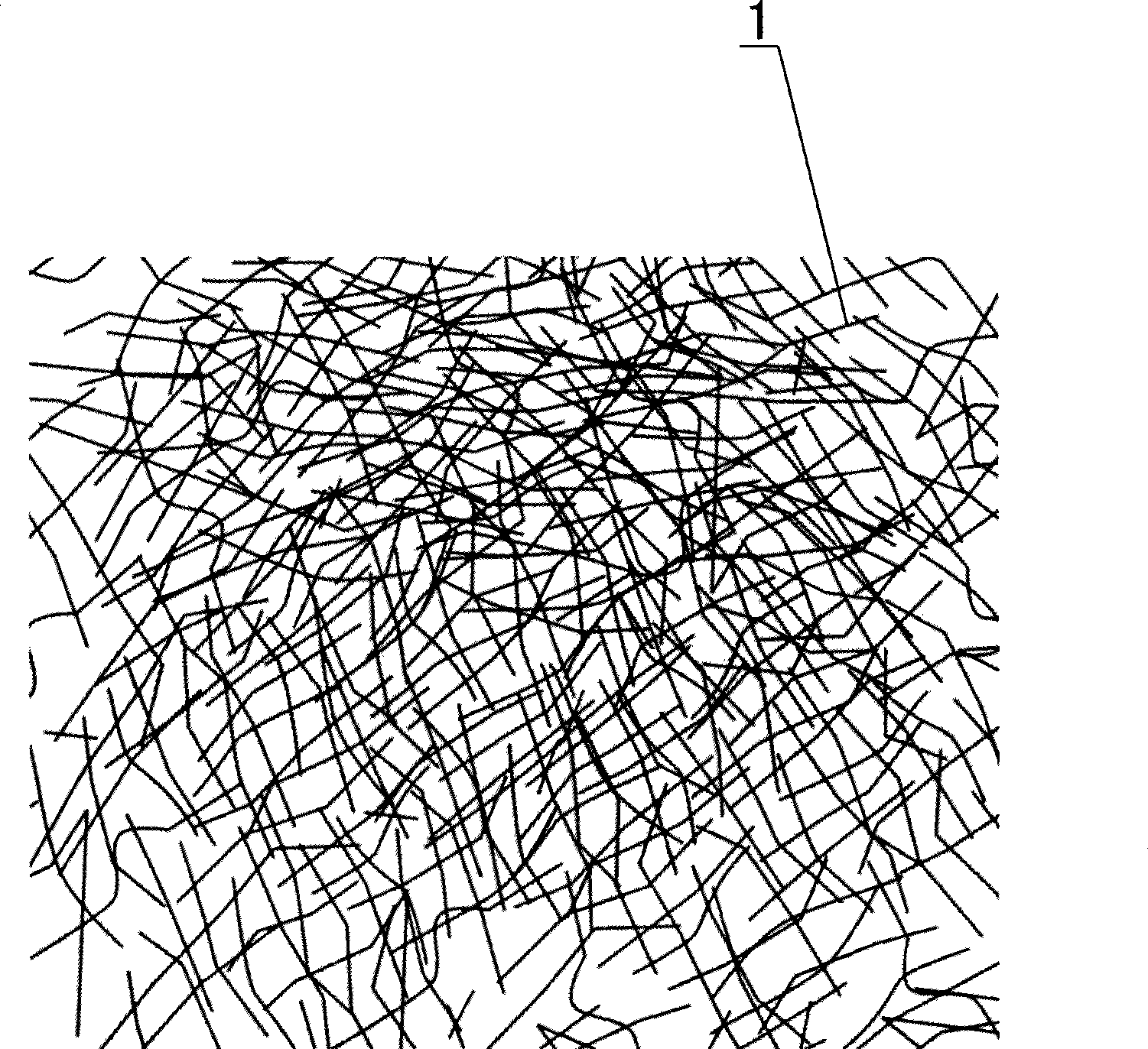

InactiveCN101476212AReduce conductionConduction block or decreaseNon-woven fabricsAdhesivesFiberNet shape

The invention provides a keeping warm flocculus which is prepared from raw material by weight including 56%-85% fine denier fibre and / or super fine denier fibre, 0-30% hollow fibre, 5-30% felt fibre. The preparing method includes steps as follows: loosing and mixing various fibre raw material; then combing, lapping for forming fibre net; then processing disorder drafting to the felt net for forming solid net shape crossing struture; then heating and baking the felt net, at least melting surface of the felt fibre for felting surrounding fibre. The fine denier fibre can increase content of still air in the keeping warm flocculus, reduce heat quantity conduction, and can divide space in the keeping warm flocculus into smaller space for avoiding or reducing air convection, accordingly increase warm keeping property of the keeping warm flocculus; the hollow fibre can increase filling power and compress rebound property of the warm keeping flocculus; filling power and compress rebound property of the warm keeping flocculus are increased after being disorder draft.

Owner:汕头市奥山服饰有限公司

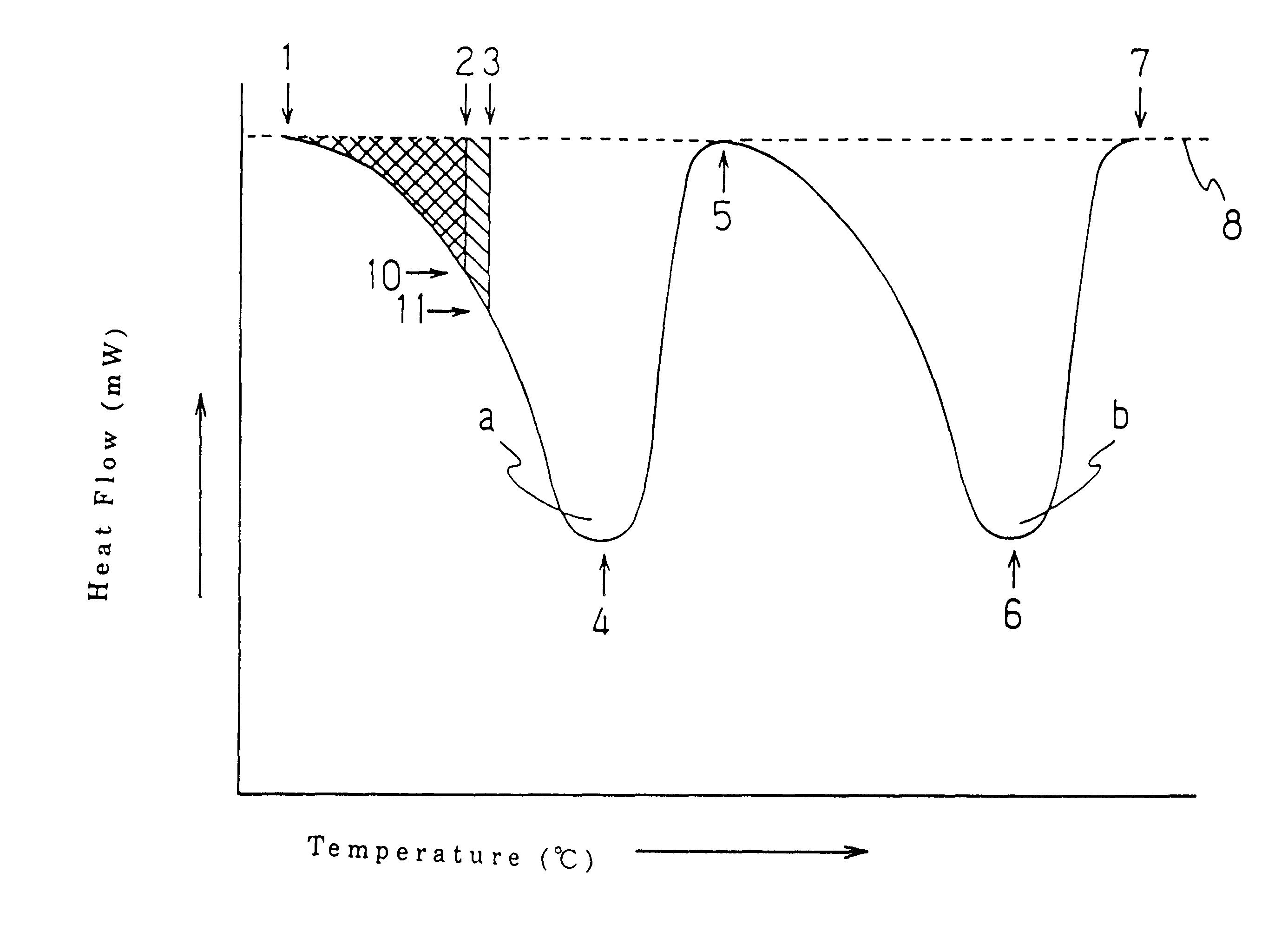

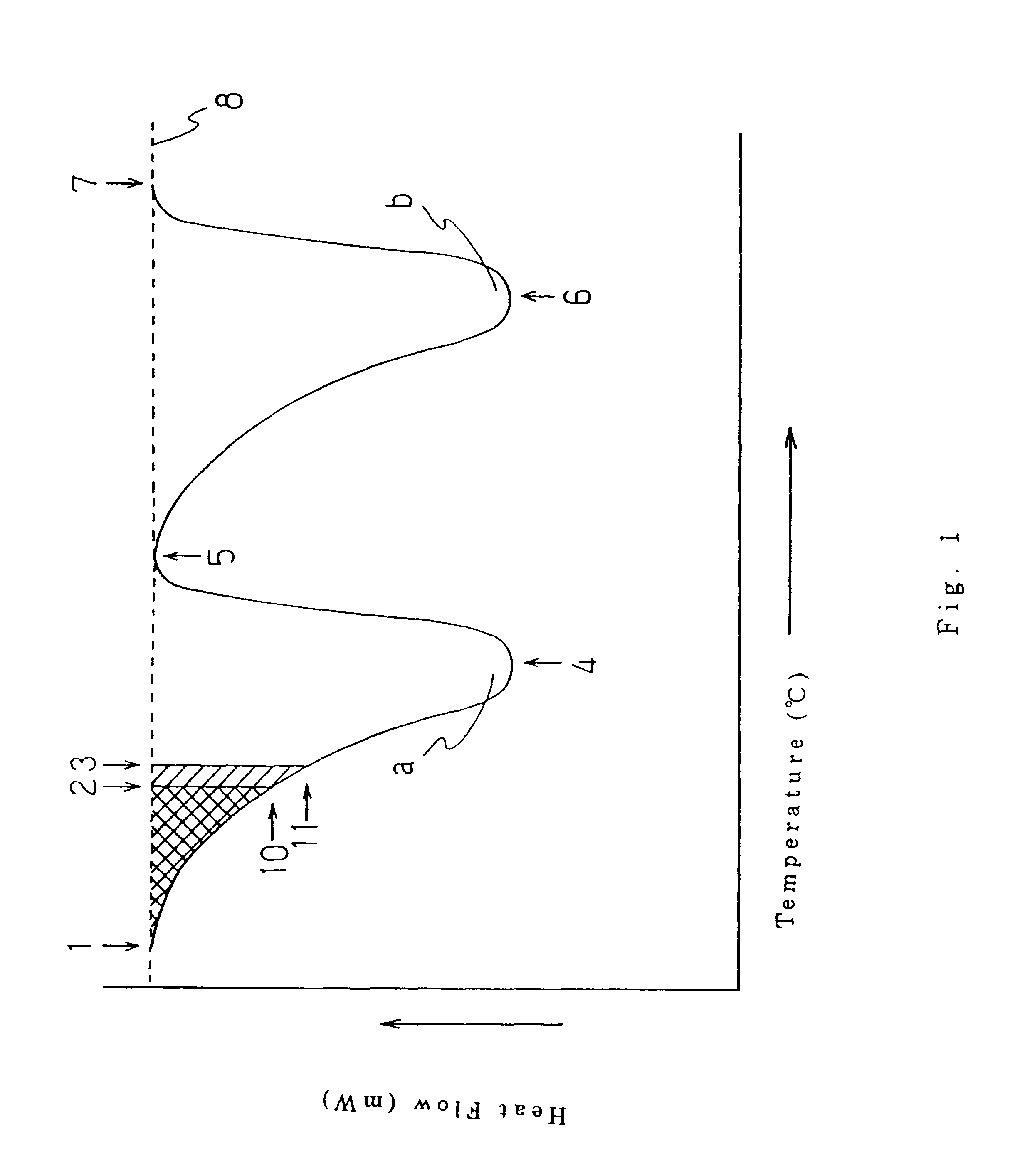

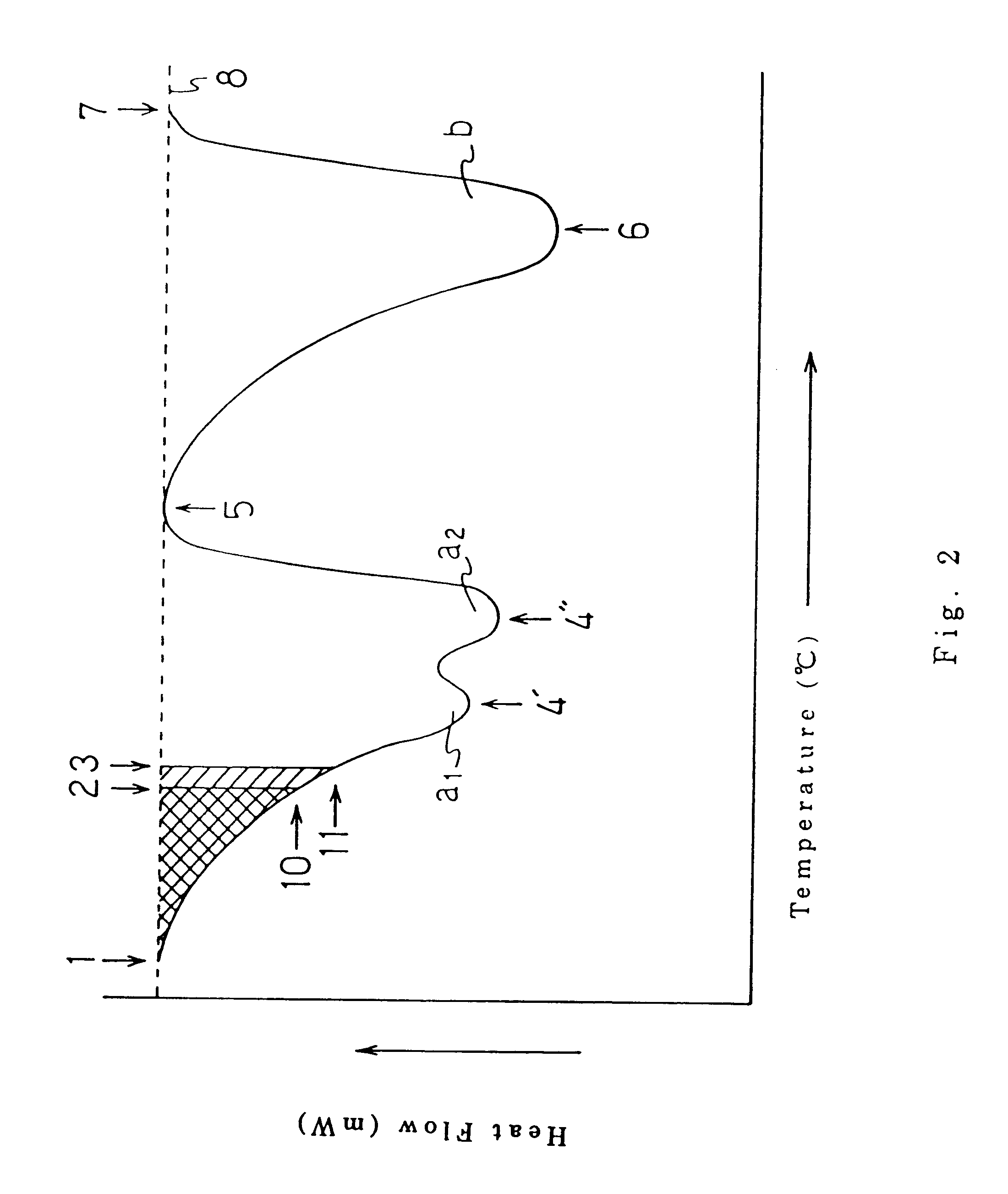

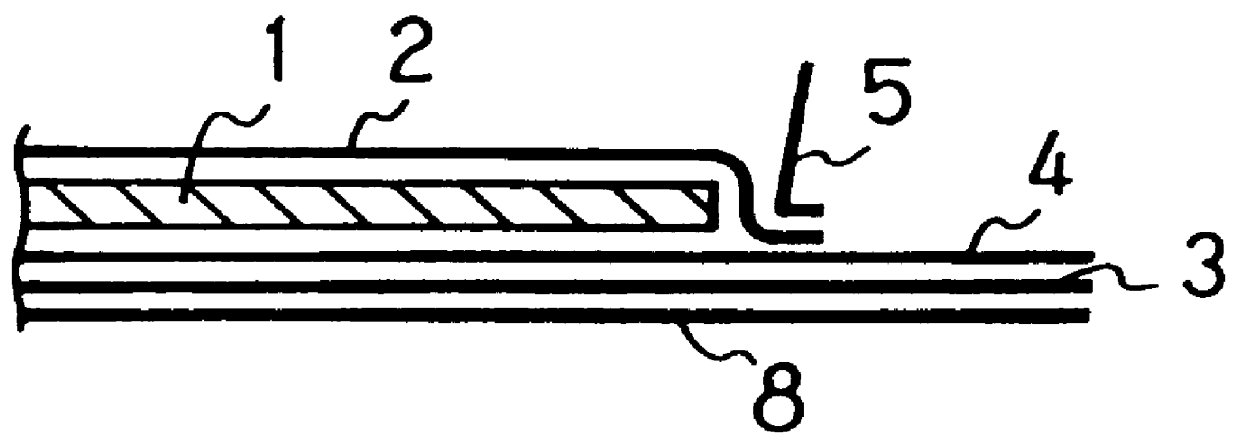

Composite sheet comprising a non-woven fabric and a film

InactiveUS6271155B1Low component requirementsComponent with highPersonal careSynthetic resin layered productsFiberThermoplastic

A composite laminated sheet comprises a thermoplastic crystalline film and a non-woven fabric having a thermoplastic conjugated fiber comprising the low melting point component and the high melting point component, in which the difference in the melting point between the low melting point component and the high melting point component is not less than 10° C.; the difference in the melting point between the thermoplastic crystalline film and the low melting point component of the conjugated fiber is not more than 30° C.; and the temperature of the position corresponding to 10% of the area from the side of the melting starting point of the endothermic peak of an entire conjugated fiber evaluated by DSC is between the melting starting point and the melting completion point of the endothermic peak of the film evaluated by DSC. According to the present invention, a composite sheet is provided in which a non-woven fabric and a film are adhered without adhesive agents, the appearance is excellent, and the adhesive strength between the non-woven fabric and the film is high. Consequently, the composite sheet of the present invention can be used for a water-proof sheets, for example, paper diapers or sanitary napkins or the like.

Owner:JNC CORP

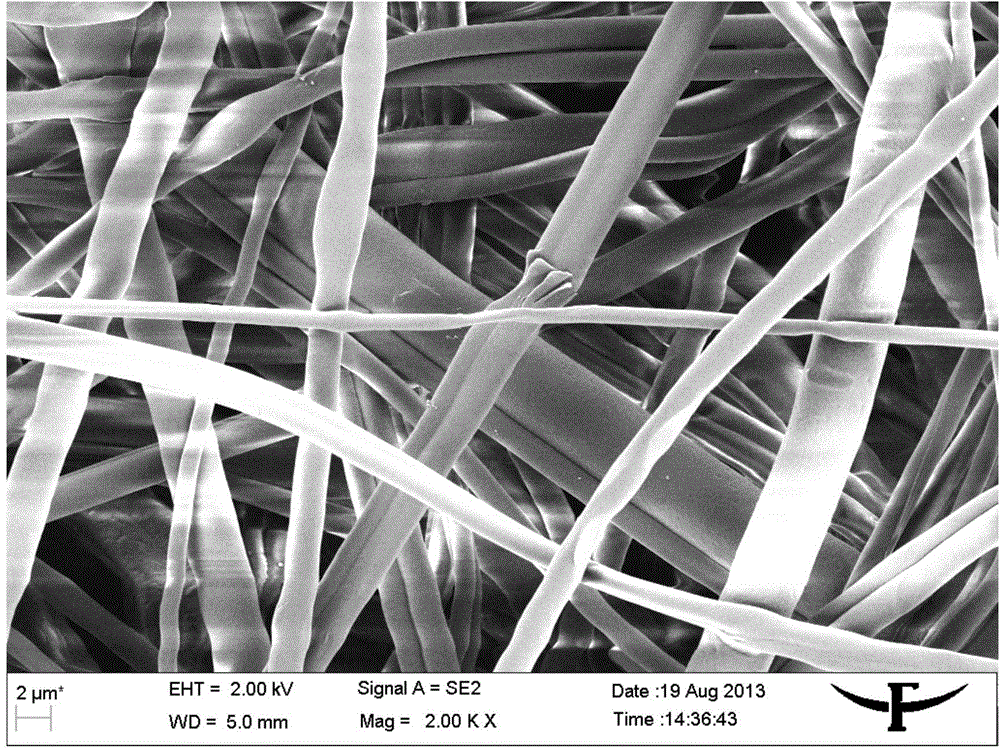

Melt-blow non-woven material capable of effectively filtering PM 2.5 particles, preparation method and production device

ActiveCN104153119AHigh filtration efficiencyImprove dust collection effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPorosityEngineering

The invention discloses a melt-blow non-woven material capable of effectively filtering PM 2.5 particles, a preparation method and a production device. The melt-blow non-woven material comprises, by weight percentage, 93-97 parts of polypropylene, 3-6 parts of electret master batch and 0.1-1 part of polyvinylidene fluoride. According to the melt-blow non-woven material capable of effectively filtering PM 2.5 particles, the polypropylene, the electret master batch and the polyvinylidene fluoride are compounded, the obtained melt-blow non-woven material is characterized by high porosity, the fiber diameter of smaller than two micrometers, large clogging capacity, high filtering efficiency and low resistance, an electret is good in charge storage performance after electret processing, the charge keeping rate can be above two years, and the electret can be used in a high-temperature and high-humidity environment. The product is environmentally friendly and free of pollution, has the advantages of being long in service life and wide in use range, and is particularly suitable for removing PM 2.5 particles in the air.

Owner:DO FLUORIDE CHEM CO LTD

Filament non-woven fabric and an absorbent article using the same

InactiveUS6090730APrevent leakageImprove bulkLayered productsAbsorbent padsThermoplasticNonwoven fabric

PCT No. PCT / JP97 / 02165 Sec. 371 Date Jan. 20, 1998 Sec. 102(e) Date Jan. 20, 1998 PCT Filed Jun. 23, 1997 PCT Pub. No. WO97 / 49853 PCT Pub. Date Dec. 31, 1997A filament non-woven fabric comprising thermoplastic conjugated filaments comprising at least one low melting point resin or low softening point resin selected from the group consisting of olefin binary copolymer or olefin terpolymer as the first component and crystalline thermoplastic resin as the second component. The thermoplastic conjugated filament contains inorganic powder in at least the first component, wherein the content of the inorganic powder is 500 to 50000 weight ppm with respect to the fibers. The present invention can provide a filament non-woven fabric that is excellent in the high adhesive property, low temperature adhesive property, hand feeling such as softness or touch etc., and uniformity. Furthermore, operating efficiency such as the spinning property is good. Absorbent articles can be produced using the above mentioned filament non-woven fabrics.

Owner:JNC CORP

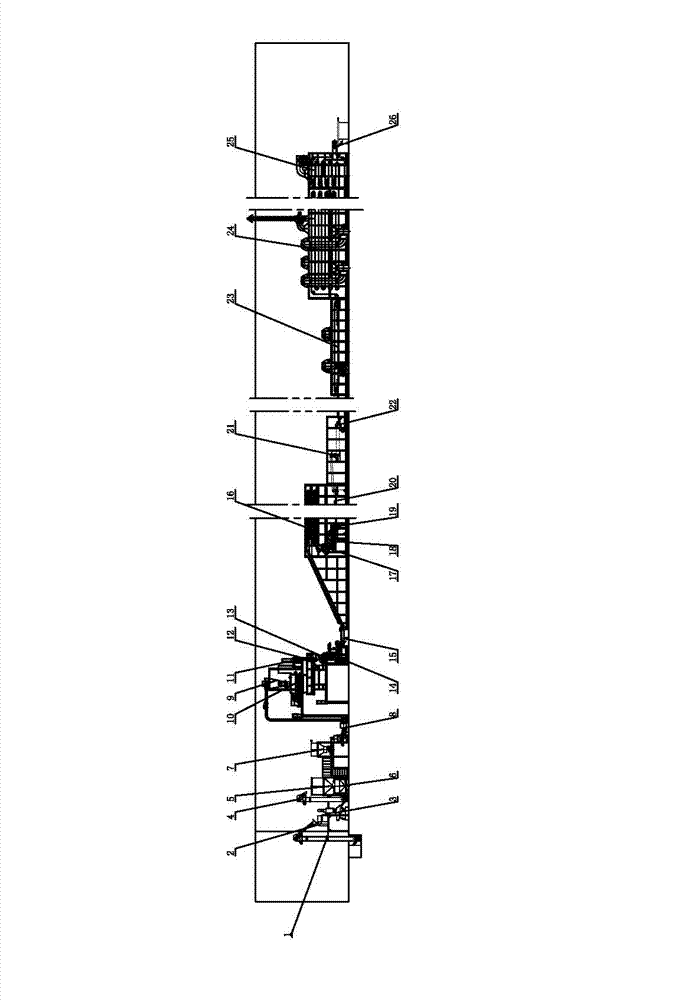

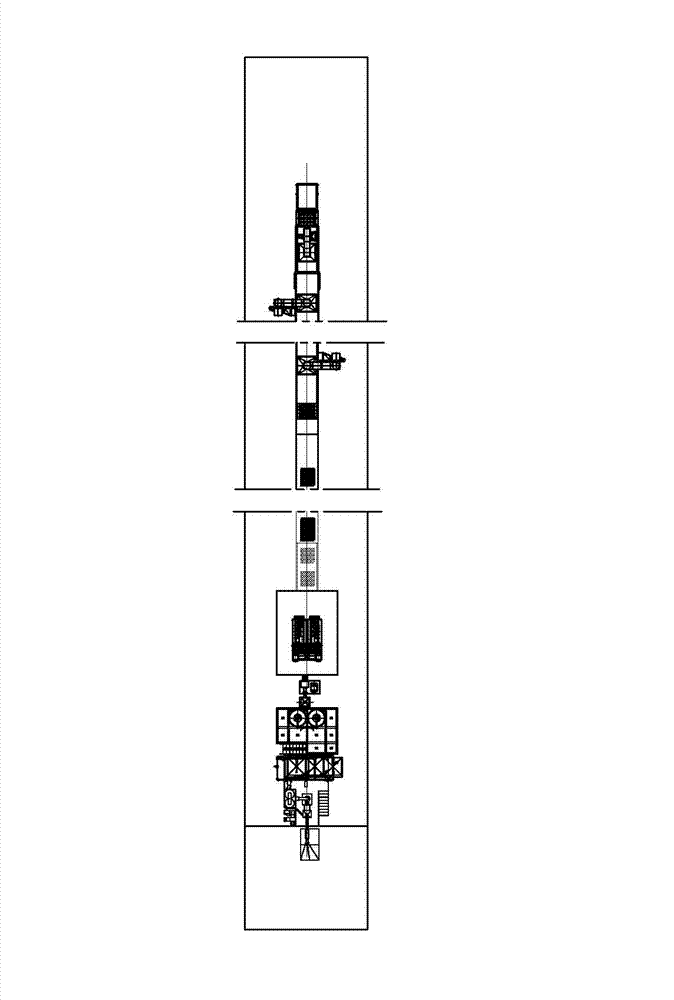

Rice noodle production line and rice noodle production process

The invention discloses a rice noodle production line and a rice noodle production process. The rice noodle production line comprises a first rice elevator, a rice polisher, a specific gravity sand remover, a second rice elevator, a rice storage tank, a jet rice washer, a water-rice separator, a rice grinder, a dry powder pneumatic conveyor, a powder mixer, a quantitative water adding barrel, a dough aging conveyor, a dough feeder, a continuous dough cooking device, a swing dough separator, a dough body aging machine, a dough body crumbler, an automatic curing machine, a noodle extruder, a noodle aging machine, a quantitative cutter, a folding forming machine, a predrying shaping machine, a drying machine, an air cooler and a packaging conveyor. The rice noodle production process comprises making rice into dough, curing, conveying, crumbling, feeding, curing, separating the dough by swinging, aging dough bodies, crumbling the dough bodies, automatically curing, extruding noodles, aging the noodles, quantitatively cutting, forming by folding, predrying, shaping, drying, air cooling and packaging. The rice noodle production line and the rice noodle production process are simple and low in cost. The rice noodles produced is fine in quality and taste and high in puffing degree.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

Minimally invasive instrument set, devices and related methods

ActiveUS8535318B2Improve visualizationMaximum line-of-sight potentialSuture equipmentsSurgical furnitureDrive shaftIliac screw

A minimally invasive system includes a bone screw and a tissue retractor having distal and proximal end portions and a partial pathway therebetween. The tissue retractor is removably couplable to the bone screw. An instrument has distal and proximal end portions and a hollow cavity and is removably couplable to the tissue retractor. A drive shaft has a diameter less than a diameter of the hollow cavity and is rotatable with respect to the instrument. A counter-torque handle has gripping and an interlock end portions with an instrument interface releasably positioned within the hollow cavity at the proximal end portion thereof and rotatably fixed thereto in an assembled configuration. The interlock end portion also includes an open-ended slot having a width greater than the drive shaft diameter such that the counter-torque handle is movable to and from the assembled configuration while the drive shaft is within the hollow cavity.

Owner:DEPUY SYNTHES PROD INC

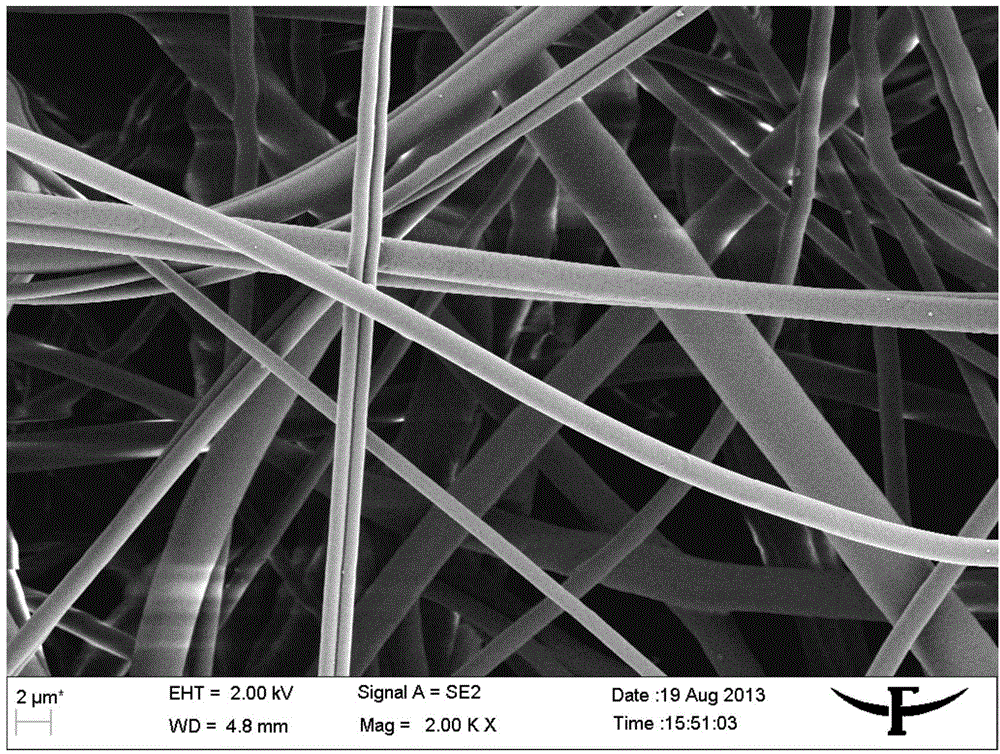

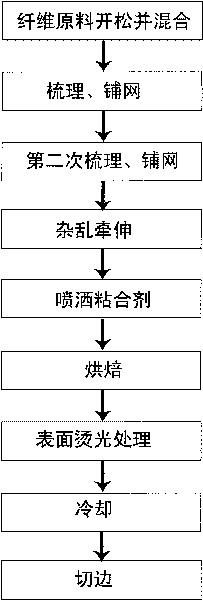

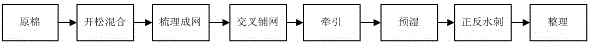

Insulation flocculus and manufacture method thereof

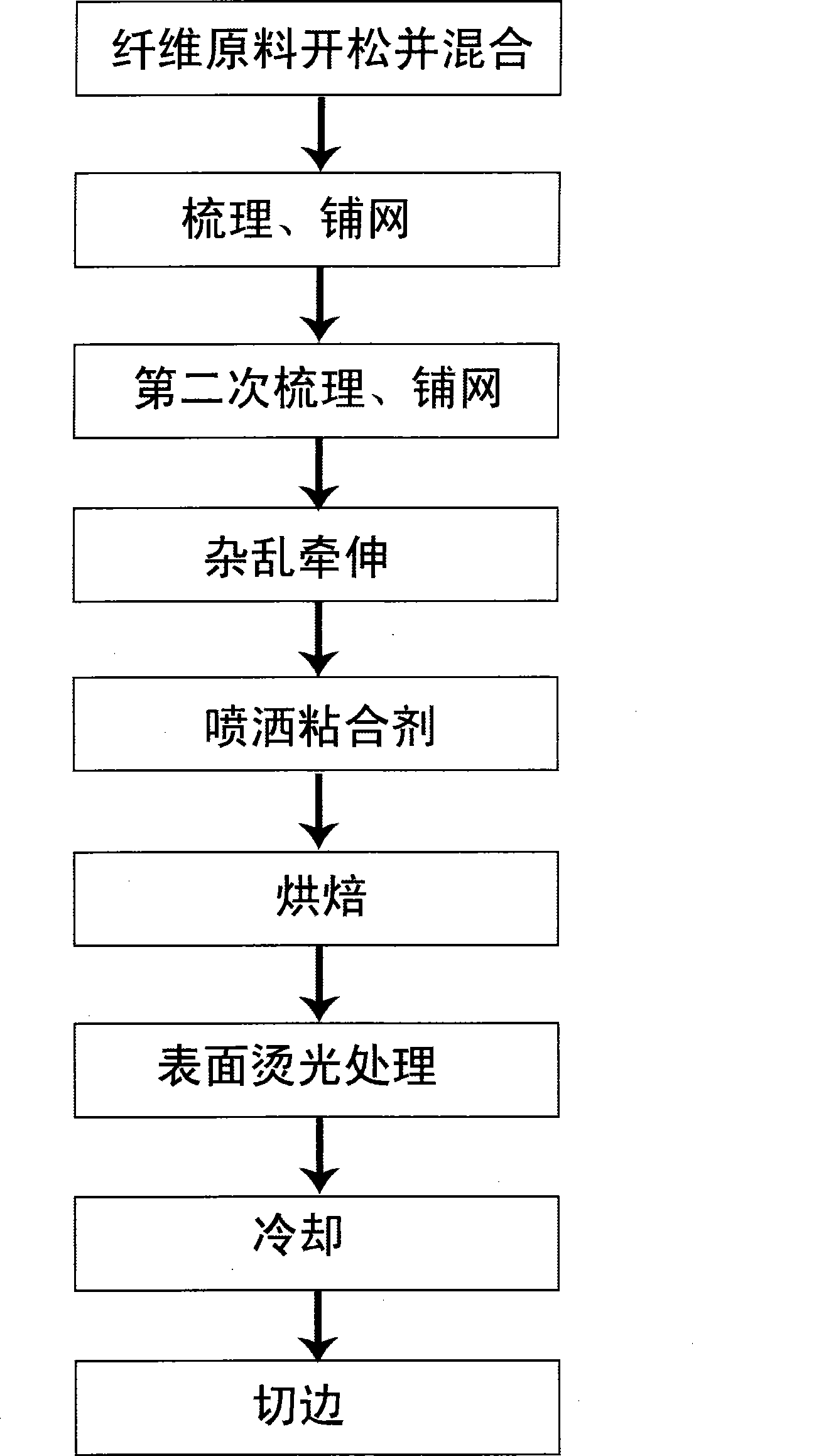

InactiveCN101718024AReduce conductionReduce convectionNon-woven fabricsAdhesivesCross ventilationRaw material

The invention relates to insulation flocculus which is made by 20-80 percent by weight of superfine denier fiber, 10-70 percent by weight of fine denier fiber, 5-30 wt% of tacky fiber and 0-5 wt% of bond. The insulation flocculus is made by adopting the following steps of: loosening and mixing the fiber raw materials; carding and lapping to form a fiber web; carrying out disorder traction on the fiber web to enable the fiber web to form a solid meshy across structure; spraying the bond on the two faces of the fiber web; heating and baking the fiber web to enable the tacky fiber to bond the fiber around and to solidify the bond. In the invention, due to the adoption of the superfine denier fiber and the fine denier fiber, heat conduction can be effectively reduced, cross ventilation in the space can be prevented or reduced, and the insulation property of the insulation flocculus is improved. In addition, due to the adoption of the tacky fiber and the bond, the fill power and the compression resilience of the insulation flocculus can be improved, and the fill power and the compression resilience of the insulation flocculus are higher through disorder traction.

Owner:汕头市奥山服饰有限公司

Thermal protection flocculus and manufacturing method thereof

InactiveCN101481851AReduce conductionConduction block or decreaseNon-woven fabricsAdhesivesFiberSurface layer

The invention discloses a heat insulation flocculus which is made from the following fiber: 10-64wt / % of fine denier fiber and / or superfine denier fiber, 31-80wt / % of hollow fiber and 5-30wt / % of tacky fiber. The heat insulation flocculus is manufactured by the following method: shredding and mixing various fiber raw materials; carding and spreading webs to form a fiber web; then performing random drafting on the fiber web to cause the fiber web to form a 3D network crossed structure; heating and baking the fiber web to cause at least the surface layer of the tacky fiber to be melted, and binding the surrounding fiber of the fiber web. The use of the fine denier fiber greatly increases the content of still air in the heat insulation flocculus, reduces heat conduction, can divide the space in the heat insulation flocculus into smaller spaces, and prevents or reduces air convection, thus improving the heat insulation performance of the insulation flocculus; the hollow fiber can improve bulkiness and compression resilience of the heat insulation flocculus; and the random drafting causes the bulkiness and the compression resilience of the heat insulation flocculus to be higher.

Owner:汕头市奥山服饰有限公司

Method for preparing cotton-like fabric through alkali decrement

InactiveCN102433729AThe texture of the cloth surface is dense and smoothSofter and fluffier than ultra cottonFibre typesFiberThermal insulation

The invention discloses a method for preparing cotton-like fabric through alkali decrement. The method comprises the steps of: a. first conducting unwinding treatment to polyester grey fabric, then carrying out sanding treatment; b. performing high temperature alkali decrement treatment in a high-temperature high-pressure overflow dyeing machine; c. dyeing and bleaching the treated fabric; d. carrying out shaping treatment to the dyed fabric for stabilizing the dimension; e. examining and packing a finished product. The high temperature alkali decrement technology consists of: with 10-15g / L of sodium hydroxide and 1g / L of a detergent, controlling the bath ratio at 1:15, first raising the temperature to 120-130DEG C at a speed of 2-5DEG C / min, conducting thermal insulation for 20-30min, then lowering the temperature to 50-80DEG C at a speed of 2-4DEG C / min, carrying out thermal insulation for 30-60min, and then lowering the temperature to normal temperature at a speed of 0.5-2.5DEG C / min. The fabric prepared by the method of the invention has the advantages that: 1. the fabric surface has dense and flat lines, the handfeel is soft and fluffy and surpasses cotton; 2. fibers have a strong fluffy feel, the luster is gentle, and the fabric surface can generates diffuse reflection to light and has gentle luster; 3. the fabric surface is smooth, has good permeability, and can improve chemical fibers, static resistance and stuffy feeling; the product can compare favorably with cotton fabric in terms of performances, and has lower price.

Owner:潘润华

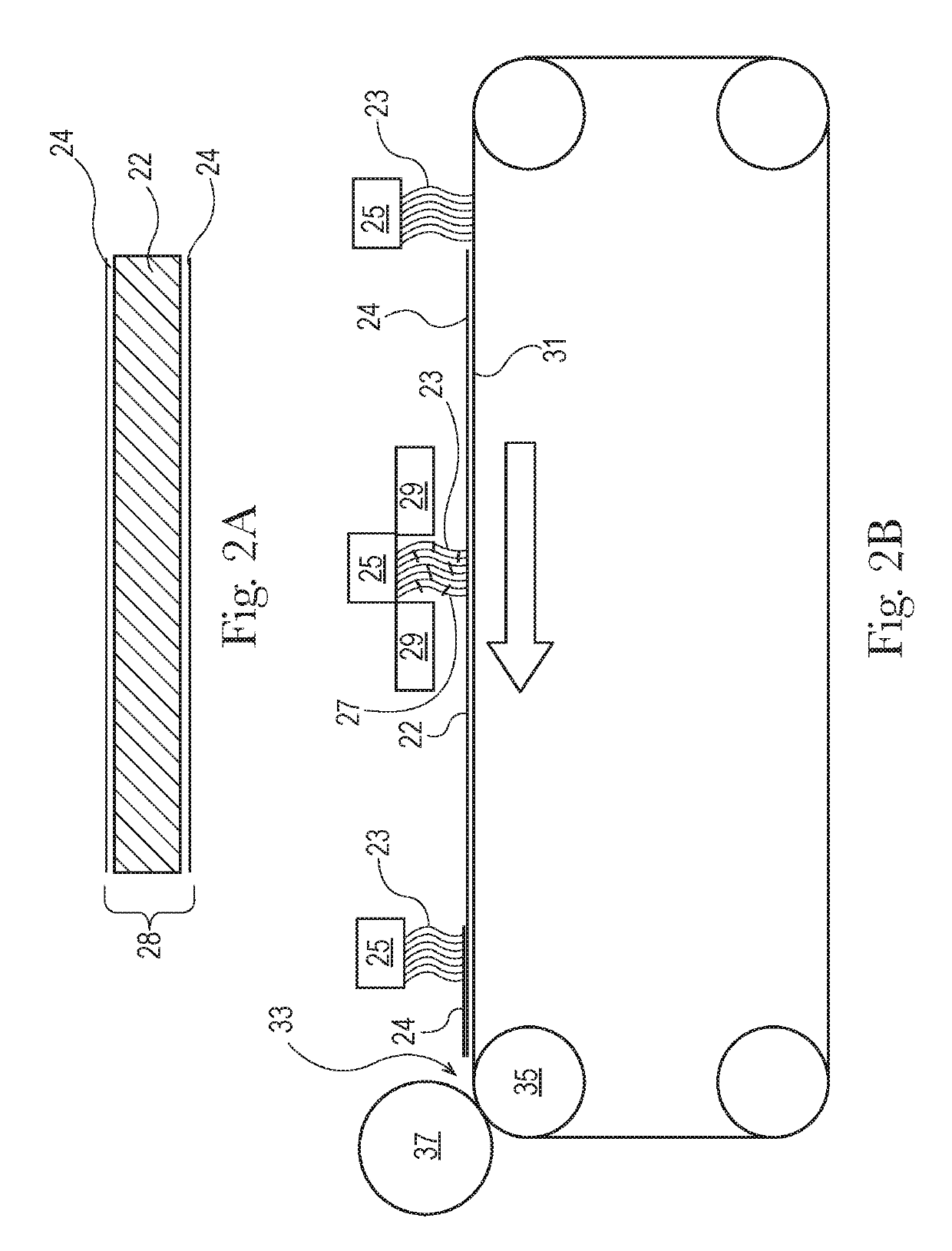

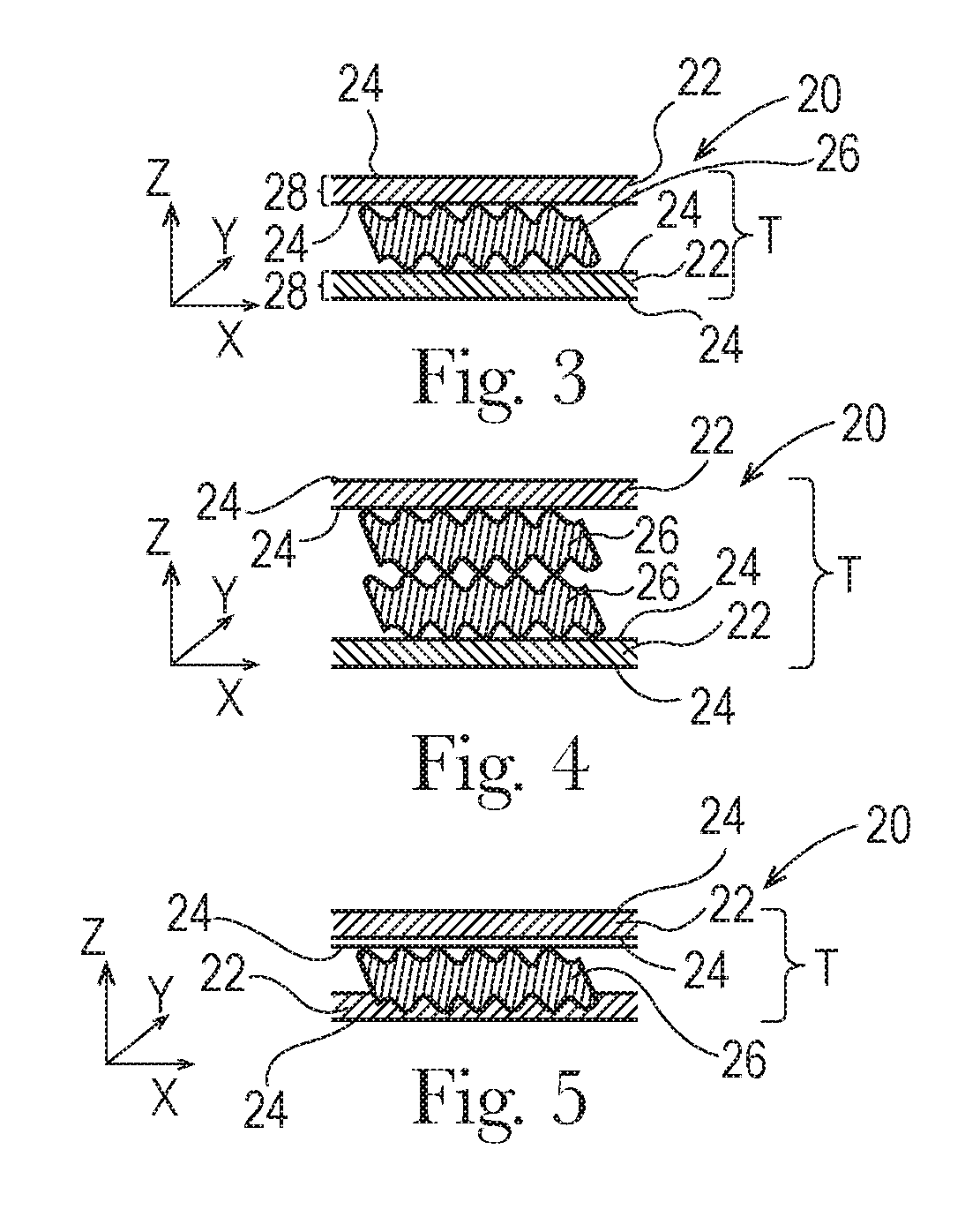

Fibrous Structure-Containing Articles that Exhibit Consumer Relevant Properties

ActiveUS20180105992A1Improve bulkImproved absorbent propertyMechanical working/deformationPersonal careFiberCellulose

Articles, such as sanitary tissue products, including fibrous structures, and more particularly articles including fibrous structures having a plurality of fibrous elements wherein the article exhibits differential cellulose content throughout the thickness of the article and methods for making same are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatus and method for degrading a web in the machine direction while preserving cross-machine direction strength

InactiveUS20050092195A1Reducing tensile ratioPrevent degradationNon-fibrous pulp additionNatural cellulose pulp/paperUltimate tensile strengthMechanical engineering

An embossing system is provided for embossing a web having a first embossing roll having embossing elements and a second embossing roll having embossing elements, wherein at least a portion of the embossing elements of the first and second embossing rolls are substantially oriented in the cross-machine direction. The embossing roll may be crowned, may have alignment means, and may be provided with precision gearing.

Owner:GPCP IP HLDG LLC

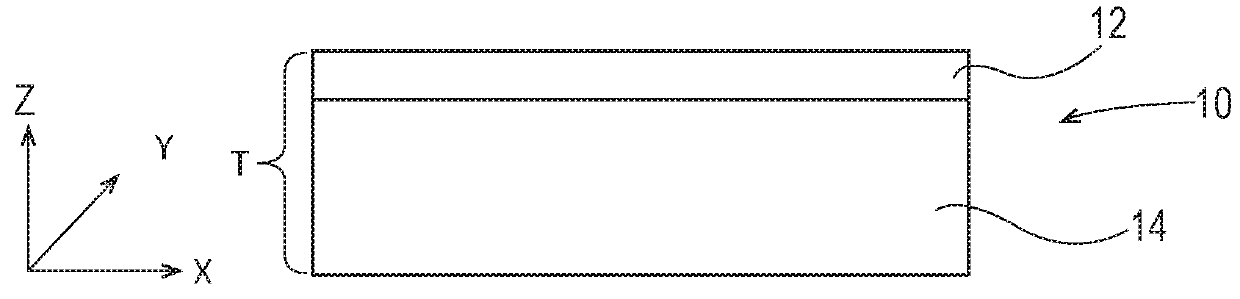

Fibrous structure-containing articles

ActiveUS10385515B2Improved bulk and absorbent propertyIncrease flexibilityMechanical working/deformationReinforcing agents additionFiberCellulose

Articles, such as sanitary tissue products, including fibrous structures, and more particularly articles including fibrous structures having a plurality of fibrous elements wherein the article exhibits differential cellulose content throughout the thickness of the article and methods for making same are provided.

Owner:THE PROCTER & GAMBLE COMPANY

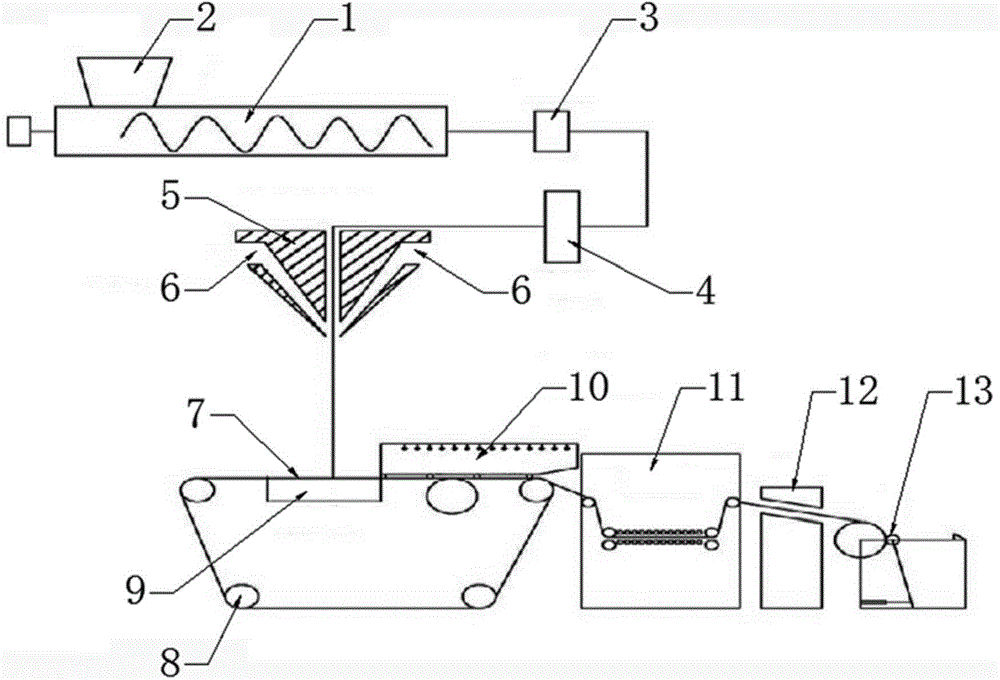

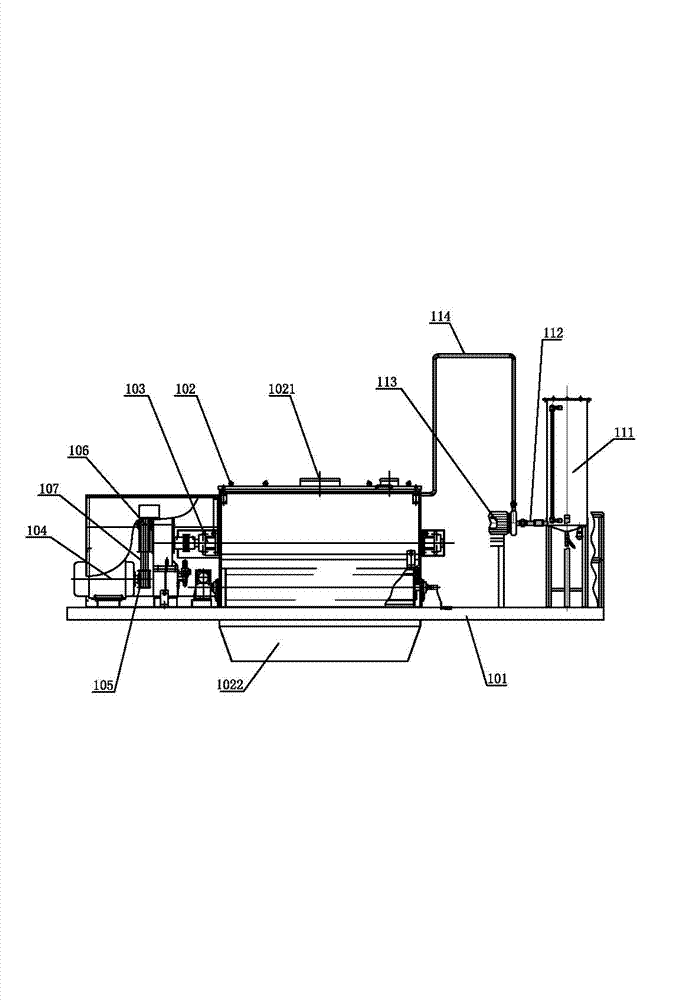

Melt-blown cloth and preparing system and preparing process thereof

ActiveCN111648041AHigh loft and air permeabilityReduce the receiving distanceSpinnerette packsSevering textilesPolypropyleneMicrofiber

The invention relates to melt-blown cloth and a preparing system and a preparing process thereof. The melt-blown cloth comprises the following components including, by weight, 75 parts of polypropylene resin, 35 parts of polyethylene terephthalate, 22 parts of titanium dioxide, 3 parts of a dispersing agent, 5 parts of a stabilizing agent and 3 parts of an auxiliary agent. The process comprises the following steps of 1, putting a raw material solution into a discharging device, and pressing the solution into a spray head assembly after the discharging device is started; 2, under the drafting action of two high-temperature airflow generators, forming superfine fibers by using the raw material solution sprayed out of the spray head assembly; 3, conducting bonding on the sprayed superfine fibers under the action of self-bonding, and forming the melt-blown cloth on a receiving device through cooling of two high-temperature airflow generators; 4, enabling the running receiving device to drive the melt-blown cloth to be conveyed leftwards and wound on a cloth winding roller; and 5, cutting the two ends of the melt-blown cloth by two edge cutting devices.

Owner:温州珍康医疗用品有限公司

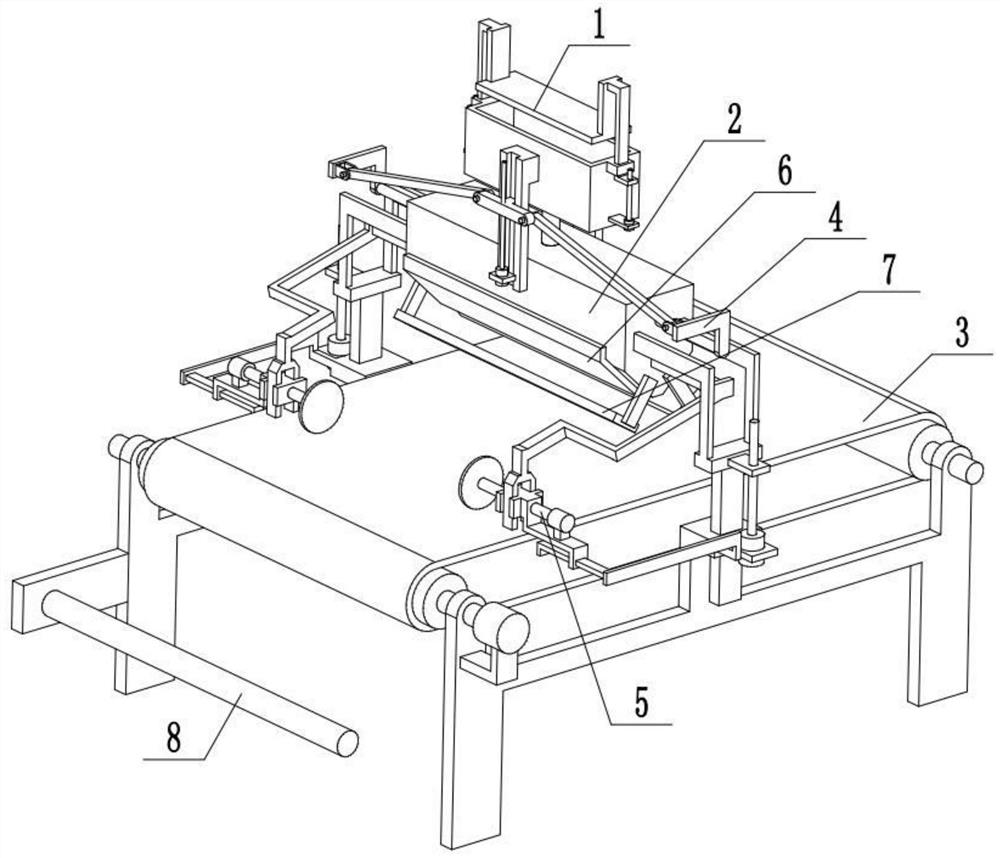

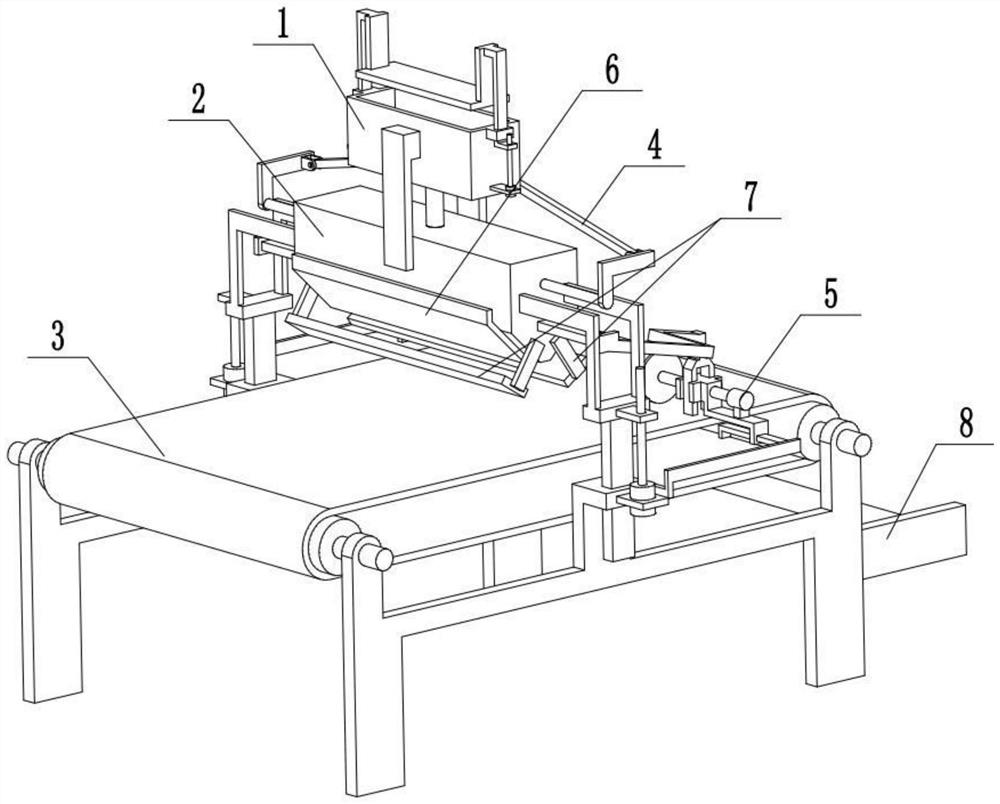

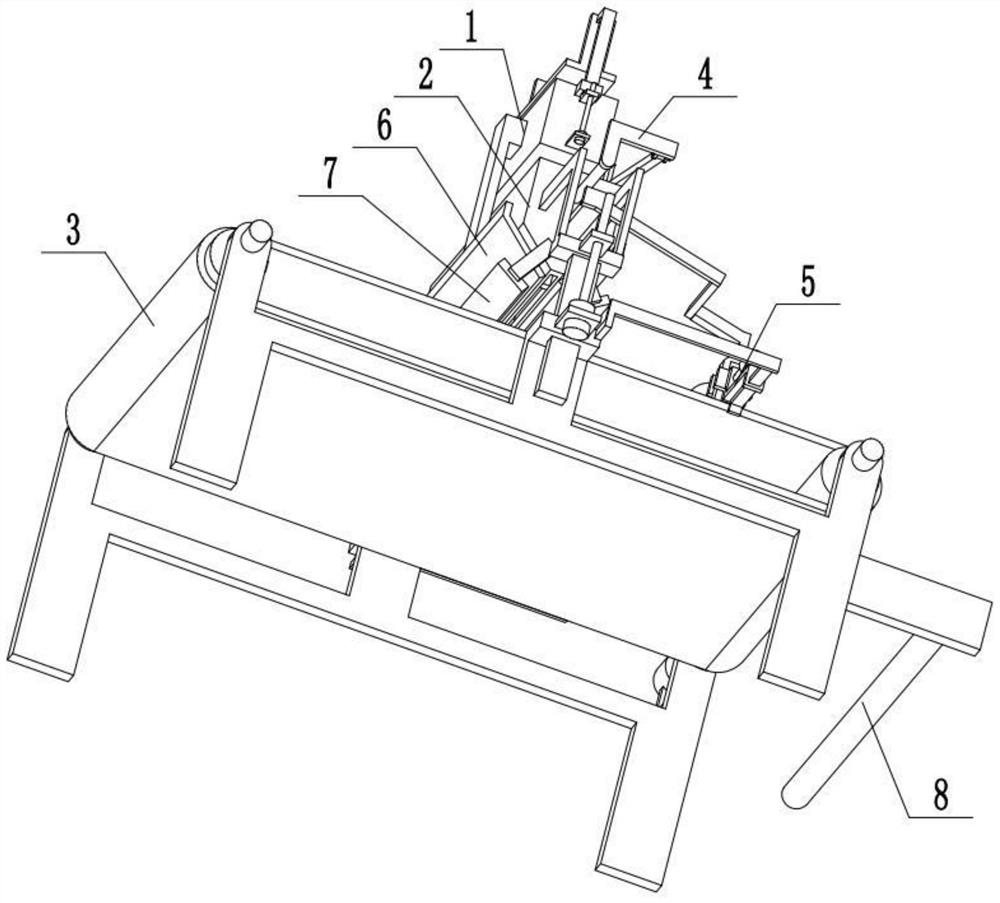

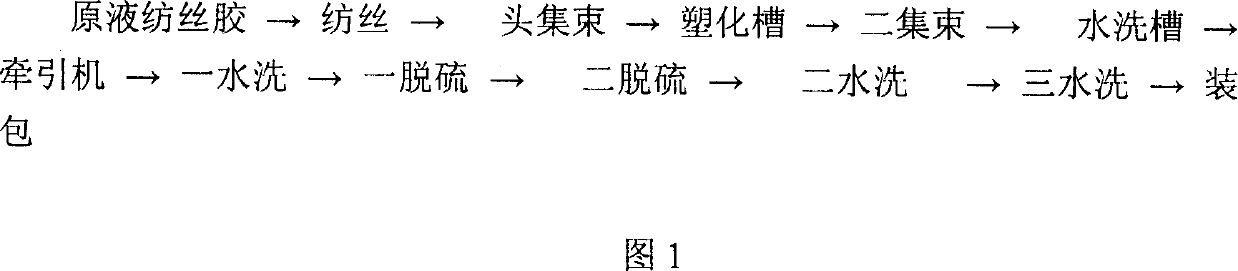

Degradable flat fibre bundle and its preparing process

InactiveCN1390990APromote environmental protectionEasy to degradeArtificial filaments from viscoseWet spinning methodsSulfonateCellulose

A flat fibre bundle is prepared from cotton pulp, wood pulp, or their mixture through alkalizing, sulfonating to obtain cellulose sulfonate as spinning dope, spinning by nozzle, bundling, plasticizing, drawing, washing in water, and desulfurizing. The coagulating bath for spinning contains sulfuric acid and zinc sulfate. Its advantages are large surface area and high looseness.

Owner:AOYANG SCI & TECH JIANGSU

Method for preparing down-proof fabric

InactiveCN102493075AFiber shrinkageFully contractedFibre typesHeating/cooling textile fabricsVolumetric Mass DensityEngineering

The invention discloses a method for preparing down-proof fabric, which comprises the steps of: a, unwinding gray fabric and then adsorbing furs of the gray fabric, wherein the gray fabric is fine denier filament; b, adding the treated gray fabric into an overflow dyeing machine, carrying out high-temperature reduction operation through programmed heating; c, dyeing the gray fabric in dyeing solution; d, putting the fabric in a setting machine for setting, and then drying the fabric, and adding wind-proof agent for setting; and e, calendaring, checking the fabric, and packaging. The method disclosed by the invention has the advantages that: 1, as polyster fibers contract sufficiently under the condition of high temperature, grains on the surface of the fabric are dense and smooth; 2, the fine denier filament are applied to reacting with the polyster fibers in a certain amount of alkali solution at a high temperature, thereby slightly corroding fiber layers on the surfaces of the fibers, increasing air permeability and reducing static generation probability of the fibers, improving bulkiness of the fibers, and enhancing the sense of puffing of the fibers; 3, by adjusting tissues of the fabric, density is increased and printing and dyeing processes are adjusted, in this way, eiderdowns and wools can be prevented from penetrating down from the fabric; and 4, the fabric is excellent in performance and low in price.

Owner:GUANGDONG SI HAI WEI YE TEXTILE TECH

Nonwoven fabric for a female component of a fastening system

InactiveUS20080208157A1High bonding strengthHigh mechanical strengthLayered productsAbsorbent padsEngineeringNonwoven fabric

A fastening system includes an engaging component and a receiving component. The engaging component has a plurality of engaging elements capable of engaging the receiving component. The receiving component includes a nonwoven fabric having composite fibers, an embossed section, and a non-embossed section. The composite fibers are bonded together in the embossed sections. The composite fibers include a first propylene polymer and a second propylene polymer, wherein the first and second propylene polymers extend continually in a longitudinal direction and are arranged such that the second propylene polymer is associated with the first propylene polymer such that the composite fiber forms a crimp therein. The embossed sections have a plurality of zigzag unit patterns arranged in a machine direction which have a ratio of W1 / W2 in the range of about 0.5 to about 2.0.

Owner:THE PROCTER & GAMBLE COMPANY

Heat bonding non-woven fabric and preparation method thereof

The invention relates to the technical field of non-woven fabric production, and provides a heat bonding non-woven fabric and a preparation method thereof. The heat bonding non-woven fabric comprises 60 percent by weight of thermoplastic fibers; the surface of the heat bonding non-woven fabric is provided with bumps; the gram weight is 25-35 g / m<2>, the integrated softness is less than or equal to 55 nN, the water absorption is more than or equal to 600%, and the liquid penetrability is less than or equal to 3 s. The heat bonding non-woven fabric provided by the invention has the advantages of simple production process, less energy consumption, high softness and fluffy degree and difficult product surface deformation, namely, the heat bonding non-woven fabric is good in hand feeling and more comfortable to use.

Owner:WEIFANG ZHIHE NON WOVEN CO LTD

Multi-Ply Fibrous Structure-Containing Articles

ActiveUS20190061302A1Improve bulkImproved absorbent propertyMechanical working/deformationPersonal careFiberPolymer science

Articles, for example multi-ply fibrous structure-containing articles such as multi-ply sanitary tissue products, containing two or more fibrous structure plies, wherein at least one of the fibrous structure plies is embossed and is bonded to at least one other fibrous structure ply by a water-resistant bond such that void volume is created between the bonded fibrous structure plies.

Owner:THE PROCTER & GAMBLE COMPANY

Fibrous Structure-Containing Articles that Exhibit Consumer Relevant Properties

ActiveUS20180105991A1Improved bulk and absorbent propertyIncrease flexibilityMechanical working/deformationFilament/thread formingFiberCellulose

Articles, such as sanitary tissue products, including fibrous structures, and more particularly articles including fibrous structures having a plurality of fibrous elements wherein the article exhibits differential cellulose content throughout the thickness of the article and methods for making same are provided.

Owner:THE PROCTER & GAMBLE COMPANY

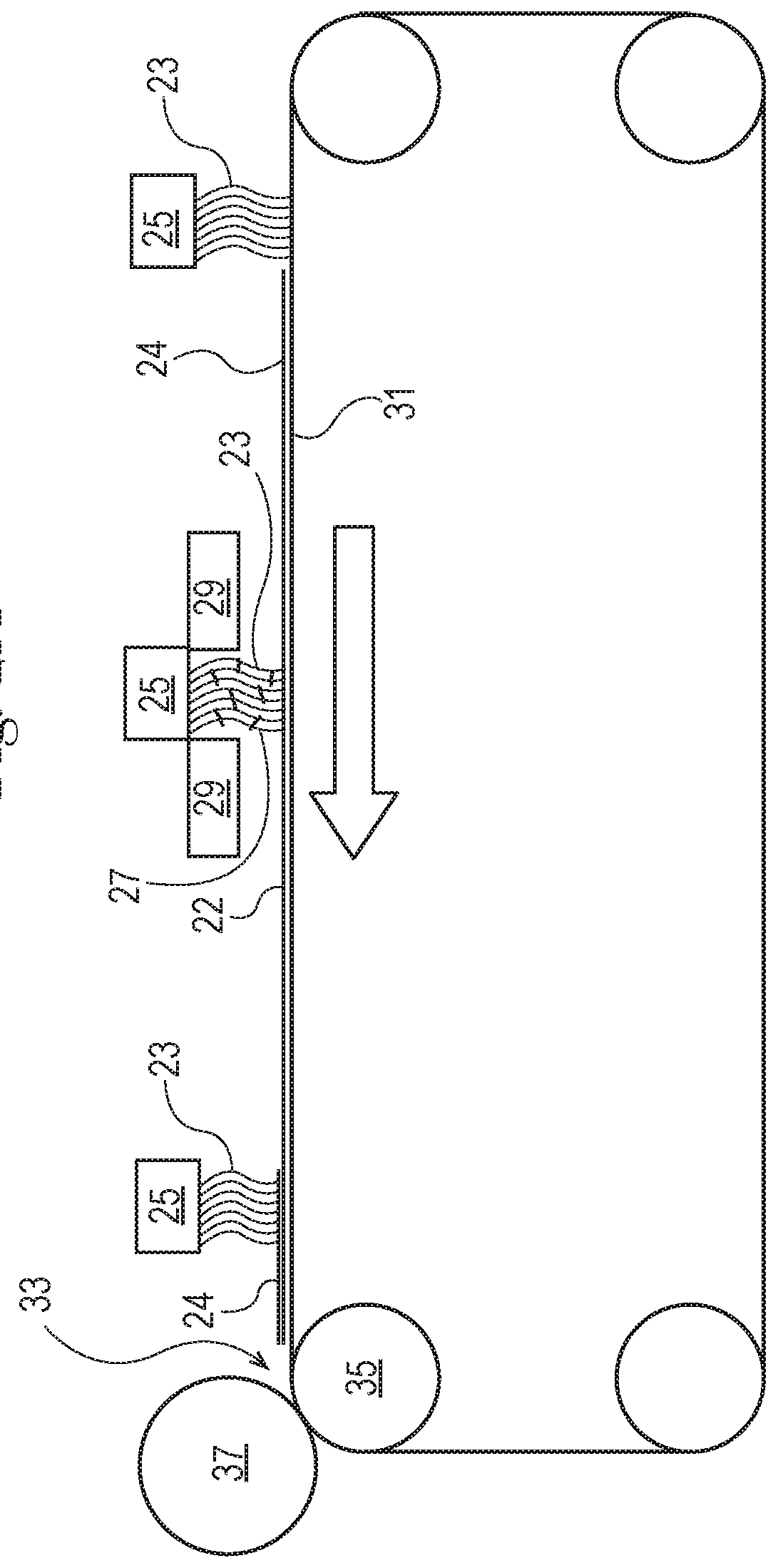

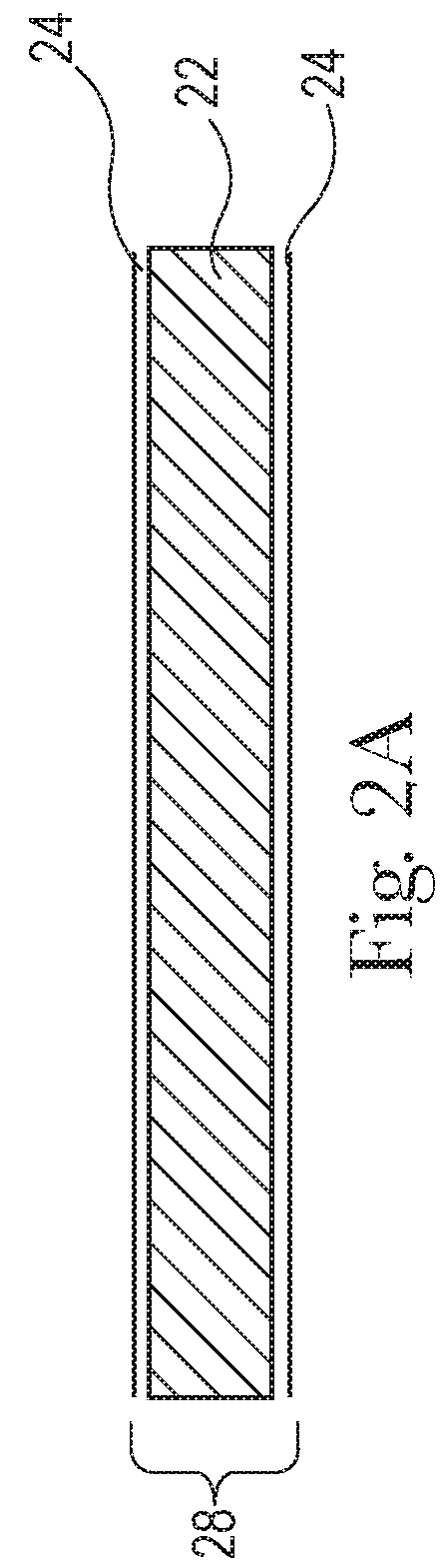

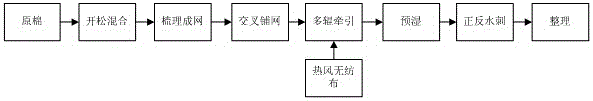

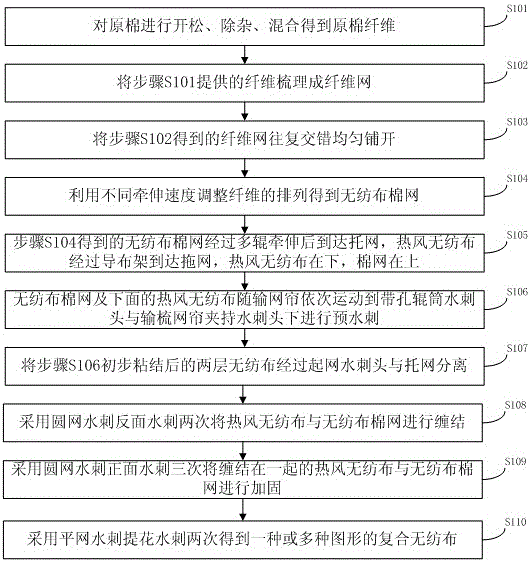

Compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric and production system thereof

ActiveCN106393945AComposite process advantagesRemove the phenomenon of bleedingLamination ancillary operationsLaminationPulp and paper industryNonwoven fabric

The invention discloses a compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric, and belongs to the technical field of nonwoven fabric production. The method comprises the following steps: taking hot air through nonwoven fabric as the bottom layer, laminating a nonwoven fabric-cotton mesh on the hot air through fabric, and carrying out pre-wetting and front-back spunlace laminating to obtain the product. According to the method, a spunlace method is used to replace chemical adhering to compound chemical fiber nonwoven fabric and all cotton spunlace nonwoven fabric; the advantages of all cotton nonwoven fabric such as softness, water absorbing property, breathability, and the like, are preserved, at the same time, the advantages of hot air through nonwoven fabric such as high filling power, good elasticity, soft hand feeling, strong warm keeping performance, air penetrating and water penetrating performance, and the like are also preserved; moreover, the glue leakage is prevented, and the peeling strength meets the requirement.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

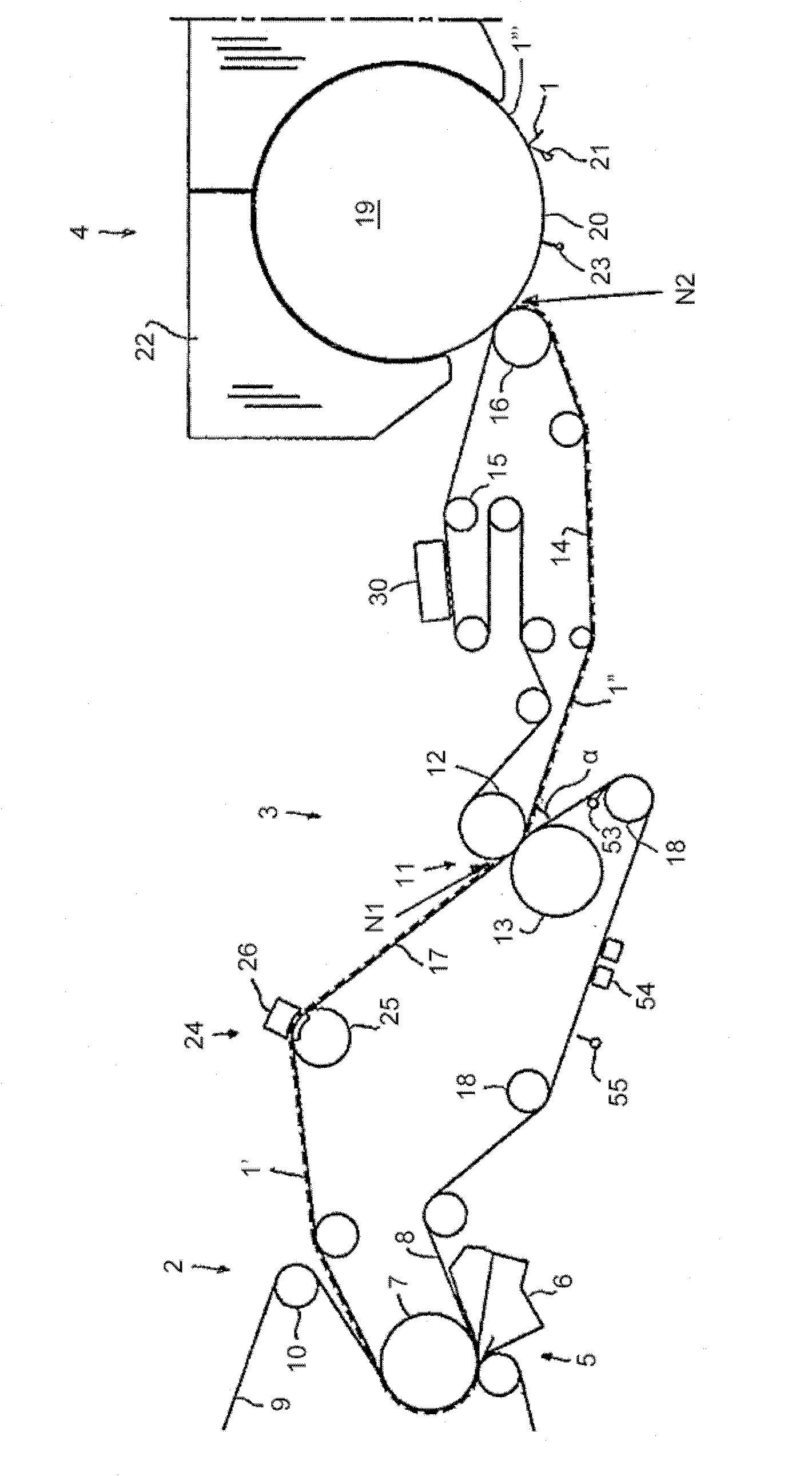

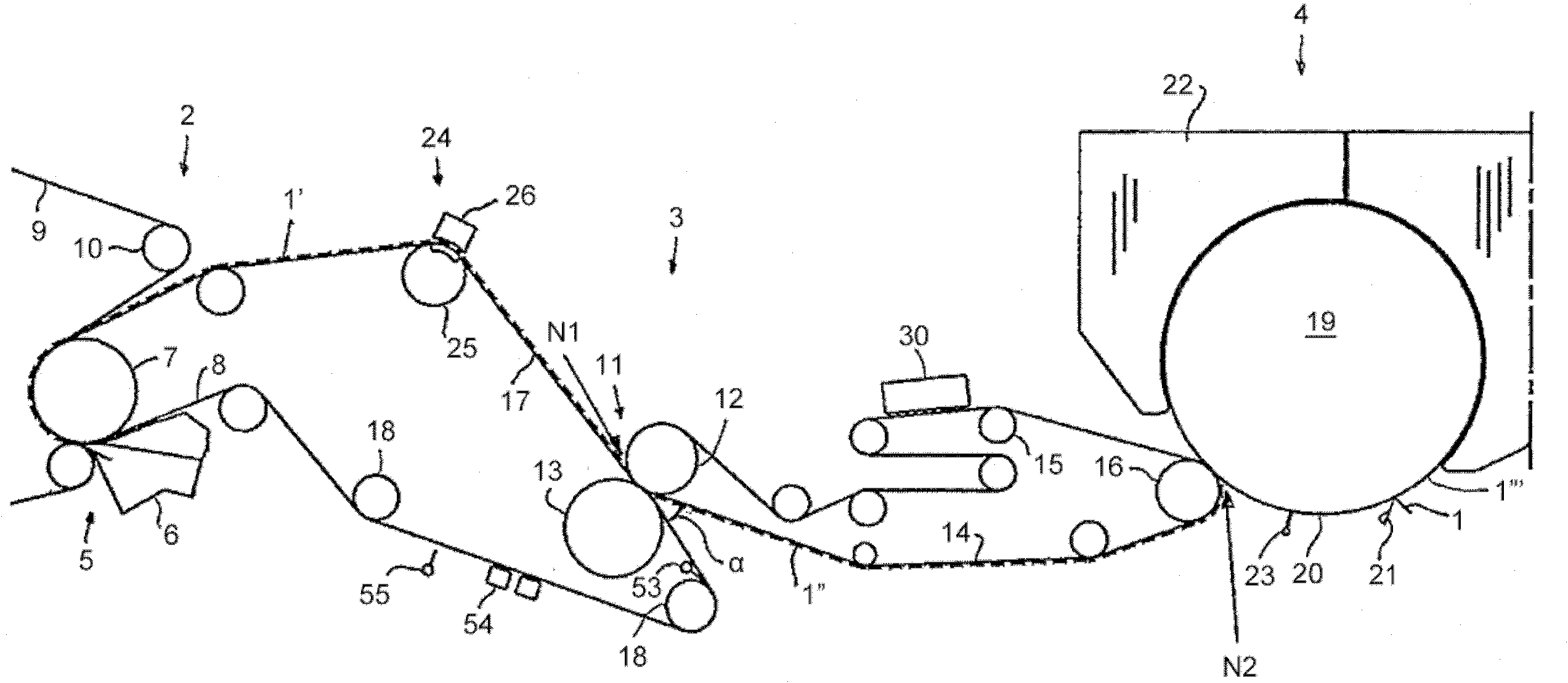

A tissue papermaking machine and a method of manufacturing a tissue paper web

ActiveCN102159767AImprove bulkGood flexibilityMachine wet endPress sectionFiberIndustrial engineering

A tissue papermaking machine is described, comprising a wet section (2) and a press section (3) comprising a single press (11) with first and second press elements (12, 13) forming a press nip (N1), and with a press felt (17) running through the press nip in contact with the formed fibre web (1'), whereby the second press element is arranged inside the loop of the press felt, and a smooth belt (14) runs through the press nip in contact with the formed fibre web, whereby the first press element is arranged inside the loop of the belt, and a transfer roll (16) arranged inside the loop of the belt forming a transfer nip (N2) with a drying surface (20), whereby the smooth belt carries the fibre web between the press nip and the transfer nip. Furthermore, the machine has a dry section (4) for final drying of the fibre web (1''). According to the invention, a pre-dewatering device (25) is arranged upstream of the press to dewater the fibre web to a dry content of 15-30%, before the fibre web runs into the press nip, and the press felt and the smooth belt, which is impermeable to water, are arranged to be separate from each other immediately after the exit of the press nip and define there between an angle a, which is at least 5 DEG , to prevent rewetting of the fibre web. The invention also relates to a method of manufacturing a tissue paper web therein and a method of lowering the energy requirement therein.

Owner:VALMET OY

Method for making low basis weight manila board from wood fiber

The invention relates to the technical field of papermaking, in particular to a method for making a low basis weight manila board from wood fiber. The method comprises the steps of: A. dissolution, i.e. dispersing wood fiber and conducting dissolution treatment to obtain a wood fiber slurry; B. beating, i.e. conducting beating treatment on the wood fiber slurry subjected to dissolution treatment; C. coarse screening, i.e. conducting coarse screening treatment on the wood fiber slurry subjected to beating treatment; D. purification, i.e. mixing the wood fiber slurry subjected to coarse screening treatment with an MW slurry, then carrying out fine screening, slag removal, concentration and heat dispersion treatment, thus obtaining a core layer slurry for making coated white board paper; E. papermaking, i.e. processing a surface layer slurry, a lining slurry, a bottom slurry and the core layer slurry prepared by step D to obtain the low basis weight manila board. The method provided by the invention can effectively improve the bulkness of finished paper, reduces the paper basis weight exceeding problem, at the same time avoids the penetration point problem of thick and large wood fiber in finished paper, and greatly reduces the production cost.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Superfine glass fiber cotton felt for photocatalytic air purification and preparation method thereof

ActiveCN111892330AImprove filtration efficiencySmall filter resistanceGlass making apparatusDispersed particle separationGlass fiberNanoparticle

The invention relates to a superfine glass fiber cotton felt for photocatalytic air purification and a preparation method thereof, and belongs to the technical field of functional composite materials.The superfine glass fiber cotton felt consists of the following components in percentage by mass: 83 to 92 weight percent of superfine glass fiber, 6 to 8 weight percent of photocatalytic nanoscale particles and 1 to 3 weight percent of bonding system. The invention also relates to a preparation method of the superfine glass fiber cotton felt for photocatalytic air purification. The preparation method comprises the following steps: uniformly atomizing and spraying turbid liquid containing photocatalytic nanoparticles and a bonding system on the surface of the superfine glass fiber prepared bya flame blowing method, and drying to obtain the superfine glass fiber cotton felt for photocatalytic air purification. Compared with a traditional glass fiber filter cotton felt, the superfine glassfiber cotton felt for photocatalytic air purification has the advantages that the function of eliminating bacteria and volatile organic compounds (TVOC) in air is added, the superfine glass fiber cotton felt is rapidly decomposed under visible light, the filtering efficiency is higher, the filtering resistance is lower, and the machining strength is better.

Owner:CHONGQING UNIV OF ARTS & SCI

Photosensitive lithographic printing plate

InactiveUS20060263720A1Improve bulkAvoid it happening againPhotosensitive materialsPhotomechanical apparatusCarbon numberPolymer science

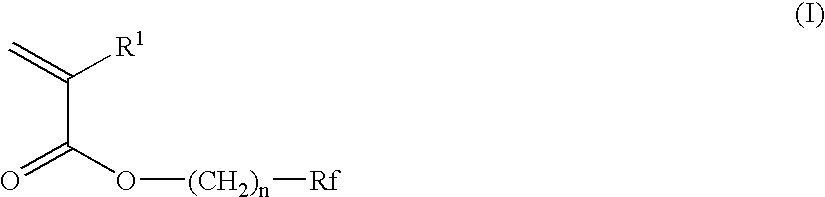

A photosensitive lithographic printing plate comprising: a support; and a polymerizable photosensitive layer that comprises: an addition-polymerizable compound having an ethylenically unsaturated double bond; a polymerization initiator; and a polymer compound having (a) a monomer represented by formula (I) and (b) a monomer represented by formula (II) as copolymerization component: wherein Rf represents a substituent containing a fluoroalkyl or perfluoroalkyl group having 9 or more fluorine atoms; n represents 1 or 2; and R1 represents a hydrogen atom or a methyl group; wherein R21 represents a hydrogen atom or a methyl group; R22 represents a divalent hydrocarbon group having a carbon number of 3 to 30 and having an aliphatic cyclic structure; A represents an oxygen atom or —NR23—; and R23 represents a hydrogen atom or a monovalent hydrocarbon group having a carbon number of 1 to 10.

Owner:FUJIFILM HLDG CORP +1

Pre-embedded bag for multi-stage remediation of uranium-contaminated soil and use method thereof

ActiveCN110369481AHigh organic contentImprove fertilityContaminated soil reclamationOrganic fertilisersEngineeringContamination

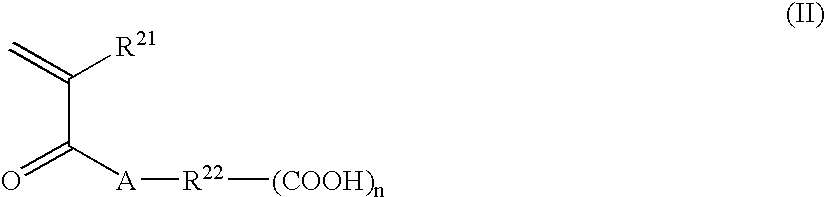

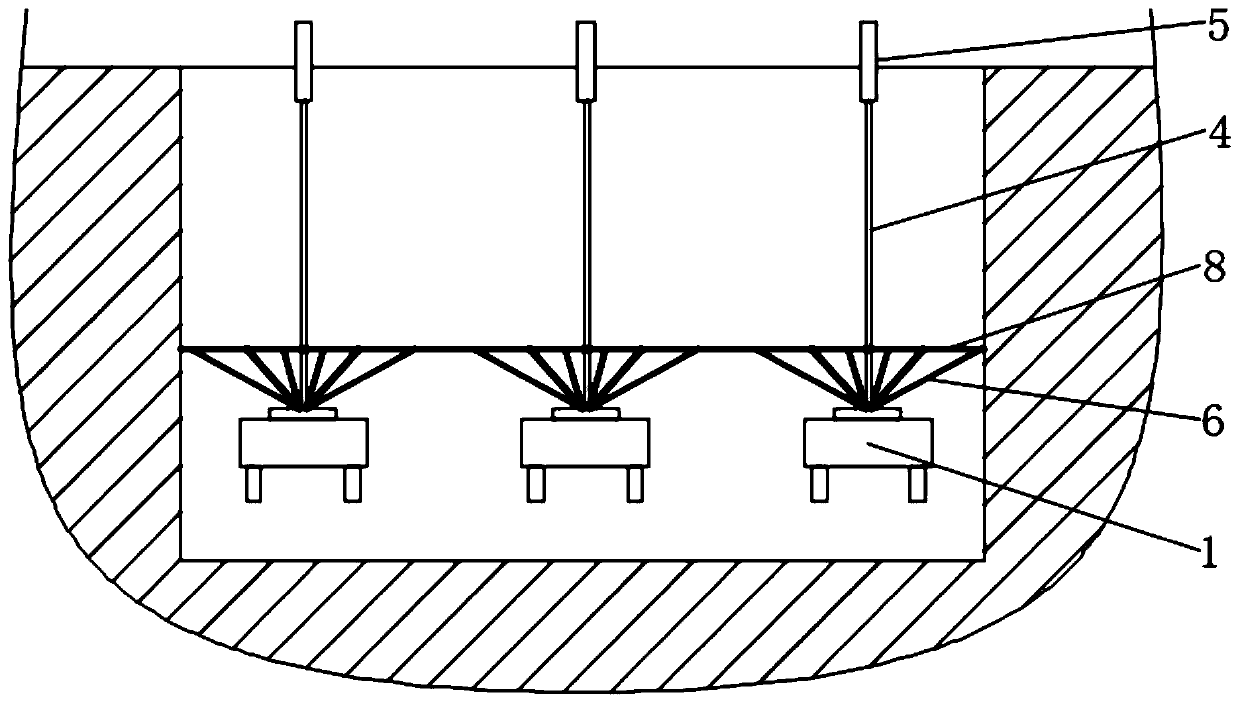

The invention discloses a pre-embedded bag for multi-stage remediation of uranium-contaminated soil and a use method thereof, and belongs to the technical field of uranium-contaminated soil remediation. The pre-embedded bag for multi-stage remediation of uranium-contaminated soil can be pre-embedded by a soil cleaning and per-embedding manner, on the one hand, uranyl ions in the soil are transferred through a strict water-conducting network, a large amount of uranyl ions are actively and quickly collected into the pre-embedded bag to facilitate fixed-point remediation, on the other hand, a special soil remediation agent is used to greatly improve adsorption and accumulation for uranyl ions, agglomeration of uranyl ions is improved based on nano porous properties, and uranyl ions are filledin micro-pores to avoid contamination and diffusion. After the active primary remediation, uranyl ions in the uranium-contaminated soil are reduced to a certain value, then natural secondary remediation, namely heavy metal uranium enrichment plant remediation, is followed, the soil organic matter content and soil fertility are increased, a soil surface structure is improved and maintained, and asolid foundation for direct use of the soil after uranium pollution remediation is laid.

Owner:绍兴市上虞区武汉理工大学高等研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com