Rice noodle production line and rice noodle production process

A production line and rice noodle technology, applied in applications, food preparation, food science, etc., can solve the problems of difficult control of self-cooking extruder, increased production cost, low production efficiency, etc., to facilitate transportation and cooking, and improve production Efficiency, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

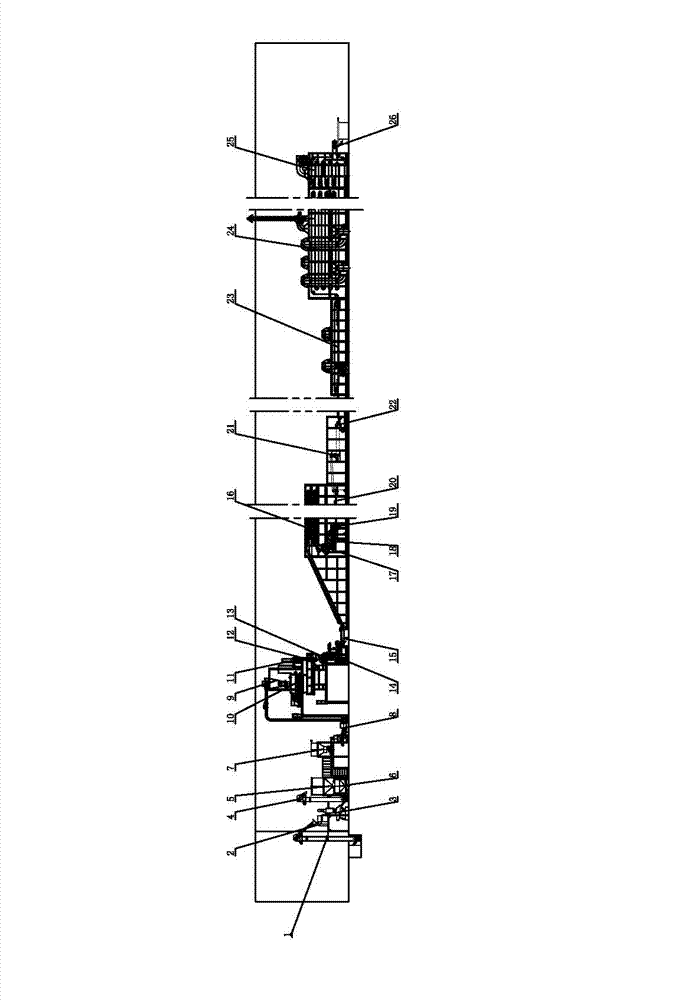

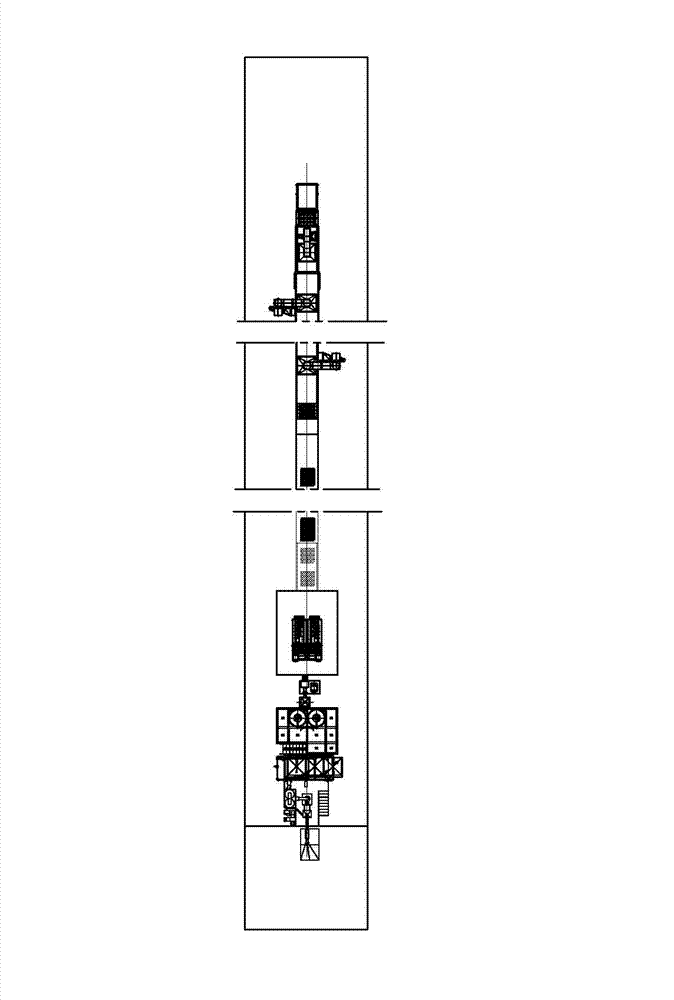

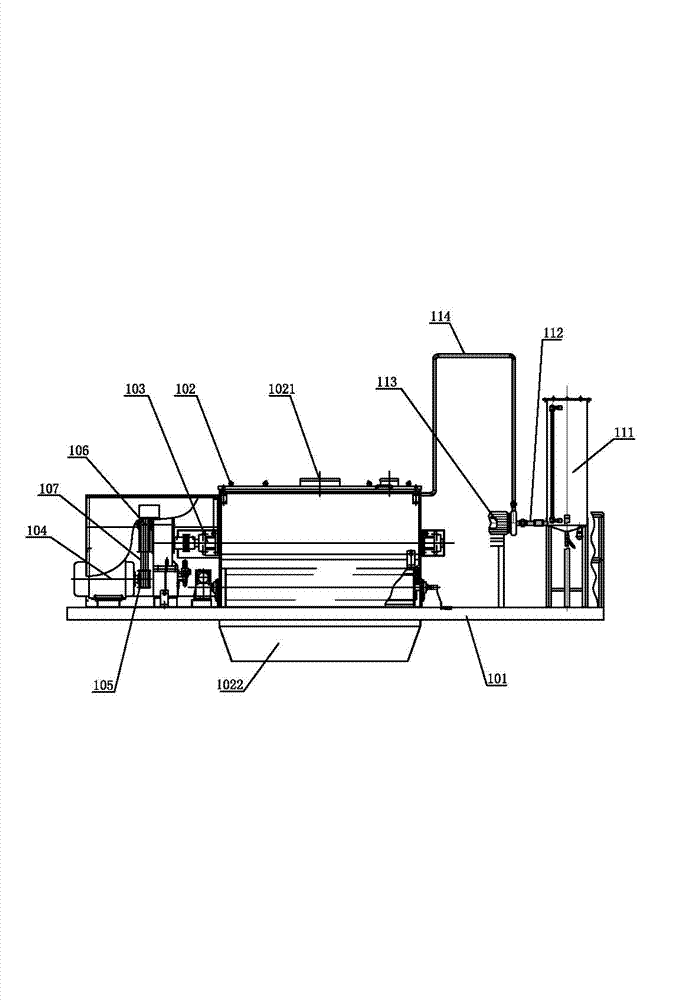

[0038] Such as figure 1 and figure 2As shown, the rice noodle production line includes the first rice hoist 1, rice polishing machine 2, specific gravity desander 3, second rice hoist 4, rice storage tank 5, jet rice washing machine 6, and water rice separator 7 according to material transmission , Rice Grinder 8, Dry Powder Air Conveyor 9, Powder Blender 10, Quantitative Water Adding Bucket 11, Dough Aging Conveyor 12, Dough Feeder 13, Dough Continuous Cooking Equipment 14, Swing Powder Loose Machine 15, Powder Aging machine 16, powder crushing machine 17, self-cooking machine 18, wire extrusion machine 19, vermicelli aging machine 20, quantitative cutting machine 21, folding forming machine 22, pre-drying and setting machine 23, dryer 24, air cooling machine 25 and packaging conveyor 26. Among them, the first rice elevator 1, ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com