Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Aging achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Face aging method based on a conditional generative adversarial network

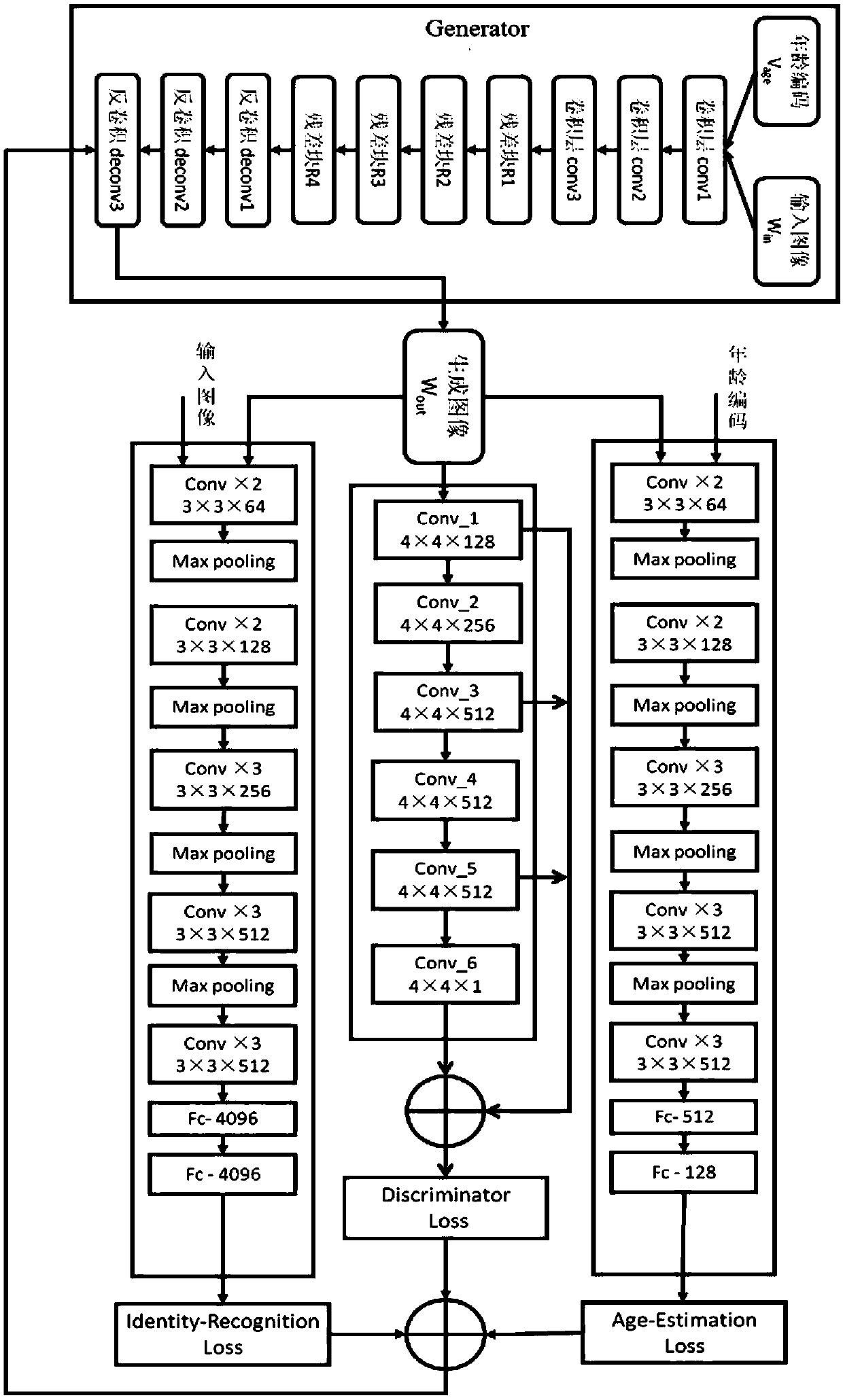

ActiveCN109523463AAging achievedHigh resolutionGeometric image transformationNeural architecturesPattern recognitionIdentity recognition

The invention provides a face automatic aging mechanism based on a conditional generative adversarial network. A conditional generative adversarial network consisting of four parts is obtained by training a large number of images of different age groups marked with ages, and the conditional generative adversarial network comprises an image generator G, an image discriminator D, an age estimation network AEN and an identity recognition network FRN. Wherein G is trained to generate an aged image, and the aged image is automatically and effectively generated by inputting the young image and a preset age condition. And D, identifying whether the generated old image is a real image or not, and ensuring that the generated old image has deception. Wherein the AEN is used for reducing the difference between the age of the generated image and a preset value, and the FRN is used for ensuring the consistency of portrait identities in the generation process. Through the design of the network structure, end-to-end training of the whole network is achieved, face aging is well shown, and high-quality face aging images with the advantages of identity consistency, high cheating performance, high resolution and the like can be generated.

Owner:SUN YAT SEN UNIV

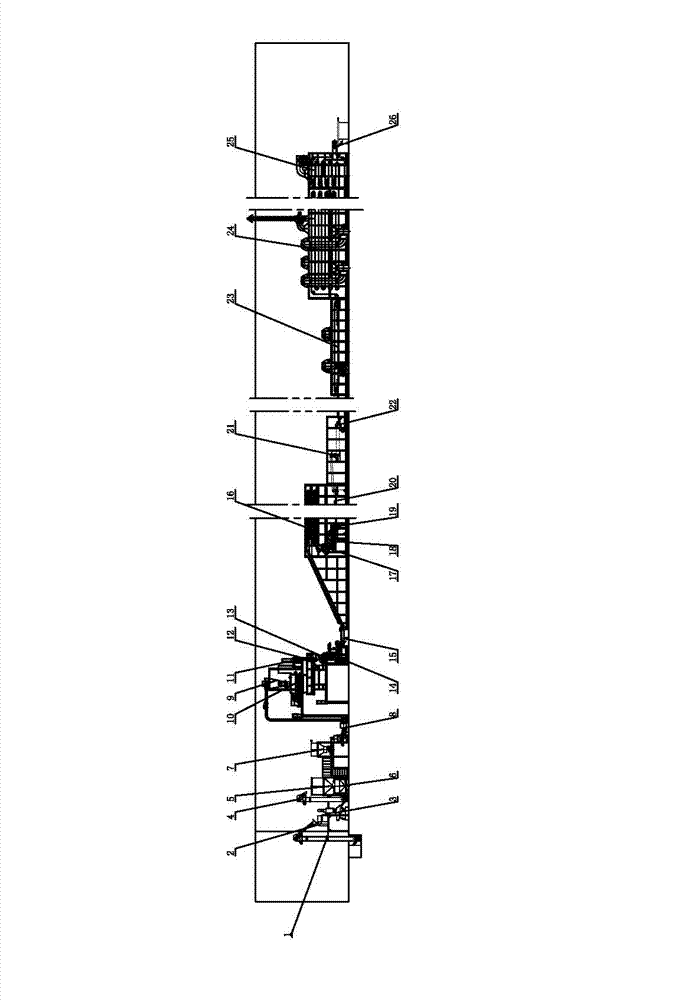

Rice noodle production line and rice noodle production process

The invention discloses a rice noodle production line and a rice noodle production process. The rice noodle production line comprises a first rice elevator, a rice polisher, a specific gravity sand remover, a second rice elevator, a rice storage tank, a jet rice washer, a water-rice separator, a rice grinder, a dry powder pneumatic conveyor, a powder mixer, a quantitative water adding barrel, a dough aging conveyor, a dough feeder, a continuous dough cooking device, a swing dough separator, a dough body aging machine, a dough body crumbler, an automatic curing machine, a noodle extruder, a noodle aging machine, a quantitative cutter, a folding forming machine, a predrying shaping machine, a drying machine, an air cooler and a packaging conveyor. The rice noodle production process comprises making rice into dough, curing, conveying, crumbling, feeding, curing, separating the dough by swinging, aging dough bodies, crumbling the dough bodies, automatically curing, extruding noodles, aging the noodles, quantitatively cutting, forming by folding, predrying, shaping, drying, air cooling and packaging. The rice noodle production line and the rice noodle production process are simple and low in cost. The rice noodles produced is fine in quality and taste and high in puffing degree.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

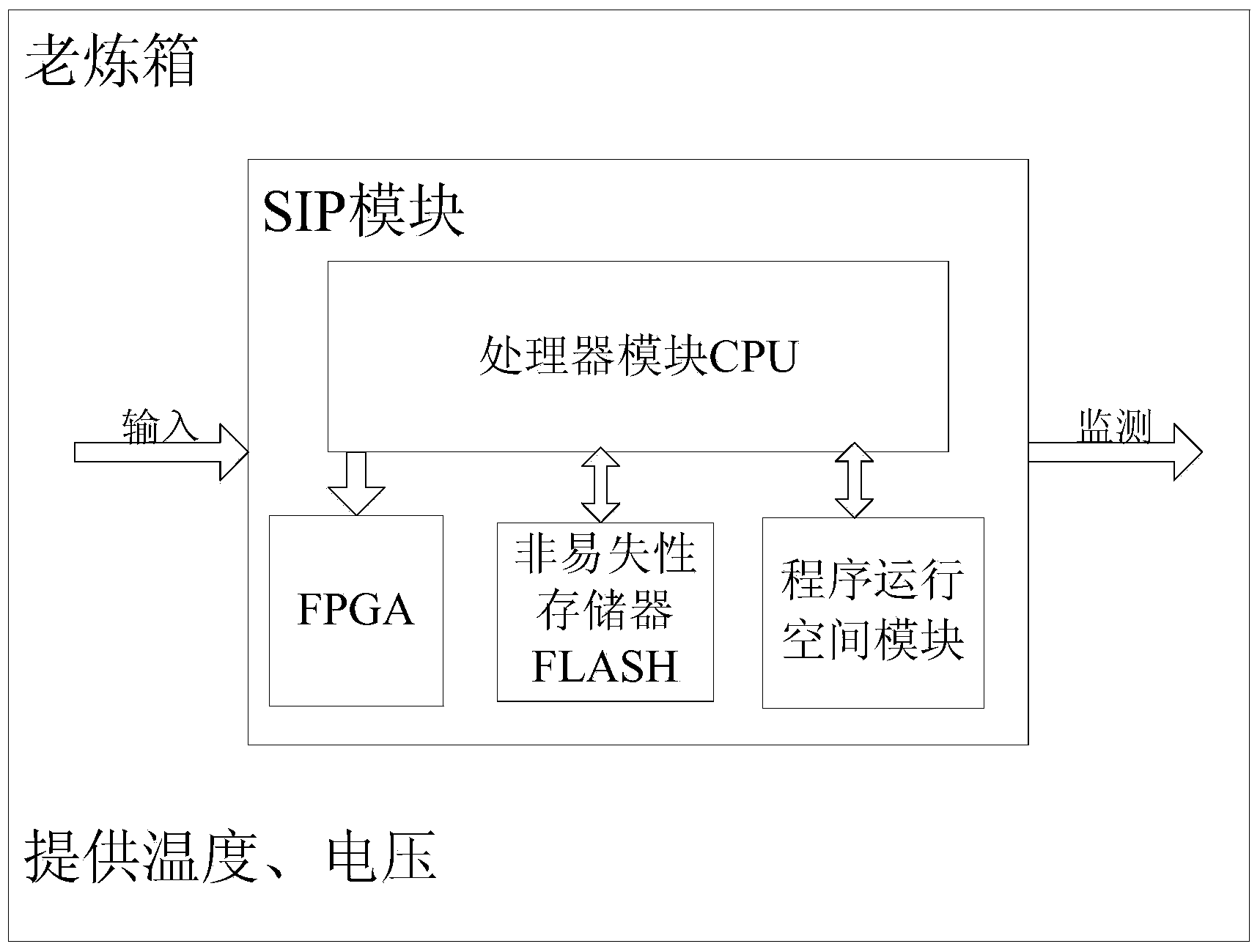

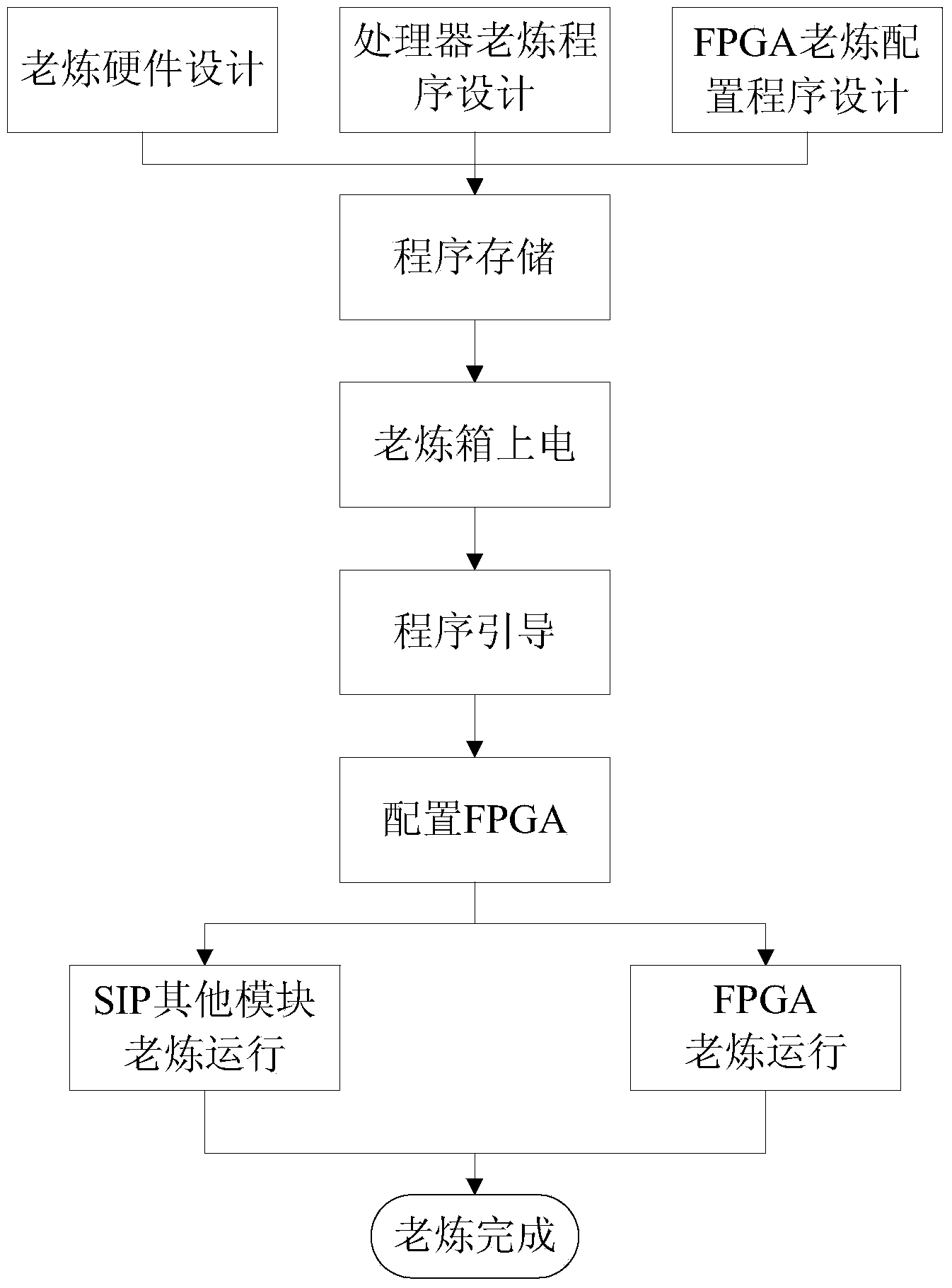

Burn-in method based on SIP module

The invention relates to a burn-in method based on an SIP module. The burn-in method is achieved in a burn-in box. The burn-in method is based on the SIP module comprising a processor module CPU, a program running space module, an FPGA module and a nonvolatile memory FLASH. According to the designed burn-in method, a burn-in program is written in the SIP module in a programmed mode, a power-on program automatically runs, the FPGA module is automatically configured, and running, access and control of all the modules are executed inside the tested SIP module in the burn-in process. The connecting circuit between the SIP module and the burn-in box is simple. According to the method, burn-in of the SIP module is achieved by fully using the functions of the SIP module, the complexity of the connecting circuit between the SIP module and the burn-in box is greatly lowered, the influences of an external circuit on the SIP module are reduced in the burn-in process, and meanwhile fault analysis can be conveniently conducted.

Owner:BEIJING MXTRONICS CORP +1

Asphalt mixture aging test method

InactiveCN102735824AAccurately judge aging performanceAccurately judge its anti-aging abilityMaterial testing goodsStructural engineeringHighway engineering

The invention discloses an asphalt mixture aging test method. The method comprises the steps that: a short-term aging hot-mixed asphalt mixture sample is obtained with a hot-mixed asphalt mixture accelerated-aging method specified by highway engineering asphalt and asphalt mixture testing procedures; the short-term aging hot-mixed asphalt mixture sample is obtained, and a testing method and testing equipments same as those of a pressure-aging-vessel-accelerated asphalt aging test specified by the highway engineering asphalt and asphalt mixture testing procedures are adopted, and an asphalt mixture long-term aging test is carried out; the performances of the long-term aging hot-mixed asphalt mixture obtained by the test is compared with the performances of an original non-aged asphalt mixture, such that the aging degree of the hot-mixed asphalt mixture can be accurately determined. With the testing method provided by the invention, the performance aging condition of the asphalt mixture after long term use in an actual environment can be simulated, such that the aging performance or the anti-aging ability of the asphalt mixture can be accurately determined.

Owner:JIANGSU SHANSHUI ENVIRONMENT CONSTR GRP

High temperature resistant inner layer material for heat radiator water pipe and preparation method thereof

The present invention provides a high temperature resistant inner layer material for a heat radiator water pipe and a preparation method thereof. The high temperature resistant inner layer material can satisfy cooling liquid aging resistance under the long time action of a high temperature medium, high resistance and no zinc in the material, and can be balanced in the aspects of compression permanent deformation, extension, physical and mechanical properties, low temperature performance, resistance and the like. The high temperature resistant inner layer material includes the following variouspreparation materials: 0-80 parts by weight of ethylene-propylene copolymer, 0-150 parts by weight of ethylene-propylene diene copolymer, 50-150 parts by weight of carbon black, 20-50 parts by weightof a plasticizer, 0-20 parts by weight of precipitation method white carbon black, 0-15 parts by weight of magnesium oxide, 0-2 parts by weight of stearic acid, 1.5 to 8 parts by weight of an antioxidant, 2.5 to 10 parts by weight of crosslinking agent BIBP, 1 to 3.5 parts by weight of crosslinking agent TMPTMA and 1-8 parts by weight of other auxiliaries.

Owner:宁海建新胶管有限公司

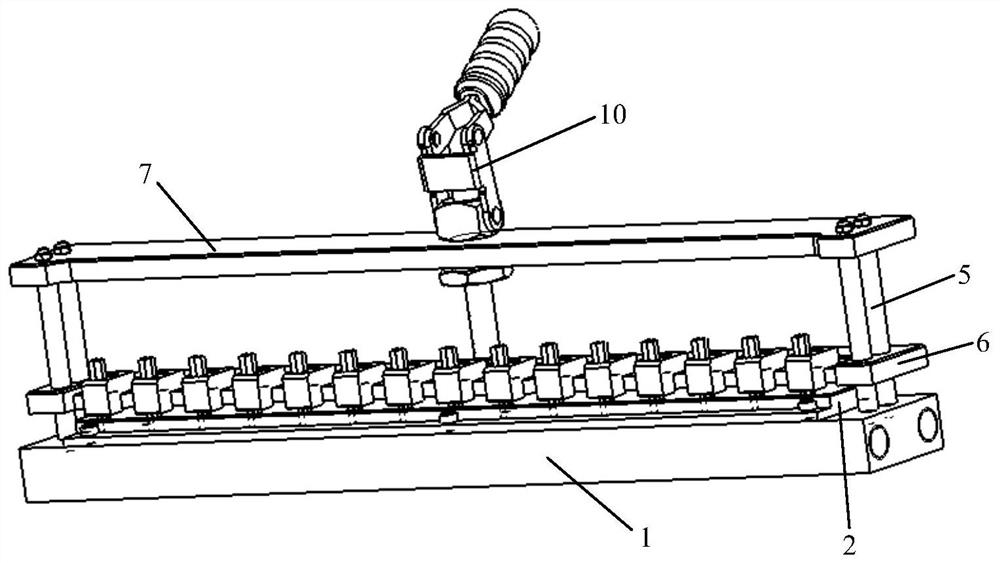

Aging clamp for semiconductor laser chip

PendingCN111999631AAging achievedEasy to operateLaser detailsElectronic circuit testingMechanical engineeringSemiconductor

The invention relates to an aging clamp of a semiconductor laser chip and belongs to the semiconductor aging clamp field. The aging clamp comprises a water cooling plate being of a cuboid structure, aCOS aging connection plate is fixed on the upper surface of the water cooling plate, the middle of the COS aging connection plate is protruded, a circuit board is fixed on the protrusion, and a plurality of limiting grooves used for placing chips are evenly arranged on one side of the circuit board. A plurality of guide shafts are vertically and fixedly arranged at the two ends of the water cooling plate and sleeved with pressing blocks, the pressing blocks can move up and down along the guide shafts, and clamp fixing plates are fixed to the upper ends of the guide shafts; a plurality of probe seats are fixed on the pressing blocks, and probes for pressing the chip are arranged on the probe seats; clamps are arranged on the clamp fixing plates and comprise clamp bodies and telescopic arms, the clamp bodies are fixed to the clamp fixing plates, and one ends of the telescopic arms are connected with the pressing blocks. During aging, rapid and accurate assembly can be achieved, and theworking efficiency is improved.

Owner:潍坊华光光电子有限公司

Aging testing device and aging testing method for chip of nitrogen and oxygen sensor

InactiveCN104808131AAging achievedRealize cyclic heating agingIndividual semiconductor device testingData acquisitionEngineering

The invention discloses an aging testing device and an aging testing method for a chip of a nitrogen and oxygen sensor. The aging testing device comprises a communication module, a control module, a signal analyzing module, an aging power supply, a sampling resistor and a chip fixture, wherein the chip fixture is provided with an elastic binding post; an aging voltage is loaded to a heating electrode of the chip of the nitrogen and oxygen sensor via the binding post; the heating electrode of the chip of the nitrogen and oxygen sensor is provided with a resistor; under the effect of the aging voltage, the heating electrode of the chip of the nitrogen and oxygen sensor is heated; the aging voltage outputted by the aging power supply is adjusted in real time through the control module, and the purpose of circularly loading the aging voltage on the heating electrode of the chip of the nitrogen and oxygen sensor is achieved; and the sampling resistor acquires a voltage so as to acquire heating current data on the electrode of the chip, whether the heating electrode of the chip of the nitrogen and oxygen sensor to be tested is burnt out or not can be determined, aging testing is implemented, and the purpose of eliminating defective products is achieved. The aging testing device has the advantages of easiness in operation and convenience in data acquisition, monitoring and tracing.

Owner:湖北丹瑞新材料科技有限公司

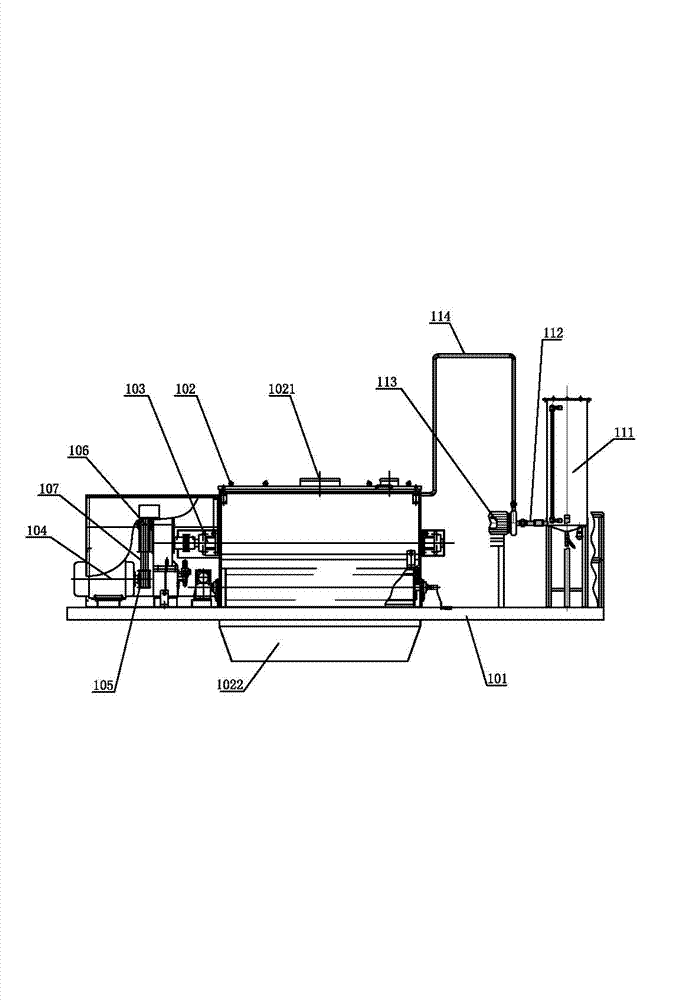

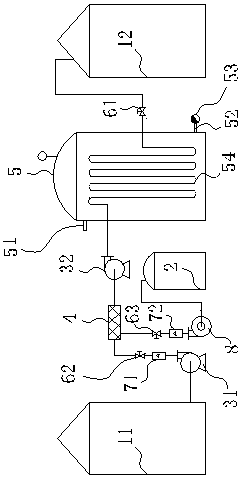

Quick aging apparatus for grape wine

The invention provides a quick aging apparatus for a grape wine, belonging to the technical field of the wine making equipment and aiming at solving the technical problems of long grape wine aging time, high cost, unachievable batch production and the like in the prior art. The quick aging apparatus comprises a first storage tank and an oxygen storage tank, wherein the first storage tank is connected with a first delivery pump, the first delivery pump is connected with a mixer, the oxygen storage tank is connected with the mixer, the mixer is connected with a second delivery pump, the second delivery pump is connected with a feeding hole of an aging tank, and the discharge hole of the aging tank is connected with the second storage tank through a first valve. The quick aging apparatus for the grape wine is capable of realizing the aging of the grape wine in short time and capable of meeting the requirements on large-scale production, and therefore, the production cost can be effectively reduced.

Owner:金丽秋

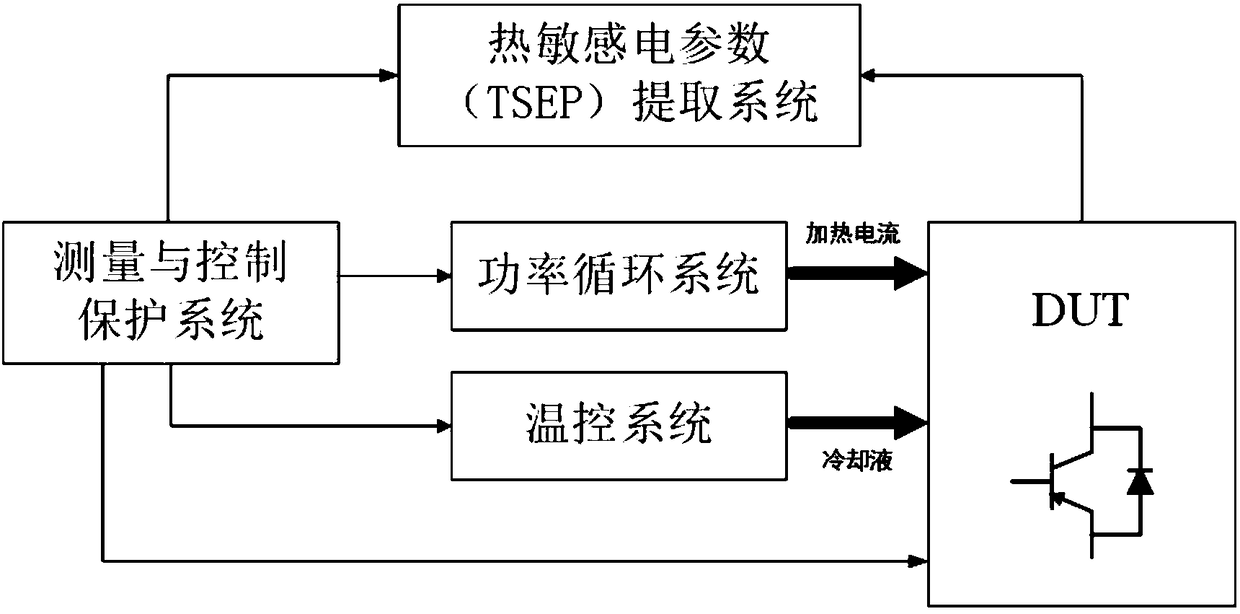

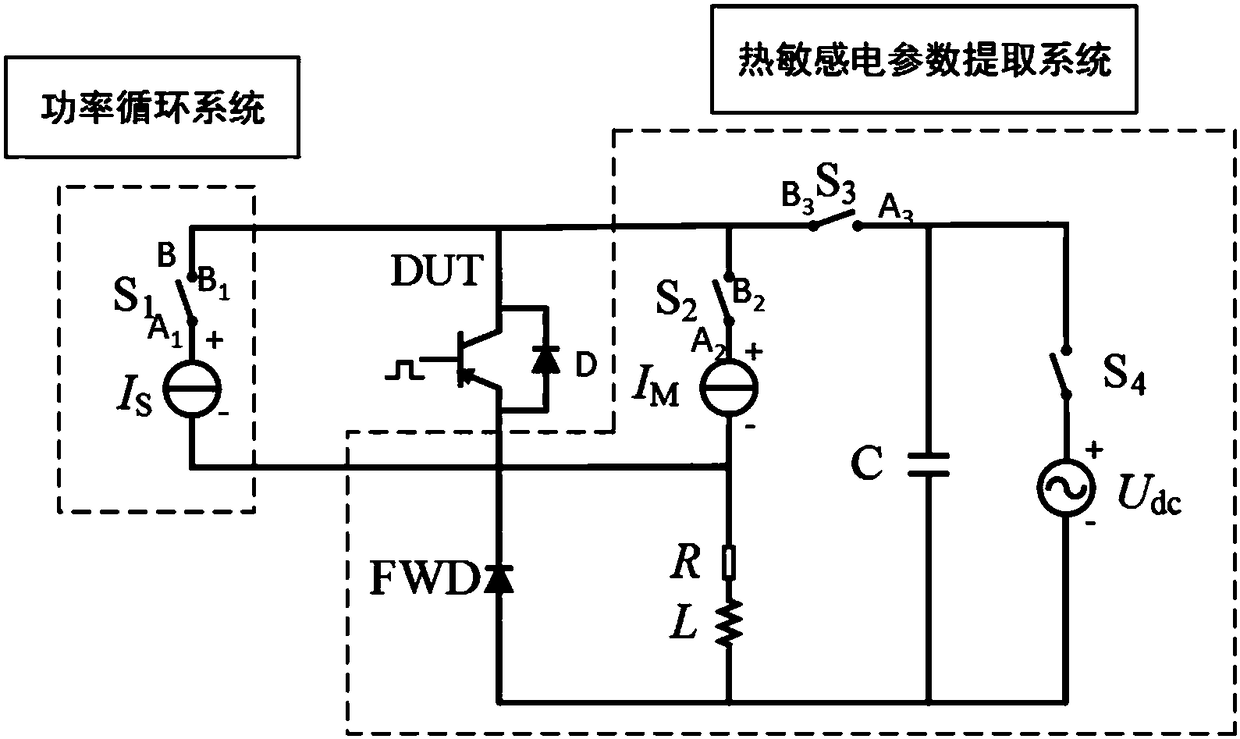

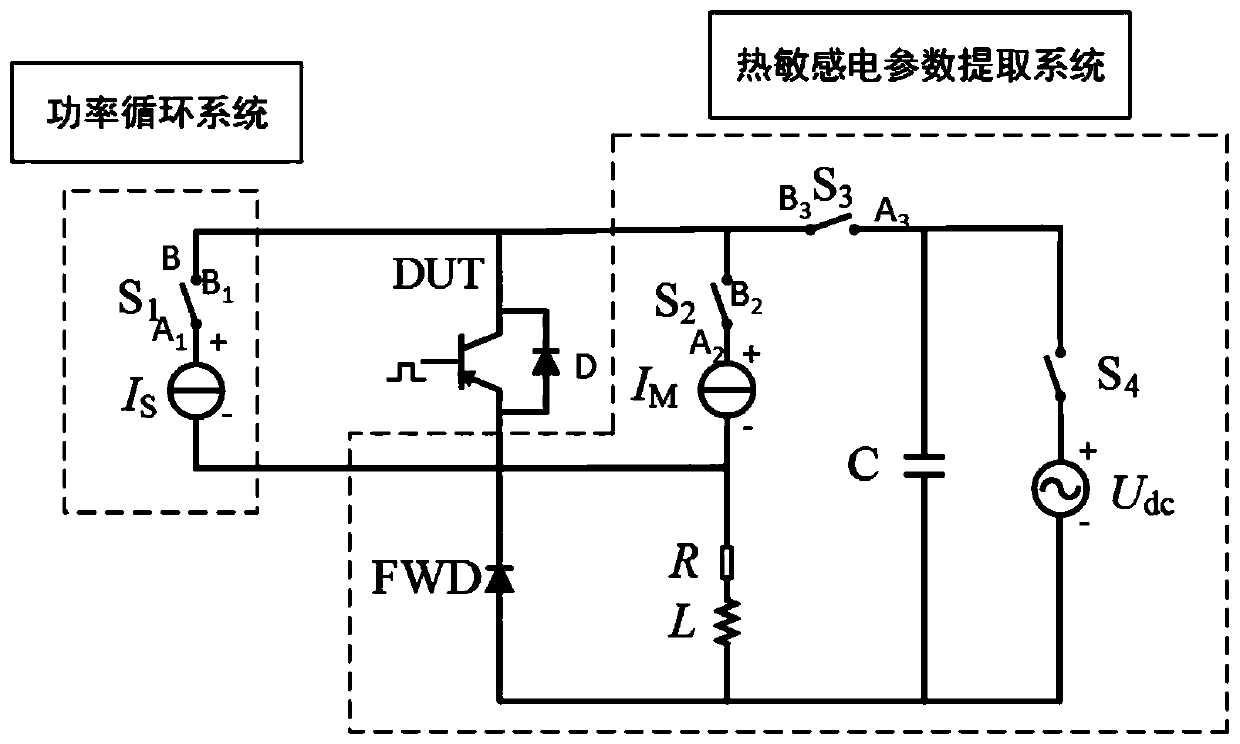

IGBT heat sensitive electric parameter extraction device

The invention discloses an IGBT heat sensitive electric parameter extraction device, which mainly comprises a power cycling system, a heat sensitive electric parameter extraction system, a test working position, a temperature control system and a measurement and control protection system, wherein the heat sensitive electric parameter extraction system mainly comprises a static heat sensitive electric parameter extraction subsystem and a dynamic heat sensitive electric parameter extraction subsystem; a to-be-tested device is placed on the test working position; the to-be-tested device outputs analog waveform signals; the measurement and control protection system heats the to-be-tested device through the power cycling system; the measurement and control protection system cools the to-be-tested device through the temperature control system; and the measurement and control protection system measures and extracts heat sensitive electric parameters in the heat sensitive electric parameter extraction system.

Owner:CHONGQING UNIV

A aging refining method based on sip module

Owner:BEIJING MXTRONICS CORP +1

State determination method and device during cable aging process and aging device

ActiveCN110346677AAging achievedFault location by conductor typesEnvironmental/reliability testsInsulation layerCondition monitoring

The invention discloses a state determination method and device during the cable aging process and an aging device. The method comprises the steps of acquiring a leakage current in a cable insulationlayer during the cable aging process at a predetermined time point during the aging process, wherein the leakage current is obtained by detection of an electrode inserted into the cable insulation layer, the electrode is inserted into the cable insulation layer by a hole punched in the cable insulation hole in advance, and the electrode, a metal shielding layer of the cable and an external conductive layer of the cable are not contacted; and determining a state of the cable insulation layer at the predetermined time point according to the leakage current. By the method, the technical problemsthat the aging state of cable insulation under an actual working condition cannot be truly reflected by a monitoring method in the prior art and the integral aging state of cable insulation during thecable aging process cannot be truly reflected are solved.

Owner:STATE GRID BEIJING ELECTRIC POWER +2

Complete-set aging test system and method for circuit board of automobile motor controller

PendingCN113376500AAchieving Dynamic AgingImprove process efficiencyElectronic circuit testingElectric machineryAutomotive engineering

The invention discloses a complete-set aging test system and method for circuit boards of an automobile motor controller. An aging box is internally provided with an analog control unit which is used for being connected with a plurality of circuit boards to be tested and performing complete-set aging on the plurality of circuit boards to be tested; the analog control unit is controlled by a monitoring assembly to provide working signals required by the aging test of the plurality of circuit boards to be tested; the read test message generated by the plurality of to-be-tested circuit boards according to the working signals are sent to the monitoring assembly; and the monitoring assembly analyzes the test message so as to judge the aging states corresponding to the plurality of circuit boards to be tested according to the serial numbers of the plurality of circuit boards to be tested and the fault information. Compared with the prior art, complete-set aging of a plurality of circuit boards to be tested in the motor controller can be realized, and the aging fault of the controller can be positioned on a single controller circuit board, so that parallel dynamic aging of the complete-set circuit board is realized, the working efficiency of procedures is remarkably improved, and the aging fault of the circuit board in the controller is positioned.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Rice noodle production line and production process

The invention discloses a rice noodle production line and a rice noodle production process. The rice noodle production line comprises a first rice elevator, a rice polisher, a specific gravity sand remover, a second rice elevator, a rice storage tank, a jet rice washer, a water-rice separator, a rice grinder, a dry powder pneumatic conveyor, a powder mixer, a quantitative water adding barrel, a dough aging conveyor, a dough feeder, a continuous dough cooking device, a swing dough separator, a dough body aging machine, a dough body crumbler, an automatic curing machine, a noodle extruder, a noodle aging machine, a quantitative cutter, a folding forming machine, a predrying shaping machine, a drying machine, an air cooler and a packaging conveyor. The rice noodle production process comprises making rice into dough, curing, conveying, crumbling, feeding, curing, separating the dough by swinging, aging dough bodies, crumbling the dough bodies, automatically curing, extruding noodles, aging the noodles, quantitatively cutting, forming by folding, predrying, shaping, drying, air cooling and packaging. The rice noodle production line and the rice noodle production process are simple and low in cost. The rice noodles produced is fine in quality and taste and high in puffing degree.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

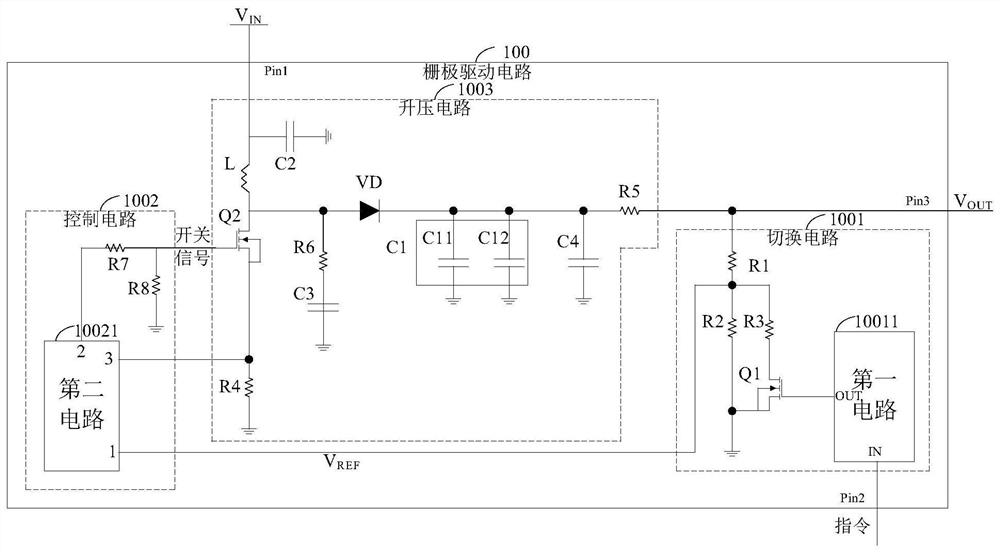

Gate drive circuit, liquid crystal panel, display device and aging method

The invention provides a gate drive circuit, a liquid crystal panel, a display device and an aging method. According to the circuit, a first pin of the gate drive circuit configured to receive an input voltage, and a second pin of the gate drive circuit is configured to adjust the resistance value of a target resistor to be greater than a preset resistance value when receiving an instruction indicating that the aging of the display device is started, and adjust the resistance value of the target resistor to be equal to a preset threshold value after a preset period of time. A third pin of thegate drive circuit is configured to output an output voltage corresponding to the target resistor through the input voltage based on the reference voltage with the amplitude kept unchanged. When the resistance value of the target resistor is greater than the preset resistance value, the amplitude of the output voltage is greater than the amplitude of the turn-on voltage of a thin film transistor TFT in the display device; when the resistance value of the target resistor is equal to the preset resistance value, the amplitude of the output voltage is equal to the amplitude of the turn-on voltageof a thin film transistor TFT in the display device. Therefore, automatic aging of the display device is realized.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

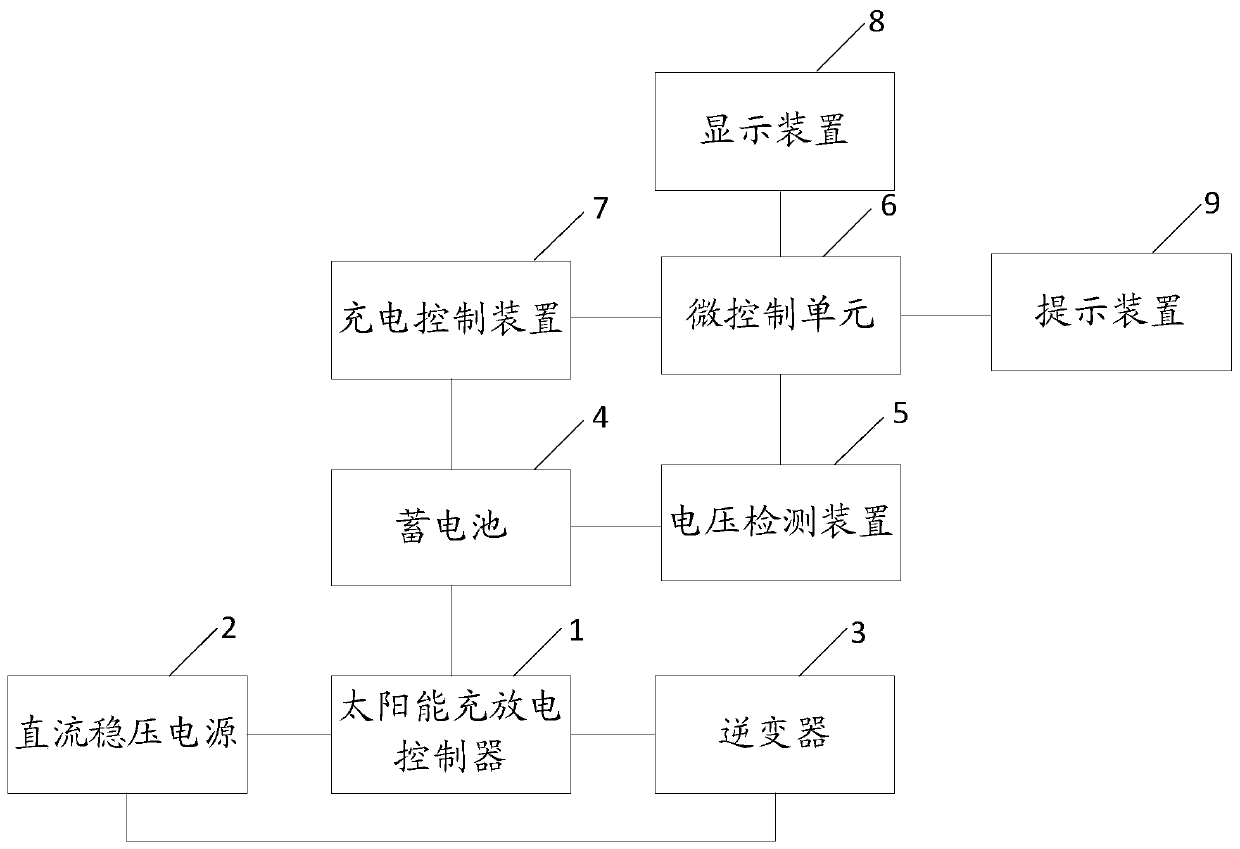

Solar charge-discharge controller aging system and method

PendingCN109995323AAging achievedAchieve recyclingBatteries circuit arrangementsPhotovoltaic monitoringElectric energyAge method

The application discloses a solar charge-discharge controller aging system, which comprises a solar charge-discharge controller, a DC regulated power supply, an inverter and a storage battery. The output end of the DC regulated power supply is connected with a first end of the solar charge-discharge controller. The input end of the inverter is connected with a second end of the solar charge-discharge controller. The output end of the inverter is connected with the input end of the DC regulated power supply. The storage battery is connected with a third end of the solar charge-discharge controller. In the application, the storage battery supplies electric energy to the solar charge-discharge controller, the solar charge-discharge controller transmits the electric energy to the inverter, theinverter transmits the electric energy to the DC regulated power supply, the DC regulated power supply transmits the electric energy to the solar charge-discharge controller, the solar charge-discharge controller transmits the electric energy to the storage battery, and so on. Thus, the solar charge-discharge controller can be aged, and moreover, electric energy can be recycled, and energy can besaved. The application also provides an aging method with the same advantages.

Owner:QINGDAO SKYWISE TECH

Novel controller aging vehicle

The invention provides a novel controller aging vehicle which comprises a tank body and slide rails. Slide plates are arranged on the slide rails; a positioning tank is detachably arranged on each slide plate; a power supply is arranged on the rear-part tank body corresponding to each positioning tank; a plug is arranged on each power supply; each positioning tank comprises a positioning seat; a through slot is formed in a side wall of the end, corresponding to the corresponding power supply, of each positioning seat; positioning plates are connected to side walls of the positioning seats; circular slots are formed in the bottom parts of the positioning seats; and directional bolts are arranged on the peripheries of the bottom parts of the positioning seats. The novel controller aging vehicle provided by the invention aims to conveniently and quickly realize the assembling and the disassembling of products, is firm and reliable in fixing and convenient to transport, can adaptively adjust a corresponding size according to the aging situations of different types of products, and is wider in application range, higher in practicability, higher in universality, and convenient to use.

Owner:TIANJIN ENERGETIC AUTO MOTOR TECH CO LTD

Grape wine ageing device

The invention provides a grape wine ageing device, belonging to the technical field of brewing equipment. The grape wine ageing device is used for solving the technical problems in the prior art that the grape wine ageing time is long, the cost is high, mass production is not likely to realize and the like. The grape wine ageing device comprises a first storage tank and an oxygen gas storage tank, wherein the first storage tank is connected with a first conveying pump, the first conveying pump is connected with a mixer, the oxygen gas storage tank is connected with the mixer, the mixer is connected with a second conveying pump, the second conveying pump is connected with a charging opening of an ageing tank, and a discharging opening of the ageing tank is connected with a second storage tank through a first valve. The grape wine ageing device can realize the ageing of grape wine in short time and meets the requirements on large-scale production, so that the production cost is reduced effectively.

Owner:广西中天领御酒业有限公司

wine aging device

The invention provides a grape wine aging device, belonging to the technical field of brewing equipment and solving the technical problems that grape wine in the prior art has long aging time, is high in cost and is not suitable for batch production. The grape wine aging device comprises a first storage tank and an oxygen storage tank, wherein the first storage tank is connected with a first delivery pump; the first delivery pump is connected with a mixer; a first flow meter and a first valve are also arranged on a pipeline between the first delivery pump and the mixer; the oxygen storage tank is connected with the mixer; a second flow meter and a second valve are arranged on a pipeline between the oxygen storage tank and the mixer; the mixer is connected with a second delivery pump; the second delivery pump is connected with a feeding hole of an aging tank via a heat exchanger; a discharge hole of the aging tank is connected with a second storage tank via the first valve. The grape wine aging device can achieve aging of the grape wine in a short time and is suitable for the requirements of large-scale production, thus effectively reducing the production cost.

Owner:睢宁县东城投资开发有限公司

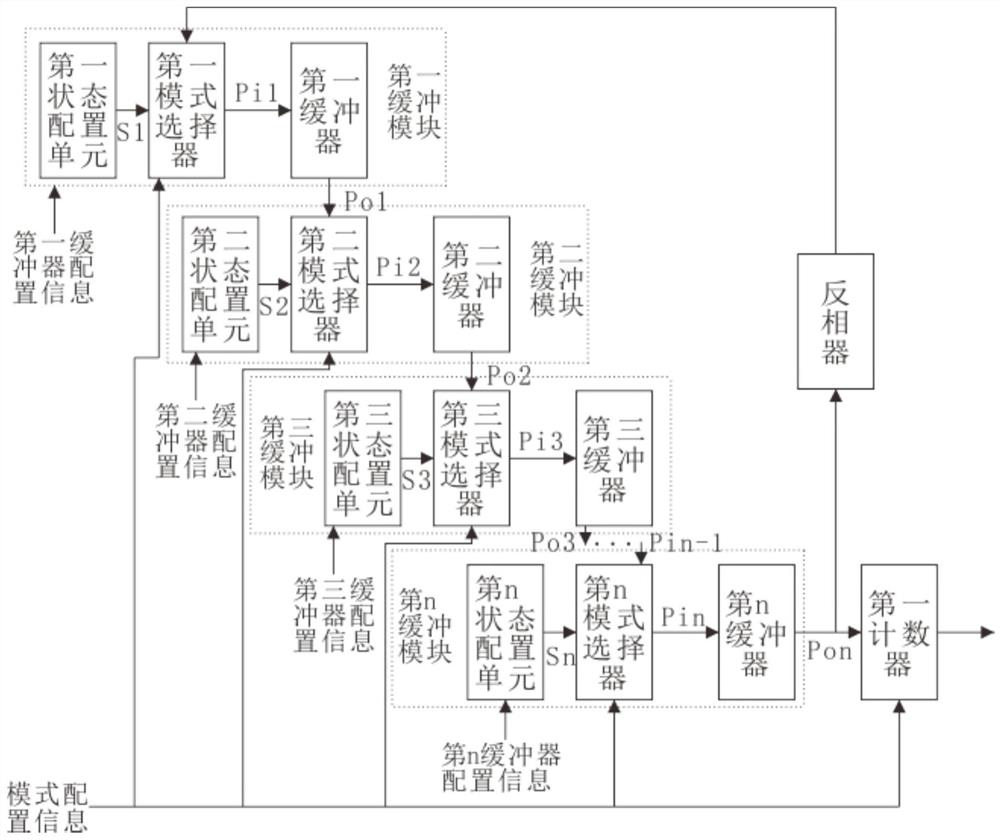

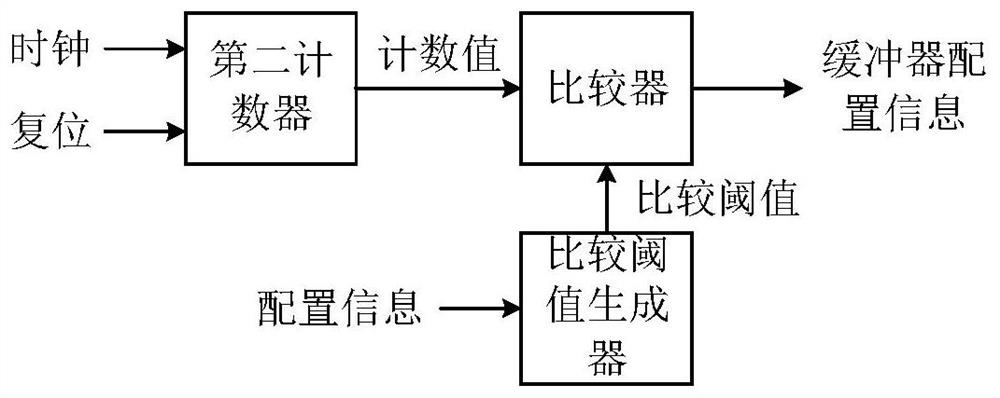

State-configurable in-situ aging sensor system

ActiveCN112698181AAging achievedIncrease flexibilityDigital circuit testingControl engineeringInverter

The invention discloses a state-configurable in-situ aging sensor system which comprises a phase inverter, n buffer modules and a first counter. Each buffer module comprises a state configuration unit, a mode selector and a buffer which are connected in sequence, the mode selector in each buffer module is the external input end of the buffer module, and the buffer in each buffer module is the output end of the buffer module; the output end of the mth buffer module is connected with the external input end of the (m+1) th buffer module; the output end of the phase inverter is connected with the external input end of the first buffer module; and the output end of the last buffer module is respectively connected with the input end of the phase inverter and the input end of the first counter. The state configuration unit is adopted, so that the signal probability and the signal turnover rate of an intermediate node of a link can be configured, and the problem that in the prior art, aging prediction cannot be performed on a complex logic circuit due to the fact that the state of the intermediate node of a combinational logic link of a sensor is fixed is solved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

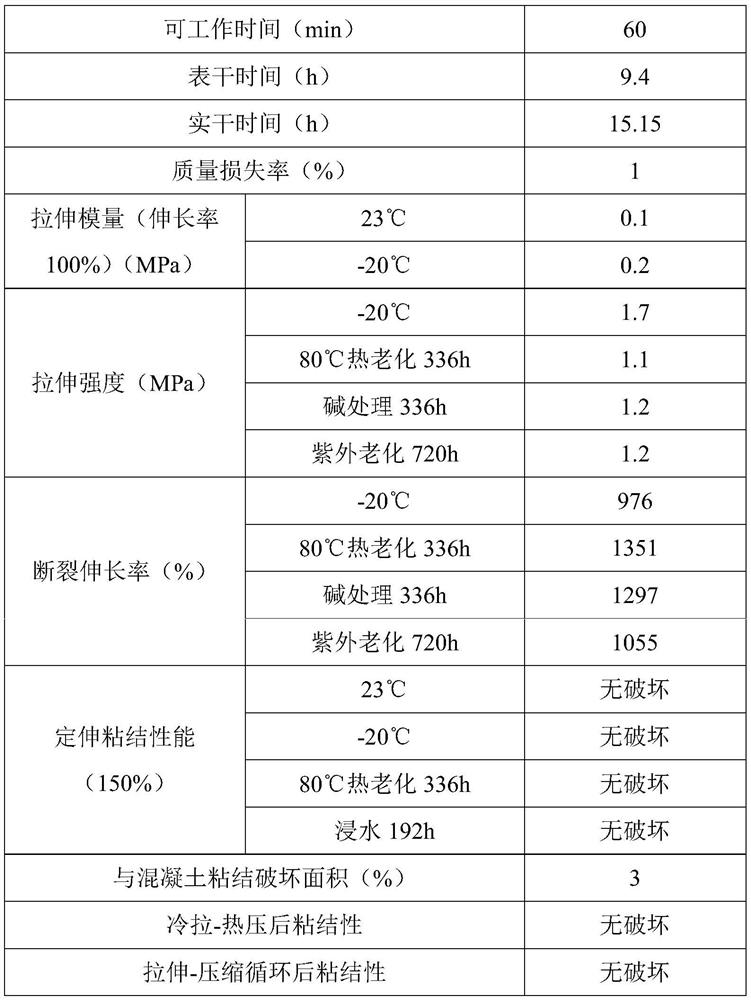

Special two-component caulking waterproof sealant for railway ballastless track and preparation method thereof

ActiveCN110527482BImprove mechanical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to the field of sealants, and more particularly, to a two-component caulking waterproof sealant for railway ballastless tracks and a preparation method thereof. A first aspect of the present invention provides a two-component caulking waterproof sealant, the two-component caulking waterproof sealant includes a component A, a component B and a primer; in parts by weight, the a The components include 25-50 parts of polyether triol, 10-20 parts of polyether diol-1, 15-40 parts of polyether diol-2, and 5-20 parts of aromatic diisocyanate; by weight , the B component includes 40-80 parts of polyether diol-3, 0.01-0.1 parts of organic tin catalyst; by weight, the primer includes 35-55 parts of cross-linking agent. The two-component caulking waterproof sealant provided by the invention does not contain white oil, asphalt, waste rubber and solvent, is odorless, non-toxic, environmentally friendly and ecological, and is suitable for use as a special caulking material for railway ballastless tracks, and is also suitable for large dynamic loads. concrete structure expansion joints, deformation joints, construction joints, structural joints, settlement joints.

Owner:陕西杨凌磐基新材料科技有限公司 +4

A device for extracting igbt thermally sensitive electrical parameters

Owner:CHONGQING UNIV

A chain link load aging device

ActiveCN104502771BAging achievedImprove aging efficiencyElectrical testingSecondary componentControl signal

The present application discloses a load aging device for chain links, which includes: first to sixth inductances connected to the first to third chain links and a control system, the first to sixth inductances are connected to the first to third inductances to form Triangular structure, the control system is used to output control signals to the first to third chain links, so that the output voltage of the first to third chain links contains the fundamental wave component with the same magnitude and phase as the grid voltage and the preset 3n times zero sequence The voltage component makes the output current of the first to third chain links contain 3n times of zero-sequence current components, and only flows inside the three chain links. A chain link is aged, thereby improving the aging efficiency.

Owner:SHENZHEN INVT ELECTRIC

Method and device for determining state in cable aging process and aging device

ActiveCN110346677BAging achievedFault location by conductor typesShort-circuit testingEngineeringElectric cables

Owner:STATE GRID BEIJING ELECTRIC POWER +2

A state-configurable in-situ aging sensor system

ActiveCN112698181BAging achievedIncrease flexibilityDigital circuit testingControl engineeringInverter

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

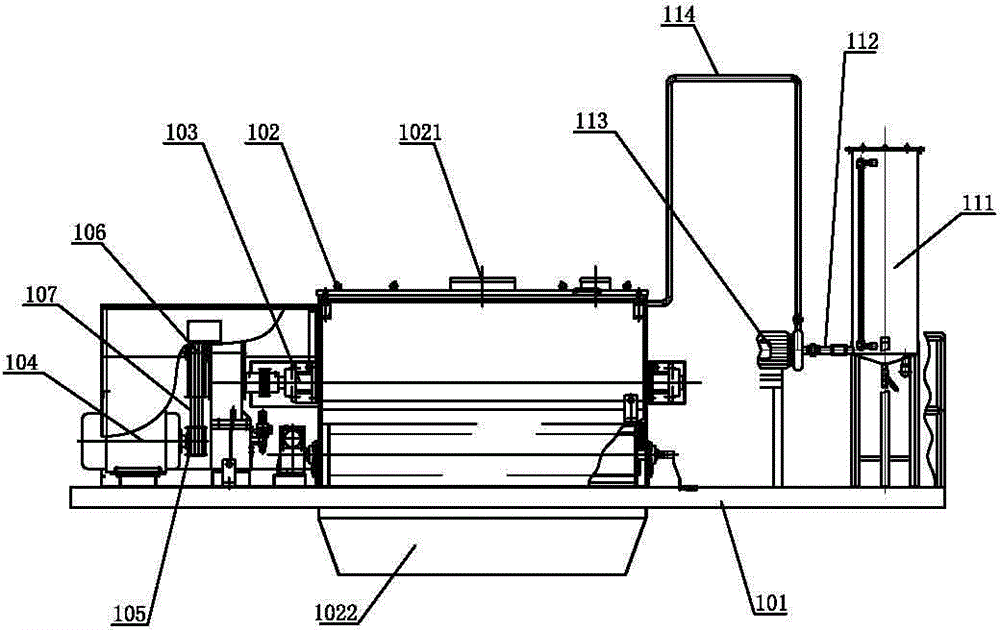

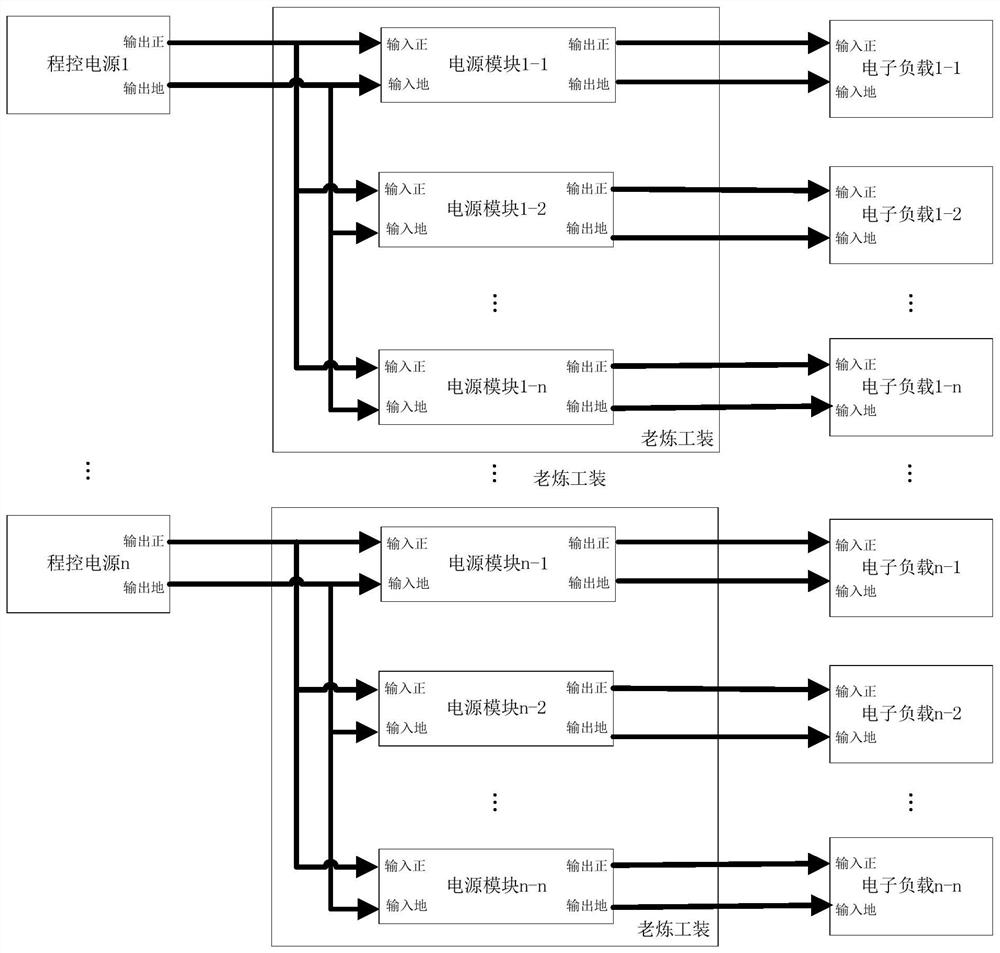

Metal fully-sealed power supply module immersed aging system and method

PendingCN113740757AAging achievedIncrease heating capacityPower supply testingElectronic loadProcess engineering

The invention discloses a metal fully-sealed power supply module immersed aging system and method in the field of power supply module aging, and the system comprises an aging box body which stores a fluorinated liquid, a constant temperature box body, a high temperature tank body and a low temperature tank body, and a plurality of power supply modules are arranged in the aging box body and are divided into a plurality of groups; the input ends of each group are respectively and commonly connected with a programmable power supply, and the output ends are respectively connected with a programmable electronic load; the high-temperature tank body and the low-temperature tank body are connected to the power supply module through a pipeline, and an electric valve is mounted on the pipeline; and the shell temperature of the power supply module and the fluorinated liquid in the constant-temperature box body and the aging box body are respectively detected by temperature sensors. The heat capacity of the aging system is improved, aging of a large number of power modules is achieved, the aging efficiency is improved, the temperature difference between different power module individuals can be reduced, and good temperature uniformity is achieved.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

A wine aging tank

ActiveCN103865744BSpeed up agingAging achievedAlcoholic beverage preparationBiochemical engineeringAgeing

The invention provides a grape wine ageing tank, belonging to the technical field of beverage equipment. The grape wine ageing tank is used for solving the technical problems in the prior art that the grape wine ageing time is long, the cost is high, mass production is not likely to realize and the like. The grape wine ageing tank comprises a tank body, wherein the tank body is provided with a charging opening and a discharging opening which are communicated with the tank body, a heating jacket capable of enabling steam to pass through is arranged outside the tank body, a plurality of partition plates are arranged in the tank body, the interior of the tank body is partitioned into a plurality of independent sections by the partition plates, a communication hole is formed in each partition plate, the communication holes of every two adjacent partition plates are located at the two sides of the axis of the tank body, and a gas inlet mechanism which can enable gas to enter the tank body is further arranged in the tank body. The grape wine ageing tank can realize the ageing of grape wine in short time and meets the requirements on large-scale production, so that the production cost is reduced effectively.

Owner:蓝山县花果庄园农业开发有限责任公司

Method and device for mac address aging in stacking system

ActiveCN109194777BAging achievedReduce the difficulty of implementationTransmissionEmbedded systemMAC address

The present invention provides a method and device for MAC address aging in a stacking system. The method includes: creating a multicast forwarding group for chips in the stacking system, and the members of the multicast forwarding group are stack ports corresponding to each chip; and Each chip creates a mirror configuration, and the destination of each chip mirror configuration is a multicast forwarding group; when any chip receives a message, if it is an ingress chip, it obtains the MAC address carried in the message; and refreshes the message corresponding to the current MAC address When it is marked as enabled, the message received by the current chip is mirrored according to the created mirroring configuration; if it is a stacked chip, it directly parses the message that is diffused to the current chip through mirroring processing, and obtains the MAC address it carries; While obtaining the MAC address carried by the message, the state of the MAC address is refreshed, and if the corresponding aging flag of the MAC address is enabled, the current MAC address is aged; the present invention does not require CPU to participate in the aging process of the MAC address , to reduce the implementation difficulty of the chip.

Owner:SUZHOU CENTEC COMM CO LTD

Gate driving circuit, liquid crystal panel, display device and aging method

The application provides a gate driving circuit, a liquid crystal panel, a display device and an aging method. The circuit includes: a first pin of the gate drive circuit configured to receive an input voltage. The second pin of the gate drive circuit is configured to adjust the resistance value of the target resistor to be greater than the preset resistance value when receiving an instruction indicating to start aging the display device, and adjust the resistance value of the target resistor after a preset time period. The value is equal to the preset resistance value. The third pin of the gate driving circuit is configured to output an output voltage corresponding to the target resistance through the input voltage based on the reference voltage whose amplitude remains constant. When the resistance value of the target resistance is greater than the preset resistance value, the magnitude of the output voltage is greater than the magnitude of the turn-on voltage of the thin film transistor TFT in the display device; when the resistance value of the target resistance is equal to the preset resistance value, the magnitude of the output voltage The value is equal to the magnitude of the turn-on voltage of the thin film transistor TFT in the display device. Thus, automatic aging of the display device is realized.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

Horizontal vulcanized rubber sleeve cable and manufacturing process and device thereof

ActiveCN102855996BImprove thermal efficiencyImprove stabilityPlastic/resin/waxes insulatorsPower cablesParaffin waxInsulation layer

The invention relates to a cable production method, discloses a horizontal vulcanized rubber sleeve cable and a manufacturing process as well as a manufacturing device thereof, and particularly relates to a horizontal vulcanized rubber sleeve cable of 35kv or above and a manufacturing process as well as a manufacturing device thereof. An insulation layer of the cable comprises the following materials in parts weight: 34-38 parts of CPE13513J, 4-6 parts of magnesium oxides, 8-12 parts of talcum powder, 0.8-1.2 parts of TA, 18-22 parts of light calcium carbonate, 0.8-1.2 parts of MT, 18-22 parts of kaolin, 0.7-0.9 part of silane, 0.1-0.22 part of RD, 0.1-0.22 part of A-150, 0.8-1.2 parts of paraffin waxes, 0.8-1.2 parts of ZD, 10-12 parts of dioctyl fat and 0.7-0.9 part of MM. The cable, process and device thereof disclosed by the invention have the beneficial effects that the cable is short in extrusion sizing time; silicone oil is taken as a medium, so that the cable has extremely small harmomegathus; the density of the silicone oil is close to that of the cable, so that the extension of the cable is stable, and a conductor is not eccentric, therefore, the cable is applicable to horizontal vulcanized pipelines; no building and no tower are used, thereby reducing the construction cost; no steam is used, related equipment is omitted, the energy consumption is low, and no emission are caused; the silicone oil is high in thermal efficiency, and the operating temperature is below 150 DEG C, so that no aging phenomenon is caused; and an effect of vulcanized crosslinking application is achieved, high-voltage cables above 35kv and extra-high-tension cables of 110-500kv are produced by using a horizontal production line, so that the production capability and level of cables are greatly enhanced.

Owner:马连红

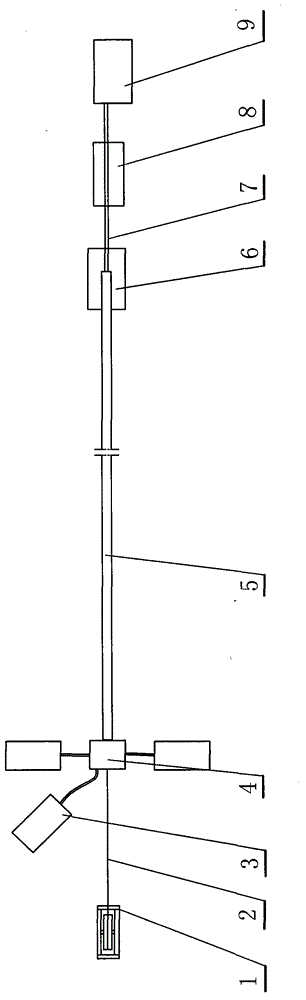

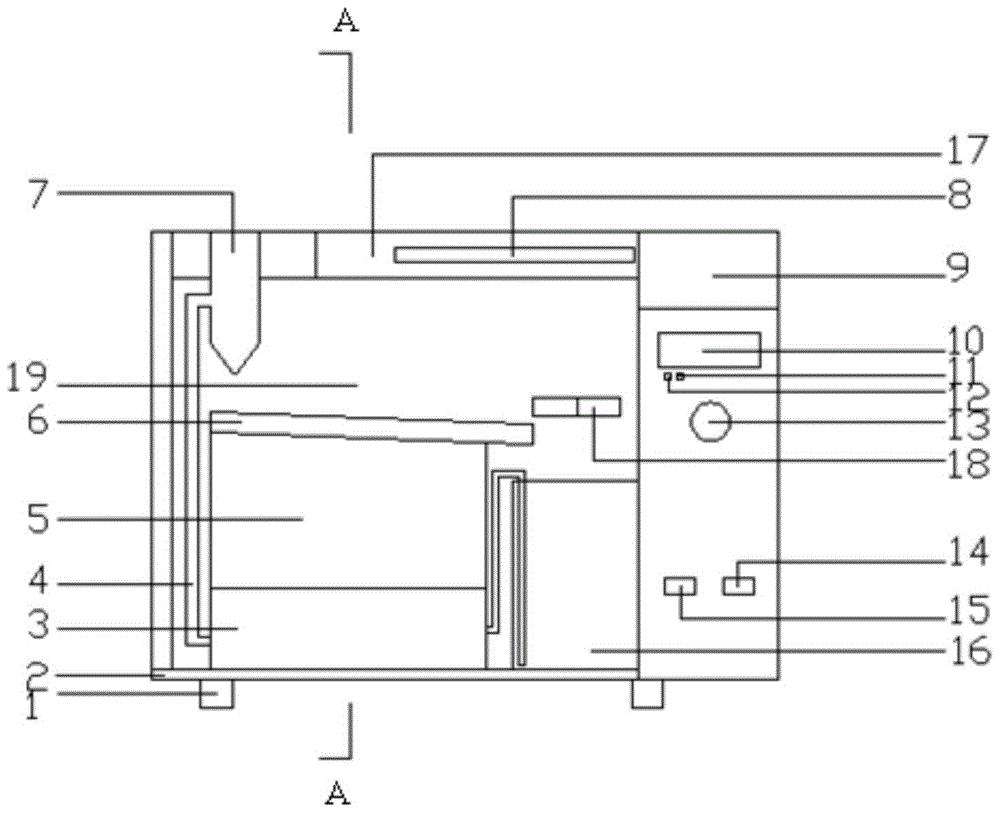

Device and method for producing aged asphalt for testing

InactiveCN104483181BAging achievedHeating evenlyPreparing sample for investigationNeedle penetrationEngineering

The invention discloses an aging asphalt production device and method for testing, which includes a temperature box, a controller and a circulation part; On the outer side of the box, there is a door on the temperature box, and the asphalt flow tank, collection bucket, pressure pump and heating components are located in the temperature box, and the entrance of the upper end of the asphalt container extends out of the temperature box through the top of the temperature box , the inlet of the pressure pump is connected to the bottom of the collection bucket, the outlet of the pressure pump is connected to the inlet on the side of the asphalt holder, the outlet at the bottom of the asphalt holder is located directly above the asphalt flow tank, and the outlet on the side of the asphalt flow tank Located directly above the top opening of the collection bucket. The invention can quickly prepare aged asphalt, and the prepared aged asphalt has the same penetration and is easy to operate.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com