Aging clamp for semiconductor laser chip

A technology of lasers and semiconductors, applied in semiconductor lasers, lasers, laser components, etc., can solve the problems of low aging efficiency and achieve the effects of saving time, improving heat dissipation efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

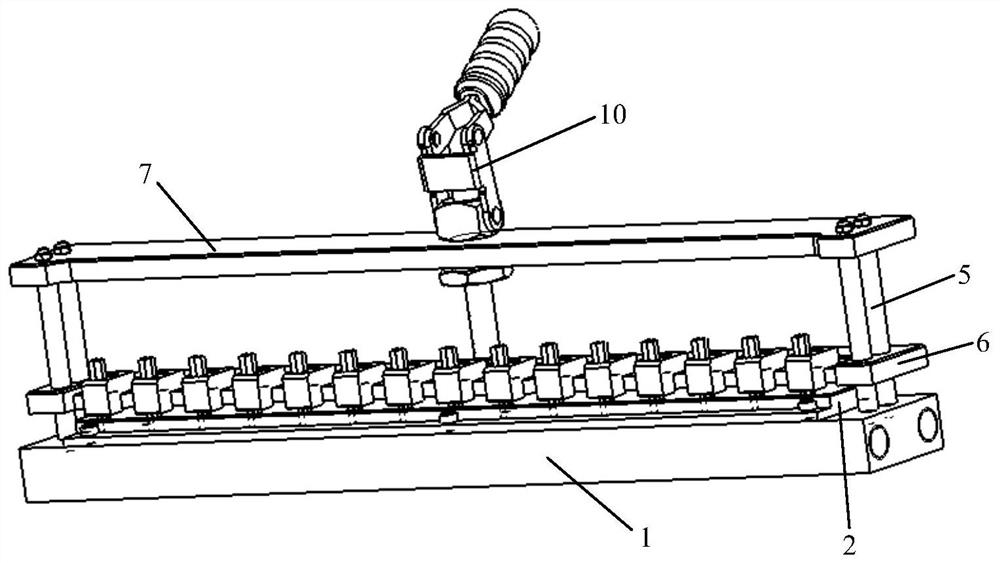

[0036] A kind of aging fixture of semiconductor laser chip, such as Figure 1~6 As shown, it includes the water cooling plate 1, the water cooling plate 1 is a rectangular parallelepiped structure, the upper surface of the water cooling plate 1 is fixed with a COS aging connecting plate 2, the middle part of the COS aging connecting plate 2 is raised, and its cross section is a “convex” shaped structure, and the protrusion is fixed on the There is a circuit board 3, and one side of the circuit board 3 is uniformly provided with a plurality of limiting grooves 4 for placing chips, such as image 3 As shown, the number of limiting slots 4 in this embodiment is 15, and 15 chips can be placed. The circuit board 3 here can connect 15 chips in series for aging, and there is no need to weld densely packed electric wires on the upper end, saving plenty of time;

[0037] Two ends of the water-cooled plate 1 are vertically fixed with a plurality of guide shafts 5, the guide shaft 5 is ...

Embodiment 2

[0041] A kind of burn-in fixture of semiconductor laser chip, its structure is as shown in embodiment 1, and difference is, the side that circuit board 3 is provided with limit groove is aligned with the raised side of COS burn-in joint board 2, namely chip and One side of the bump on the COS burn-in board is aligned, and the chip has an angle when emitting light. The bump is to prevent the light path from hitting the COS burn-in board, which will affect the burn-in effect.

Embodiment 3

[0043]An aging jig for a semiconductor laser chip, its structure is as shown in Embodiment 1, the difference is that the upper surface of the water cooling plate 1 is provided with screw holes for fixed connection with the COS aging connecting plate 2 and the guide shaft 5, all through screw connection, the inside of the water cooling plate 1 is provided with a circulating water channel 1-1 along its length direction, such as figure 2 As shown, the area of the circulating water channel can be maximized, that is, it can occupy the inner space of the water-cooled plate to the maximum, which is beneficial to the heat dissipation of the semiconductor laser, and the heat is taken away by the circulating water in the circulating water channel, saving the aging time. Improved work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com