Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Improve aging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grid-connection feedback device of high-voltage inverter and control method of grid-connection feedback device

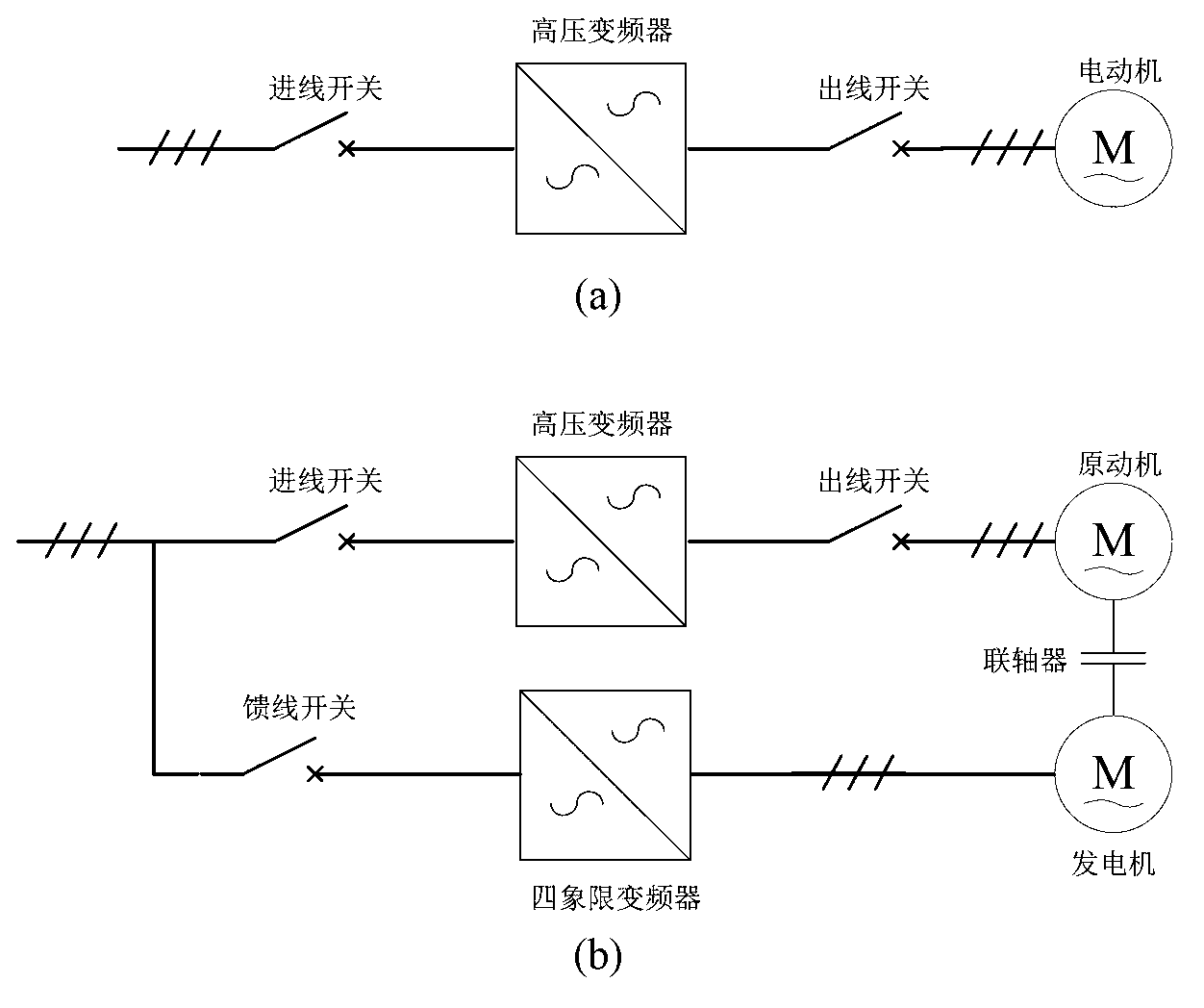

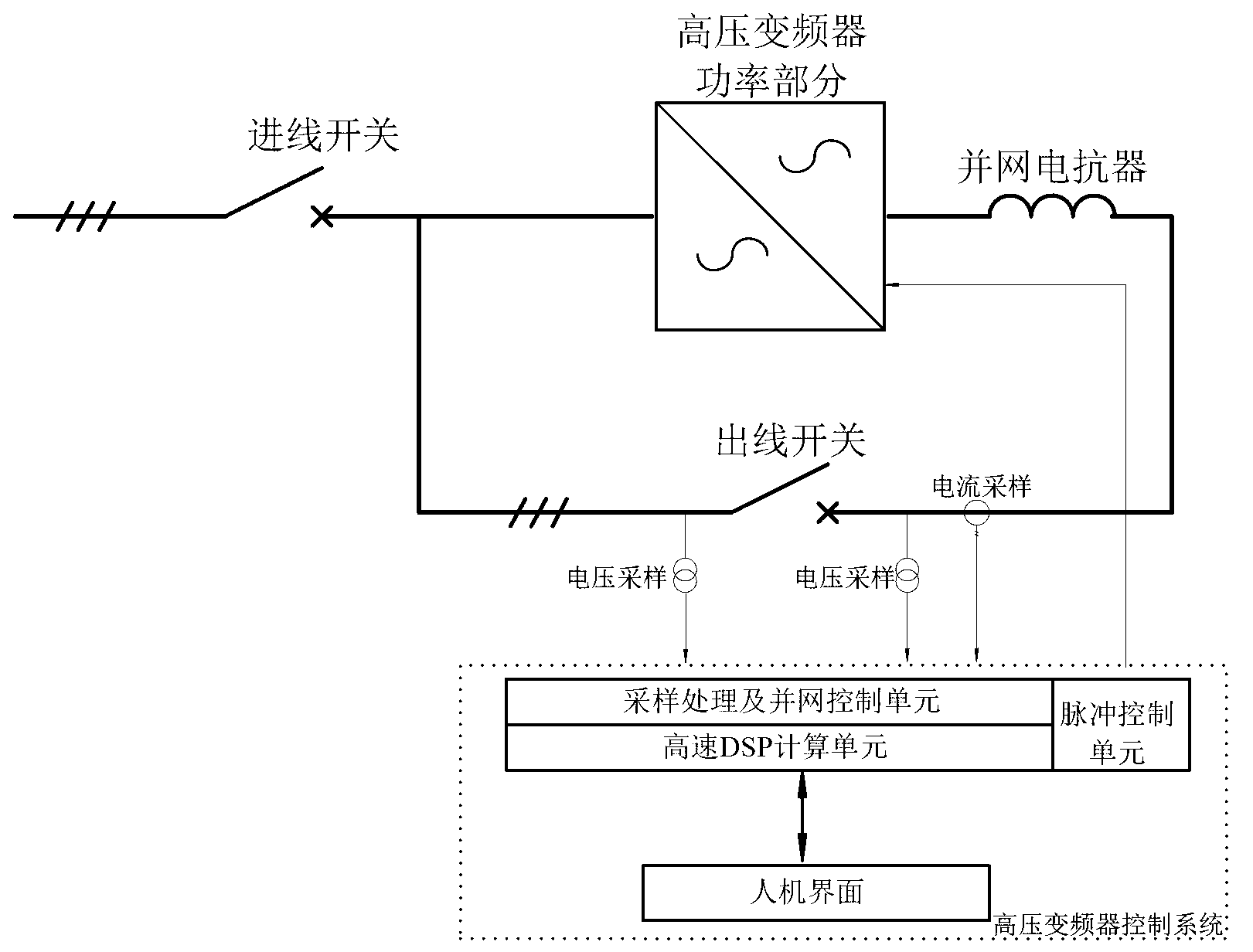

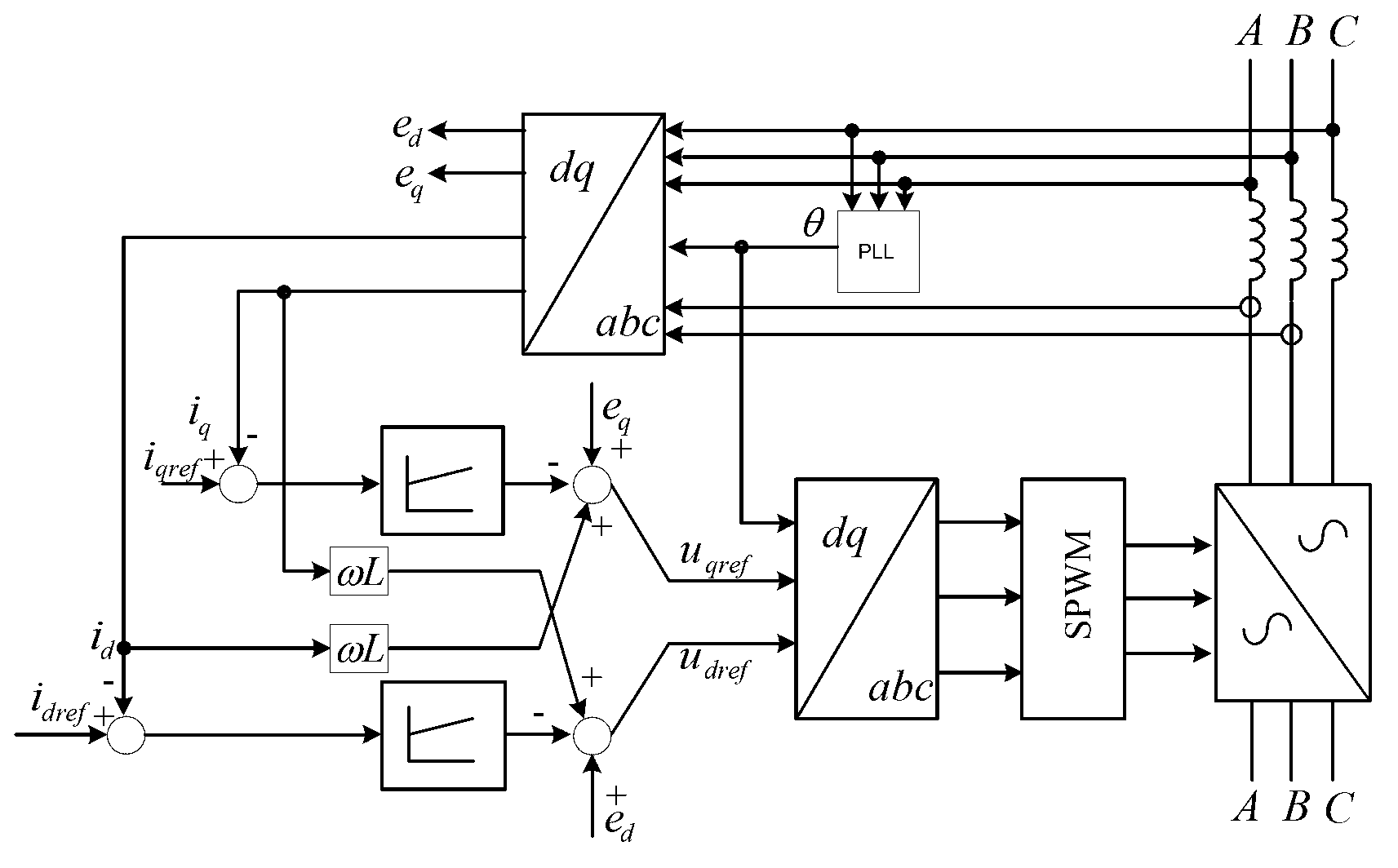

InactiveCN103023063AImprove aging efficiencyAgingSingle network parallel feeding arrangementsPower flowControl system

The invention discloses a grid-connection feedback device of a high-voltage inverter. The grid-connection feedback device comprises an inlet switch, a high-voltage inverter, a control system, a grid-connection electric reactor and an outlet switch. The grid-connection feedback device is characterized in that the inlet switch is connected with an input end of the high-voltage inverter; an output end of the high-voltage inverter is connected with the grid-connection electric reactor, the electric reactor is connected with the outlet switch, the outlet switch and an output end of the inlet switch are connected with an input end of the high-voltage inverter; the control system of the high-voltage inverter samples a voltage of a power network and an output current of the high-voltage inverter, processes the voltage of the power network and the output current of the high-voltage inverter, controls the output pulse of the high-voltage inverter and feeds back energy to the power network. By utilizing the grid-connection feedback device, grid-connection of the high-voltage inverter and energy feedback to the power network are achieved, the purpose of aging a whole high-voltage inverter is achieved, and meanwhile, saving energy and reducing consumption can be achieved; the floor area is small, the operability is strong and the production efficiency is improved.

Owner:GUODIAN NANJING AUTOMATION

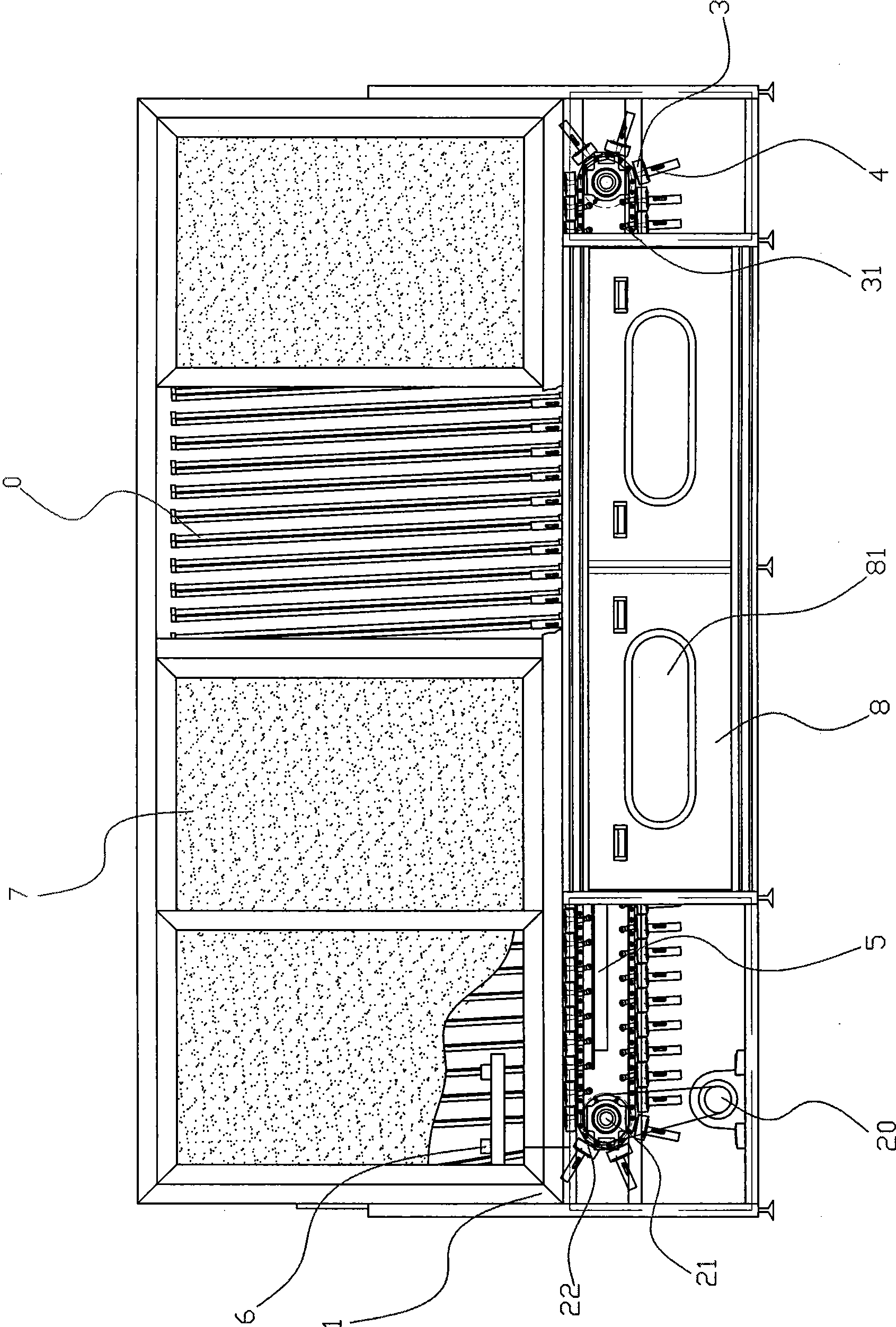

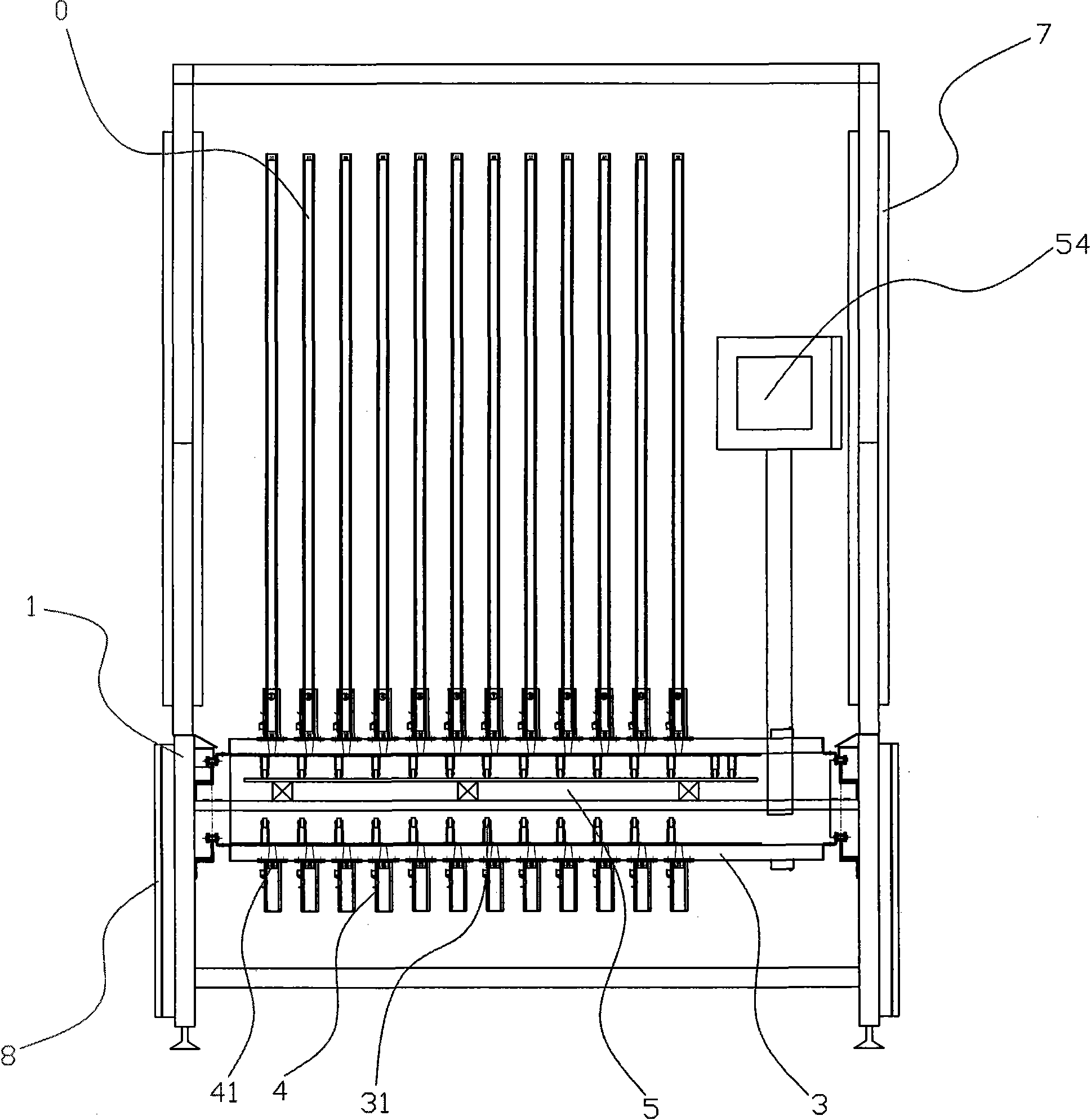

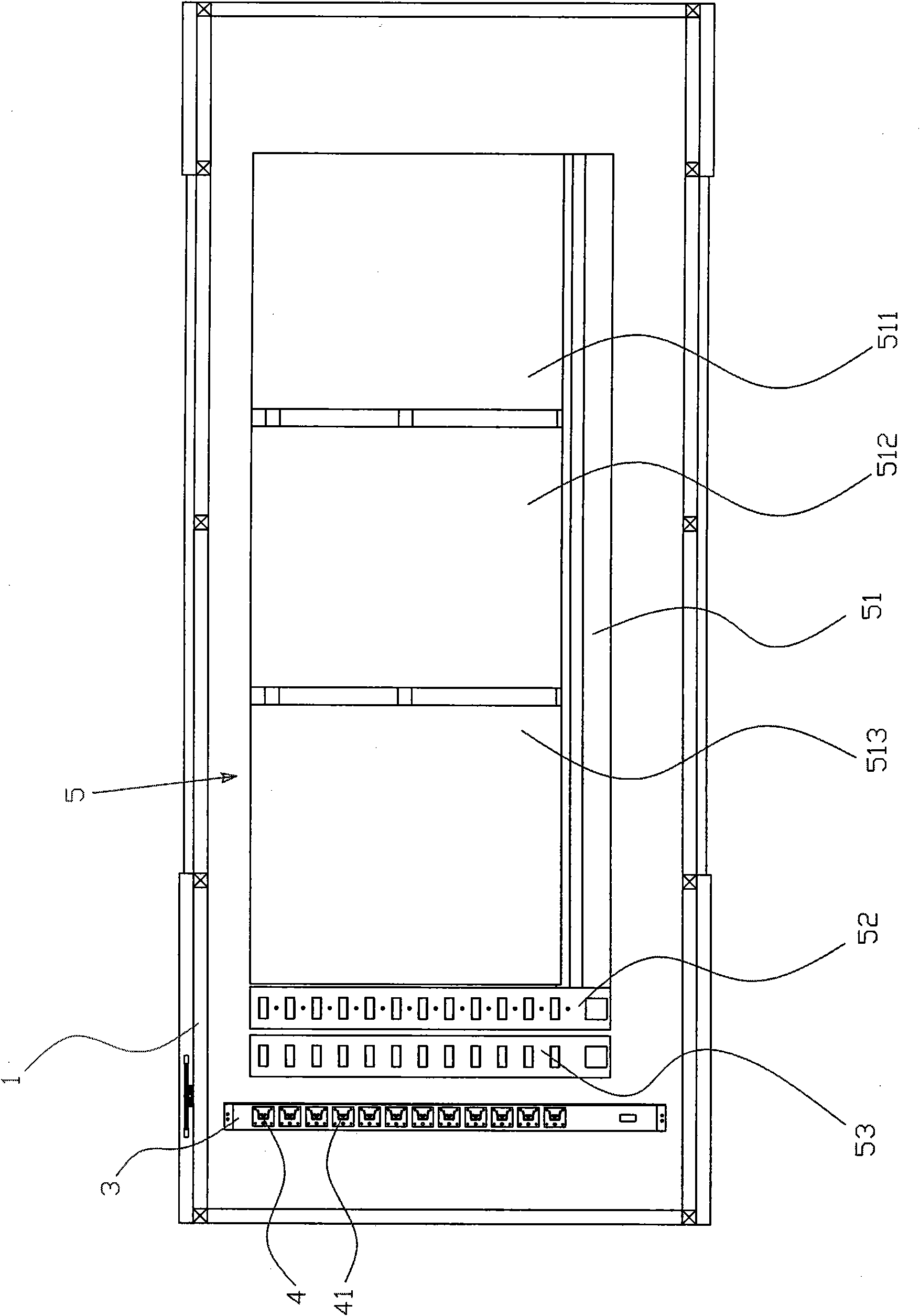

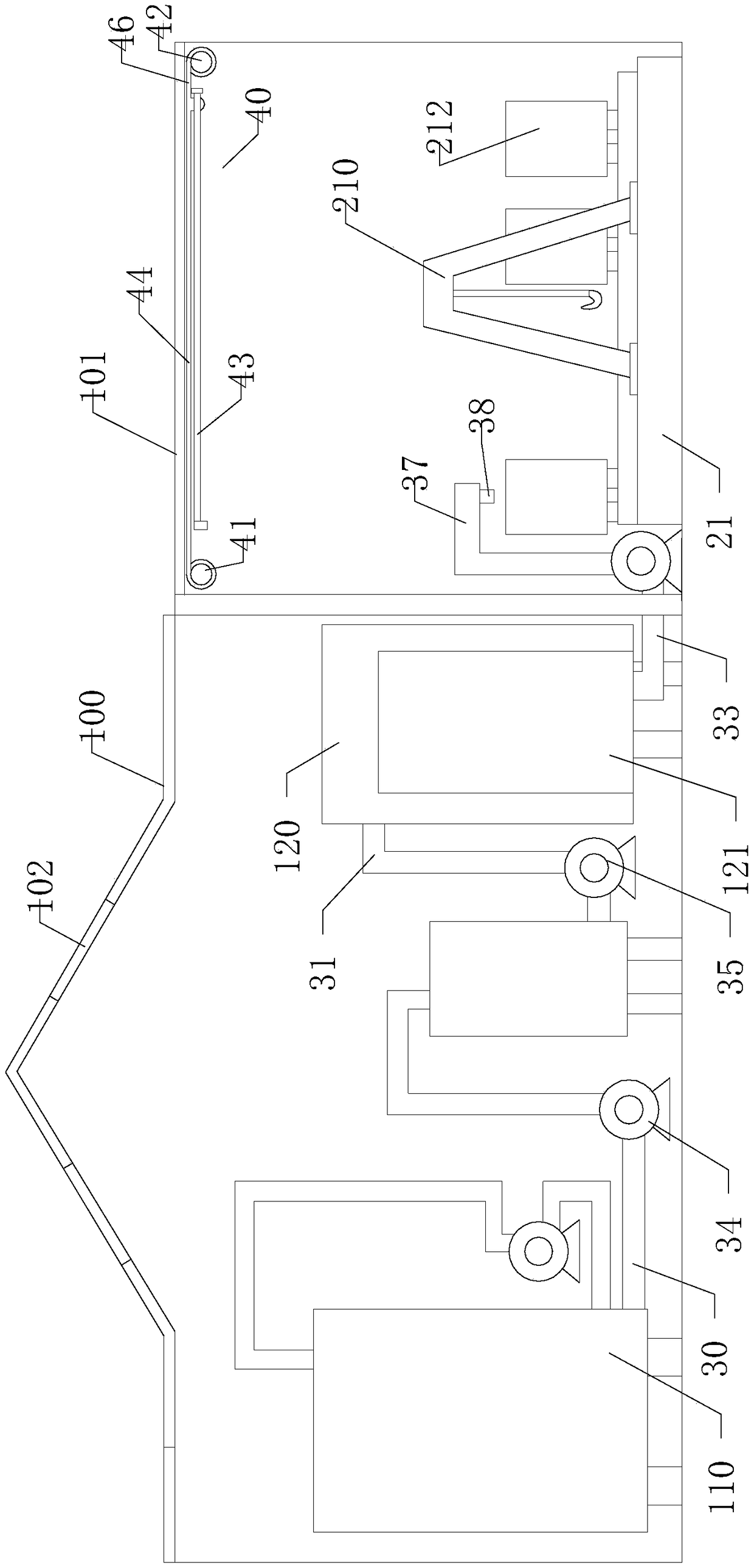

Fixture whole lamp aging detection line and operating mode thereof

InactiveCN101893690ACompact and reasonable structureSmall footprintLamps testingElectrical and Electronics engineeringElectrically conductive

The invention discloses a fixture whole lamp aging detection line, which comprises a fixture and a power mechanism, wherein the machine frame is provided with conveying chains through a transmission assembly; the transmission assembly is in transmission connection with the power mechanism; chain plates are arranged above the conveying chains in a row; a plurality of fixture lamp holders are arranged above the chain plates in a row along the length direction of the chain plates; conductive sockets for fixture whole lamps to be inserted into are arranged in the fixture lamp holders; conductive brushes which are connected with the conductive sockets of the fixture lamp holders electrically are arranged below the chain plates respectively; the machine frame is also provided with a conductive plate connected with an external aging power supply; the conductive plate is positioned below the upper-layer conveying chains; conductive areas corresponding to the middle and rear parts of the conveying chains are distributed on the upper surface of the conductive plate; and the conductive areas are contacted correspondingly through the conductive brushes above the conductive area. The fixture whole lamp aging detection line can be used for mounting a plurality of fixture whole lamps, makes equipment structure compact and reasonable, ensures high aging efficiency and is a fixture whole lamp aging detection line with high comprehensive performance.

Owner:胡三传

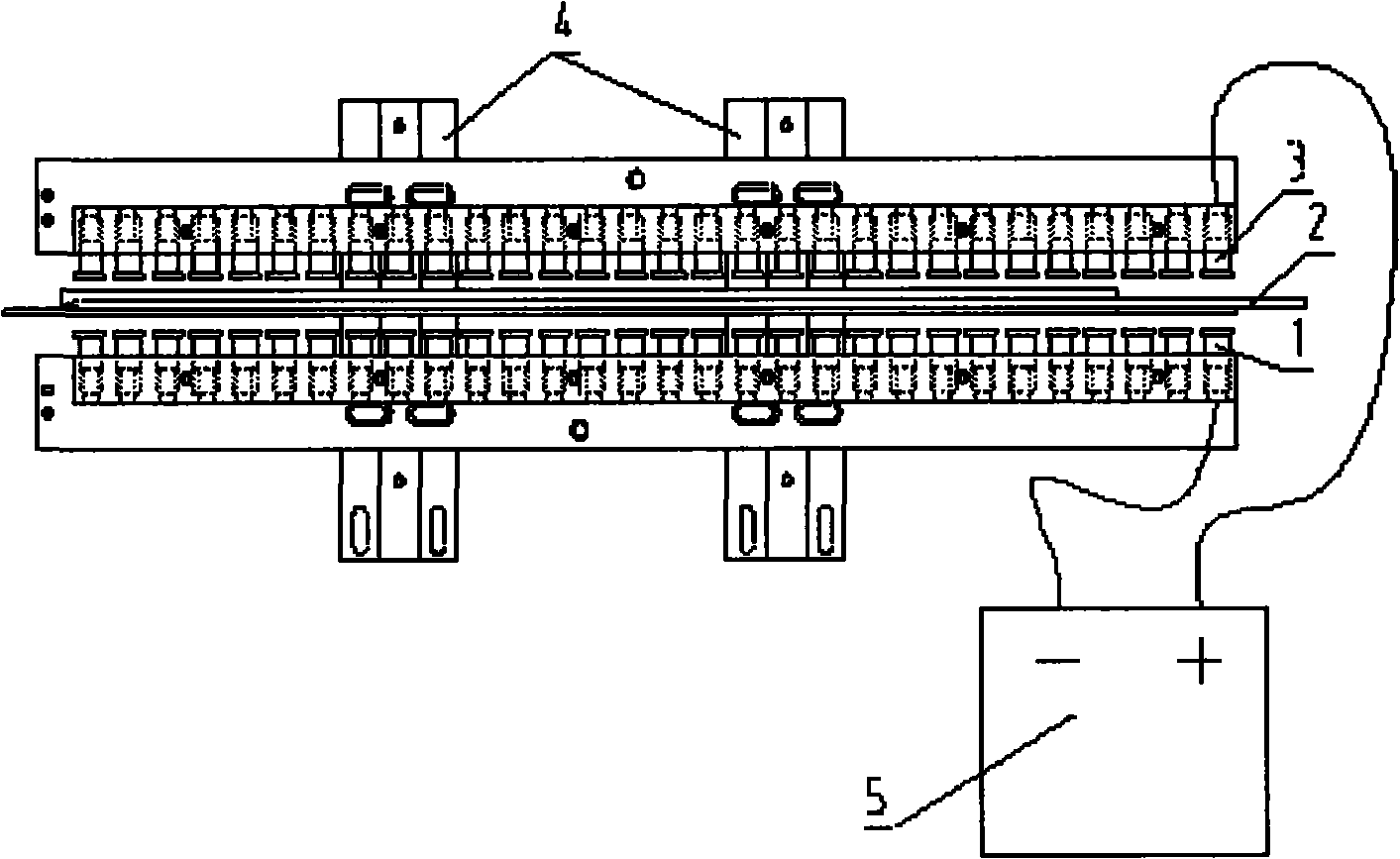

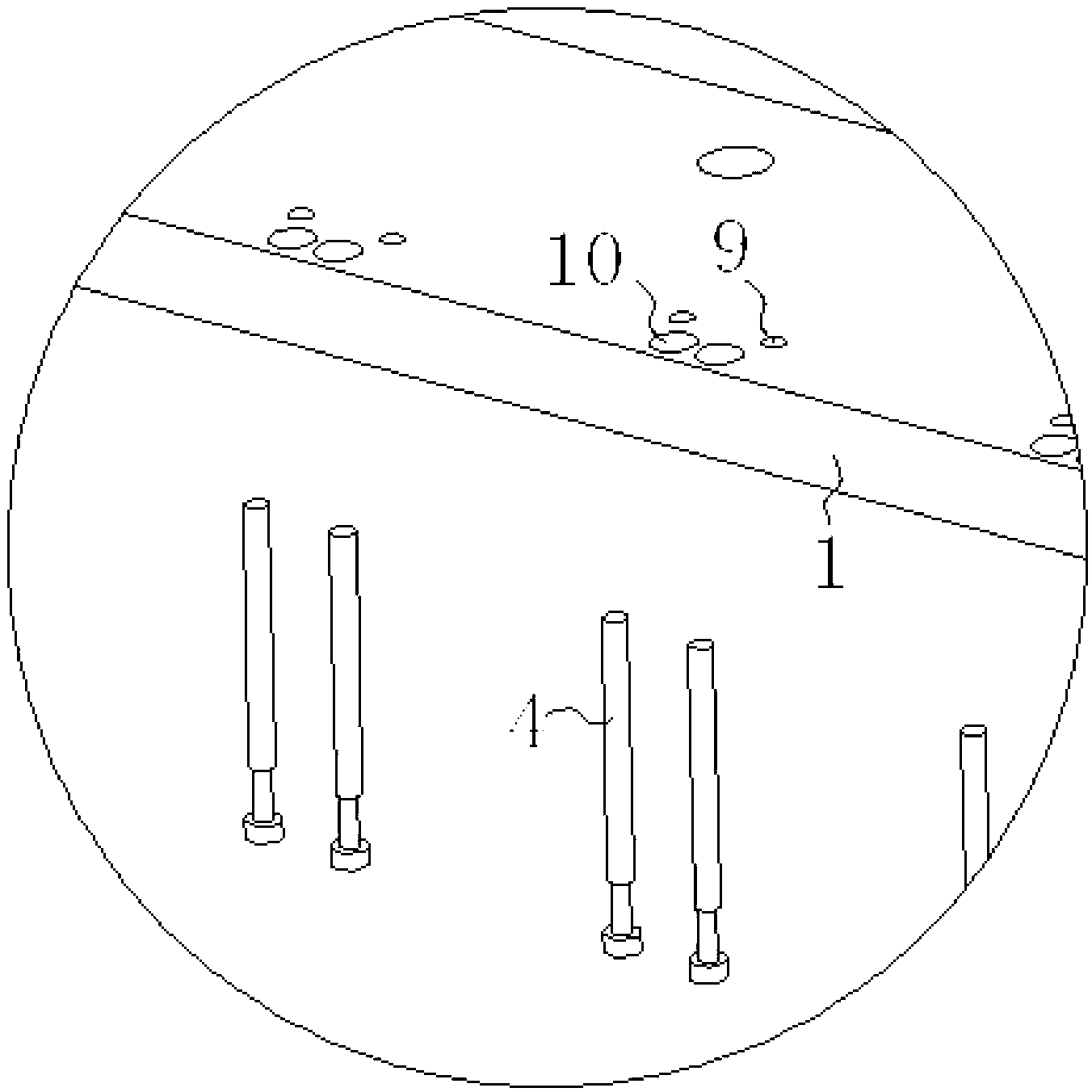

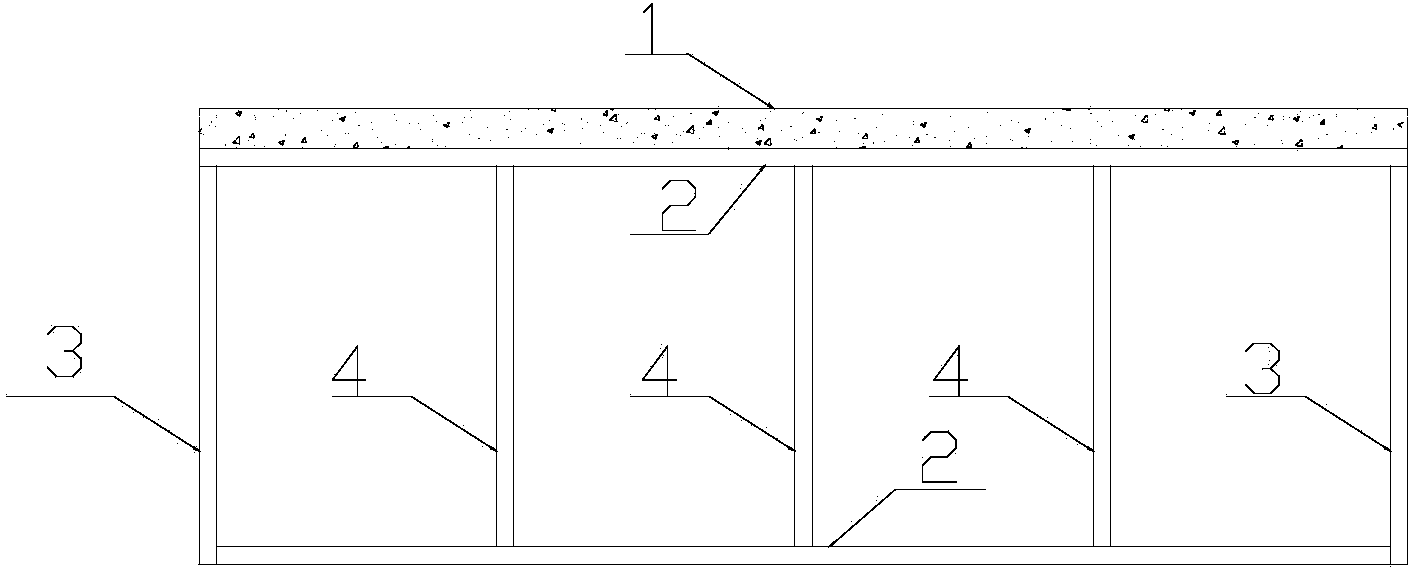

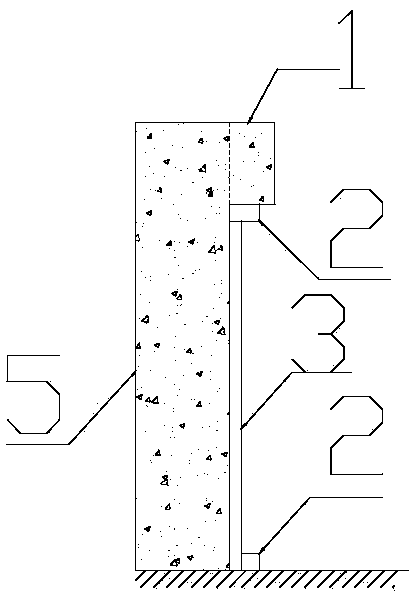

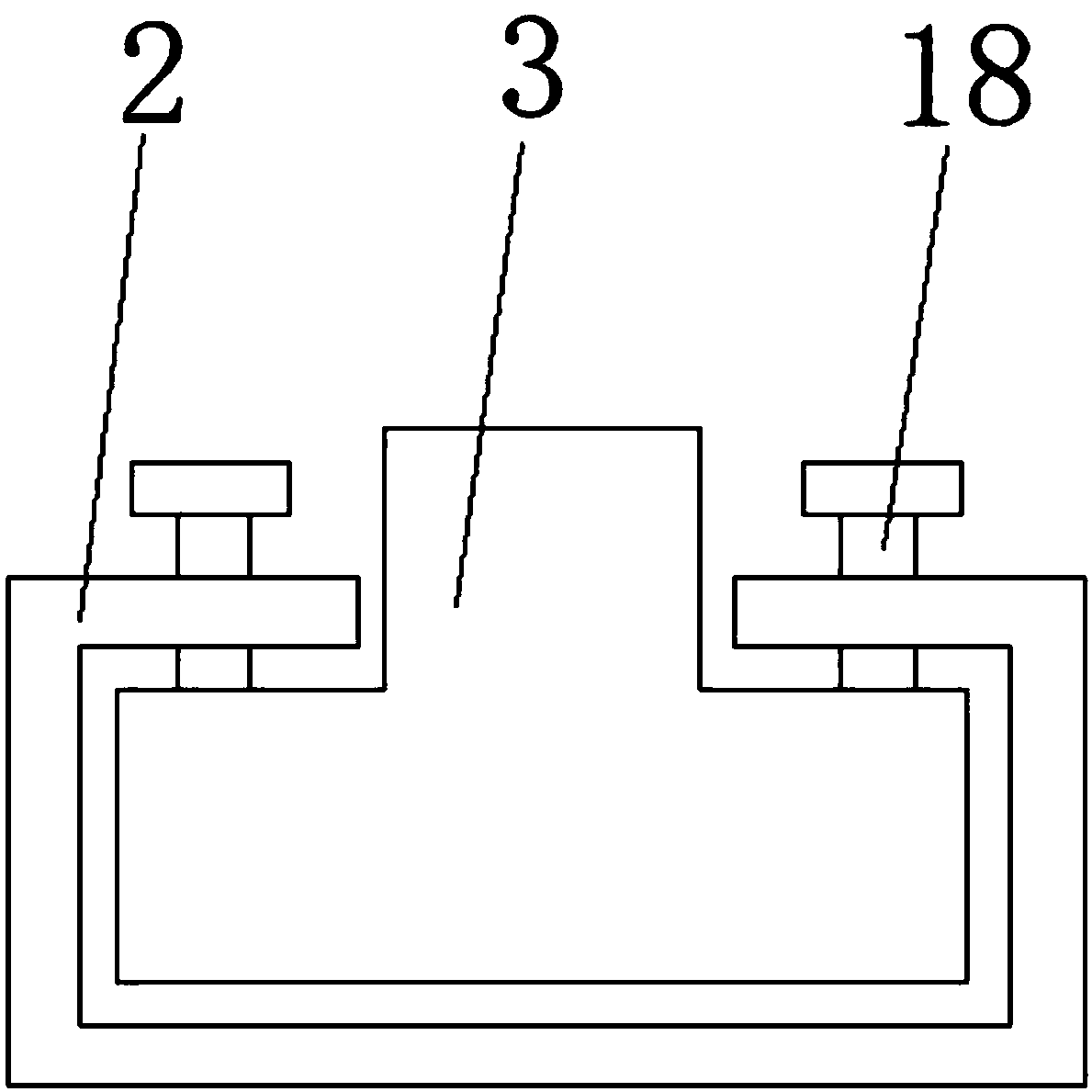

Preprocessing method and apparatus for aging aluminium electrolysis capacitor

InactiveCN101329944AAccelerated agingSpeed up agingElectrolytic capacitorsCapacitor manufactureAluminium electrolysisAge method

The invention relates to an aging method applied to processing an aluminum electrolytic capacitor and a device thereof, and provides a preprocessing method of an aluminum electrolytic capacitor before aging and a device thereof. Before aging, a charging process of the aluminum electrolytic capacitor is carried out; the current loaded to the two electrodes of the capacitor is DC current or pulse current, the current value is 30A to 150A; the voltage value is 6.3V to 120V; in the current and voltage, the burr and raw edge produced in material cutting and nail coiling processes of the aluminum electrolytic capacitor can be burned. The device of the invention consists of an anode contact (1), an isolation insulation board (2), a cathode contact (3), a sliding seat (4) of the anode and cathode contacts and a fixed power source (5). When in charge, the device can straighten the bent anode and cathode lines, thereby being conducive to aging and clipping of the capacitor. Therefore, aging speed can be increased and aging efficiency can be improved.

Owner:HUNAN AIHUA GRP

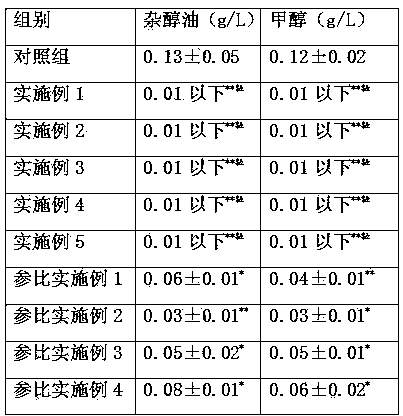

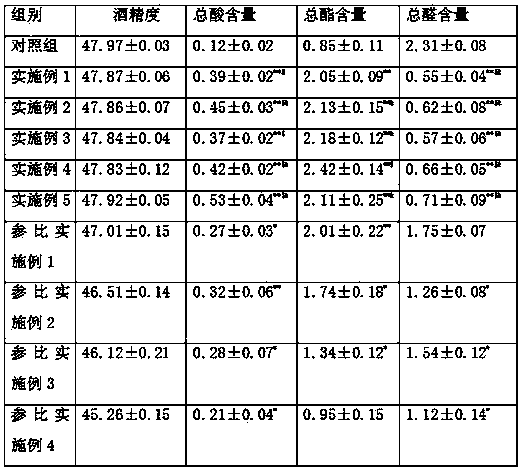

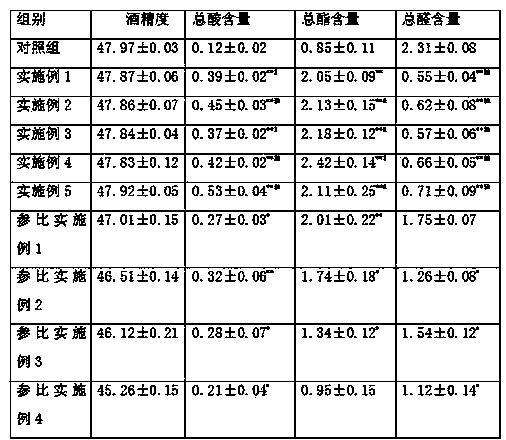

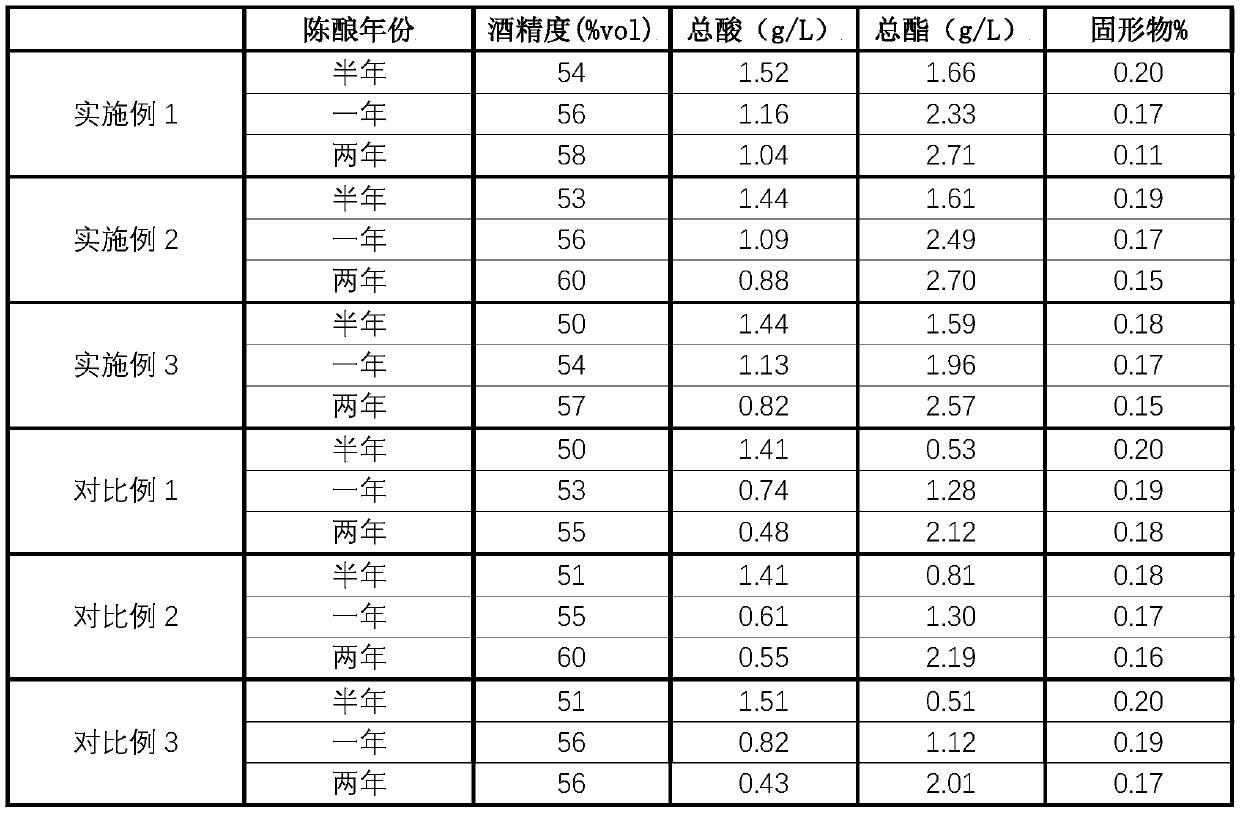

Distillation method and combined ageing method of solid state brewed liquor

InactiveCN103409298AIncreased total ester contentReduce subsequent processing costsAlcoholic beverage preparationProcess engineeringDistillation method

The invention discloses a distillation method and a combined ageing method of solid state brewed liquor, and belongs to the field of liquor brewage. In order to overcome the defects of an existing ageing method, such as long ageing time and insufficient flavor after ageing, the invention provides the distillation method and the combined ageing method of the solid state brewed liquor. The method combines distillation ventilation treatment, enzyme treatment, heating temperature control, ultrasonic treatment and micro-oxygenation to promote association of molecules in the liquor and bump of molecular energy while accelerating generation of flavor substances, so as to promote ageing of the liquor. The ageing method can obviously shorten the ageing of liquor, and the total acid and total ester in the liquor reach the national standard; in addition, the method effectively reduces the content of harmful substances in the liquor, and is suitable for demands of large-scale industrialization. Accordingly, the invention has quite wide market prospects.

Owner:广东省九江酒厂有限公司

Method for accelerating aging of vinegar with ultrasonic wave

InactiveCN104232460AAccelerated agingFacilitate chemical reactionsVinegar preparationAlcohol ethylAccelerated aging

The invention discloses a method for accelerating aging of vinegar with ultrasonic wave, and belongs to the technical field of vinegar aging acceleration. The method comprises the following steps: storing newly brewed vinegar and ethanol which accounts for 0.55-0.85% of the volume of the vinegar in a container, sealing the mount of the container, keeping the temperature inside the container to be 30-40 DEG C, and applying low-frequency high-intensity ultrasonic wave with the frequency of 18-29 KHz and the ultrasonic density of 40-60 W / 100mL (the volume ratio of the ultrasonic power to the aging accelerated vinegar) to the vinegar in the container for 60-80 minutes. By adoption of the method, the aging effect of 3-5 years of natural aging can be achieved within 60-80 minutes, the aging time is greatly shortened, and the aging acceleration effect is remarkable.

Owner:JIANGSU UNIV

Method for accelerating aging of brandy by oxidation-reduction potential combined high-pressure and micro-aerobic condition

ActiveCN103525674AAccelerated agingShorten aging timeAlcoholic beverage preparationAccelerated agingAerobic digestion

The invention relates to the technology of accelerating aging of brandy, and in particular relates to a method for quickly aging brandy by controlling irregular oak by oxidation-reduction potential combined high-pressure and micro-aerobic. The method comprises the following steps: putting brandy raw wine into a container; adding irregular oak; introducing oxygen into the brandy raw wine in the container, and applying a certain electric field intensity to control the oxidation reduction potential of the brandy raw wine to be 20mV-200mV. Therefore, extraction on the irregular oak by the brandy raw wine can be accelerated, and the aging time can be shortened. According to the method, the effect of aging the brandy raw wine for 10-30 minutes can be close to that of natural aging for 6-12 months, the aging time can be greatly shortened, and the aging efficiency can be remarkably improved.

Owner:HUIZHOU UNIV +2

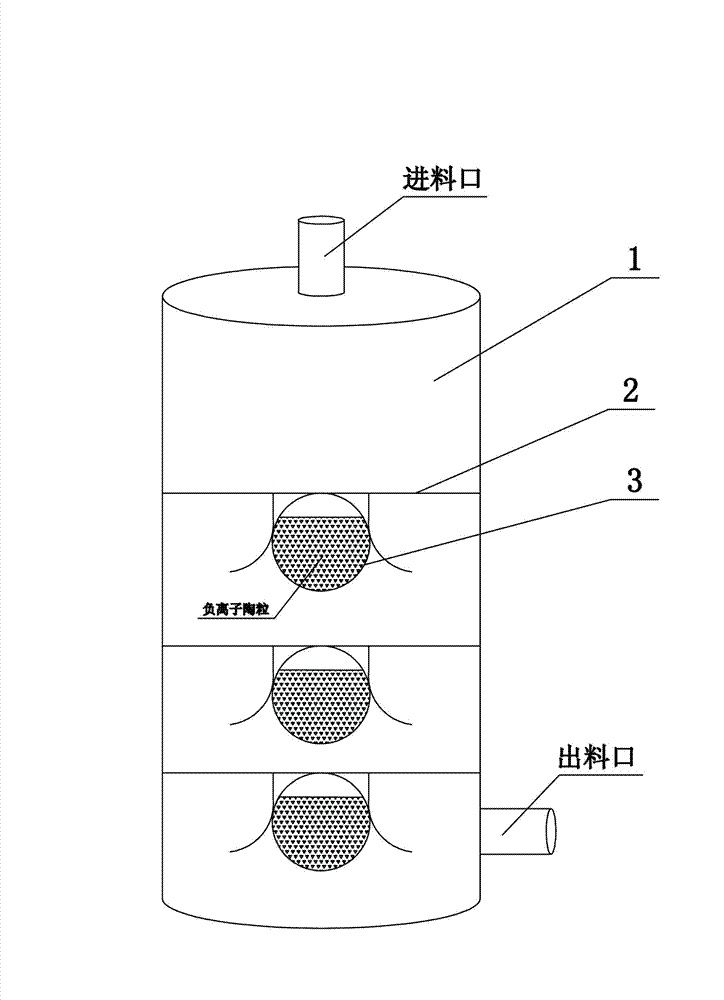

Anion ceramsite for ageing white spirit, preparation method of anion ceramsite and white spirit ageing equipment

InactiveCN103113084AChange affinityTo achieve the purpose of aging liquorAlcoholic beverage preparationClaywaresNano catalystPtru catalyst

The invention provides an anion ceramsite for ageing white spirit, a preparation method of the anion ceramsite and white spirit ageing equipment. The anion ceramsite is prepared by mixing high-activity anion ceramsite composite powder with other silicatematerials, adding trace nano catalysts, namely, ZNS (Zinc Sulfide) and CU (Copper), and then firing at high temperature, and can change the affinity among the molecules of the white spirit, thus the purpose of ageing the white spirit can be realized, and as a result, the newly produced base liquor can reach the standard of 5-year or 10-year-storage liquor quality. By adopting the anion ceramsite, the white spirits at all levels can be aged, and the filtered and aged liquor is mellow, sticky and fragrant, and is free from biting taste.

Owner:周云山

Liquid state liquor distillation method and combined ageing method thereof

InactiveCN103409299AIncreased total ester contentReduce subsequent processing costsAlcoholic beverage preparationTemperature controlLiquid state

The invention discloses a liquid state liquor distillation method and a combined ageing method thereof, and belongs to the field of liquor brewage. In order to overcome the defects of an existing ageing method, such as long ageing time and insufficient flavor after ageing. The invention provides a liquid state liquor distillation method and a combined ageing method thereof. The distillation technology in the method employs ventilation and temperature control to effectively remove harmful components in the liquor; the ageing method combines distillation ventilation treatment, microbiological treatment, heating temperature control, ultrasonic treatment and micro-oxygenation to promote association of molecules in the liquor and bump of molecular energy while accelerating generation of flavor substances, so as to promote ageing of the liquor. The distillation method and the ageing method can obviously shorten the ageing of liquor, and the total acid and total ester in the liquor reach the national standard; in addition, the methods effectively reduce the content of harmful substances in the liquor, and are suitable for demands of large-scale industrialization. Accordingly, the invention has quite wide market prospects.

Owner:广东省九江酒厂有限公司

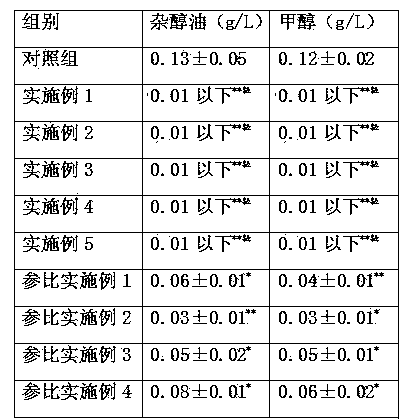

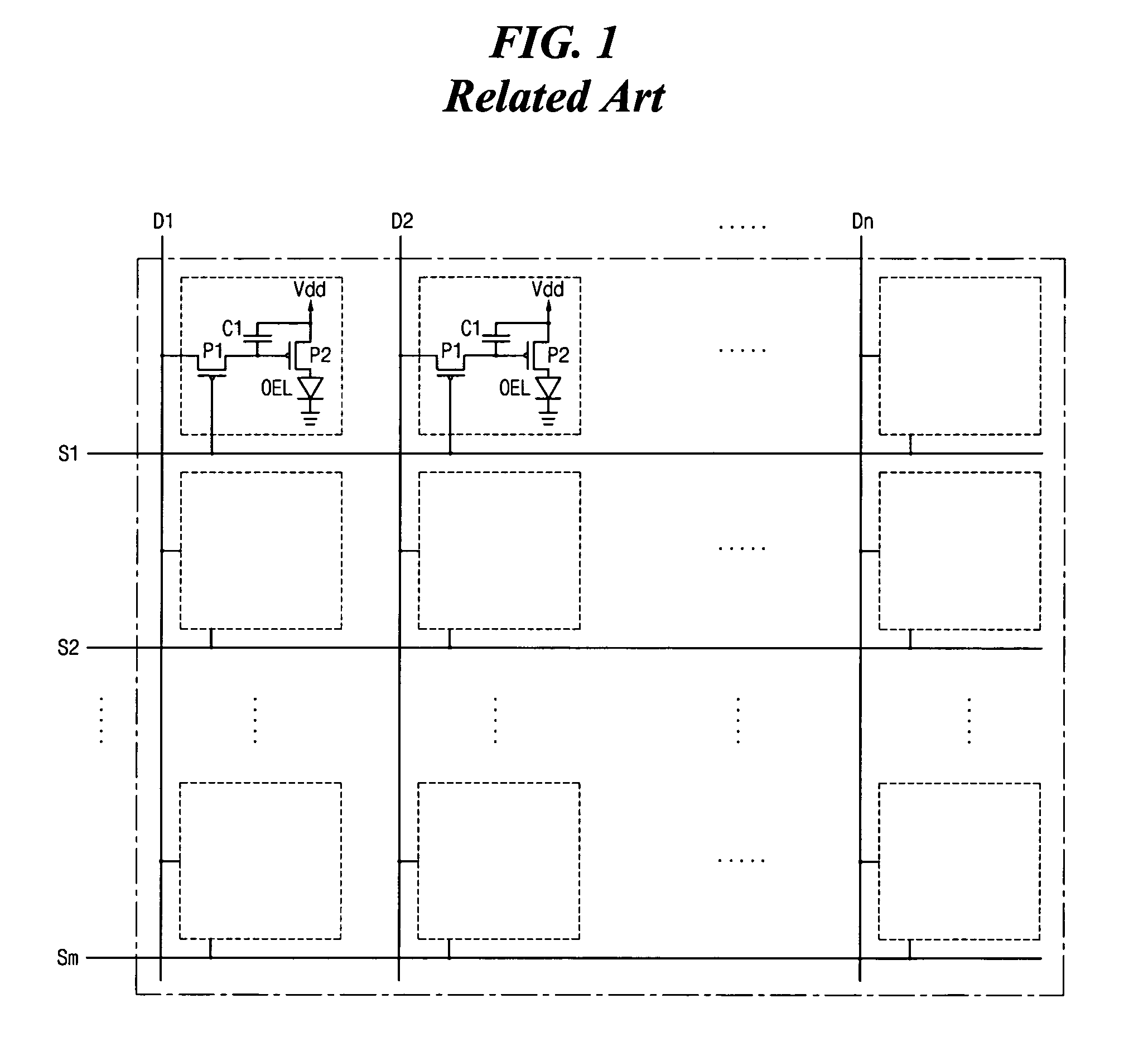

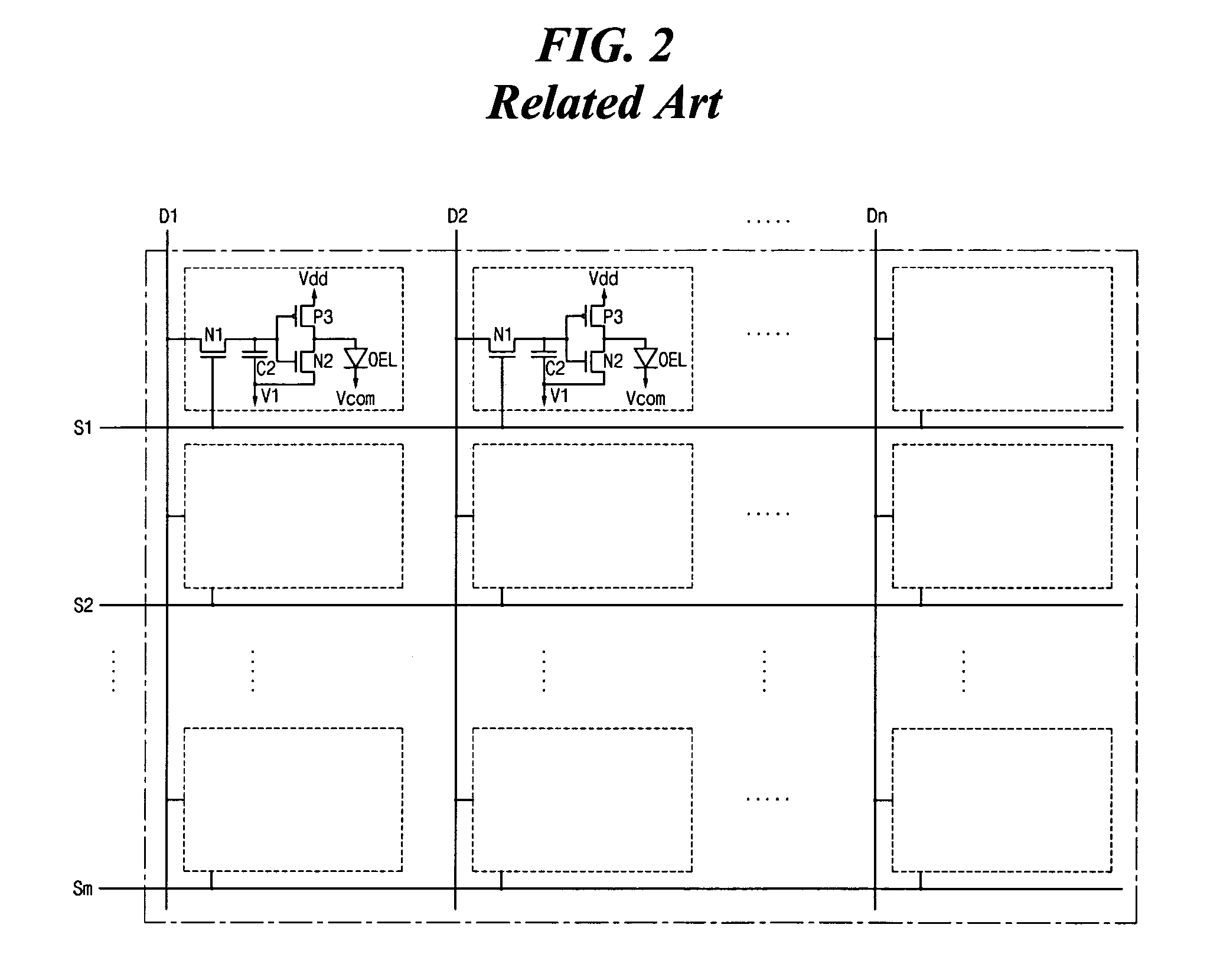

Organic electroluminescent display device and driving method thereof

ActiveUS7187133B2Reduce stepsAverage power consumptionElectrical apparatusElectroluminescent light sourcesData signalEngineering

An organic electroluminescent display device includes a gate line receiving a gate signal, a data line crossing the gate line, the data line receiving a data signal, a first transistor switching the data signal according to the gate signal, the first transistor being turned on during a single horizontal scan time period having first and second sub-periods, a second transistor switching a source voltage according to the data signal and connected to the first transistor, a storage capacitor connected to a first node between the first and second transistors and connected to the source voltage, a third transistor switching a first voltage signal and connected to the second transistor, the first voltage signal having different voltage levels during the first and second sub-periods of the scan time period, and an organic electroluminescent diode connected to a second node between the second and third transistors and connected to a ground voltage.

Owner:LG DISPLAY CO LTD

Catalytic cracking catalyst continuous aging method and device

The invention relates to a catalytic cracking catalyst continuous aging method and a catalytic cracking catalyst continuous aging device. The method comprises the steps that: a catalyst enters a bottom of a dilute-phase combustion tube, and then mixed with oxygen-containing gas and a fuel; the mixture is combusted and flows upward; gas-solid separation is carried out at the port of the dilute-phase combustion tube; catalyst obtained by separation enters a fluidized-bed reactor; the catalyst is subjected to a reaction with steam, such that activity is reduced; gas-solid separation is carried out at the top of the fluidized-bed reactor, and gas is discharged out of the device; the catalyst enters a catalyst buffering tank from the bottom of fluidized-bed reactor, and is circulated back to the bottom of the dilute-phase combustion tube through a control valve; when aging is finished, the catalyst is unloaded; material level in the catalyst buffering tank is maintained, and the catalyst continues to participate in circulation reaction in the dilute-phase combustion tube and the fluidized-bed reactor. The invention also relates to a device used for realizing the aging method. With the aging method and device provided by the invention, combustion reaction and hydro-thermal reaction operation conditions can be respectively controlled; and activity of aged catalyst is uniformly distributed. When the catalyst is used in hydrocarbon oil catalytic cracking reactions, product distribution can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

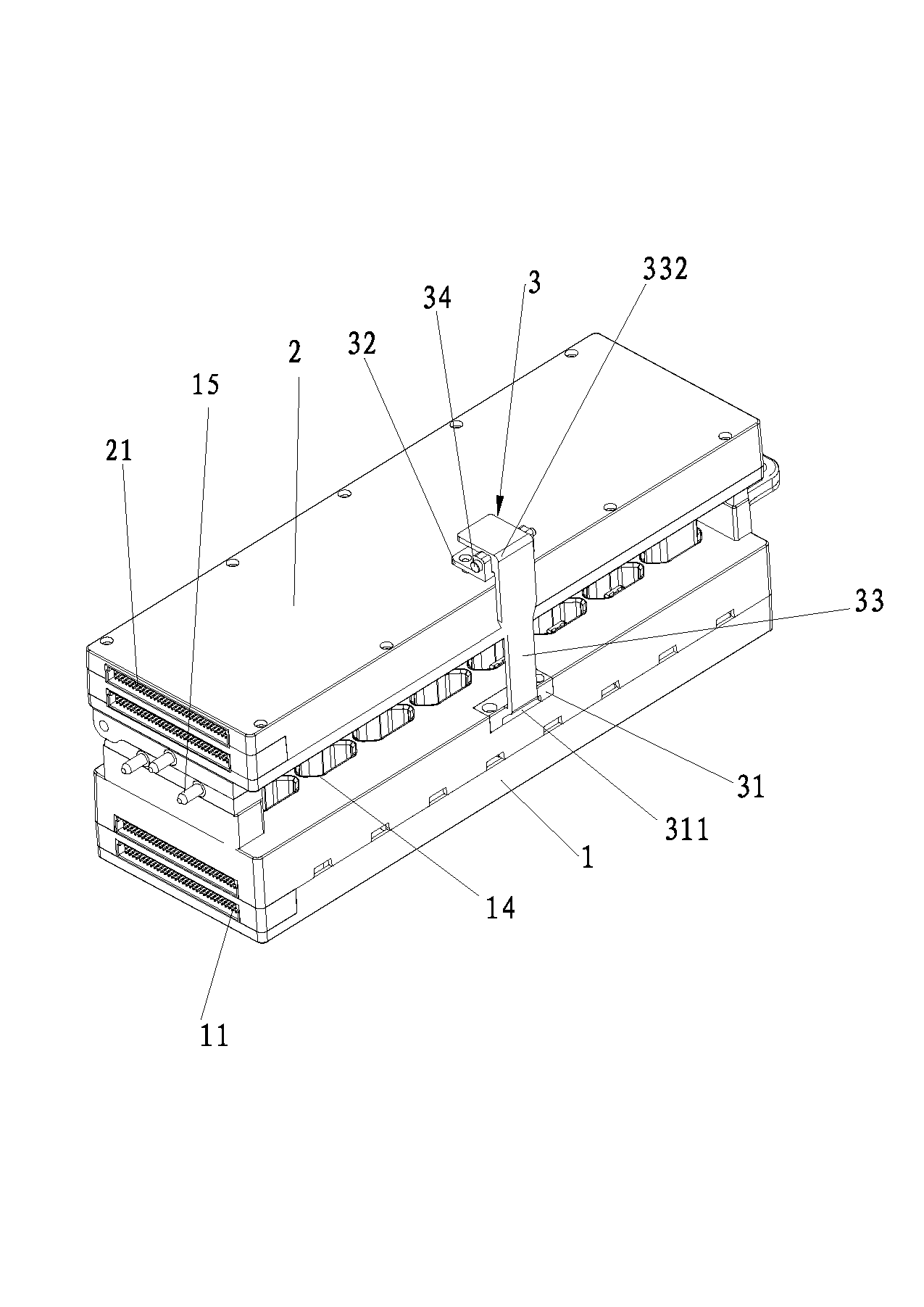

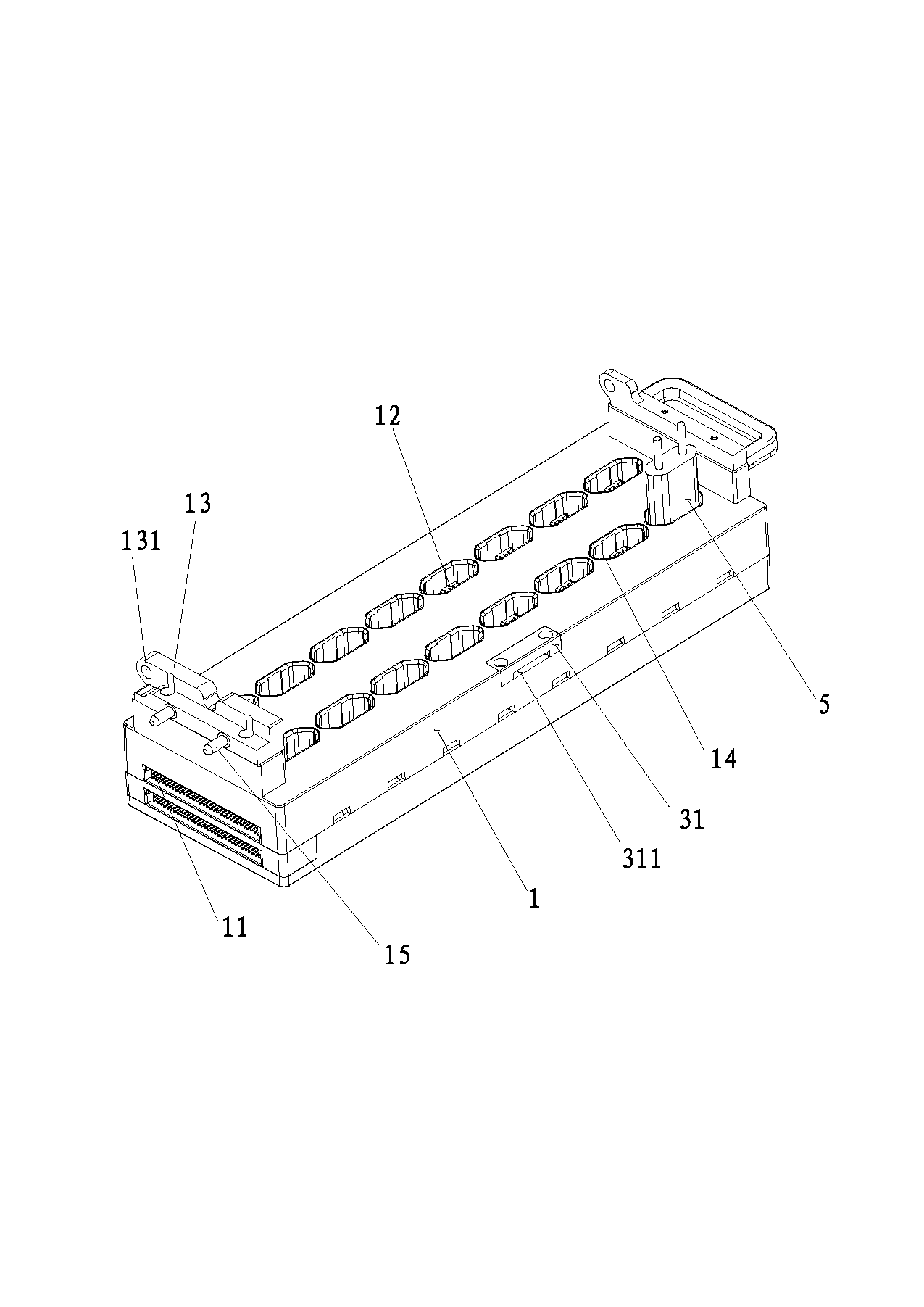

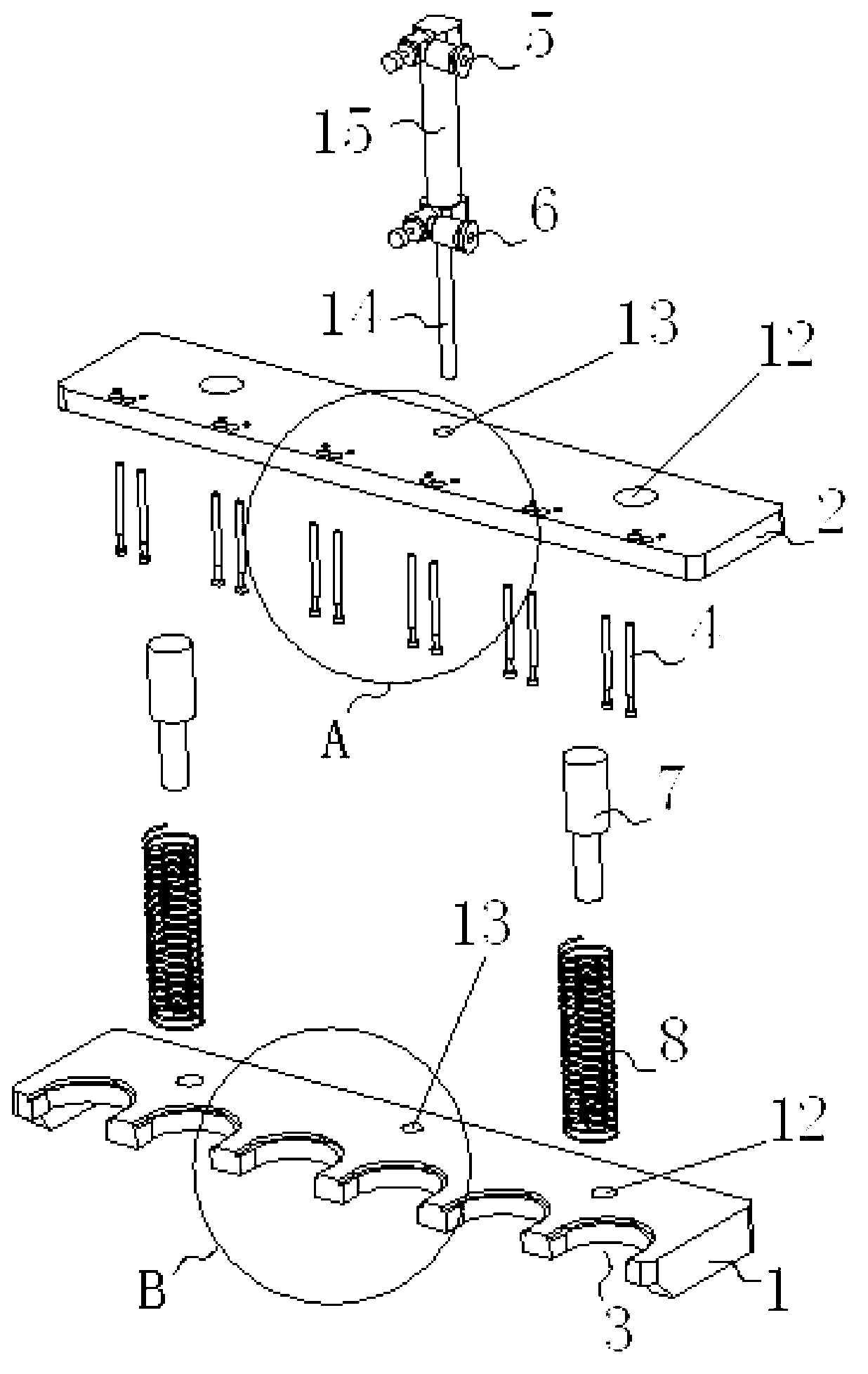

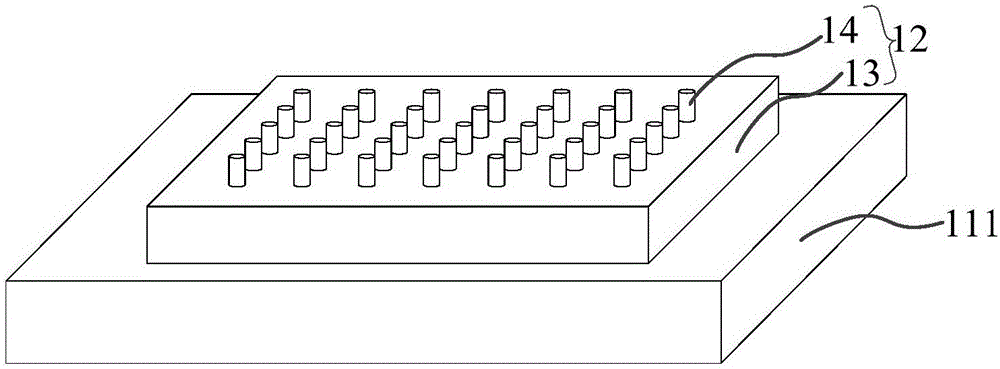

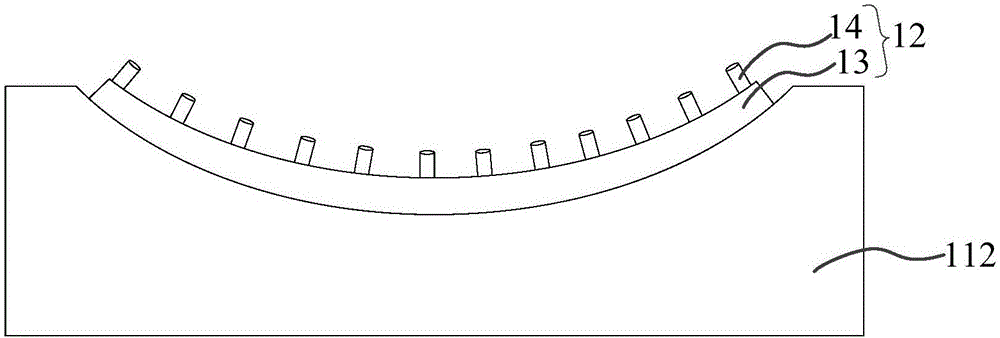

Jig for aging tests

ActiveCN102590667AImprove aging efficiencyImprove test efficiencyElectrical testingMeasurement instrument housingTest efficiencyEngineering

The invention relates to the technical field of ageing tests, particularly relates to a jig for aging tests, and structurally comprises a base and an upper cover arranged above the base. The base is provided with a base printed circuit board (PCB) which is provided with a direct current (DC) signal connecting device, a product placing groove is arranged on the inner surface of the base opposite to the upper cover, and a DC signal interface is arranged in the produce placing groove and electrically connected with the DC signal connecting device through the base PCB. An upper cover PCB is arranged in the upper cover and provided with an alternating current (AC) signal connecting device, and the AC signal connecting device is electrically connected with an AC signal interface. The jig for aging tests has the advantages of being simple in structure, simple and rapid to operate and high in aging testing efficiency, and particularly meets requirements for rapid development of modern enterprises.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

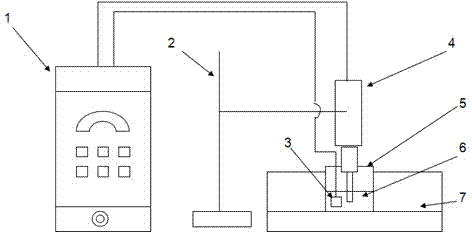

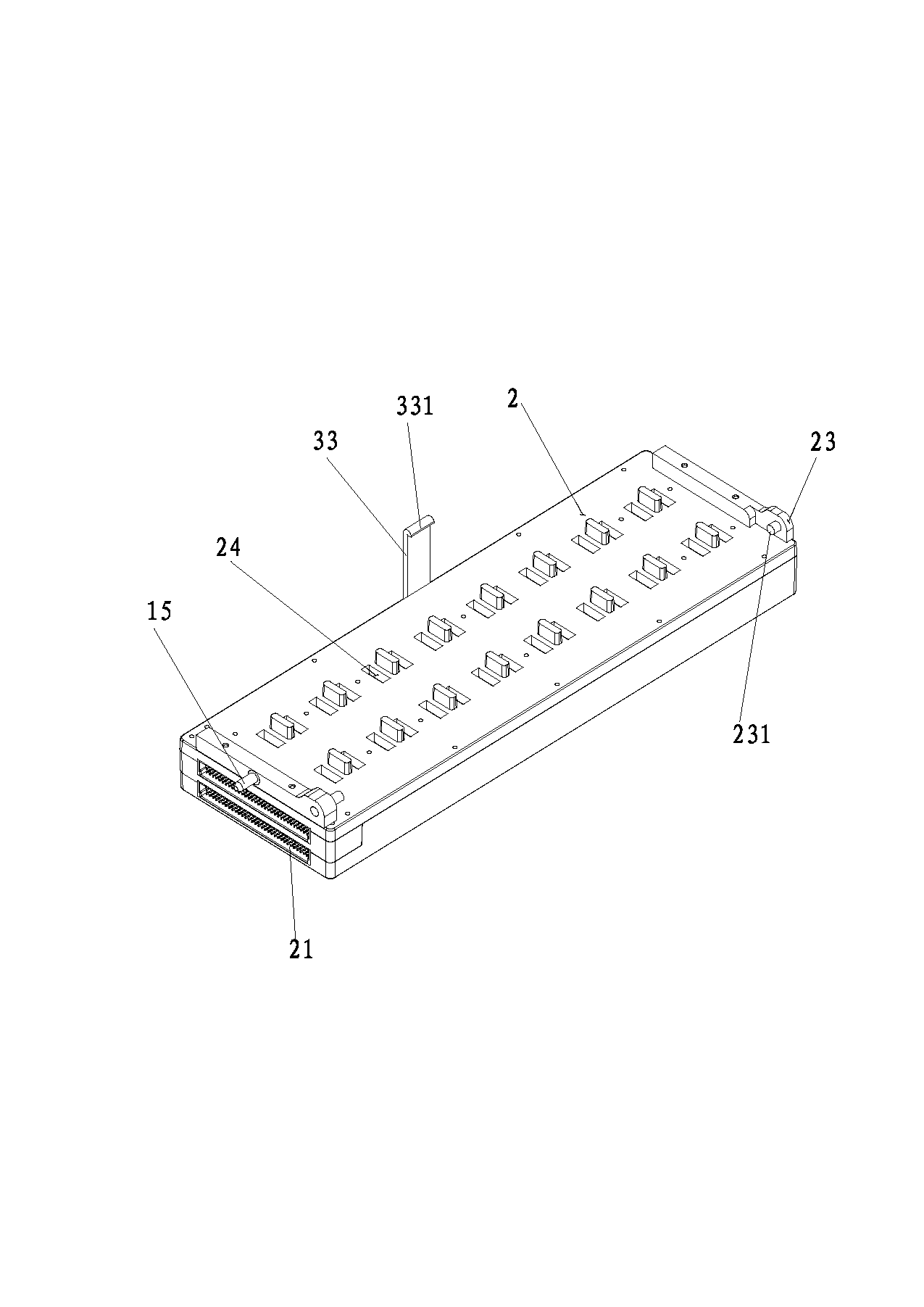

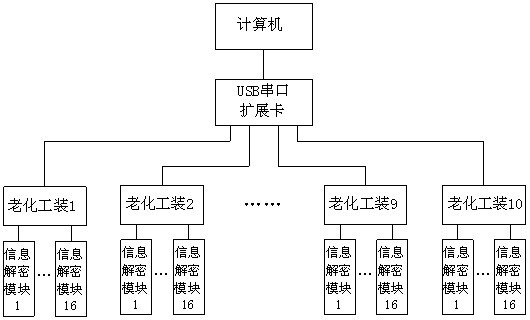

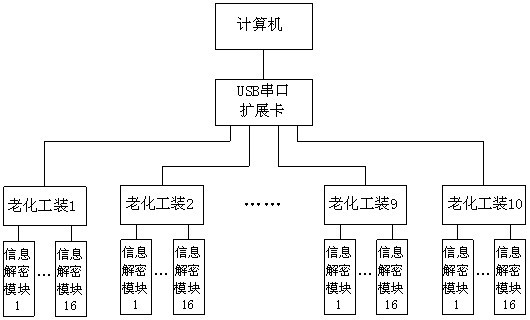

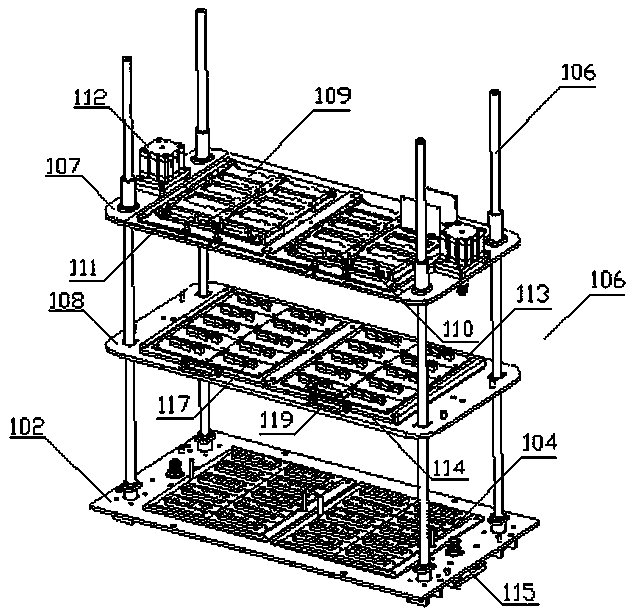

Batch aging tooling system for information decryption module of second-generation ID (Identification) card reader

The invention discloses a batch aging tooling system for an information decryption module of a second-generation ID (Identification) card reader, which comprises a computer, a USB (Universal Serial Bus) serial-port expansion card, at least one aging tooling and a plurality of information decryption modules, wherein one end of the USB serial-port expansion card is connected with the computer through a USB interface; the other end of the USB serial-port expansion card is connected with the aging tooling through a serial interface; each ageing tooling is connected with at least one information decryption module; the aging tooling mainly comprises a microcontroller, a patch cable socket, a decoder chip, light emitting diodes and a data switching circuit; the patch cable socket, the decoder chip, the light emitting diodes and the data switching circuit are respectively connected with the microcontroller; and each light emitting diode is respectively connected with the output of a decoder. The aging tooling system disclosed by the invention has the characteristics of batch aging, high aging efficiency, long service life, high reliability for reading the card, favorable work stability ofthe information decryption modules, capability of monitoring the work conditions of the information decryption modules and the like.

Owner:成都因纳伟盛科技股份有限公司 +1

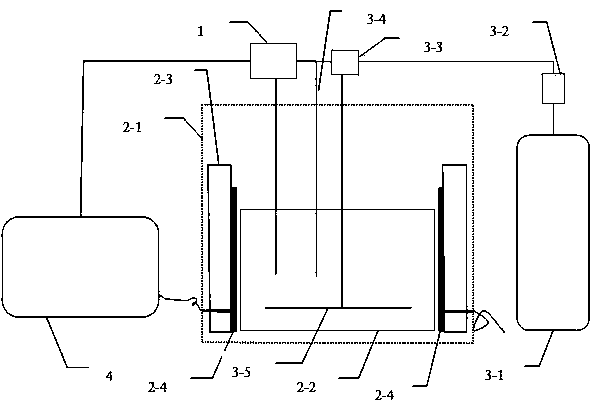

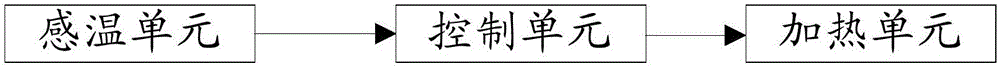

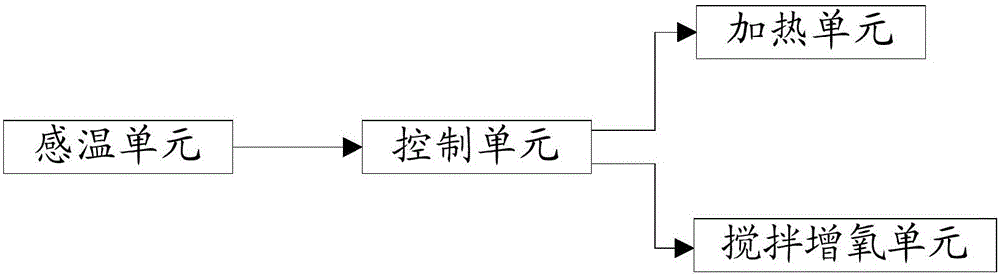

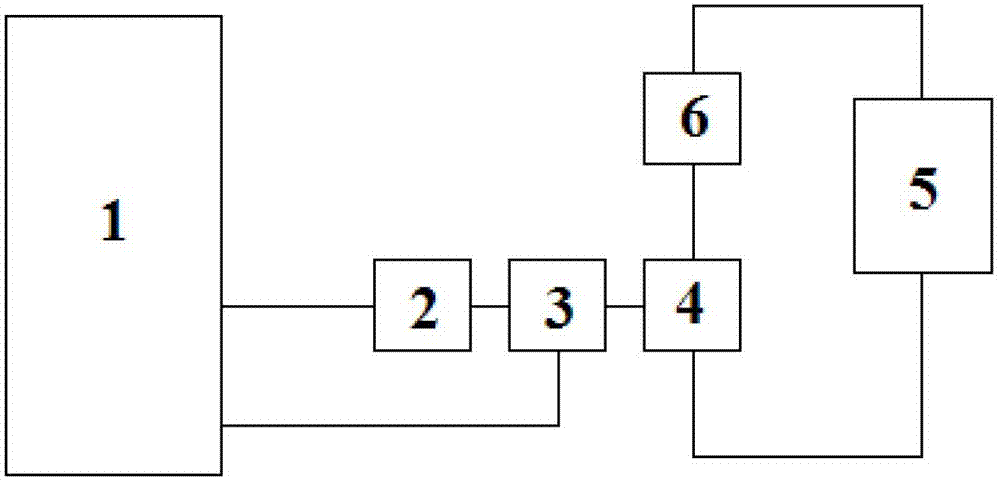

Yellow rice wine or Hualushao wine aging control system

InactiveCN106591076APromote aging reactionImprove aging efficiencyAlcoholic beverage preparationControl systemEngineering

The invention discloses a yellow rice wine or Hualushao wine aging control system. The system comprises a control unit, a temperature sensing unit connected to the control unit and a heating unit connected to the control unit. The temperature sensing unit is used to acquire the temperature value of the base wine. The control unit is used for comparing the temperature value with a preset first temperature threshold and controlling starting or stopping of the heating unit according to the comparison result. The temperature sensing unit measures a temperature value of the base wine and transmits the temperature value to the control unit, and the control unit compares the received temperature value and the preset first temperature threshold and controls starting or stopping of the heating unit according to the comparison result so that under control of the control unit, the heating unit heats the base wine or stops heating. The yellow rice wine or Hualushao wine aging control system promotes the aging reaction of the base wine, improves the aging efficiency, simplifies the control system of the aging device and reduces the production cost.

Owner:NANTONG UNIVERSITY

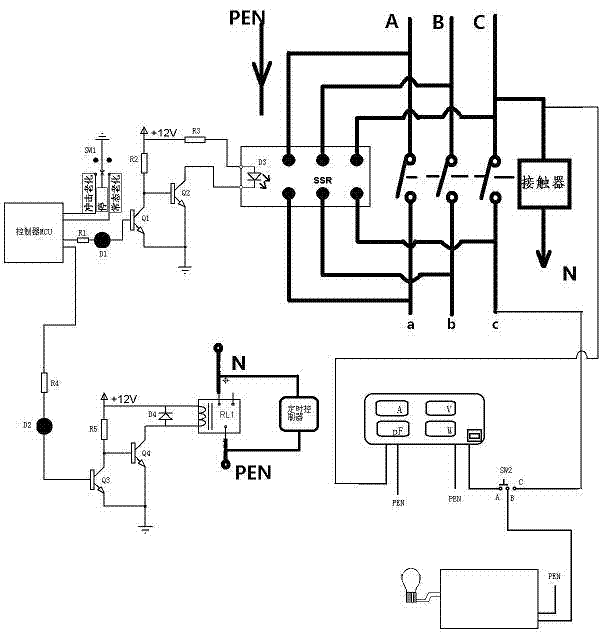

Multifunctional electrodeless lamp aging device

InactiveCN102810442AExtended service lifeEasy to useTube/lamp factory adjustmentHemt circuitsEngineering

The invention discloses a multifunctional electrodeless lamp aging device, which comprises a control MCU (Microprogrammed Control Unit), a solid state relay (SSR), an SSR driving circuit, a contactor, a contactor driving circuit, a time controller and a first select switch SW1; when the first select switch SW1 is an impact aging state, the SSR is switched on and off at intervals; when the first select switch SW1 is in a normal aging state, the SSR is switched on, and the contactor is pulled in; the SSR is switched off thereafter; and when the first select switch SW1 is in a stand-by state, a user can select a multifunctional power parameter measuring instrument for working. Due to the adoption of the multifunctional electrodeless lamp aging device, high-speed switch-on and switch-off can be realized at intervals, the phenomenon of fire striking at a pulling-in moment can be avoided for the contactor, and aging operation can be performed at a time interval when the electricity price is low to save electricity charge and energy. Above all, the multifunctional electrodeless lamp aging device has the advantages of simple structure, high reliability, high practicability and high aging efficiency.

Owner:JIANGSU GODLIGHT LIGHTING TECH

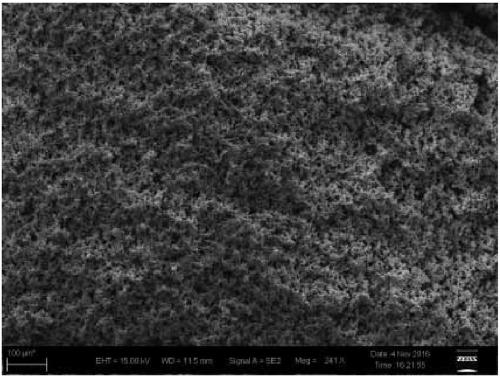

Method for preparing SiC aerogel through ultrasonic-mixing silicon source and carbon source

The invention discloses a method for preparing a SiC aerogel through ultrasonic-mixing a silicon source and a carbon source, relates to a preparation method for an aerogel, and belongs to the technical field of the aerogel. The method aims to solve technical problems of a current method for preparing the SiC aerogel that cost is high and no pore channel is existent. The method comprises the following steps: firstly, preparing a SiC precursor; and secondly, preparing the SiC aerogel. The method is capable of using inorganic silicon source water glass, and lower in cost. In a process of preparing the SiC, a method that ultrasonic for performing a carbon thermal reduction reaction with ultrasonic under the inert atmosphere conditions of a high-temperature furnace is used, atom interface mixing of Si and C is realized, and a distance between atoms is within a reaction free path range, so integrity and uniformity of the pore channel are kept, and the integrity of the pore channel is better.A SiC aerogel composite material prepared by the method can be made as a practically needed shape, and applied to the field of special-shaped piece application.

Owner:江西宏柏新材料股份有限公司

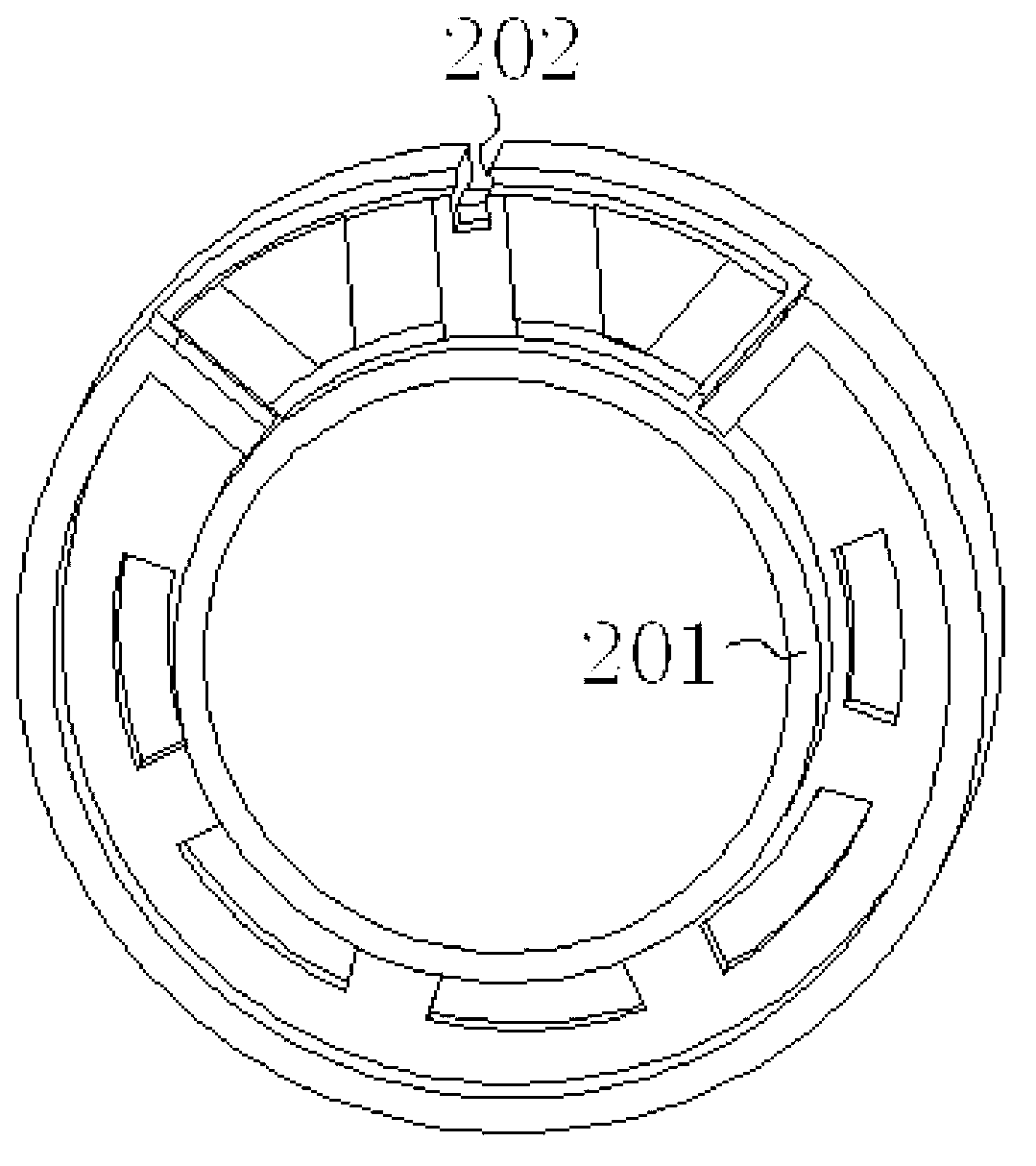

Automatic aging tool for speakers

ActiveCN103237286AImprove aging efficiencyImprove accuracyElectrical apparatusEngineeringControl switch

The invention relates to an aging tool, in particular to an aging tool for speakers. The aging tool comprises a top cover and a base which are corresponding to each other. Positioning grooves for accommodating the speakers are reserved on the base. Probes for contacting two electrodes of the speakers are fixed at the lower end of the top cover and are connected with a signal generator in series. A pushing unit for pushing the top cover to move up and down is fixed at the upper end of the top cover, and is connected with a control switch through a timer. A guide extension device is connected between the top cover and the base. With the structure, workers are only required to put products on the aging tool, required aging time is set on the timer, the workers step on pedals when operations are completed, and the tool is automatically separated when time is up. During aging, indicating lamps are off if corresponding products are not aged, and the products are taken out by the workers to be aged again. The aging tool is simple in structure, convenient to operate and low in cost, and aging efficiency and accuracy of the speakers are improved.

Owner:BESTAR HLDG

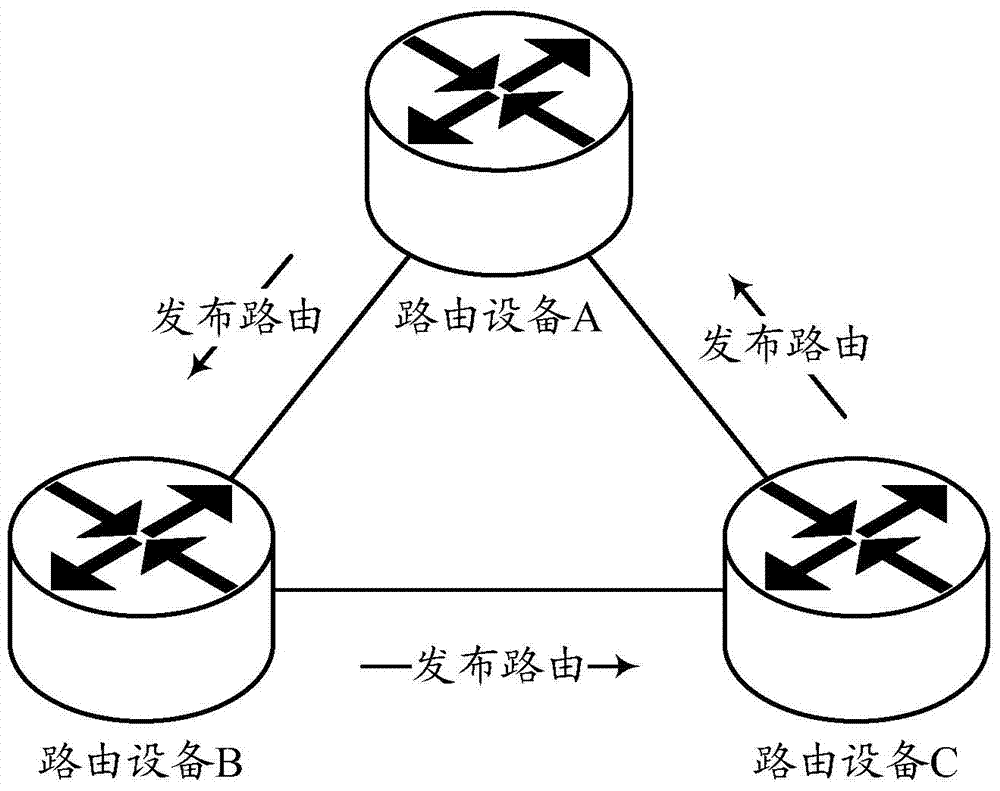

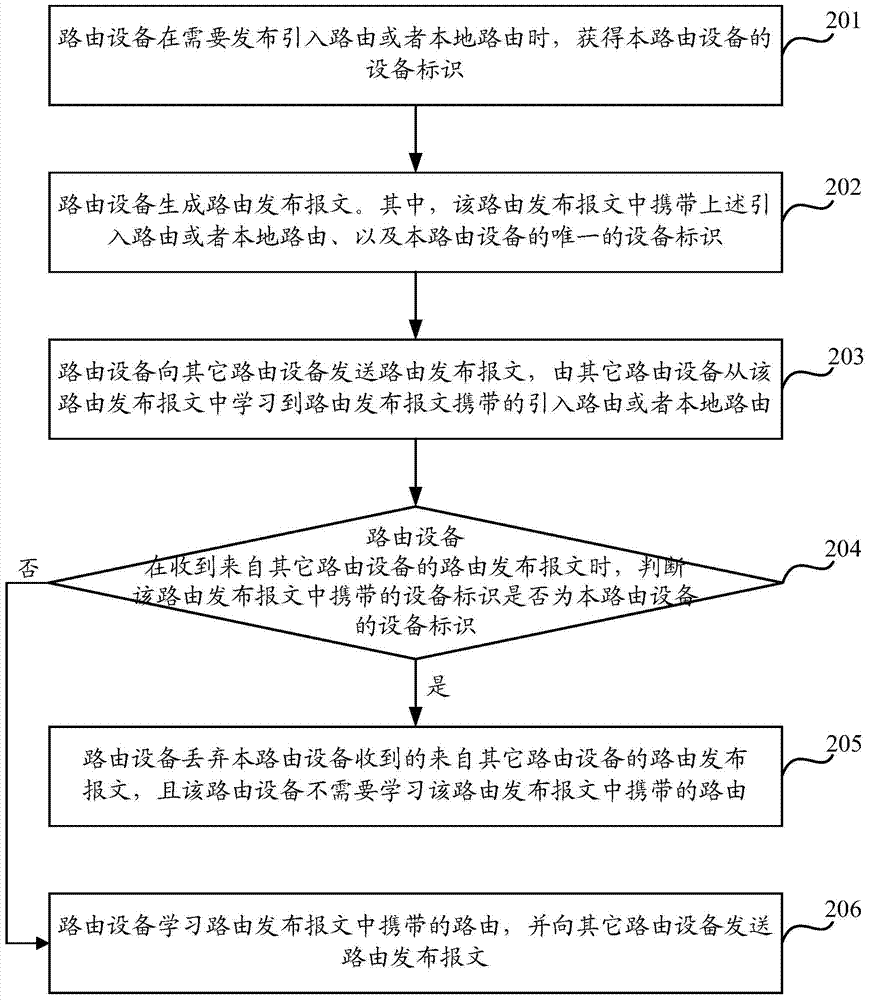

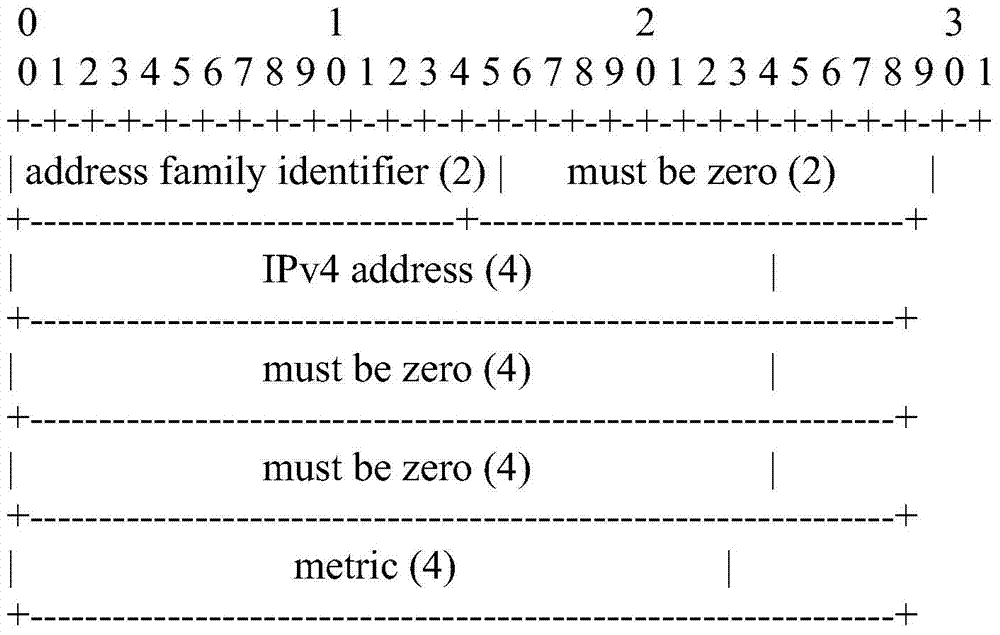

Route releasing method and device

InactiveCN103944823ADelete as soon as possibleImprove aging efficiencyData switching networksDistributed computingRelease methods

The invention discloses a route releasing method and device. The method includes the steps that when a route device needs to release an import route or a local route to obtain a device identification of the route device, the device identification of the route device is used for generating a route releasing message, and the route releasing message carries the import route, or the local route and the device identification; the route device sends the route releasing message to other route devices; when the route device receives route releasing messages from other route devices, if the route releasing messages carry the device identification of the route device, the route device abandons the route releasing messages. In the embodiment of the route releasing method and device, after the route is invalidated, a route loop can be prevented from forming, and route calculating efficiency can be improved.

Owner:NEW H3C TECH CO LTD

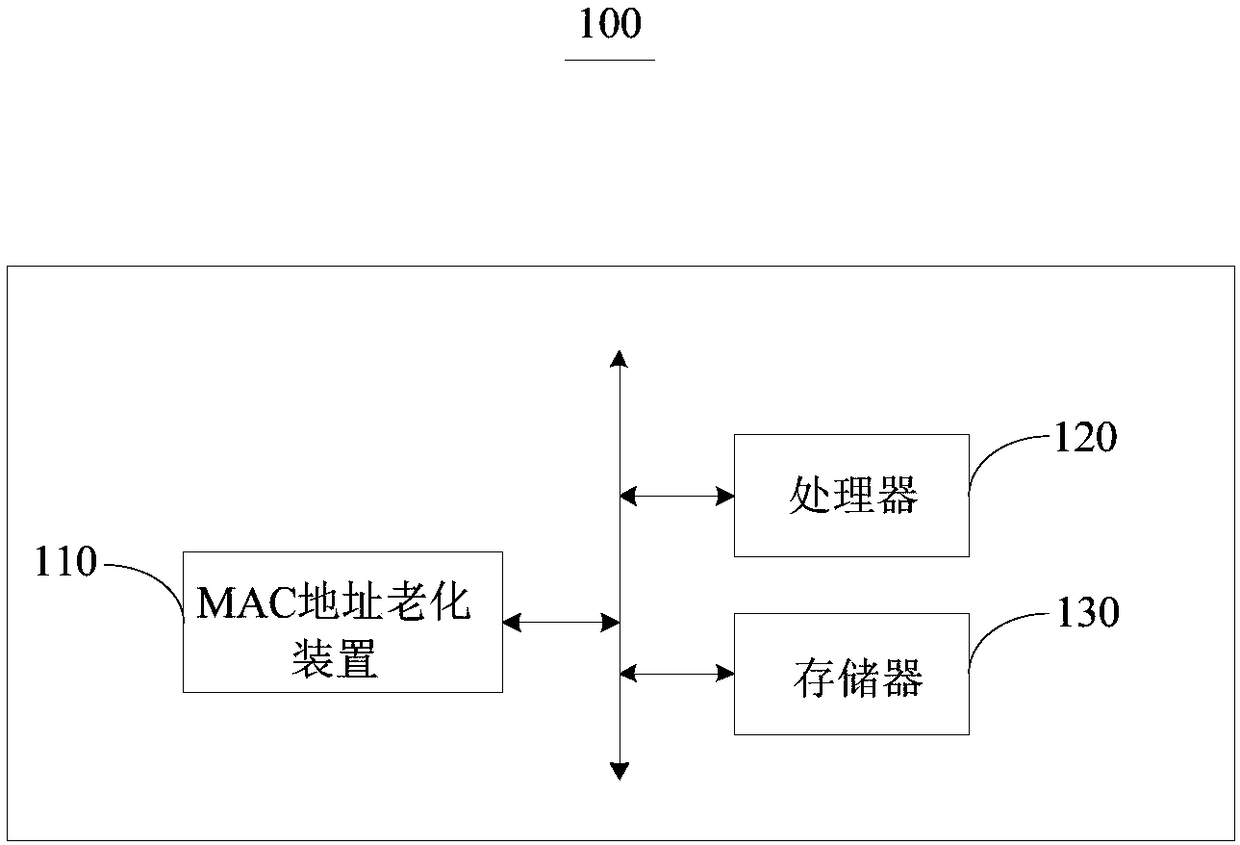

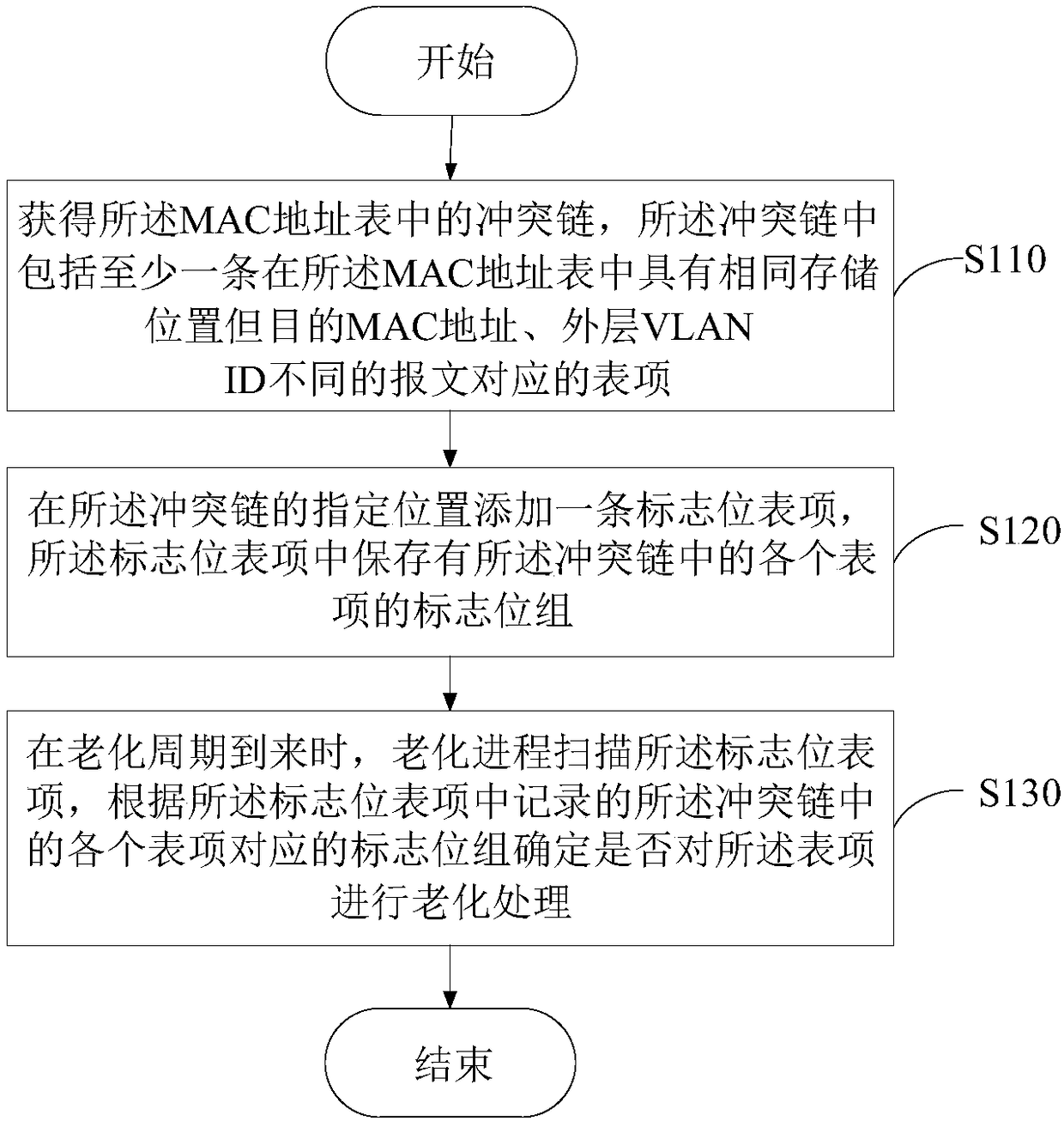

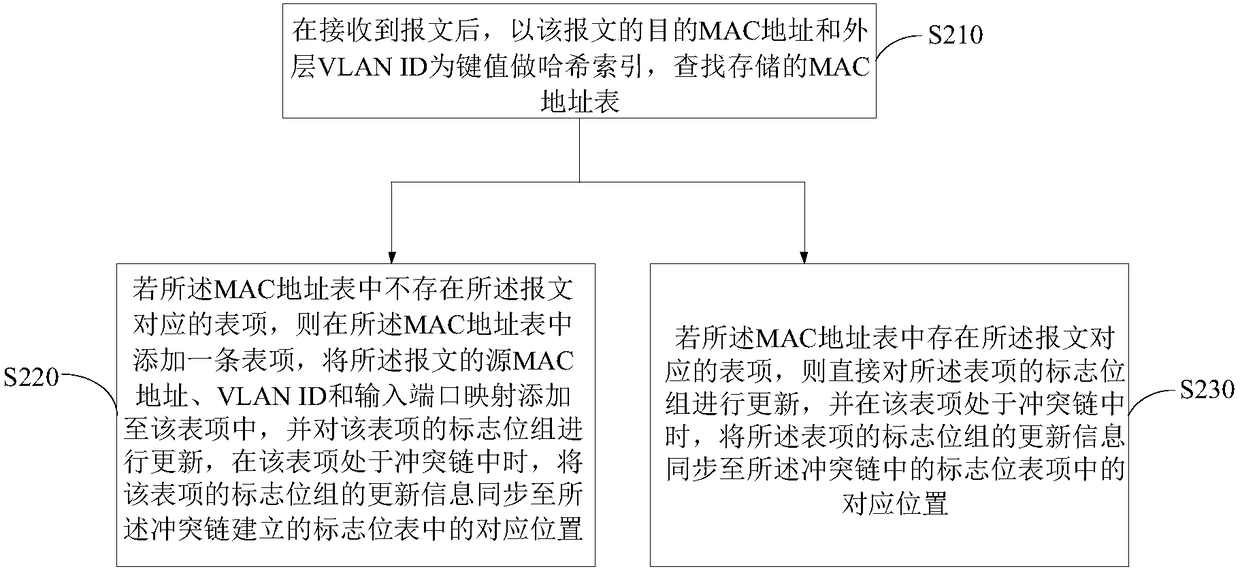

MAC address aging method and device and electronic equipment

The embodiment of the invention provides an MAC address aging method and device and electronic equipment. An MAC address table is saved in the electronic equipment. The method includes the steps of obtaining a conflict chain in the MAC address table, wherein the conflict chain includes at least a table item corresponding to a serial port with a same saving position in the MAC address table and a different target MAC address and outer-layer VLAN ID; adding a zone bit table item at a designated spot of the conflict chain, wherein a zone bit set of each table item in the conflict chain is saved in the zone bit table item; when an aging period comes, making an aging process scan the zone bit table item, and according to the zone bit set which corresponds to each table item in the conflict chain and is recorded in the zone bit table item, determining whether or not aging treatment is conducted on the table item. According to the MAC address aging scheme, by adding the zone bit table item, the zone bit table item can be directly scanned when aging is conducted, according to the aging-related zone bit set of each table item in the conflict chain in the zone bit table item, whether or notaging treatment is conducted on the table item is determined, and the aging efficiency is improved.

Owner:SHENZHEN FORWARD IND CO LTD

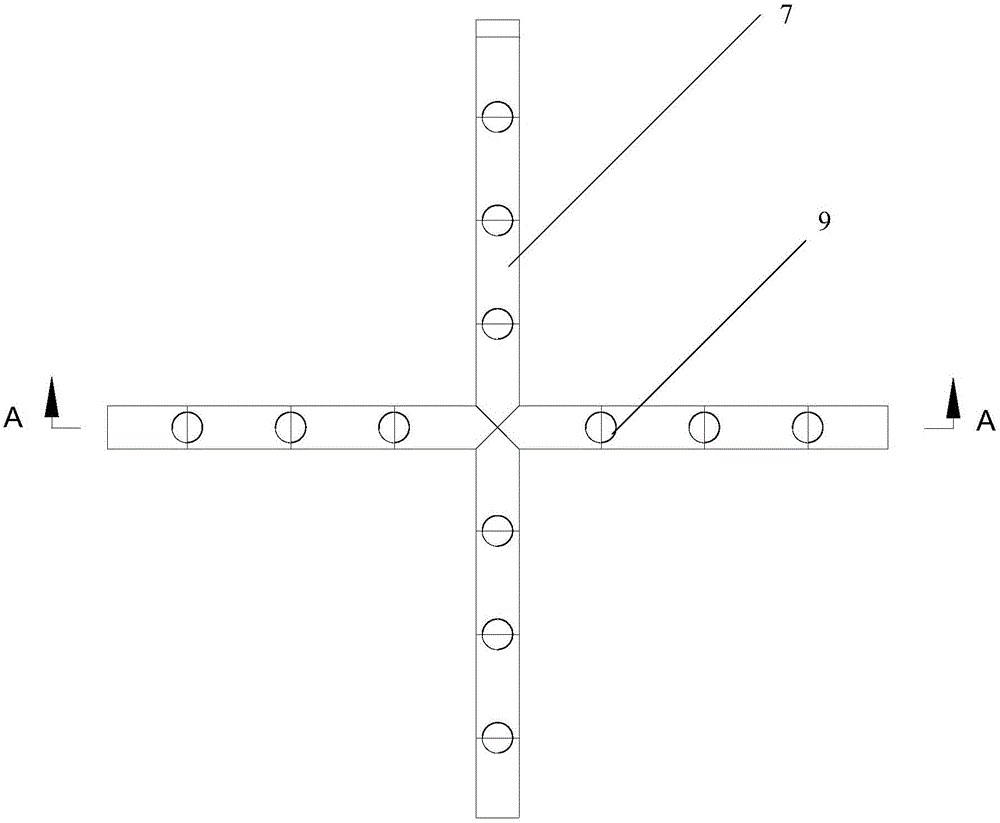

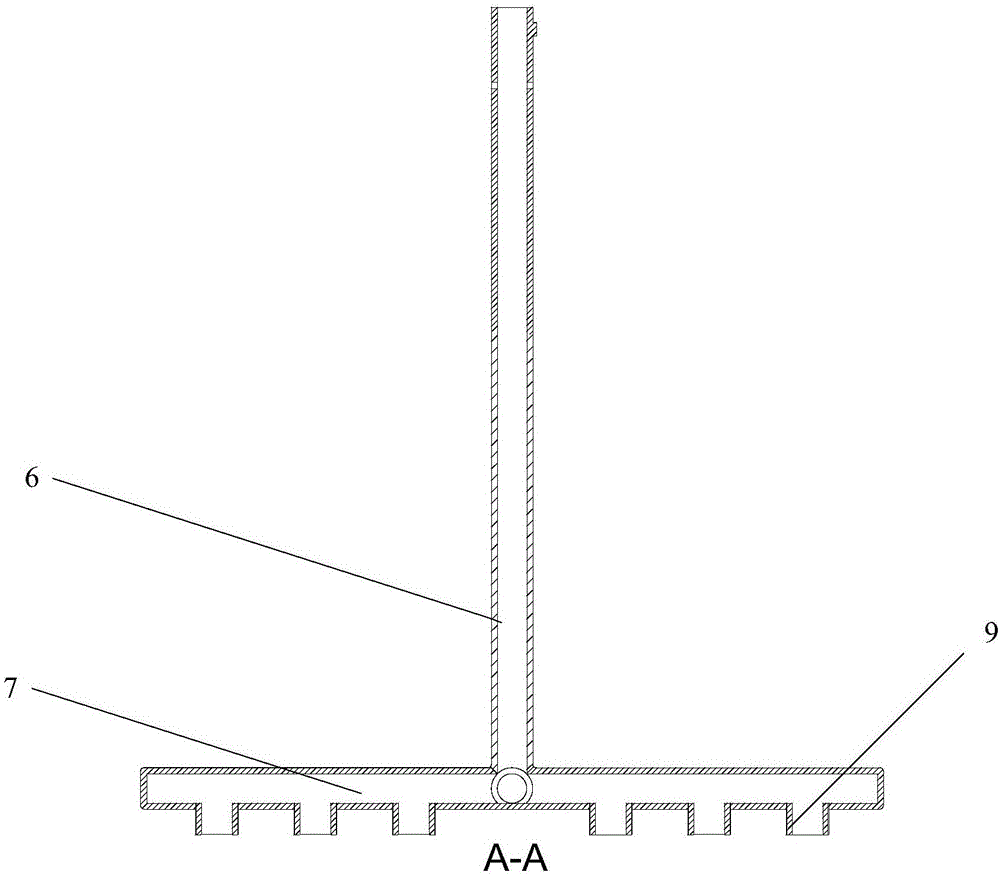

Space-saving LED fluorescent lamp tube aging rack

InactiveCN103645353AImprove aging efficiencyNot easy to damageMeasurement instrument housingEngineeringDaylight

The invention provides a space-saving LED fluorescent lamp tube aging rack, which comprises a roof, a cross arm, a fixed bracket, a sliding wheel bracket and a sliding wheel, an LED fluorescent lamp tube supporting hook and an LED fluorescent lamp tube bulb pin wire, wherein the cross arm contains a sliding rail and comprises an upper cross arm and a lower cross arm which are fixed on the wall, two sections of the upper cross arm and the lower cross arm are connected to the fixed bracket, the pulley bracket is connected with the cross arm through the sliding wheel in the sliding rail, and the widths of the fixed bracket and the sliding bracket are changed through sliding the sliding wheel back and forth so as to adapt to different LED fluorescent lamp widths; the LED fluorescent lamp bulb pin wire is arranged on the sliding wheel bracket and the fixed bracket, when aging is carried out on the LED fluorescent lamp tube, the LED fluorescent lamp tube is placed on the LED fluorescent lamp tube supporting hook, the fluorescent lamp tube bulb pin wire is inserted in an LED fluorescent lamp tube bulb pin, and aging is carried out after a power supply is connected. The space can be saved when aging is carried out on the LED fluorescent lamp tube by adopting the aging rack provided by the invention.

Owner:大连亮景实业有限责任公司

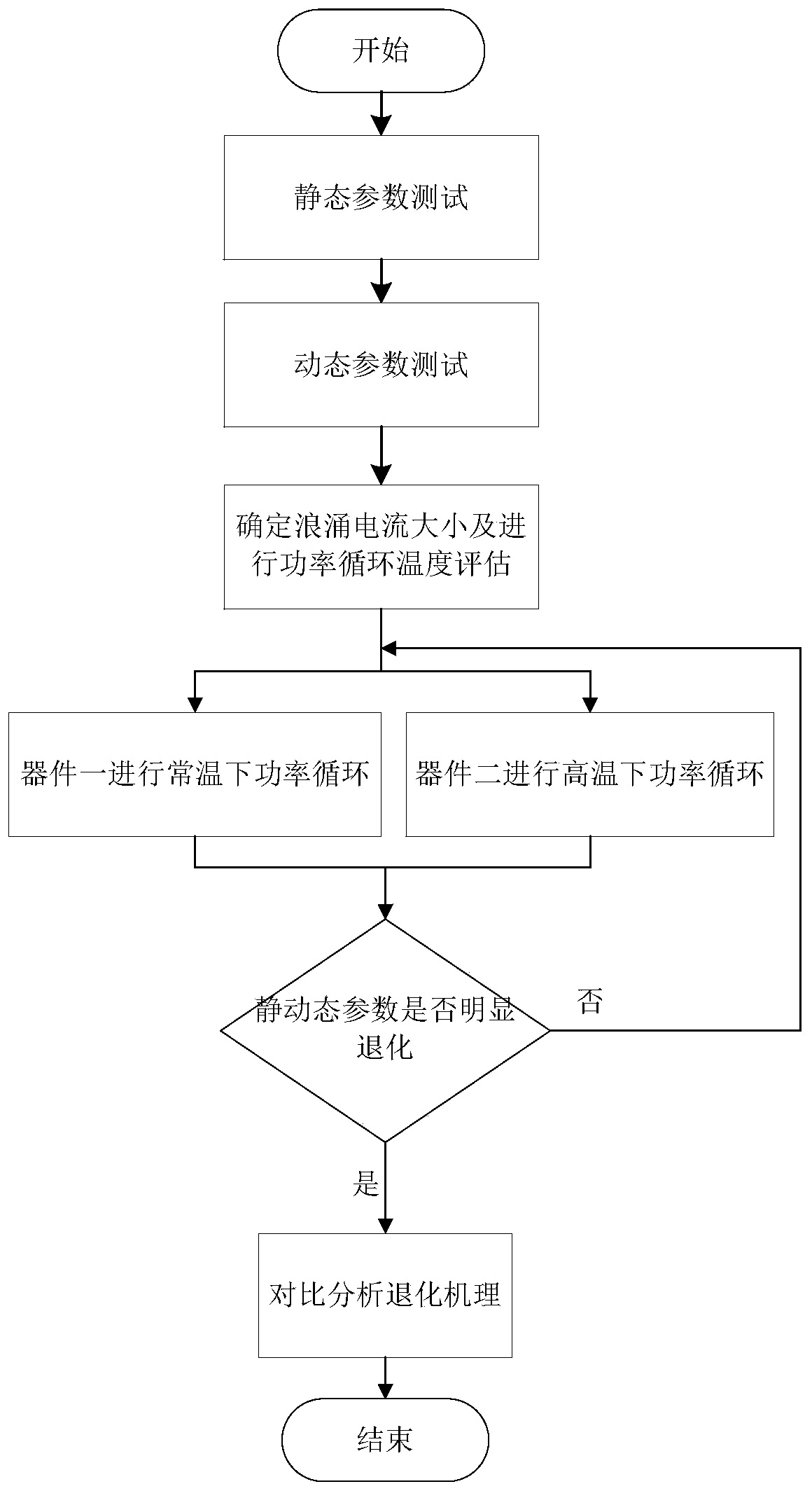

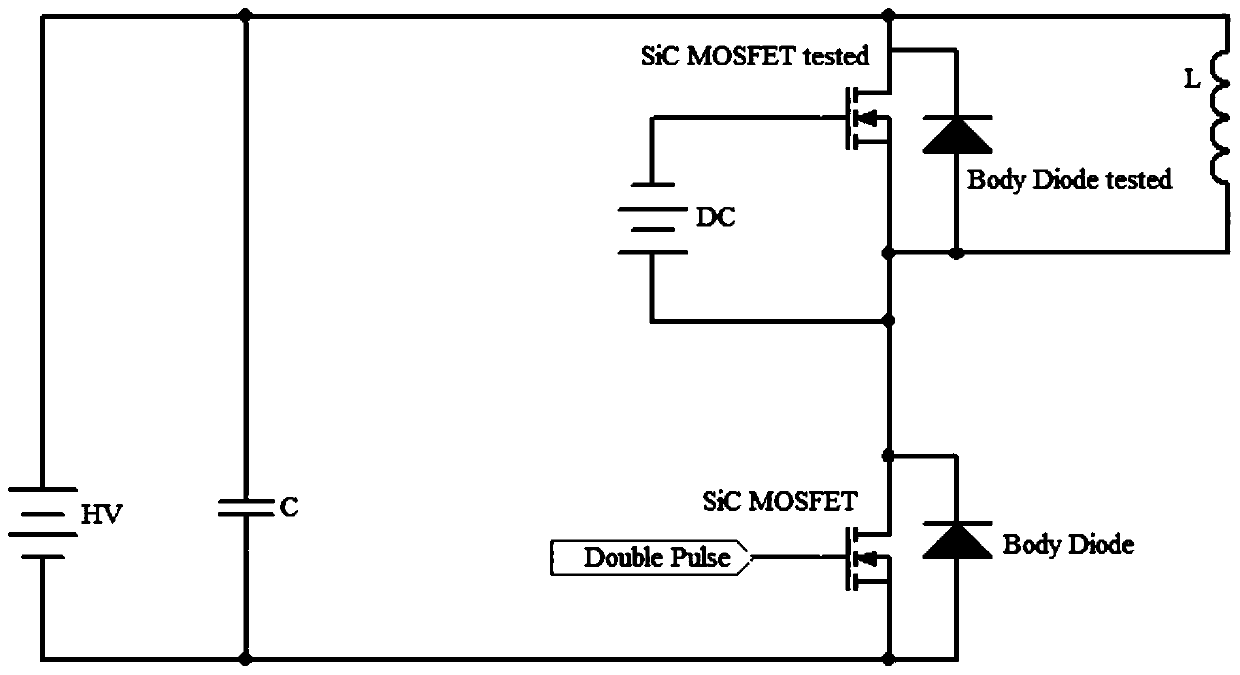

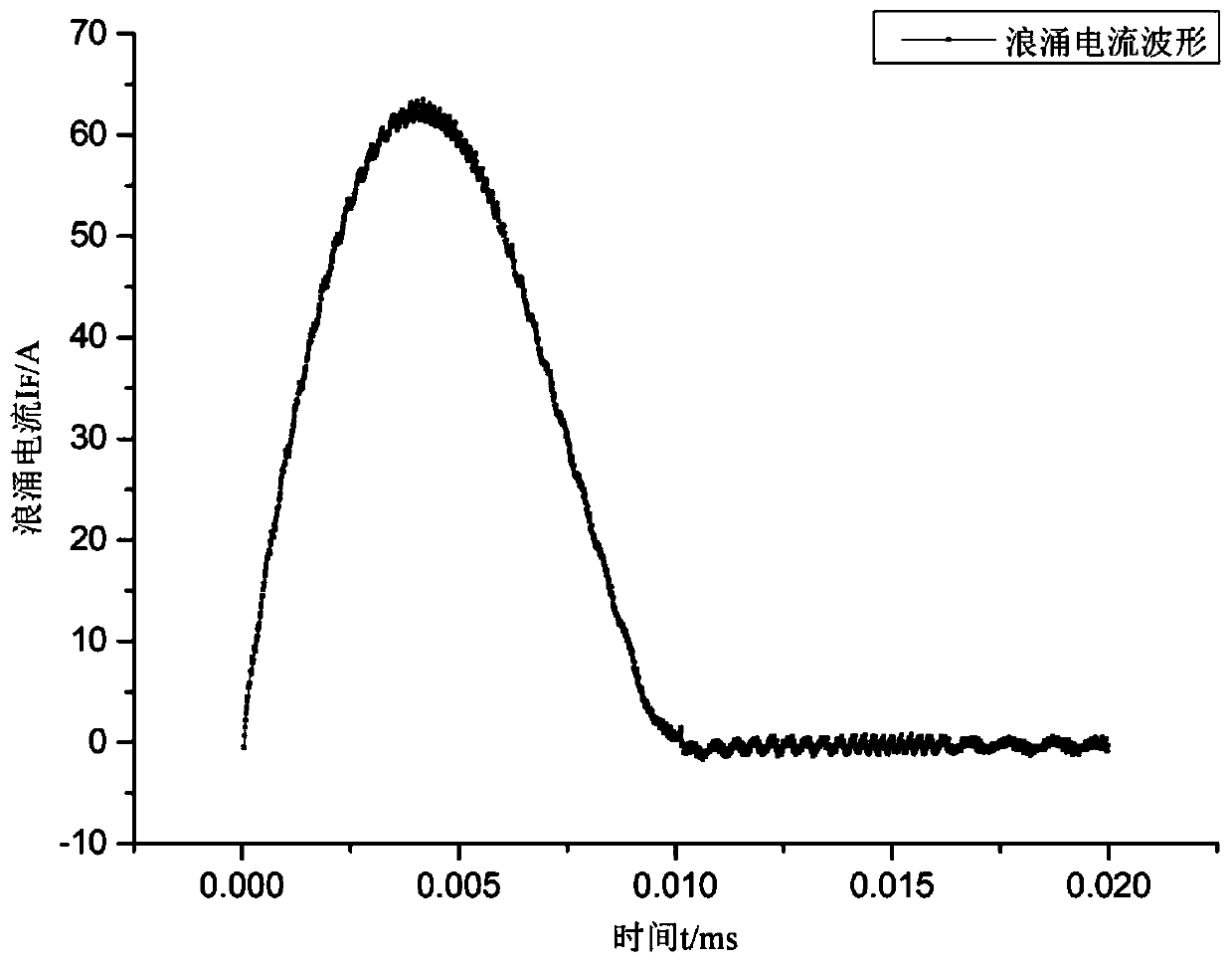

Power cycle method for accelerating bipolar degradation of SiC MOSFET body diode

InactiveCN110907791ANo accumulationOvercome limitationsSemiconductor operation lifetime testingMOSFETThermodynamics

The invention discloses a power cycle method for accelerating bipolar degradation of a SiC MOSFET body diode, and the method comprises the steps: firstly determining a proper repeated surge current, and carrying out temperature evaluation of power cycle at normal temperature and high temperature; carrying out repeated surge current power cycle test on the body diode of an SiC MOSFET discrete device I at normal temperature; performing repeated surge current power cycle test on the body diode of an SiC MOSFET discrete device II of the same model at a high temperature; when the body diodes of theSiC MOSFET discrete device I and the SiC MOSFET discrete device II are aged to a certain degree, measuring degradation of static characteristics (forward IV characteristics) and dynamic characteristics (reverse recovery current waveform) of body diodes of the SiC MOSFET discrete device I and the SiC MOSFET discrete device I Repeated surge current power circulation at high temperature overcomes the limitation of direct current stress power circulation, is simple to control and high in reliability, has no continuous heat accumulation in the power circulation period, has no influence on packaging characteristics, can be carried out in a high-temperature environment, improves the aging efficiency and accelerates bipolar degradation.

Owner:XI AN JIAOTONG UNIV +1

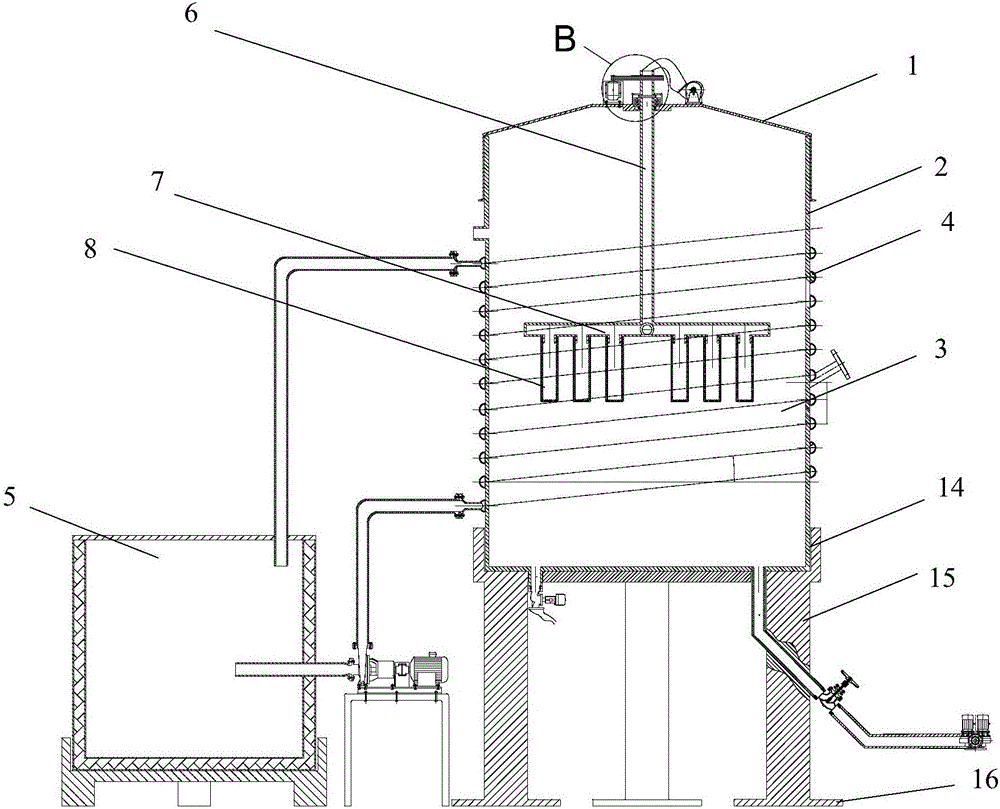

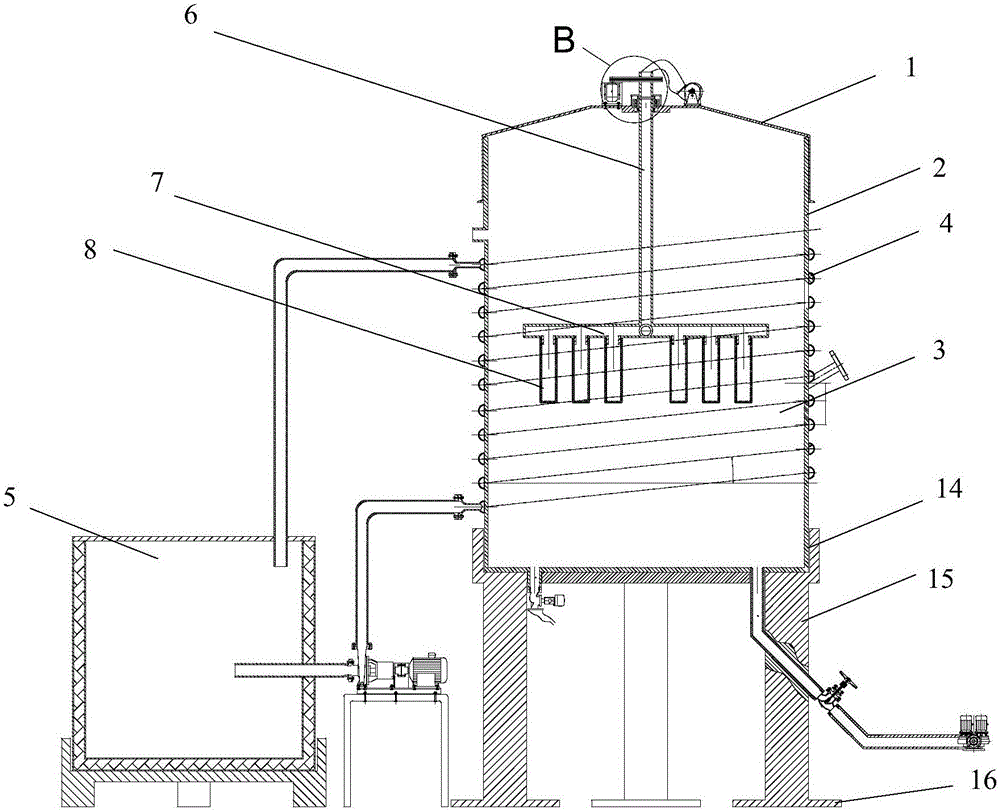

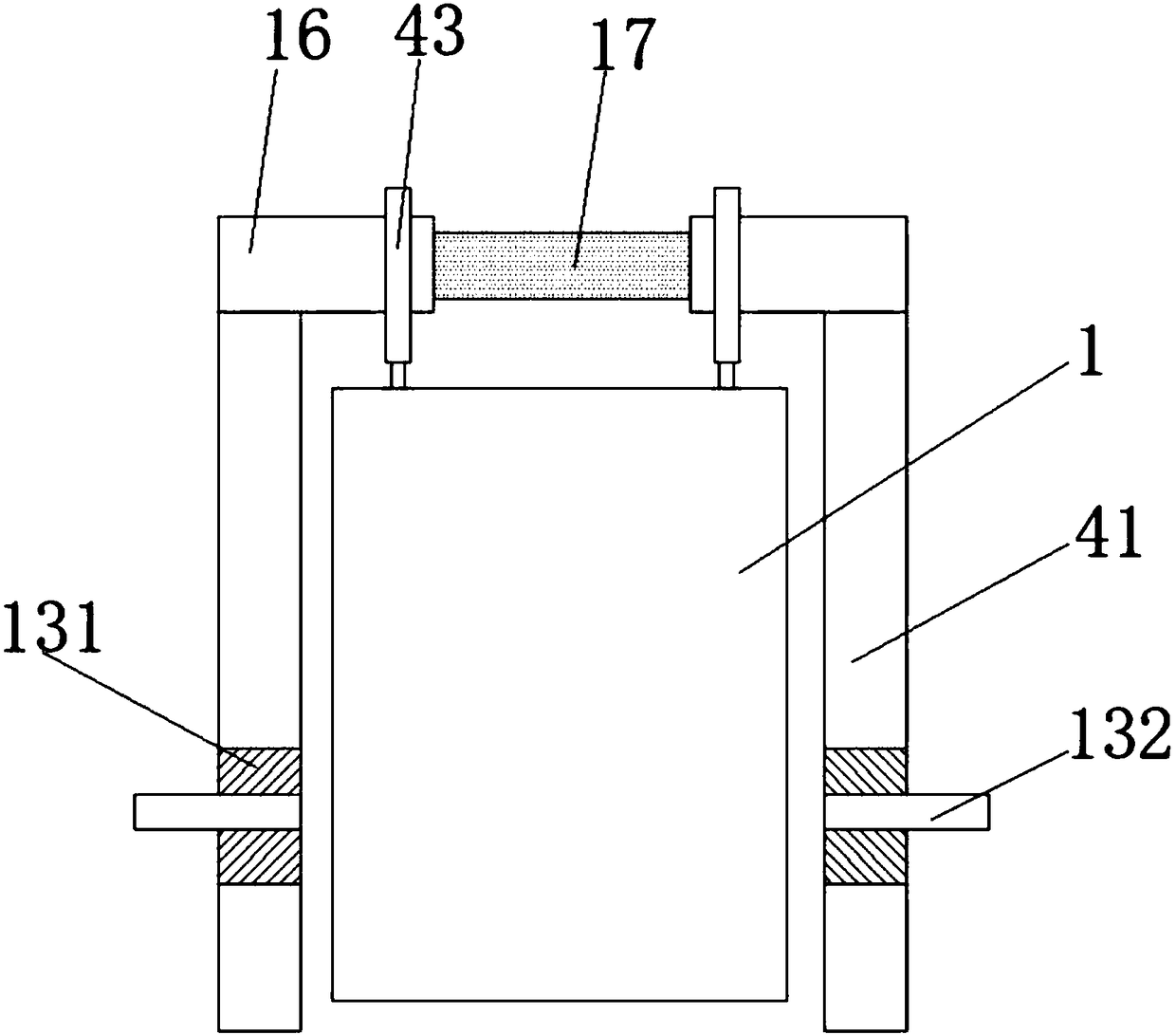

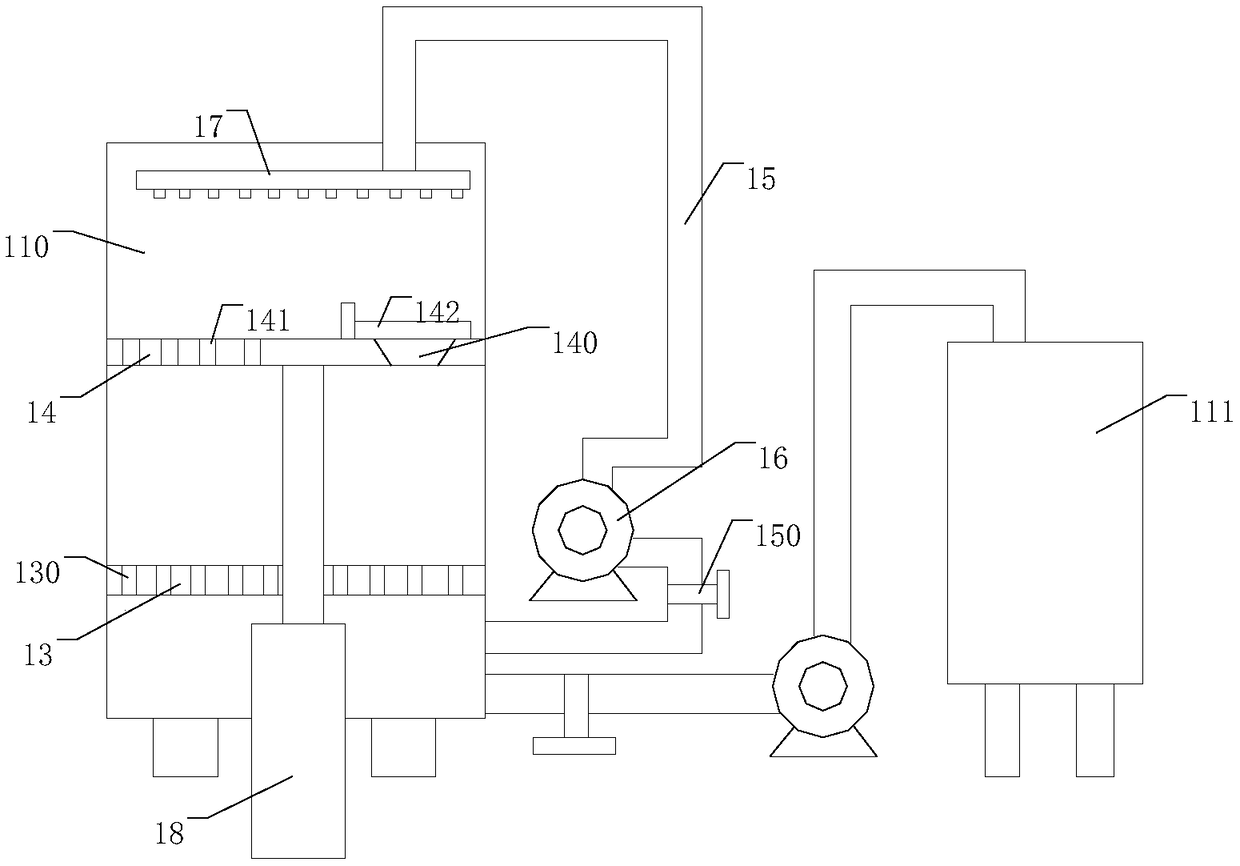

Reaction kettle

InactiveCN106591075ASpeed up the aging reactionImprove aging efficiencyAlcoholic beverage preparationChemistry

The invention discloses a reaction kettle. The reaction kettle comprises a kettle body, wherein the kettle body is internally provided with a reaction cavity, and the kettle body is further provided with a feeding port and a discharging port which are respectively communicated with the reaction cavity and a heating device arranged in the kettle body. Basic liquor ageing reaction is accelerated by arranging the kettle body, arranging the reaction cavity capable of containing basic liquor in the kettle body and arranging the heating device capable of heating the basic liquor in the reaction cavity, the ageing efficiency is improved, and the production cost is reduced.

Owner:NANTONG UNIVERSITY

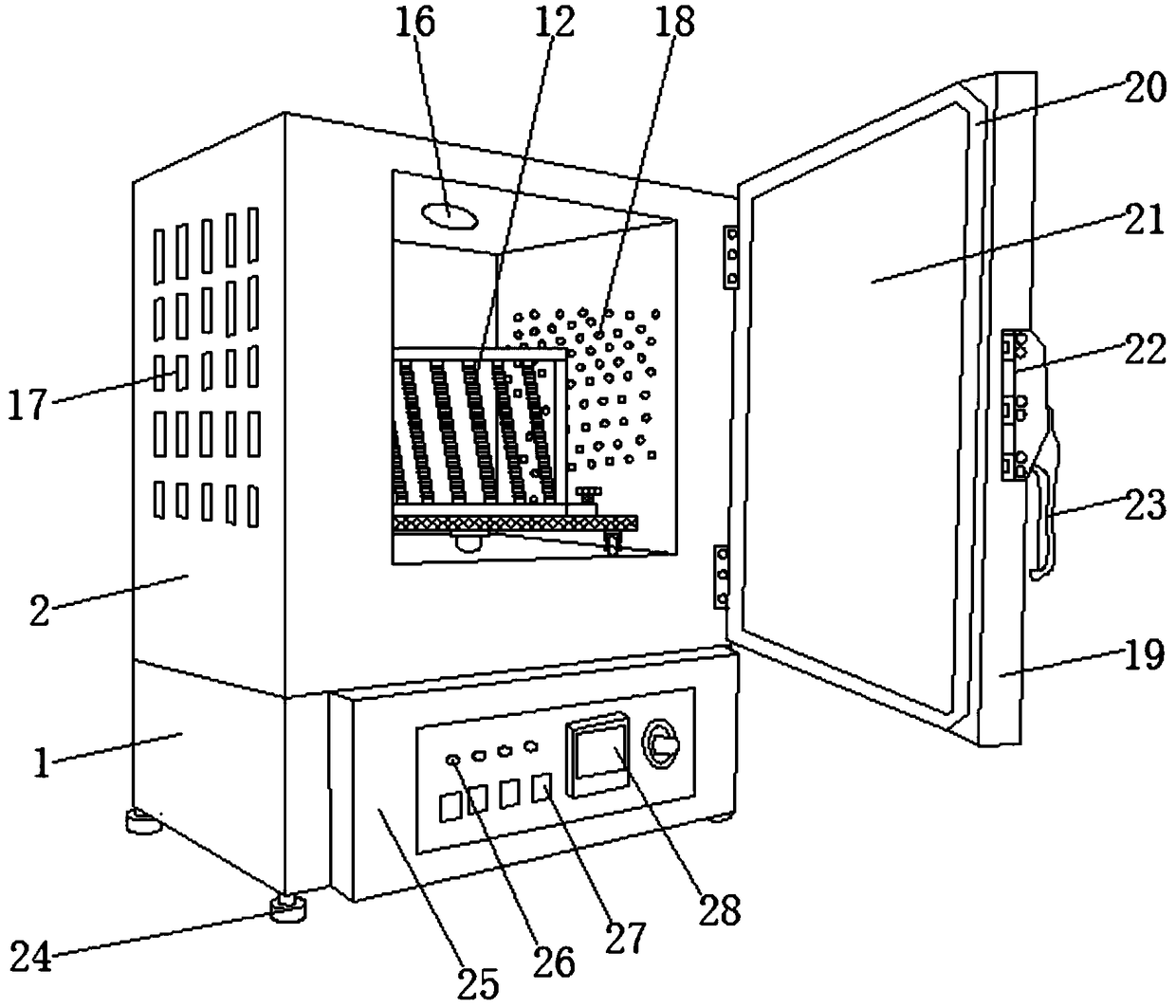

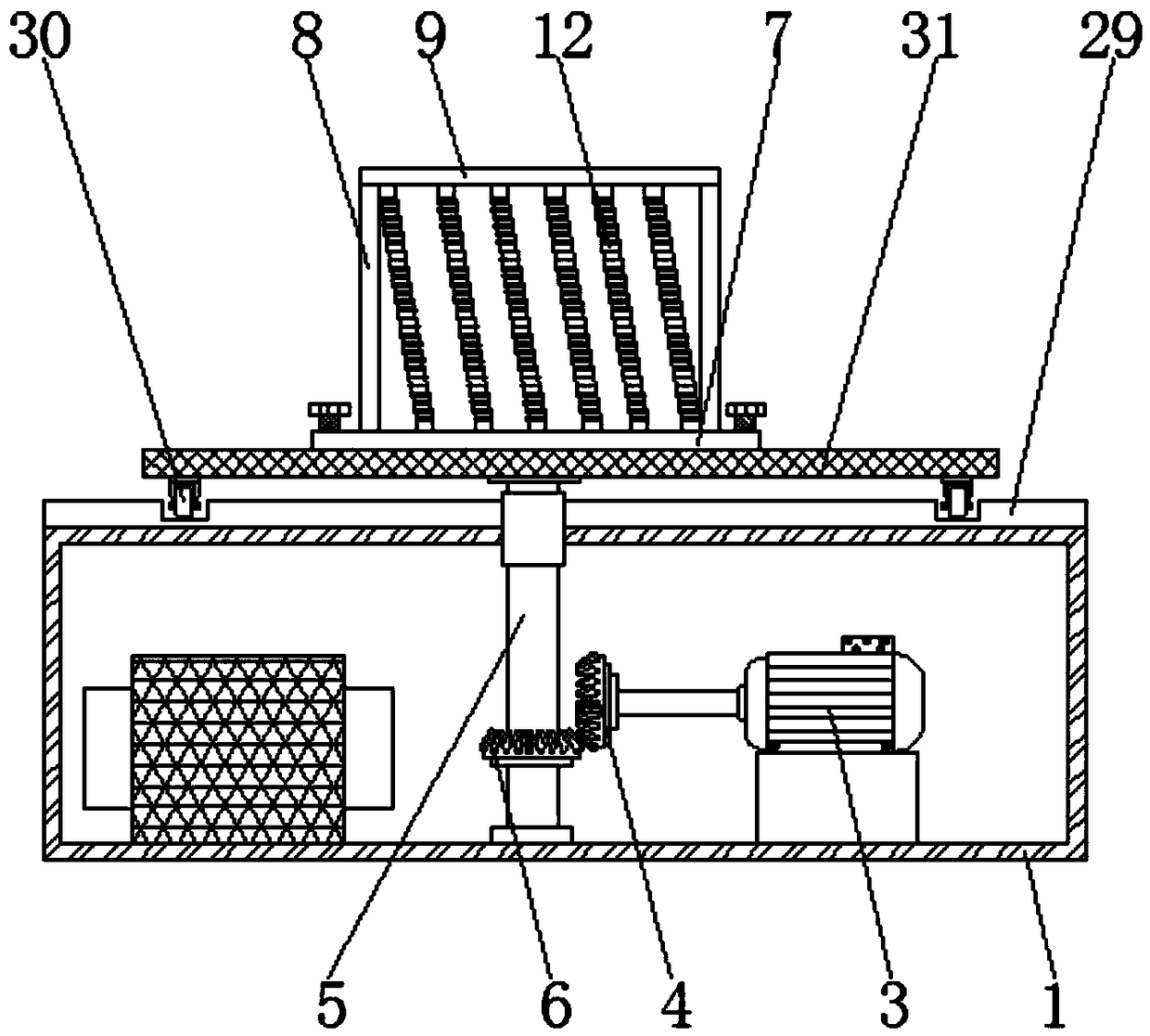

Universal optical module aging device

InactiveCN109470451AUniform aging effectThe test result is accurateOptical apparatus testingOptical ModuleComputer module

The invention discloses a universal optical module aging device and relates to the technical field of aging of optical modules. The device comprises a motor box and an aging box, the top of the motorbox is fixedly connected to the bottom of the aging box, the bottom of an inner cavity of the motor box is fixedly connected with a motor through a support plate, and an output shaft of the motor is fixedly connected with a first bevel gear; the bottom of the inner cavity of the motor box is rotatably connected with a rotating rod through a bearing. According to the universal optical module agingdevice, when the aging box is in operation, the motor controls a frame structure to rotate, so that an aging plate on the frame structure is uniformly subjected to aging treatment, the purpose of aging light templates uniformly is achieved, it is ensured that products of the same batch are all aged in a same set aging environment, convenience is provided for obtaining more accurate test results inthe later period, the quality of the products is improved, the aging plate is convenient to take and place, the aging efficiency and the aging quality are greatly improved, and an observation windowprovides convenience for workers to observe internal conditions of the aging box.

Owner:WUHAN PRECISE ELECTRONICS TECH

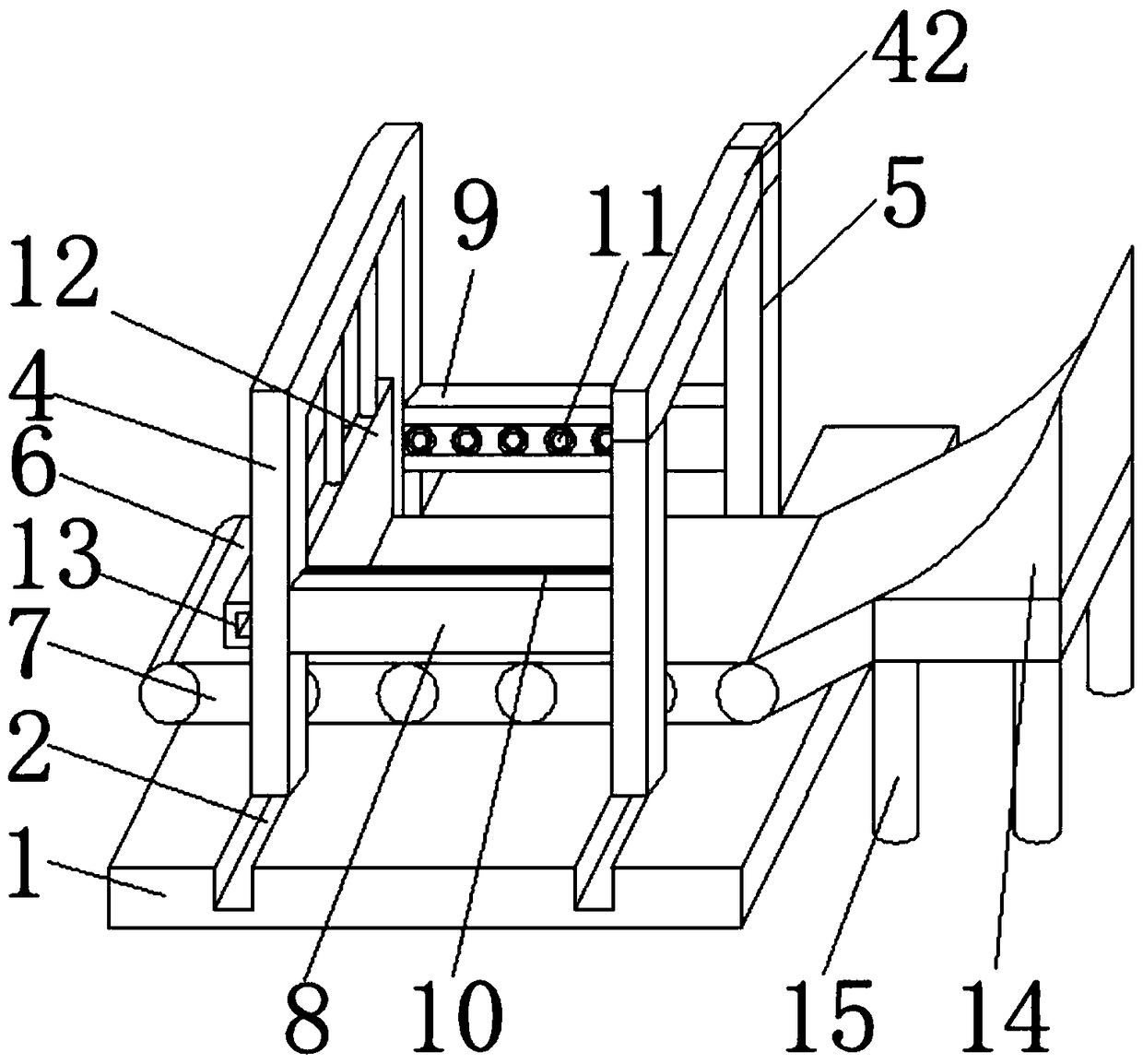

Capacitor aging device

ActiveCN108400027ARealize the clamping functionAvoid false sophisticationProtecting/adjusting hybrid/EDL capacitorCapacitor manufactureTransmission beltEngineering

The invention discloses a capacitor aging device. The device comprises a base, two concave sliding chutes in longitudinal symmetric arrangement are formed on the top of the base; two convex sliding blocks are sleeved in the inner wall of each concave sliding chute, the top ends of the convex sliding blocks at the inner wall of the concave sliding chute are fixedly connected with a first frame anda second frame; a horizontal transmission belt is fixedly arranged at the top of the base through a bracket; the transmission belt is in gap junction with each of a first frame and a second frame; theinside wall of the transmission belt is in rotary connection with a transmission assembly; a first clamp plate component and a second clamp plate component in symmetric distribution are orderly connected between the first frame and the second frame along the longitudinal direction; the first clamp plate component directly faces the second clamp plate component, and a first electrode plate is arranged at one side, close to the second clamp plate component, of the first clamp plate component. The capacitor sophisticating device disclosed by the invention is simple in structure and convenient for operation, the false aging problem caused by bad contact is effectively avoided, the automatic arrangement is realized after the feeding, the automatic degree is improved, and the aging efficiency is higher.

Owner:ANHUI MASCOTOP ELECTRONICS

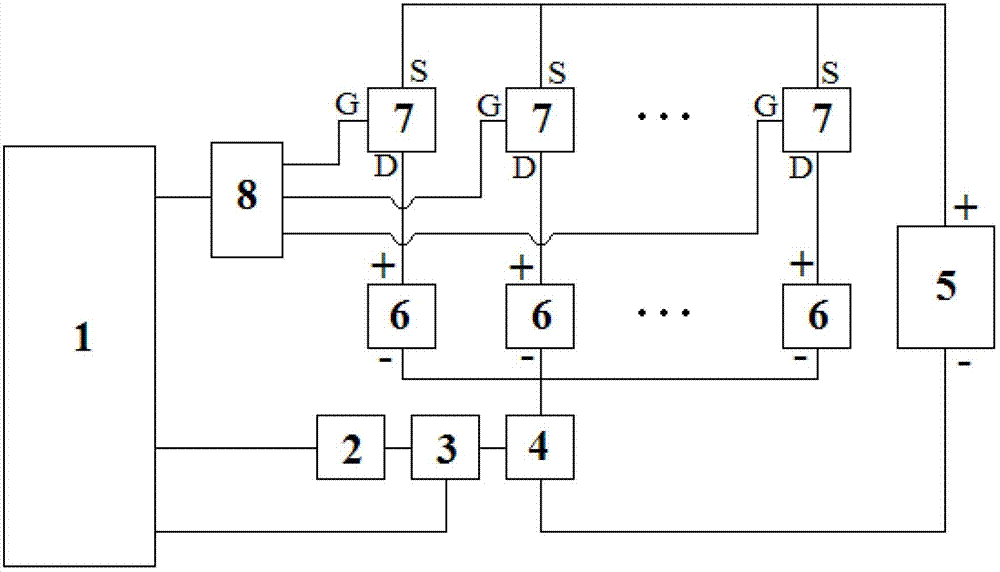

Multi-output aging power supply for pulse lasers

InactiveCN102882123ASmall duty cycleWith time-division multiple output functionLaser detailsSemiconductor lasersMicrocontrollerTime-sharing

The invention discloses a multi-output aging power supply for pulse lasers and relates to the field of aging power supplies of semiconductor lasers. The power supply can well overcome the defects of low efficiency and long period in the conventional aging method, can be used for the aging of a plurality of pulse lasers, and greatly improves the aging efficiency of the pulse lasers. The aging power supply comprises a plurality of high-power switches and a decoder, wherein the decoder is connected with a singlechip and the high-power switches respectively; the lasers are connected with the high-power switches; and the multi-way high-power switches are connected with the lasers in parallel and then connected with a voltage-controlled current source and a direct current regulated power supply. According to the characteristic of low duty ratio of the pulse lasers during aging, the multi-output aging power supply for the pulse lasers has the function of time-sharing multi-output function, can drive the plurality of lasers in a time-sharing way to implement the aging of the lasers at the same time, and can further shorten the aging period greatly and improve the aging efficiency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Gate drive circuit, liquid crystal panel, display device and aging method

The invention provides a gate drive circuit, a liquid crystal panel, a display device and an aging method. According to the circuit, a first pin of the gate drive circuit configured to receive an input voltage, and a second pin of the gate drive circuit is configured to adjust the resistance value of a target resistor to be greater than a preset resistance value when receiving an instruction indicating that the aging of the display device is started, and adjust the resistance value of the target resistor to be equal to a preset threshold value after a preset period of time. A third pin of thegate drive circuit is configured to output an output voltage corresponding to the target resistor through the input voltage based on the reference voltage with the amplitude kept unchanged. When the resistance value of the target resistor is greater than the preset resistance value, the amplitude of the output voltage is greater than the amplitude of the turn-on voltage of a thin film transistor TFT in the display device; when the resistance value of the target resistor is equal to the preset resistance value, the amplitude of the output voltage is equal to the amplitude of the turn-on voltageof a thin film transistor TFT in the display device. Therefore, automatic aging of the display device is realized.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

Technology for wine storage in pit and pottery jar

InactiveCN111234999ALow costPrevent rancidityAlcoholic beverage preparationMicroorganismMontmorillonite

The invention belongs to the technical field of wine brewing and especially relates to a technology for wine storage in a pit and a pottery jar. The technology comprises the following steps: (S1) mudpreparation, (S2) pit preparation, (S3) jar preparation, (S4) wine storage, (S5) unsealing and the like. 1. Materials applied in the technology are easy to get and are mainly agricultural by-productswith low cost. 2. The technology is mature, wherein the pit can create a good micro environment for storage and ageing of green wine, fragrance of the wine is deepened by a wine body aged with protective mud, ageing efficiency is increased, the quality of the wine body is improved, complexity of the wine body fragrance is increased, a taste of the wine body is improved, and rancidity of the greenwine is avoided. 3. In the technology, a formula is rational, beneficial microorganisms in the protective mud are promoted by modified montmorillonite to release flavor substances, the flavor substances and volatile sundries in the wine body can be exchanged rationally, and ageing effects of white spirit are improved.

Owner:HEBEI GUXIANGYANG WINE CO LTD

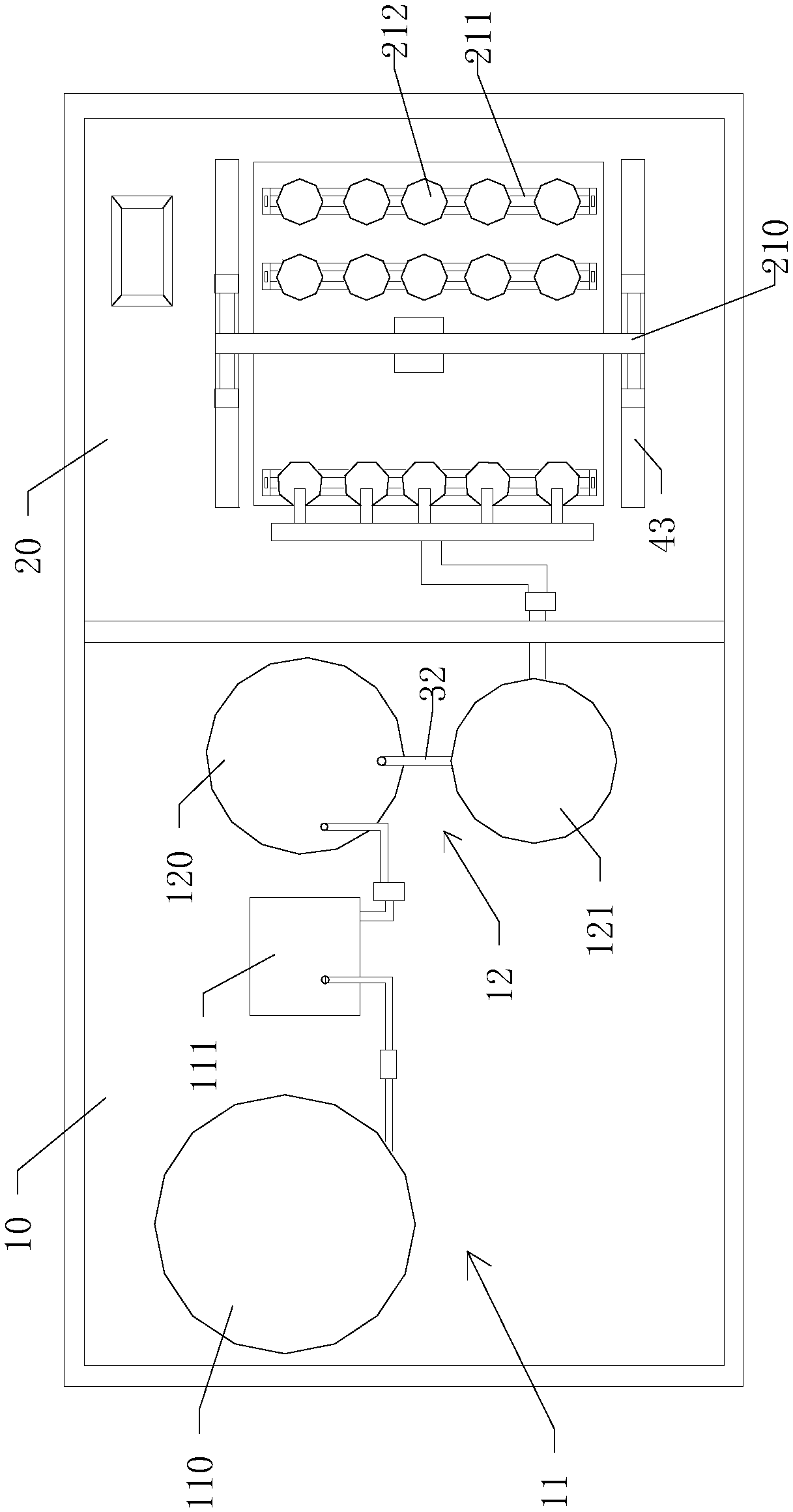

Automatic aging-detection equipment

PendingCN108761251AEffective detection of working status informationQuality improvementElectrical testingElectricityPower flow

The invention relates to automatic aging-detection equipment which comprises a main control cabinet, a load cabinet and a test cabinet, wherein a plurality of modules to be tested are arranged in thetest cabinet; paths of loads are arranged in the load cabinet; the loads are electrically connected with the modules to be tested in a one-to-one correspondence manner; an industrial control computer,a relay control circuit and a CAN (Controller Network Area) communication module are arranged in the main control cabinet; the industrial control computer is electrically connected with the relay control circuit; the relay control circuit is electrically connected with all the modules to be tested; and all the modules to be tested are electrically connected with the industrial control computer through the CAN communication module. The automatic aging-detection equipment disclosed by the invention can effectively detect working state information of the modules to be tested in a loaded state, and parameter information such as working current acquired by the modules to be tested is fed back to the industrial control computer through a CAN bus, so that the industrial control computer precisely monitors the parameter information such as the working current of the modules to be tested in an aging process in real time and provides a basis for management and control of quality improvement, and the automatic-aging detection equipment is favorable for improving the quality of a product.

Owner:WUHAN SOUTH SAGITTARIUS INTEGRATION CO LTD

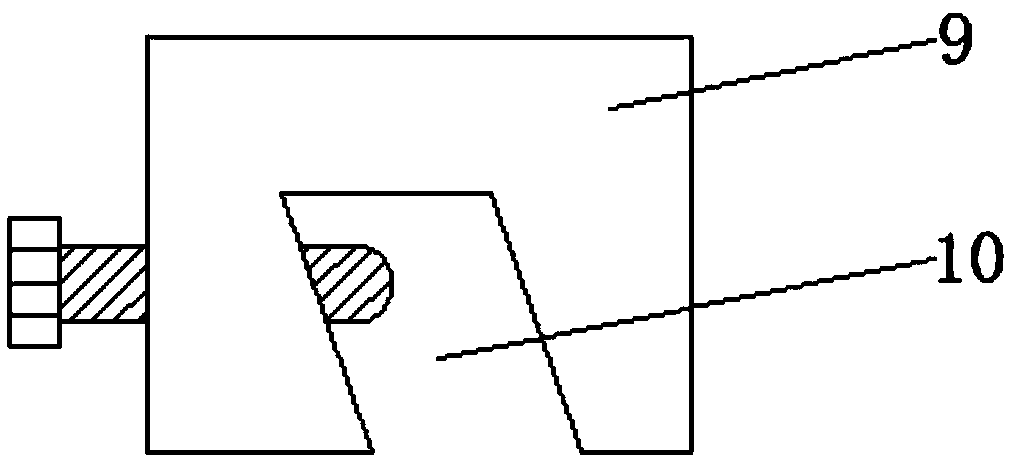

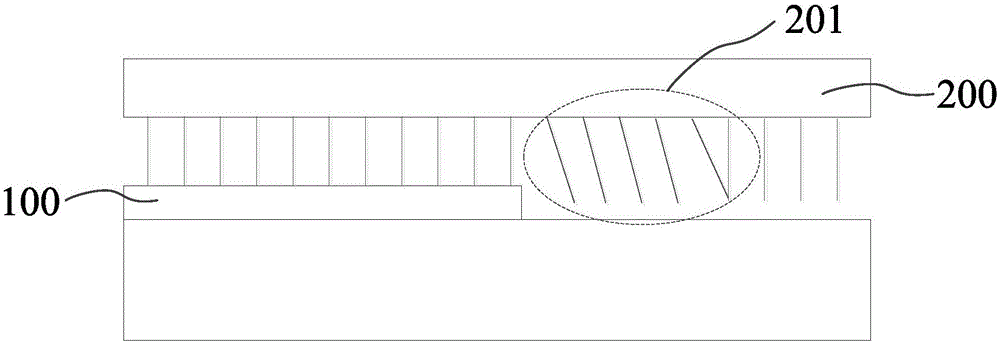

Rubbing cloth treatment apparatus and rubbing alignment apparatus

InactiveCN106483716AImprove aging efficiencyReduce scrap rateNon-linear opticsForeign matterEngineering

An embodiment of the invention discloses a rubbing cloth treatment apparatus and a rubbing alignment apparatus, wherein the rubbing cloth treatment apparatus comprises a carrier and a rubbing baseplate fixed to the carrier; the rubbing baseplate comprises a baseplate and a plurality of protrusions positioned on the baseplate. The technical scheme provided in the embodiment of the invention allows pile knots on rubbing cloth to be opened and piles to be smoothened, foreign matters on the rubbing cloth are removed, and it is also avoided that piles of the rubbing cloth knot and residue in the piles damages an alignment film during generation of a display panel. When piles of the rubbing cloth bifurcate and gather, the rubbing alignment apparatus may comb the piles of the cloth again, and therefore, the pile knots on the rubbing cloth are opened in time and the foreign matters on the piles are removed in time, the piles that are deviated and gathered are combed and returned. It is possible for the display panel to gain uniform alignment, display effect of the display panel is improved, and production yield of the display panel is increased.

Owner:CHENGDU TIANMA MICROELECTRONICS +1

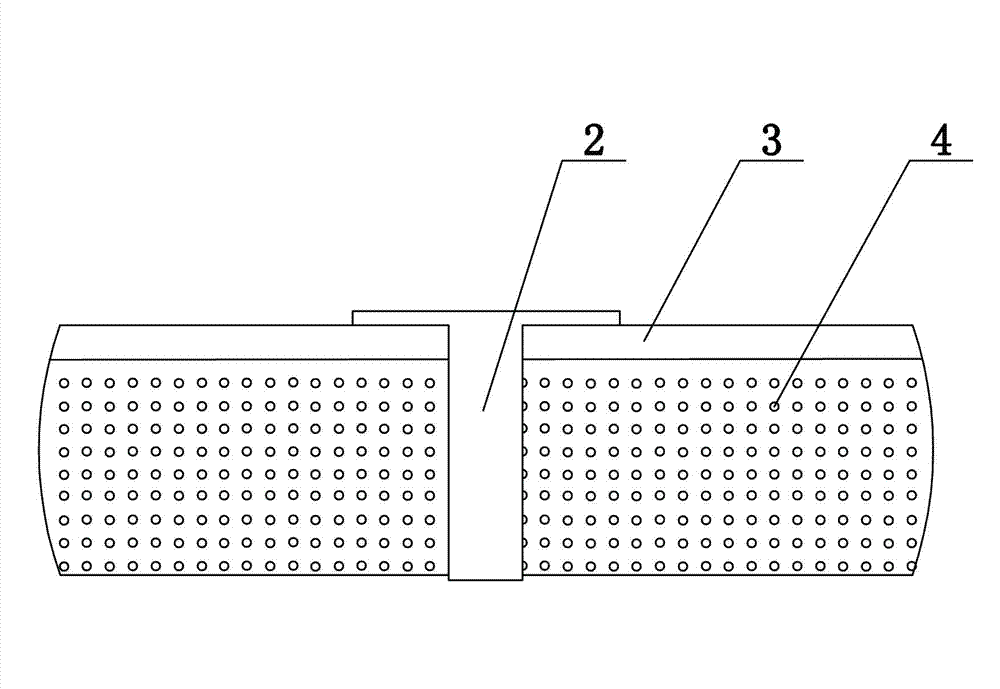

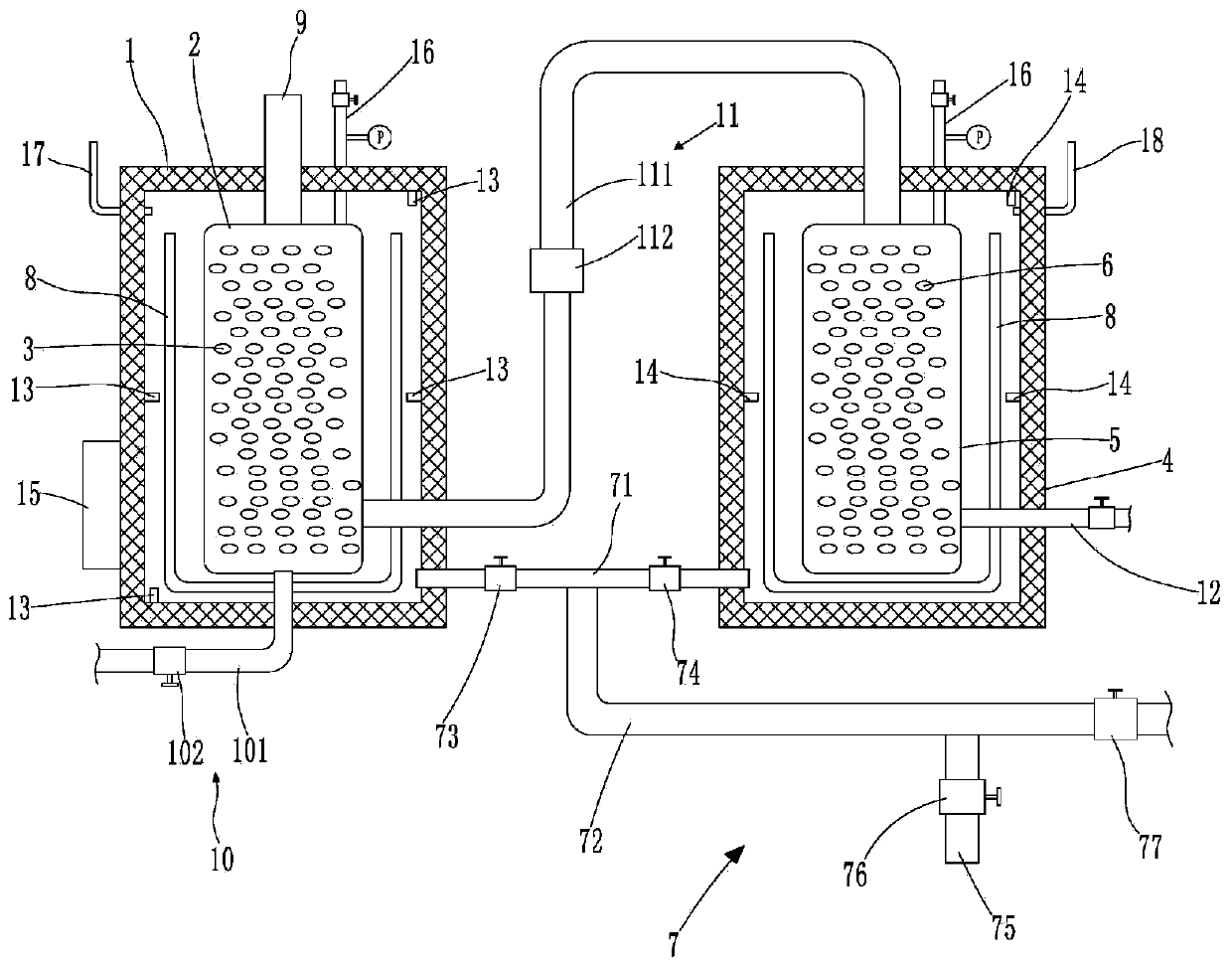

Liquor aging equipment

PendingCN111254037APlay a role in heat preservationImprove aging efficiencyAlcoholic beverage preparationThermodynamicsProcess engineering

The invention provides liquor aging equipment. The equipment includes an oxidation tank and an esterification tank; the oxidation tank includes a first heat preservation tank body and an oxidation inner tank installed in the first heat preservation tank body, and the interior of the oxidation inner tank is filled with an oxidation medium; the esterification tank includes a second heat preservationtank body and an esterification inner tank installed in the second heat preservation tank body, and the interior of the esterification inner tank is filled with an esterification medium; the first heat preservation tank body and the second heat preservation tank body are provided with a water inlet system, and electric heating pipes are installed in the first heat preservation tank body and the second heat preservation tank body; the top of the oxidation inner tank is provided with a liquor inlet pipe extending from the first heat preservation tank body, and an oxygen supply system is arranged at the bottom of the oxidation inner tank; a tank transfer system is arranged between the bottom of the oxidation inner tank and the top of the esterification inner tank; and a liquor outlet pipe isarranged at the bottom of the esterification inner tank. The equipment improves the situations of long natural aging time and larger loss of liquor.

Owner:LUZHOU VOCATIONAL & TECHN COLLEGE

Solar table vinegar aging room

InactiveCN109456873AImprove aging efficiencyImprove utilization efficiencyVinegar preparationElectricityEngineering

The invention provides a solar table vinegar aging room, and relates to the field of seasoning production equipment. The solar table vinegar aging room comprises a plurality of side walls and a closedspace defined by a roof; an aging room body is divided into a fermentation and purification chamber and a solar aging room by means of a partition; the roof of the aging room body comprises a first roof installed on the top of the purification chamber, and a second roof installed on the top of the solar aging room; a plurality of photovoltaic panels are fully distributed on the first roof, and the second roof is made from a transparent material; the solar aging room is internally provided with an electricity storage device; the photovoltaic panels are electrically connected with the electricity storage device by means of cables; a shading mechanism used for adjusting the light intensity of light entering the solar aging room is installed at the inner side of the second roof. The solar table vinegar aging room can convert the renewable energy such as solar energy into electrical energy for use and storage; the converted solar energy can be used for adjusting the aging temperature of table vinegar, can improve the aging efficiency of the table vinegar, guarantees the production quality, and reduces the production cycle.

Owner:NINGXIA JINBOLE FOOD TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com