Automatic aging tool for speakers

A loudspeaker and automatic technology, applied in the direction of electrical components, etc., can solve the problems of increased labor intensity of employees, product leakage and other problems, and achieve the effects of improving efficiency and accuracy, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

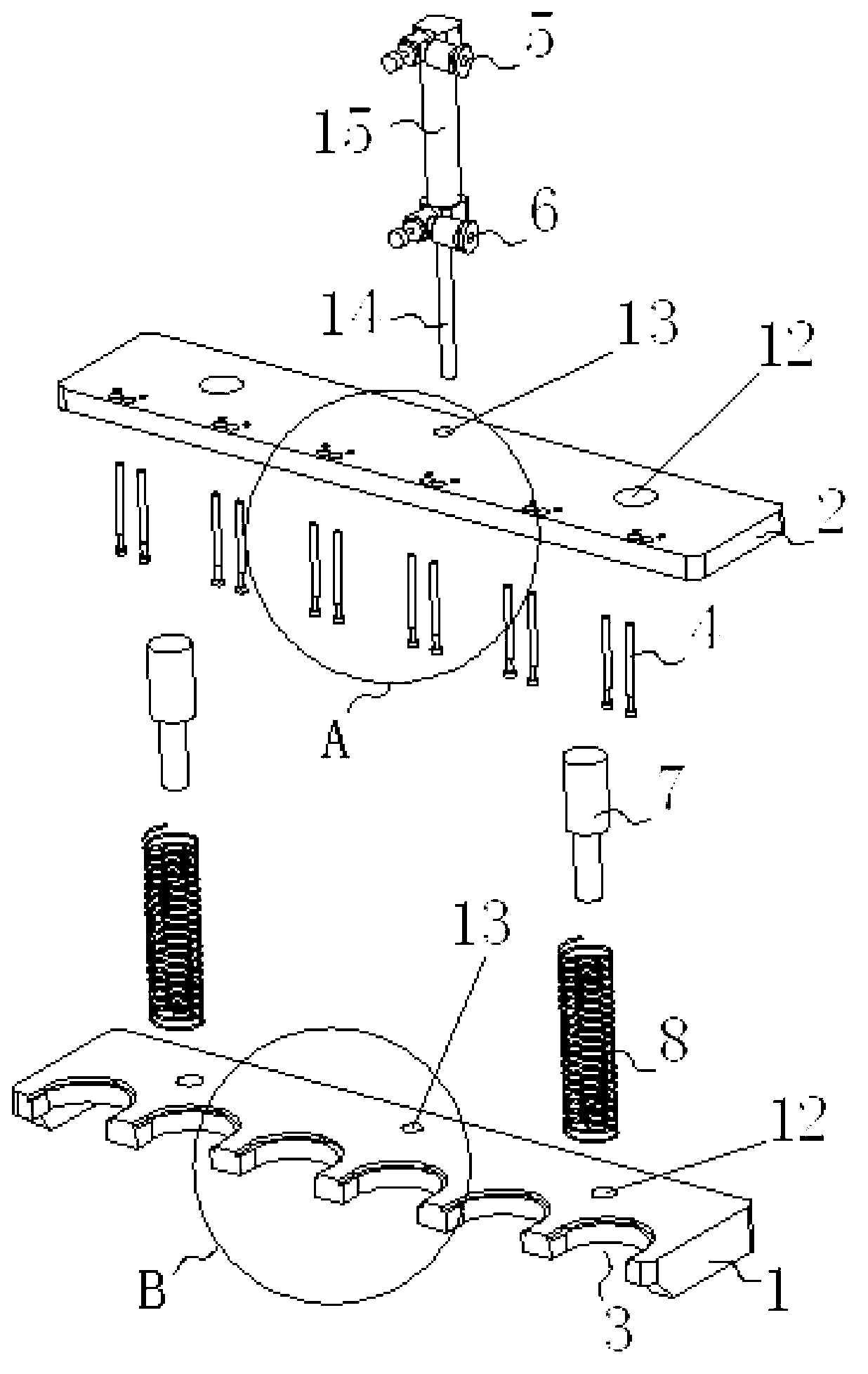

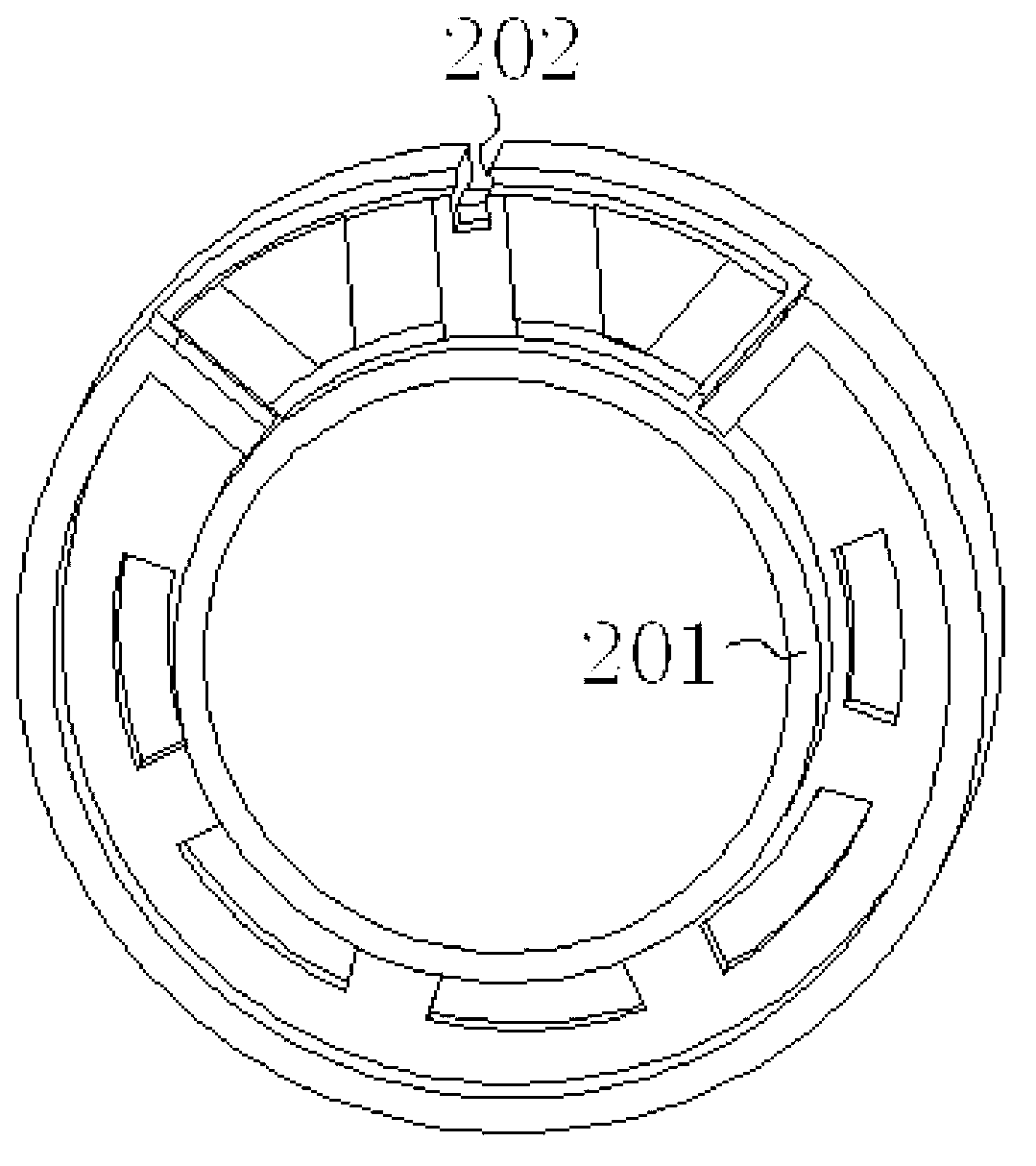

[0022] Such as figure 1 As shown, the speaker automatic aging tool of the present invention includes a corresponding upper cover 2 and a base 1, and the base is provided with a positioning groove 3 for placing the speaker. Such as Figure 4 As shown, the positioning groove 3 is provided with a stepped surface, and the present invention needs aging loudspeakers such as figure 2 As shown, the edge of the loudspeaker 201 is placed on the stepped surface of the positioning groove 3, so that the diaphragm located at the lower end of the loudspeaker is elevated, which is convenient for the staff to touch and detect whether the diaphragm vibrates.

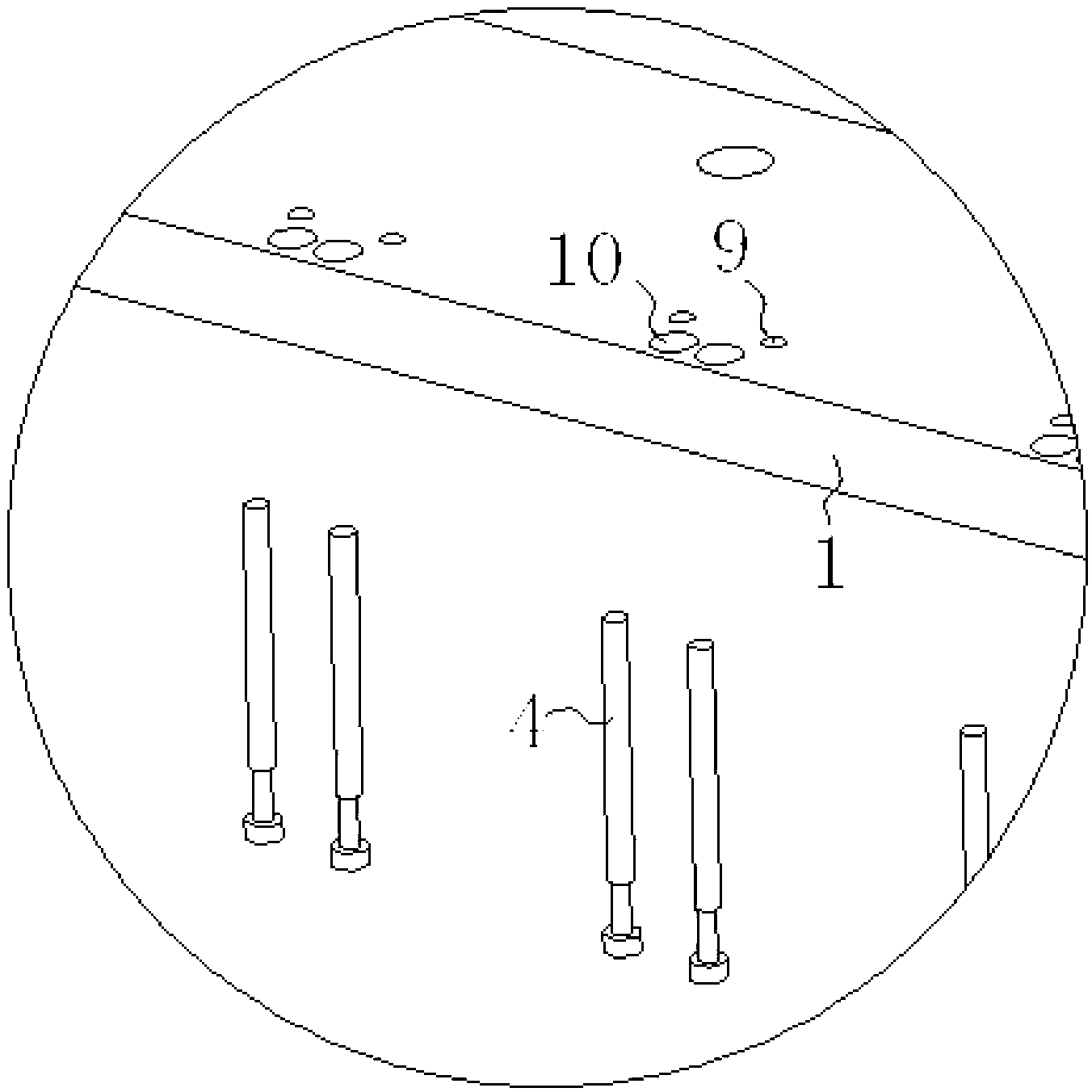

[0023] The aging of the speaker needs to pass a high-power signal to the two poles of the speaker to make the diaphragm of the speaker vibrate for a period of time to see if the speaker can always work normally. In order to feed the signal to the poles of the speaker, such as image 3 As shown, there is a probe installation hole 9 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com