Jig for aging tests

A technology of aging testing and fixtures, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., and can solve problems such as cumbersome operation, unfavorable production and processing, and inaccurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

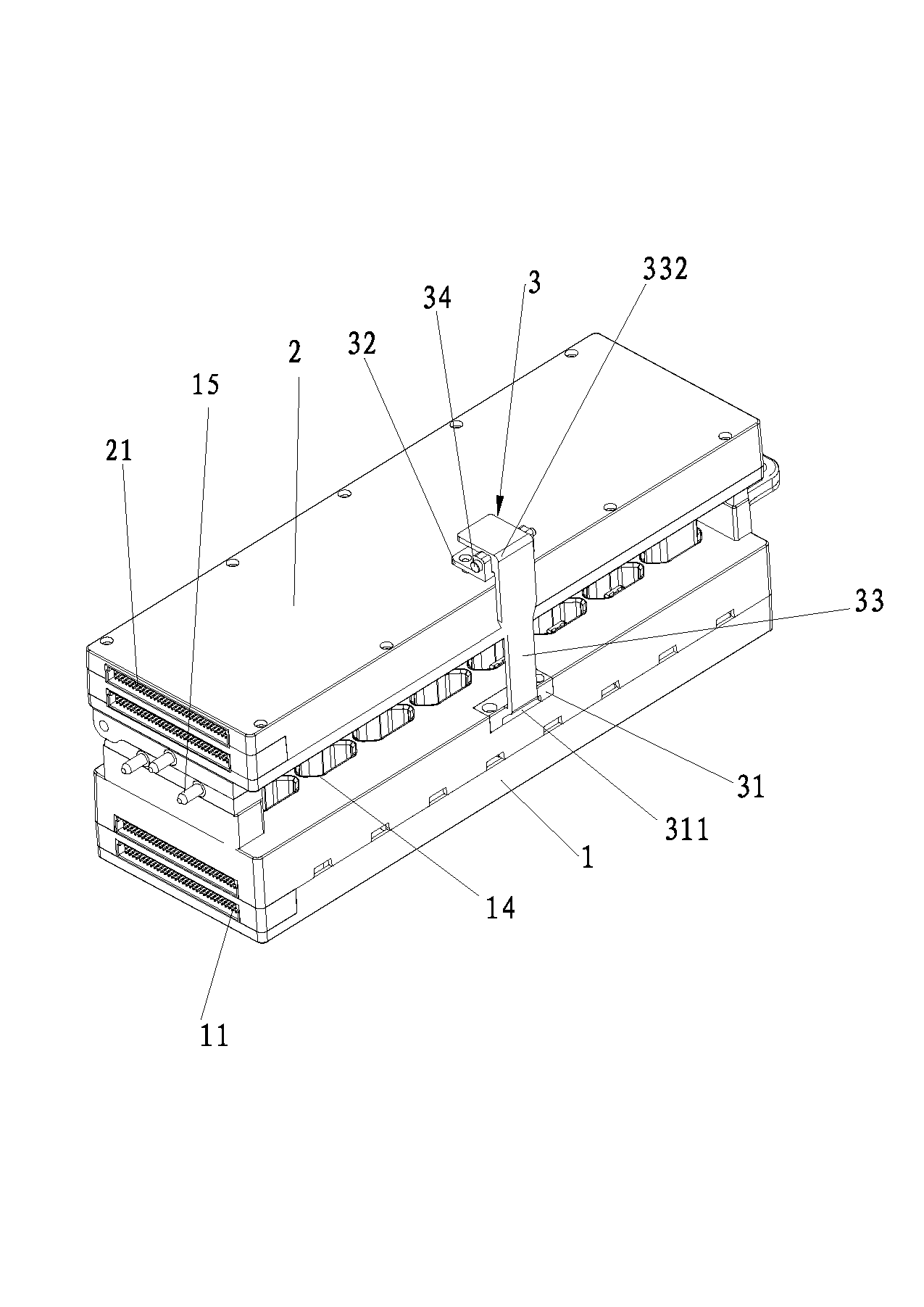

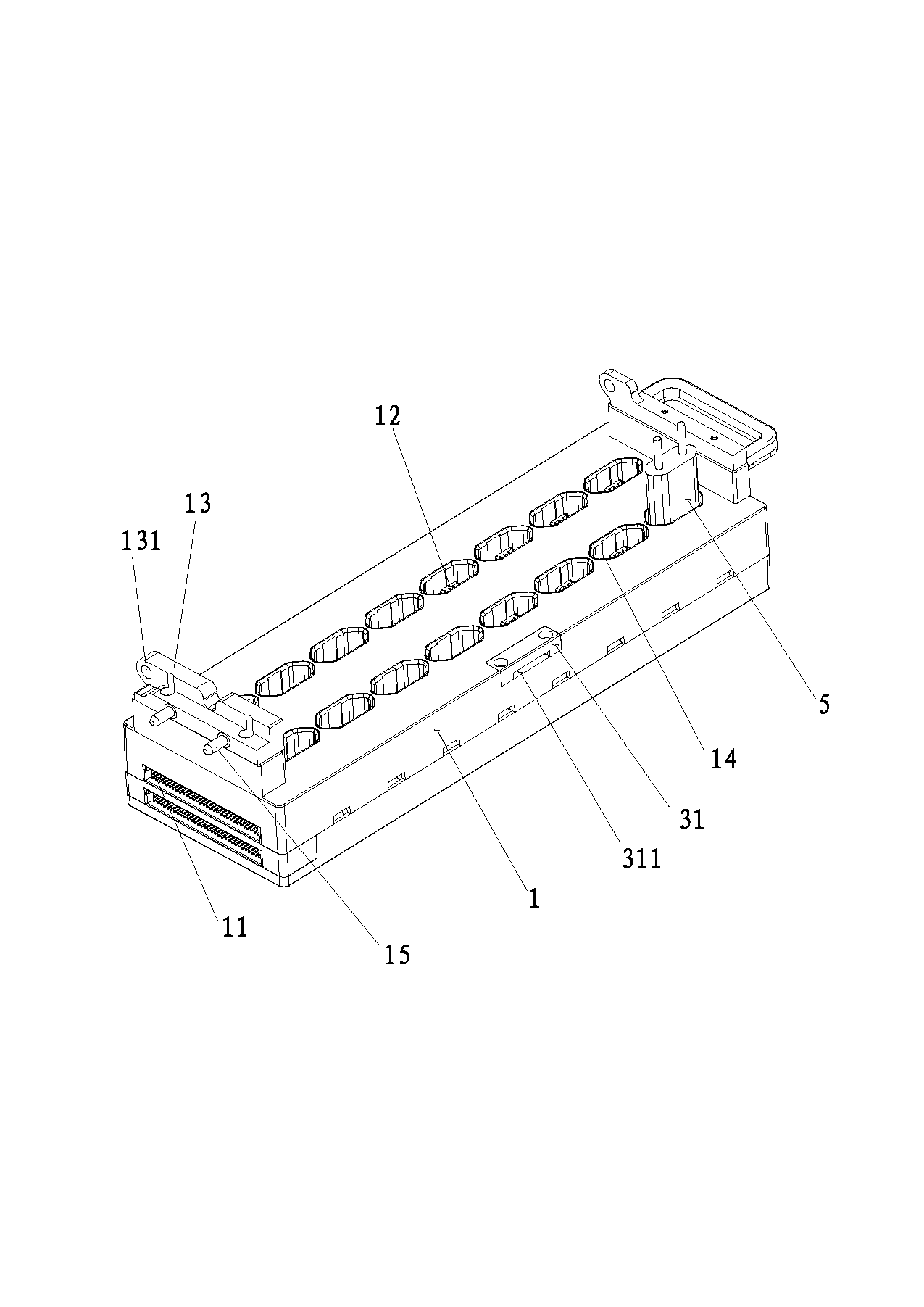

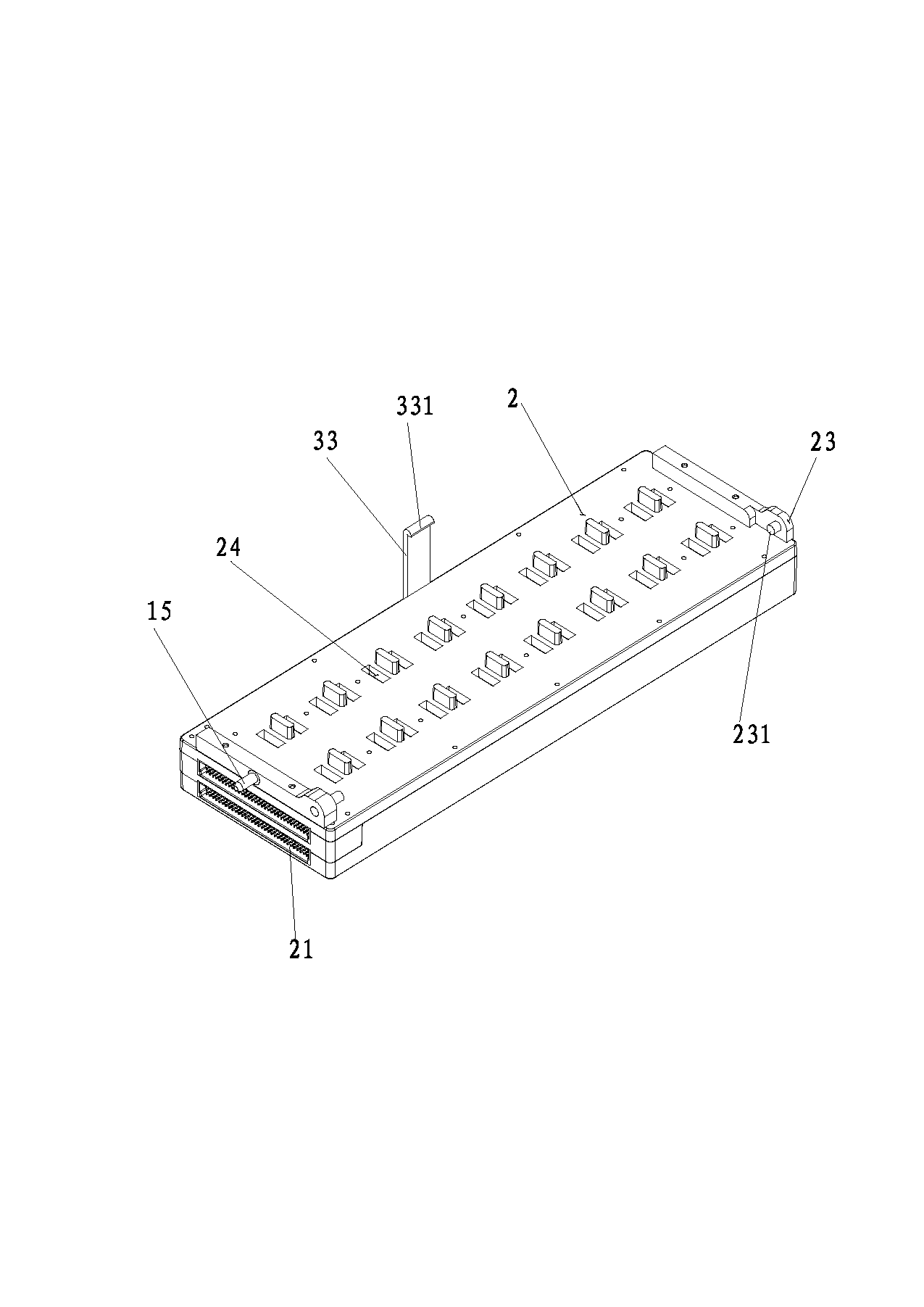

[0039] Embodiment 1 of a kind of aging test jig of the present invention is as Figure 1 to Figure 8 As shown, it includes a base 1 and an upper cover 2 arranged above the base 1, wherein: the base 1 is provided with a base PCB board, the base PCB board is provided with a DC signal connection device 11, and the inner surface of the base 1 opposite to the upper cover 2 is opened There is a product placement slot 14 for placing electronic products 5 . The product placement slot 14 is provided with a DC signal interface 12, and the DC signal interface 12 is electrically connected to the DC signal connection device 11 through the base PCB board; the upper cover 2 is provided with an upper cover PCB board, and the upper cover PCB board is provided with an AC signal connection device 21 and an AC signal interface electrically connected to the AC signal connection device 21 .

[0040] Before the aging test of the electronic product 5, the electronic product 5 is installed in the pro...

Embodiment 2

[0055] A kind of aging test fixture of the present embodiment sees figure 1 and Figure 4 , on the basis of Embodiment 1, the features not explained in this embodiment adopt the explanations in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0056] The aging test fixture also includes a locking device 3, which is used to lock the upper cover and the base 1 without relative movement when they are closed.

[0057] The locking device 3 includes a first support 31 fixed to the base 1 , a second support 32 fixed to the upper cover 2 , and a locking arm 33 , one end of the locking arm 33 is clamped to the first support 31 , The other end of the locking arm 33 is hinged to the second support 32 .

[0058] Specifically, the locking arm 33 is in an inverted L shape, the bent portion 332 of the locking arm 33 is provided with a hinge shaft 34 , the hinge shaft 34 is hinged to the second support 32 , and the hinge shaft 34 is ...

Embodiment 3

[0063] A kind of aging test fixture of the present embodiment sees figure 1 , Figure 5 to Figure 8 , on the basis of Embodiment 1, the features not explained in this embodiment adopt the explanations in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0064] refer to Figure 5 , the aging test fixture also includes a load device 4 for providing electronic load required for aging.

[0065] refer to Image 6 , the load device 4 includes a housing 41, a base 42, and a load DC signal connection device 43 and a load AC signal connection device 44 arranged on the base 42, wherein:

[0066] refer to Figure 8 A power supply 421 , a timing board 422 and an electronic load 423 are arranged under the base 42 to provide the power supply and electronic load required for aging.

[0067] refer to Figure 7 The bottom of the housing 41 is provided with a conductive copper plate 411 through which the load device 4 can be energi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com