Device for generating micro/nano-fibers with controllable waveforms

A technology of micro-nano fibers and generating devices, which can be applied in fiber processing, filament/thread forming, and bundling of newly ejected filaments, etc., can solve the problems of not being able to control the shape and size of corrugated fibers well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

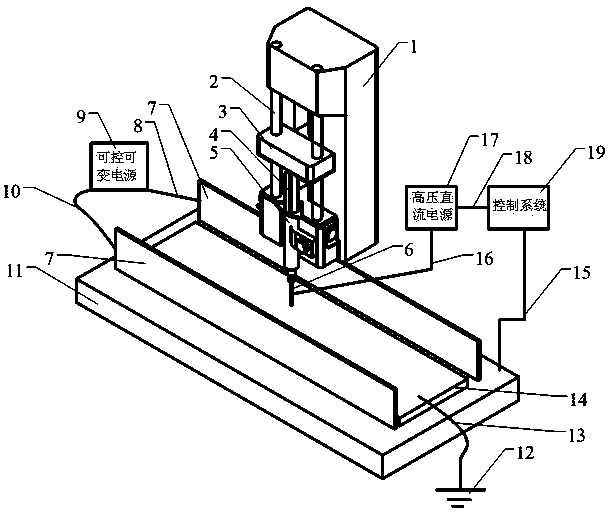

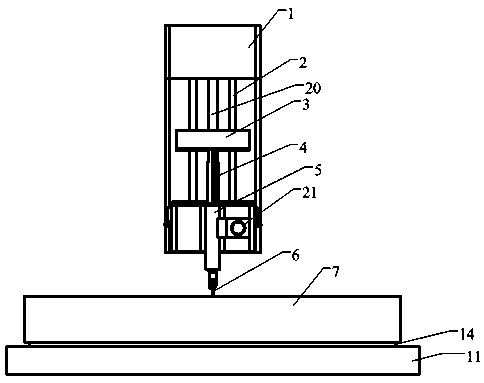

[0018] The controllable waveform micro-nano fiber generation device of the present invention includes a precision injection pump 1, a precision injection pump feed mechanism guide rail 2, a precision injection pump power transmission slider 3, a syringe push rod 4, a syringe 5, and an electrospinning nozzle 6. Auxiliary electrode 7, controllable power supply 9, motion platform 11, collector 14, high-voltage DC power supply 17, control system 19, power screw 20, syringe 5 is fixedly installed on the precision injection pump 1, and the precision injection pump 1 passes the power The lead screw 20 is connected with the precision syringe pump power transmission slider 3, the precision syringe pump power transmission slider 3 is connected with the syringe push rod 4, one end of the syringe push rod 4 is connected with the syringe push rod 4, and the other end of the syringe push rod 4 is installed Set in the hollow cavity of the syringe 5, the power output of the precision syring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com