Self-reinforced bionic material and manufacture method thereof

A technology of bionic materials and manufacturing methods, applied in the field of medical materials, can solve problems such as melting and fiber shape maintenance, and achieve stable product performance and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Two kinds of polylactic acid (code A and B) with different molecular weight and crystallinity were selected. A was L-polylactic acid with a number average molecular weight of 100,000 and a crystallinity of 70%; B was a mesopolylactic acid with a number average molecular weight of 60,000 and a crystallinity of 30%.

[0034] (1) Long fibers of polylactic acid A were prepared by melt spinning method, and the fiber fineness was 6D;

[0035] (2) The polylactic acid B film was prepared by the blown film method, and the film thickness was 15um;

[0036] (3) Stacking 60% long fibers and 40% films by mass by guiding the mold;

[0037] (4) Using an ultrasonic welding machine to continuously compound the stacked materials, the ultrasonic power is 3KW, and the production speed is 10m / min to prepare the self-reinforced polylactic acid material.

[0038] The performance test was performed after the above materials were naturally placed at room temperature for 24 hours. The tensile ...

Embodiment 2~6

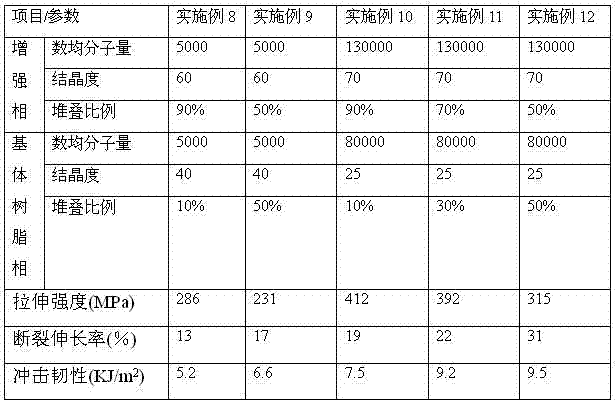

[0040] Select polylactic acid with different molecular weight and crystallinity to prepare different reinforcing phases and continuous phases. The composite method is the same as in Example 1, and the results are shown in the following table.

[0041]

[0042]

Embodiment 7

[0044] Two polyglycolic acids with different molecular weights and crystallinity (code-named D and E) were selected. D has a number-average molecular weight of 100,000 and a crystallinity of 70%; E has a number-average molecular weight of 50,000 and a crystallinity of 40%.

[0045] (1) The non-woven fabric of polyglycolic acid D was prepared by melt spinning method, and the grammage was 40g / m 2 ;

[0046] (2) A film of polyglycolic acid E was prepared by casting method, and the film thickness was 15um;

[0047] (3) Stack 60% non-woven fabric and 40% film by mass percentage by guiding the mold;

[0048] (4) Using an ultrasonic welding machine to continuously compound the stacked materials, the ultrasonic power is 3KW, and the production speed is 12m / min to prepare self-reinforced polyglycolic acid materials.

[0049] The above materials were tested after being naturally placed at room temperature for 24 hours. The tensile strength was 380MPa, the elongation at break was 24%, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com