Fabricated internal partition wall system and installation method thereof

An installation method and technology for internal partition walls, applied in the direction of walls, sound insulation, insulation layers, etc., to achieve the effect of simple assembly, convenient and fast installation, and a small number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

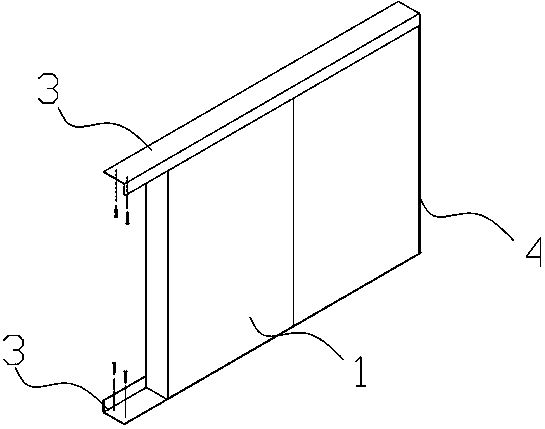

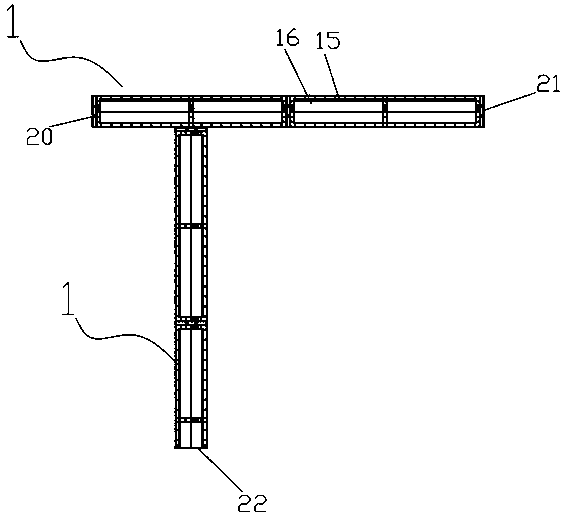

[0039] exist figure 1 , figure 2 , image 3 , Figure 4 In the illustrated embodiment, a prefabricated interior partition wall system includes:

[0040] Partition wall module 1, the main body of the modular partition wall system for direct decoration and quick splicing by film-coating the outer layer, and module buckle structures 2 are respectively arranged on the sides of the partition wall module 1;

[0041] The sky and earth keel 3 is installed on the top surface and the ground, and is used to fix the keel at the upper and lower ends of the partition wall module 1;

[0042] The sealing plate 4 is a plate used to seal the starting position or the ending position of the installation on both sides of the partition wall module 1; the sealing plate 4 is provided with a sealing plate buckle structure that cooperates with the module buckle structure 2 to realize splicing connection 5.

[0043] The partition wall modules 1 are plugged together and assembled together, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com