Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1450 results about "Experimental laboratory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

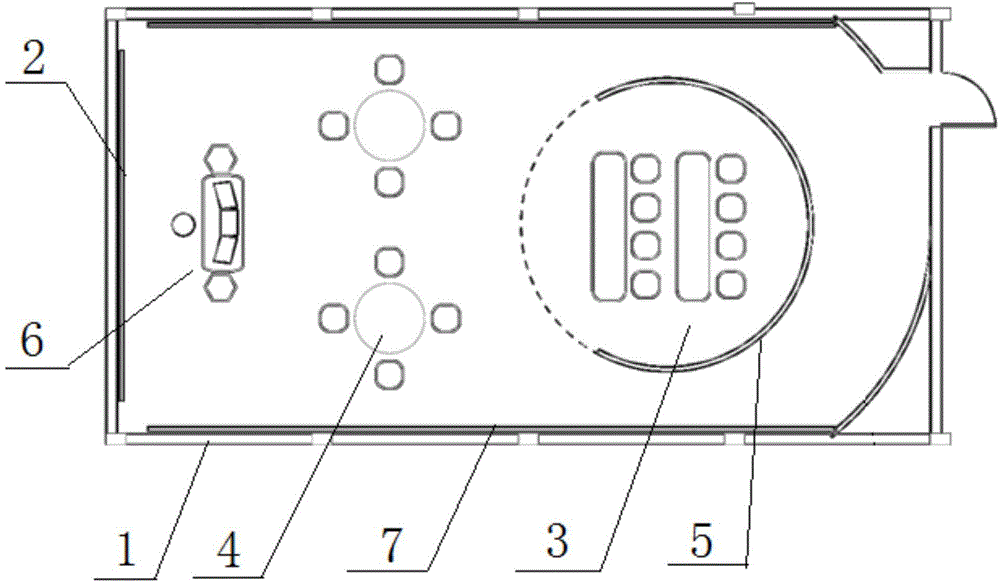

Experiential digitalized multi-screen seamless cross-media interactive opening teaching laboratory

ActiveCN104575142ASupports real-time processingRealize analysisElectrical appliancesPhysical spaceVirtual space

An experiential digitalized multi-screen seamless cross-media interactive opening teaching laboratory is integrated in testing, researching and analyzing. Experiment and data analysis are performed in a real teaching environment; under support of the multi-screen interactive technology, the laboratory comprises a laboratory functional partition, an operation support system, a data working system, an experiment information acquisition system and an audio and video input and output device; a screen jilting function among multiple mobile terminals is realized; the data working system comprises a server, a database, education resource cloud, a U-teaching system, a learning analysis and evaluation system, a mobile device, a cross-screen management module, a recording and broadcasting system and an Internet; learning space for cross-media interactive learning is provided, technologies of holographic imaging, multi-screen interaction, learning analysis and the like are integrated, and seamless fusion of the physical space and the virtual space is realized; seamless fusion of supporting technologies from formal learning to informal learning, multiple learning modes, cross-terminal, cross-media and the like is realized, and good learning experience is provided for learners.

Owner:SHANGHAI OPEN UNIVERSITY

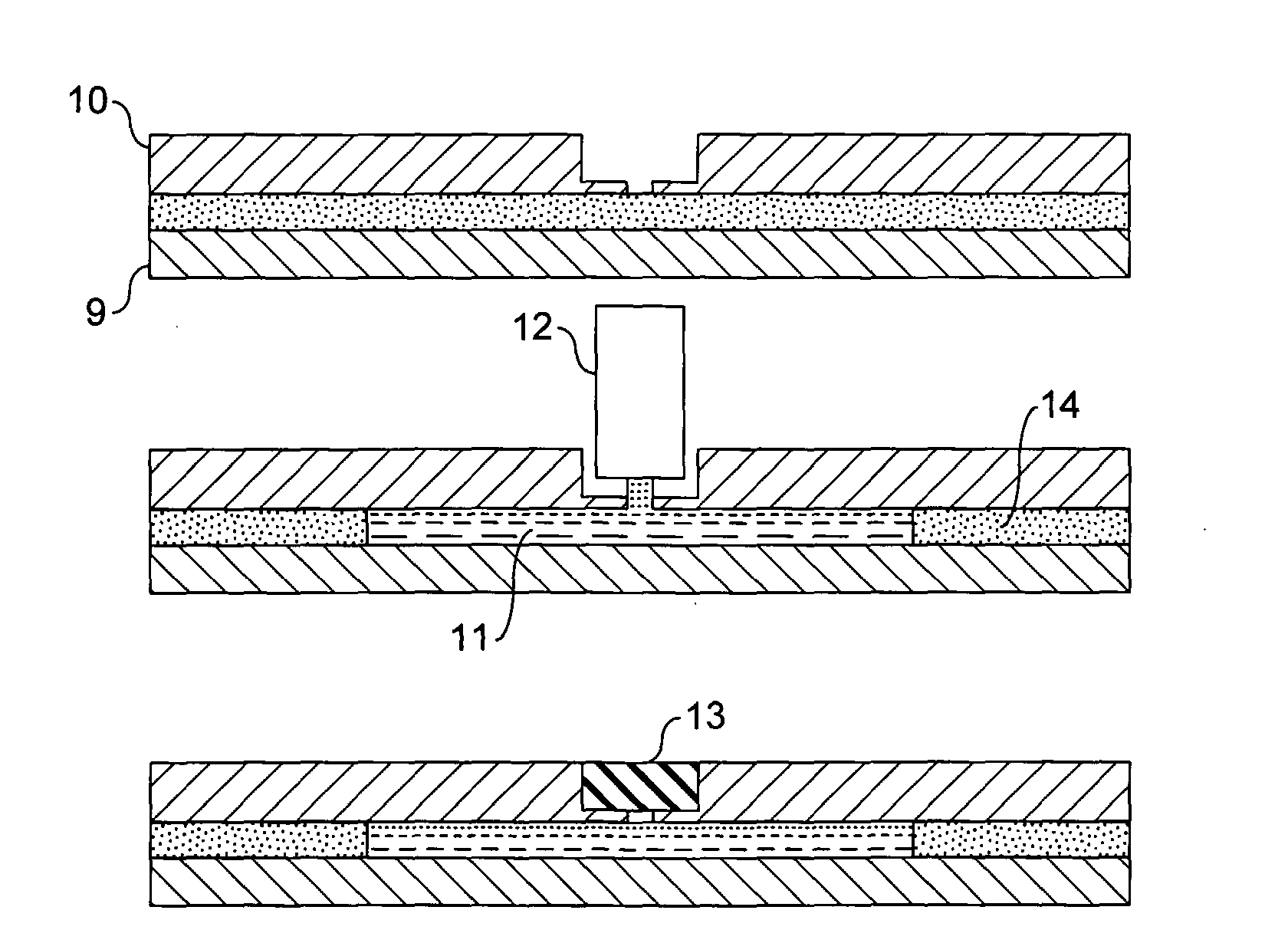

Device For Carrying Out A Biological Assay

InactiveUS20080248590A1Minimize the possibilityReaction can be limitedBioreactor/fermenter combinationsBiological substance pretreatmentsBiologic AssaysBio molecules

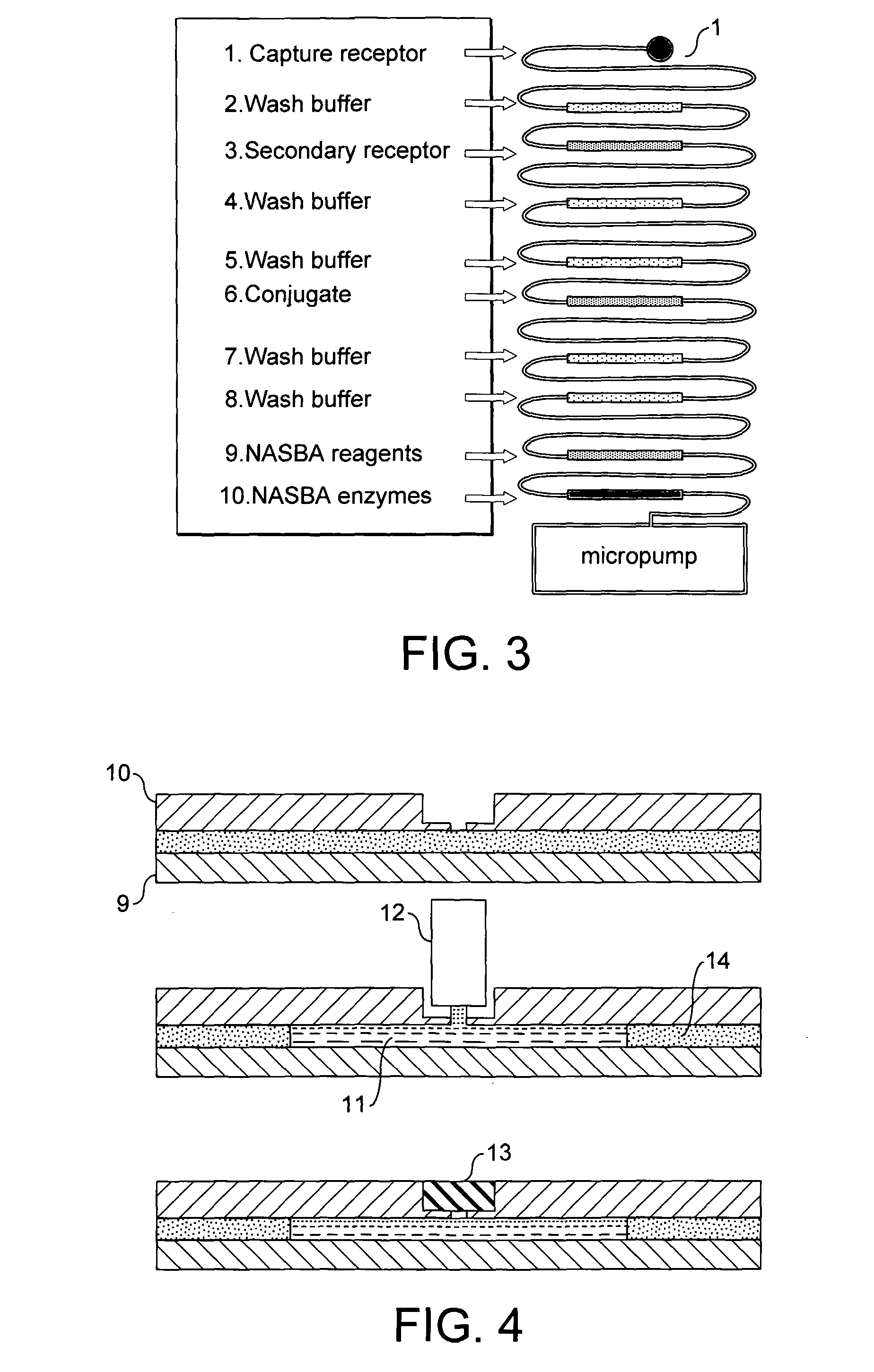

An integrated lab-on-a-chip device for carrying out an assay to detect the presence of a biological molecule in a fluid sample, the device comprising: (a) an inlet for a fluid sample; (b) one or more reaction sites each in fluid communication with the inlet; (c) one or more reagent reservoir systems each containing reagents required for an assay to detect a biological molecule, the reagents being arranged sequentially in each reservoir system in the order in which they are required for the assay and separated from one another by a fluid.

Owner:NORCHIP AS

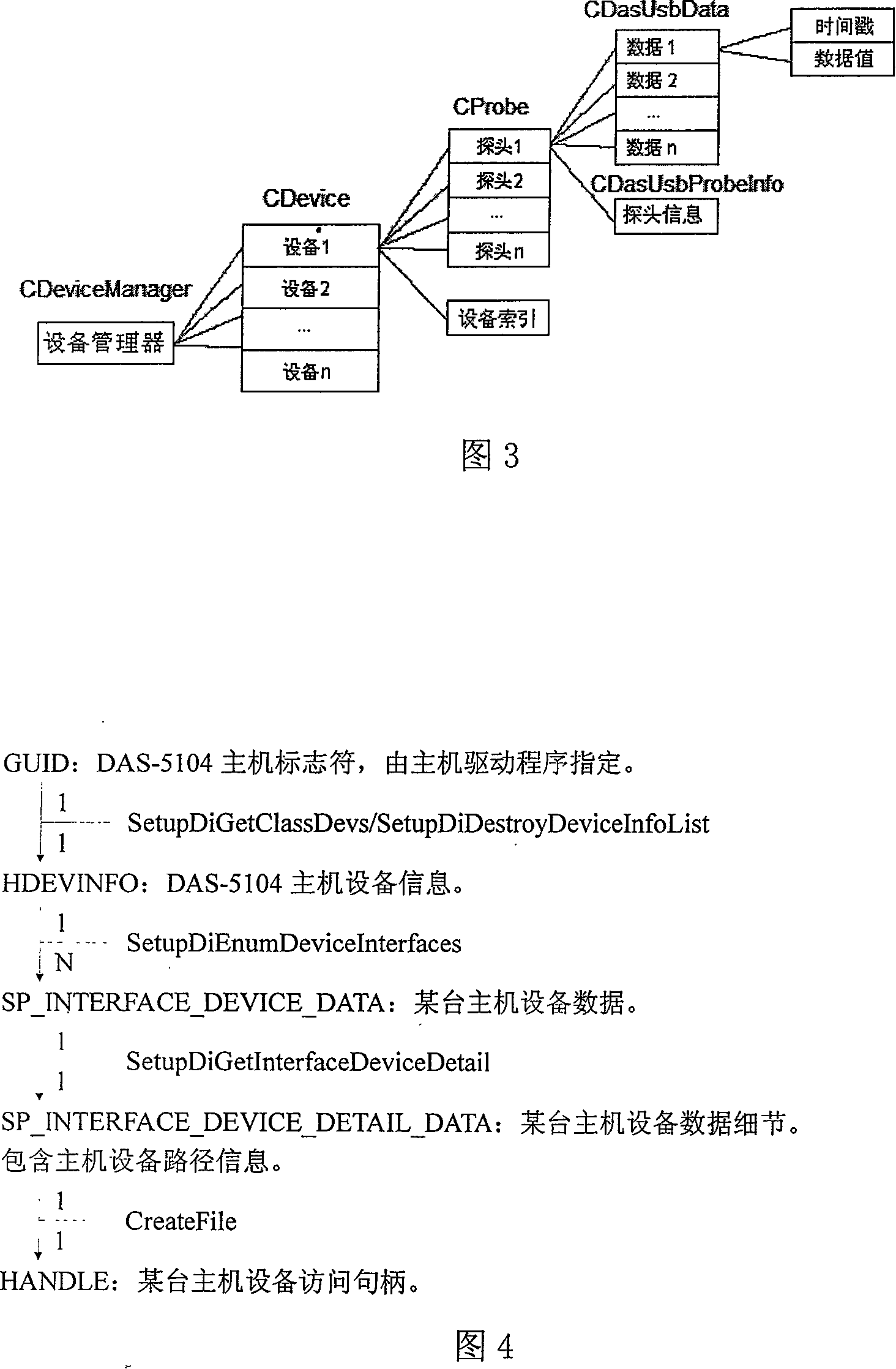

Apparatus and method for monitoring and controlling laboratory information and/or instruments

InactiveUS6594588B1Data processing applicationsVisual/graphical programmingGraphical user interfaceInstrumentation

A system and method for handling laboratory information includes a graphical user interface with a plurality of windows. A palette of icons is provided in a first one of the windows, each icon representing a predetermined task to be executed by a processor in communication with the graphical user interface. The processor is also in communication with a database containing static laboratory data (such as the type of sample to be analysed) as well as dynamic laboratory data (such as the name of the specific sample to be tested and the results of that test). A user can select icons from the first window and "drag and drop" them into a second window. A sequence of tasks may thus be built up, in the form of a tree structure, and when run the processor executes the sequence of tasks in turn by reference to the static and dynamic laboratory data.

Owner:THERMO BIO ANALYSIS

System and method for open intelligent management of laboratory

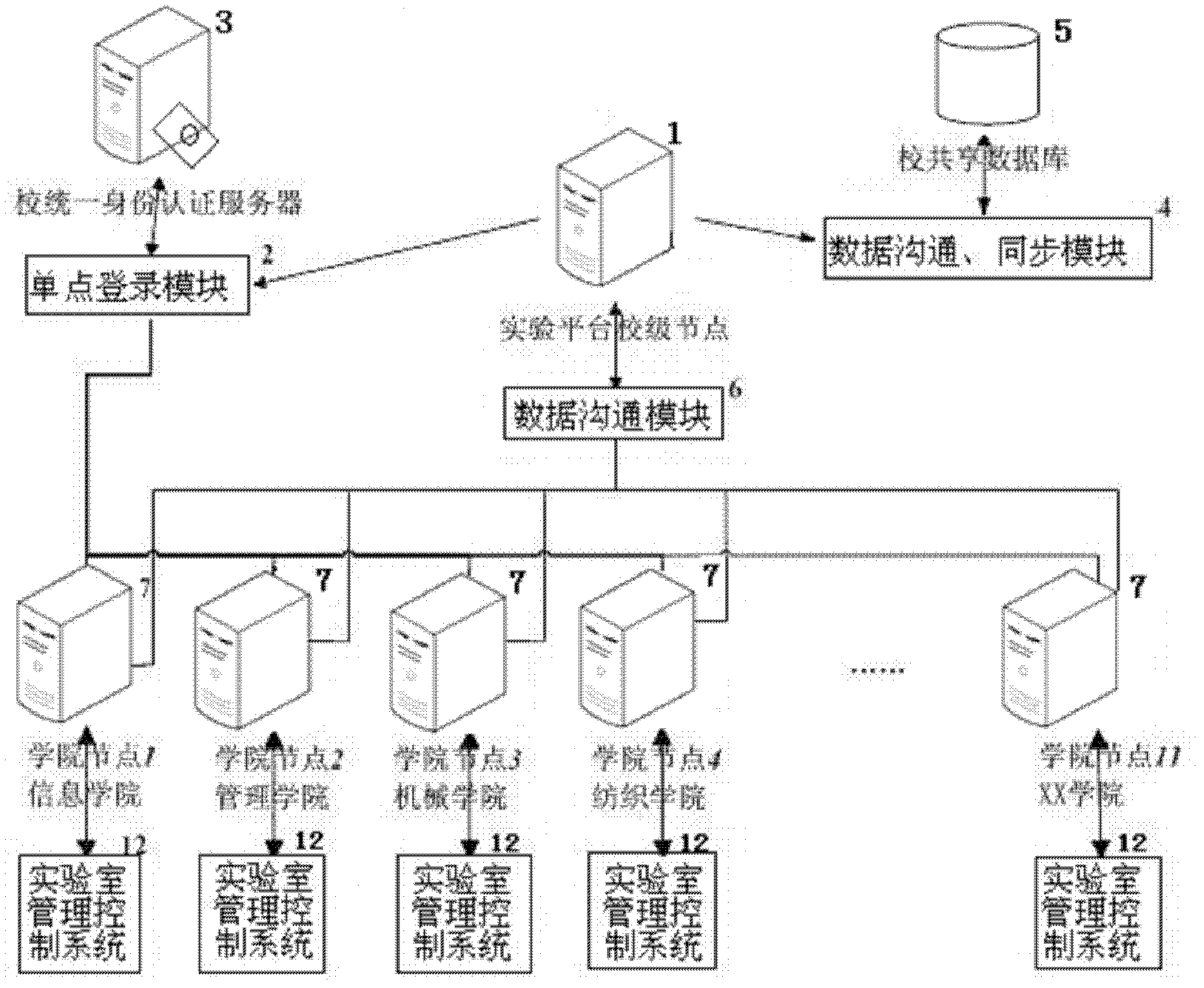

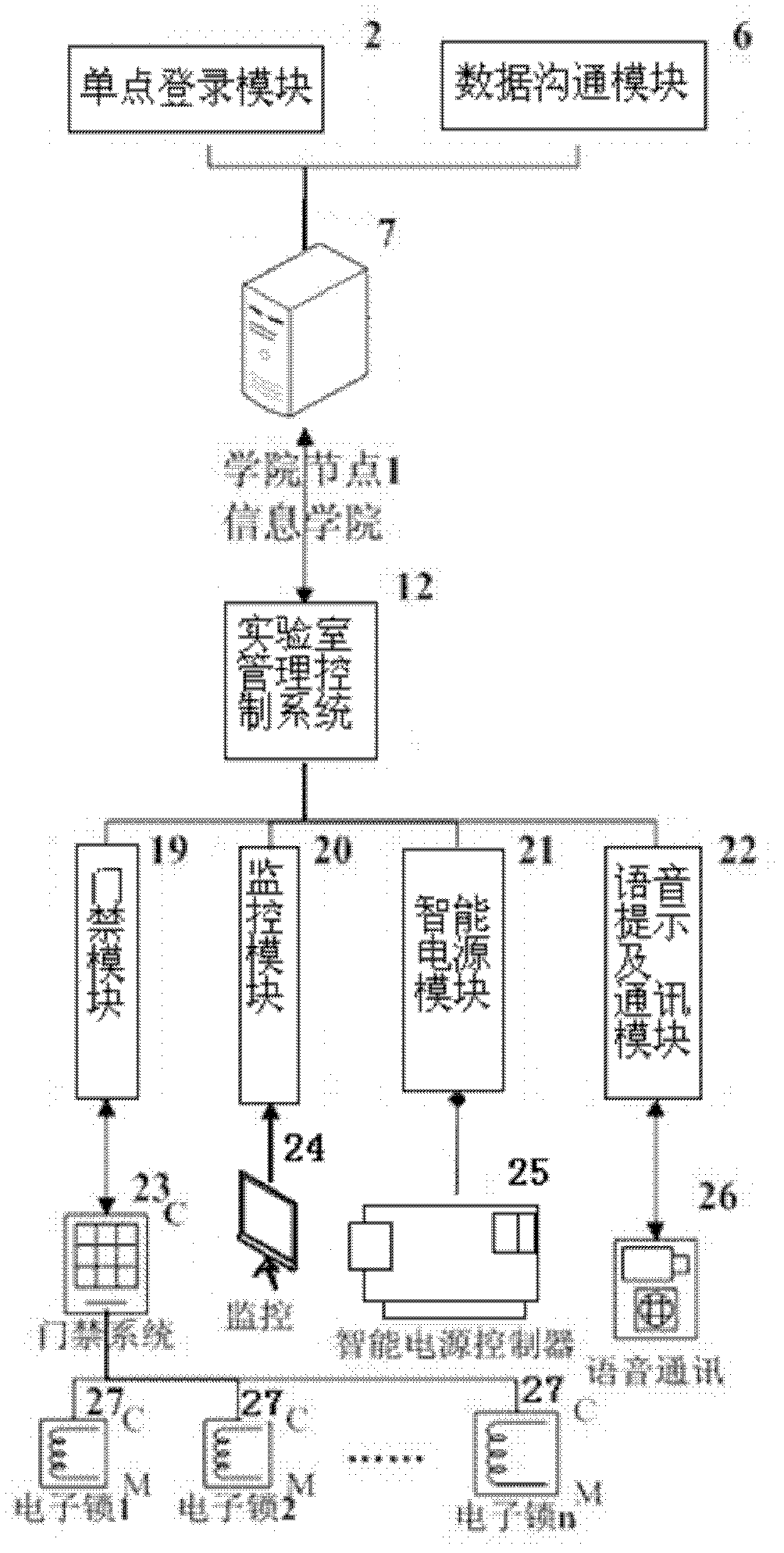

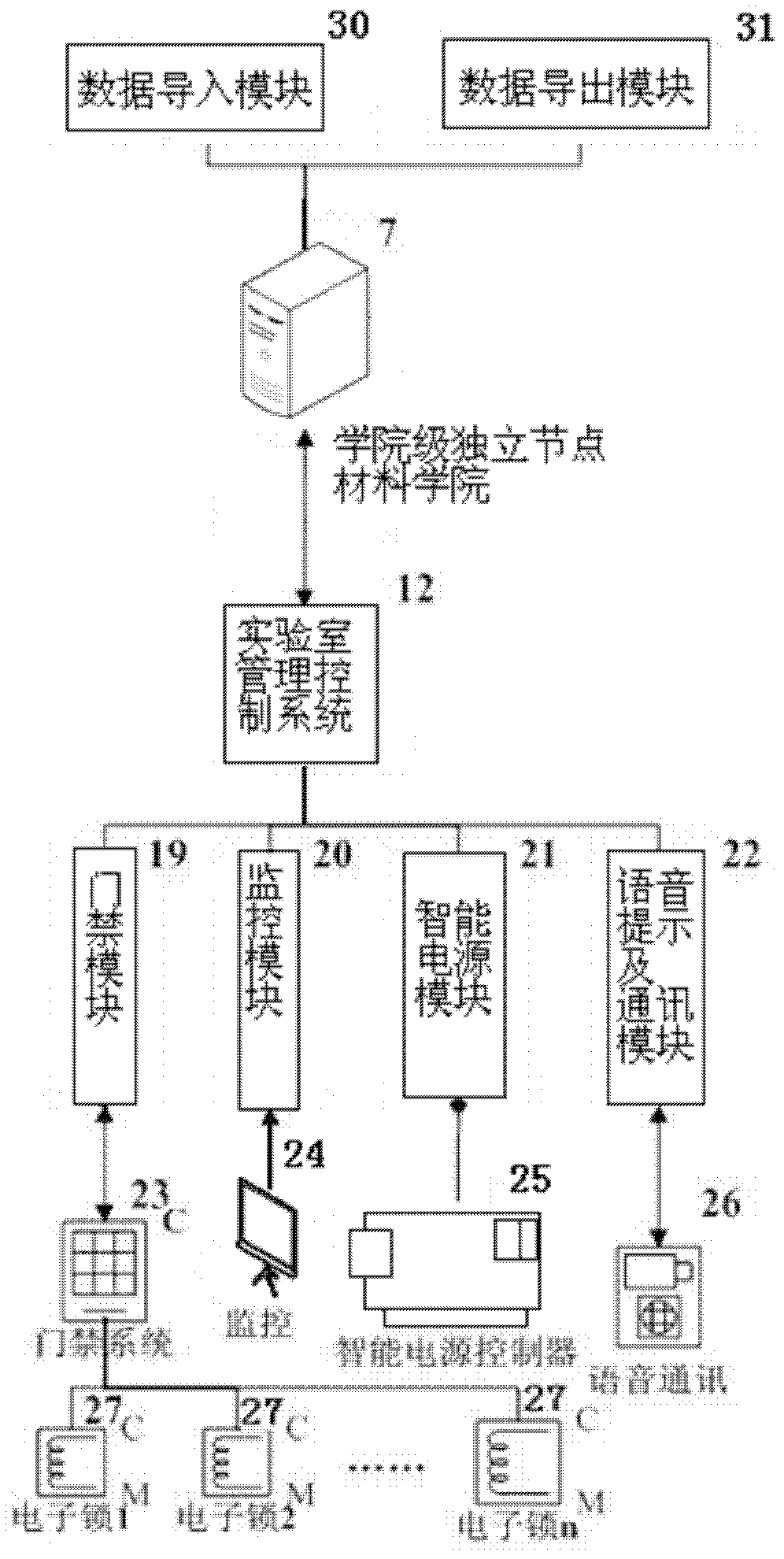

InactiveCN102306342AOpen implementationImprove work efficiencyData processing applicationsControl systemThe Internet

The invention relates to a system and a method for open intelligent management of a laboratory. The system comprises a server and a client, wherein the server comprises a university level platform node server and a plurality of college level platform node servers; the university level platform node server performs data communication with a university shared data base through a data communication module and a synchronous module, and performs data communication with the college level platform node servers through the data communication module; the client is connected with the server through a campus network inside a university and through the INTERNET outside the university; and the client comprises a laboratory management control system and an intelligent laboratory management system. The method comprises the management of experiments or experiment courses specified in a teaching program and the management of open experiments or equipment usage outside the teaching program. According to the invention, all-day open of the laboratory can be realized, and the working efficiency of laboratory management personnel can be greatly improved.

Owner:DONGHUA UNIV

Processes and Systems for Characterizing and Optimizing Fracturing Fluids

A workflow to optimize a fracturing fluid for injection into a subterranean formation is provided. The workflow comprises measurement of fundamental properties and characteristics of reservoir rock and fluid, their interaction with fracturing fluid, computer-based models and laboratory performance testing to select preferred fracturing base fluid and additives package for use in fracturing / re-fracturing stimulation of specific shale formations to enhance hydrocarbon recovery.

Owner:CHEVROU USA INC

Integrated instrumentation for the analysis of biofluids at the point-of-care

ActiveUS20150004717A1Improve performanceMinimize intra-assay CVMaterial analysis by optical meansChemical methods analysisPoint of careLab-on-a-chip

Owner:RICE UNIV

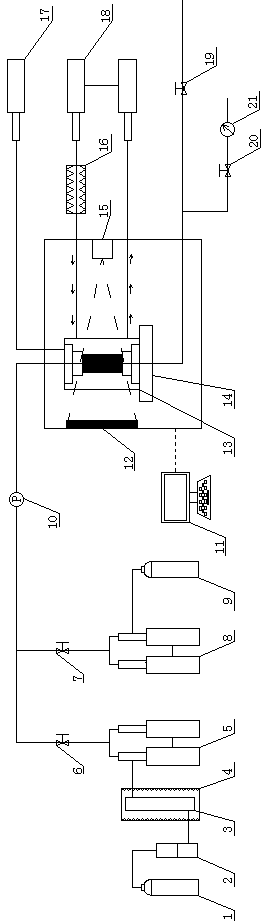

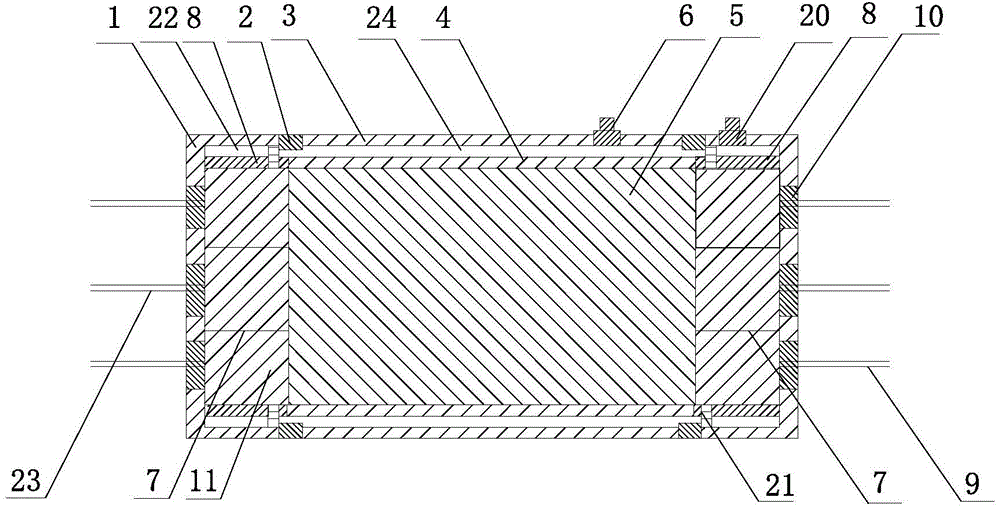

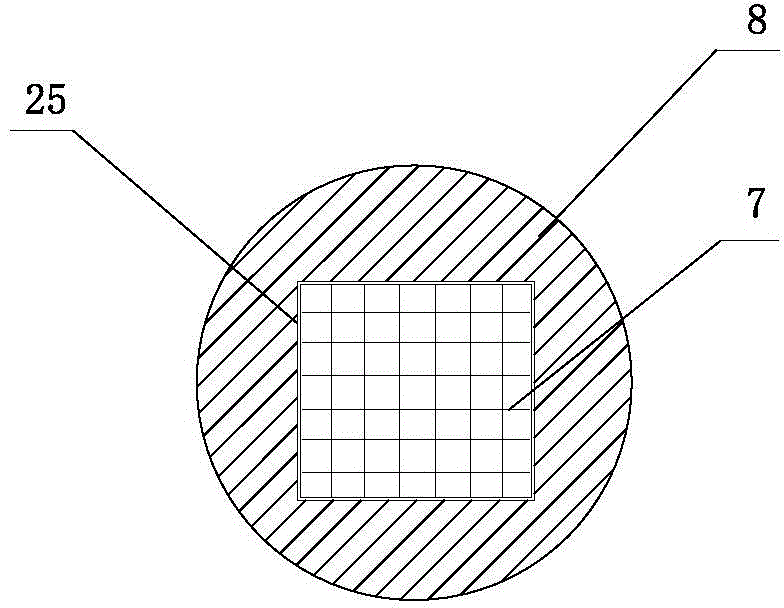

Pressure grouting experiment device

InactiveCN103048439AGuaranteed physical and mechanical propertiesSuitable for useMaterial testing goodsExperimental laboratoryClassical mechanics

The invention provides a pressure grouting experiment device comprising a slurry supplying device, wherein the slurry supplying device is communicated with a slurry hole of an experiment mould; a lower slurry hole of the experiment mould is communicated with a slurry recycling barrel; a plurality of pipelines are arranged on the outer wall of the experiment mould from top to bottom; each pipeline is provided with a pressure gage; and throttling valves are arranged between the slurry supplying device and the experiment mould and also between the experiment mould and the slurry recycling barrel. According to the pressure grouting experiment device disclosed by the invention, grouting stone bodies with the regular shape can be easily and conveniently obtained through using different moulds, and slurry dispersion radiuses under the different conditions can be obtained. In the testing process, pressure P provided by matching the pressure gages and a flow meter with a jack can relatively and effectively analyze influences of a testing parameter to each physical mechanical property of the stone bodies and the slurry dispersion radiuses. According to the pressure grouting experiment device disclosed by the invention, the grouting amount can be quantized, so that components of the stone bodies are also quantized. The pressure grouting experiment device is small and exquisite, convenient and easy to use, and is particularly suitable for being used in a laboratory.

Owner:CHINA THREE GORGES UNIV

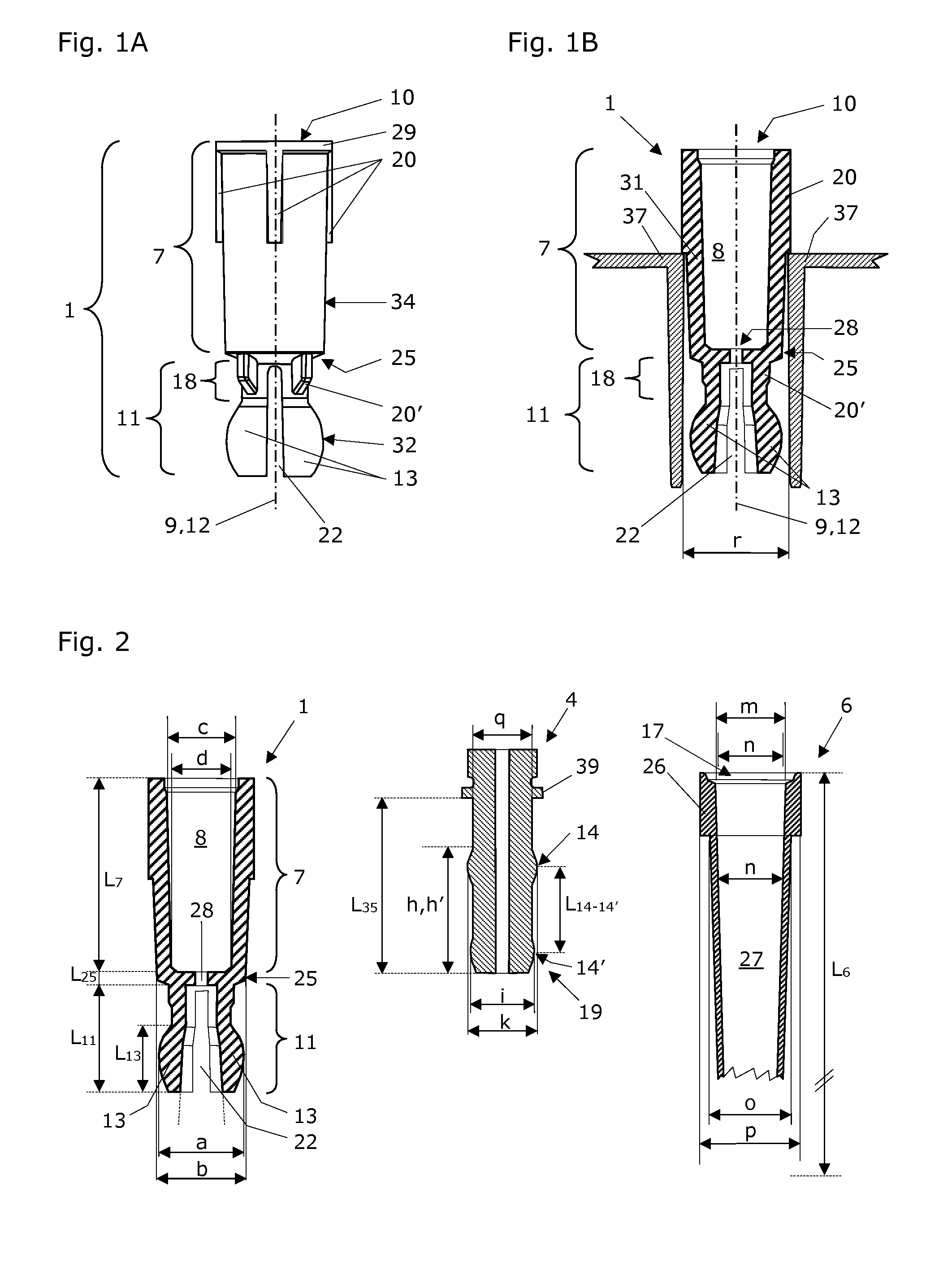

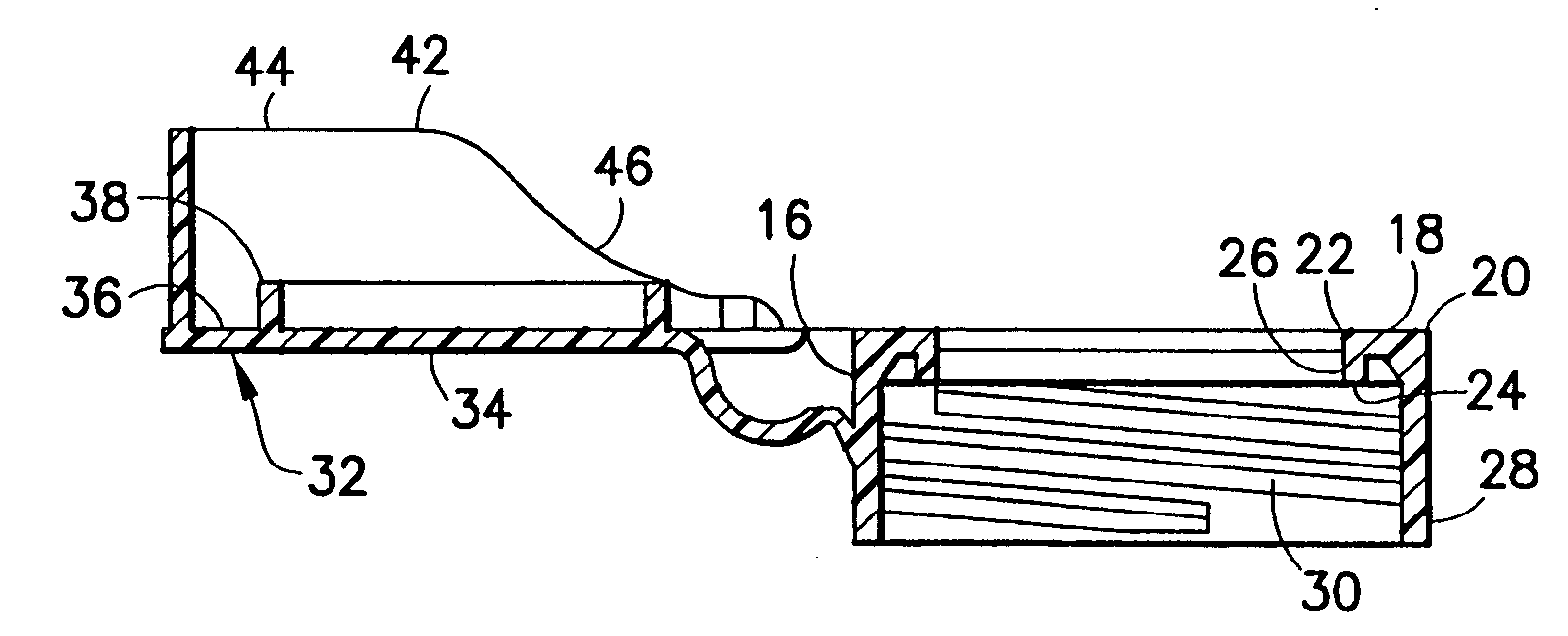

Transport Tool for Transporting A Laboratory Article

ActiveUS20150239129A1Reduce weightGood chemical resistanceGripping headsLoad-engaging elementsPipetteMechanical engineering

A transport tool for transporting a laboratory article using a pipette of a pipetting system includes at least one plug-in sleeve, which is implemented for the releasable plugging-in of a receptacle cone of a pipette, and which can be plugged onto the receptacle cone of the pipette instead of a disposable pipette tip. In addition, the transport tool includes an article holder having at least one holding part, which is implemented to form a support connection with a laboratory article. A connecting part connects the article holder to the plug-in sleeve, so that holding axes of the article holder and the sleeve axis of the plug-in sleeve are arranged coaxially or axially-parallel to one another.

Owner:TECAN TRADING AG

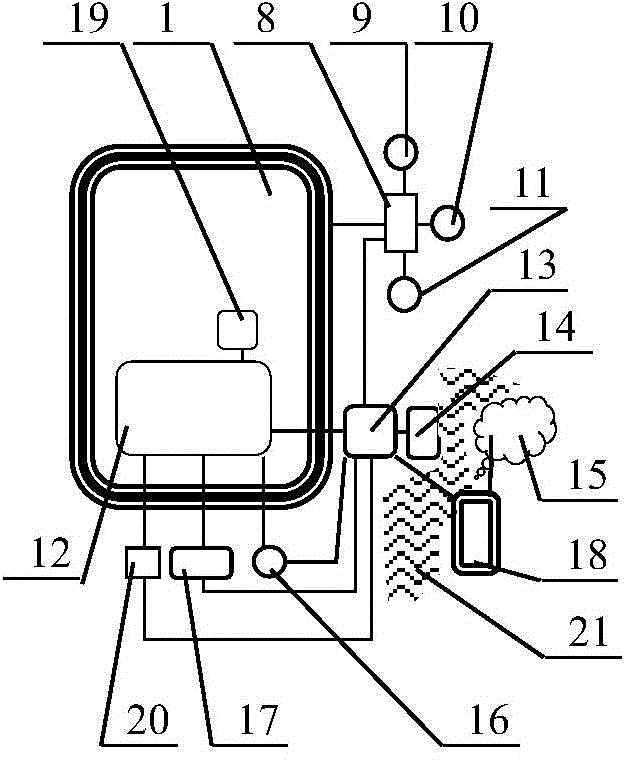

Supercritical carbon dioxide coal rock fracturing CT imaging and evaluation device under simulated in situ condition and use method thereof

InactiveCN109507077AComprehensive evaluation of fracturing effectsPermeability/surface area analysisLaboratory researchMeasurement device

The invention discloses a supercritical carbon dioxide coal rock fracturing CT imaging and evaluation device under a simulated in situ condition and a use method thereof, belonging to the field of intensified mining of coalbed methane. The device provides a supercritical carbon dioxide fracturing device under a geological environment condition in which the size of a test piece is Phi 50*100 mm, anaxial pressure and a peripheral pressure of the test piece reach 50 MPa separately, environment temperature of the test piece reaches 100 DEG C, burial depth of a simulated coal bed reaches 2000 m. The device consists of an in situ environment simulation device, a CT scanning device, a supercritical carbon dioxide fracturing device, a penetration rate measurement device and a data collection device. By adopting the device provided by the invention, the defect that in existing laboratory study, crack patterns after supercritical carbon dioxide fracturing cannot be observed intuitively under the simulated in situ condition is overcome, the crack patterns in the coal after supercritical carbon dioxide fracturing can be observed in real time, and supercritical carbon dioxide fracturing effectcan be evaluated comprehensively by combining coal penetration changes before and after supercritical carbon dioxide fracturing.

Owner:TAIYUAN UNIV OF TECH

Method for quickly detecting saturation exponent n in laboratory

The invention provides a method (three-point method) for quickly detecting a saturation exponent n in a laboratory. The method realizes the following three particular targets: (1) on the premise that capillary force and resistivity balance are ensured, the water saturation and resistivity of a core can be measured accurately; (2) the experiment testing period is shortened to 2 weeks from 2 months; and (3) whether the relationship between the resistance increase and the water saturation of rock conforms to the Archie relationship or not can be judged, and the saturation exponent n is given if the relationship between the resistance increase and the water saturation of rock conforms to the Archie relationship. The three-point method can efficiently detect reservoir saturation without risk.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

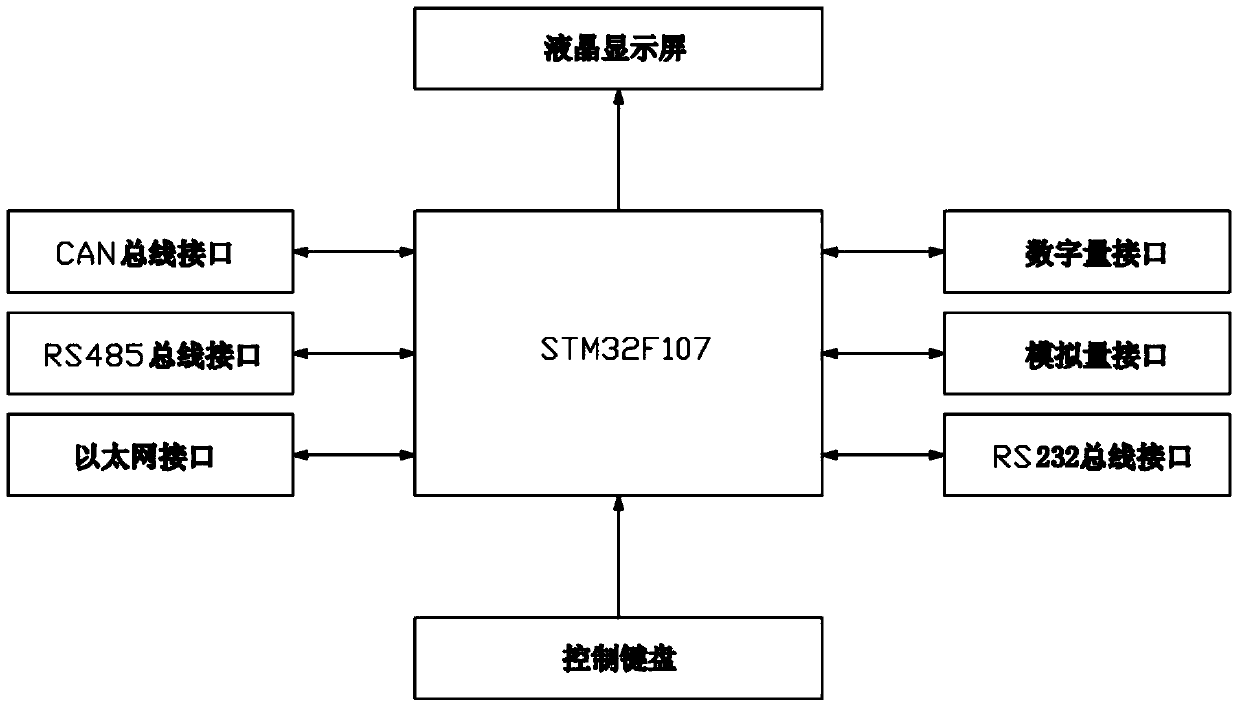

High-risk laboratory monitoring system based on Internet of Things

InactiveCN106249679AAvoid influenceQuick collectionProgramme controlComputer controlInstrument controlInternet of Things

The invention relates to the technical field of risky experiments, and discloses a high-risk laboratory monitoring system based on the Internet of Things. The high-risk laboratory monitoring system comprises a monitoring center server, and a camera, an experimental environment monitoring module, a high-risk experimental instrument and a laboratory infrastructure monitoring module which are connected with the monitoring center server, wherein the camera is used for transmitting real-time video information of a laboratory to the monitoring center server; the experimental environment monitoring module is used for transmitting environmental information of the laboratory to the monitoring center server in real time; the high-risk experimental instrument is used for transmitting its real-time state and / or experimental data to the monitoring center server, and receiving an instrument control command issued by the monitoring center server; and the laboratory infrastructure monitoring module is used for transmitting real-time states of infrastructures to the monitoring center server, and receiving an infrastructure control command issued by the monitoring center server, so as to control the corresponding infrastructures to complete corresponding actions. The high-risk laboratory monitoring system based on the Internet of Things realizes internet-of-things, remote and real-time monitoring and control of the risky laboratory.

Owner:CHONGQING BOAN KECHUANG TECH

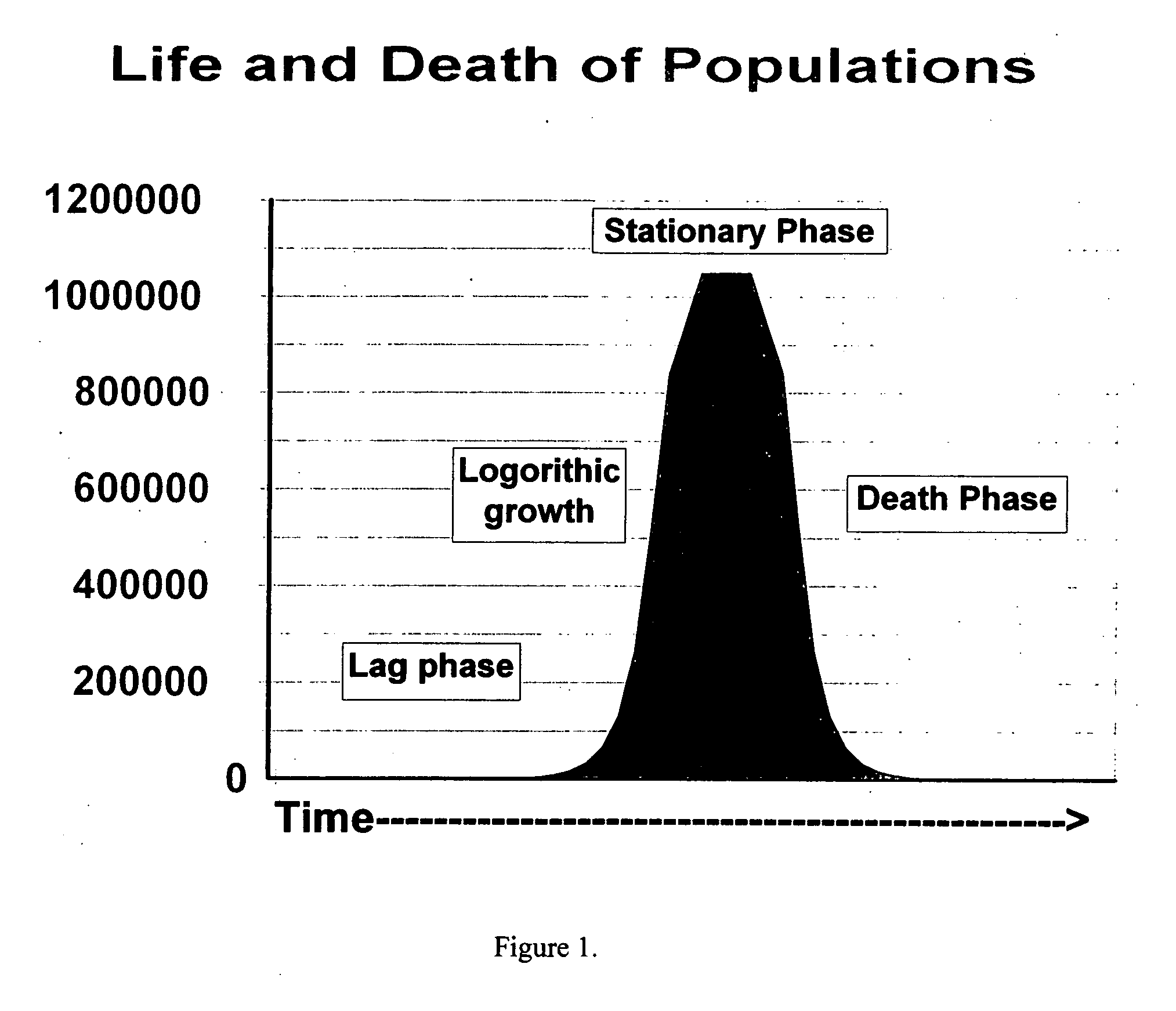

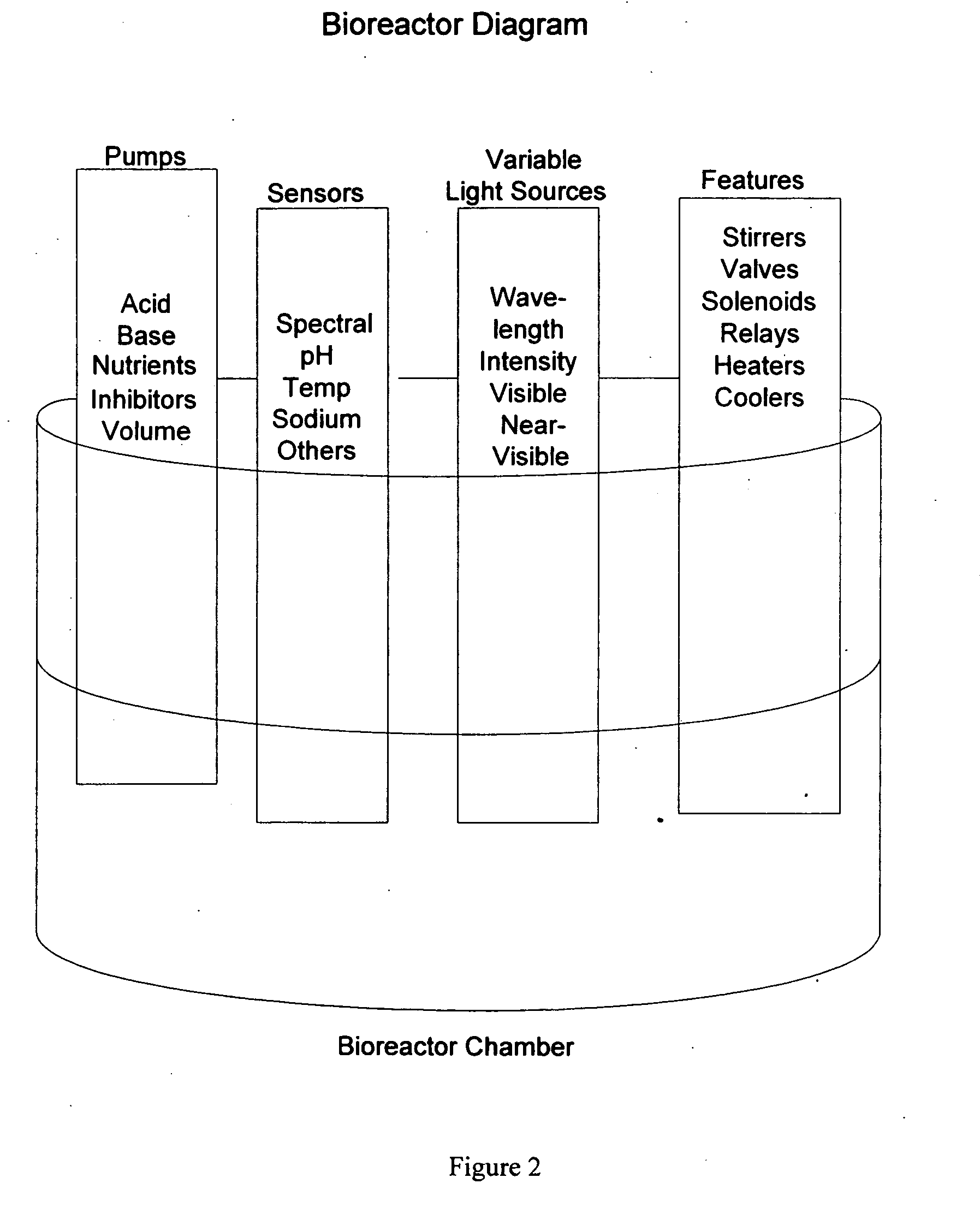

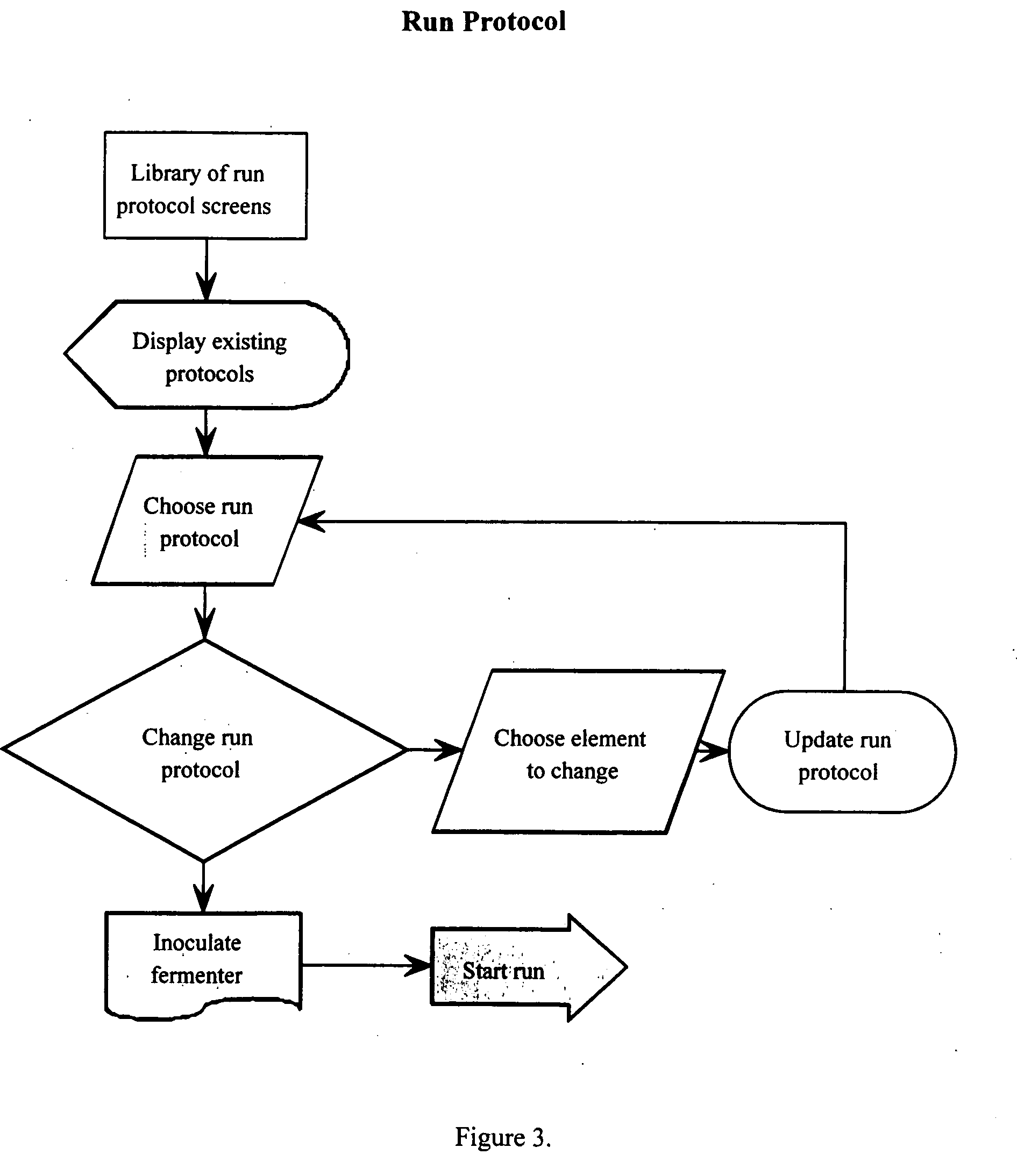

Decision-making spectral bioreactor

InactiveUS20050208473A1Bioreactor/fermenter combinationsBiological substance pretreatmentsComputer generationParameter control

This invention fills several voids in bioreactor technology that allows efficient connection of aspects of physical science (optics, electronics, physical chemistry, sensors) to aspects of microbial and cell culture physiology in a uniquely interactive manner. This is accomplished mathematically through decision making software that utilizes detected changes in the course of fermentation. Decisions are aimed at determining the optima for cellular growth, optimizing for production or degradation of metabolites or substrates, or determining the limits of growth under various combinations of conditions. The invention determines optima or limits in a manner more quickly and at less cost than traditional methods. The basis for the computer generated decisions may be first or second derivative changes observed such as inflection points, limits on allowable rates of change, or the like. The most common measured parameter controlling the decision making process is the optically observed growth of the cells (e.g. microbial, animal, or plant cell cultures) under study. Any other measurable parameter (e.g. pH, temperature, pigment production) may be used to control the process (i.e., the independent variable). This process and variations of this process on a laboratory scale are valuable for research and development, education, pilot plant models, and bio-manufacturing optimization, including scale up to production volumes.

Owner:KRICHEVSKY MICAH I +4

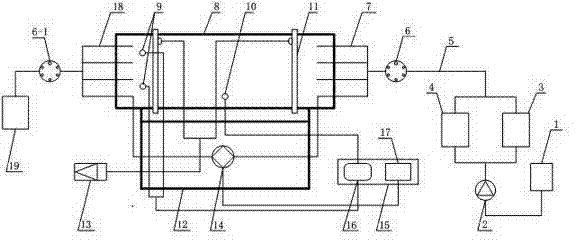

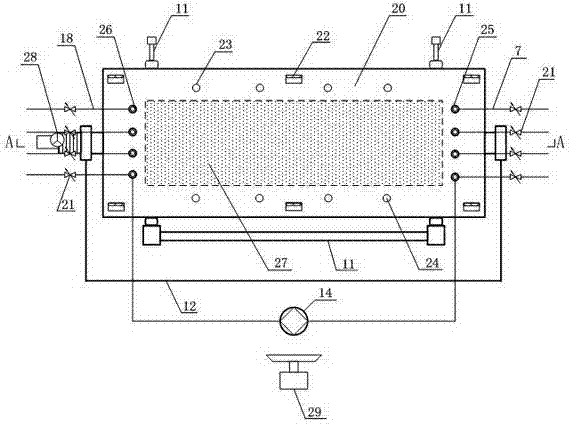

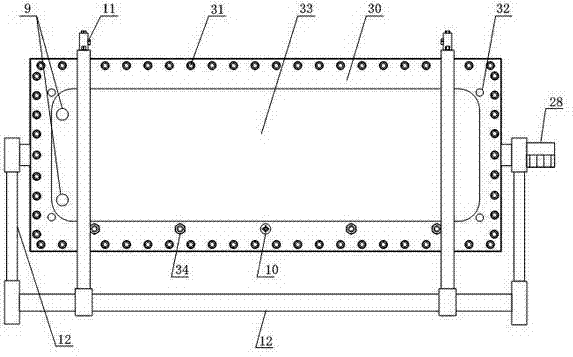

Device and method for large-size visual physical simulation of fingering of acid liquid in acid fracturing crack

InactiveCN102928556AFast heatingIn line with the real environmentFluid removalMaterial analysisAcid fracturingDifferential pressure

The invention relates to a device and a method for large-size visual physical simulation of fingering of an acid liquid in an acid fracturing crack in an oilfield chemistry and acid fracturing laboratory and a research laboratory. The device and the method can simulate flowing and reaction conditions of an acid liquid in an acid fracturing crack, can be used for observation of fingering of an acid liquid, and can determine associated parameters. The device is characterized in that a high-pressure constant-flow pump of a liquid pumping unit is connected to a liquid storage tank; a liquid outlet of the high-pressure constant-flow pump is connected to middle containers; the middle containers are connected to a six-way valve; the six-way valve is connected to a liquid inlet of a crack simulation unit; a stainless steel front frame is connected to a rear cover by fastening bolts; exhaust holes and drainage holes are arranged respectively at an upper part and a low part of the stainless steel front frame; liquid inlet holes and liquid outlet holes are arranged respectively at a left end and a right end of the stainless steel front frame; an observation window is arranged in the center of the stainless steel front frame; a rock plate is arranged between the stainless steel front frame and the rear cover; an electric heating panel and a heating probe are embedded in an outer side of the rear cover; a temperature sensor is arranged in the center of the rear cover; the liquid inlet holes and the liquid outlet holes of the stainless steel front frame are provided with a differential pressure transducer; and an image gatherer is installed right in front of the crack simulation unit. The device and the method improve a degree of mechanization and automation. A simulation experiment carried out by the device satisfies storage layer real-environment requirements, and is safe and fast.

Owner:SOUTHWEST PETROLEUM UNIV

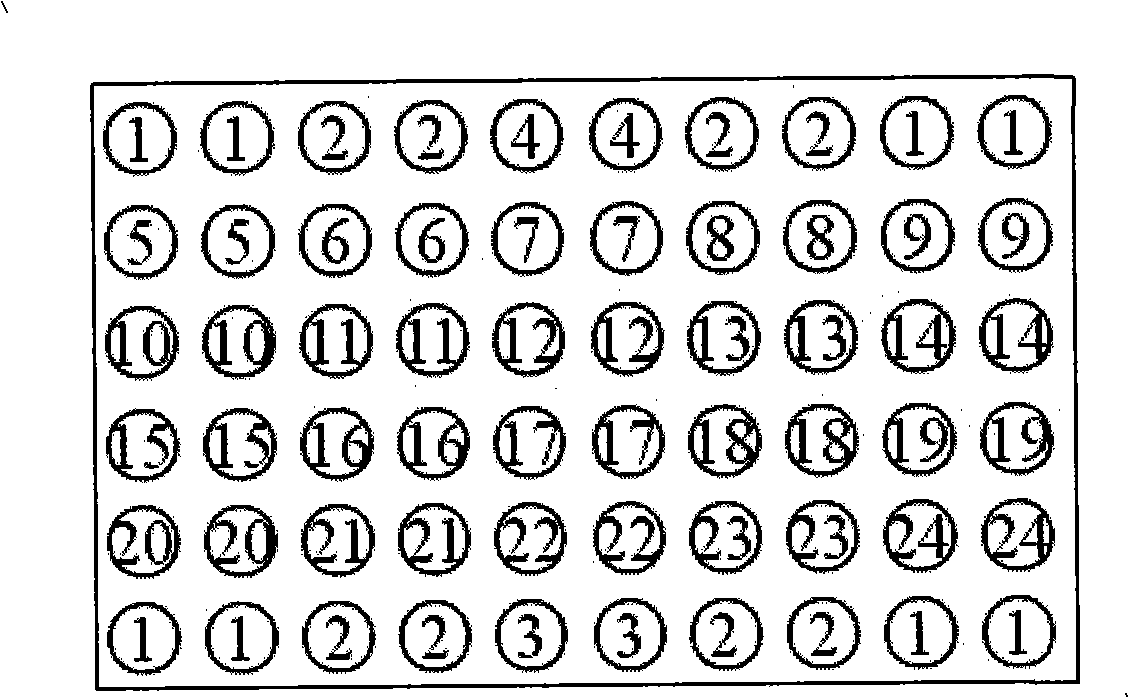

Pathogenic epiphyte detection gene chip

InactiveCN101492743AQuick checkHigh sensitivityMicrobiological testing/measurementMicroorganism based processesRNA SequenceOligonucleotide

The invention relates to a gene chip for detecting pathogenic fungi, comprising a solid phase carrier, a specific oligonucleotide probe fixed on the solid phase carrier, wherein the specific oligonucleotide probe fixed on the solid phase carrier comprises oligonucleotide sequences represented by SEQ ID NO:1-SEQ ID NO:20 or DNA or RNA sequences complementary to the oligonucleotide sequences represented by SEQ ID NO:1-SEQ ID NO:20. The invention further relates to a preparation method and use method thereof. The gene chip of the invention is capable of simultaneously and rapidly detecting pathogenic fungi, has the characteristics of high sensitivity, good specificity and simple operation, does not require special instrument, and is suitable for development in clinical laboratory.

Owner:ARMY MEDICAL UNIV

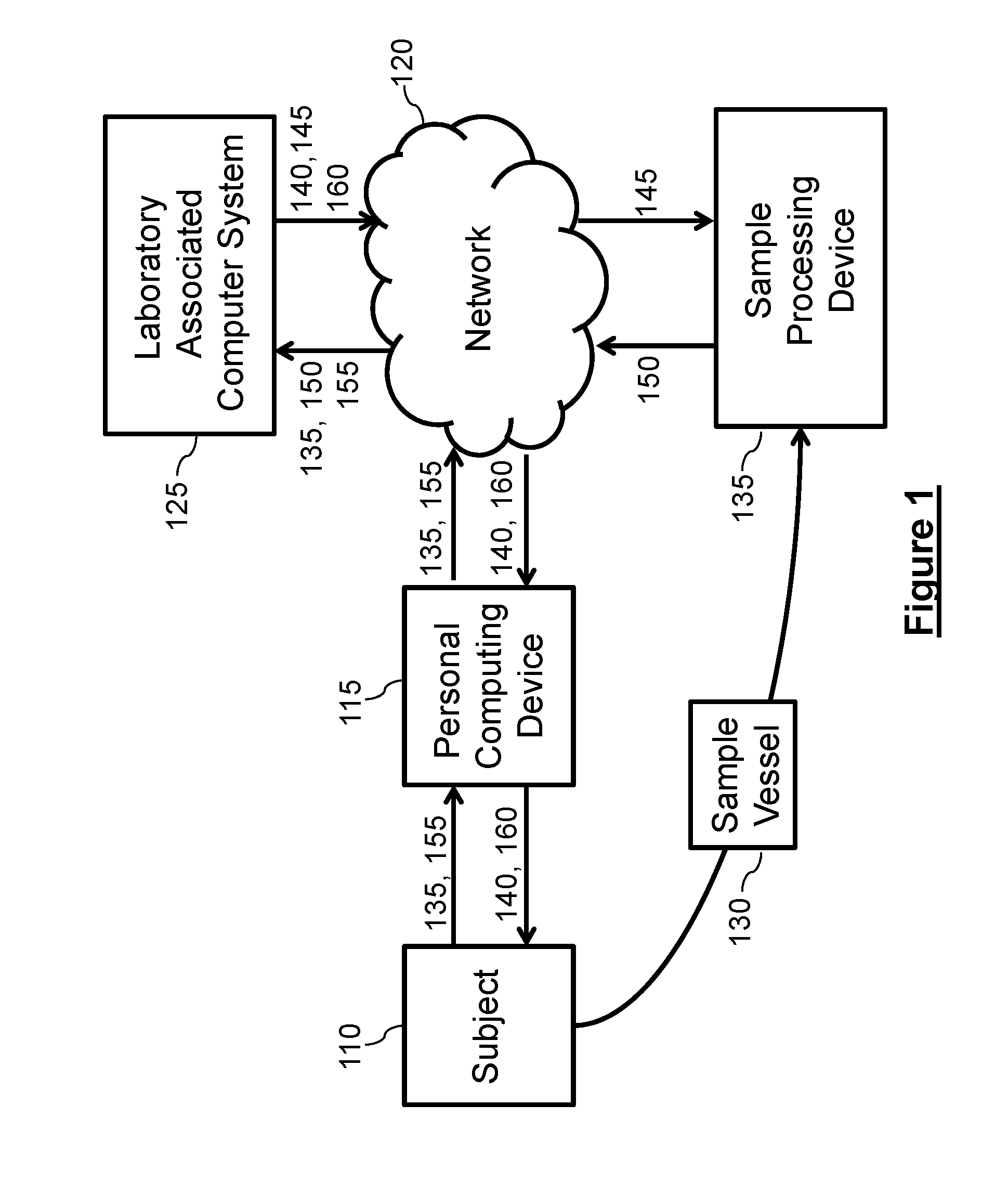

Automated laboratory test ordering and result tracking

InactiveUS20070294103A1Data processing applicationsComputer-assisted medical data acquisitionComputerized systemTest order

Computerized systems and methods are provided for coordinating clinical laboratory testing from initial order entry to results notification. A laboratory testing manager provides a centralized conduit for interfacing entities placing orders for laboratory testing and laboratories performing testing. Entities, such as healthcare providers, patients, and the like, may access the laboratory testing manager to enter orders for laboratory testing. The laboratory testing manager may determine an eligible laboratory to perform the laboratory testing based on information provided in each order, such as the type of testing requested and insurance coverage information. After a laboratory performs testing specified in an order, the laboratory may enter the testing results, which are routed to recipients indicated for the results.

Owner:CERNER INNOVATION

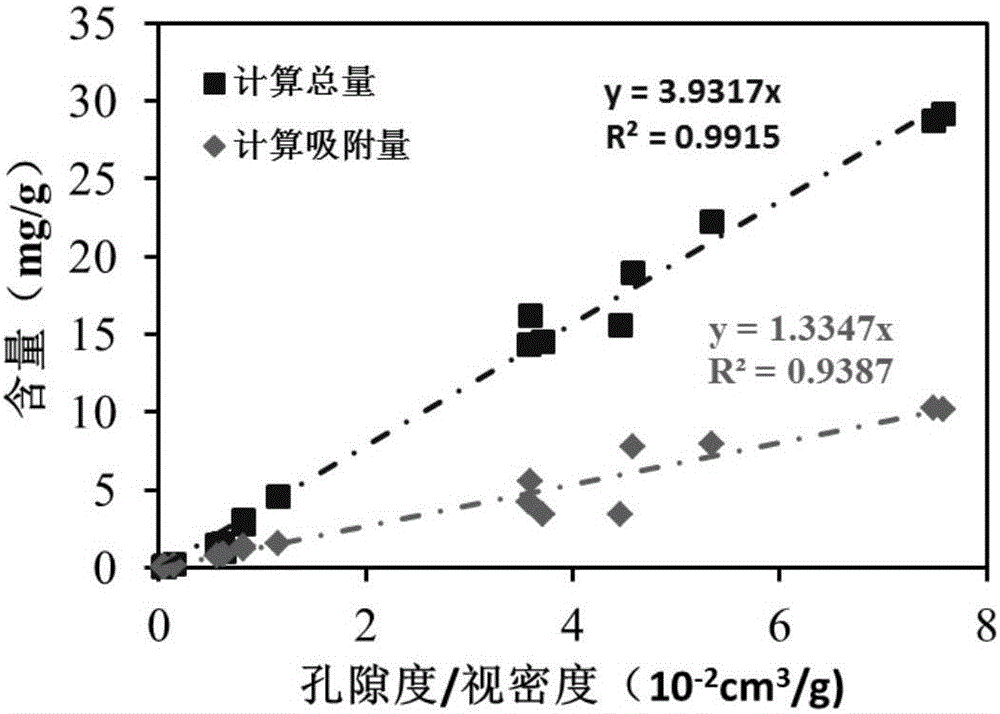

Shale oil adsorption capacity and movable capacity evaluation model as well as establishment and application method thereof

ActiveCN106547966AEasy to operateImprove accuracyEarth material testingDesign optimisation/simulationCapillary condensationApparent density

The invention belongs to the field of shale oil occurrence and shale oil quantitative evaluation, and in particular relates to a shale oil adsorption capacity and movable capacity evaluation model as well as an establishment and application method thereof. Based on a capillary condensation theory, the shale oil adsorption capacity and movable capacity evaluation model is established under laboratory conditions, thus a shale oil adsorption capacity which is as shown in the description, a movable capacity Qc=(betaV2-kdS2hn)p2, a total occurrence amount Qt=Qa+Qc, and the respective percentage of the adsorption capacity and the movable capacity can be quantitatively calculated; the model application method is established under reservoir conditions, a hydrocarbon adsorption capacity and the total occurrence amount are expressed into a function of porosity and apparent density; the hydrocarbon adsorption capacity, the movable capacity and the percentages of the hydrocarbon adsorption capacity and the movable capacity are evaluated according to distribution of the porosity and oil saturation evaluated by well-log data in the longitudinal direction of a shale reservoir; and the method is simple, convenient and easy to operate, high in accuracy, strong in operability and practicability and convenient for geological popularization and application.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method and device for performing simulating profile control to heterogeneous reservoir in laboratory

A method and a device for performing simulating profile control to a heterogeneous reservoir in a laboratory. The invention mainly aims to solve a problem that there is no effective method and device for achieving the simulating profile control to the heterogeneous reservoir in the laboratory in the prior art. The device includes a heterogeneous core model, an injection metering apparatus and an extraction collection apparatus. The heterogeneous core model is composed of an inlet outer-buckle fixer, a core main body holder, and an outlet outer-buckle fixer. The method includes following steps: (1) when relative data is acquired by the device, calculating single-layer practical injection amount V and fluid channeling amount V<ci> at each layer; (2) when the fluid channeling rate at the highest layer reaches a diversion limit in a practical mine field, changing a profile control liquid and injecting the profile control liquid through a pump, and stopping the pump until the accumulated injection amount at a core injection end reaches the injection amount required to be simulated in the practical mine field; (3) changing the profile control liquid into the original injection liquid again, starting the pump for simulating a subsequent displacement process to respectively obtain fluid channeling rate C at each layer, thereby achieving a profile control quantitative effect after injection of the profile control liquid.

Owner:山东宇生文化股份有限公司

River ecological flow process derivation method for fish habitat protection

InactiveCN109615076AUniversalData processing applicationsFuzzy logic based systemsHydrometryExperimental laboratory

The invention discloses a river ecological flow process derivation method for fish habitat protection, and the method specifically comprises the steps: carrying out the investigation of the current situation of fish resources in a research region, and determining a target fish obtained through the ecological flow derivation; the method comprises the following steps: carrying out targeted survey ontarget fishes, carrying out a laboratory stress experiment, screening key water environment factors, and establishing a quantitative response relationship between different life stages of the targetfishes and the key environment factors by utilizing data obtained by the laboratory and field survey; Basic data of hydrology, water quality, topography, meteorology and the like of a research area are collected, a fish habitat model is established by adopting a fuzzy mathematics principle and is coupled with a water environment model, a fish habitat evaluation system is established, and a dynamicresponse relation between the habitat and flow is obtained; and determining a reference system for river ecological flow process calculation, comprehensively considering habitat demands of target fishes at different life stages and seasonal changes of natural runoff, and deducing a complete hydrological annual ecological flow process of the river. Constraint conditions can be provided for reservoir-oriented eco-friendly scheduling, and a practical and reliable basis is provided for drainage basin water resource distribution and management.

Owner:NANJING HYDRAULIC RES INST

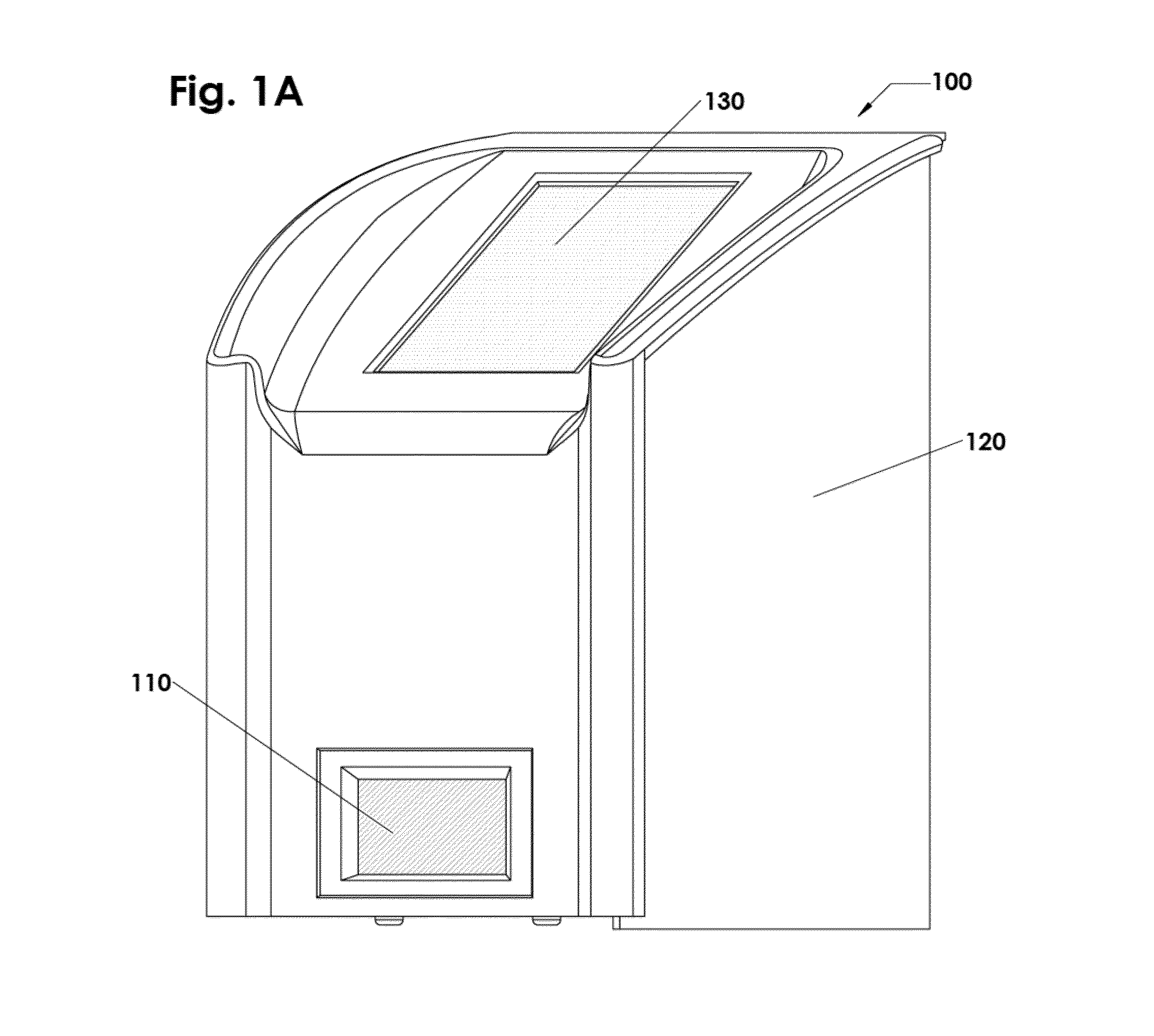

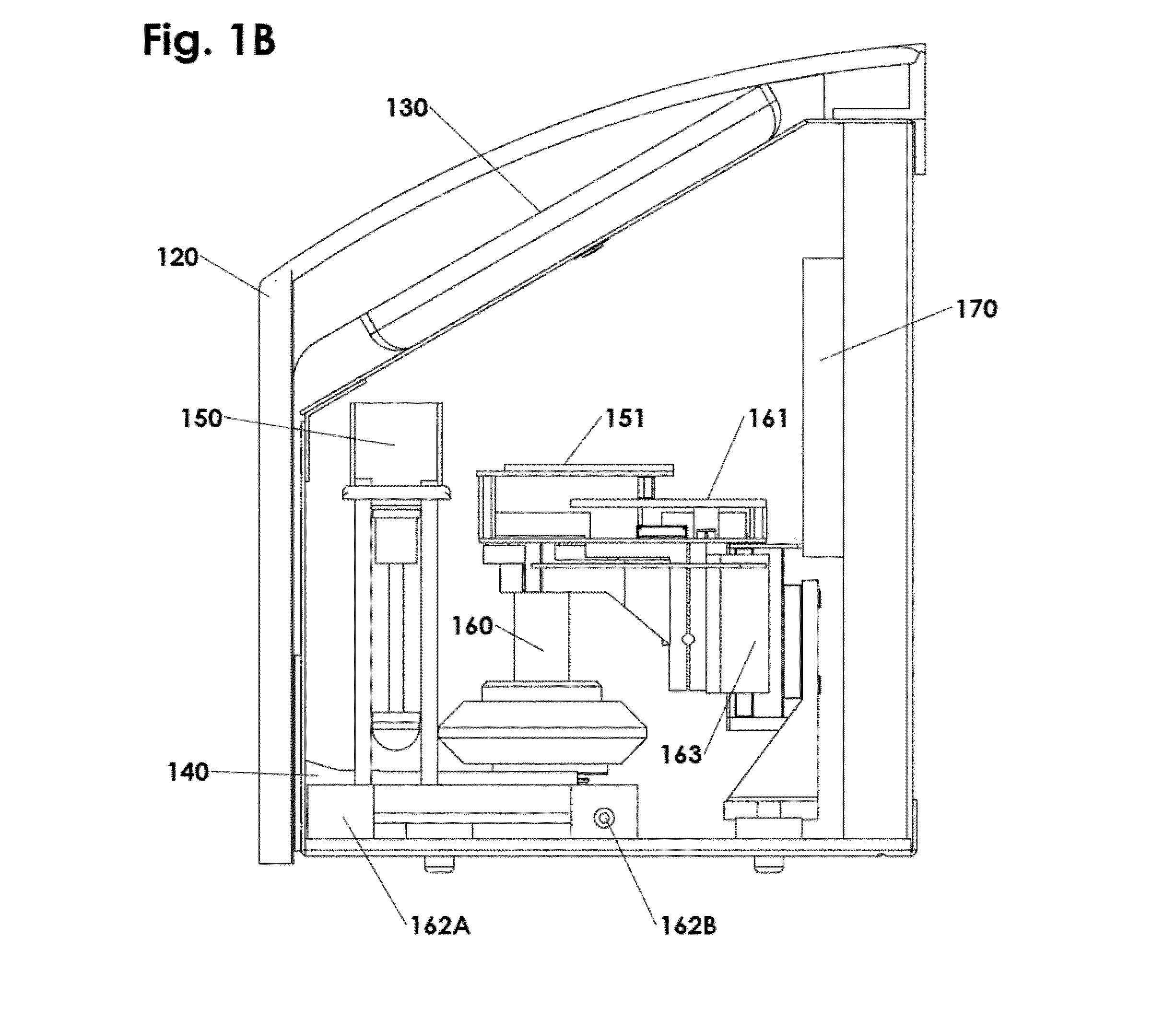

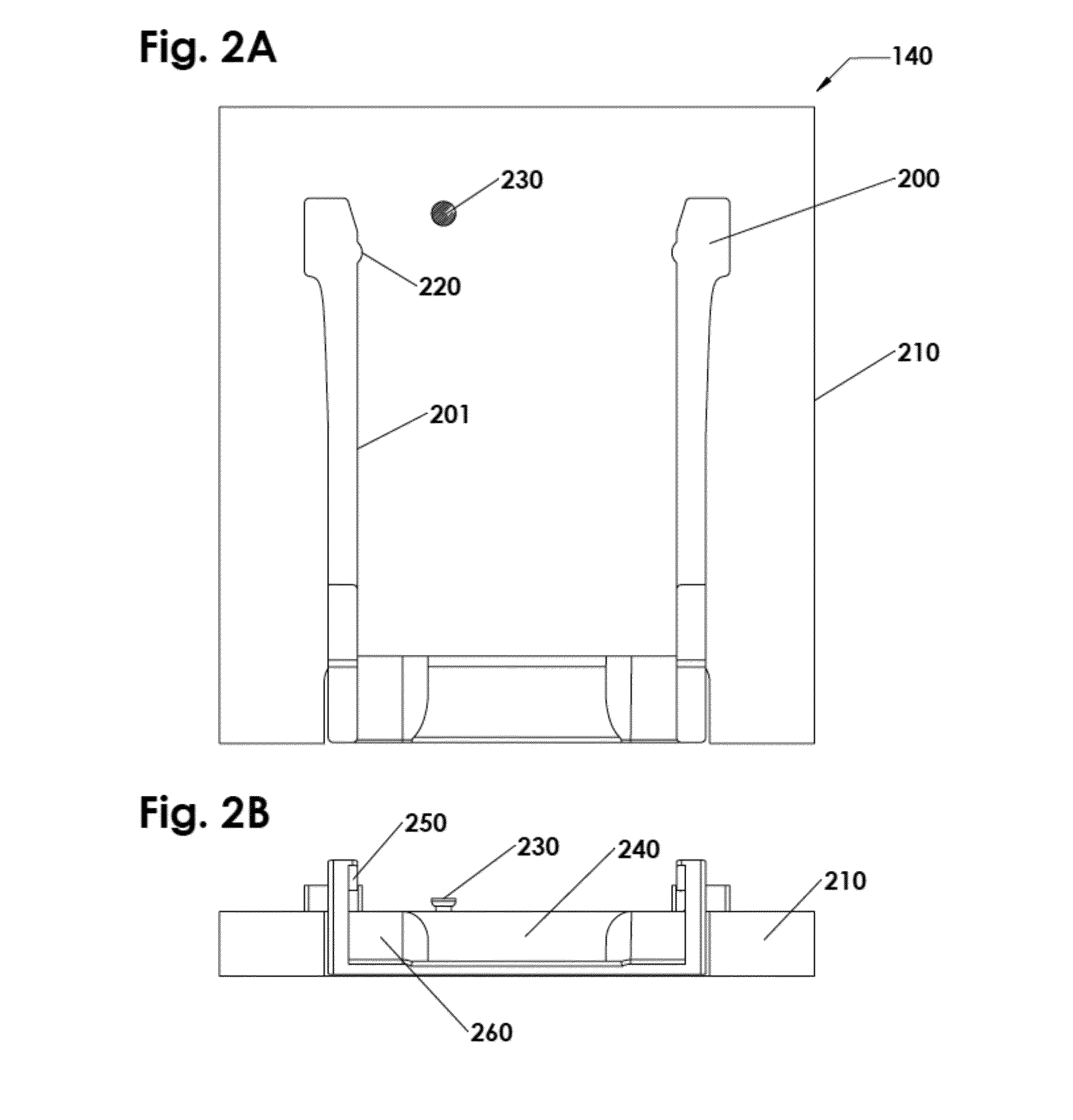

System for selectively proceeding a sample

InactiveUS20130109106A1Stimulates demandSimple stepsHeating or cooling apparatusWithdrawing sample devicesBinding siteManipulator

The invention relates to a method and a system (100) for selectively processing a sample (130) according to one of a plurality of different assays, for example for detecting a certain target component in the sample. The system comprises a plurality of “specific reagent reservoirs” (120) that contain different sets of reagents, wherein each set is required for one of the assays. Moreover, the system (100) comprises a “universal reagent reservoir” in which reagents for several assays are provided, preferably reagents for all assays. The universal reagent reservoir may preferably be a cartridge (110) in which the processing of a sample (130) can take place and which comprises a plurality of binding sites that are selective for different target components. Depending on the assay to be performed with a sample (130) at hand, the appropriate specific reagent reservoir (121b) is chosen and processed in the universal cartridge (110). This can particularly be done by a manipulator (140) in a high-throughput automated laboratory system.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

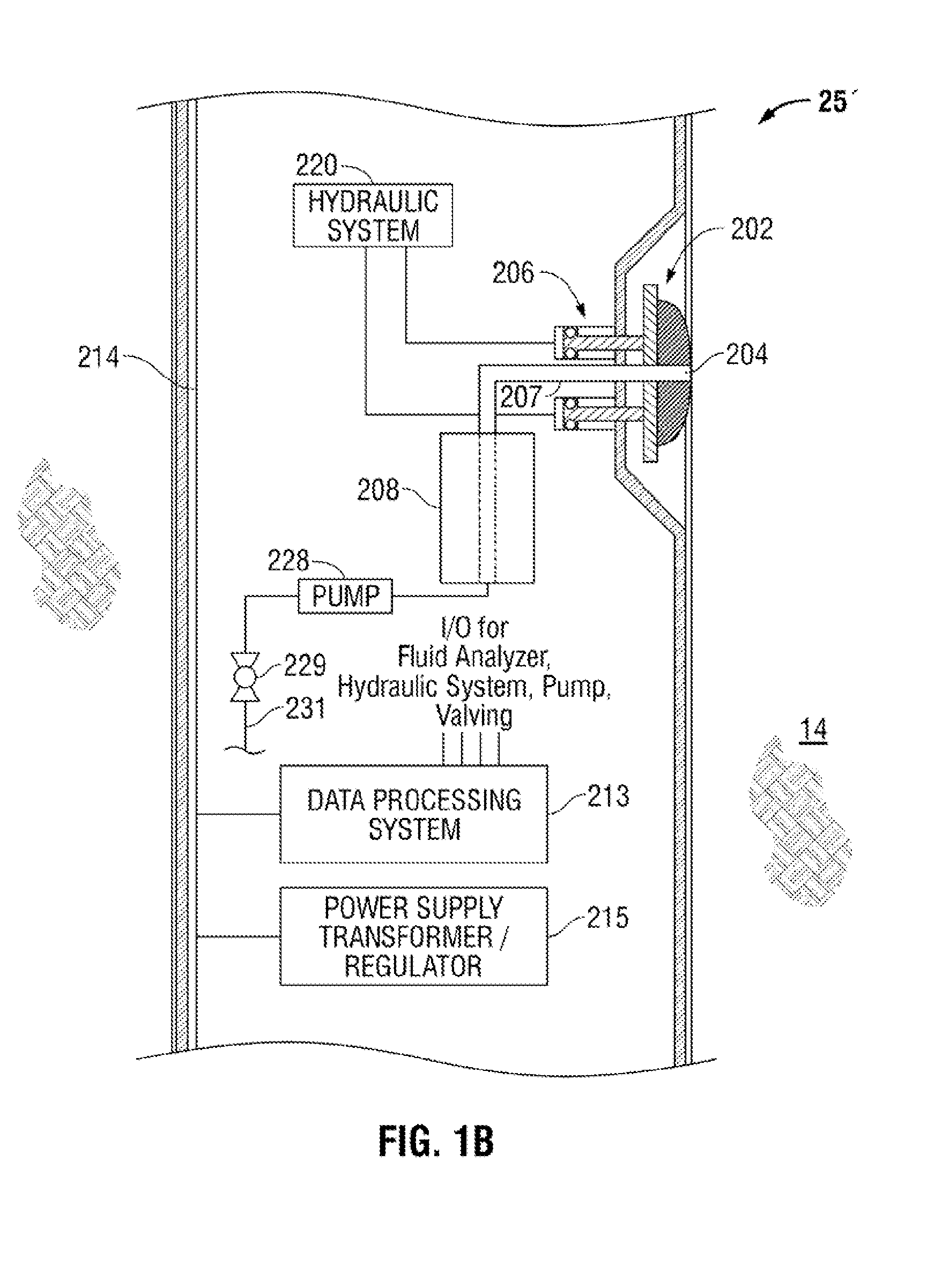

Methods For Reservoir Evaluation Employing Non-Equilibrium Compositional Gradients

ActiveUS20140200810A1Efficiently understoodElectric/magnetic detection for well-loggingConstructionsCarbon dioxideEngineering

A method for determining reservoir architecture using modeling of a non-equilibrium distribution of at least one analyte in reservoir fluids. The analyte(s) of the analysis preferably has (have) significant compositional variation in the reservoir. For example, the analyte can be a later charging single gas component (such as methane, carbon dioxide, or hydrogen sulfide) in a multi-component fluid system. In this case, the model can assume that the components of the early charge are in a stationary state or in equilibrium, whereas the later charge is in a state of non-equilibrium. The non-equilibrium distribution of the analyte(s) derived from the model is compared to the distribution of the analyte(s) derived from downhole or laboratory fluid analysis of reservoir fluid, and the architecture of the reservoir is determined based upon such comparison.

Owner:SCHLUMBERGER TECH CORP

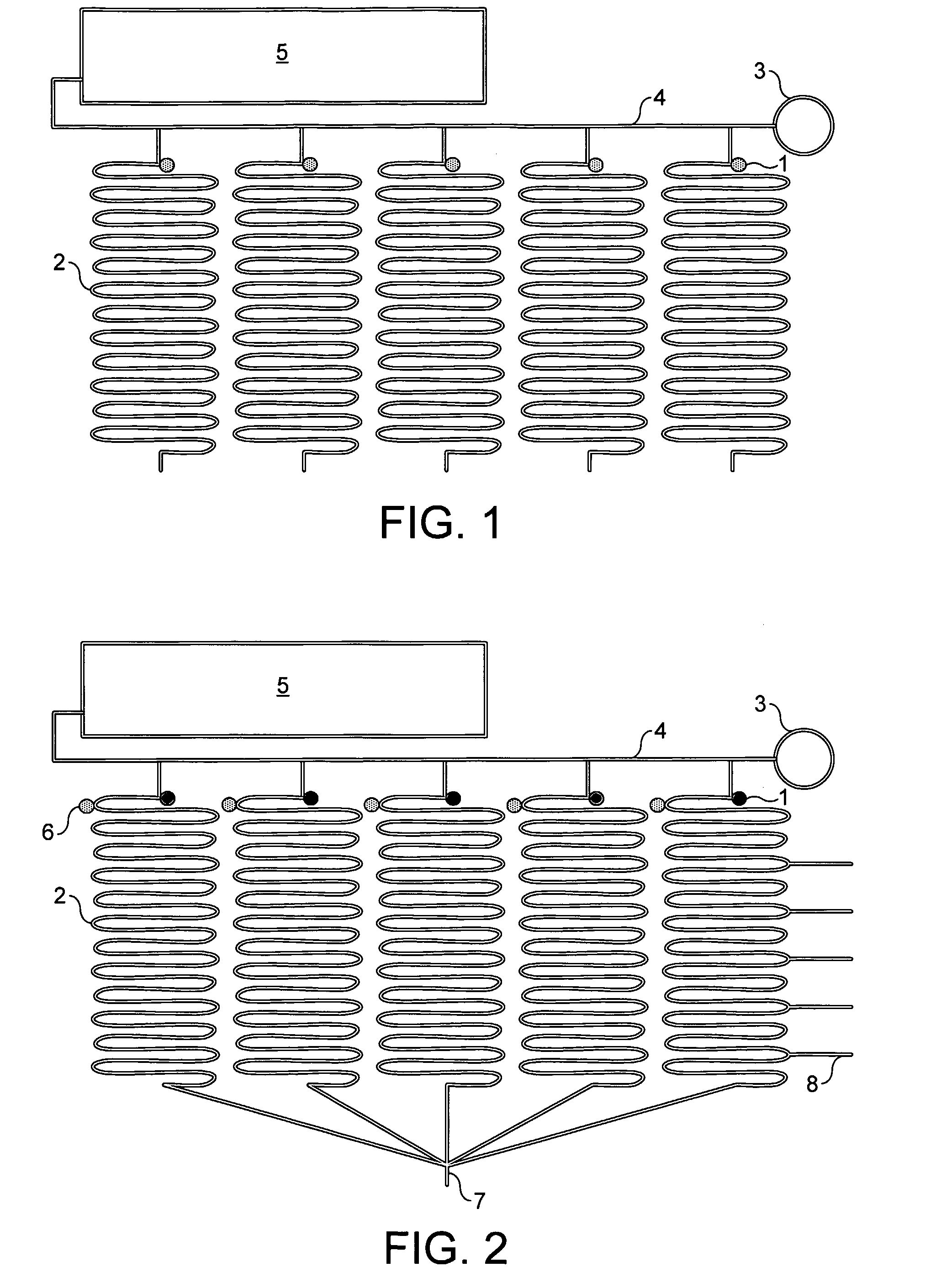

Laboratory product transport element and path arrangement

The invention concerns a laboratory product transport element for a laboratory transport system with an energy receiver and / or energy accumulator to provide drive power, at least one signal receiver to receive control signals, a control unit to generate drive signals as a function of at least one control signal obtained from the at least one signal receiver, movement devices for independent movement of the laboratory product transport element on a transfer path as a function of the drive signals of the control unit, in which the drive devices are driven by the drive power and at least one holder to hold a laboratory product being transported. The invention also concerns a laboratory transport system with at least one laboratory product transport element according to an embodiment of the invention and a transfer path arrangement. The invention also concerns methods for operation of laboratory transport systems according to an embodiment of the invention.

Owner:BECKMAN COULTER INC

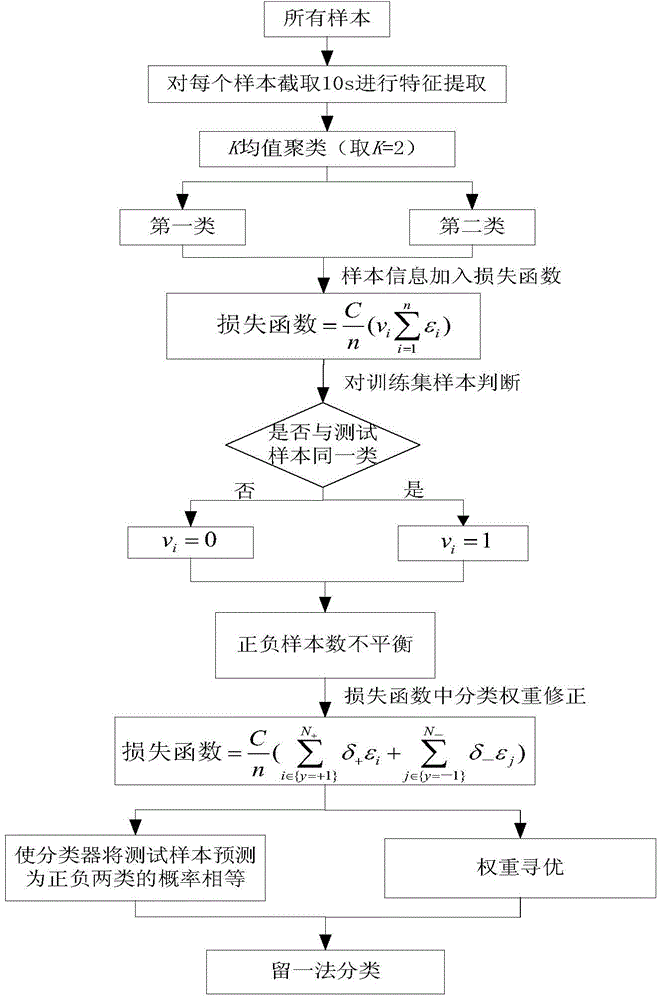

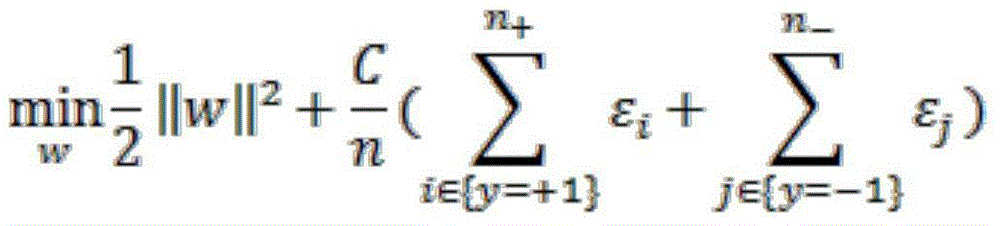

Method for classifying individual differences in psychological stress assessment

InactiveCN103605721AReduce acute stress responseUnderstanding emotional behaviorCharacter and pattern recognitionSpecial data processing applicationsSelf evaluationClassification methods

The invention discloses a method for classifying individual differences in psychological stress assessment. The method includes steps of 1, designing an effective experimental scheme for inducing psychological stress in laboratories and creating a stimulation material library for psychological stress materials; 2, acquiring psychological stress data of sEMGs (surface electromyographic signals); 3, preprocessing the raw data; 4, extracting and processing psychological stress characteristics of the sEMGs; 5, classifying psychological stress assessment by the aid of a classifier of an improved support vector machine. The method has the advantages that the psychological stress data are acquired via the simple and feasible experimental scheme, so that researchers can deeply understand psychological stress on the basis of careful analysis on mass data, and the method is beneficial to understanding emotional behavior of human; psychological stress assessment and research implemented by the method on the basis of the psychological signals have objective characteristics as compared with a self-assessment mode implemented by the aid of questionnaires and the like, accordingly, the method is wide in application range and favorable for psychological stress and health research.

Owner:YANSHAN UNIV

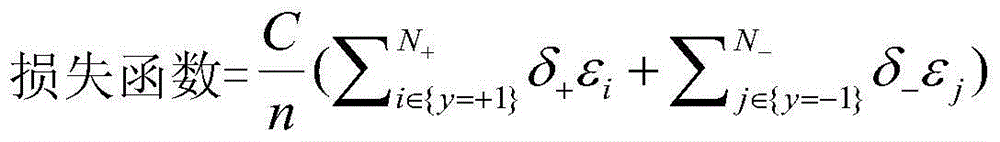

Digitization experimental laboratory system and data control method thereof

The invention relates to an experiment device system, in particular to a digital laboratory system and the data control method thereof. The digital laboratory system provided by the invention comprises sensors (10) which are mutually connected, a student terminal (20) and a teacher control platform (30), wherein, the experiment data is transmitted to the student terminal (20) via the sensors (10), the student terminal (20) displays, temporarily stores, sends and simply analyzes the data, if storage and further analysis are needed, the data can be transmitted to the teacher control platform (30) via the wireless network, a management analysis software of the teacher control platform (30) carries on storage and further data processing, analysis and generates the final experiment results. In addition, the invention provides a data control method of the digital laboratory system.

Owner:宁波奇科威数字信息技术有限公司

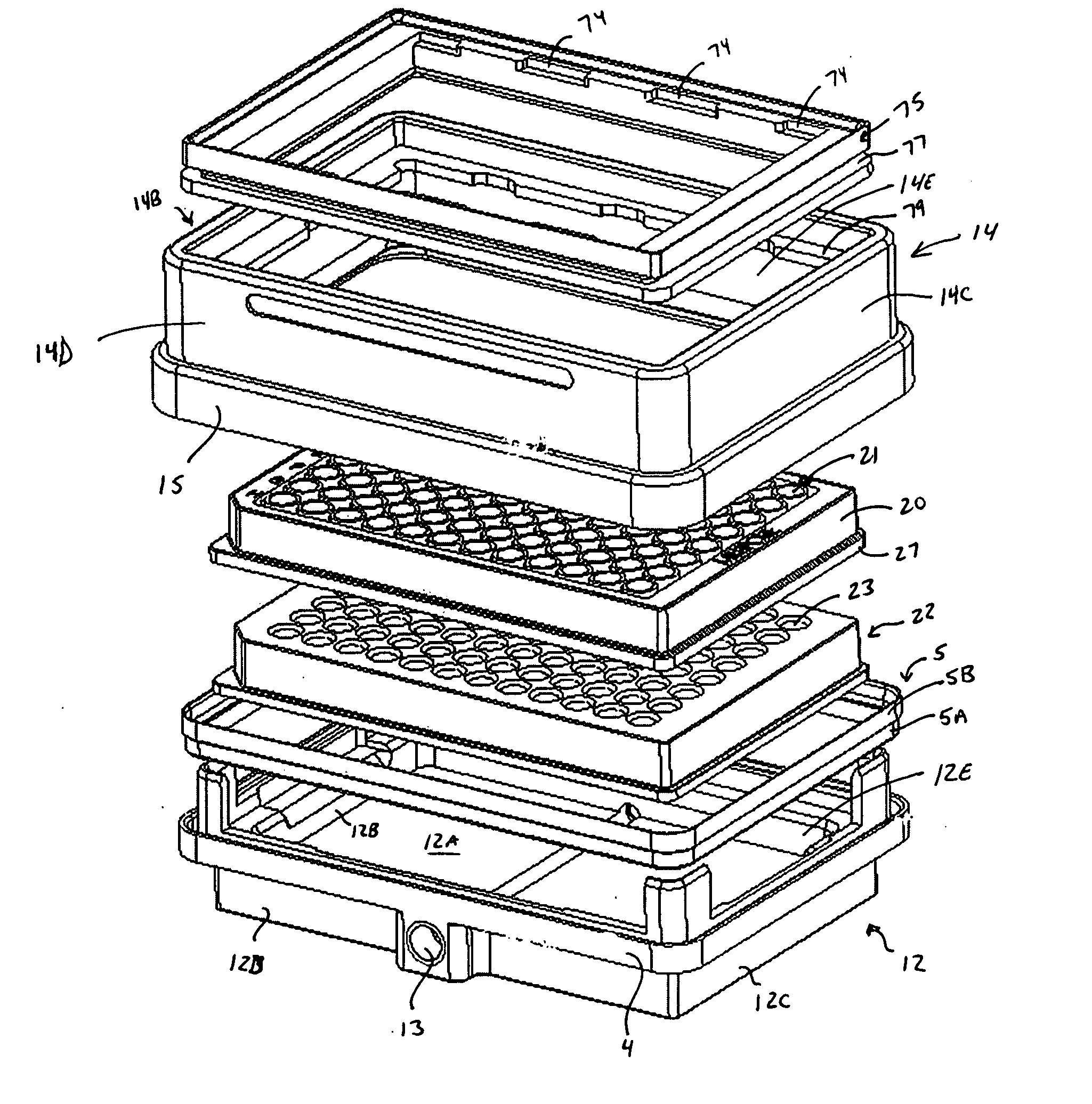

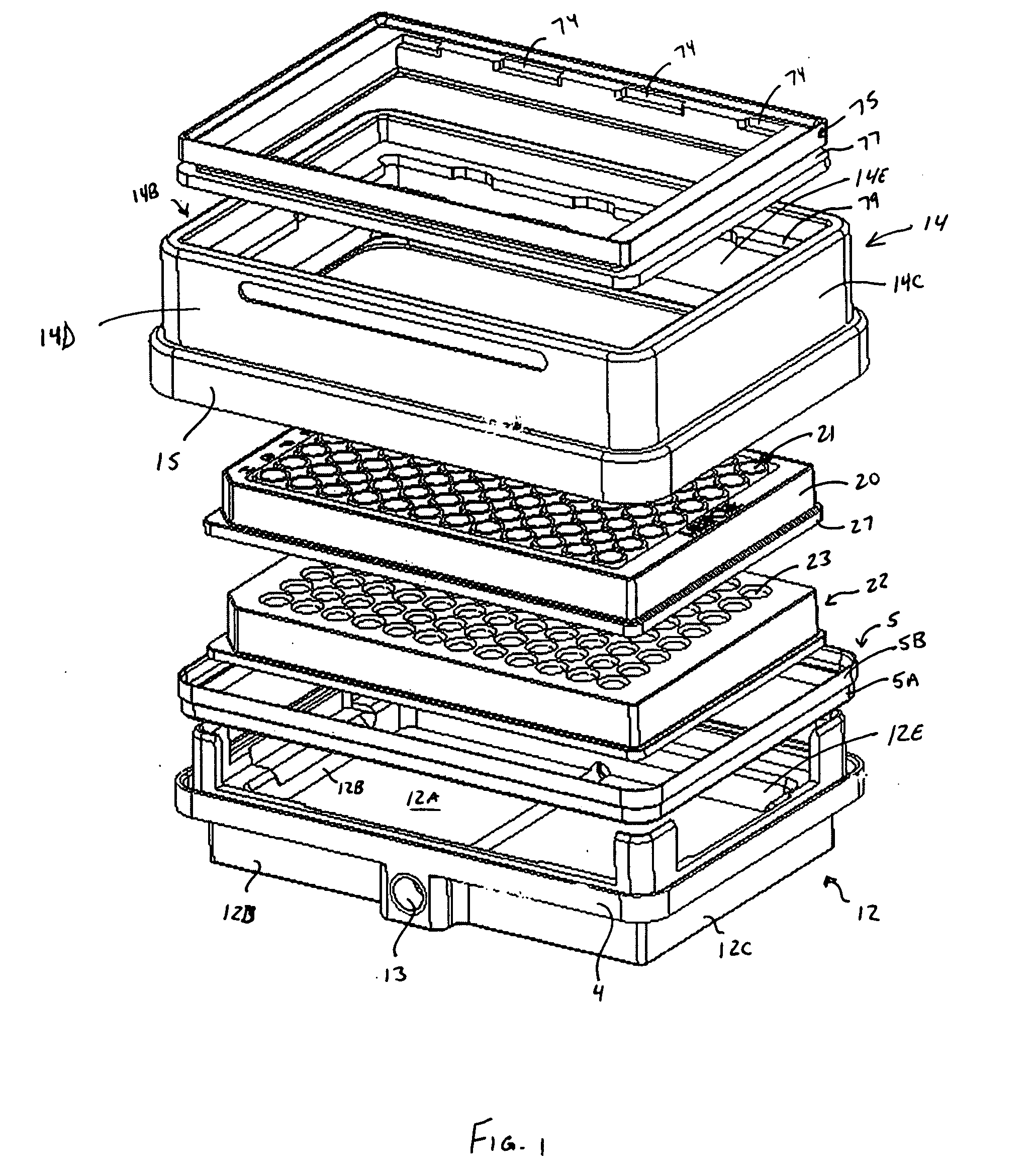

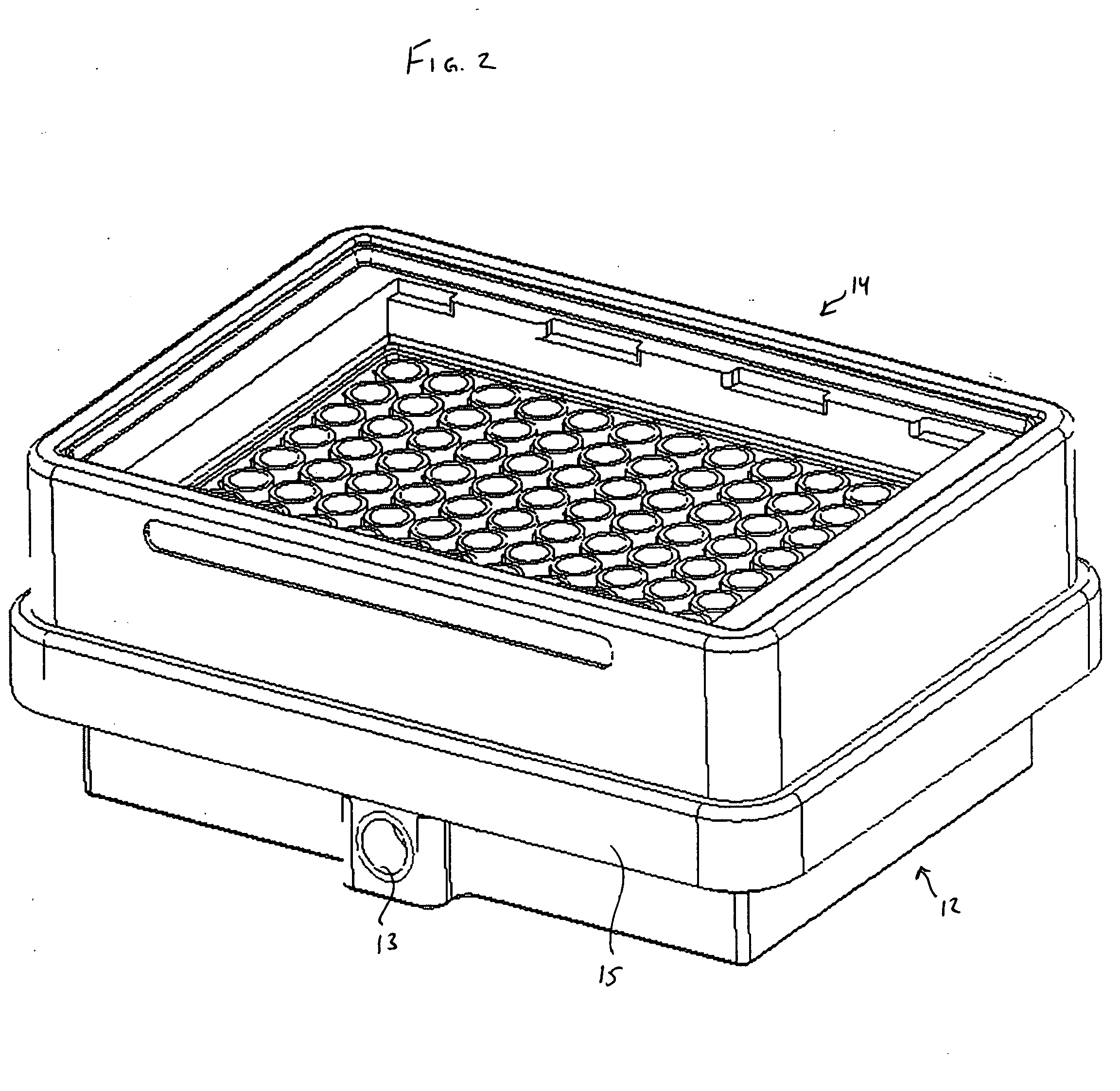

Multifunctional vacuum manifold

ActiveUS20040265186A1Analysis using chemical indicatorsChemical analysis using titrationModularityModular design

A laboratory device design particularly for a multiplate format that includes a manifold wherein the position of the plate is not a function of gasket compression or vacuum rate applied. In one embodiment, the device has a modular design, wherein removable inserts with different functionalities can be positioned between a base component and a collar component. The particular inserts chosen depend on the desired sample preparation or assay to be carried out. The inserts are stacked and are positioned between the base and collar as a unit, so that the stack within the manifold does not move during evacuation of the vacuum chamber. The consistent position of the multiplate facilitates using vacuum sample processing with automated liquid handlers.

Owner:MILLIPORE CORP

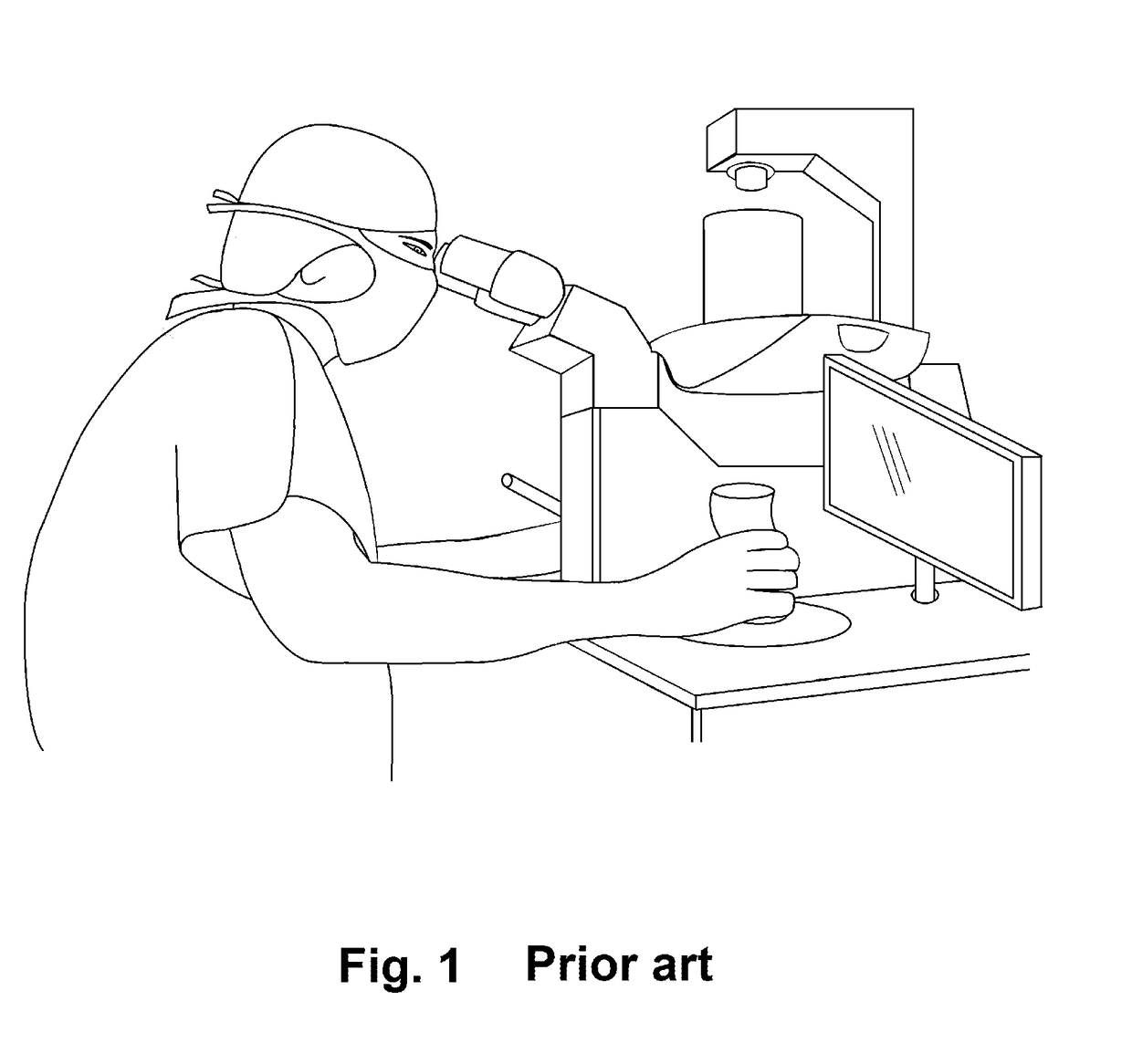

System and method for following and conducting laboratory procedures

ActiveUS20180256304A1Relieve stressAvoid mistakesAnimal reproductionStatic indicating devicesEyewearVisual perception

There is provided a system and method for following and conducting laboratory procedures for preventing errors and fatigue of the user. The system involves input means, such as a microscope, and a camera connected to the input means, while the camera creates images of the input means. A computer is connected to the camera, and it processes the images so that augmented reality glasses which are also connected to the computer, are capable of having those images projected thereon. The computer also has laboratory protocol files installed thereon, and it projects images of the protocols onto the glasses. The projected images do not interfere with a user's natural vision.

Owner:SHEENA HAIM

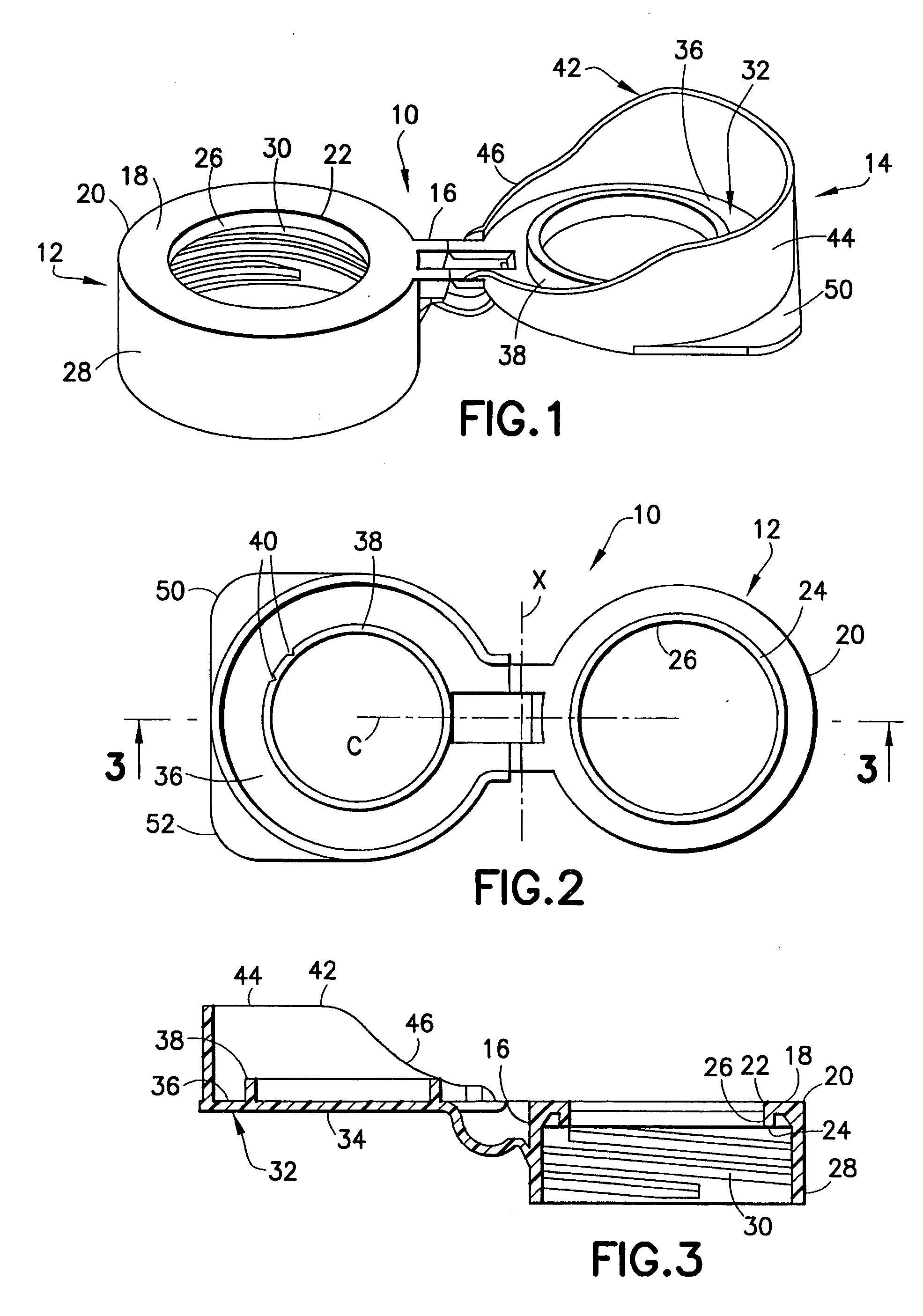

Flip top cap

A cap is provided for a laboratory vessel. The cap includes a lid that can be rotated relative to the laboratory vessel from a closed position to an open position. The lid includes at least one tab dimensioned and disposed for receiving manual digital pressure for opening and / or closing the lid. The tab is in an offset position to prevent a thumb or forefinger from passing over and in contact with the opening to the vessel. Additionally, the lid includes a shield inwardly from the tab for further preventing contact between a finger and the open top of the vessel.

Owner:CORNING INC

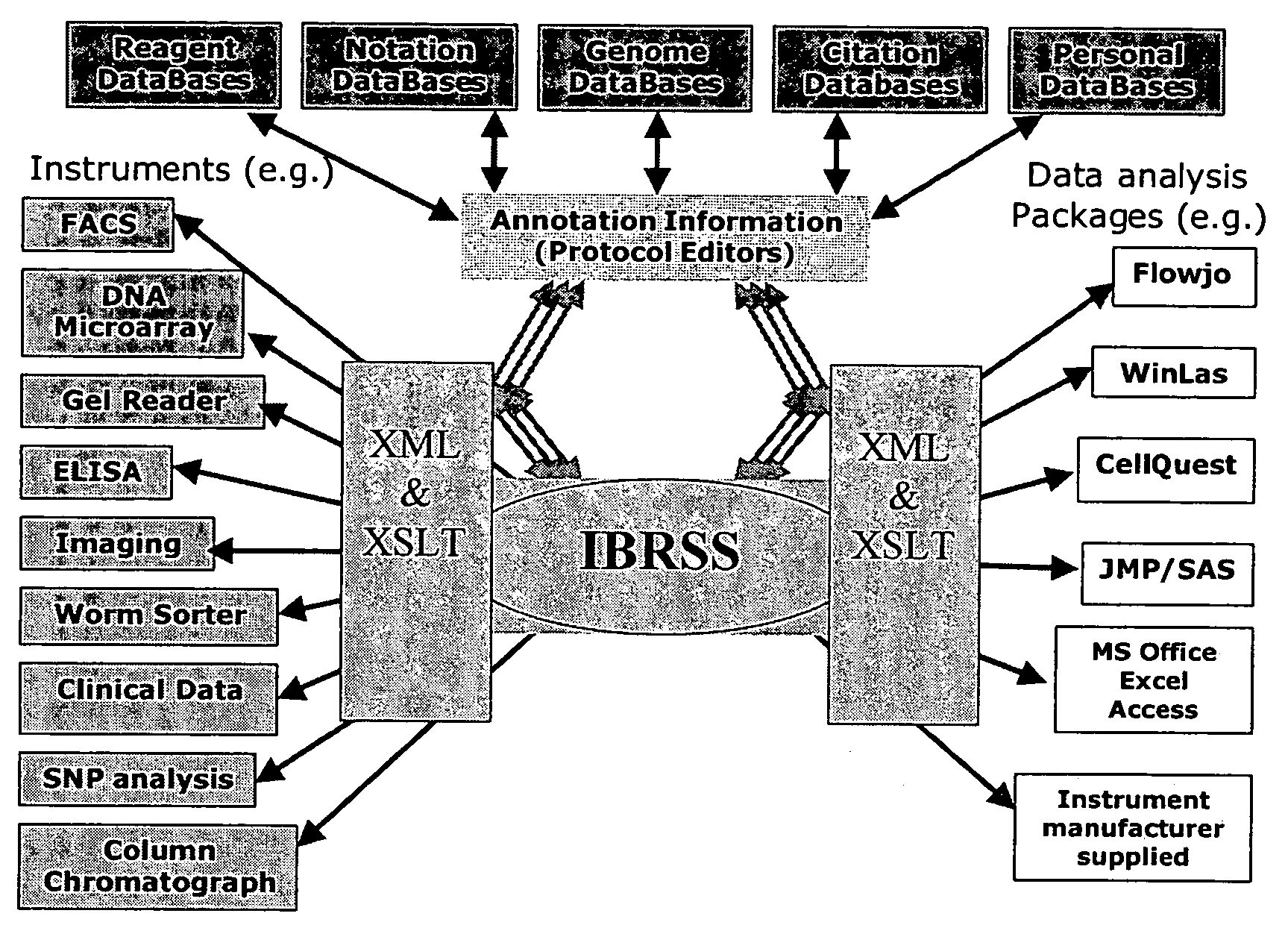

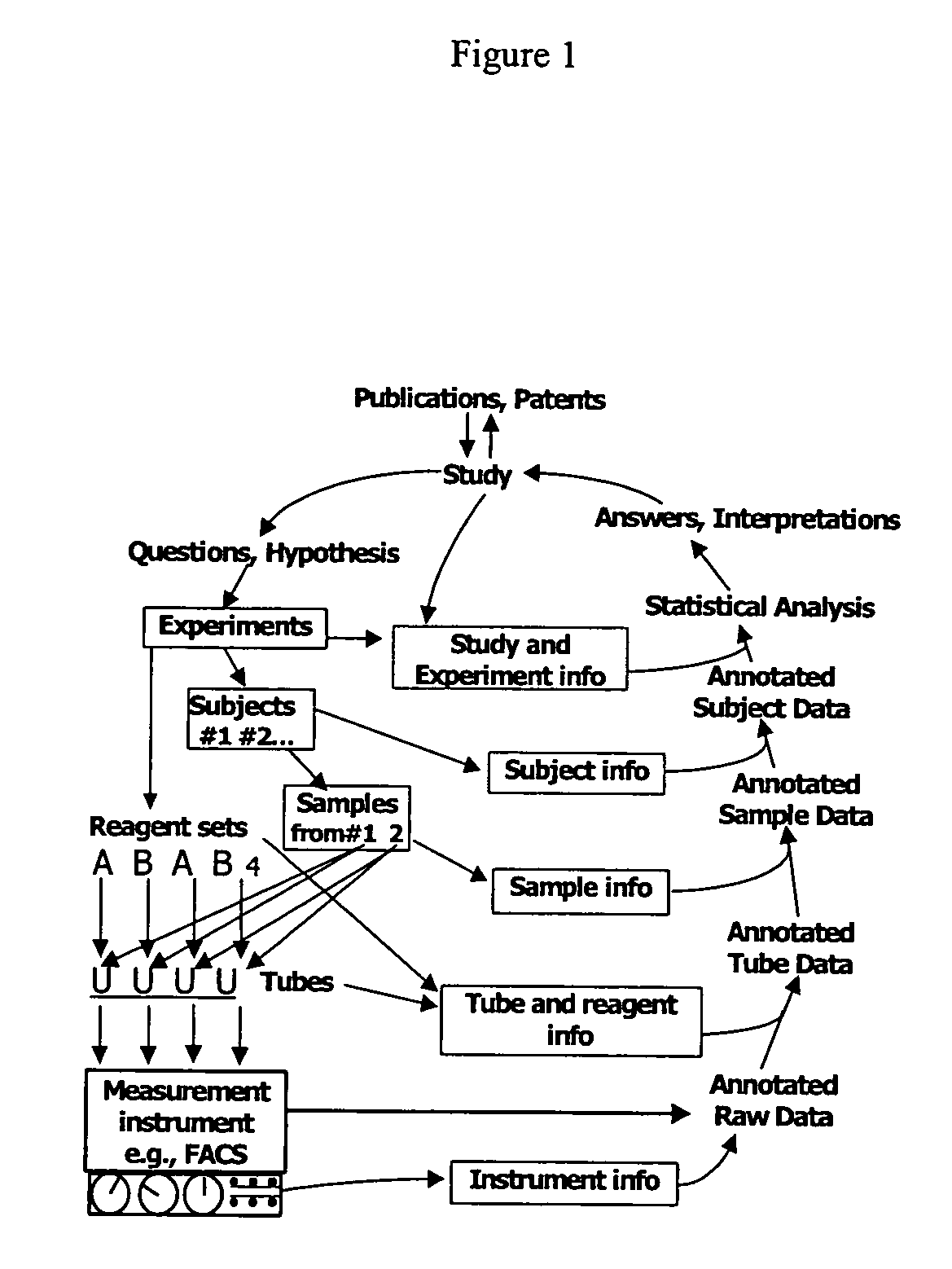

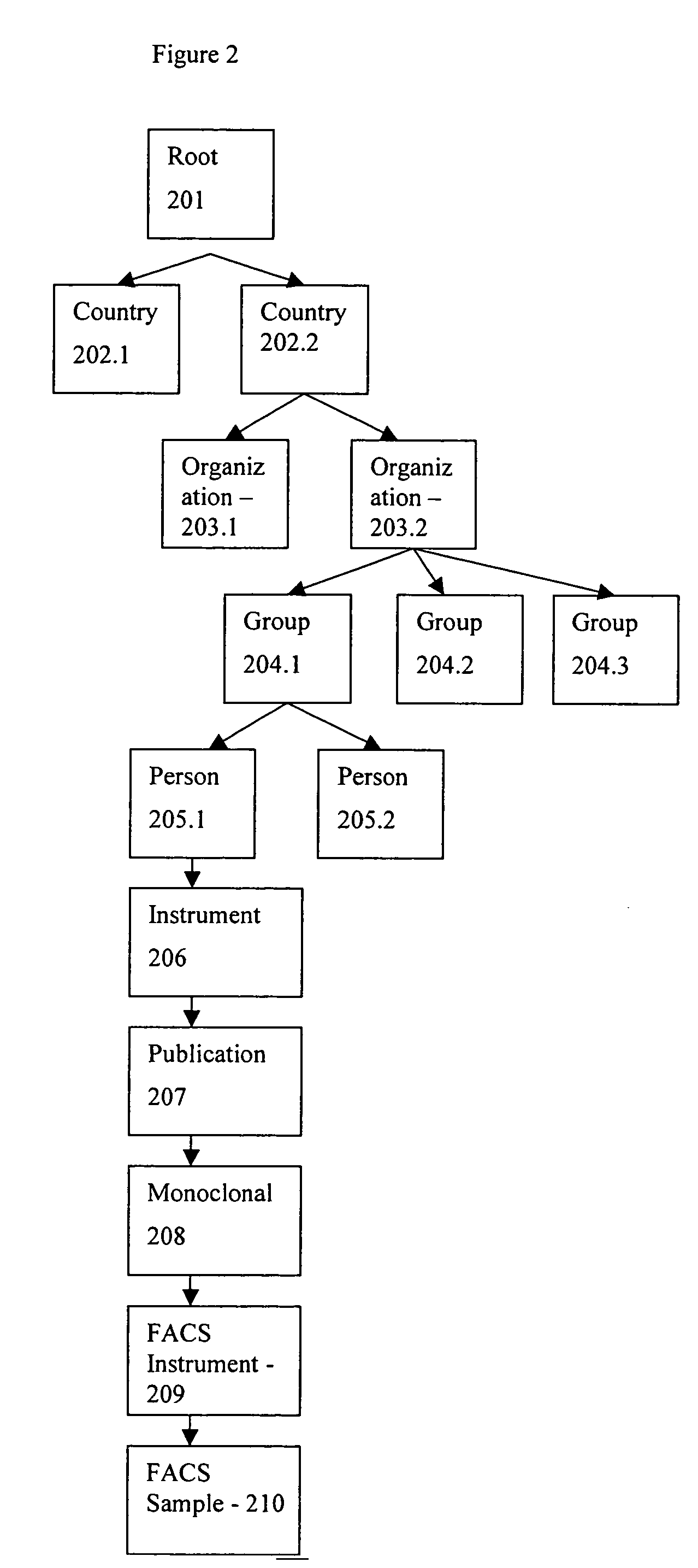

System and method for internet-accessible tools and knowledge base for protocol design, metadata capture and laboratory experiment management

InactiveUS7555492B2Easily share their dataEasy to share dataData processing applicationsDigital data processing detailsExperimental laboratoryProtocol design

The present invention is related to databases and the exchange of scientific information. Specifically the invention discloses a laboratory data management system including a knowledge base that stores characteristics of laboratory reagents, experiment subjects, tissues and cells. The invention also includes an experiment input module that accepts input of parameters of an experiment and data from a knowledge base module. Further, the invention includes a protocol creator connected to the knowledge base module and the experiment input module that creates a laboratory protocol for an experiment based on data supplied from the knowledge base module and the experiment input module. The invention also includes methods to use the described system.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Systems and methods for ordering laboratory tests and providing results thereof

InactiveUS20160292393A1Computer-assisted medical data acquisitionPatient personal data managementExperimental laboratorySoftware engineering

Systems and methods for ordering laboratory tests, performing laboratory tests, and providing results thereof are provided. Laboratory tests may be ordered, performed, and the results of the tests provided to a subject without a subject being required to provide information relating to his or her identity.

Owner:LABRADOR DIAGNOSTICS LLC

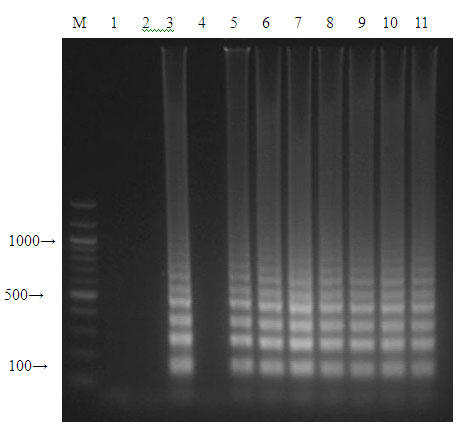

Method for quickly detecting transgenic corn by using LAMP method

InactiveCN101985661AEasy to identifyStrong specificityMicrobiological testing/measurementBiotechnologyExperimental laboratory

The invention relates to the field of transgenic plant detection, in particular to a method for quickly detecting transgenic corn. The method detects glufosinate-resistant Bar genes in the transgenic corn by using loop-mediated isothermal amplification (LAMP). The method does not need special instruments (such as PCR instrument), and is quicker and more economic compared with a conventional laboratory method. The method is simple and convenient in identification, has extremely high specificity, and can judge whether a destination fragment is amplified only by observing with naked eyes or detecting the precipitation turbidity with an ultraviolet imaging system of a turbidity meter so as to judge whether a genome of a core plant sample for detecting contains the glufosinate-resistant Bar genes, and a gel electrophoresis method for observation is not needed.

Owner:BEIJING AGRO BIOTECH RES CENT

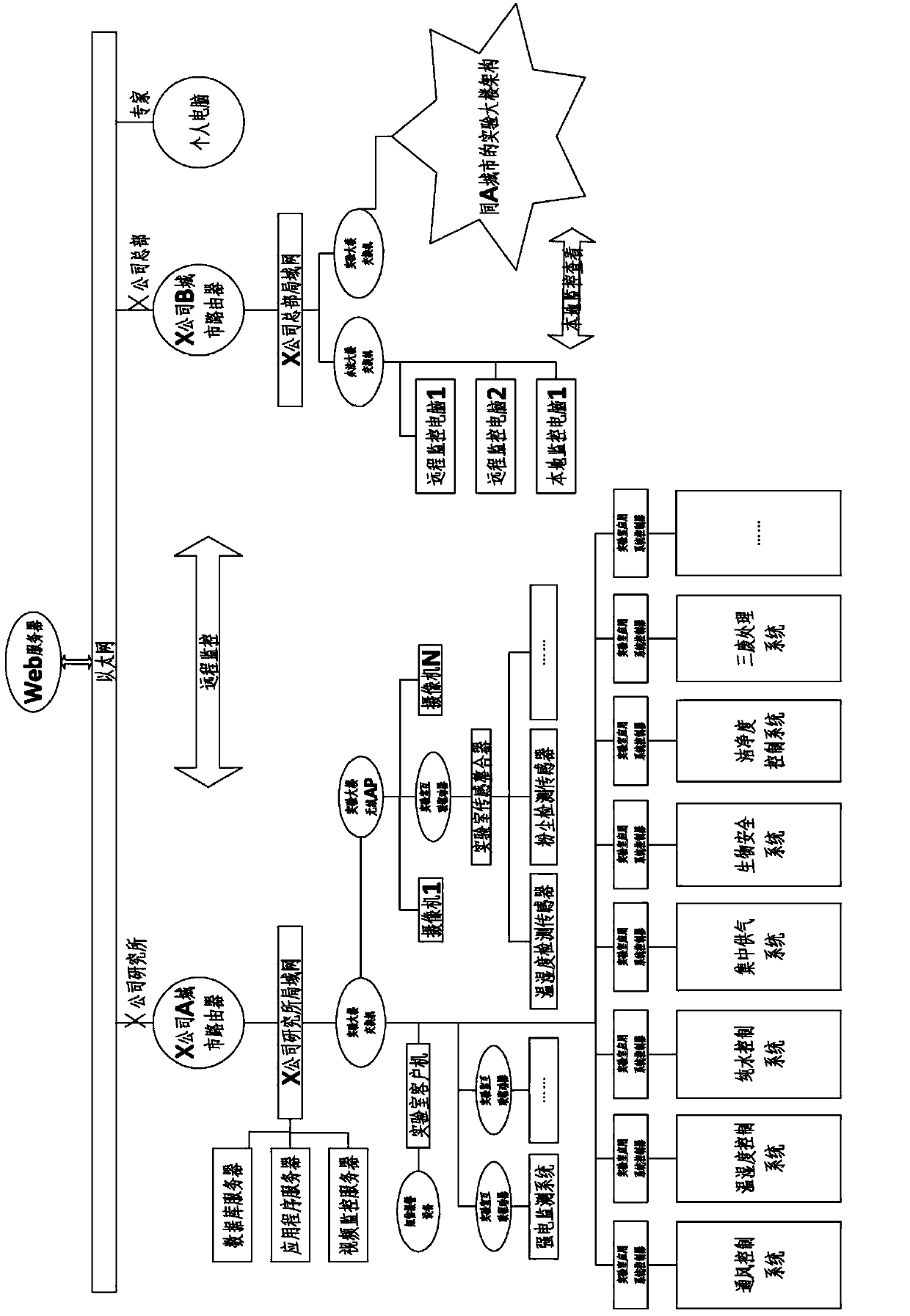

Intelligent type science laboratory integrated platform

ActiveCN103745633AEnsure controllabilityEnsure consistencyEducational modelsNetworks interconnectionVideo serverApplication server

Provided is an intelligent type science laboratory integrated platform. Laboratories of an X company in cities A and B are accessed via an Ethernet, and a Web server of the company is also accessed via the Ethernet. A personal computer of an expert is accessed to the Ethernet via a wireless network card. In the city A, the Ethernet network is accessed via a router. A company local area network below the router is accessed to the router, and a database server, an application program server, a video server and an experiment building switch are accessed to the company local area network. The experiment building switch is accessed to laboratory client computers of each laboratory, multiple laboratory interconnection drivers, wireless APs and multiple laboratory application system controllers. In the city B, the Ethernet is accessed via the router, and the lower of the router is accessed to the company local area network, and an office building switch and an experiment building switch are accessed to the local area network. The accessing mode and relation below the experiment building switch are identical to the framework of the experiment building of the city A. Monitoring computers below the office building switch are connected with the office building switch.

Owner:WUHAN KEBEI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com