Preparation method and application of electrostatic spinning modified membrane adsorption material

A technology of electrospinning and membrane adsorption, applied in chemical instruments and methods, adsorption water/sewage treatment, filament/thread forming, etc., can solve the problems of poor hydrophilicity of membrane materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

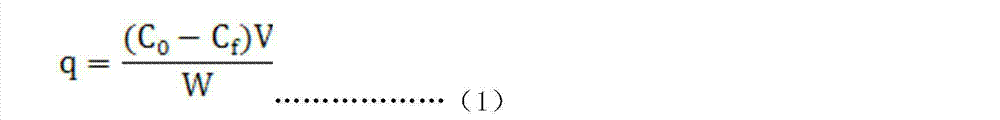

Method used

Image

Examples

Embodiment 1

[0024] 1. Configuration of spinning solution

[0025] Weigh 5.1g of PET solid particles and dissolve in 30ml of trifluoroacetic acid / dichloromethane mixed solution, wherein the volume ratio of trifluoroacetic acid to dichloromethane is 9:1, the mass of PET and the volume ratio of mixed solvent is 17%, stir for 24h until completely dissolved.

[0026] 2. Preparation of PET nanofiber membrane by electrospinning

[0027] Take the PET solution prepared above and put it into the injection device of the electrospinning device to prepare PET nanofiber film. The spinning solution propulsion speed is 0.002mm / s, the spinning voltage is 25Kv, and the receiving distance is 15cm.

[0028] 3. N 2 Plasma treatment of PET film

[0029] Place the PET nanofiber membrane in the reaction chamber of the low-temperature plasma treatment instrument, and use N 2 Low temperature plasma treatment, set discharge time 60s, discharge power 150W, N 2 The air intake is 100sccm.

[0030] 4. Acrylic aci...

Embodiment 2

[0037] 1. Configuration of spinning solution

[0038] Weigh 5.1g of PET solid particles and dissolve in 30ml of trifluoroacetic acid / dichloromethane mixed solution, wherein the volume ratio of trifluoroacetic acid to dichloromethane is 9:1, the mass of PET and the volume ratio of mixed solvent is 17%, stir for 24h until completely dissolved.

[0039] 2. Preparation of PET nanofiber membrane by electrospinning

[0040] Take the PET solution prepared above and put it into the injection device of the electrospinning device to prepare PET nanofiber film. The spinning solution propulsion speed is 0.002mm / s, the spinning voltage is 25Kv, and the receiving distance is 15cm.

[0041] 3. N 2 Plasma treatment of PET film

[0042] Place the PET nanofiber membrane in the reaction chamber of the low-temperature plasma treatment instrument, and use N 2 Low temperature plasma treatment, set discharge time 60s, discharge power 150W, N 2 The air intake is 100sccm.

[0043] 4. Acrylic aci...

Embodiment 3

[0052] 1. Configuration of spinning solution

[0053] Weigh 5.1g of PET solid particles and dissolve in 30ml of trifluoroacetic acid / dichloromethane mixed solution, wherein the volume ratio of trifluoroacetic acid to dichloromethane is 9:1, the mass of PET and the volume ratio of mixed solvent is 17%, stir for 24h until completely dissolved.

[0054] 2. Preparation of PET nanofiber membrane by electrospinning

[0055] Take the PET solution prepared above and put it into the injection device of the electrospinning device to prepare PET nanofiber film. The spinning solution propulsion speed is 0.002mm / s, the spinning voltage is 25Kv, and the receiving distance is 15cm.

[0056] 3. N 2 Plasma treatment of PET film

[0057] Place the PET nanofiber membrane in the reaction chamber of the low-temperature plasma treatment instrument, and use N 2 Low temperature plasma treatment, set discharge time 180s, discharge power 150W, N 2 The air intake is 100sccm.

[0058] 4. Acrylic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com