Preparation method and application of bionic multi-component fiber

A multi-component fiber and bionic technology is applied in the field of preparation of bionic multi-component fibers to achieve the effects of convenient assembly and manipulation, good mechanical and electrical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

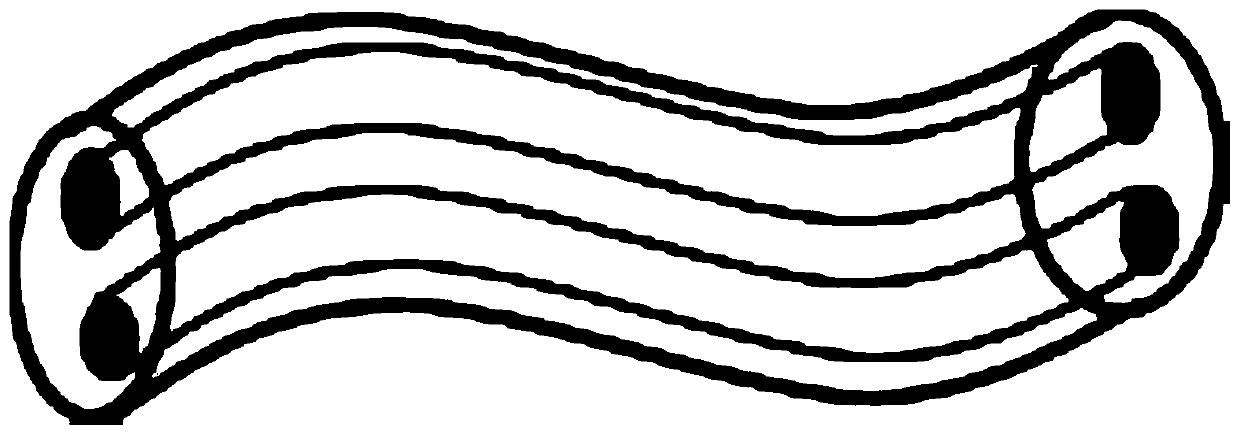

[0030] The preparation method of the described bionic multi-component fiber, its preparation comprises the following steps:

[0031] (1) Preparation of a multi-component microfluidic device: by coaxially assembling several tapered capillaries into the mesophase capillary as the shell precursor solution channel as the core fluid channel, and then all the capillaries are axially inserted into the outer phase collection capillary of the fluid channel for the solidified shell precursor solution;

[0032] (2) Prepare a core solution with good electrical properties for preparing the inner core layer, a shell precursor solution with good mechanical properties for preparing the shell layer, and a curing solution for curing the shell precursor solution; pass into step (1) respectively In several capillary inner core fluid channels, interphase capillary fluid channels and outer phase collection capillary fluid channels, and make all the fluids flow in the same direction;

[0033] (3) A...

Embodiment 1

[0043] The preparation of embodiment 1 biomimetic multi-component fiber

[0044] (1) Preparation of multi-component microfluidic spinning device:

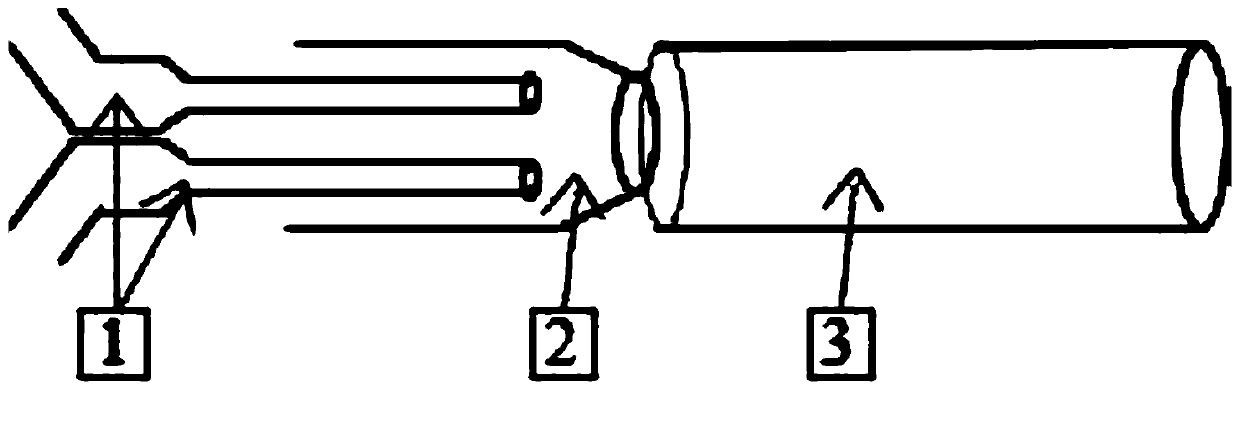

[0045]according to figure 2 The schematic diagram of the structure of the microfluidic device is given. A plurality of internal phase capillary channels, intermediate phase capillary channels and external phase collection tube channels are coaxially assembled and connected to the liquid inlet devices of each phase.

[0046] (2) Configure related solutions

[0047] Choose the internal phase solution to be 1:1 mixed with 0.15wt% single-walled carbon nanotube aqueous dispersion liquid of 10% polyvinyl alcohol (PVA), the middle phase is the polyurethane / dimethylformamide of mass volume ratio 1:5 ( PU / DMF) solution, the outer phase collection liquid is alcohol solution.

[0048] (3) Connect the internal phase, intermediate phase, and external phase solutions obtained by the configuration to the syringes of each phase and the syringe...

Embodiment 2

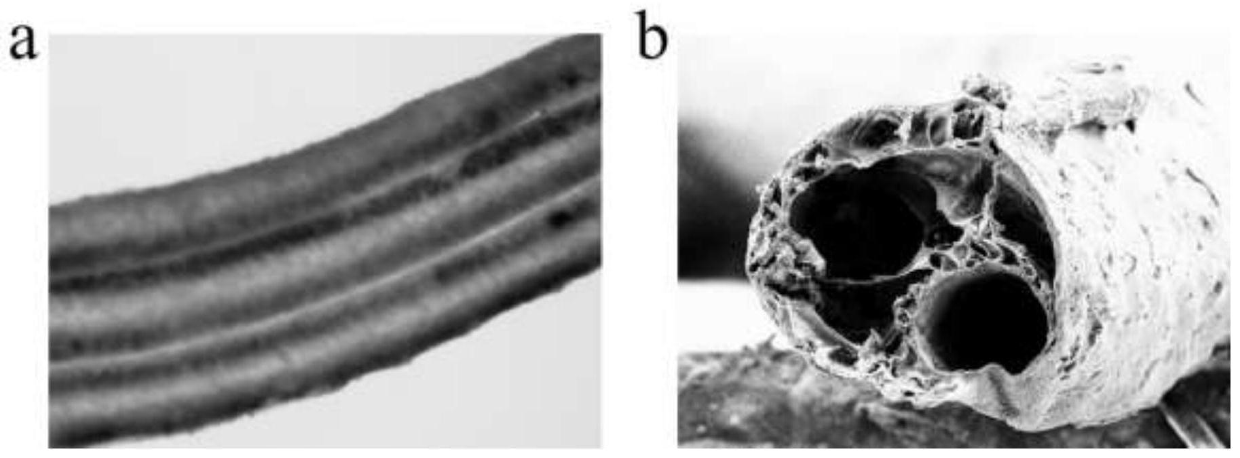

[0049] Example 2 Morphological control of bionic multi-component fibers

[0050] A microfluidic device with dual internal capillaries was selected, and the inner diameters of the internal capillaries were determined to be 100 μm and 140 μm. During the fiber preparation process, by adjusting the flow rate of the internal phase CNTs solution or the flow rate of the intermediate phase PU solution, the change of the fiber wall thickness can be measured in real time in the online observation device, and the precise control of the fiber wall thickness can be realized, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com