Method and device for preparing BN fiber through electron beam irradiation crosslinking

An electron beam irradiation, electron beam technology, applied in the directions of irradiation device, fiber treatment, fiber chemical characteristics, etc., can solve the problem of lack of infusible treatment methods for BN fibrils, and achieve improved mechanical properties, excellent dielectric properties, and crystallinity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

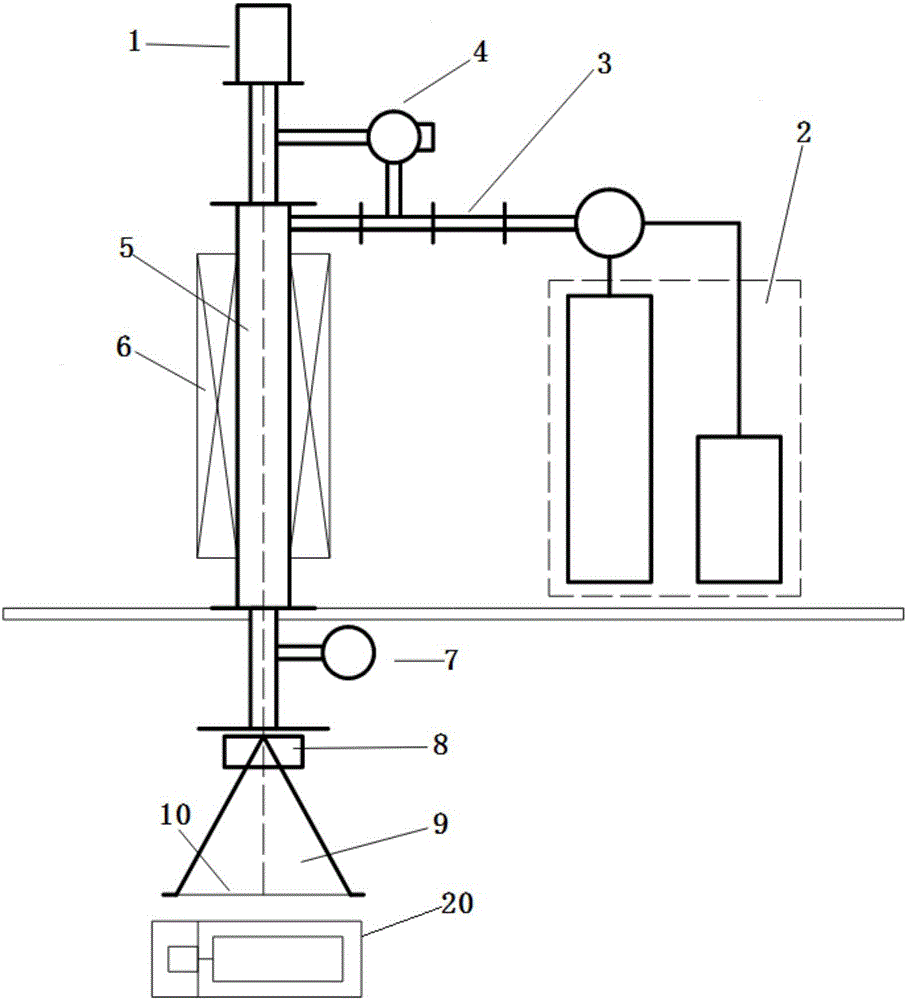

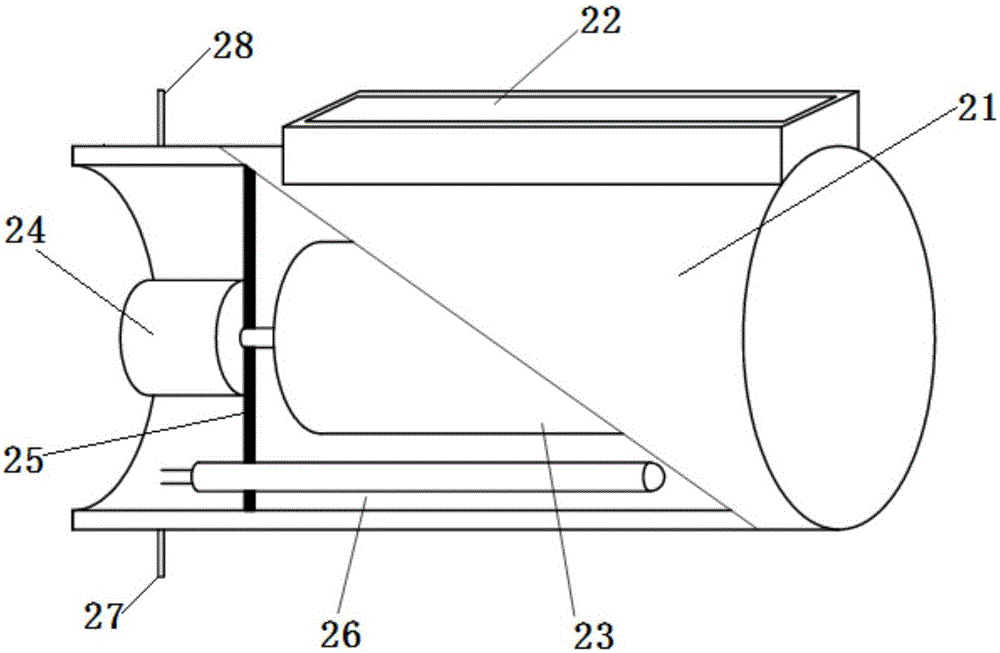

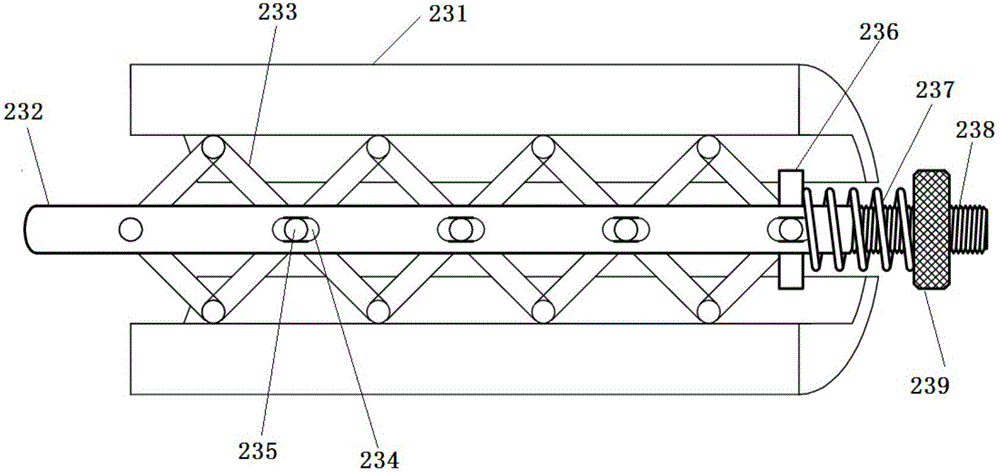

Method used

Image

Examples

Embodiment 1

[0039] The first step of melt spinning: heat the polyborazane precursor to 170°C in the feed tank, stand still for 4 hours, exhaust, then lower the temperature to 150°C, and control the spinning pressure to 0.5MPa to obtain Polyborazane fibrils 100g. The diameter of the spinneret hole is 0.4 mm, and the spinning speed is 600 m / min.

[0040] The second step of electron beam irradiation: the fiber precursors obtained in the first step are placed in a crosslinking box and protected by nitrogen gas. Then carry out cross-linking by electron beam irradiation, the energy is 1.5 MeV, the beam current is 2.5 mA, and the irradiation is 3.0 hours. During the irradiation process, first pass the cooling water to the cross-linking box to cool down, so as to prevent the temperature from being too high during the cross-linking process, resulting in the melting of the filaments; secondly, by adjusting the tension of the filaments, the shrinkage of the fibrils is controlled at 2%- 5%.

[004...

Embodiment 2

[0044] The first step of melt spinning: heat the polyborazane precursor to 170°C in the feed tank, stand still for 4 hours, exhaust, then lower the temperature to 150°C, and control the spinning pressure to 0.5MPa to obtain Polyborazane fibrils 100g. The diameter of the spinneret hole is 0.4 mm, and the spinning speed is 600 m / min.

[0045] The second step of electron beam irradiation: the fiber precursors obtained in the first step are placed in a crosslinking box and protected by nitrogen gas. Then carry out cross-linking by electron beam irradiation, the energy is 2.5 MeV, the beam current is 1.5 mA, and the irradiation is 2.5 hours. During the irradiation process, first pass the cooling water to the cross-linking box to cool down, so as to prevent the temperature from being too high during the cross-linking process, resulting in the melting of the filaments; secondly, by adjusting the tension of the filaments, the shrinkage of the fibrils is controlled at 2%- 5%.

[004...

Embodiment 3

[0049] The first step of melt spinning: heat the polyborazane precursor to 170°C in the feed tank, stand still for 4 hours, exhaust, then lower the temperature to 150°C, and control the spinning pressure to 0.5MPa to obtain Polyborazane fibrils 100g. The diameter of the spinneret hole is 0.4 mm, and the spinning speed is 600 m / min.

[0050] The second step of electron beam irradiation: the fiber precursors obtained in the first step are placed in a crosslinking box and protected by nitrogen gas. Then carry out cross-linking by electron beam irradiation, the energy is 2.5 MeV, the beam current is 2.5 mA, and the irradiation is 2.0 hours. During the irradiation process, first pass the cooling water to the cross-linking box to cool down, so as to prevent the temperature from being too high during the cross-linking process, resulting in the melting of the filaments; secondly, by adjusting the tension of the filaments, the shrinkage of the fibrils is controlled at 2%- 5%.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com