Submicron/nanometer anaerobic silicon carbide fiber felt and preparation method thereof

An oxygen-free silicon carbide, sub-micron technology, applied in fiber processing, fiber chemical characteristics, filament/wire forming, etc., can solve problems affecting fiber high temperature resistance, achieve complete fiber morphology, and improve high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

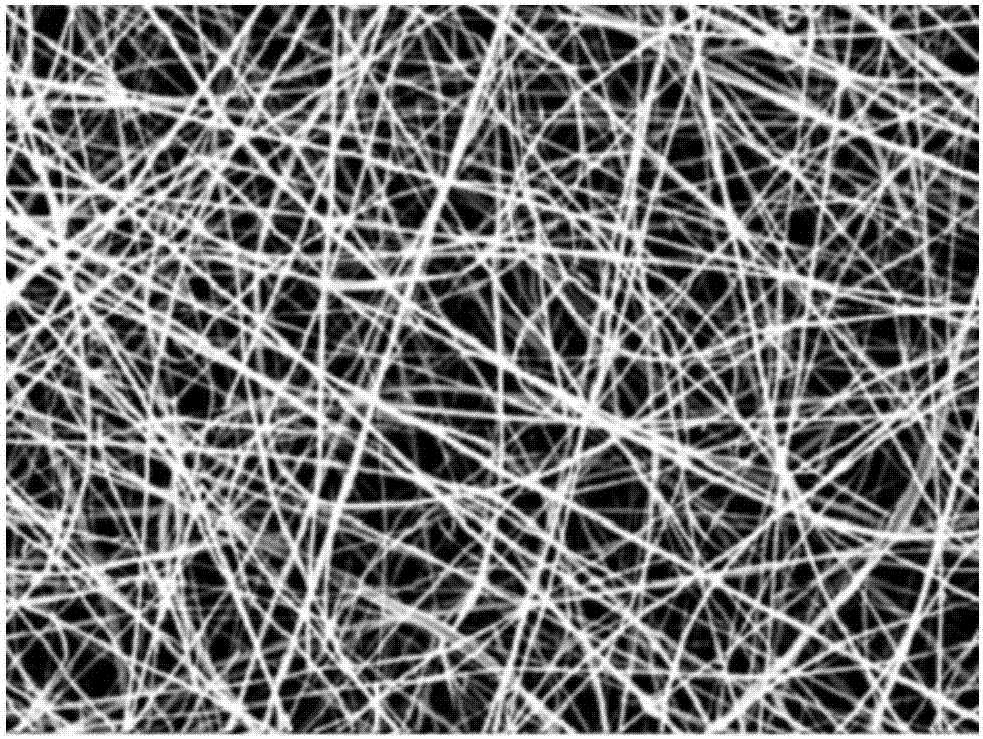

[0021] One aspect of the embodiments of the present invention provides a method for preparing a submicron / nano-oxygen-free silicon carbide fiber mat, which includes:

[0022] Provide high molecular weight polycarbosilane, the M of the high molecular weight polycarbosilane w Greater than 8000, it does not melt during the process of heating from room temperature to 1000 °C;

[0023] providing a spinning solution containing the homogeneously mixed high molecular weight polycarbosilane, a spinning-assisting polymer and an organic solvent, and performing electrospinning with the spinning solution to obtain a precursor fiber mat;

[0024] In a protective atmosphere, the precursor fiber mat is heated and pyrolyzed to obtain a submicron / nanometer oxygen-free silicon carbide fiber mat.

[0025] As one of the preferred embodiments, the preparation method includes: removing low-molecular-weight polycarbosilane in polycarbosilane with a non-good solvent for polycarbosilane to obtain the ...

Embodiment 1

[0058] (1) Pour PDMS into an autoclave, react at 470°C for 4 hours, add xylene to dissolve the product, filter out the insoluble matter, and evaporate the xylene to obtain T s ≈250~262℃, M w = PCS-1 of 4650. Wrap PCS-1 with filter paper, put it into a Soxhlet extractor, and extract it with acetone 20 times. Rinse the insoluble matter in the filter paper three times with acetone, put it into an oven and dry it under vacuum at 50°C to obtain the M of HPCS-1. w for 8000.

[0059] (2) Under the condition of magnetic stirring, dissolve HPCS-1 and PS in the mixed organic solvent of xylene and dimethylformamide, stir well until a transparent and clear solution is formed, which is the spinning solution. Among them, the mass ratio of HPCS-1:PS:organic solvent is 30:5:65.

[0060] (3) Put the spinning solution obtained above into the electrospinning device, the diameter of the spinneret is 1.0 mm, the set output voltage is 14 kV, the feeding rate is 20 μl / min, the distance of the sp...

Embodiment 2

[0064] (1) Pour PDMS into an autoclave, react at 480°C for 2 hours, add xylene to dissolve the product, filter out the insoluble matter, and evaporate the xylene to obtain T s ≈267~283℃, M w = PCS-2 of 4760. Wrap PCS-2 with filter paper, put it into a Soxhlet extractor, and extract it with isopropanol 10 times. Rinse the insoluble matter in the filter paper three times with isopropanol, put it in an oven and dry it under vacuum at 70°C to obtain the M of HPCS-2. w for 9970.

[0065] (2) Under the condition of magnetic stirring, dissolve HPCS-2 and PEO in a mixed organic solvent of xylene and acetone, and stir well until a transparent and clear solution is formed, which is the spinning solution. Among them, the mass ratio of HPCS-2:PEO:organic solvent is 12:3:85.

[0066] (3) Put the spinning solution obtained above into the electrospinning device, the diameter of the spinneret is 1.2mm, the set output voltage is 20kV, the feeding rate is 10μl / min, the distance of the spinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com