Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Good diameter uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Procesxs for producing continuous silicon carbide fibre by skin and core double-composition fibre method

InactiveCN1465549AExcellent fiber weaving performanceSmall diameterInorganic material artificial filamentsFilament/thread formingCarbon fibersChemical composition

The production process of continuously preparing SiC fibre includes the following steps: dissolving high-molecular polymer in solvent to prepare skin solution, dissolving or dispersing the dispersingagent, high-molecular polymer, SiC powder and sintering adjuvant into solvent to prepare core solution, extruding skin solution and core solution from microhole of skin-core composite spinning component under the pressure to make skin solution cover exterior of the core solution, using wet process or dry process to solidifying fluid-flow wire, drawing, drying and winding so as to obtain raw fibre, its core portion is ceramic powder adhered by polymer and its skin portion is made of pure high-molecular material.

Owner:XIAMEN UNIV

Composite melt-blown non-woven fabric and preparation method thereof

ActiveCN110438666AImprove adsorption capacityHigh quality lightweight warmthNon-woven fabricsNonwoven fabricMelt spinning

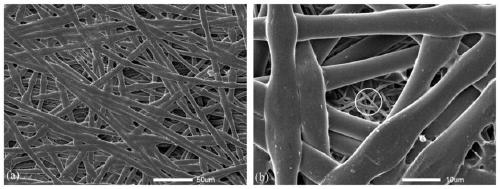

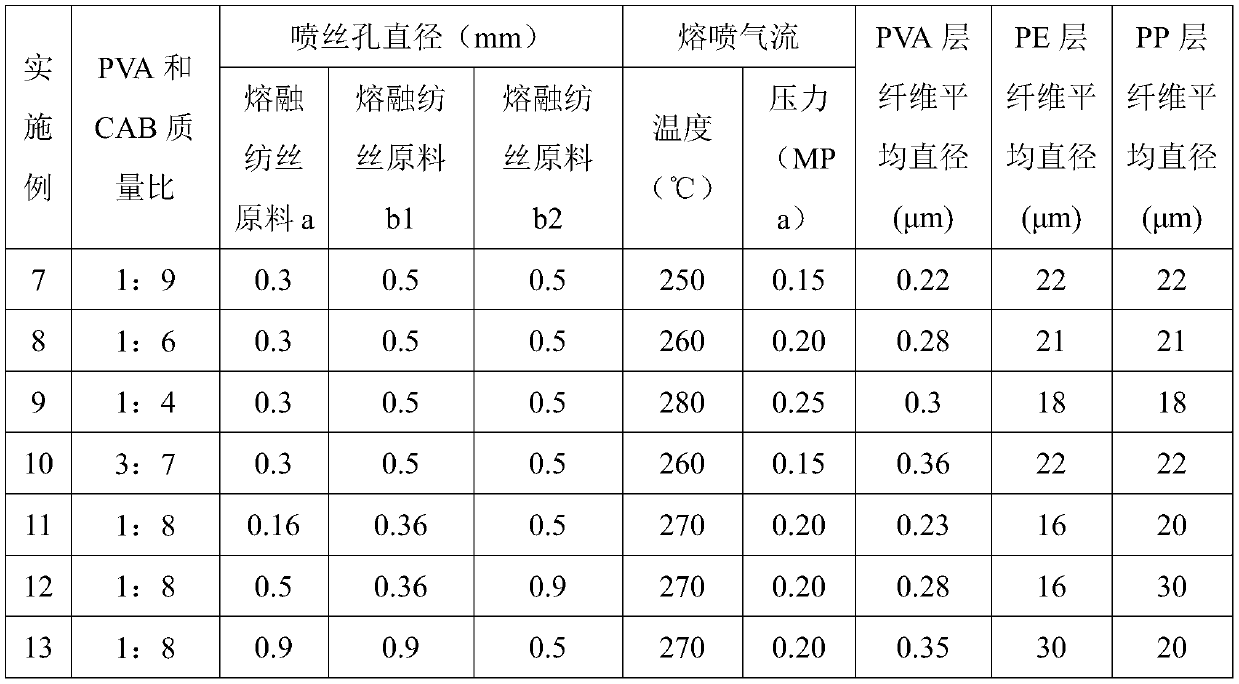

The invention provides a composite melt-blown non-woven fabric and a preparation method thereof. The composite melt-blown non-woven fabric comprises at least one superfine fiber layer and at least onecommon fiber layer. The superfine fiber layers and the common fiber layers are superposed layer by layer through multi-nozzle melt spinning, and are finally reinforced to obtain the composite melt-blown non-woven fabric. Each superfine fiber layer is a superfine fiber layer with the diameter less than 500 nm, and is obtained by melt blended spinning of thermoplastic polymer and a matrix which areincompatible thermodynamically and removing the matrix through solvent extraction; each common fiber layer is obtained by melting and spinning a thermoplastic polymer without a matrix; and finally the composite melt-blown non-woven fabric with excellent comprehensive performance is obtained through hot rolling reinforcement treatment. The problems of complex preparation method, difficulty in large-scale production and nonuniformity of fiber performance in the prior art are solved, and a new idea is provided for preparing the functional non-woven fabric.

Owner:WUHAN TEXTILE UNIV +1

Method for preparing emulsified medicinal composition containing oleum fructus bruceae

InactiveCN101683367AGood diameter uniformityImprove physical stabilityMetabolism disorderDigestive systemYolkHemolysis

The invention discloses a method for preparing an emulsified medicinal composition containing oleum fructus bruceae, which comprises the following steps: (1) mixing a proper amount of water and 1 to 10ml of glycerin; (2) adding at least one of yolk lecithin and poloxamer into liquid prepared in step (1), and performing shear mixing uniformly, wherein the yolk lecithin is between 0.5 and 10g, and the poloxamer is between 0.1 and 5g; and (3) slowly adding 5 to 30ml of oleum fructus bruceae into liquid prepared in step (2), adding water to make the total content be 100ml, adjusting the pressure of a high pressure homogenizer, adopting two-step emulsification method, and continuously circulating 3 to 6 times to prepare the emulsified medicinal composition containing the oleum fructus bruceae.The oleum fructus bruceae emulsion injection prepared by the method has good stability, no hemolysis in a period of validity, and safety, and is favorable for clinical promotion and application.

Owner:ZHEJIANG JIUXU PHARMA

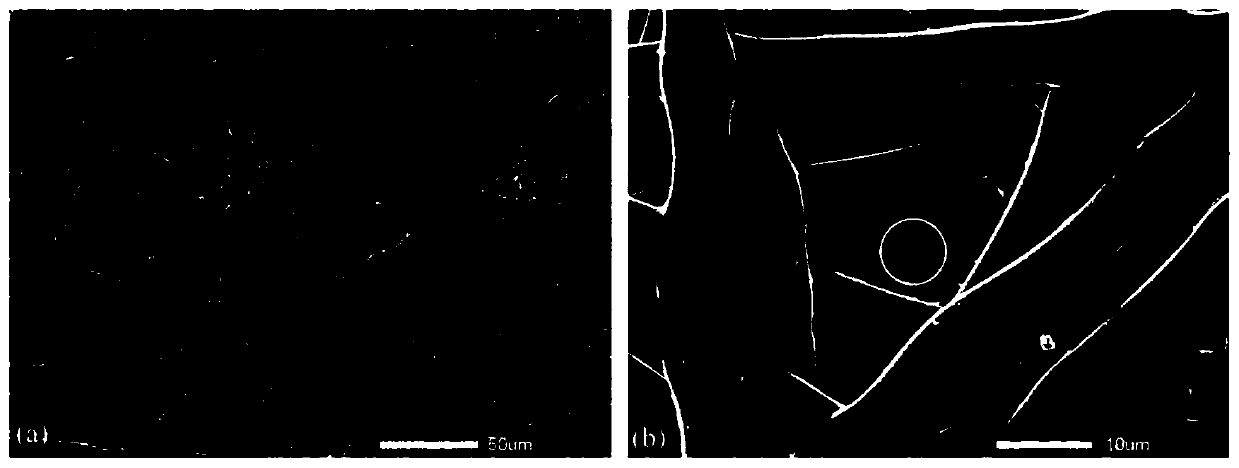

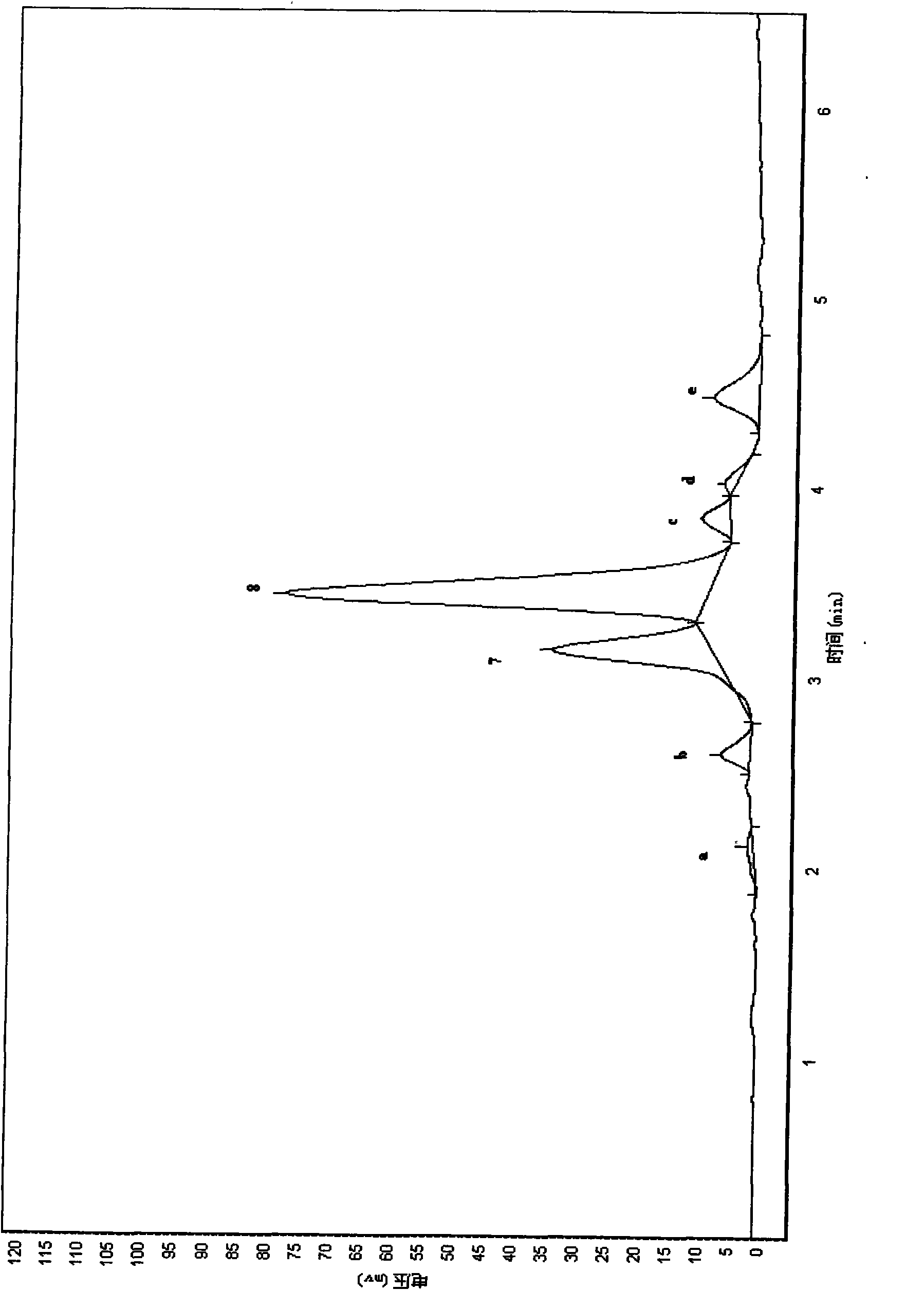

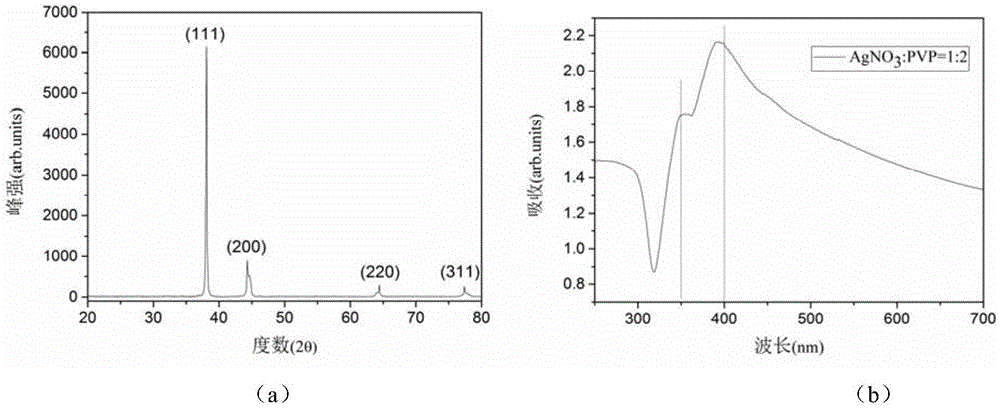

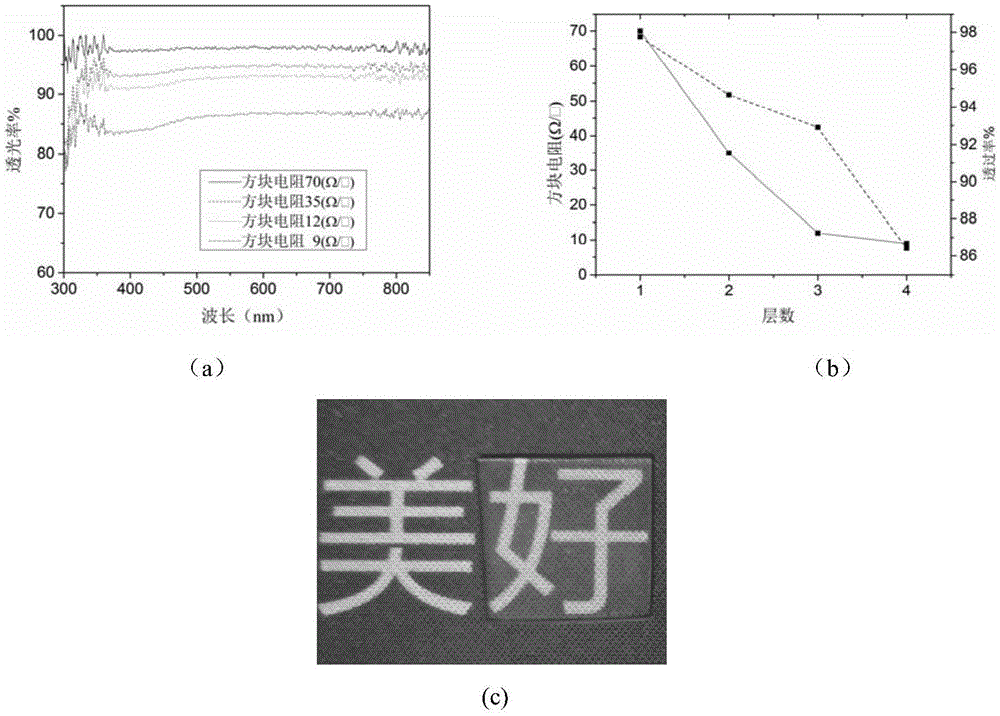

Method of preparing silver nanowire and transparent conductive film of silver nanowire

InactiveCN105750559AEasy to prepareGood diameter uniformityMaterial nanotechnologyTransportation and packagingElectrically conductiveMaterial synthesis

The invention discloses a method of preparing a silver nanowire and a transparent conductive film of the silver nanowire, and belongs to the technical field of nano material synthesis and thin film preparation.The transparent conductive film has high light transmission and low surface resistance.The method for preparing the silver nanowire is simple, the prepared silver nanowire is good in diameter uniformity, the conductive film is good in light transmission and low in surface resistance, and the silver nanowire can be applied to preparation of the transparent conductive film, so that the prepared conductive film is good in light transmission and low in surface resistance.Under the condition of similar light transmitting performance, the prepared transparent conductive film is low in square resistance, and meanwhile good adhesion performance is achieved.

Owner:深圳市东方亮化学材料有限公司

Emulsified pharmaceutical composition containing oleum fructus bruceae and processes for producing same

InactiveCN101129419AGood diameter uniformityImprove physical stabilityPharmaceutical non-active ingredientsEmulsion deliveryYolkHemolysis

The invention discloses an emulsifying drug composition with oleum fructus bruceae and making method, which comprises the following parts: at least one of among oleum fructus bruceae, yolk lecithine and mooring luoshamu, glycerol with added water to 100ml to be homogeneous emulsification with grain diameter<=15um. The making method comprises the following steps: (1) adding at least one of yolk lecithine and mooring luoshamu into oleum fructus bruceae to shear-mix uniformly; (2) mixing glycerol and water; (3) adding liquid in step (1) into liquid in step (2) slowly at stirring state to add water of 100ml total amount and adjusting pressure of high-pressure homogeneity machine to adopt method of two-step emulsification to cycle 3-6 times continuously to form product. The invention discloses an injection of oleum fructus bruceae with good stability and without hemolysis in security, which facilitates spreading application of clinic.

Owner:ZHEJIANG JIUXU PHARMA

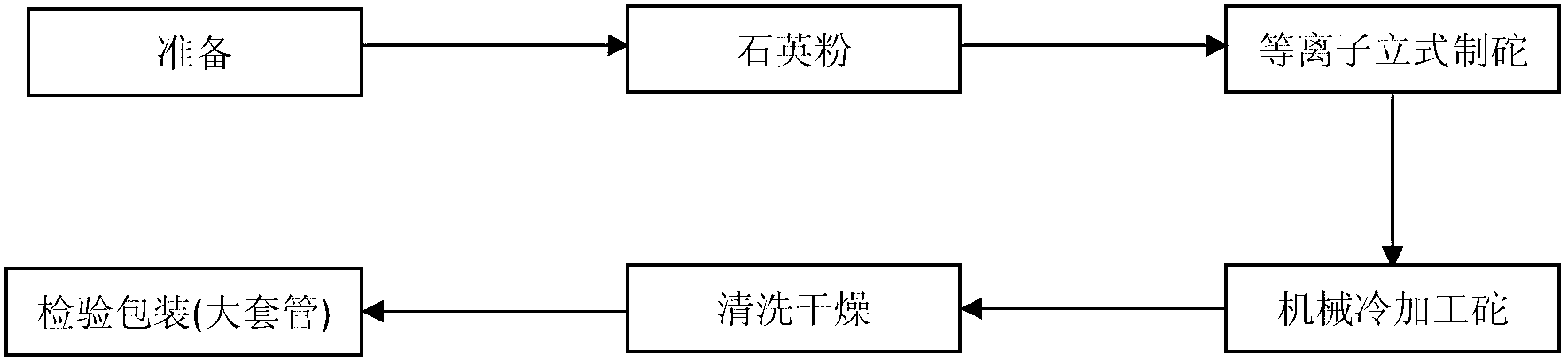

Preparation method of low-hydroxyl large-diameter large-length quartz piece

InactiveCN103224319ALow hydroxyl contentHigh purityGlass shaping apparatusGlass deposition burnersTemperature resistanceVertical axis

The invention relates to a preparation method of a quartz product, and especially relates to a preparation method of a low-hydroxyl large-diameter large-length quartz piece. According to the invention, the piece is prepared with a plasma vertical solid-phase external deposition method. One or a plurality of plasma torches can be configured. During a smelting process, the plasma torch is maintained unmoved, or is subjected to translational motions up and down on a vertical axis. The smelting temperature which is quartz piece surface temperature is 1800-2500 DEG C. Quartz sand is delivered in from a blanking pipe at a plasma torch upper port or by plasma device central airflow. A central base pipe or base rod is fixed on a glass machine tool, and simultaneously rotates when performing translational movements up or down on the vertical axis. Along with the relative movements of the plasma flame and the central base pipe or base rod, the quartz sand is deposed and molten layer by layer, such that a hollow quartz blank piece or a solid quartz blank piece is formed. With the plasma vertical solid-phase external deposition novel method, the prepared quartz piece has the characteristics high purity, low hydroxyl content, high softening point, high strength, high temperature resistance, and uniform diameter.

Owner:久智光电子材料科技有限公司

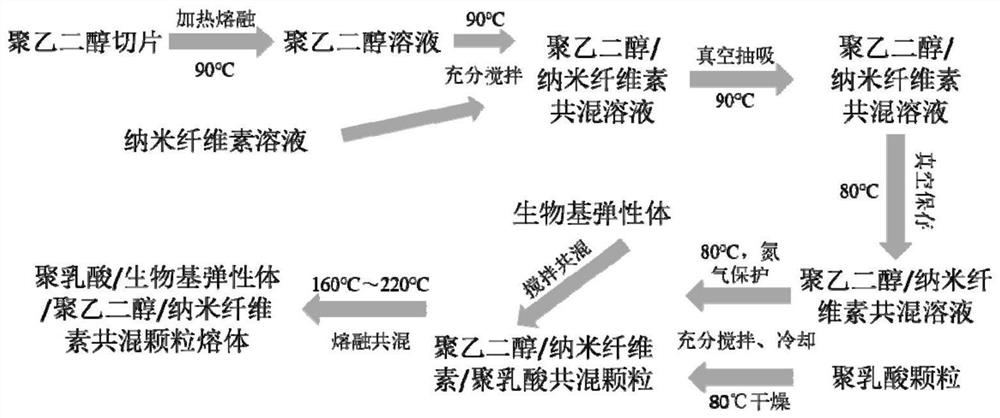

Polylactic acid elastic superfine fiber non-woven material as well as preparation method and application thereof

ActiveCN113293517ASave resourcesHigh crystallinityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsElastomerPolymer science

The invention belongs to the field of melt-blown non-woven materials, and relates to preparation of superfine fibers, in particular to a polylactic acid elastic superfine fiber non-woven material as well as a preparation method and application thereof. The method comprises the following steps of (1) preparing a polyethylene glycol / nanocellulose blended solution; (2) preparing a polylactic acid / polyethylene glycol / nanocellulose blended raw material; (3) carrying out melt blending molding on polylactic acid blended particles and a bio-based elastomer; (4) carrying out melt-blowing forming of a polylactic acid elastic superfine fiber web; and (5) carrying out a multi-stage hot drafting process of the polylactic acid elastic superfine fiber non-woven material, so that finally, the polylactic acid elastic superfine fiber non-woven material with strength, elasticity and biodegradable characteristics is obtained. The method has the characteristics of environmental protection, reliability and low production cost, and has the advantage of large-scale application.

Owner:河南驼人医疗器械研究院有限公司 +1

Method for extracting cellulose nanowhiskers from corn husks

InactiveCN104762845AShorten the lengthSmall discreteCellulose treatment using microorganisms/enzymesChemistryMechanical crushing

The invention provides a method for preparing cellulose nanowhiskers from corn husks. The method is characterized by comprising the following specific steps: performing pretreatment, biochemical treatment, mechanical crushing, DMSO (dimethyl sulfoxide) treatment and TEMPO (tetramethylpiperidinooxy) oxidation treatment, putting an obtained mixture into a stirrer, and stirring to obtain a corn husk fiber powder suspension; performing centrifugation treatment to obtain a corn husk fiber precipitate; performing dispersion treatment to obtain a corn husk cellulose nanowhisker suspension; and performing freeze-drying to obtain the corn husk cellulose nanowhiskers. The method provided by the invention has the advantages of simple preparation process, high yield, low energy consumption, no emission of toxic and harmful substances in the production process and large-scale popularization and application potential; and the used corn husks are rich in resources and low in cost, the problem of environmental pollution is solved, and the added value of the corn husks is also improved.

Owner:DONGHUA UNIV

Steel wire rope used for high-rise high-speed elevator

InactiveCN103103838AMeet the use requirementsGood diameter uniformityTextile cablesEngineeringUltimate tensile strength

The invention relates to a steel wire rope used for a high-rise high-speed elevator. The steel wire rope used for the high-rise high-speed elevator is characterized by comprising a sisal hemp core, inner layer strands and outer layer strands. Eight inner layer strands wrap the sisal hemp core in a twisted mode, eight outer layer strands wrap the inner layer strands in a twisted mode, and the sisal hemp core is formed by sisal hemp silk strands in a stranding and twisting mode through one-step molding. Due to the fact that the sisal hemp core is formed by the sisal hemp silks in the stranding and twisting mode through the one-step molding, and two layers of steel wire rope strands are used for wrapping the sisal hemp core in a twisting mode to form the steel wire rope, diameter evenness is good, strength level and bearing capacity are improved, fatigue life is prolonged, service life is prolonged, and use demands of the high-rise high-speed elevator are satisfied.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

Resin coating metal core steel wire rope for superspeed elevator

InactiveCN106436392AImprove impact resistanceGood diameter uniformityElevatorsTextile cablesResin coatingShock resistance

The invention discloses a resin coating metal core steel wire rope for a superspeed elevator. The resin coating metal core steel wire rope comprises a center strand, eight inner-layer stands are symmetrically twisted outside the center strand, the eight inner-layer strands are coated with a resin coating, and eight outer-layer strands are symmetrically twisted outside the resin coating. The resin coating metal core steel wire rope for the superspeed elevator is formed by twisting the eight outer-layer strands outside a resin metal rope core, and the resin metal rope core is formed by evenly wrapping a metal rope core by resin. The steel wire rope of the structure has high shock resistance and diameter uniformity, and the bearing capacity of the steel wire rope is improved. Compared with an elevator steel wire rope with the same diameter and strength grade on the current market, the diameter uniformity of the steel wire rope of the structure is improved by 15%, the shock resistance of the steel wire rope is improved by 10%, and the bearing capacity of the steel wire rope is improved by 5%.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

A method for extracting cellulose nano whiskers from corn bracts

InactiveCN104762845BIncrease added valueImplement extractionCellulose treatment using microorganisms/enzymesFiberCellulose

The invention provides a method for preparing cellulose nanowhiskers from corn husks. The method is characterized by comprising the following specific steps: performing pretreatment, biochemical treatment, mechanical crushing, DMSO (dimethyl sulfoxide) treatment and TEMPO (tetramethylpiperidinooxy) oxidation treatment, putting an obtained mixture into a stirrer, and stirring to obtain a corn husk fiber powder suspension; performing centrifugation treatment to obtain a corn husk fiber precipitate; performing dispersion treatment to obtain a corn husk cellulose nanowhisker suspension; and performing freeze-drying to obtain the corn husk cellulose nanowhiskers. The method provided by the invention has the advantages of simple preparation process, high yield, low energy consumption, no emission of toxic and harmful substances in the production process and large-scale popularization and application potential; and the used corn husks are rich in resources and low in cost, the problem of environmental pollution is solved, and the added value of the corn husks is also improved.

Owner:DONGHUA UNIV

A kind of polylactic acid elastic superfine fiber nonwoven material and its preparation method and application

ActiveCN113293517BSave resourcesHigh crystallinityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsElastomerPolymer science

The invention belongs to the field of melt-blown nonwoven materials, and relates to the preparation of ultrafine fibers, in particular to a polylactic acid elastic ultrafine fiber nonwoven material and its preparation method and application. It includes the following steps: (1) preparation process of polyethylene glycol / nanocellulose blend solution; (2) preparation process of polylactic acid / polyethylene glycol / nanocellulose blending raw material; (3) polylactic acid blending Melt blending molding process of particles and bio-based elastomer; (4) Melt blown molding process of polylactic acid elastic ultrafine fiber web; (5) Multi-stage thermal drawing process of polylactic acid elastic ultrafine fiber nonwoven material; final A polylactic acid elastic superfine fiber nonwoven material having strength, elasticity and biodegradable properties is obtained; the method has the characteristics of green environmental protection, reliable method and low production cost, and has the advantage of large-scale application.

Owner:河南驼人医疗器械研究院有限公司 +1

Polyimide nanofiber membrane as well as preparation method and application thereof

InactiveCN112226910ASmall diameterGood diameter uniformityMonocomponent synthetic polymer artificial filamentNon-woven fabricsImidePolymer science

The invention relates to a polyimide nanofiber membrane as well as a preparation method and application thereof. The problems of large surface aperture, easy ion conduction and low diaphragm strengthof the polyimide nanofiber membrane in the existing electrostatic spinning technology are solved. The preparation method of the polyimide nanofiber membrane comprises the following steps carrying outelectrostatic spinning on a polyamic acid salt solution to obtain a polyamic acid salt nanofiber membrane; and carrying out imidization on the polyamic acid salt nanofiber membrane to obtain the polyimide nanofiber membrane. The polyamic acid salt solution comprises a solvent and polyamic acid salt, the surface tension of the polyamic acid salt solution is 40-65 mN / m, and the apparent viscosity ofthe polyamic acid salt solution is 5-20 Pa.s, according to the technical scheme, the problems are better solved, and the method can be used for continuous production of polyimide nanofiber membranes.

Owner:CHINA PETROLEUM & CHEM CORP +1

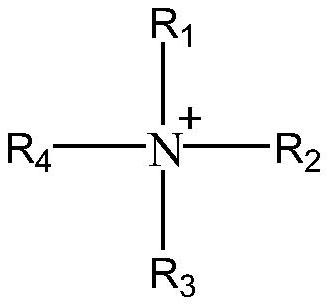

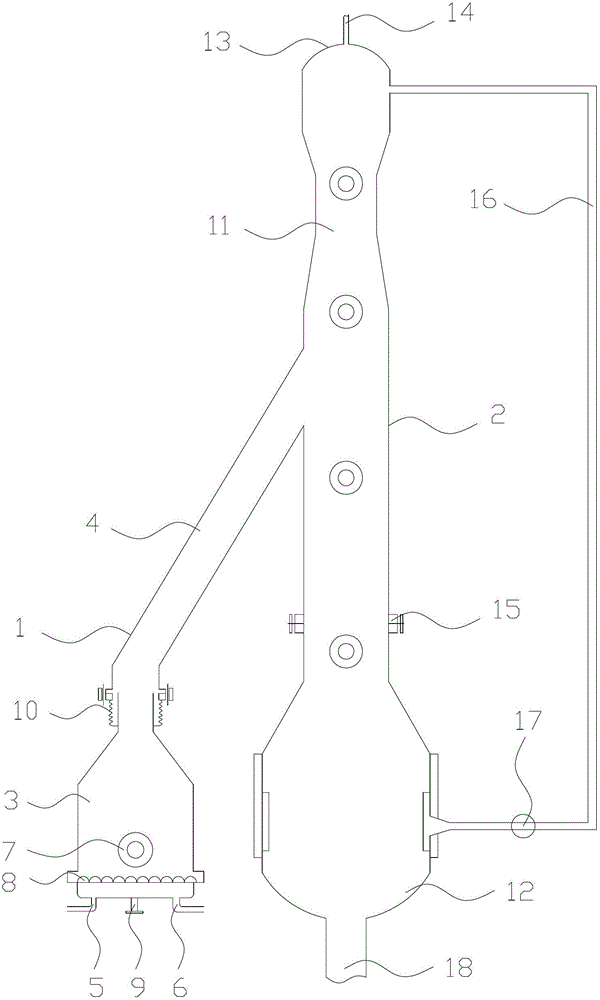

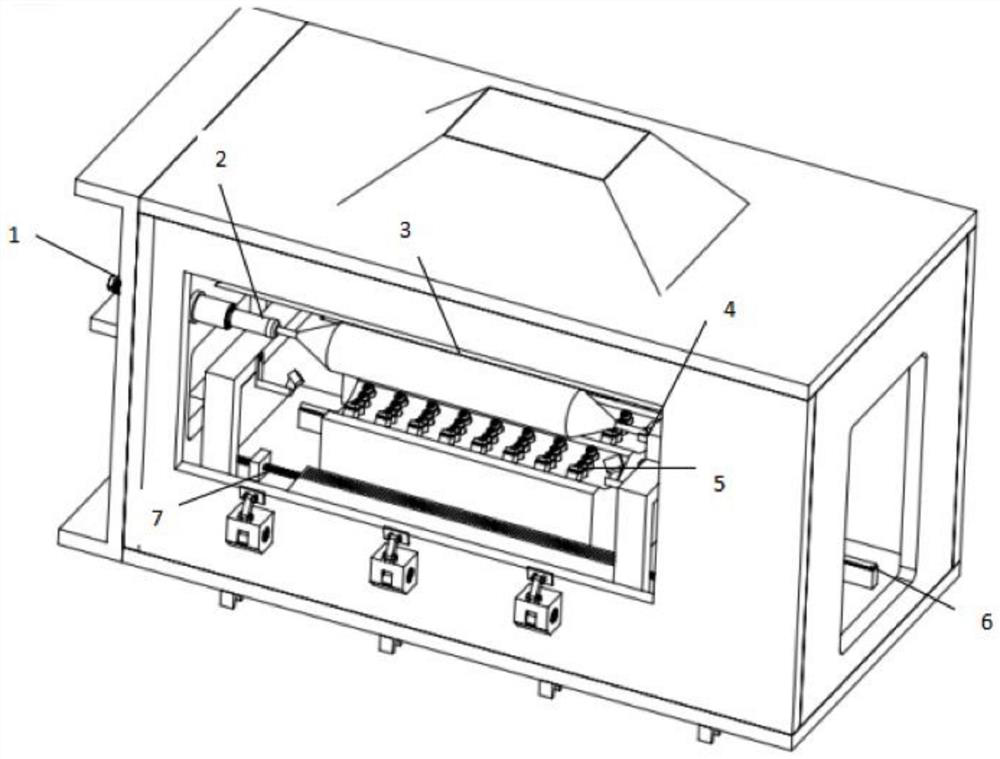

Uniform ion exchange resin granule production equipment

ActiveCN103145904AImproved diameter uniformityImprove possession rateElectric machineryPolymer chemistry

The invention relates to uniform ion exchange resin granule production equipment, and belongs to the field of resin production equipment. The uniform ion exchange resin granule production equipment comprises a monomer generation system and a monomer forming system, wherein the monomer generation system comprises a monomer box and a fluidized pipeline; the top of the monomer box is connected with the fluidized pipeline, and the bottom of the monomer box is provided with a raw material inlet and a liquid discharge port; the outer wall of the monomer box is provided with a viewing mirror; the monomer box is internally provided with a shower spray head, and the monomer box is connected with a vibrating motor; the connecting position of the monomer box and the fluidized pipeline is provided with a ripple compensator; the monomer forming system comprises a fluidized tank and a heating tank; the fluidized tank is provided with an upper cover; the upper cover is provided with an air exhaust port; the bottom of the fluidized tank is connected with the heating tank through a flange; the fluidized tank and the heating tank are provided with fluid circulating pipelines; the fluid circulating pipelines are connected with a circulation motor; and the bottom of the heating tank is provided with a discharge port. The uniform ion exchange resin granule production equipment disclosed by the invention can improve the diameter uniformity of ion exchange resin monomer granules, enhances the product spheroidization rate, reduces the cost and increases the production efficiency.

Owner:蚌埠市天星树脂有限责任公司

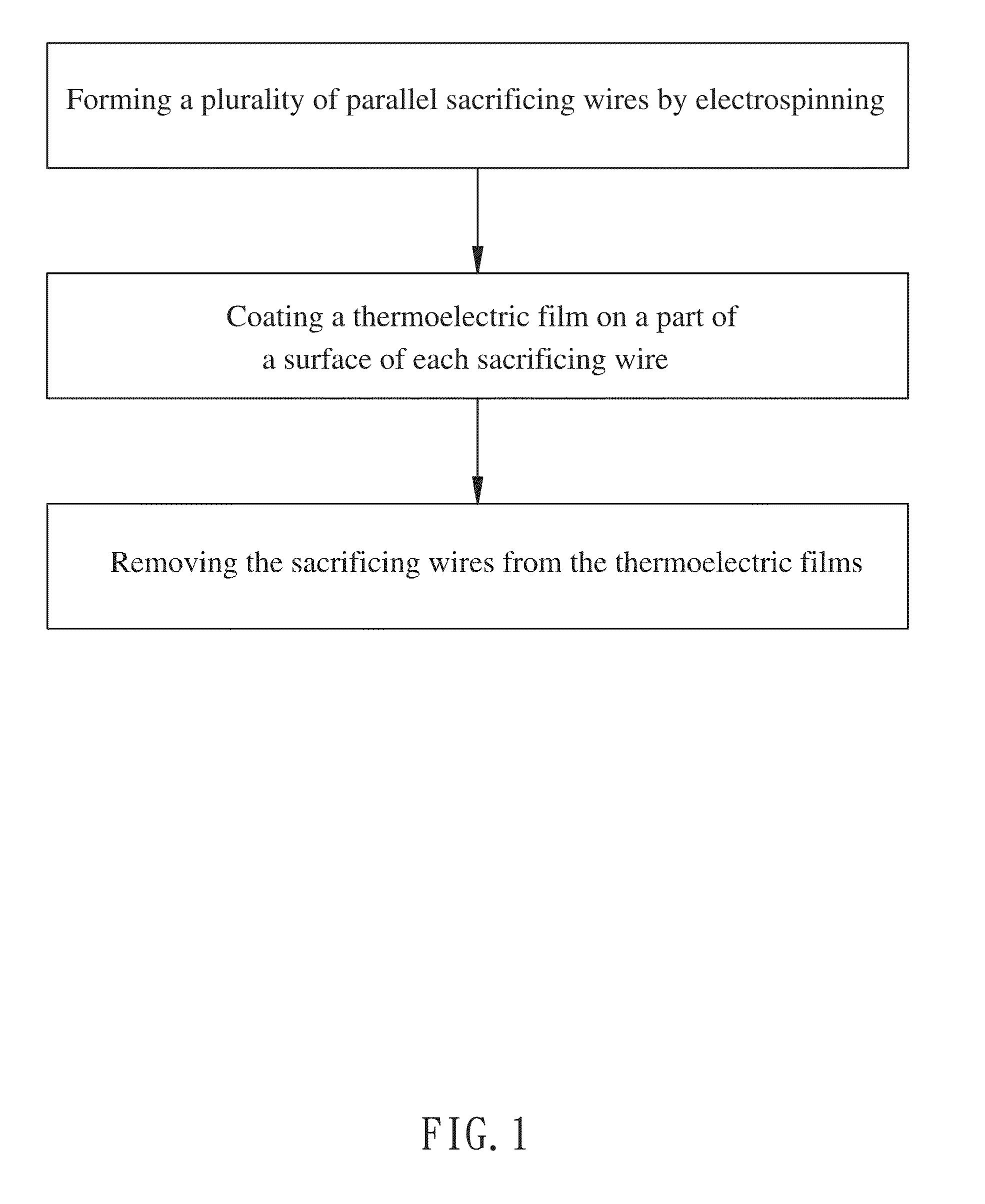

Method for forming a thermoelectric film having a micro groove

InactiveUS20150357548A1Uniform diameterGood diameter uniformityThermoelectric device manufacture/treatmentSemiconductor/solid-state device manufacturingMean free pathPtru catalyst

A method for forming a thermoelectric film having a micro groove includes the following steps: A) forming a plurality of parallel sacrificing wires by electrospinning, a diameter of each sacrificing wire being 100-500 nm; B) coating a thermoelectric film having a thickness of 80-200 nm on a part of a surface of each sacrificing wire; and C) removing the sacrificing wires from the thermoelectric films and thus obtaining the thermoelectric films each having the micro groove, a radio side of each thermoelectric film being open to the surroundings. The thermoelectric films finally prepared can have higher size uniformity without the disadvantage of catalyst residual. Further, the thermoelectric films each have a size smaller than the mean free path of phonons in one dimension, and thus the thermoelectric properties of the thermoelectric films can be improved.

Owner:NAT CENT UNIV

Steel wire rope core for elevators and making method thereof

The invention provides a steel wire rope core for elevators and a making method thereof. The steel wire rope core is mainly prepared from the following raw materials, by weight, 30-35 parts of polyester fibers, 15-20 parts of polyethylene fibers, 12-15 parts of aramid fibers, 8-10 parts of graphene, 8-10 parts of metal sulfide, 2-5 parts of silicon carbide, and 5-25 parts of filler. The performances of the steel wire rope core for elevators are better than those of imported rope cores. The steel wire rope core for elevators has high strength, high modulus, high density and good oil absorption performance, has the advantages of high diameter uniformity, high bending fatigue resistance, high abrasion resistance, high resistance to chemical corrosion and the like, and is a novel energy-saving and environment-friendly high-tech material. By adopting a steel rope made of the steel wire rope core, smooth operation of elevators is realized, and the fatigue life of the steel rope can be prolonged.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

Manufacturing method of steel wire ropes for high-rise elevators

The invention discloses a manufacturing method of steel wire ropes for high-rise elevators, comprising the following steps: a, selecting wires; b, drawing at a time; c, performing heat treatment; d, drawing at a second time; e, entwisting strands, entwisting the steel wires drawn at a second time according to needed structures and specifications to form outer layer strands and inner layer strands for the steel wire ropes and repeatedly bending after forming the strands to manufacture steel wire rope strands; f, entwisting center sub-ropes, packaging and entwisting 3 helm cores with 8 inner layer strands obtained in the step e to manufacture the centre sub-ropes of the steel wire ropes; j, entwisting the ropes, packaging and entwisting the centre sub-ropes obtained in the step f with 8 outer layer strands obtained in the step e to entwist the needed steel wire ropes, and repeatedly bending after forming the strands to manufacture the steel wire ropes. The steel wire ropes manufactured by using the manufacturing method of the steel wire ropes for the high-rise elevators have the advantage of good diameter uniformity; the elevators have the advantages of good comfort level and stability in the operation process; the steel wire ropes are suitable for the elevators used by high-rise buildings.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

OVD device with high deposition qualification rate

ActiveCN110194588ADeposition went wellGuaranteed mobilityGlass making apparatusEngineeringCompression member

The invention relates to an OVD device with high deposition qualification rate. The device includes: a deposition box body, support structures, chuck rod fixed structures, blowtorches and a ventilation system. Specifically, the support structures are arranged at one side in a deposition cavity, each support structure includes a fixed seat, a sliding ring, a fixed pipe and a compression member, andis used for fixing one end of a preform rod loose body or core rod. The chuck rod fixed structures are disposed at the other side in the deposition cavity, and each chuck rod fixed structure includesa chuck rod for fixing the other end of the preform rod loose body or core rod, and the chuck rod is connected to a driving apparatus and can be driven by the same to rotate. The OVD device providedby the invention makes the preform rod loose bodies or core rods cannot slide in the sliding bearing support structures or slide out of the bearing support structures, thus ensuring that the whole preform rod loose bodies or core rods do not move back and forth or slide out of the clamps, and enhancing the deposition qualification rate of the preform rod loose bodies or core rods.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

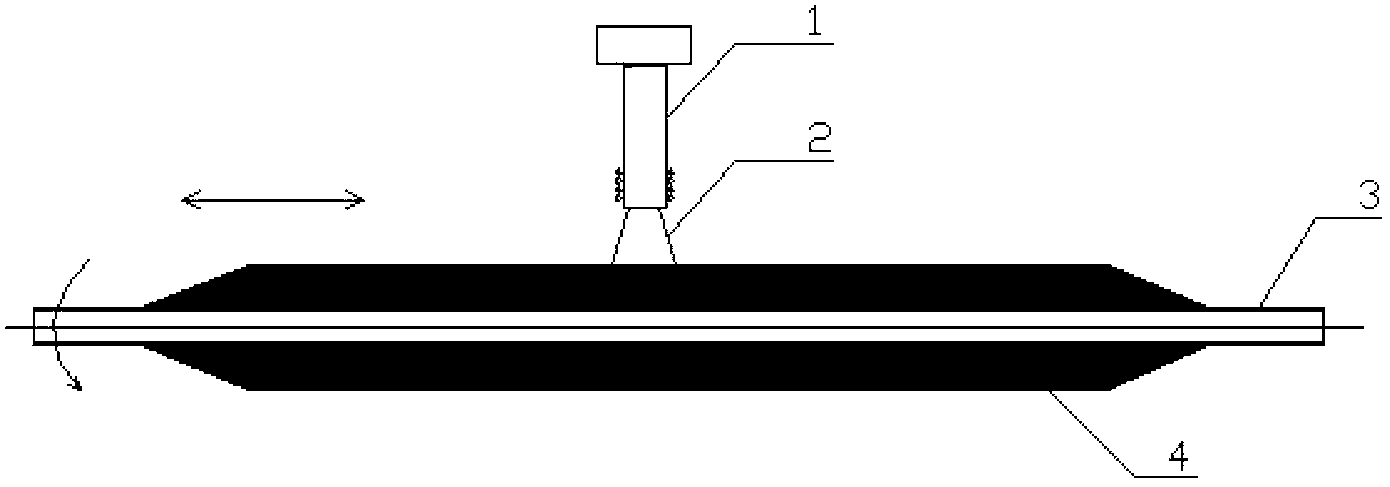

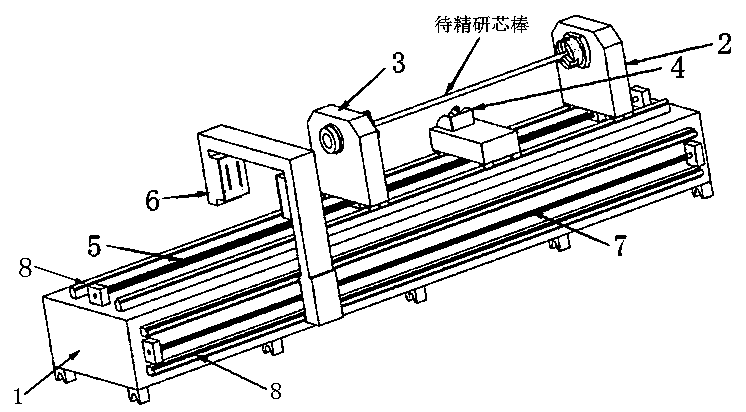

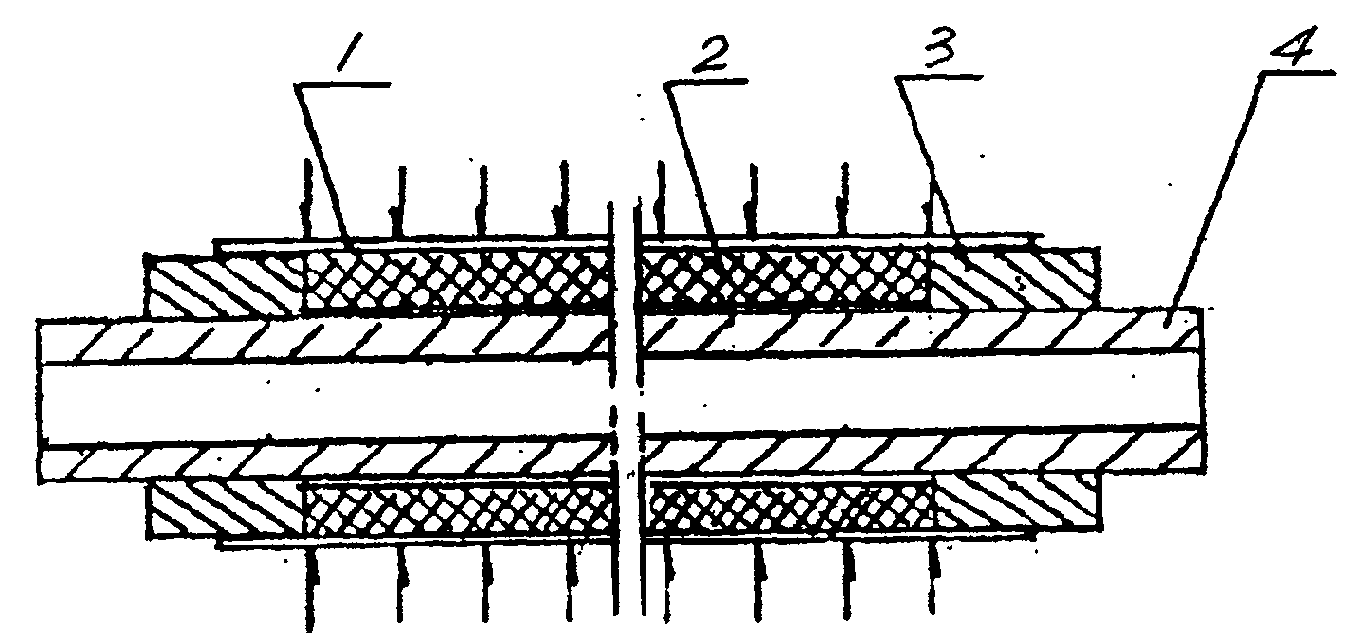

Lapping device capable of improving mandrel diameter difference and lapping method of lapping device

PendingCN109437547AAvoid scrappingGood diameter uniformityGlass making apparatusButt jointEngineering

The invention discloses a lapping device capable of improving mandrel diameter difference. A fixed chuck and a sliding chuck are respectively mounted on the upper lathe surface of a lapping machine tool; a torch lamp is further arranged on the upper lathe surface of the lapping machine tool; the torch lamp is arranged between the fixed chuck and the sliding chuck; a first transmission lead screw is further arranged on the upper lathe surface of the lapping machine tool; a diameter scanner is arranged on the side lathe surface of the lapping machine tool; the diameter scanner is 7-shaped; the upper part of the diameter scanner stretches over the upper lathe surface of the lapping machine tool; a second transmission lead screw is further arranged on the side lathe surface of the lapping machine tool; the fixed chuck, the sliding chuck, the torch lamp and the diameter scanner are all externally connected with a controller; and the controller controls and drives the fixed chuck, the sliding chuck and the torch lamp to move correspondingly along the first transmission lead screw, and controls and drives the diameter scanner to move correspondingly along the second transmission lead screw, so that mandrel butt-joint and lapping are realized, and therefore, mandrel diameter uniformity is effectively improved; a mandrel utilization rate and a wire-drawing qualification rate are increased; and meanwhile, the total length of the mandrel is enabled to reach the standards, and waste of raw materials is reduced.

Owner:JIANGSU TONGDING OPTICAL WAND

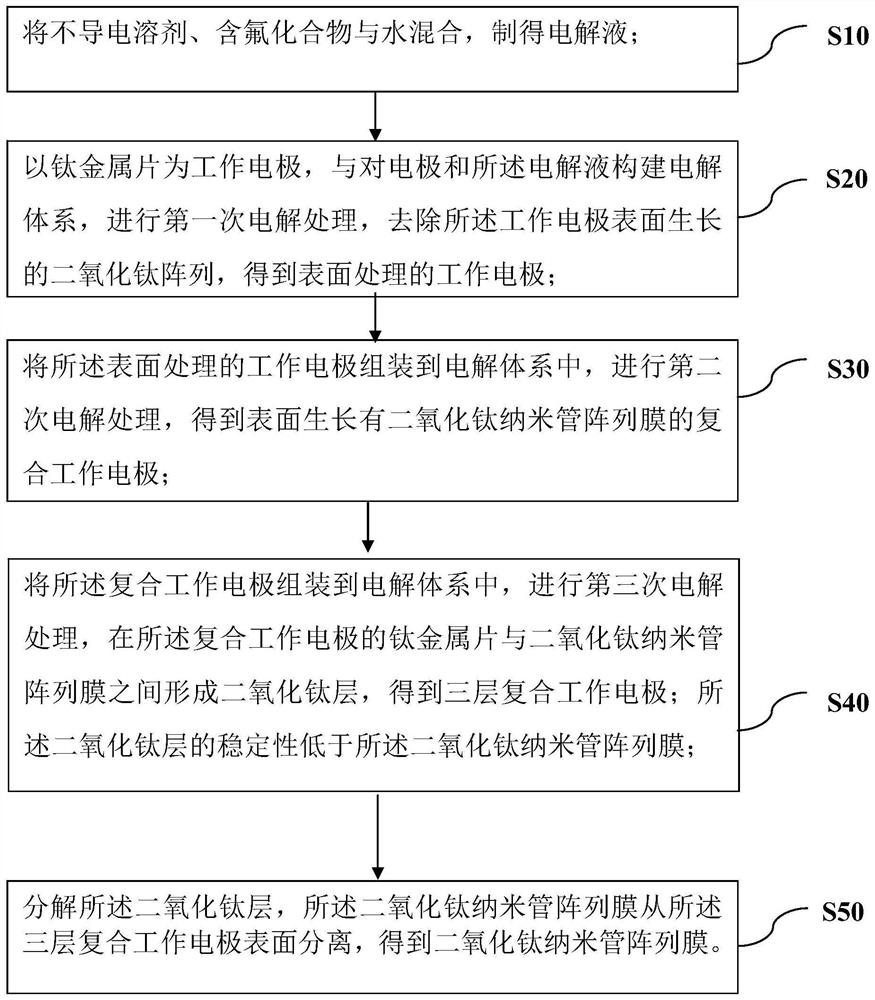

Titanium dioxide nanotube array film, preparation method thereof and photoelectric device

PendingCN114045544AImprove growth efficiencyImprove distribution uniformitySurface reaction electrolytic coatingElectrolytic agentTitanium metal

The invention belongs to the technical field of materials, and particularly relates to a titanium dioxide nanotube array film, a preparation method thereof and a photoelectric device. The preparation method of a titanium dioxide nanotube array film comprises the following steps: constructing an electrolysis system by using a titanium metal sheet as a working electrode, a counter electrode and an electrolyte, carrying out primary electrolytic treatment, and removing a titanium dioxide array growing on a surface of the working electrode; carrying out secondary electrolytic treatment, wherein a titanium dioxide nanotube array film grows on the surface of the working electrode; carrying out third electrolytic treatment to form a titanium dioxide layer between the titanium metal sheet and the titanium dioxide nanotube array film; and decomposing the titanium dioxide layer to obtain the titanium dioxide nanotube array film. According to the preparation method provided by the invention, through three times of electrolytic treatment, the growth efficiency and quality of the titanium dioxide nanotube array film are improved, preparation of a large-size array film is realized, and the complete and large-size titanium dioxide nanotube array film is obtained.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Micro rotating wire rope for high-rise express elevator and preparation method thereof

ActiveCN102127876BImprove securityGood anti-rotation performanceRope making machinesEngineeringHigh rise

The invention discloses a micro rotating wire rope for a high-rise express elevator and a preparation method thereof. The wire rope comprises a central strand, 8 inner layer strands and 8 outer layer strands, wherein the 8 inner layer strands are uniformly twisted outside the central strand, and the 8 outer layer strands are uniformly twisted outside the inner layer strands. The preparation method of the wire rope comprises the following steps: stranding, eliminating the strand stress, and twisting to form the rope. Compared with the traditional elevator wire rope, the wire rope prepared by the method disclosed by the invention has the advantages of strong bearing capacity, favorable rotating property, low percentage of elongation and uniform diameter, and is suitable for high-rise express elevators.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

Uniform ion exchange resin granule production equipment

ActiveCN103145904BGood diameter uniformityImprove possession rateElectric machineryIon-exchange resin

The invention relates to uniform ion exchange resin granule production equipment, and belongs to the field of resin production equipment. The uniform ion exchange resin granule production equipment comprises a monomer generation system and a monomer forming system, wherein the monomer generation system comprises a monomer box and a fluidized pipeline; the top of the monomer box is connected with the fluidized pipeline, and the bottom of the monomer box is provided with a raw material inlet and a liquid discharge port; the outer wall of the monomer box is provided with a viewing mirror; the monomer box is internally provided with a shower spray head, and the monomer box is connected with a vibrating motor; the connecting position of the monomer box and the fluidized pipeline is provided with a ripple compensator; the monomer forming system comprises a fluidized tank and a heating tank; the fluidized tank is provided with an upper cover; the upper cover is provided with an air exhaust port; the bottom of the fluidized tank is connected with the heating tank through a flange; the fluidized tank and the heating tank are provided with fluid circulating pipelines; the fluid circulating pipelines are connected with a circulation motor; and the bottom of the heating tank is provided with a discharge port. The uniform ion exchange resin granule production equipment disclosed by the invention can improve the diameter uniformity of ion exchange resin monomer granules, enhances the product spheroidization rate, reduces the cost and increases the production efficiency.

Owner:蚌埠市天星树脂有限责任公司

Composite molybdenum wire for wire cutting and production method thereof

ActiveCN105772877BImprove wear resistanceReduce the probability of crackingElectrical-based machining electrodesRare earthWire cutting

The invention discloses a composite molybdenum wire used for linear cutting and a manufacturing method. The composite molybdenum wire is made of molybdenum powder containing solid solution metal elements and rare earth oxide. The solid solution metal elements are selected from at least one of Co, W, Ni, Hf or Re, and the weight content of the solid solution metal elements is 0.01%-0.30%. The rare earth oxide is selected from at least one of La2O3 or Y2O3, and the weight content of the rare earth oxide is 0.005%-0.20%. The manufacturing method comprises the following steps that secondary solid-liquid mixing is conducted, and uniform mixed molybdenum powder is obtained; then a molybdenum rod billet is obtained through pressing; the sintered molybdenum rod billet is rolled into a molybdenum coil rod; then the composite molybdenum wire used for linear cutting is obtained through drawing by repeatedly conducting a hot draw technique and a cold draw technique; and annealing is conducted repeatedly in the process, and the composite molybdenum wire is obtained. According to the composite molybdenum wire used for linear cutting, the abrasion resistance can be substantially improved, the service life is longer during cutting, the cutting speed is higher, and the rate of finished products is larger.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

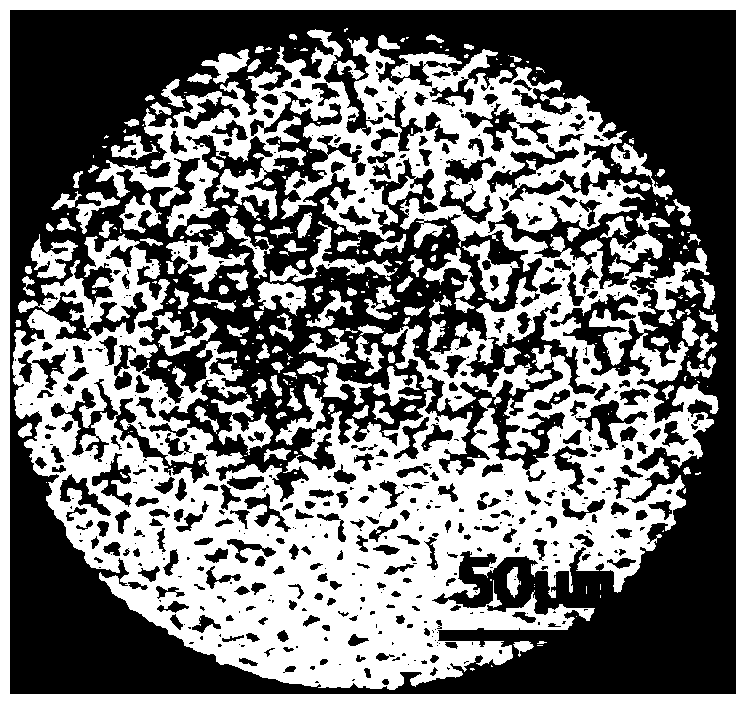

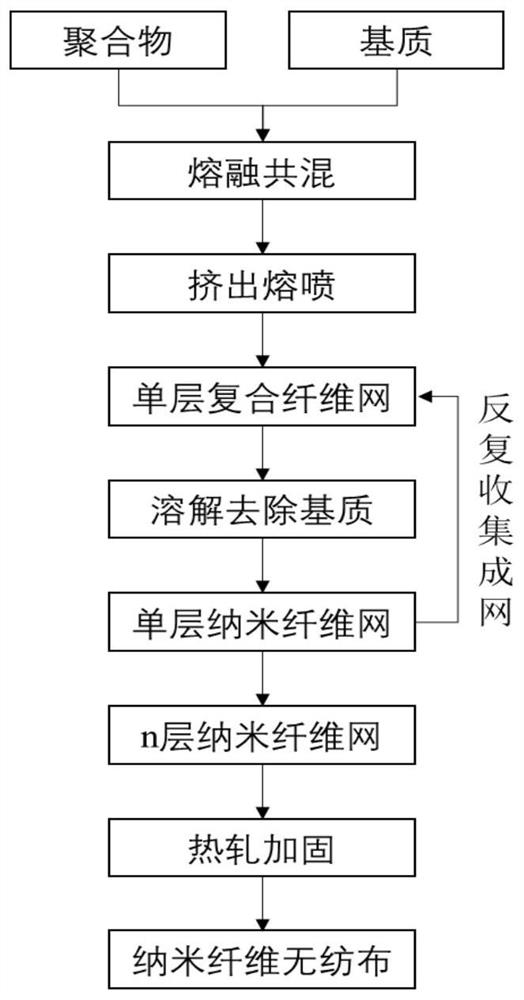

A kind of preparation method of nanofiber non-woven fabric

ActiveCN110396771BReduce thicknessNo pollution in the processFilament forming substance formingMelt spinning methodsPolymer scienceNanofiber

The invention discloses a preparation method of a nanofiber non-woven fabric. A thermoplastic polymer and a substrate which have thermodynamic incompatibility performance are subjected to melt blending according to a certain mass ratio, through melt extrusion and melt blowing, composite fibers are obtained, and the single-layer composite fibers are deposited on a receiving device; under the adhesion effect of the composite fibers, a single-layer composite fiber web is obtained; the substrate in the composite fiber web is dissolved and removed by adopting a solvent, a nanofiber web with a thermoplastic polymer phase is obtained, then the same method is adopted for collecting the second polymer nanofiber web layer, the third polymer nanofiber web layer,..., and the n polymer nanofiber web layer on a single-layer nanofiber non-woven fabric in sequence, and finally, the nanofiber non-woven fabric is obtained through hot rolling reinforcement treatment. By means of the preparation method, the nanofiber non-woven fabric with the nanofiber diameter smaller than 200 nanometers and the thickness of 0.2-5 microns can be prepared, and the preparation method of the nanofiber non-woven fabric has the advantages that the fiber diameter uniformity and strength are high, the preparation method is simple, the cost is low, and large-scale preparation can be achieved.

Owner:WUHAN TEXTILE UNIV +1

Yarn made of short fibers obtained by stretching and controlling fracture of long fibers and articles thereof

ActiveCN114059206AHigh strengthGood diameter uniformityWeft knittingWarp knittingYarnPolymer science

The invention provides a yarn made of short fibers obtained by stretching and controlling fracture of long fibers and a product thereof. Each single-strand yarn comprises a plurality of tightly combined short fibers. The plurality of tightly combined short fibers are obtained by stretching N strands of long fiber bundles and controlling fracture, and are spun by a spinning process, and N is a natural number. According to the invention, within a sampling length equal to or less than 10 meters, the ratio of the number of short fibers having a length equal to or greater than 60% of the set fiber length among the plurality of short fibers to the total number of the plurality of short fibers is equal to or greater than 60%. The fiber length is set to be equal to or greater than 65 mm. The weight distribution dispersion of the average length of the single yarn according to the invention is equal to or less than 60%.

Owner:郭俊荣

Shaping method of slight ceramic tube

InactiveCN100579750CImprove body strengthGuaranteed diameter uniform performanceCeramic shaping apparatusClay processing apparatusHigh densityHigh pressure

The invention discloses a slender ceramic pipe and a shaping method thereof. The slender ceramic pipe with high density and good roundness can be produced according to the shaping method. The manufacture method of bidirectional isopiestic shaping for the slender ceramic pipe comprises the steps that: briquettes disposed by vacuum refining mud and mossiness are formed and dried by a vacuum pipe extruder; a flexible internal die is arranged on the internal pore wall of the briquette; a flexible external die is sleeved on the external wall of the briquette pipe; furthermore, a flexible internal die piston and a flexible external die piston hermetically seal two ends of the briquette ; the flexible internal die piston is provided with a central through hole; the briquette shaping component is arranged in a high-pressure container to carry out the internal and external bidirectional isopiestic shaping; the finished slender ceramic pipe is then gained by demoulding, normal burning and long processing. The slender ceramic pipe provided by the invention can be widely applied to the ceramic roller in kilns or other situations which require the slender ceramic pipes.

Owner:何锡伶

An ovd deposition device with high deposition pass rate

ActiveCN110194588BDeposition went wellGuaranteed mobilityGlass making apparatusSlider bearingClassical mechanics

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

A kind of manufacturing method of high-rise elevator wire rope

The invention discloses a manufacturing method of steel wire ropes for high-rise elevators, comprising the following steps: a, selecting wires; b, drawing at a time; c, performing heat treatment; d, drawing at a second time; e, entwisting strands, entwisting the steel wires drawn at a second time according to needed structures and specifications to form outer layer strands and inner layer strands for the steel wire ropes and repeatedly bending after forming the strands to manufacture steel wire rope strands; f, entwisting center sub-ropes, packaging and entwisting 3 helm cores with 8 inner layer strands obtained in the step e to manufacture the centre sub-ropes of the steel wire ropes; j, entwisting the ropes, packaging and entwisting the centre sub-ropes obtained in the step f with 8 outer layer strands obtained in the step e to entwist the needed steel wire ropes, and repeatedly bending after forming the strands to manufacture the steel wire ropes. The steel wire ropes manufactured by using the manufacturing method of the steel wire ropes for the high-rise elevators have the advantage of good diameter uniformity; the elevators have the advantages of good comfort level and stability in the operation process; the steel wire ropes are suitable for the elevators used by high-rise buildings.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

A kind of composite melt-blown non-woven fabric and preparation method thereof

ActiveCN110438666BImprove adsorption capacityHigh quality lightweight warmthNon-woven fabricsPolymer scienceNonwoven fabric

The invention provides a composite melt-blown non-woven fabric and a preparation method thereof. The composite melt-blown non-woven fabric comprises at least one superfine fiber layer and at least onecommon fiber layer. The superfine fiber layers and the common fiber layers are superposed layer by layer through multi-nozzle melt spinning, and are finally reinforced to obtain the composite melt-blown non-woven fabric. Each superfine fiber layer is a superfine fiber layer with the diameter less than 500 nm, and is obtained by melt blended spinning of thermoplastic polymer and a matrix which areincompatible thermodynamically and removing the matrix through solvent extraction; each common fiber layer is obtained by melting and spinning a thermoplastic polymer without a matrix; and finally the composite melt-blown non-woven fabric with excellent comprehensive performance is obtained through hot rolling reinforcement treatment. The problems of complex preparation method, difficulty in large-scale production and nonuniformity of fiber performance in the prior art are solved, and a new idea is provided for preparing the functional non-woven fabric.

Owner:WUHAN TEXTILE UNIV +1

OVD deposition equipment and method for automatically adjusting deposition speed to be matched with target weight

PendingCN112299702AImprove pass rateGood diameter uniformityGlass deposition burnersWorkbenchElectrical and Electronics engineering

The invention creatively provides OVD deposition equipment capable of automatically adjusting deposition speed to match target weight. The equipment comprises a fixing frame and a support frame whichare correspondingly arranged on a workbench of a deposition box body, wherein a chuck rod for fixing a core rod is arranged on the fixing frame, a gravity sensor for monitoring the weight of the corerod in real time is arranged on the support frame, a deposition device connected with the gravity sensor is mounted on the workbench, a controller in the deposition device is matched with the sprayingamount of each shaft according to the weight fed back by the gravity sensor in real time, the deposition device comprises a feeding unit for providing raw materials for a blowtorch through a discharging pipe, and a differential pressure sensor is installed on the discharging pipe. According to the equipment and the method provided by the invention, the comprehensive percent of pass of wire drawing of the preform can be effectively improved, and the efficiency and the deposition capacity of OVD deposition equipment are improved.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com