Shaping method of slight ceramic tube

A ceramic tube and slender technology, which is applied in the field of forming slender ceramic tubes, can solve the problems of ceramic tube blanks not having fluidity, slender ceramic tube blanks, poor roundness of finished ceramic tubes, etc., to achieve Guaranteed uniform diameter performance, less damage to semi-finished products, and low firing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

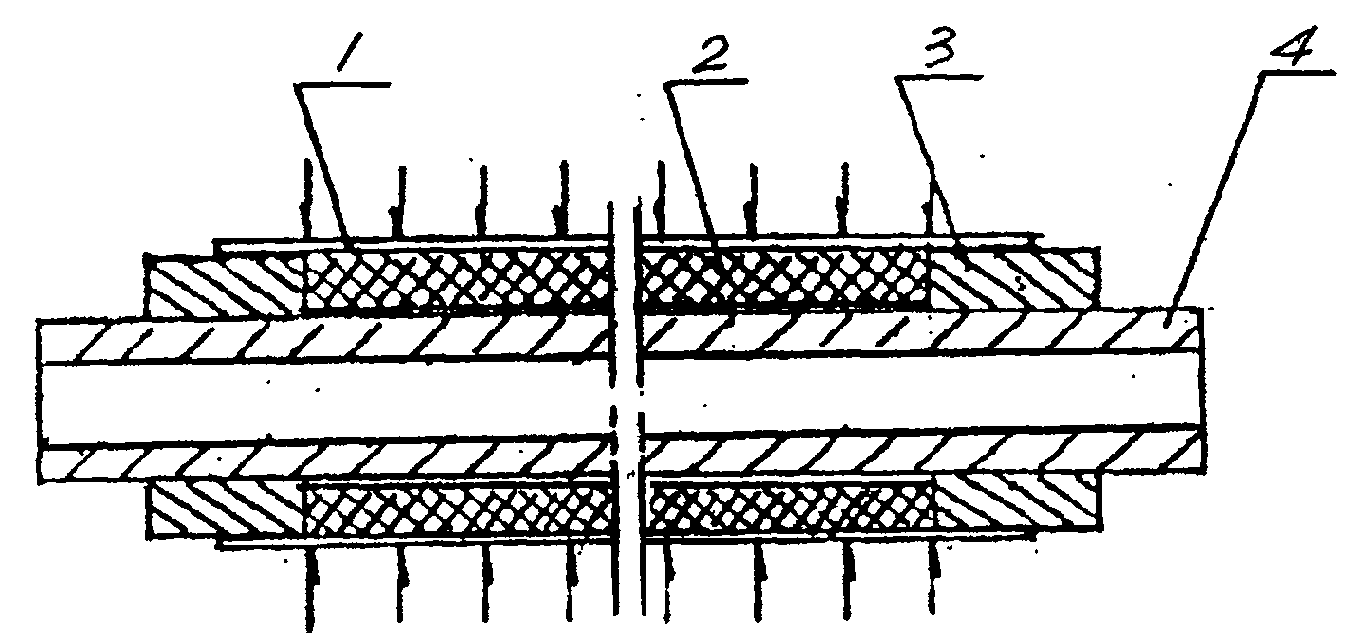

[0045] The slender ceramic tube 18-1 made by the present invention through two-way isobaric shaping refers to Figure 5 As shown, the B-B sectional view of the elongated ceramic tube 18-1 is shown in Figure 6 shown. The manufacturing method steps of the elongated ceramic tube 18-1 of the present embodiment are as follows:

[0046] (1) The following formula mud with a water content of 15% is stale for 2-3 days after vacuum refining mud: calculated in weight percentage, aluminum oxide 20, corundum sand 35, clay 30.

[0047] (2) through stale processing mud billet, water content is controlled at 14%, is formed by vacuum extruding machine, and extruding length is 3000mm, and external diameter is Φ 60mm, and pipe wall thickness is the slender ceramic pipe body 18 of 10mm, place On the V-shaped aluminum tank, put it into the drying room for drying, and the drying temperature range is 50°C-80°C.

[0048] (3) When the elongated ceramic tube body 18 is dried in the drying chamber t...

Embodiment 2

[0053] The external dimensions of the elongated ceramic tube body 18 in this embodiment are: the length is 6000 mm, the outer diameter is Φ150 mm, and the tube wall thickness is 15 mm. Formula mud: calculated by weight percentage, alumina 23, corundum sand 28, clay 35, water 14. The moisture content of the mud body after stale treatment is 13%. The pressure for the inner and outer two-way isobaric shaping of the ceramic tube blank is 110Mpa, and the pressure is maintained for 3 minutes. All the other processing methods and steps are the same as in Example 1.

Embodiment 3

[0055] The external dimensions of the elongated ceramic tube body 18 in this embodiment are: the length is 1000 mm, the outer diameter is Φ20 mm, and the tube wall thickness is 4 mm. Formula mud: calculated by weight percentage, alumina 30, corundum sand 25, clay 32, water 13. The moisture content of the mud body after stale treatment is 12%. The pressure for bidirectional isobaric shaping of the ceramic tube blank inside and outside is 90Mpa, and the pressure is maintained for 2 minutes. All the other processing methods and steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com