Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1373 results about "Small head" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

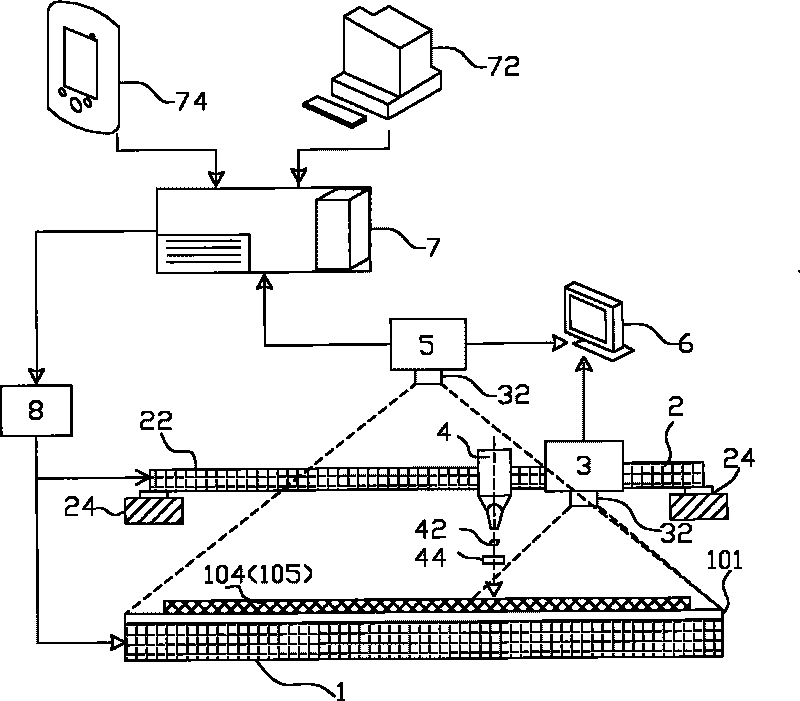

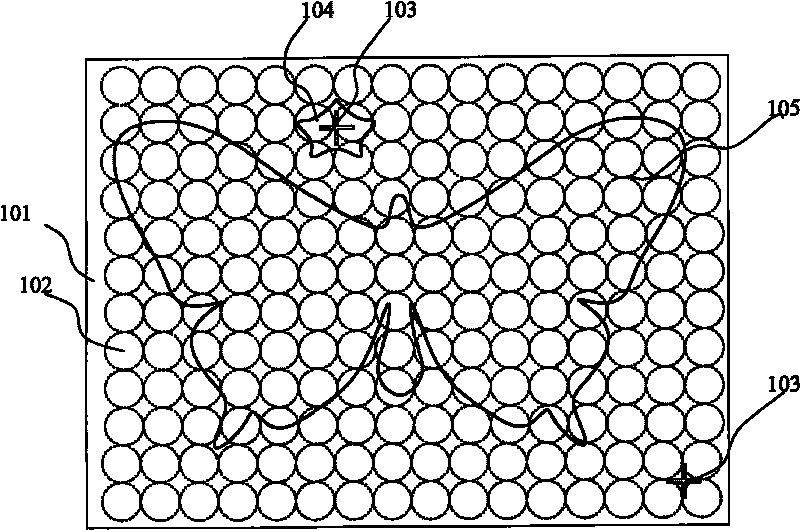

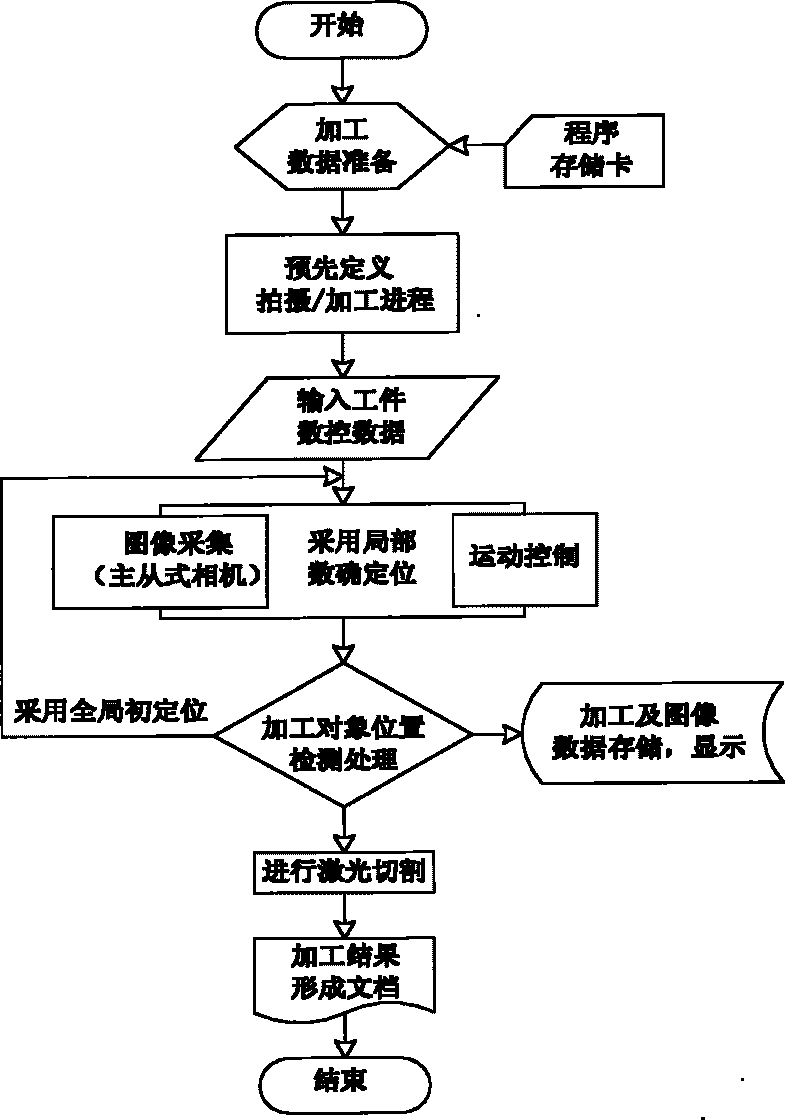

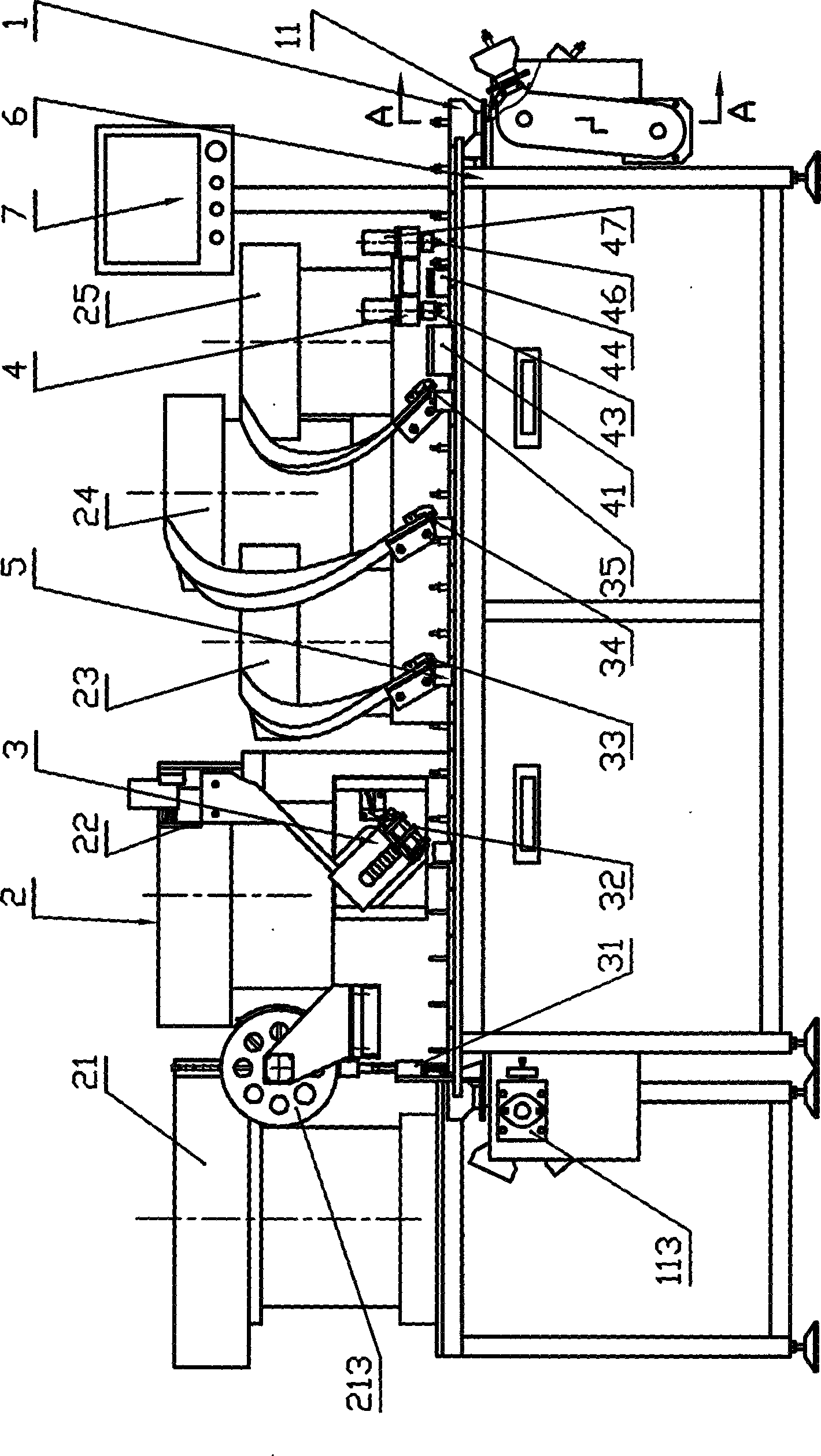

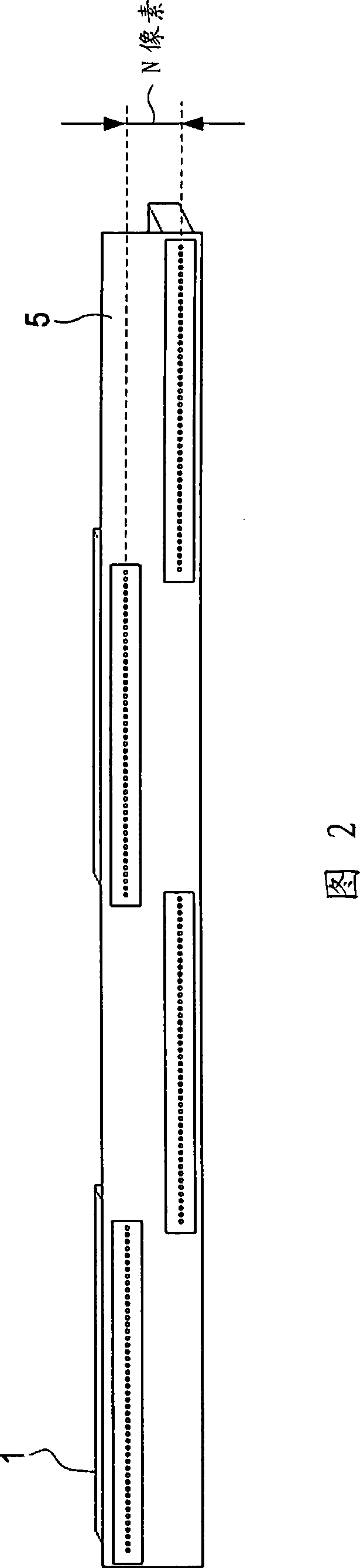

Intelligent laser cutting system provided with master-slave camera and cutting method thereof

ActiveCN101733558AOvercoming distortion effectsImprove measurement efficiencyLaser beam welding apparatusVisual field lossComputer terminal

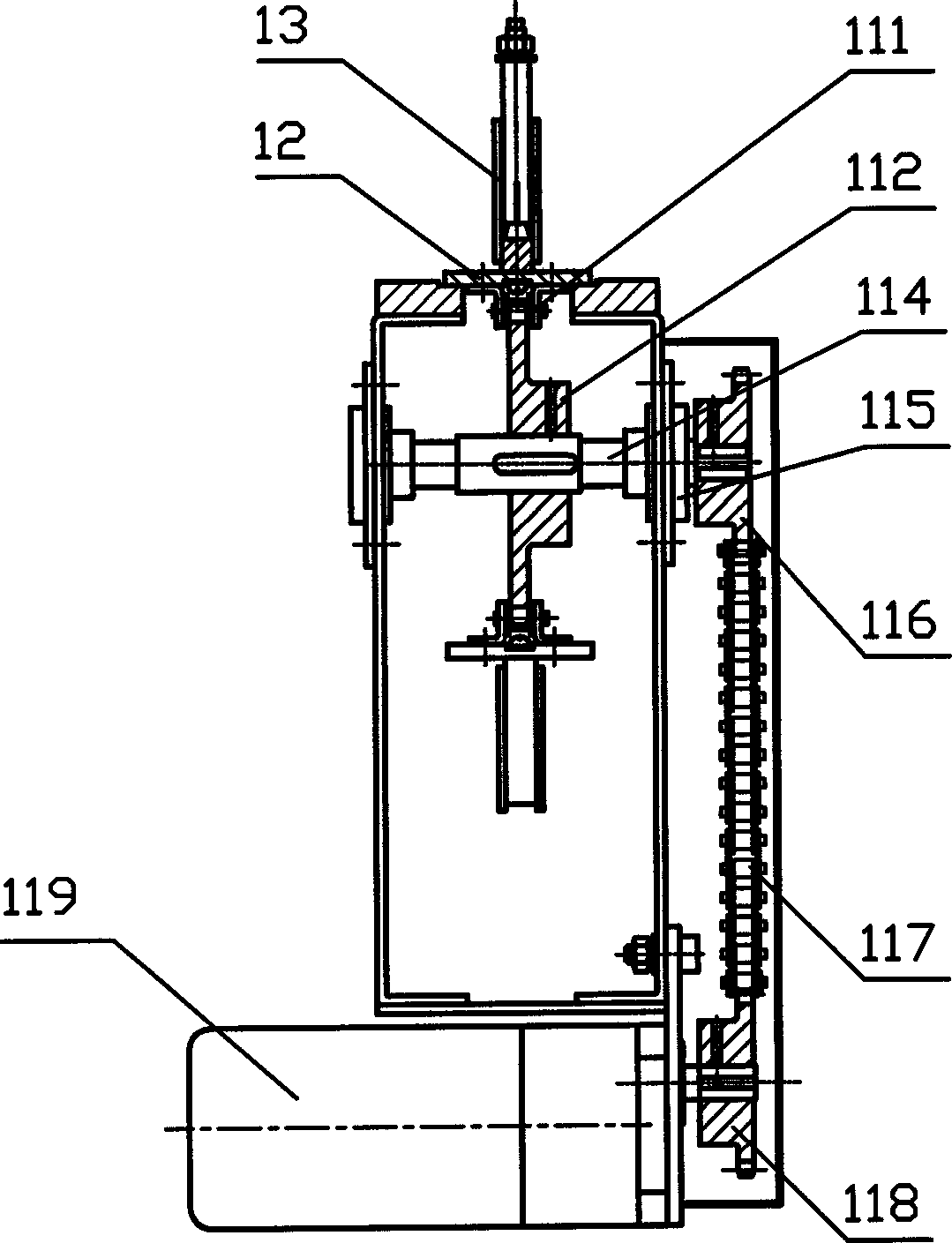

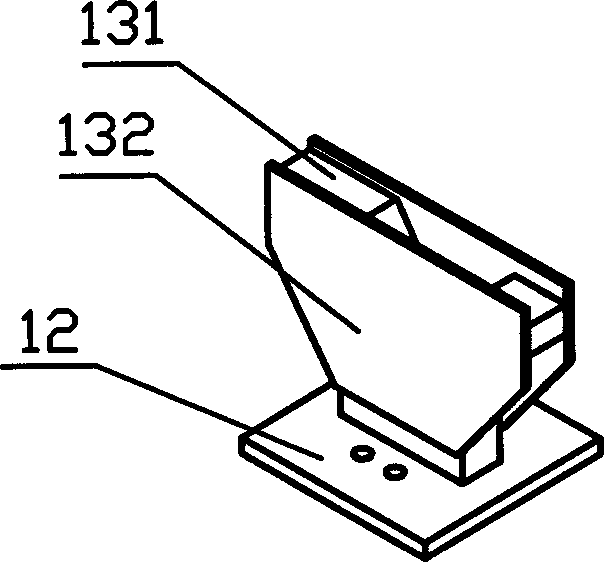

The invention provides an intelligent laser cutting system provided with a master-slave camera and a cutting method thereof. The intelligent laser cutting system provided with the master-slave camera comprises a worktable, a small head stock, a local slave camera and a laser head, a global master camera, a monitoring terminal, a main controller and a driving motor, wherein the worktable is positioned at the bottom; the small head stock is arranged above the worktable; the local slave camera and the laser head are fixedly arranged with the small head stock; the global master camera is hung on the top; the monitoring terminal is used for monitoring images of the global master camera and the local slave camera; the main controller is electrically connected with the global master camera; the driving motor is controlled by the main controller and is connected with the worktable and the small head stock; a lens visual field of the global master camera comprises the entire worktable; the driving motor drives the small head stock to move; and the local slave camera moves synchronously along with the small head stock and performs local image acquisition on the worktable. High-efficiency and high-accuracy laser cutting processing can be performed on various applicable objects without depending on the accuracy of the main controller of a laser cutting machine and a mechanism.

Owner:GUANGDONG HANS YUEMING LASER GRP CO LTD +1

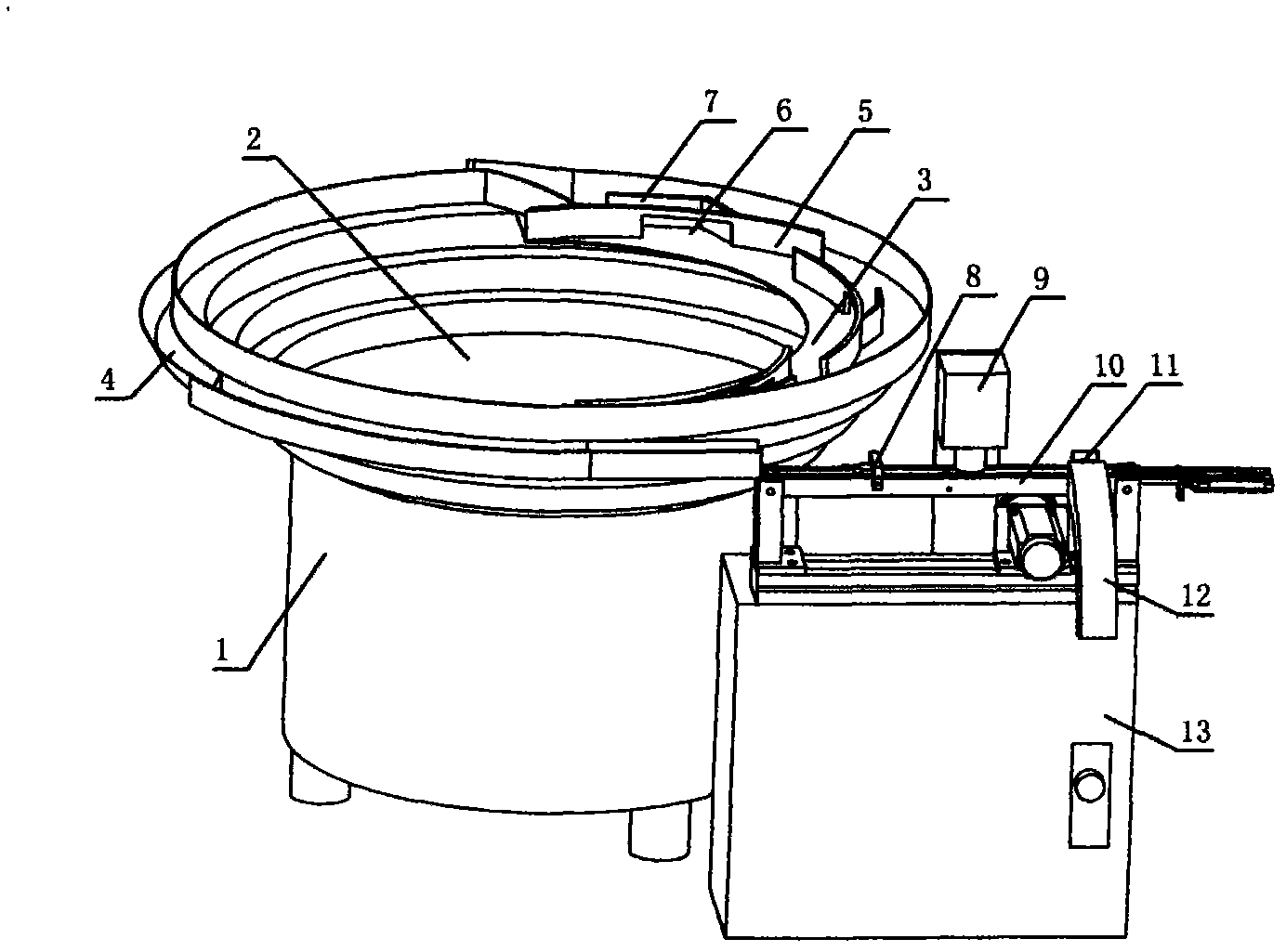

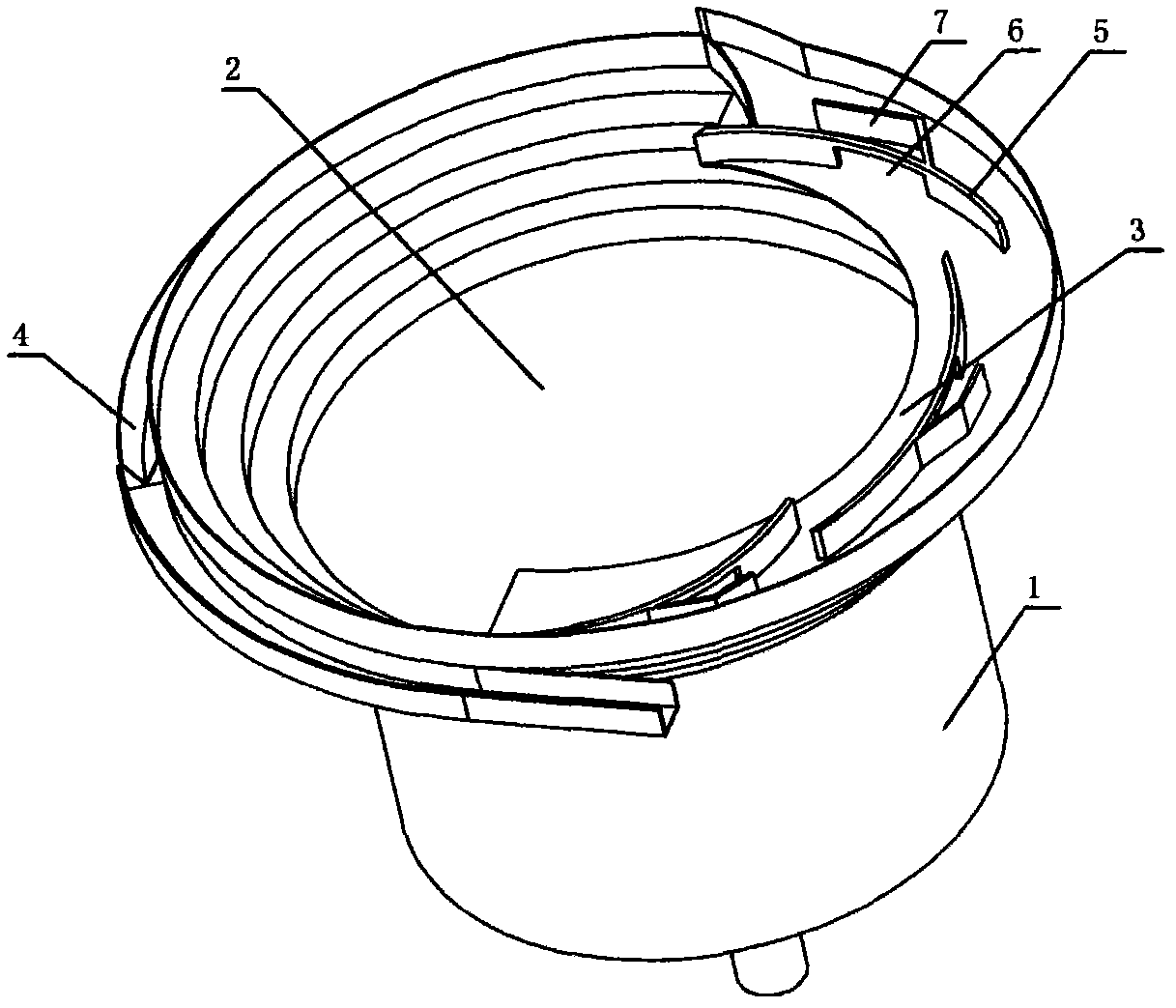

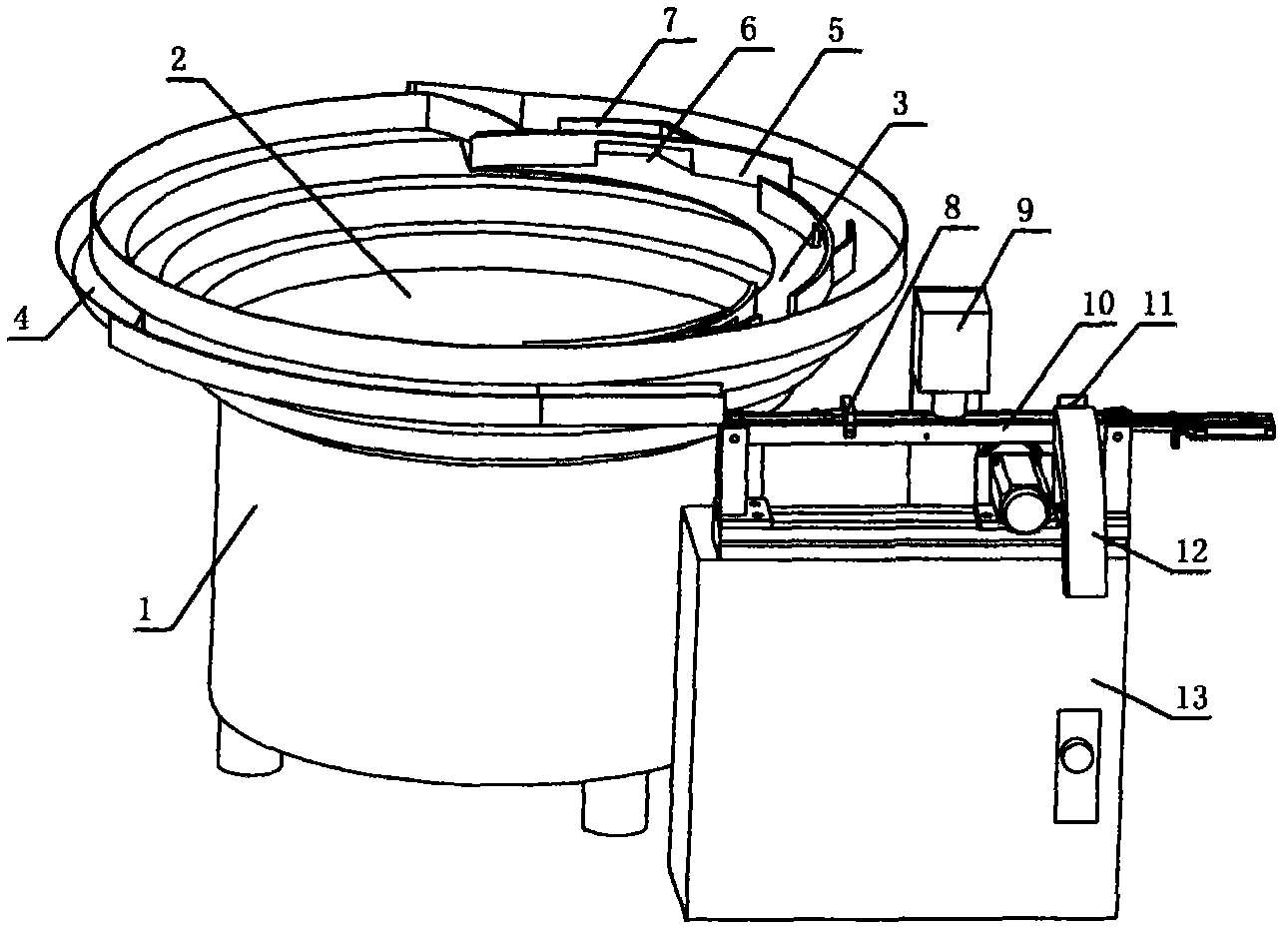

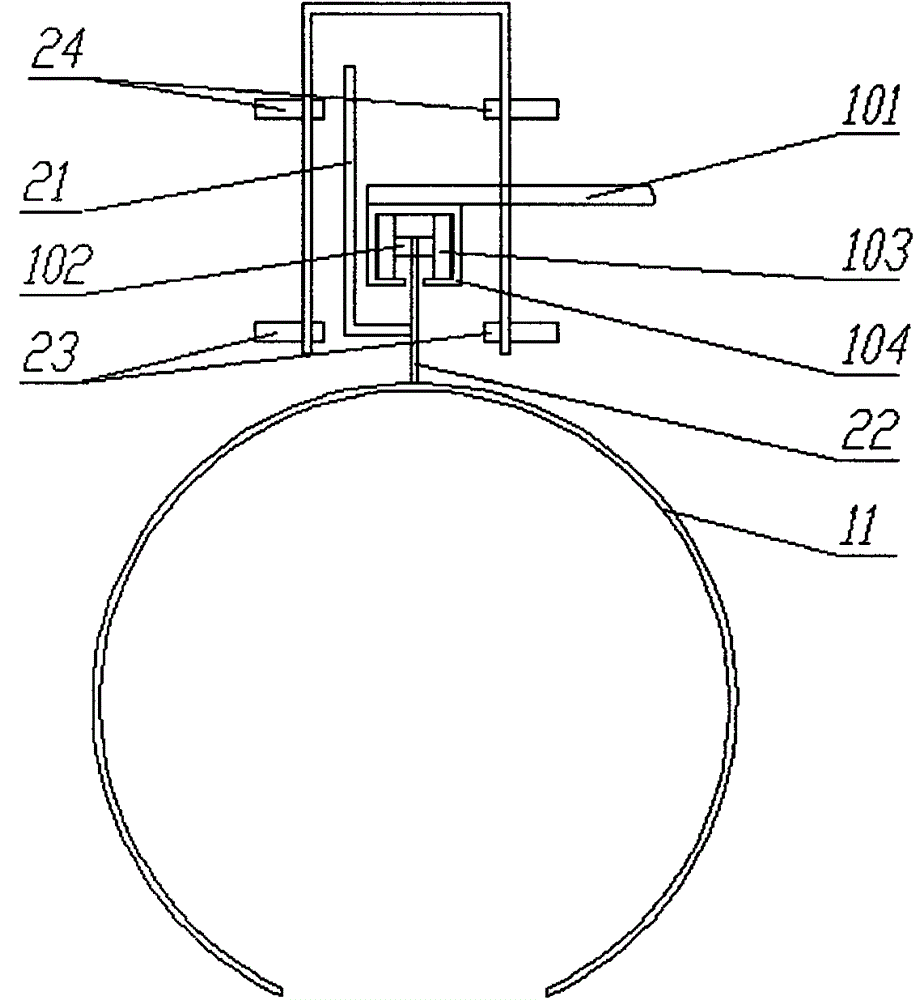

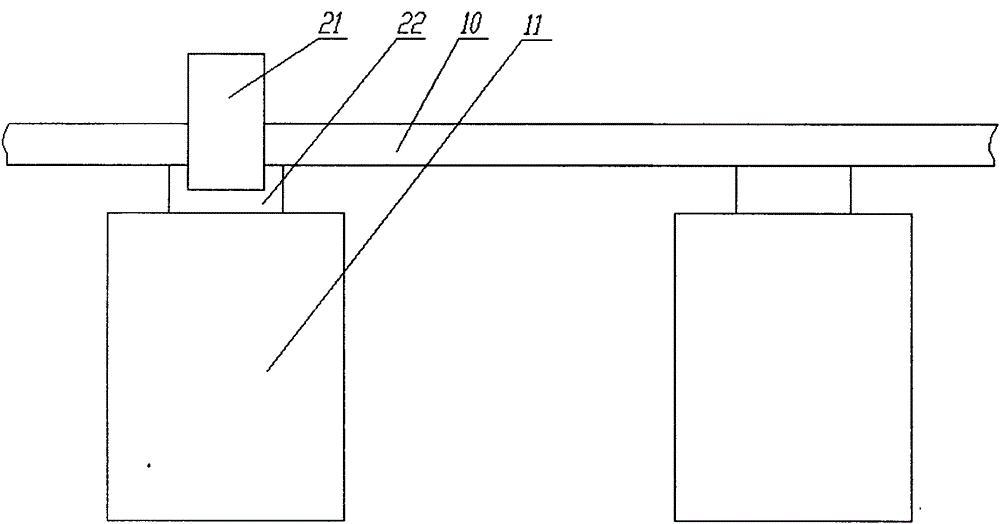

Method and equipment for automatically feeding badminton feathers

InactiveCN102658958AReduce volumeReduce maintenance costsControl devices for conveyorsJigging conveyorsEngineeringFeather

The invention discloses a method and equipment for automatically feeding badminton feathers. The feathers are sorted, kept in the same direction and turned in the vibrating conveying process under the combined action of a vibrator, a guide channel, a large and small head distinguishing mechanism and a conveying channel, and the conveyed feathers meet the requirements of the same direction and consistent bending angles by combining the recheck control of a subsequent detection mechanism. The whole feather feeding process is automatically finished, conveying efficiency is high, conveying quality is stable and reliable, and the subsequent feather inserting process can be continuously performed for 24 hours; and the corresponding production equipment is small in size, low in maintenance and production cost, high in loading speed and completely suitable to be matched with the conventional badminton production equipment.

Owner:SHANTOU HONGSHEN SPORTS GOODS

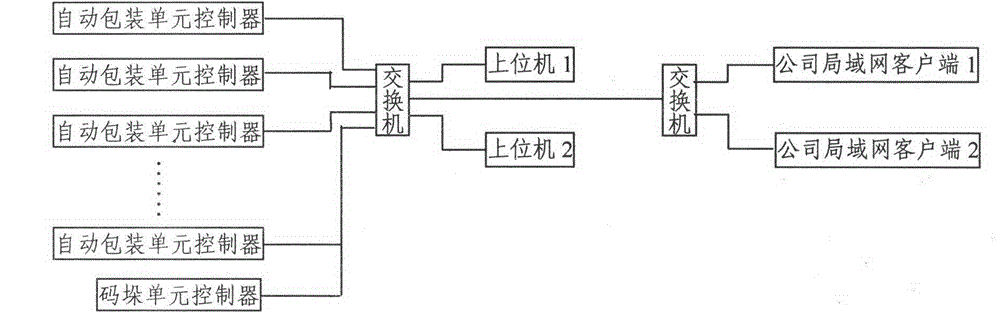

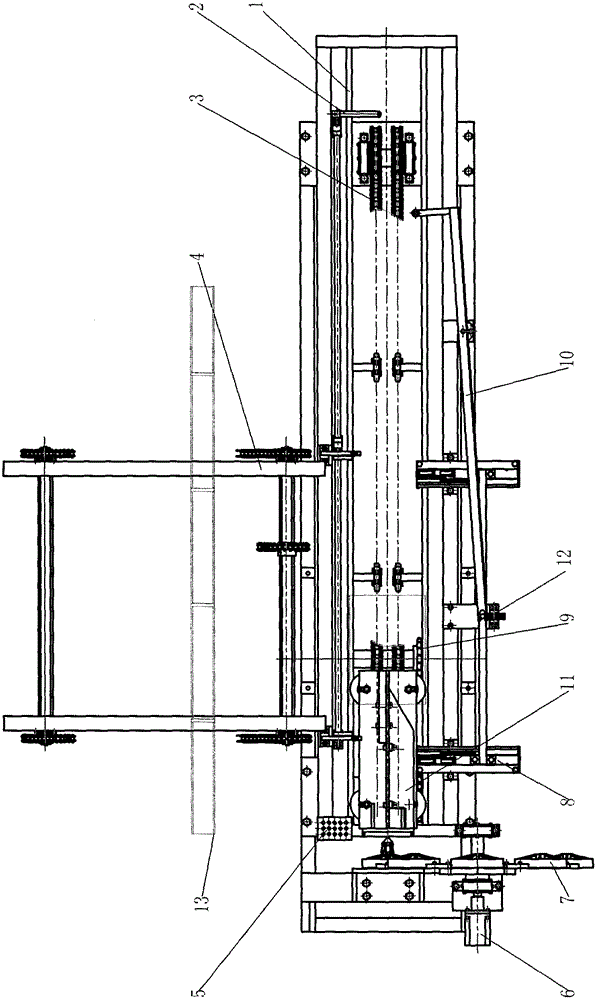

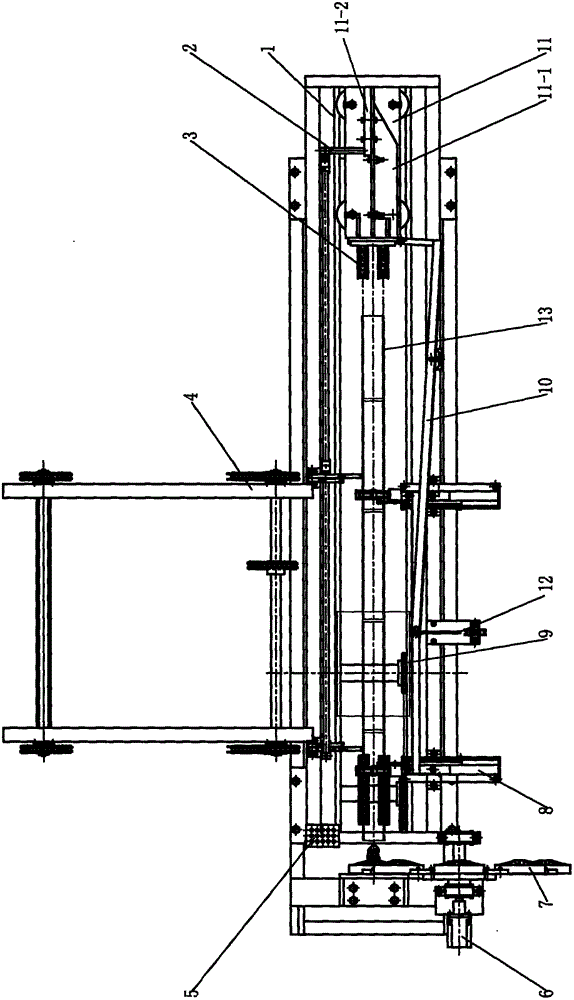

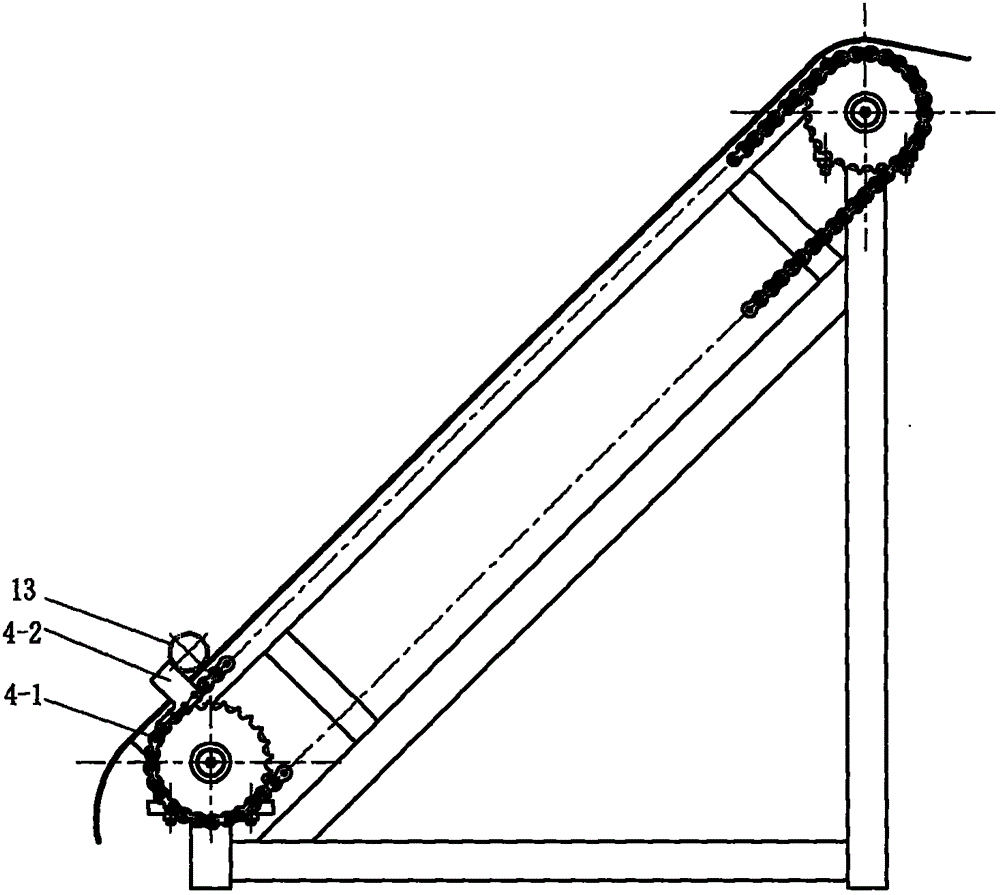

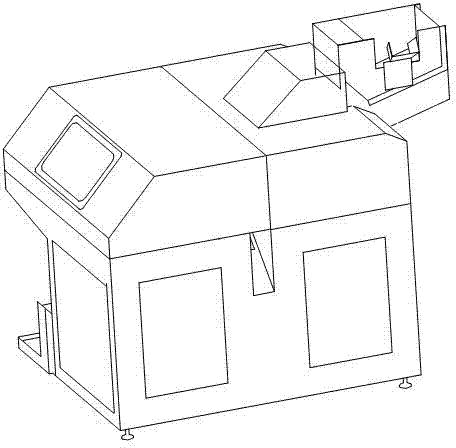

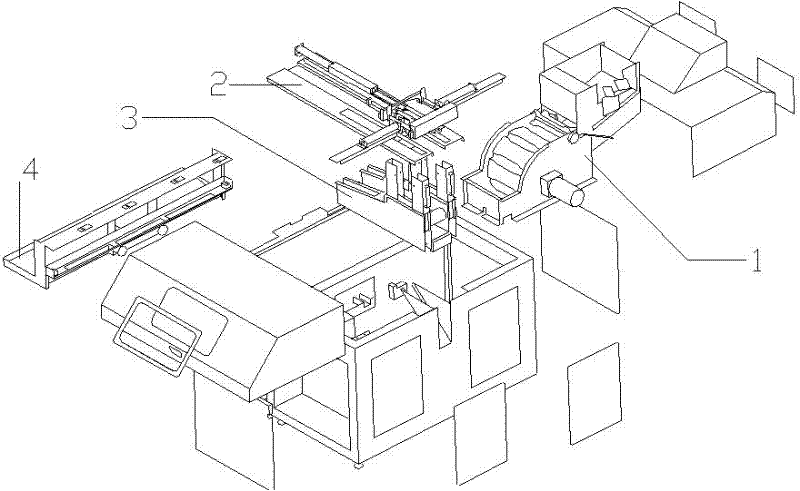

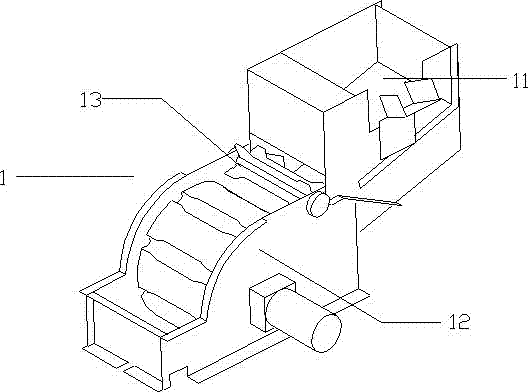

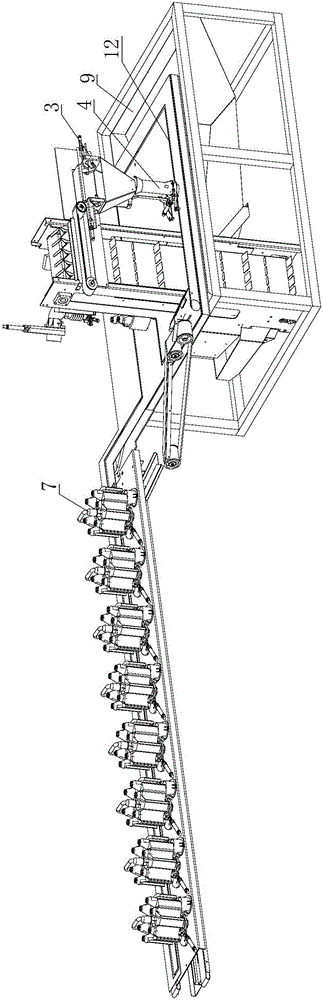

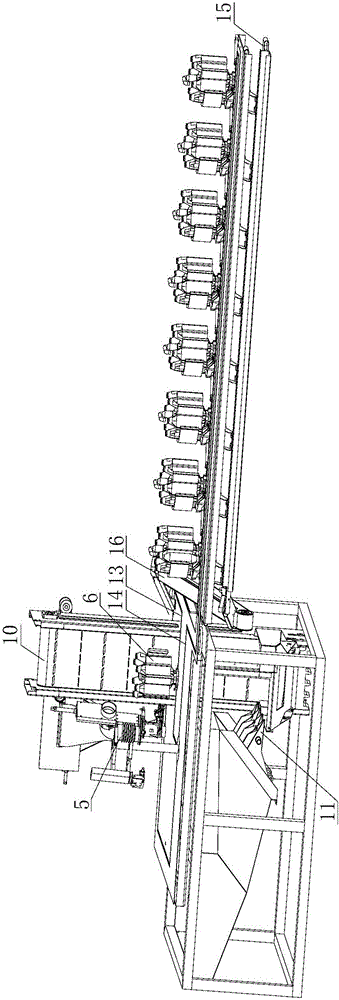

Automatic packaging system of cheeses

InactiveCN104443476AReduce packaging laborPackaging automatic controlIndividual articlesControl systemEngineering

The invention relates to the packaging of cheese products produced by spinning enterprises, in particular to an automatic packaging system of cheeses. An automatic packaging unit can automatically and selectively unload the cheeses from a cheese conveying device according to information stored in an upper computer of a control system, cheese varieties and groups thereof for packaging; the packaging process comprises packaging of plastic bags, loading of woven bags, sealing of the woven bags, binding of the woven bags and stacking of the woven bags; the final packaging mode is the woven bags; the numbers of the cheeses packaged in all the woven bags are appointed numbers; and for conical cheeses, the directions of large and small heads of any two adjacent cheeses in the woven bags are opposite, so that the demands of automatic grouping and packaging of the cheeses of present domestic spinning enterprises in the packaging process according to the varieties can be satisfied.

Owner:TIANJIN POLYTECHNIC UNIV

Novel numerical control bamboo splitting machine

ActiveCN102717414AAchieve broken bambooRealize empty back movementWood splittingVeneer manufactureNumerical controlMeasurement device

The invention relates to a novel numerical control bamboo splitting machine, which includes a lathe bed guide rail, a rotation mechanism, a driving chain, a bamboo tube loading mechanism, a bamboo tube diameter measurement device, a stepping motor, a cutter combination assembly, a bamboo centring combination assembly, a transmission system, a swinging mechanism, a push plate combination assembly, and a sash weight, and is characterized in that a push plate combination component is arranged on tool body guide rails; a driving chain for driving the push plate combination component to move back and forth is arranged between the two guide rails; a rotational cutter disc combination component is arranged at the front ends of the tool body guide rails; a bamboo tube loading mechanism is arranged on right sides of the tool body guide rails; two movable bamboo tube centering combination components are arranged on the upper left sides of the tool body guide rails; and when the push plate combination component does backlash motion, the bamboo tube loading mechanism conveys a bamboo tube into a measuring device to measure the diameter of a small head of the bamboo tube, the bamboo tube enters two V-shaped bearings, and combination cutters which are matched are rotated to the center of the bamboo tube and aligned; and a transmission system is reversed, and the push plate combination component pushes the bamboo tube to the combination cutters, so that the bamboo tube is split into bamboo chips. Compared with the conventional bamboo splitting machine, the numerical control bamboo splitting machine has the advantages that automatic loading, automatic tool changing and automatic centering of the bamboo tube are realized, one operator is reduced, the labor strength is lowered, the width error of the split bamboo clips is reduced, and the utilization rate of bamboo woods is improved.

Owner:沛县汉腾建设发展有限公司

Tube managing machine

The invention relates to a tube managing machine which comprises a case. The tube managing machine is characterized in that the case is internally provided with a tube storing mechanism (1), a tube sorting mechanism (2) and a tube turning mechanism (3). The tube sorting mechanism (2) is connected with a PLC (Programmable Logic Controller) through multiple photoelectric sensors and color sensors to control a main driving cylinder (23), a downward turning cylinder (28) and branch cylinders (29) for distinguishing the existence of yarns and colors of various yarns; a small head of a bobbin is enabled to point downwards through the tube turning mechanism (3) and is transmitted into a cart through a conveying belt (34). The tube managing machine disclosed by the invention can be used for identifying bobbins with or without yarns, and distinguishing the colors of the bobbins, straightening out big and small heads of the bobbins without yarns, and realizes automation of the whole process without manual operation, thus manual operating intensity of workers is greatly reduced and employment number of enterprises and ease employment pressure of enterprises can be effectively decreased.

Owner:江阴市凯业纺织机械制造有限公司

Automatic delivery device for bobbin yarn

ActiveCN106115371AEasy to separateHigh degree of automationFilament handlingConveyor partsBobbinHead finding

The invention relates to an automatic delivery device for bobbin yarn. The automatic delivery device comprises a rack, wherein a feed inlet, an auxiliary hopper, a lifting belt, a large-small head overturning device and a bobbin yarn tubing device which sequentially delivery bobbin yarn are mounted on the rack; a yarn shovel provided with a scissors device is arranged between the feed inlet and the auxiliary hopper; a bobbin yarn separation plate is mounted on the lifting belt; a tray moving device is further arranged on the rack; the tray moving device comprises a channel I, an automatic head finding device, a channel II and a channel III; a bobbin yarn release device is arranged on the channel II; an output end of the channel II communicates with an input end of the channel I; an output end of the channel III is connected with an input end of a yarn head leaving device; an output end of the yarn head leaving device drops an empty tray on a lower conveying belt below; and a rising belt is arranged at an output end of the lower conveying belt. The automatic delivery device has the beneficial effects that the devices are mutually matched, after being separated from the bobbin yarn, the tray can be automatically collected and circularly utilized again, the automation degree is high, and the working efficiency is improved.

Owner:常州长荣纺织有限公司 +1

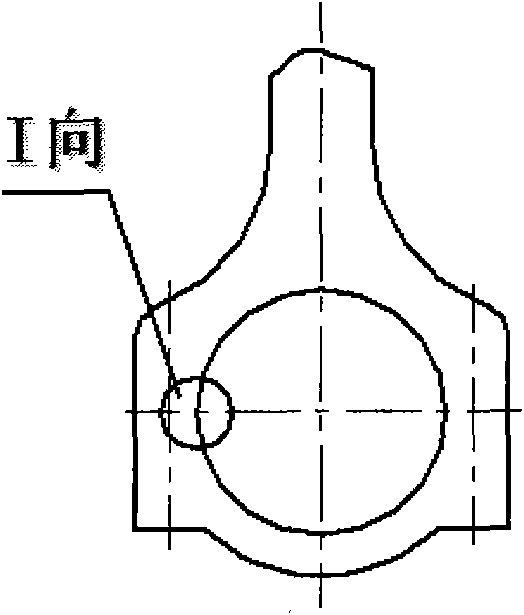

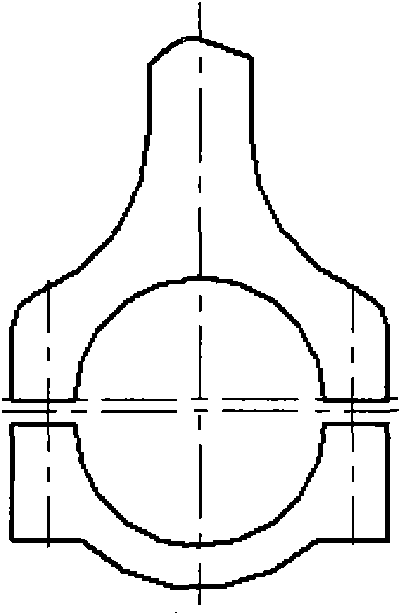

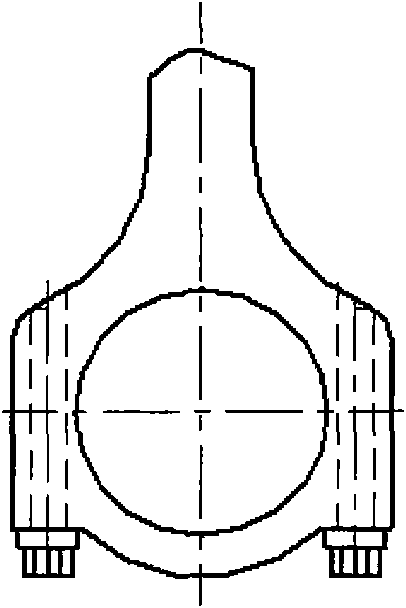

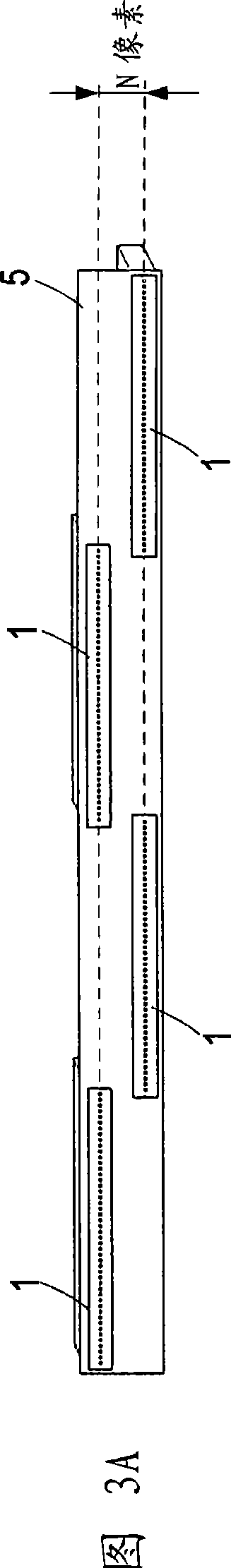

Machining process of engine connecting rod

The invention discloses a machining technology of an engine connecting rod. The machining process comprises the following steps: forging, blank making and cutting, and taking high carbon non-hardened steel as a raw material; main procedures of the forging and blank making: blanking, heating, blank making, blocker forging, finish forging, trimming, punching, normalizing after shaping, and forced cooling in a forced cooling mode so as to reduce the temperature of a forging parts below 600 DEG C in 10min; cutting after defect detection and powerful shot blasting; the main procedures of the cutting: coarsely grinding or milling two end faces, roughly boring a big head pore and a small head pore, drilling and tapping a bolt hole, and cutting and machining a cracking tank on the big head pore of the connecting rod by cracking tank machining equipment; putting the connecting rod into the cracking equipment for breaking due to expansion, and assembling bolts; and finely grinding the sides of the connecting rod, finely boring the big pore and the small head pore, washing and checking. The technical proposal can help save time, reduce manufacturing procedures and improve assembly accuracy of the connecting rod.

Owner:ZHEJIANG YUEJIN MACHINERY

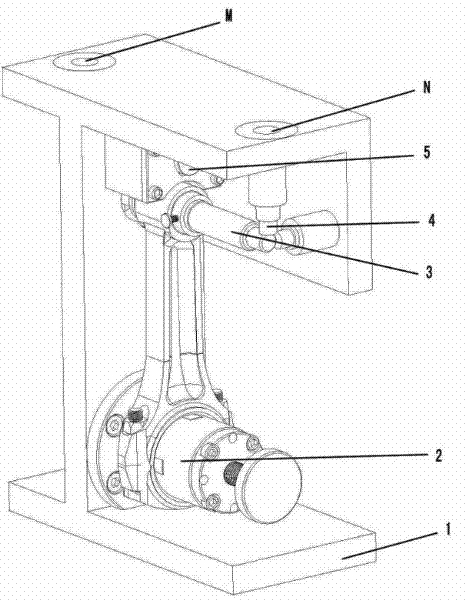

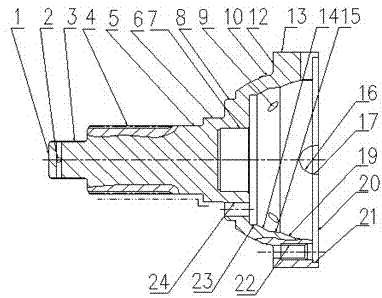

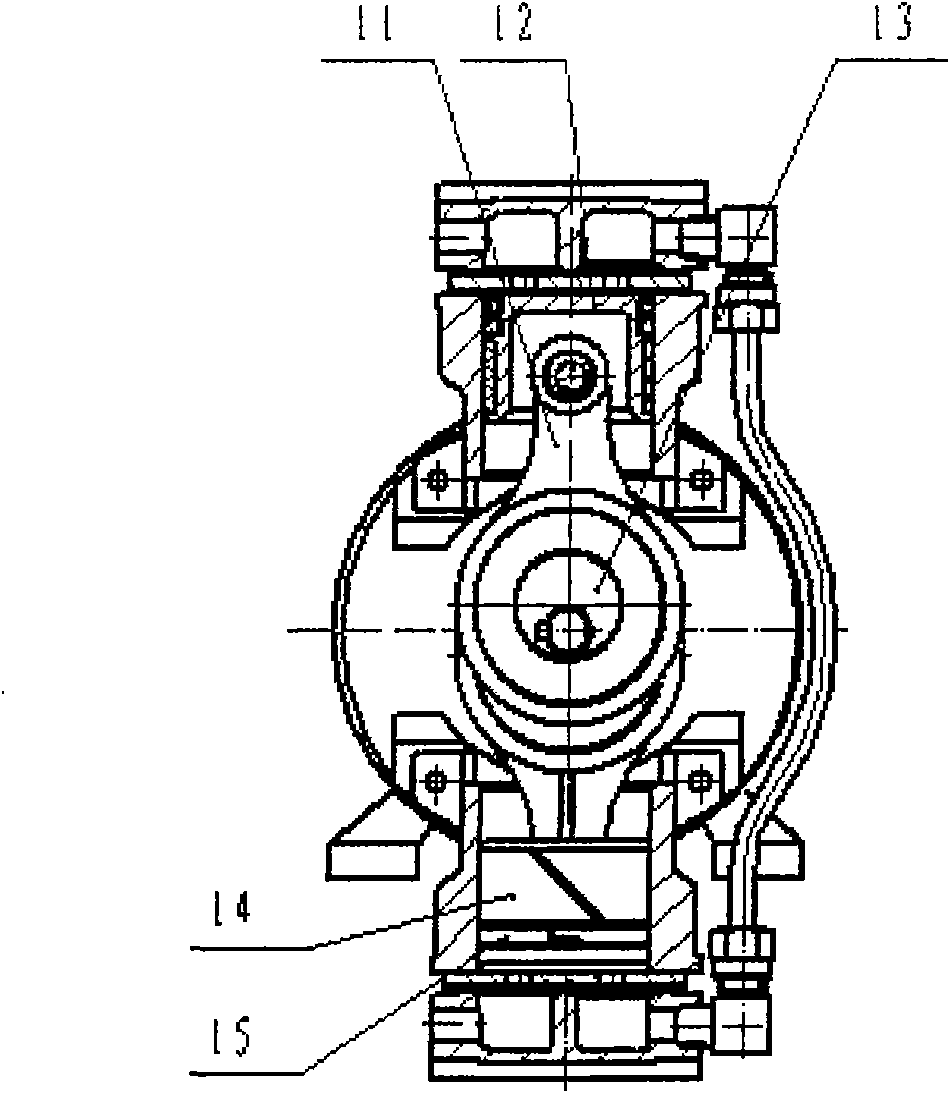

Automatic assembly equipment for fixed torque bolt of splitting connecting rod

InactiveCN101811251AMovement speed is adjustableAdjustable frequencyMetal working apparatusSlagEngineering

The invention relates to automatic assembly equipment for a fixed torque bolt of a splitting connecting rod, which is special equipment provided for the assembly process of a bolt of a splitting connecting rod, and is applicable to a straight incision connecting rod and a tilted incision connecting rod. The equipment mainly comprises a mechanical system and a pneumatic system, wherein the mechanical system comprises a connecting rod locating mechanism, a connecting rod compressing and oscillation deslagging mechanism, a connecting rod cover opening and closing mechanism, a fixed torque wrench and feeding structure, a bolt rotation and guidance mechanism, a bolt automatic feeding and separation mechanism and the like. The connecting rod mechanism comprises a connecting rod big-end locating piece and a connecting rod small-end locating piece, connecting rod big-end and small-end locating clamps are replaceable to suitable for the processing of connecting rods with different models, the connecting rod small-end locating clamp can be regulated and located within a certain range along X direction and Y direction, so as to be applied to the straight incision connecting rods and tilted incision connecting rods. The equipment of the invention is adopted to assembly the splitting connecting rod bolt, thus significantly improving the processing quality significantly, ensuring bolt assembly to meet design requirements, avoiding slag inclusion of surface of fracture, ensuring the reassembling accuracy of the splitting connecting rod and the like.

Owner:CHANGCHUN JIYANGHUAXIN SCI & TECH

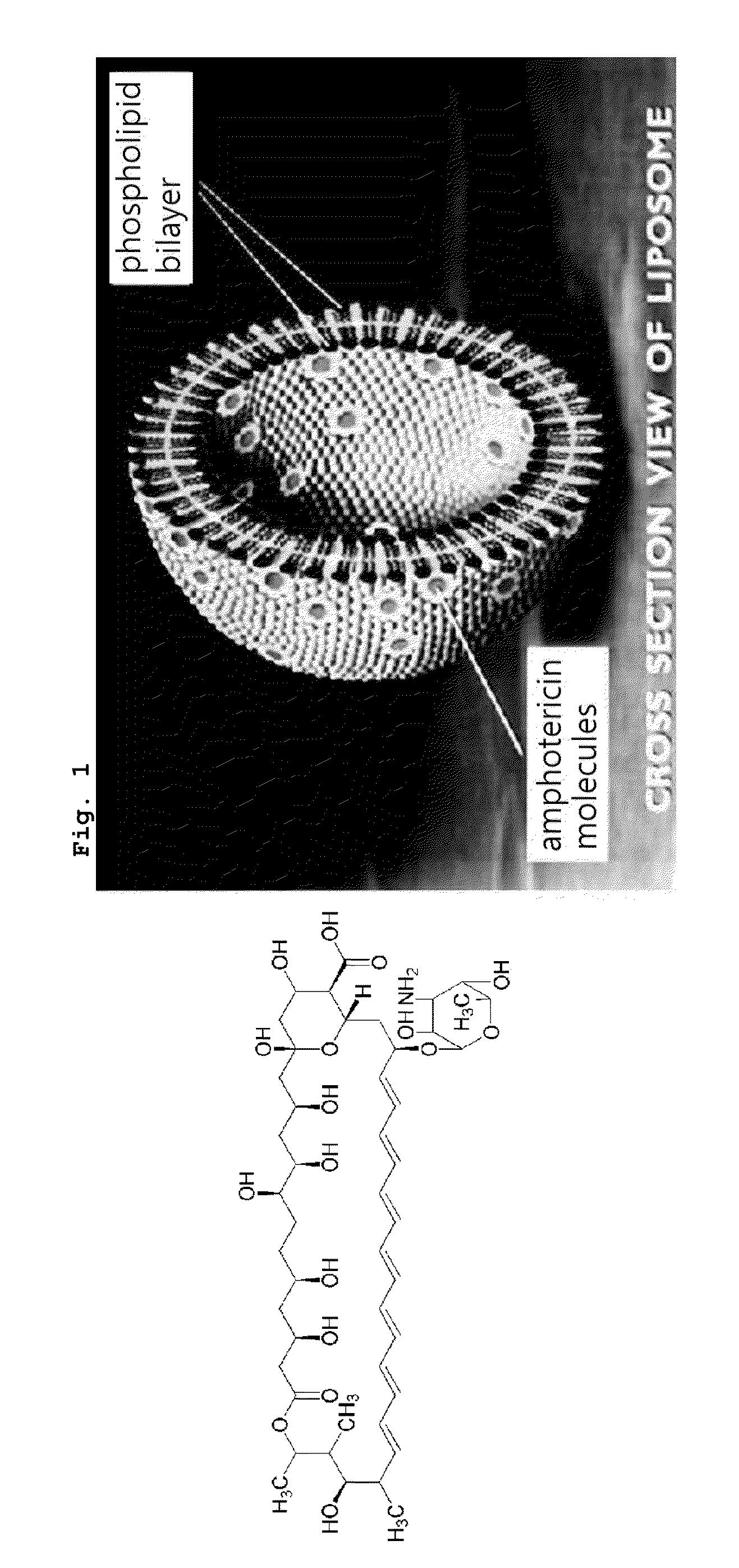

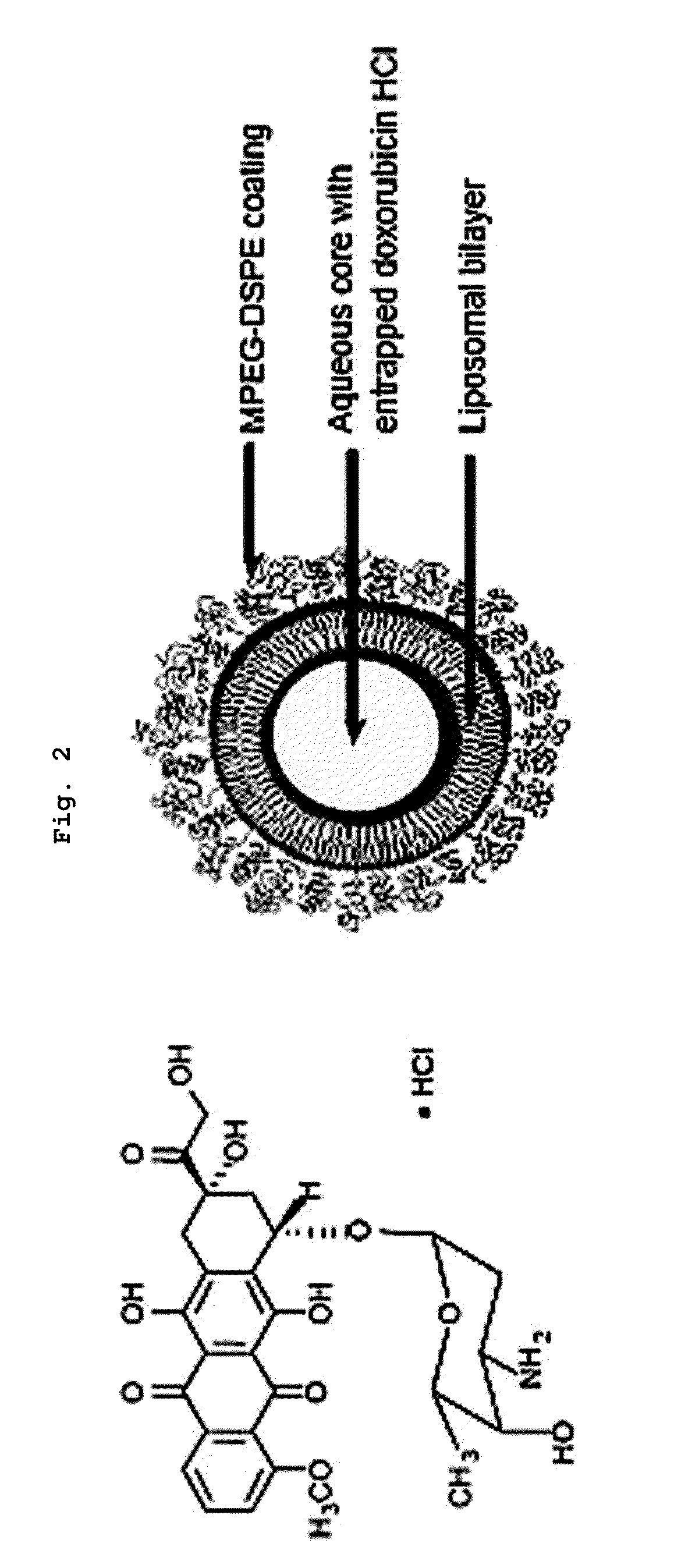

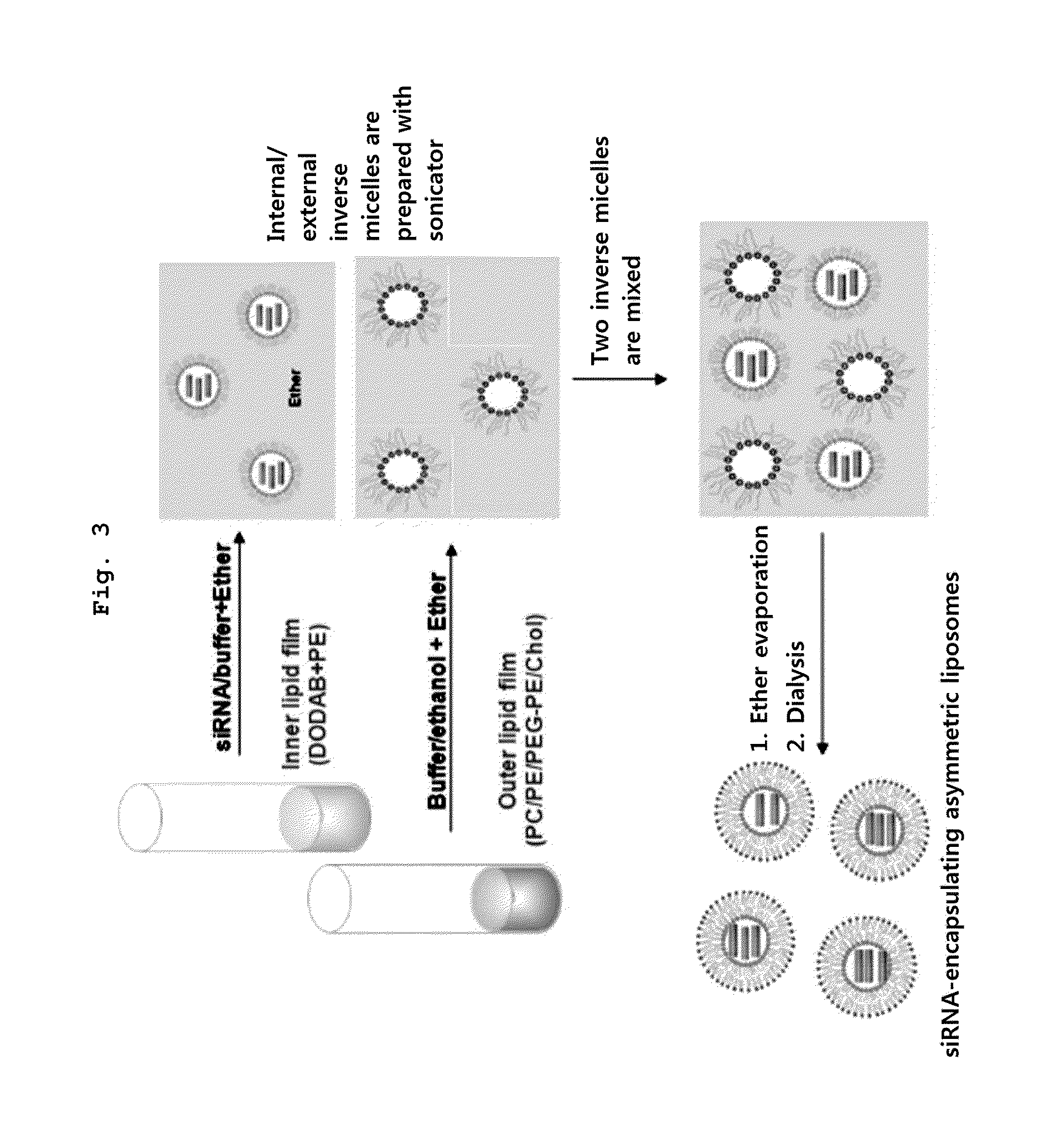

Asymmetric Liposomes for the Highly Efficient Encapsulation of Nucleic Acids and Hydrophilic Anionic Compounds, and Method for Preparing Same

InactiveUS20130149374A1Improve efficiencyCarbohydrate active ingredientsFermentationFluorescenceLiposome

The present invention relates to asymmetric liposomes for high encapsulation efficiency of nucleic acids and hydrophilic anionic compounds, and to a method for preparing same, and specifically, to asymmetric liposomes consisting of a cationic lipid having a small head group as an internal lipid and a neutral or PEGylated lipid having a big head group as an external lipid, wherein nucleic acids and / or anionic compounds are encapsulated in the internal lipid. According to the present invention, asymmetric liposomes, in which nucleic acids and hydrophilic anionic compounds are encapsulated with high efficiency, may be prepared, and thus the same may be used for various purposes, such as gene therapy, and the delivery of hydrophilic anionic drugs which are difficult to prepare as prodrugs, and drug delivery, imaging, etc. can be carried out by encapsulating a fluorescent contrast agent in the liposome.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

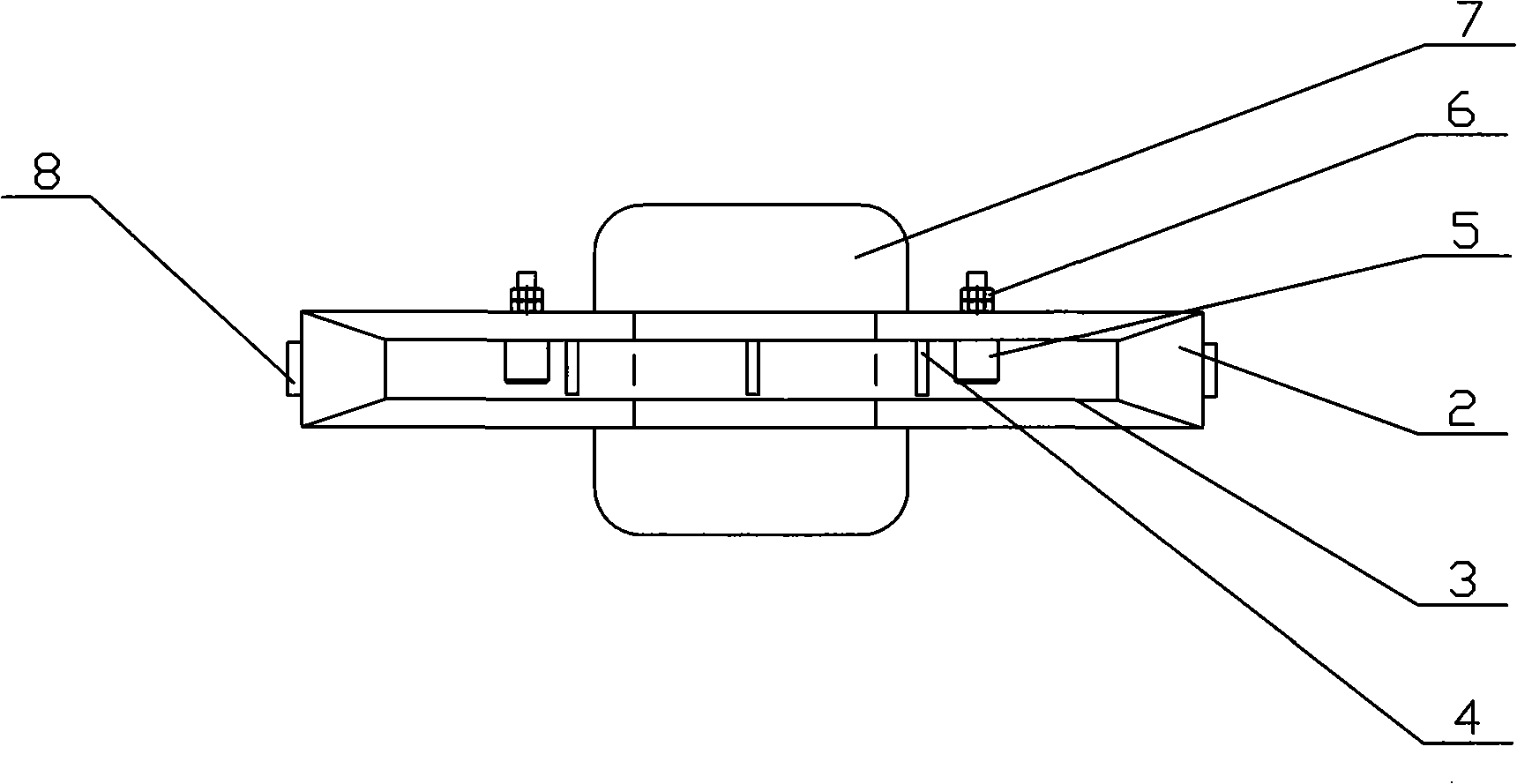

Automatic assembling machine of expansion screw bolts

The invention relates to an automatic assembling machine of expansion screw bolts and belongs to the field of hardware machinery. The assembling machine consists of a chain plate type conveying device, a part feeding device, a part escapement device, a screw nut screwing device, a screw rod small head lateral positioning device, a machine frame and a control system, wherein the part feeding device and the part escapement device are used for the ranging, the storage for package and the one-by-one release of parts, the chain plate type conveying device is arranged on the machine frame, semi-finished products and finished products with different stations are transferred through expansion screw bolt seat combination elements arranged on a chain plate, the screw rod small head lateral positioning device is arranged at the front end of the part escapement device for realizing the lateral positioning of each station screw rod, the screw nut screwing device comprises a screw nut pre-screwing friction plate, a first screw nut screwing wheel, a clamping stagnation release friction plate, a second screw nut screwing wheel, a small motor and the like. The assembling machine can realize the automatic assembly of each part of the expansion screw bolts and has the characteristics that the assembly efficiency is high, and the cost is low; and screw nuts are subjected to two links of pre-screwing and screwing, and the assembly quality is ensured.

Owner:ZHENGZHOU UNIV

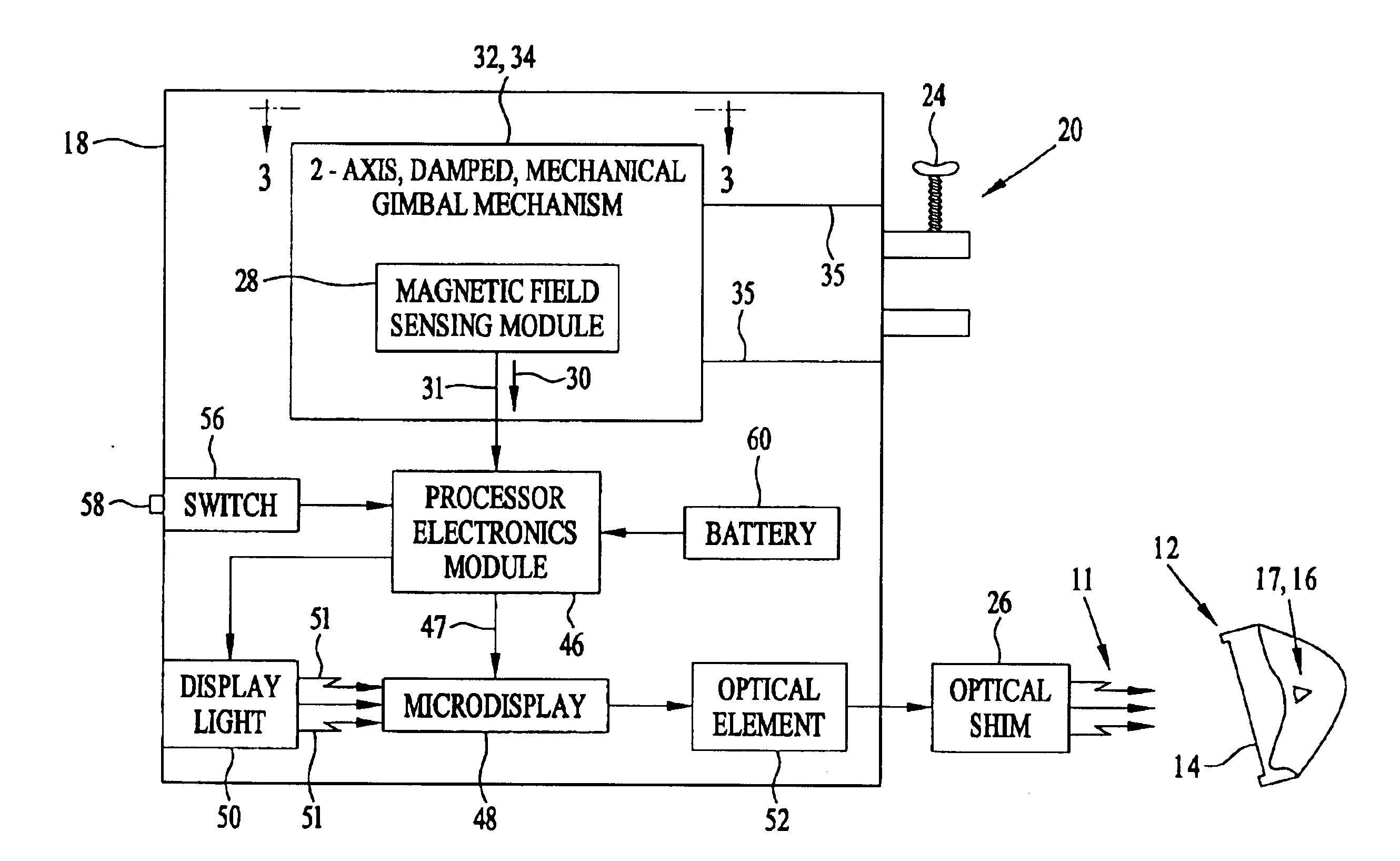

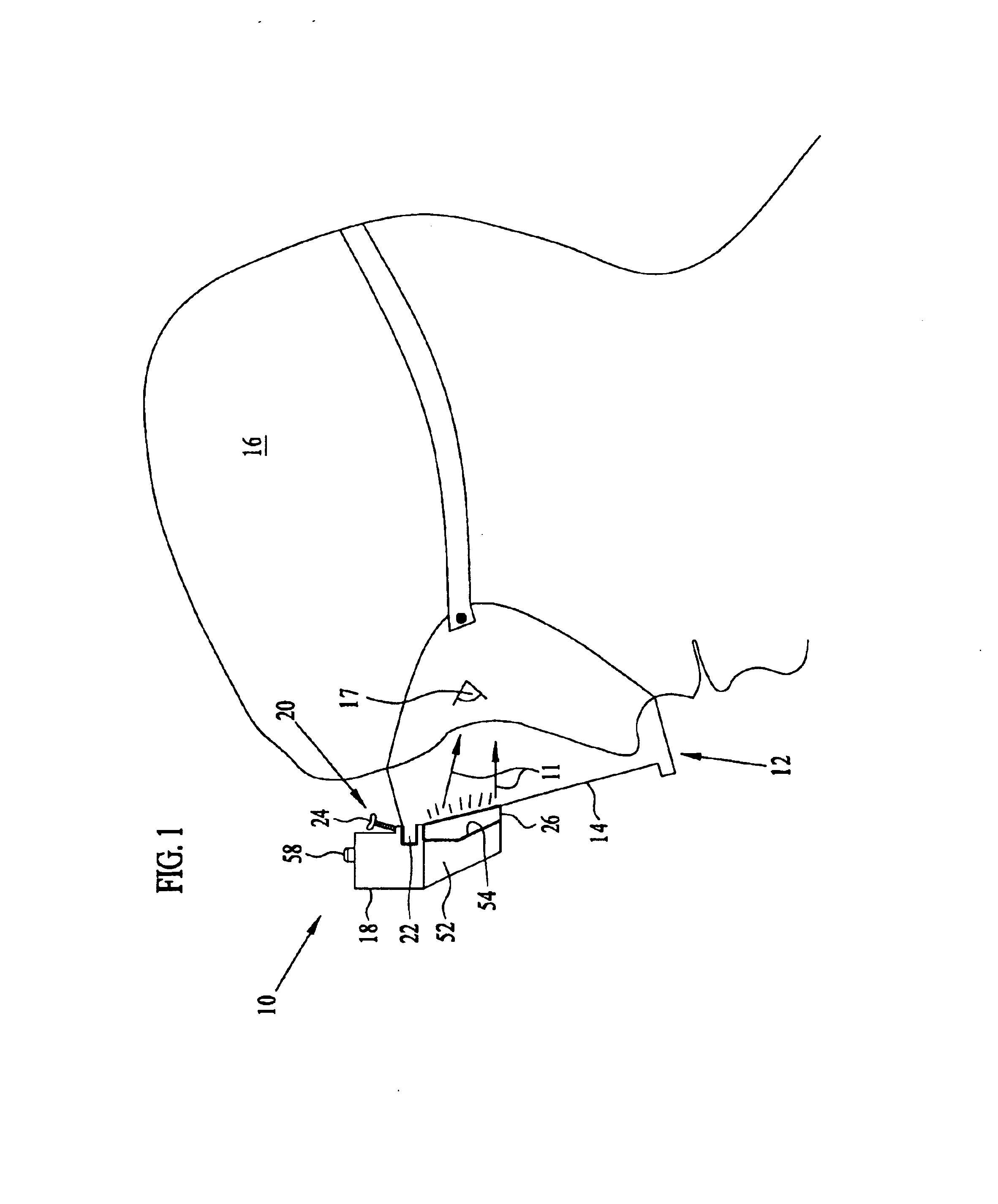

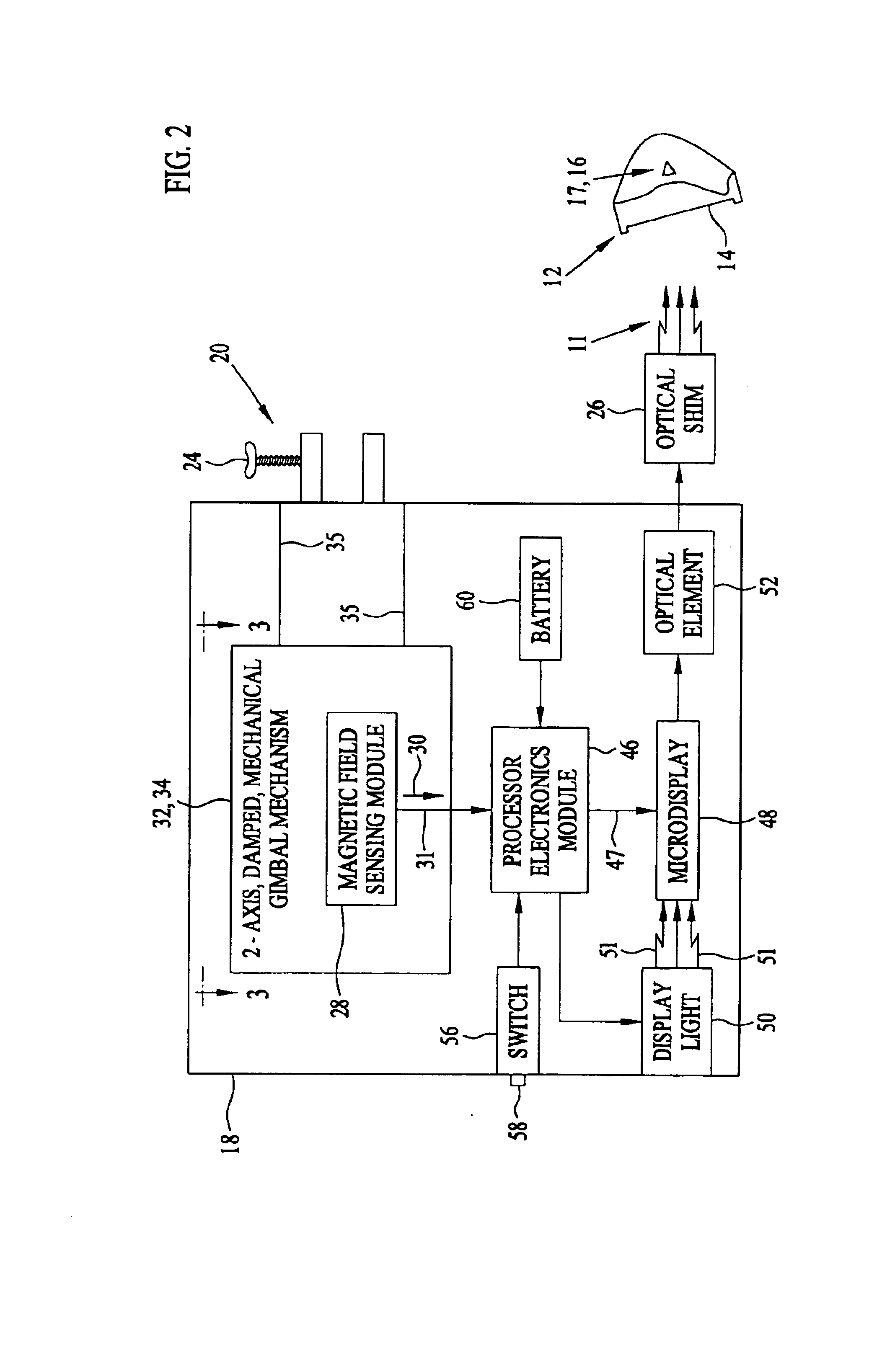

Small head-mounted compass system with optical display

ActiveUS6868360B1Hand heldProcess stabilityDigital computer detailsSpeed measurement using gyroscopic effectsWide fieldComputer module

A system and method indicate the direction faced by an operator. A waterproof housing has a mounting mechanism to engage a part of a headgear worn by an operator to position the housing in a portion of the operator's forward field of view. A two-axis gimbal mechanism is inside the waterproof housing and has a protective housing connected to the waterproof housing. The protective housing contains ring structure coupled to two orthogonal axis structures. A magnetic field sensor module is mounted on one of the axis structures and provides magnetic field data signals representative of the direction faced by the operator. An optical element has a wide field of view to transmit compass data images representative of the magnetic field data signals to the eyes of the operator.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

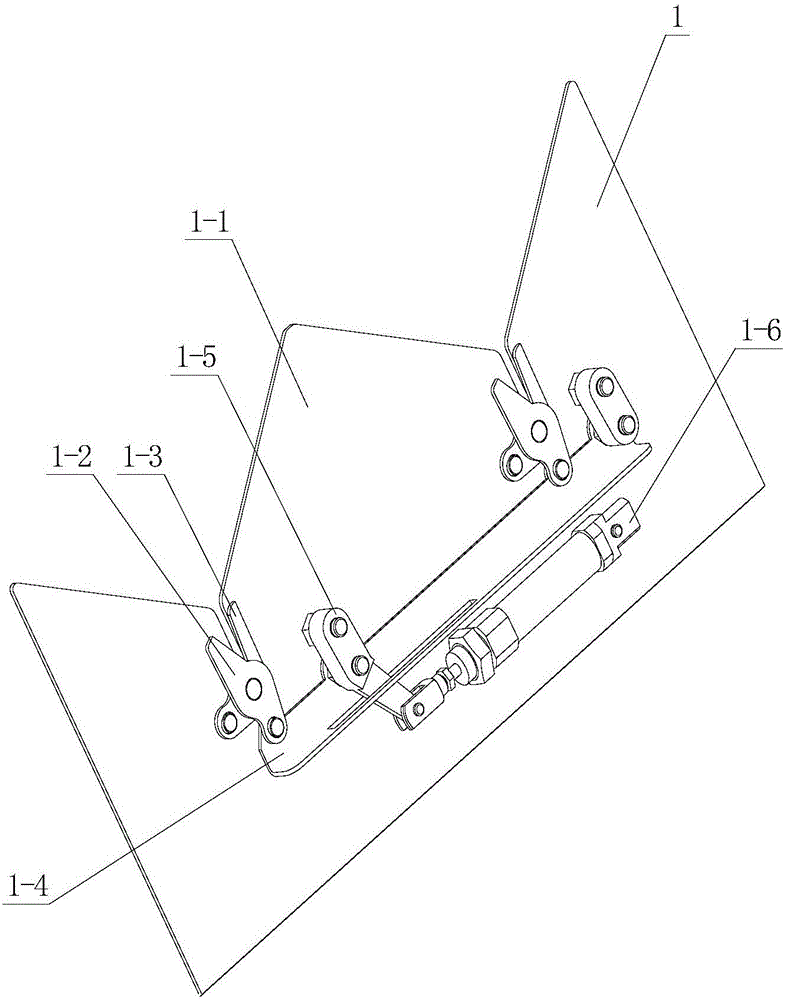

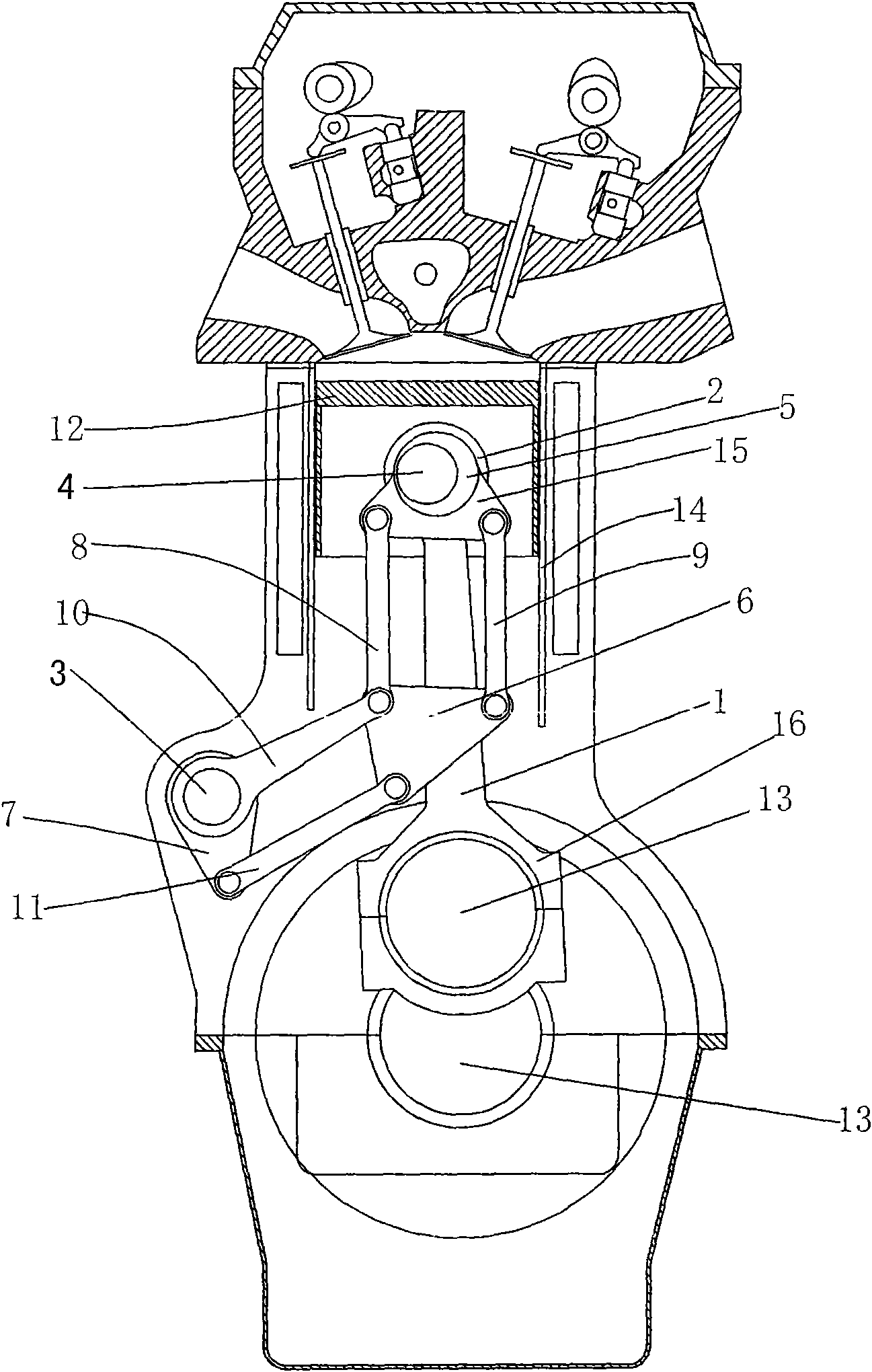

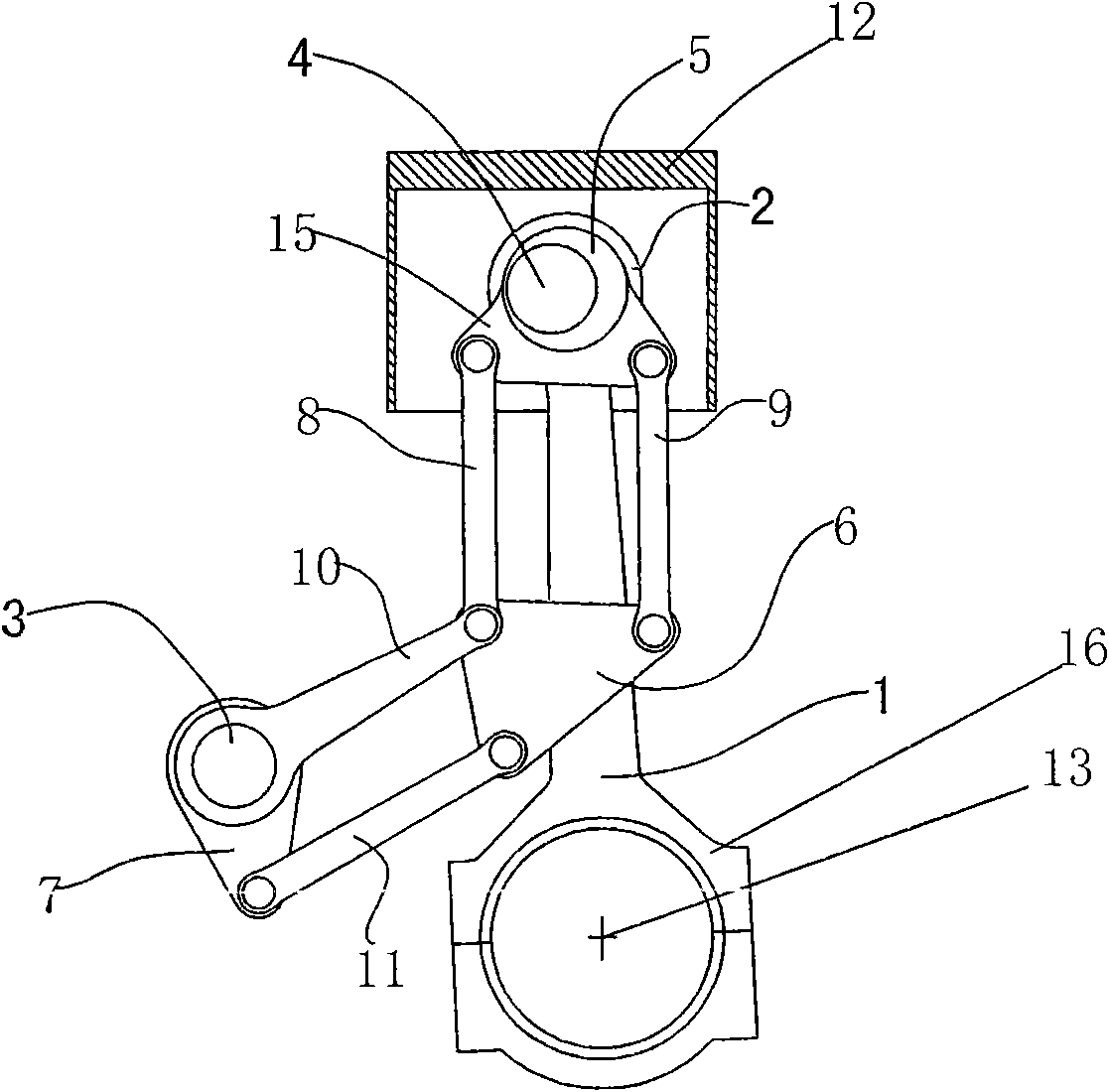

Variable compression ratio device of automobile engine

InactiveCN101560917ADynamic balance does not affectSimple structureEngine controllersMachines/enginesCrankcaseControl theory

The invention discloses a variable compression ratio device of an automobile engine, comprising a crank shaft, a main connecting rod, a piston, an eccentric sleeve, a hinge bar transmission mechanism and a regulating shaft; a small end of the main connecting rod is connected with the piston by a piston pin, and a large end thereof is connected with the crank shaft; the eccentric sleeve is arranged between the small end of the main connecting rod and the piston pin, a connecting rod neck and the large end of the main connecting rod, or a main journal of the crank shaft and a main bearing saddle bore of a crank shaft case; the hinge bar transmission mechanism is used for the transmission between the regulating shaft and the eccentric sleeve. The hinge bar transmission mechanism controls the rotation of the eccentric sleeve, and can change the position of a dead point on the piston so as to change the compression ratio of the engine; furthermore, the hinge bar transmission mechanism is formed by two parallelogrammic hinged four-bar linkage mechanisms, so that the variable compression ratio device has the advantages of simple structure, easy fabrication, convenient control, reliable use, durability and low cost.

Owner:张志强

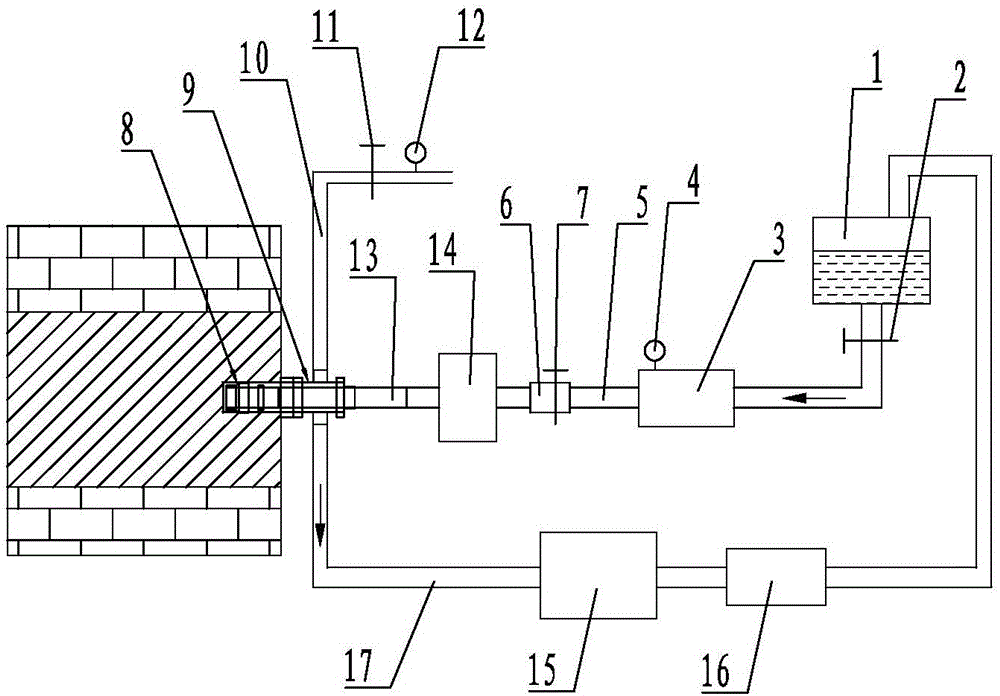

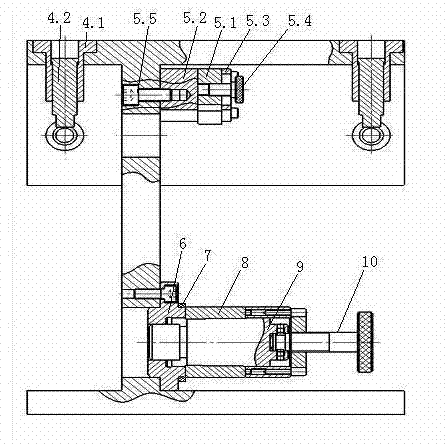

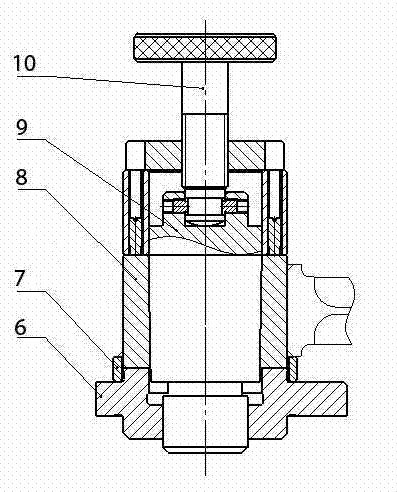

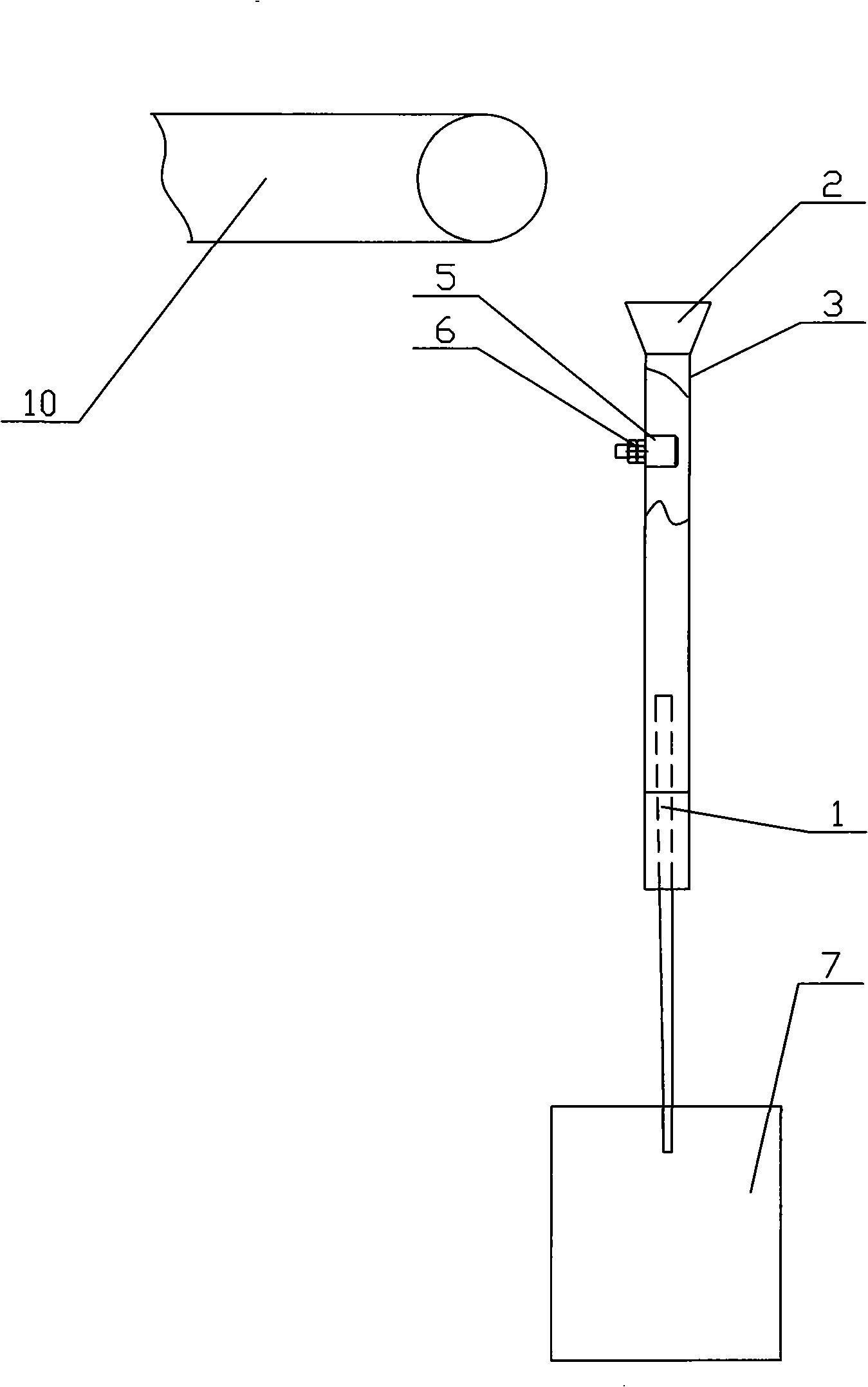

High-pressure water jet punching-drilling-expanding-cutting integrated antireflection device for coal seam, and related method

ActiveCN106320985AHigh strengthExtended service lifeDrill bitsConstructionsPunchingHigh pressure water

The invention discloses a high-pressure water jet punching-drilling-expanding-cutting integrated antireflection device for coal seam, which comprises a drilling machine, a drilling rod and a drill bit. The drill bit comprises a cylindrical body, wherein the front end of the body extends forward to form a cone-like reaming portion. A reaming cutter is fixed on the conical surface of the reaming cutter. The end face of the small head end of reaming portion extends forward to form a drilling cutter. The rear end of the body is extended backward to form a slitting portion, and the rear end of the slitting portion is fixedly connected with the drilling rod. Pore passages allowing liquid to pass through are provided in the reaming portion, the body and the slitting portion. The rear end of the pore passages is connected with the center hole of drilling rod. The front hole of the pore passages is provided with a punched hole nozzle. A horizontal slit nozzle is provided within the slitting portion, and the pore passages are also provided with a valve core. Therefore, the invention provides a punching-drilling-expanding-cutting integrated antireflection device for the coal seam, and also provides a method for the antireflection of the coal seam by using this punching-drilling-expanding-cutting integrated antireflection device, in order to effectively avoid the borehole deviation, improve the construction environment, reduce water waste and gas waste, and improve work efficiency.

Owner:CHONGQING UNIV

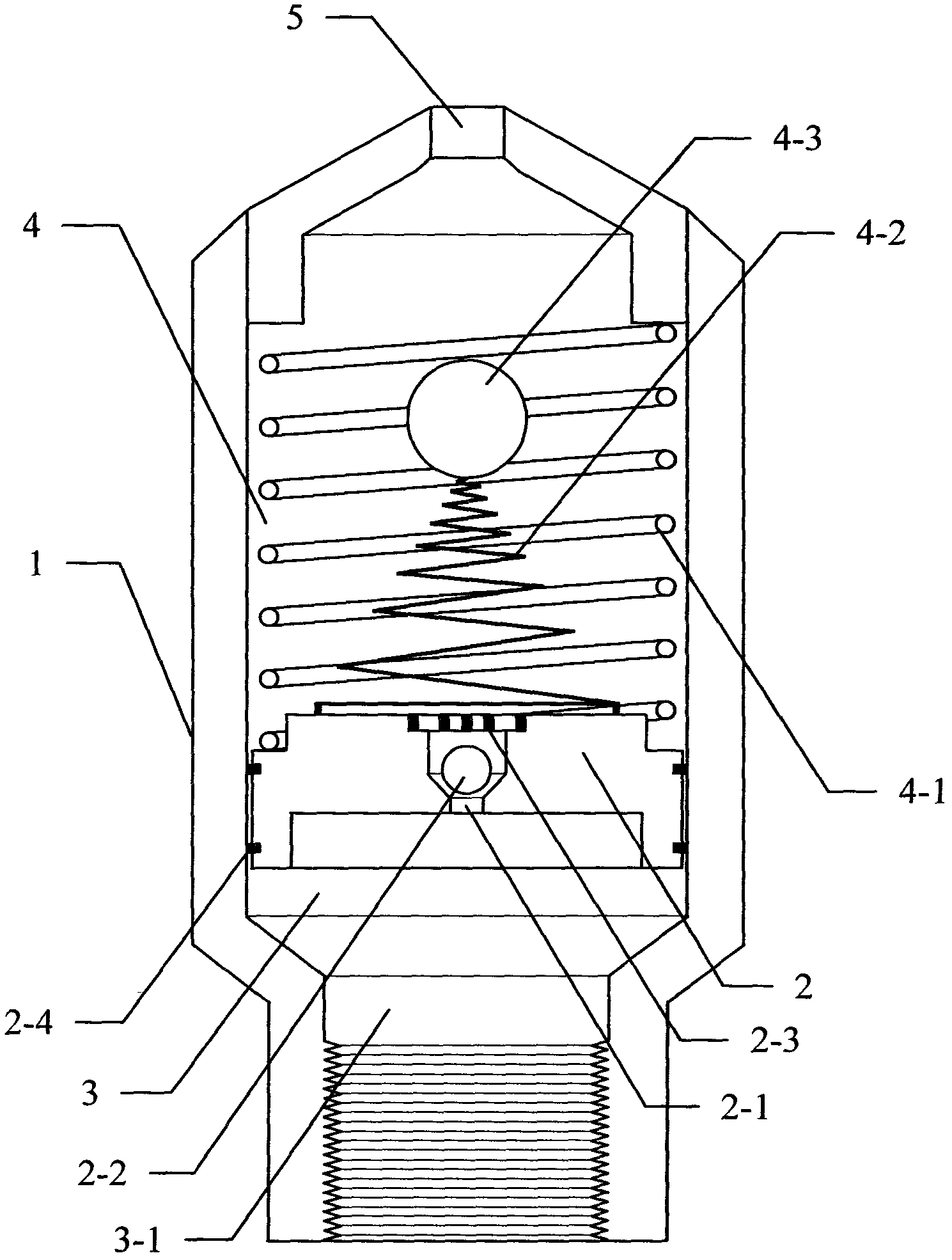

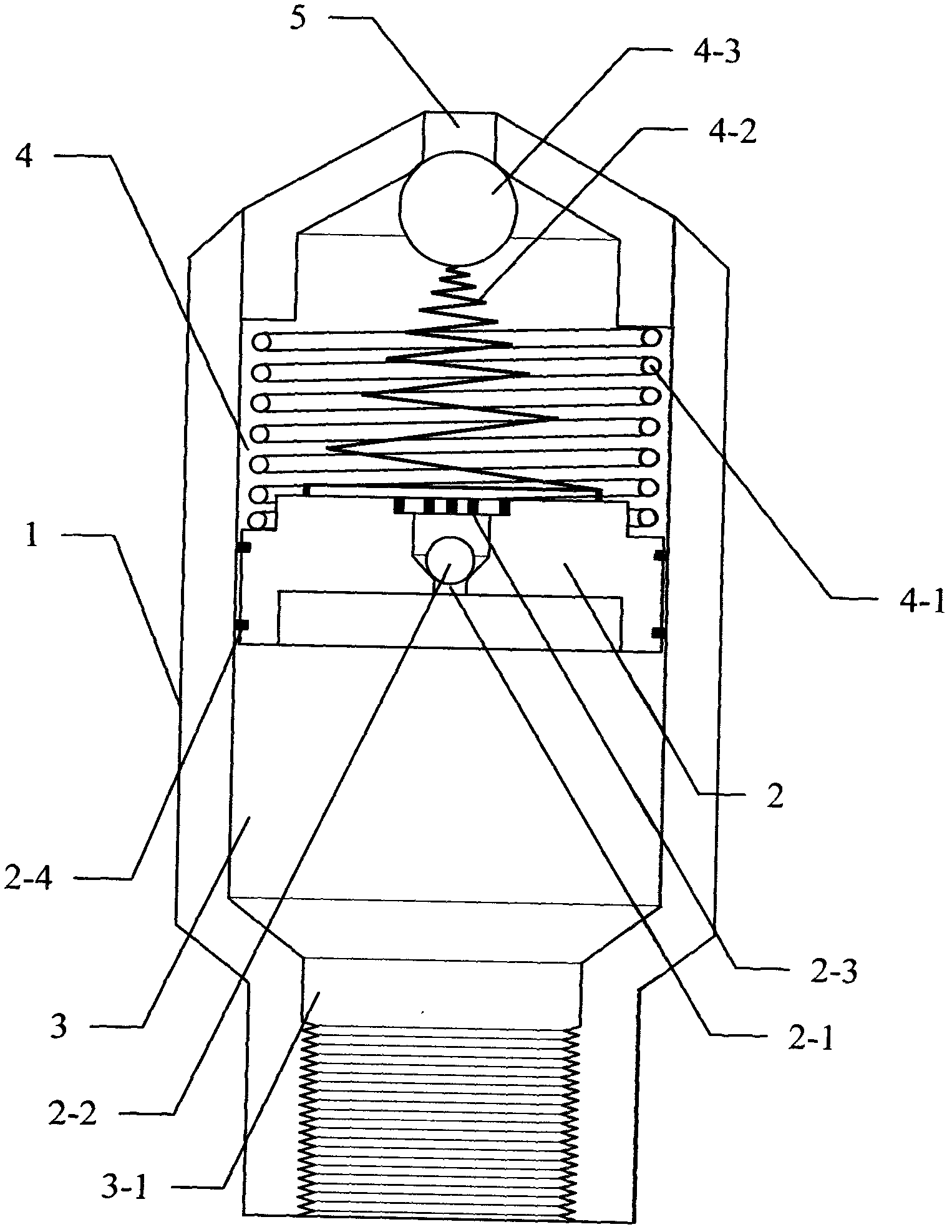

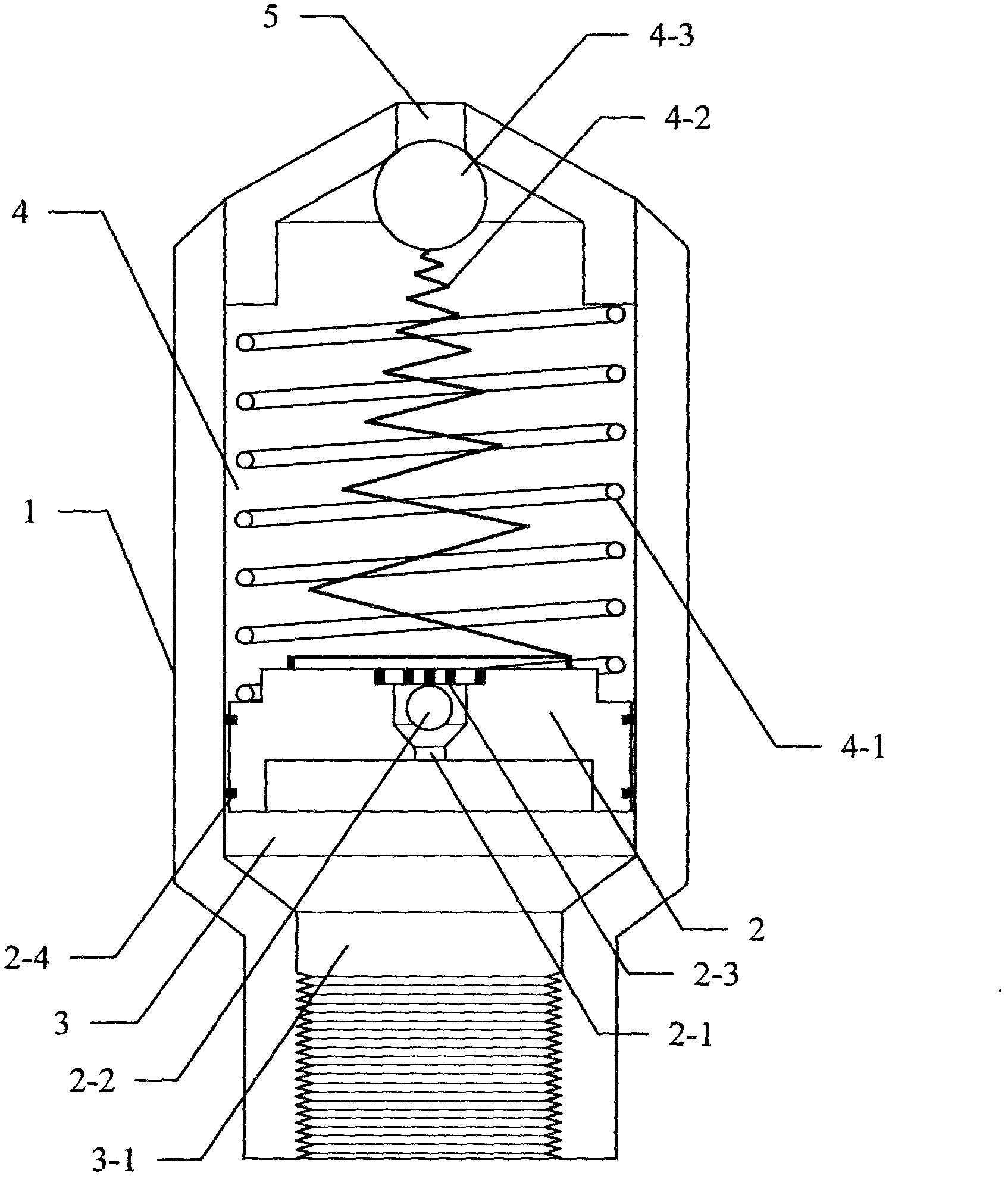

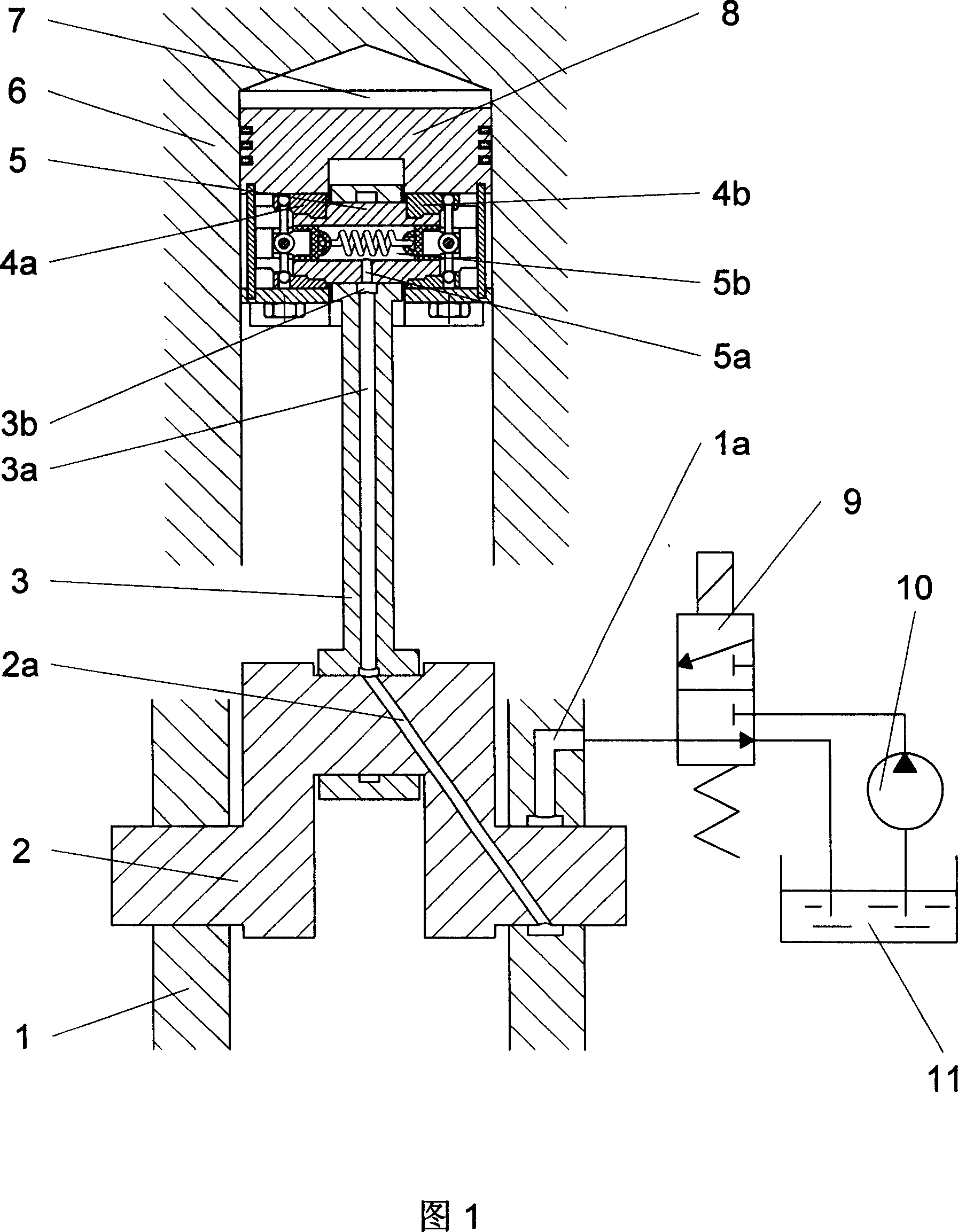

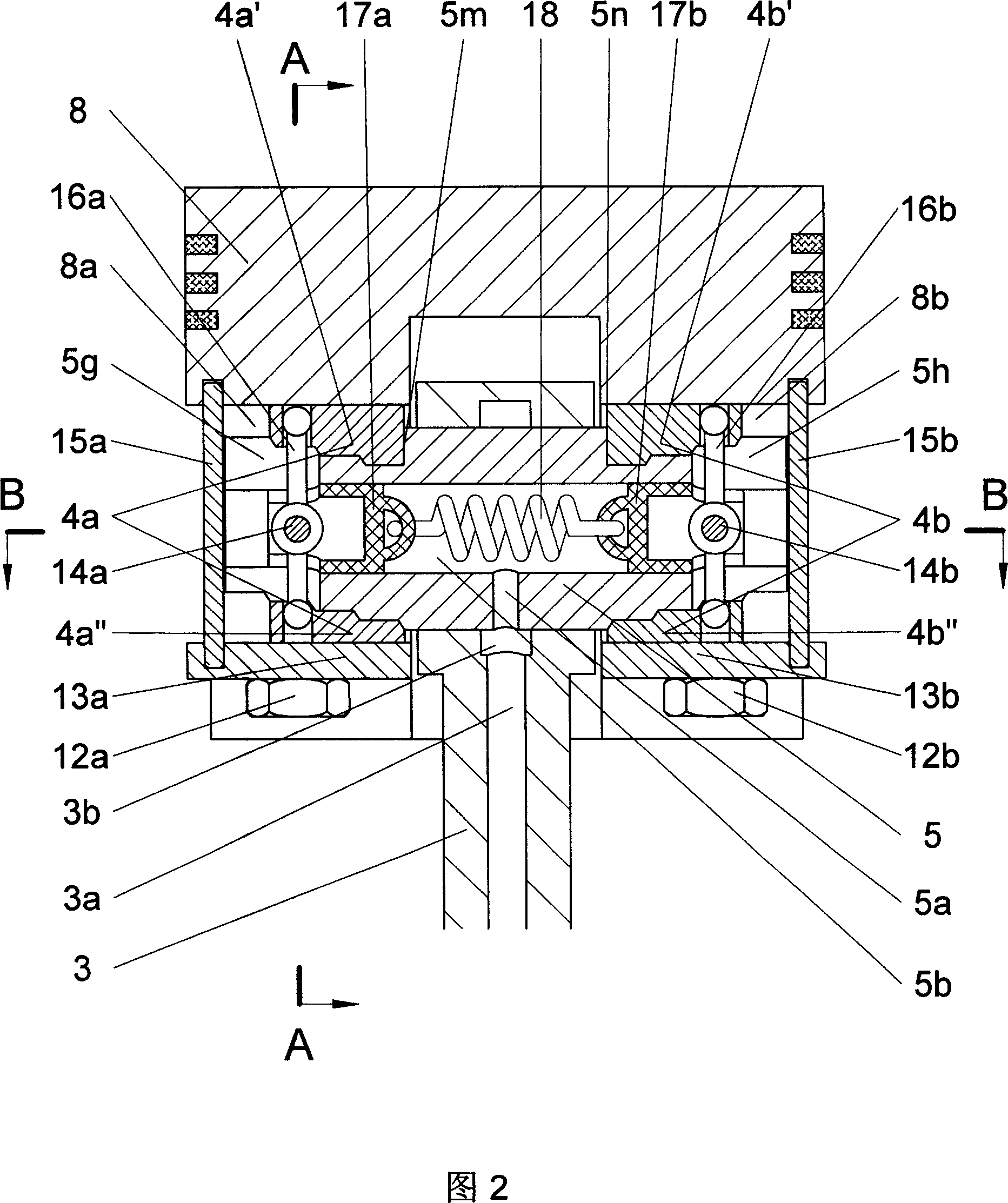

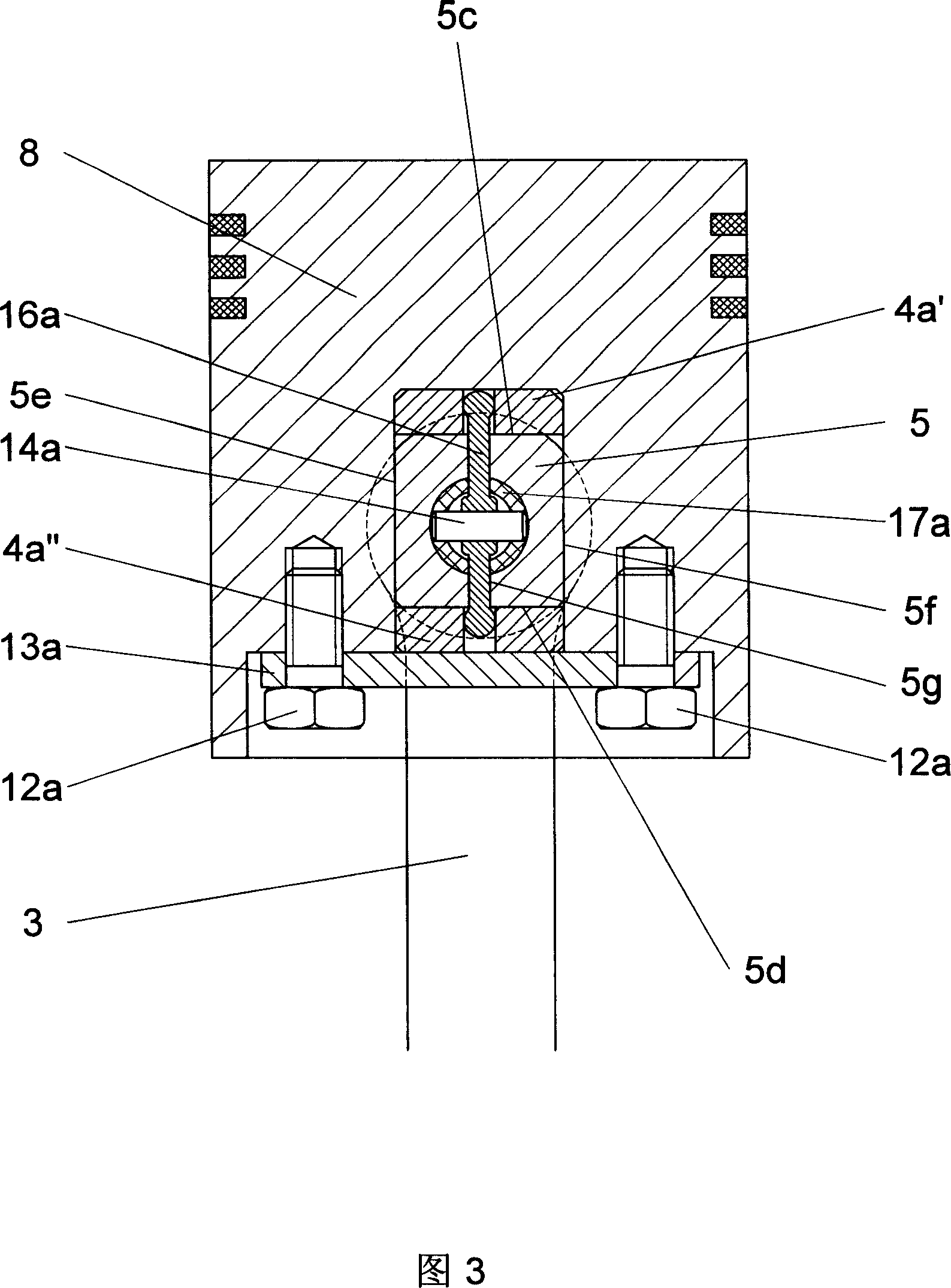

Fluid pulse spraying device

InactiveCN102357439ASimple structureLow input costWatering devicesSpray nozzlesSolenoid valveEngineering

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

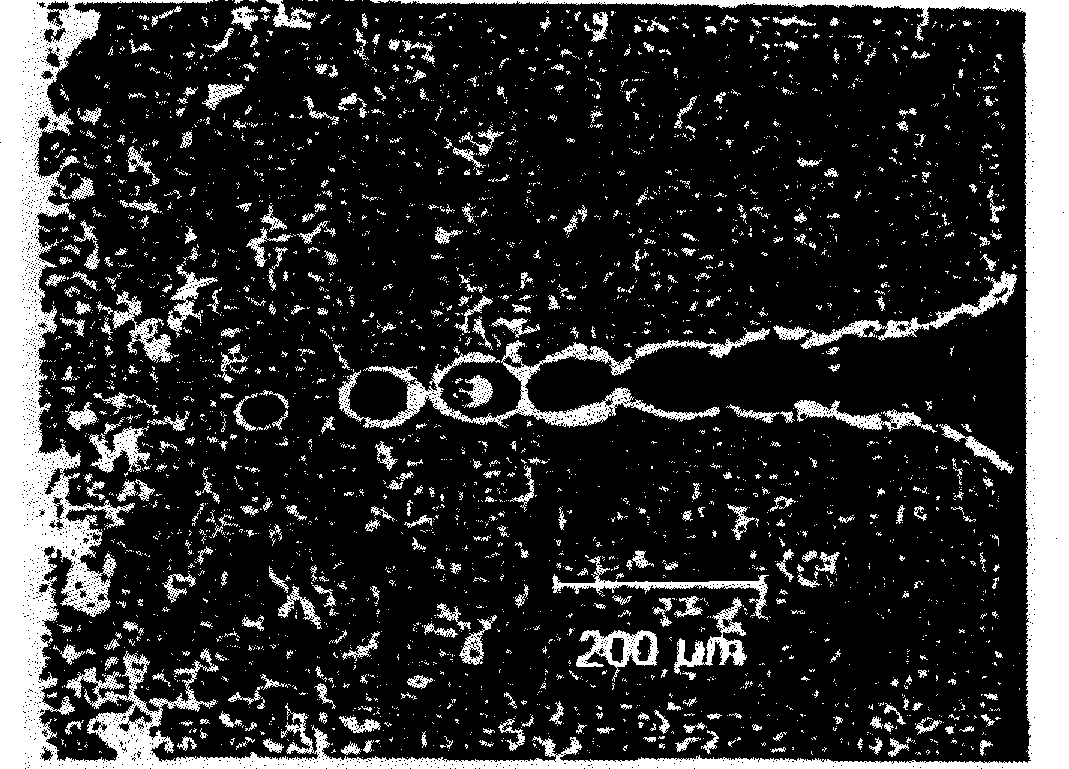

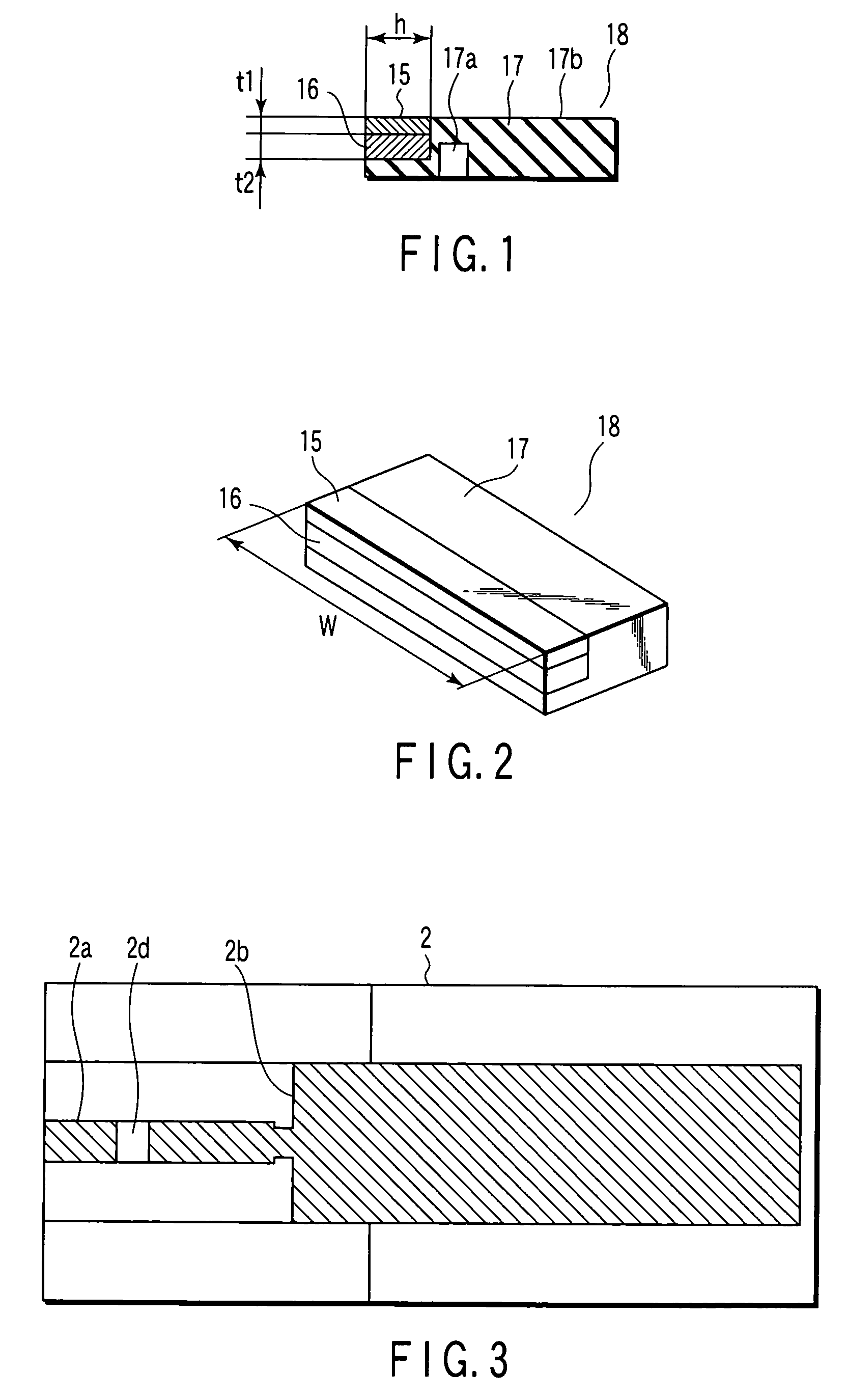

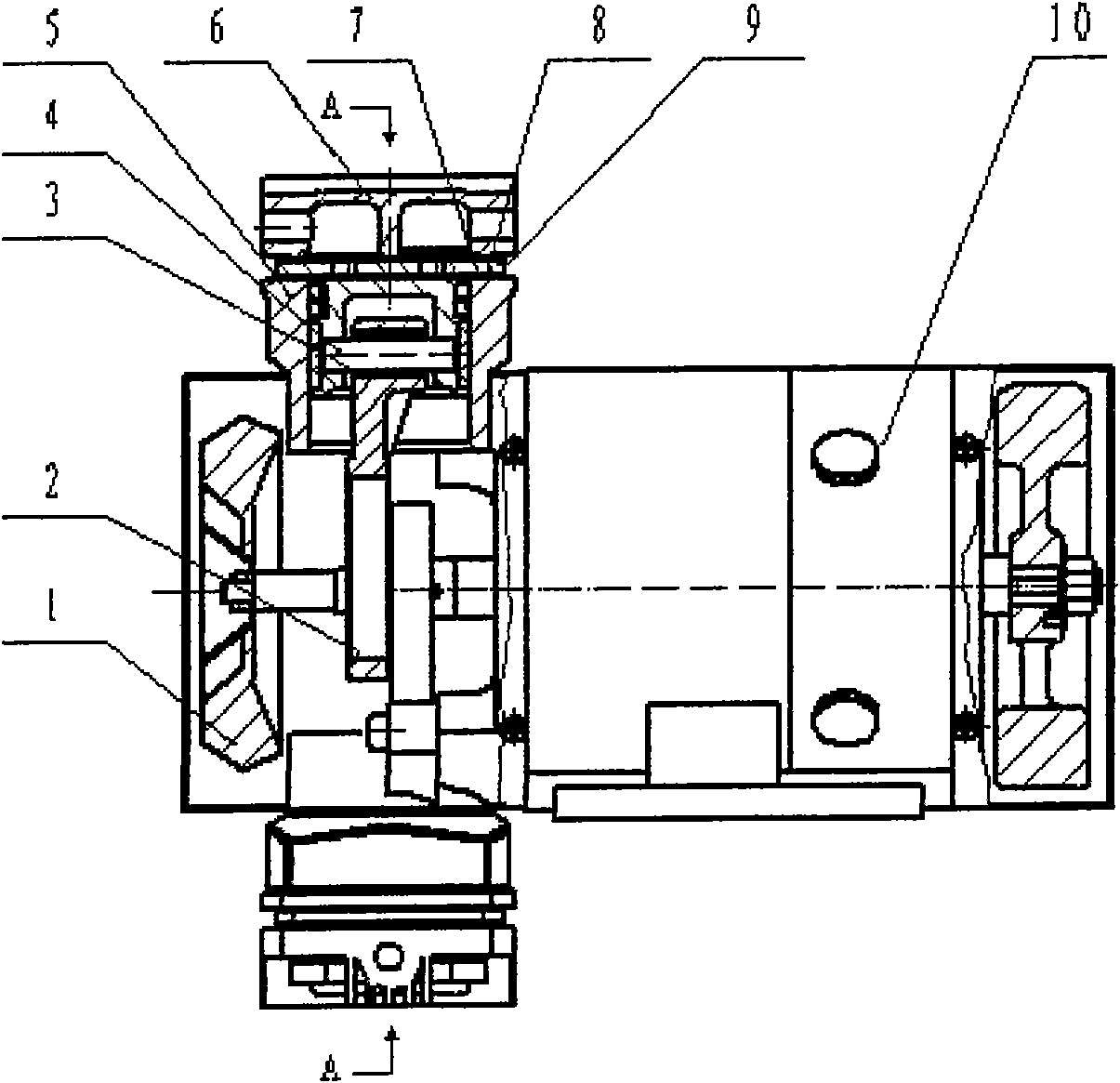

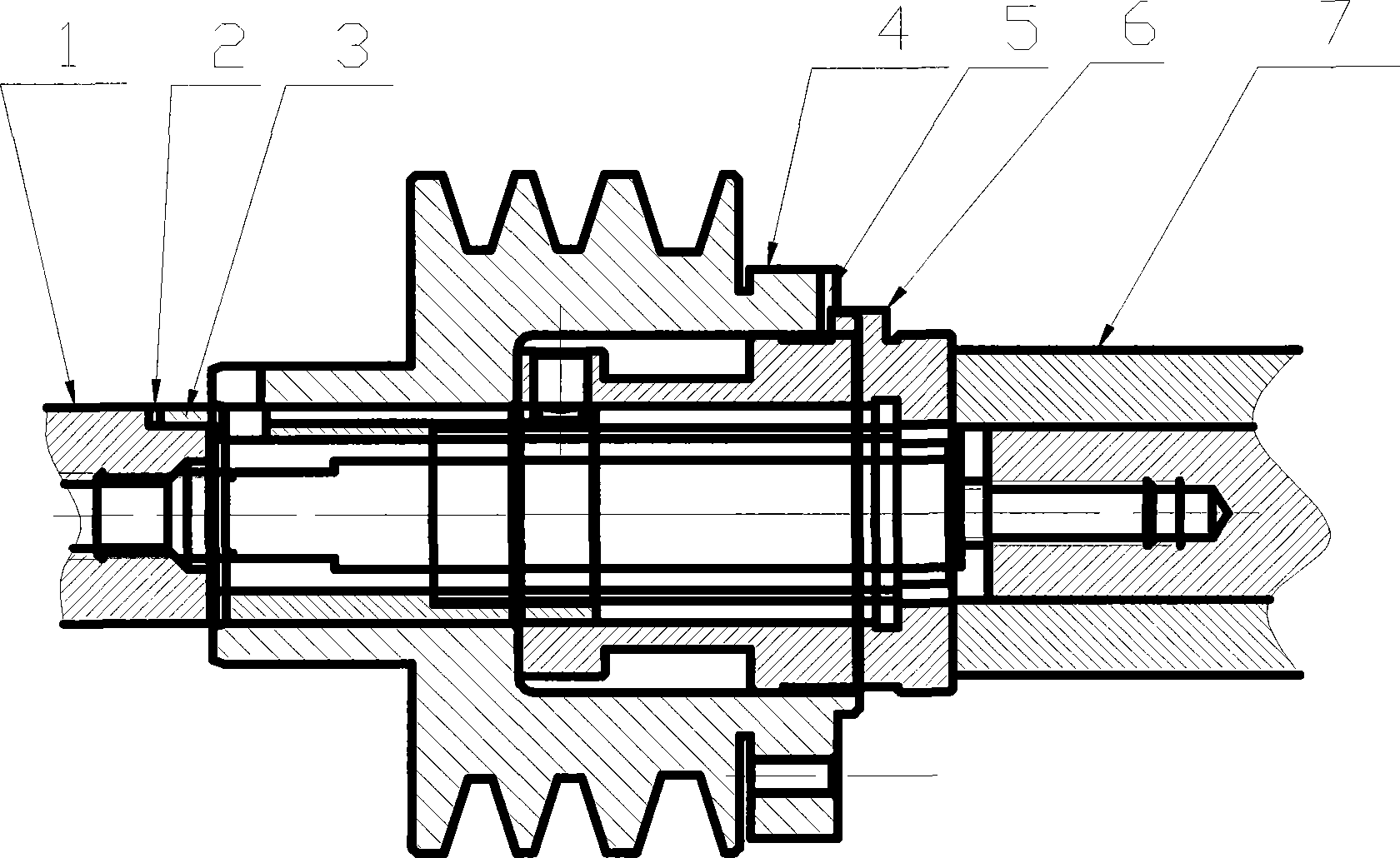

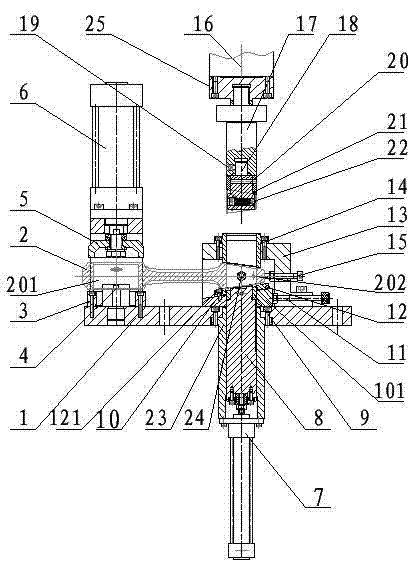

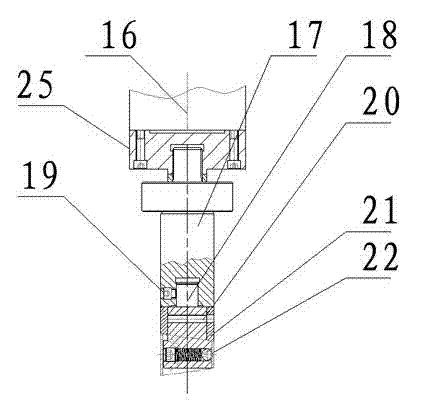

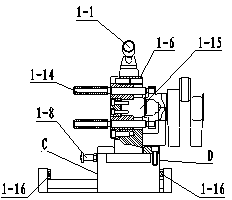

Device for measuring parallel degree, distortion degree and center distance of large and small head holes of connecting rod of piston engine

InactiveCN102175208AEasy to measurePrecise positioningMeasurement devicesSecuring devicesDistortionPiston

The invention discloses a device for measuring a parallel degree, a distortion degree and a center distance of large and small head holes of a connecting rod of a piston engine. The device comprises a pedestal, a connecting rod location mechanism, a connecting rod fastening mechanism, a measuring shaft, and measuring contacts; the pedestal is provided with a bottom plate, a vertical upright plate, a horizontal top plate, and a vertical side plate; the bottom plate, the top plate and the upright plate are combined into an I shape; the side plate and the top plate are combined into an L shape; the upright surface of the upright plate, the top surface of the top plate and the facade of the side plate are three-dimensional reference surfaces; the connecting rod location mechanism is mounted on the lower part of the upright plate, and the connecting rod is vertically arranged; a low hole of the connecting rod is sleeved on the location mechanism to make a central axis of the hole vertical to the upright plate; the connecting rod fastening mechanism is mounted on the upper part of the upright plate and corresponds to the high end of the connecting rod to compress and fix the connecting rod on the pedestal; the measuring shaft is mounted in a high hole of the connecting rod and is in close fit with the hole; two pairs of measuring contacts are arranged, wherein one pair of measuring contacts is vertically arranged on the top plate and corresponds to upper edges of the two ends of the measuring shaft; and the other pair of measuring contacts is horizontally arranged on the side plate and corresponds to side edges of the two ends of the measuring shaft. The device has the advantages that: the connecting rod to be measured is precisely located, and the detection data is high in precision and small in error; and the device performs measurement easily and quickly, has strong generality, and can measure connecting rods of engines in various types, specifications and purposes.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

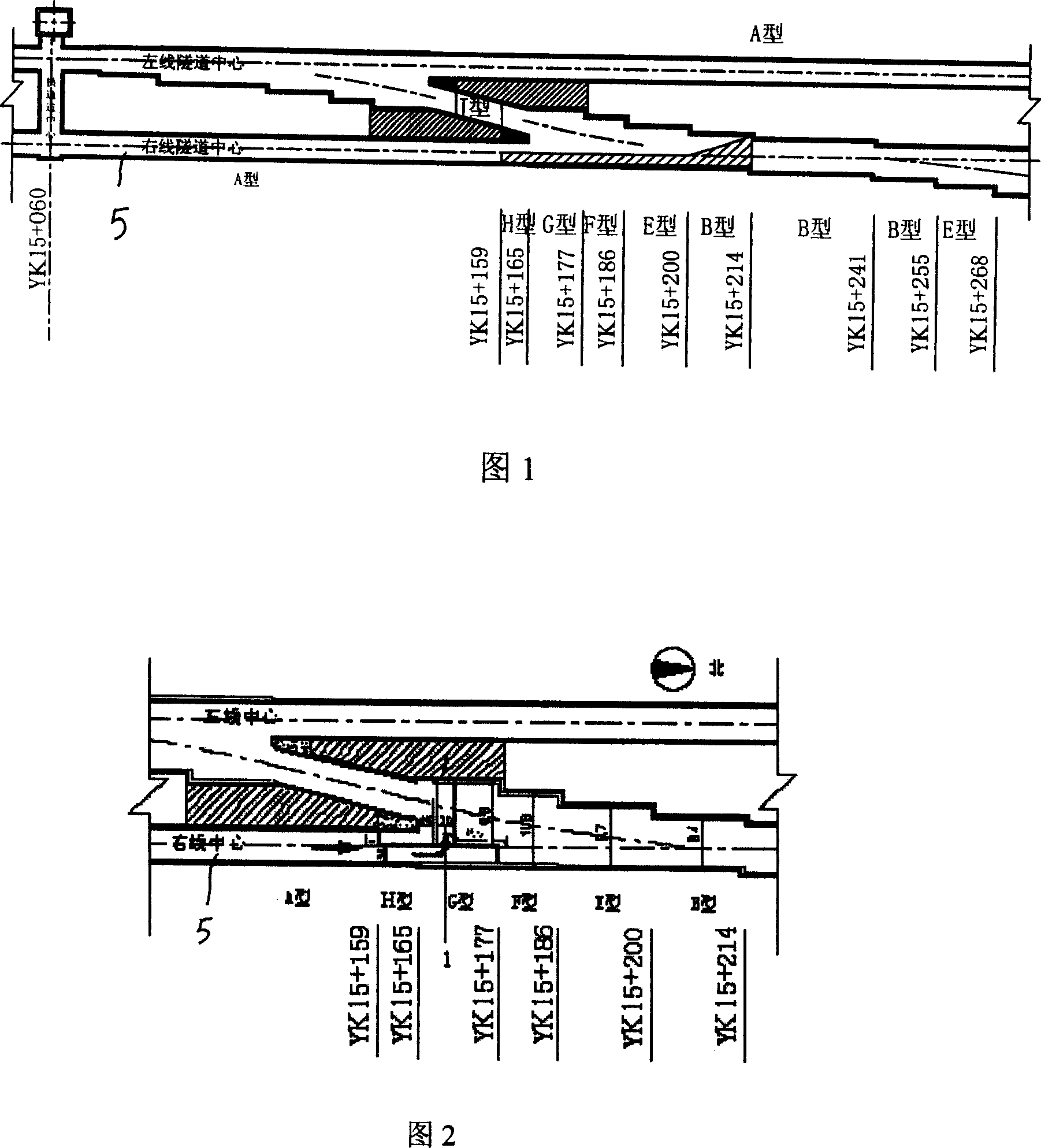

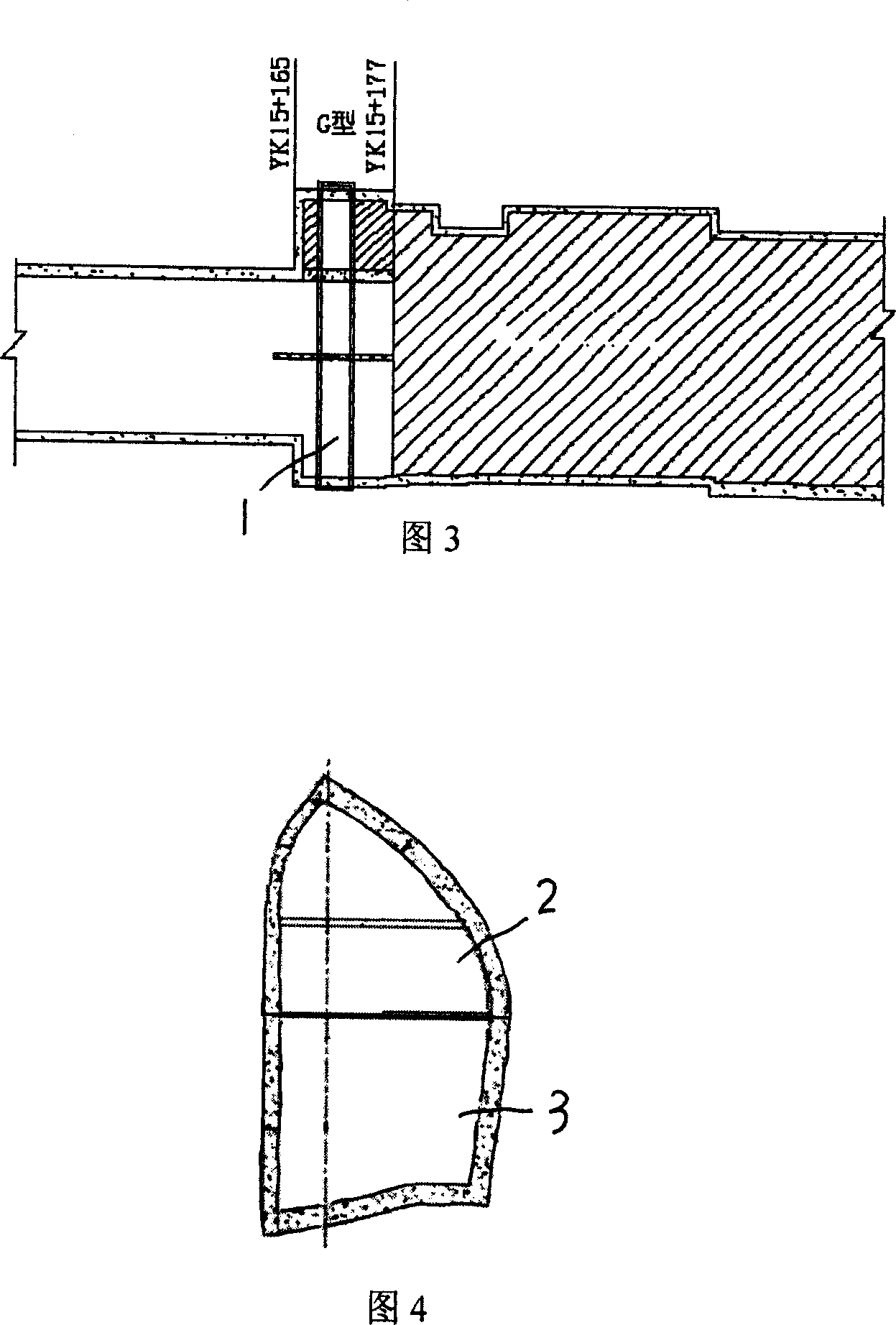

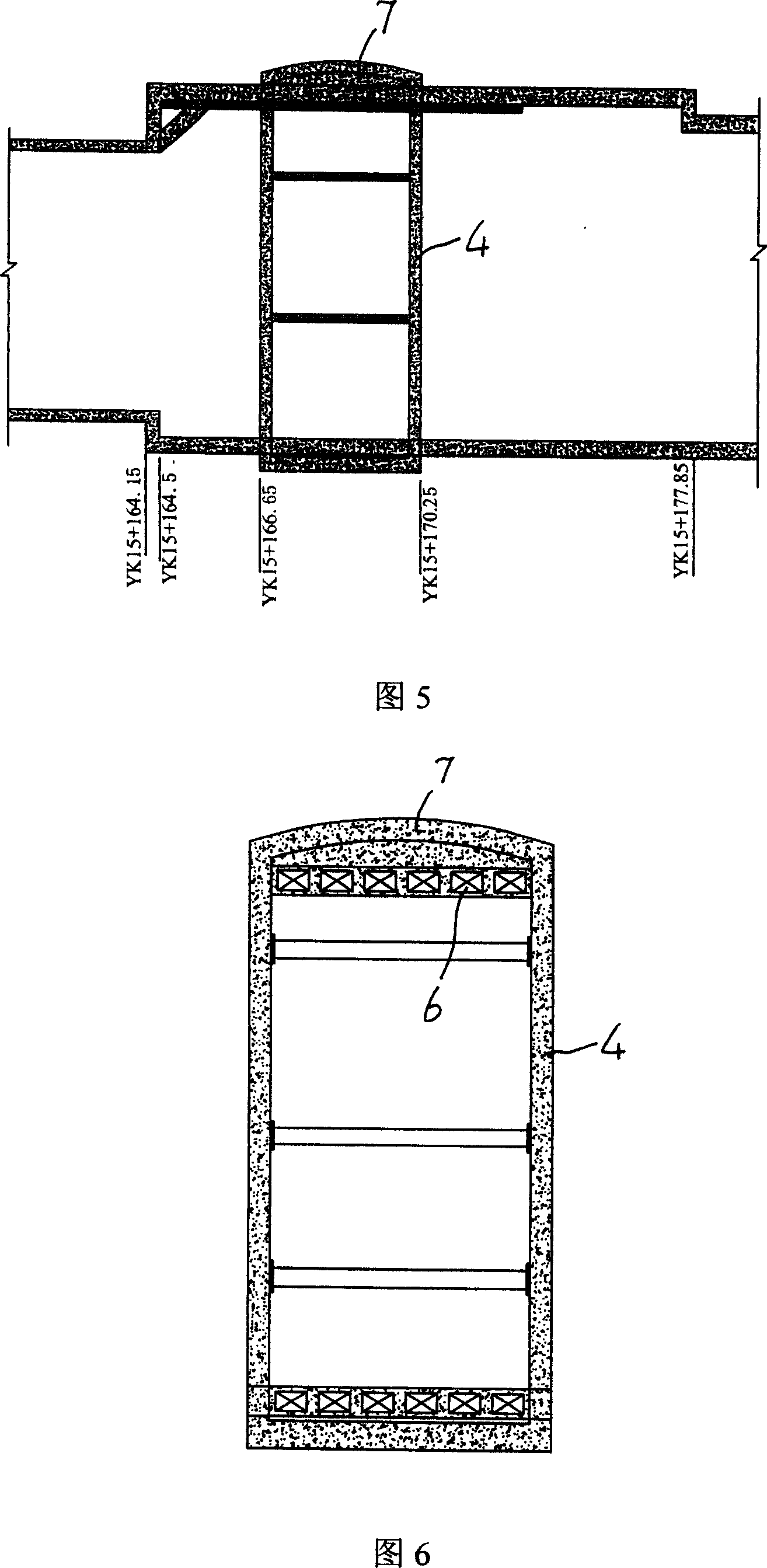

Rapid-construction method for rapid change of small-section into large-section tunnel

InactiveCN1952350AThere is no secondary disturbanceEliminate potential safety hazardsTunnelsEngineeringFront and back ends

The invention relates to a quick construction method that small section is changed to big section in tunnel construction abruptly, characterized in that first of all, small heading on the one side of small section is transited to side heading on the relative side of big section; then by the portrait space formed in side heading of the big section transverse heading is dug on the big section; permanent early support for the big section is constructed in the transverse heading so as to form permanent early closed ring for all section; the whole early support for big section is in the transverse heading; digging and support for big section tunnel is constructed on the front and back ends of the big section in the working plane formed by the transverse heading. The invention is provided with low cost, good safety and simple construction technology so on.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

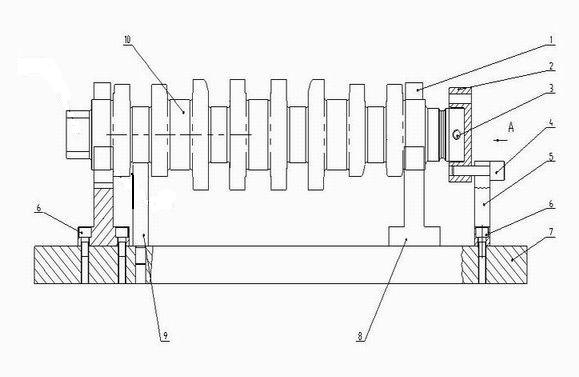

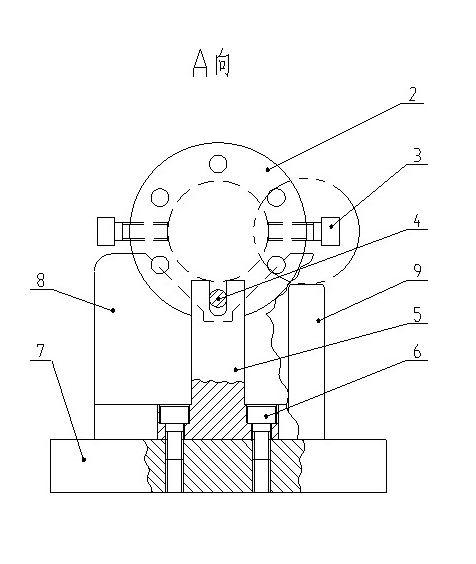

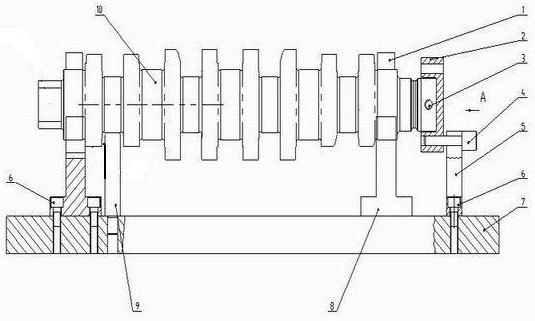

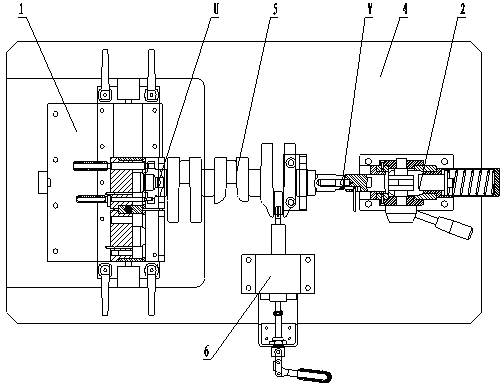

Polyhedron-milling dividing device

InactiveCN101966662AReduce labor intensityCompact structurePrecision positioning equipmentEngineeringCrankshaft

The invention relates to a polyhedron-milling dividing device. The device comprises a crankshaft support positioning mechanism and a dividing mechanism, wherein a V-shaped support block of the support positioning mechanism is supported below main journals at two ends of a crankshaft and is matched with a crankshaft pressing mechanism to clamp and fix the crankshaft; the diving mechanism comprises a dividing plate, a positioning pin and a positioning block; a blind hole matched with a large end excircle of the crankshaft is axially formed in the center of the dividing plate; the dividing plate is arranged and fixed at a large end of the crankshaft by a compression screw; a plurality of dividing positioning holes are distributed on the outside periphery of the blind hole of the dividing plate; the positioning block is arranged on a clamping apparatus body; the upper end of the positioning block is provided with a U-shaped groove with an upward opening; and the positioning pin passes through the U-shaped groove and is inserted into the dividing positioning hole on the dividing plate to perform corresponding circumferential dividing and positioning. The polyhedron-milling dividing device has the advantages of compact structure, reliable positioning and high efficiency of dividing actions, is suitable for cooperating with the clamping apparatus body and the crankshaft pressing mechanism to divide and clamp the crankshaft, and finishes the processing of flat surface milling or polyhedron milling of the crankshaft at a small head on a plain milling machine.

Owner:TIANRUN IND TECH CO LTD

Variable compression ratio device of piston reciprocating internal combustion engine

InactiveCN101016863ARealize infinitely variable compression ratioContinuously variable compression ratioEngine controllersMachines/enginesHydraulic cylinderCompression device

The invention relates to a variable-compression device of piston reciprocating internal combustion engine, comprising a connecting rod, a piston pin, and a piston. The middle of the piston pin is hinged in a small pin hole of the connecting rod, while two ends of the piston pin are sheathed with blocks sliding along end axis, and two sides of the piston are arranged with sliding grooves in which the blocks embedded slide, the sliding motion of blocks in the piston pins are relative to the sliding motion in the sliding grooves, the hydraulic cylinder executor is integrated with the piston pin, the piston pin contains a drawing spring to draw near two end blocks, the hydraulic force and the drawing spring can move near or far the blocks, when the block is added with a servo control valve, via operating a V-shaped groove at the bottom of the cylinder, the V-shaped groove via the connecting rod operates the servo control valve to realize stepless compression change. The invention has simple structure or the like.

Owner:袁辉

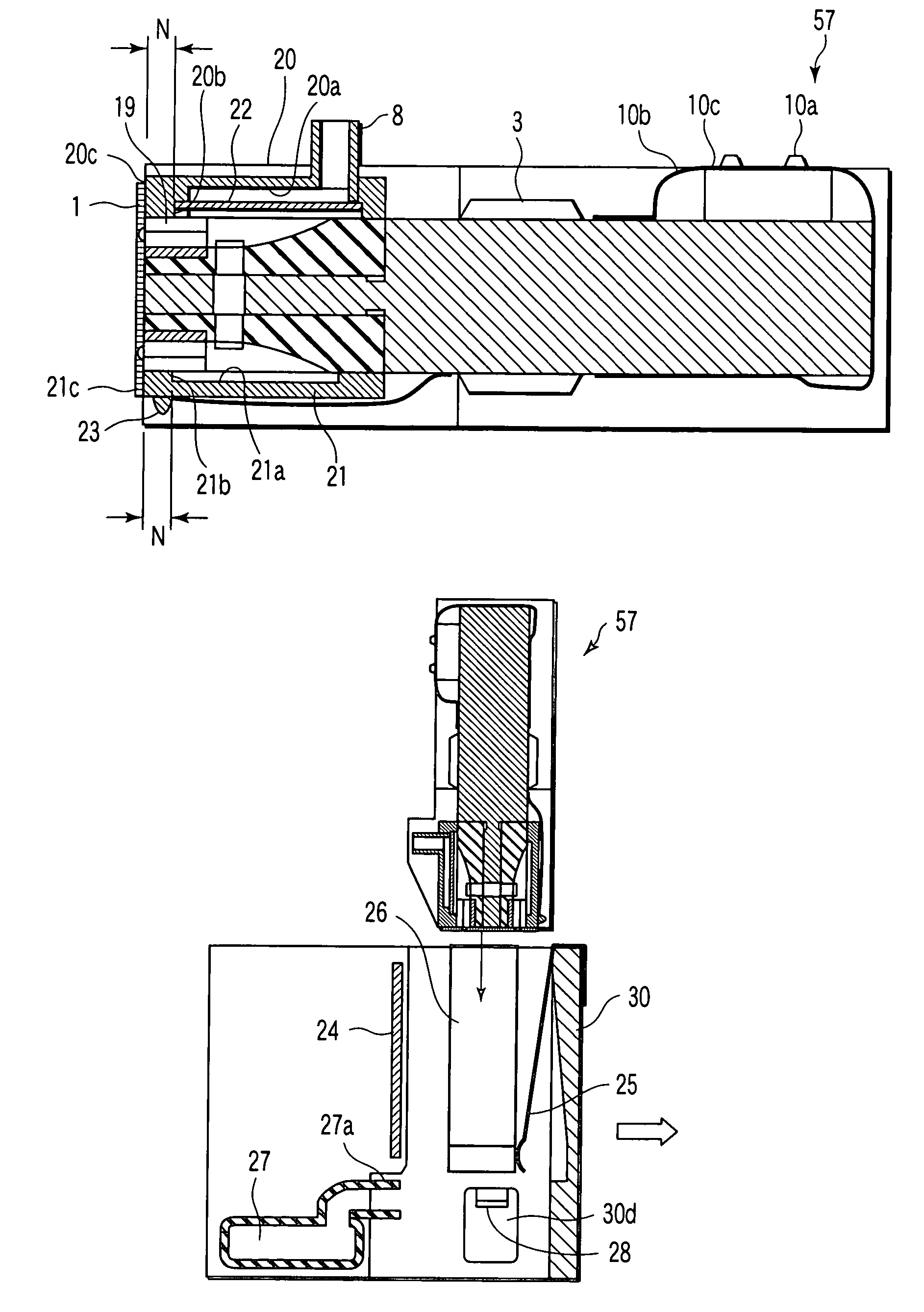

Ejection condition adjustment apparatus, droplet ejecting apparatus, and ejection condition adjustment method and program

InactiveCN101372172AHigh yieldReduce manufacturing costInking apparatusOther printing apparatusEngineeringSmall head

An ejection condition adjustment apparatus includes a unit configured to set, in a case where a large head to be driven includes a plurality of small heads each having a number of orifices and the small heads are disposed adjacent to one another on the large head such that regions of the respective small heads where the orifices are provided partially overlap one another, a range of orifices to be used and an ejection timing for the individual small heads such that positional shifts between adjoining ones of patterns formed by the respective small heads are minimized.

Owner:SONY CORP

IC link rod manufacture process

InactiveCN101260903AAchieve fixed positionRealize installation positioningConnecting rodsEllipseEngineering

The invention relates to a process for manufacturing an internal-combustion engine connecting rod. The steps of the process are: forging, by a forging die, an integral blank of a connecting rod having a big end ad a small end, with the small end of the blank provided with opposite circular pits, the big end of the blank provided with opposite pits or a through hole, the edges of the pits or the hole on the big end being elliptical, the difference between a major axis and a minor axis being from 5 to 8mm, and the major axis superposing on the axis of the connecting rod or forming an included angle of 45 degrees with the axis of the connecting rod; subjecting the integral blank to blasting shot, flaw detection and phosphorization, then roughly milling two planes of the integral blank of the connecting rod, and machining an mounting hole for a piston pin on the small end; incising along the minor axis of the ellipse of the big end of the integral blank to form a blank of a connecting rod body and a blank of a connecting rod cover board, milling the incising junction surfaces; merging the junction surfaces, synchronously drilling the mounting jump-holes on the connecting rod body and the connecting rod cover board, and machining a crank mounting hole corresponding to the piston pin mounting hole on the big end; threading through the mount jump-holes on the connecting rod body, and machining a gap block position-limiting grooves in the connecting rod body and the connecting rod cover board; and removing burrs, and setting a positioning fixed bolt.

Owner:常州久弘金属材料有限公司

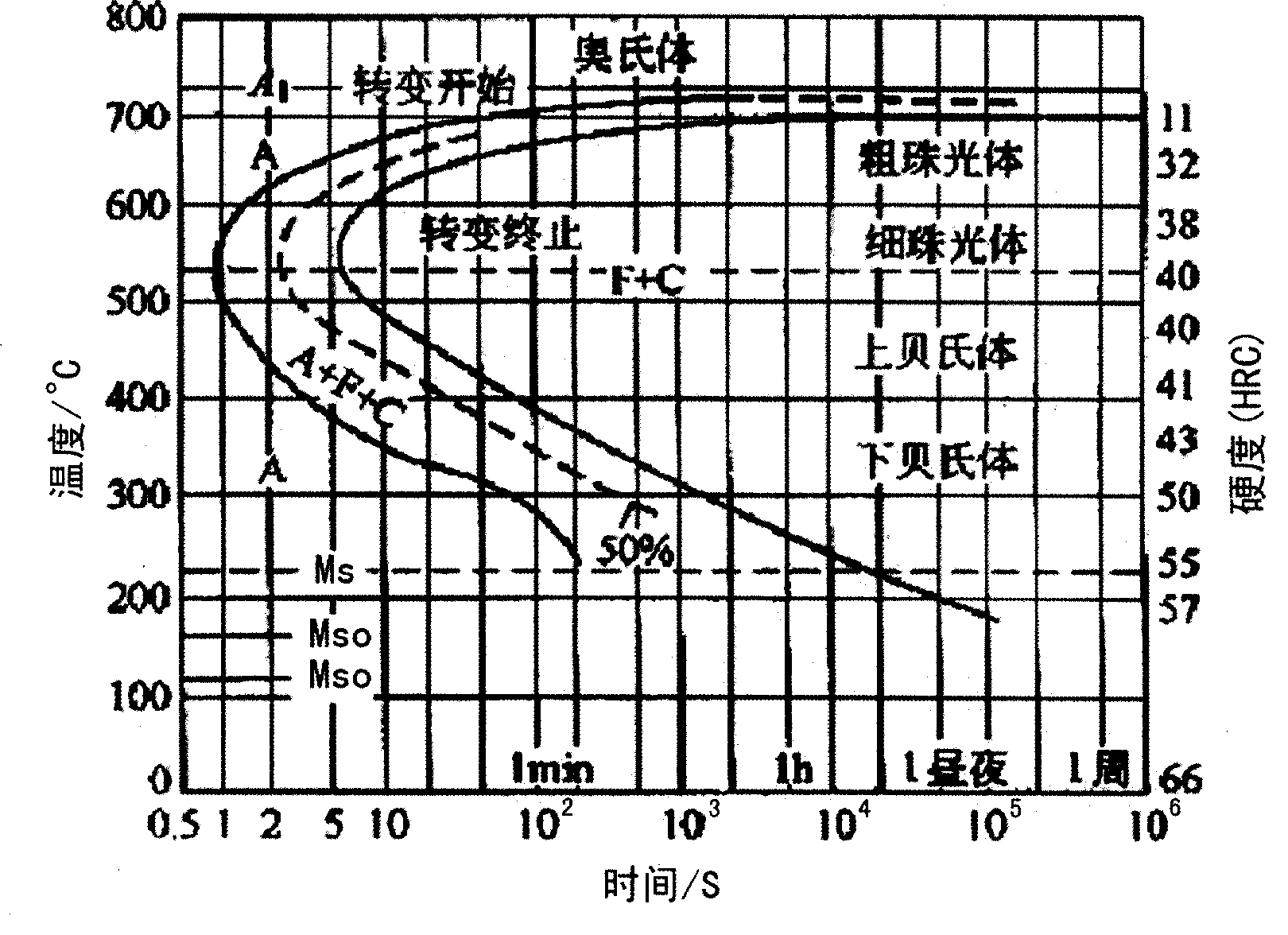

Method for machining front shell of differential mechanism

ActiveCN103639666AQuality improvementExtended service lifeDifferential gearingsGearing detailsEngineeringQuenching

A method for machining a front shell of a differential mechanism includes the following steps of (1) blank forging, (2) rough turning of a small head, (3) rough turning of a large head, (4) quenching and high temperature tempering, (5) finish turning of the small head, (6) finish turning of the large head, (7) drilling and tapping, (8) spline rolling, (9) surface hardening, (10) external grinding, (11) drilling of a lock pin hole, (12) drilling of an oil hole, (13) drilling of a crossed hole of the small head, (14) assembling, (15) boring of a crossed hole of the large head, (16) chamfering and washing, and (17) inspecting and storing a finished product according to a product drawing. According to the method, quality of the product is improved, the service life of the product is prolonged, production cost is reduced, and the method is used for production of an automobile accessory.

Owner:JIANGSU HENGYI IND TECH CO LTD

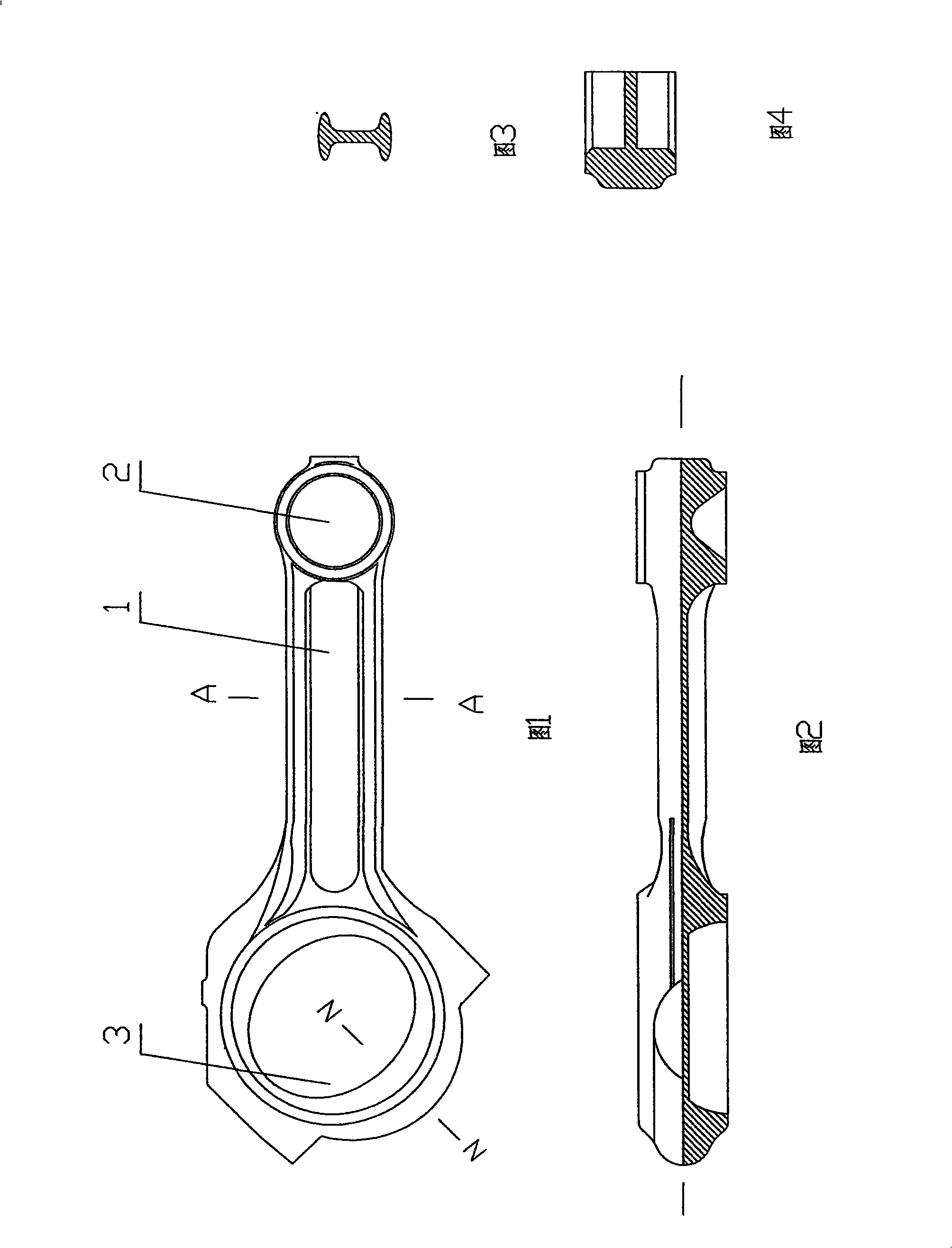

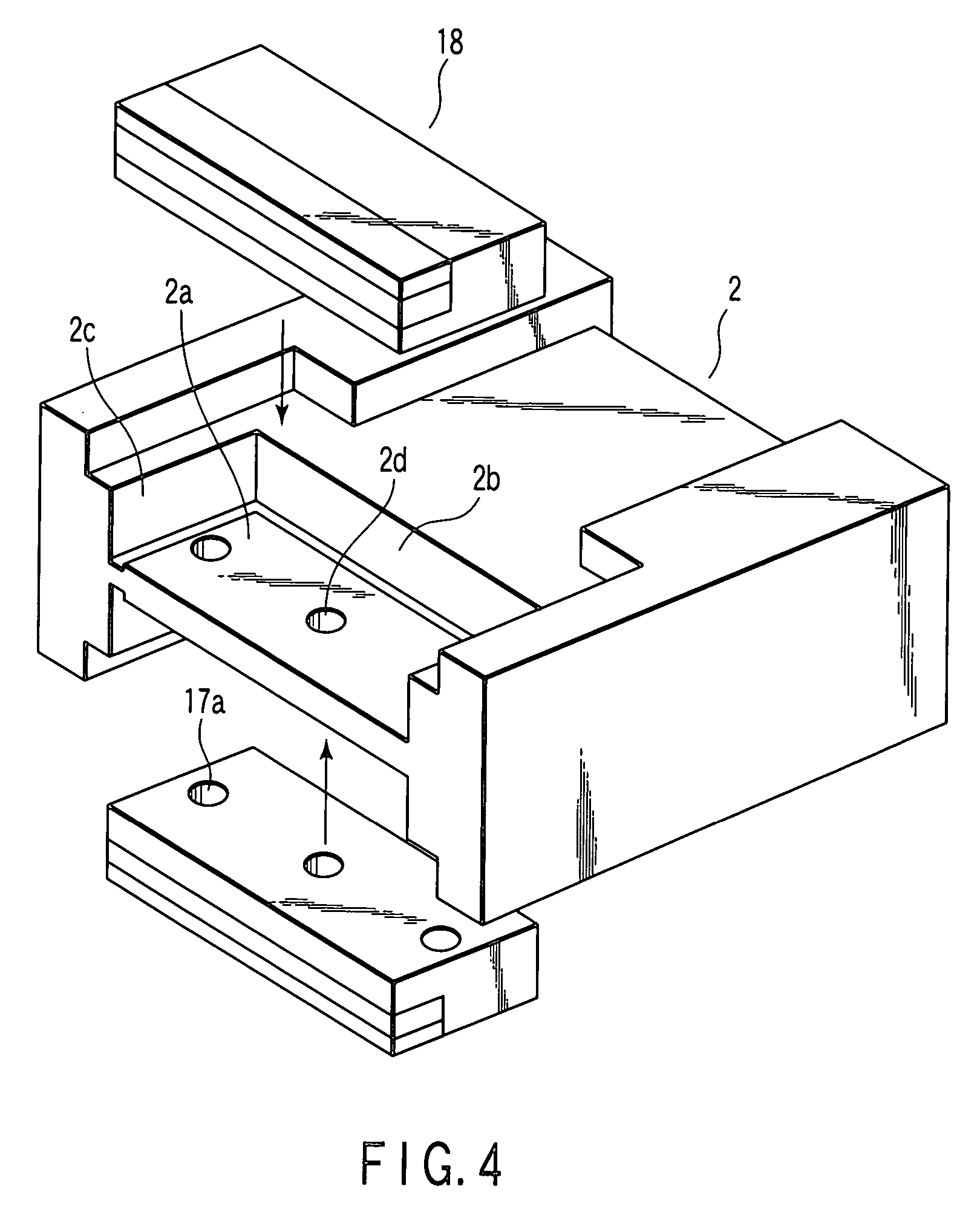

Image forming apparatus including line head

An image forming apparatus has a recording head portion constituted of head modules having a configuration in which a plurality of small heads are detachably attached in a head mount at alternate positions in a recording medium width direction and a drive portion is also mounted.

Owner:RISO KAGAKU CORP

Chopsticks collating unit

InactiveCN101273869AReasonable designCompact structureTableware washing/rinsing machinesConveyor partsFood hygieneEnergy conservation

The invention pertains to tableware cleaning equipment, particularly relates to an arranging device of chopsticks, which is characterized in that: the arranging device is composed of a sorting mechanism and a collecting basket, the collecting basket is arranged below a bottom opening of the sorting mechanism; the sorting mechanism consists of a chopstick entering funnel, a sorting shell, flexible guide sheets and a mechanism for regulating the sizes of the small ends of the chopsticks, the upper part of the sorting shell is a flat cuboid, and the lower part is shaped like a hopper; the upper part of a top opening of the sorting shell is provided with the chopstick entering funnel, a plurality of flexible guide sheets are distributed along the long inner side surface below the top opening of the sorting shell, one end of each flexible guide sheet is connected on the long inner side surface, the other end thereof is suspended, and the mechanism for regulating the sizes of the small ends of the chopsticks which is composed of nuts and regulating pins is symmetrically arranged on the long side surface which connects the lower surfaces of the flexible guide sheets. The arranging device has the advantages of reasonable design, compact structure, simplicity, practicality, high arranging efficiency, energy conservation, low cost, very convenient usage and so on, which is further in line with food hygiene.

Owner:DALIAN JIAOTONG UNIVERSITY

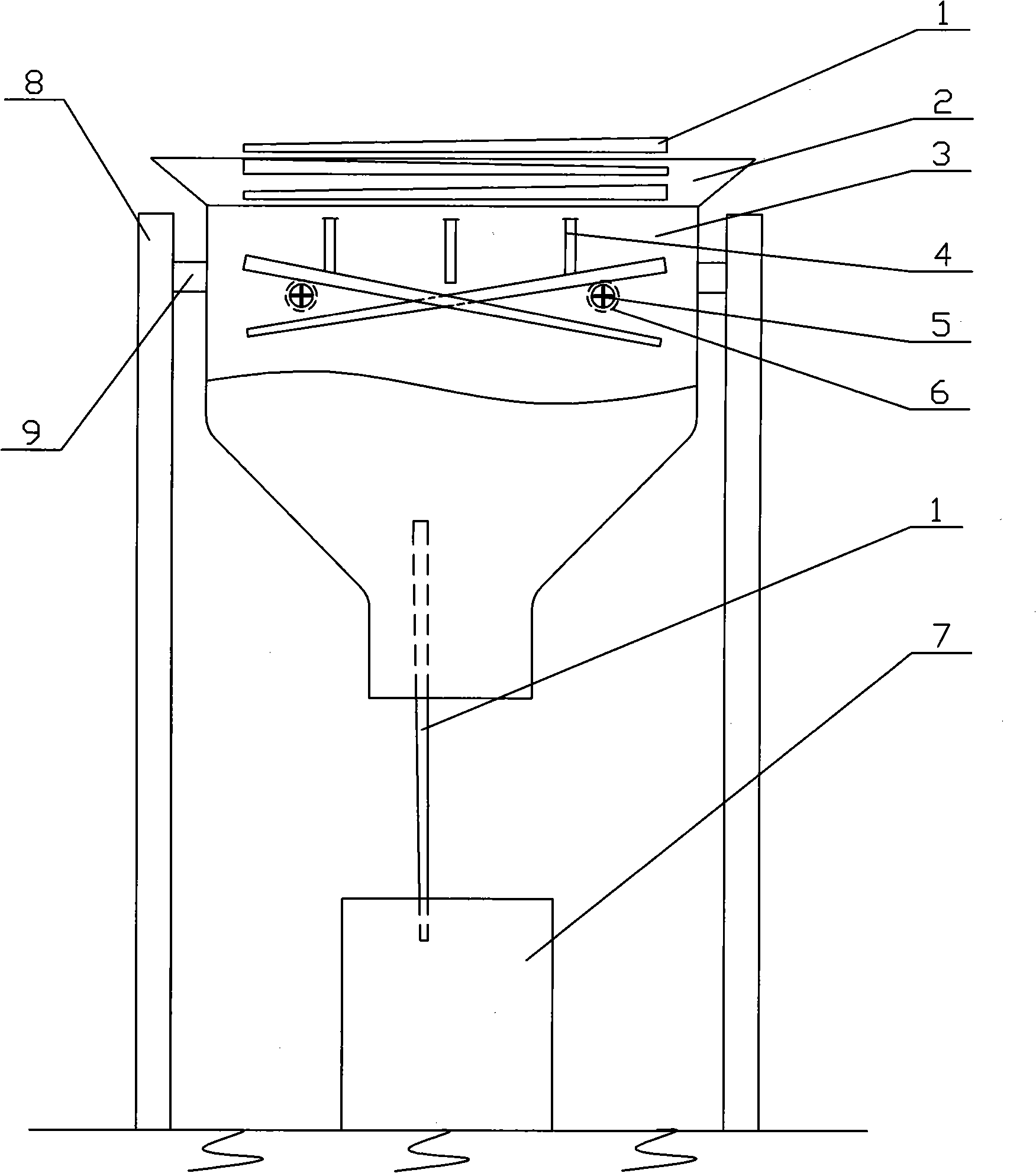

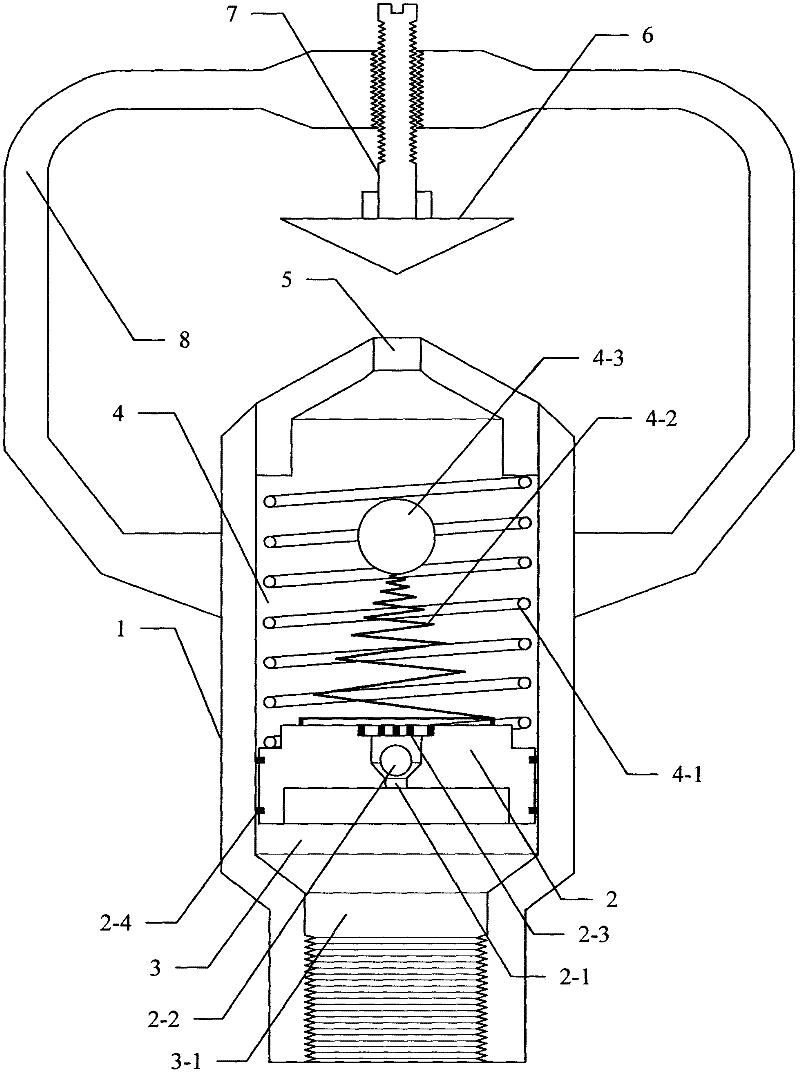

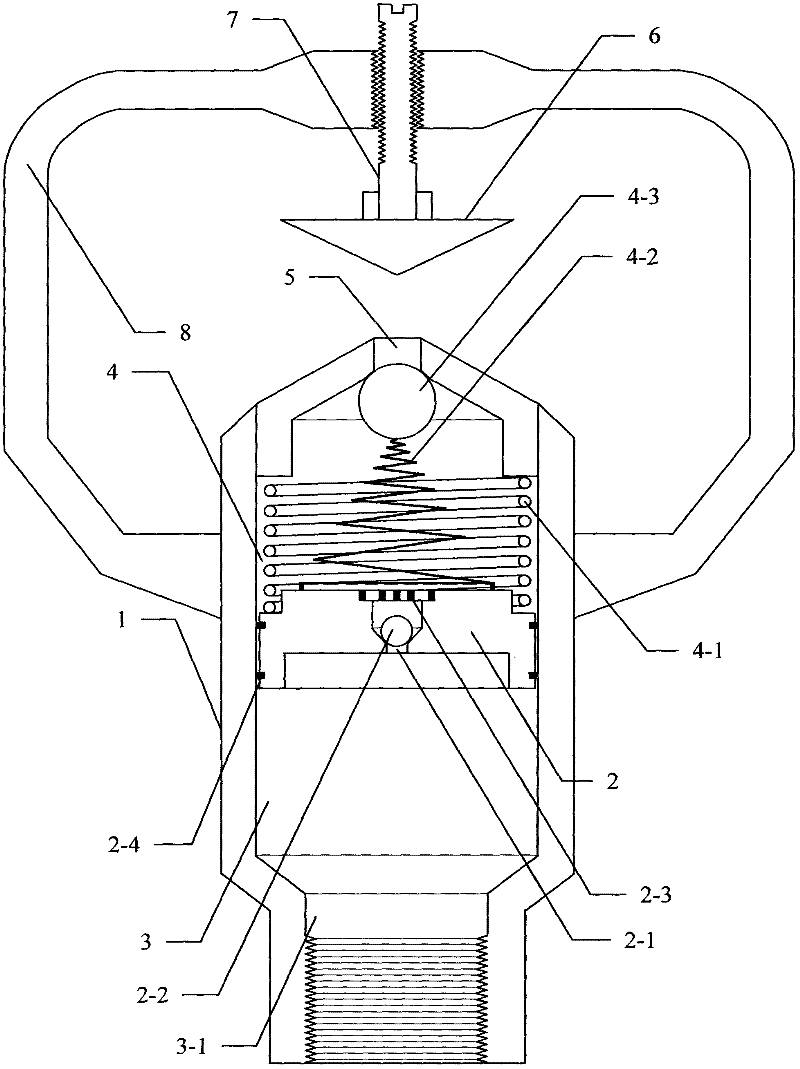

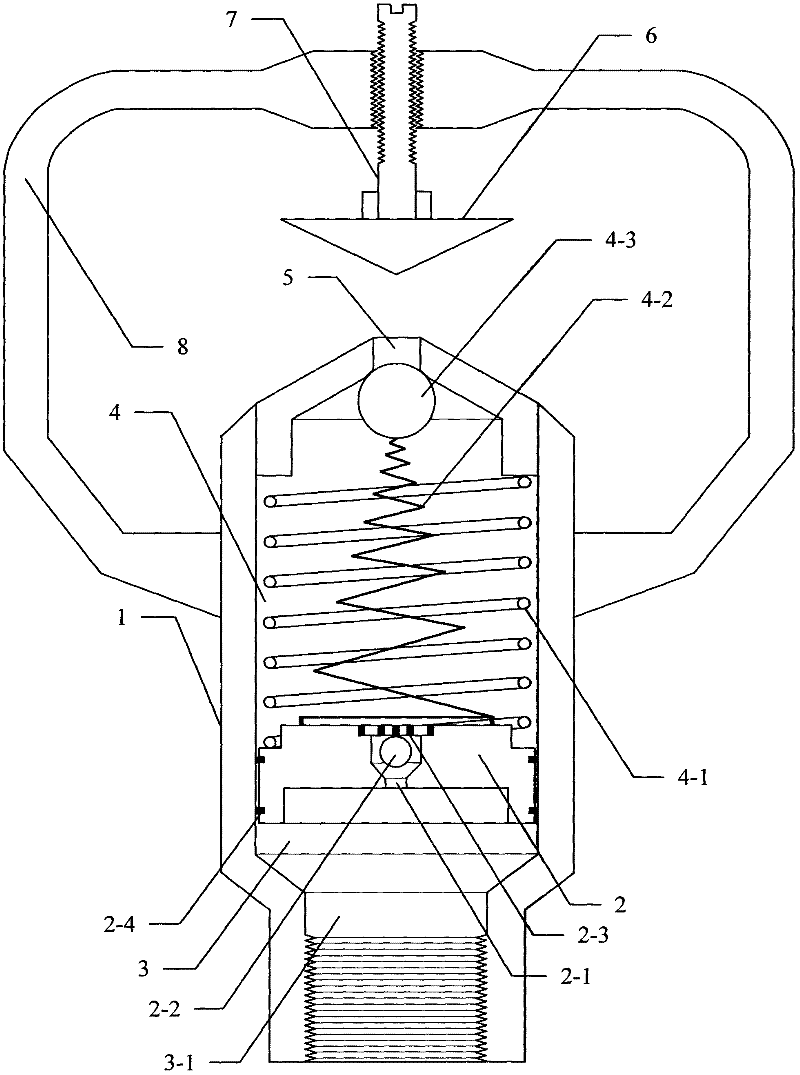

Pulse type micro-sprinkling irrigation spray head

InactiveCN102500475AImprove performance uniformityImprove spray uniformityClimate change adaptationWatering devicesEngineeringTower

The invention belongs to the technical field of field irrigation and particularly relates to a pulse type micro-sprinkling irrigation spray head which comprises a casing and a piston. The piston divides an inner cavity of the casing into a water inlet cavity and a compression cavity, the water inlet cavity is connected with a micro-sprinkling irrigation water-conveying vertical pipe through a water inlet flow channel, and the piston is provided with a compression cavity moisturizing check valve and an elastic water-stopping ring. A compression spring, a tower-shaped spring, a spherical elastic valve body and a spraying hole are arranged in the compression cavity, the compression spring is sleeved outside the tower-shaped spring, one end of the compression spring abuts against the piston, the other end of the compression spring abuts against an inner wall of the casing close to the spraying hole, a large end of the tower-shaped spring is fixed on the piston, and a small end of the tower-shaped spring is fixed on the spherical elastic valve body. A curved surface of a water inlet of the spraying hole is matched with a curved surface of the spherical elastic valve body, and a refraction cone is arranged over the spraying hole. Compared with an imported pulse type micro-sprinkling irrigation system, the pulse type micro-sprinkling irrigation spray head is similarly excellent in anti-blocking performance and sprinkling evenness, simple in structure, low in input cost, suitable for China's actual conditions and easy to popularize and apply.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

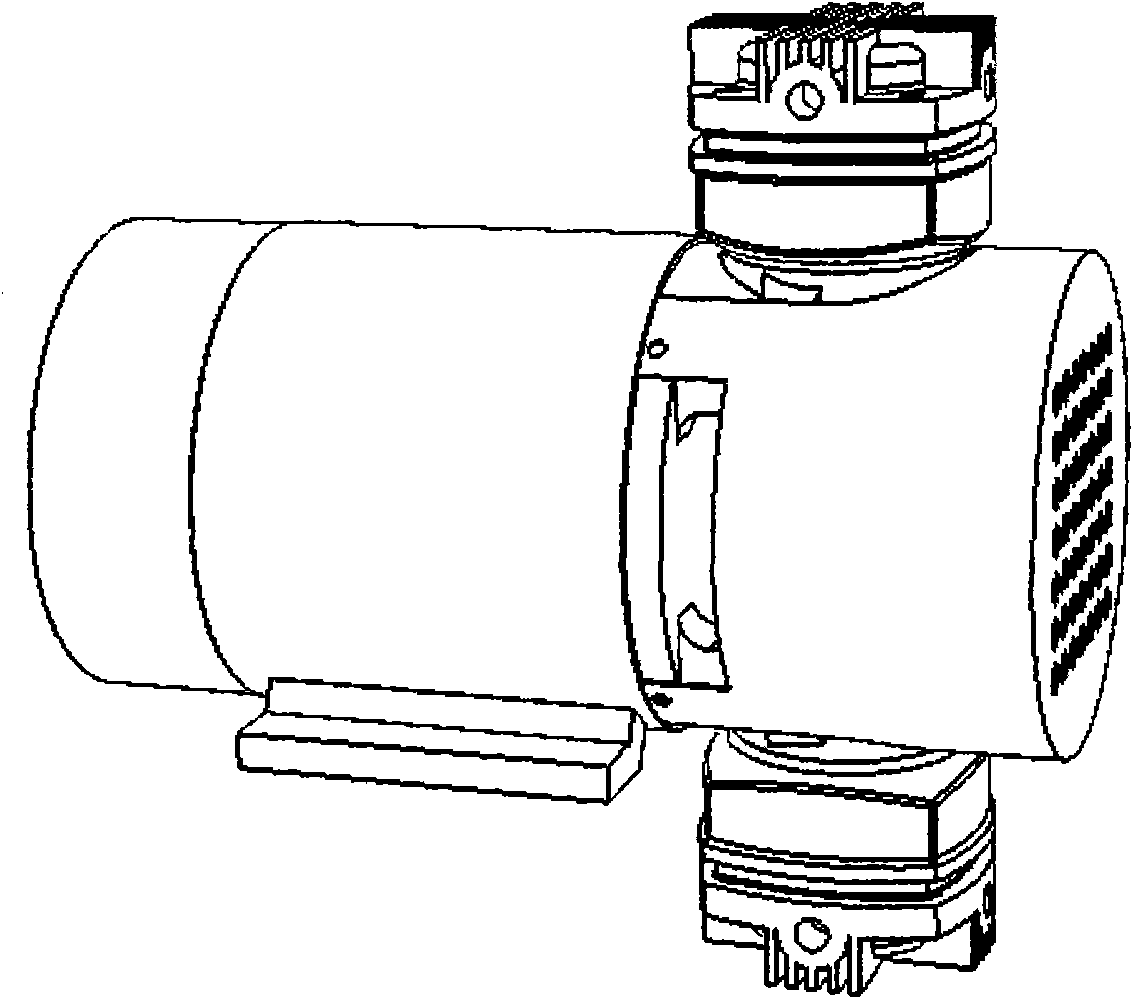

Oil-free compressor used in locomotive

InactiveCN101614200AIncrease the bearing areaImprove the state of stressPositive displacement pump componentsPiston pumpsNeedle roller bearingBall bearing

The invention belongs to the technical field of air compressors, relates to an oil-free compressor used in a locomotive, in particular to an eccentric block-connecting rod reciprocating piston total oil-free lubricated compressor. The oil-free compressor comprises a motor, cylinders, a piston connecting rod assembly, an air valve assembly, cooling fan and the like, wherein, two cylinders are symmetrically arranged above and below a motor shaft, and can also be arranged at the left and the right of the motor shaft, and the two cylinders are coaxial. Connecting rods are sheathed on the motor shaft by a radial ball bearing and an eccentric block, small top end of each connecting rod is provided with two needle roller bearings with an one-side sealed structure, and a crank-connecting rod mechanism drives a piston to realize reciprocating motion in the cylinders. An air inlet valve, a valve plate and an air outlet valve are arranged between the cylinders and cylinder caps, and the valve plate is of a flat-sheet structure, and is provided with an inlet flow channel and an outlet flow channel. The cylinder caps are provided with air inlet chambers and air outlet chambers. The oil-free compressor has the advantages of oil saving, environmental protection, and simple operation and maintenance.

Owner:HEFEI GENERAL MACHINERY RES INST

Crank pulley assembly method and guiding tool

ActiveCN101456113AGuaranteed assembly accuracyGuaranteed assembly stabilityMetal working apparatusInterference fitEngineering

The invention relates to an assembly method for a crankshaft pulley and a guide tool of the method. The crankshaft pulley is arranged on a crankshaft through interference fit. A small end of the crankshaft and the crankshaft pulley are provided with positioning grooves respectively. A pulley assembly guide tool is arranged on the crankshaft pulley. The crankshaft wheel and the pulley assembly guide tool are arranged on the small end of the crankshaft together and are pressed. The pulley assembly guide tool comprises an internal circular sleeve and an external circular sleeve, wherein an axial long slide way is arranged between the internal circular sleeve and the external circular sleeve. The internal circular sleeve is provided with a positioning key which is matched with the positioning groove of the small end of the crankshaft. The external circular sleeve is provided with a positioning key which is matched with the positioning groove of the crankshaft pulley. The method and the guide tool of the method are used for assembling crankshaft pulleys of diesel engines, solves the problem of difficult alignment of positioning groove of the crankshaft pulley and the positioning groove of the small end of the crankshaft, avoids phase angle change of the crankshaft pulley relative to the small end of the crankshaft during the pressing process of the crankshaft pulley and ensures the assembly accuracy of the crankshaft pulley and the stability of the assembly quality.

Owner:GUANGXI YUCHAI MASCH CO LTD

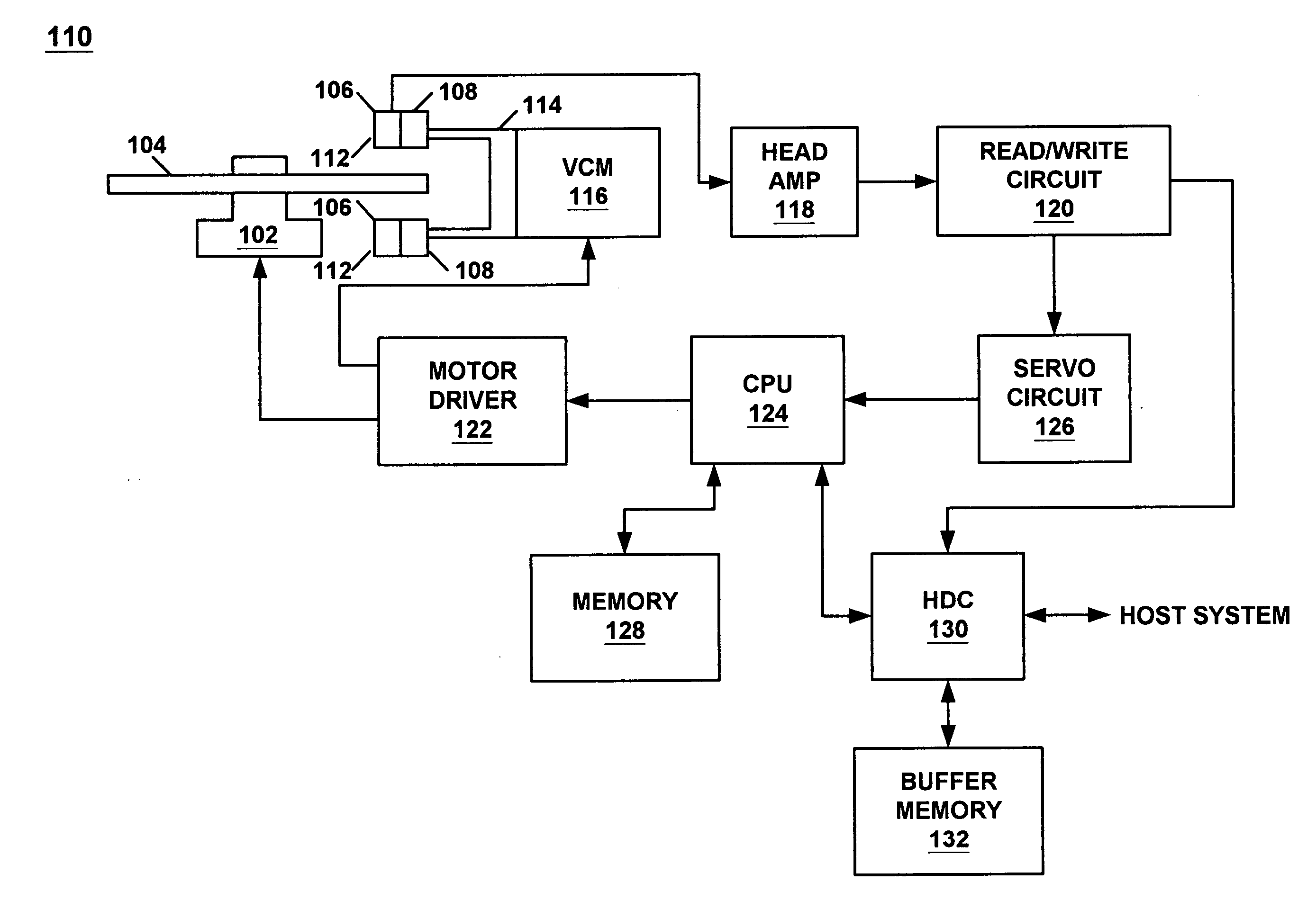

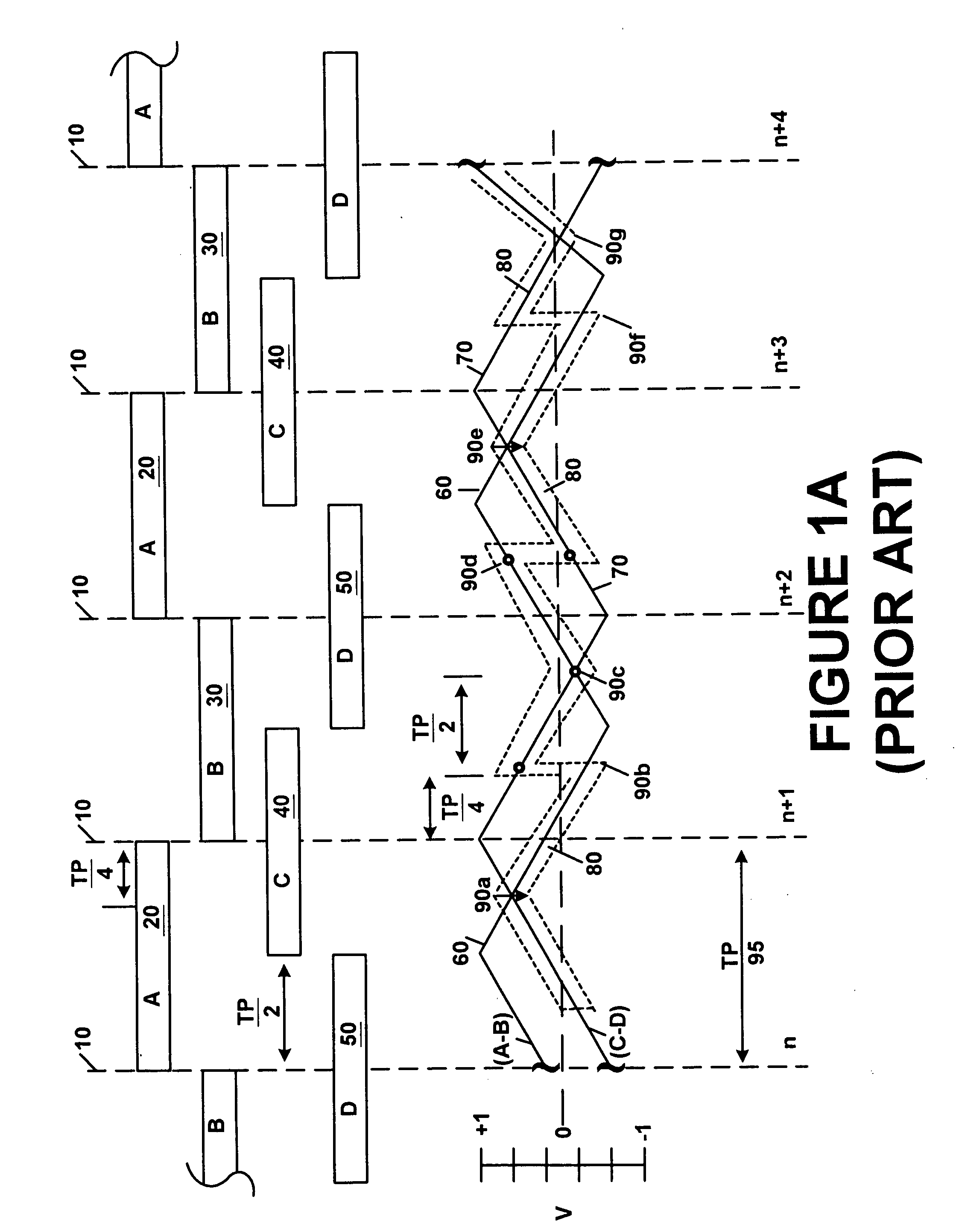

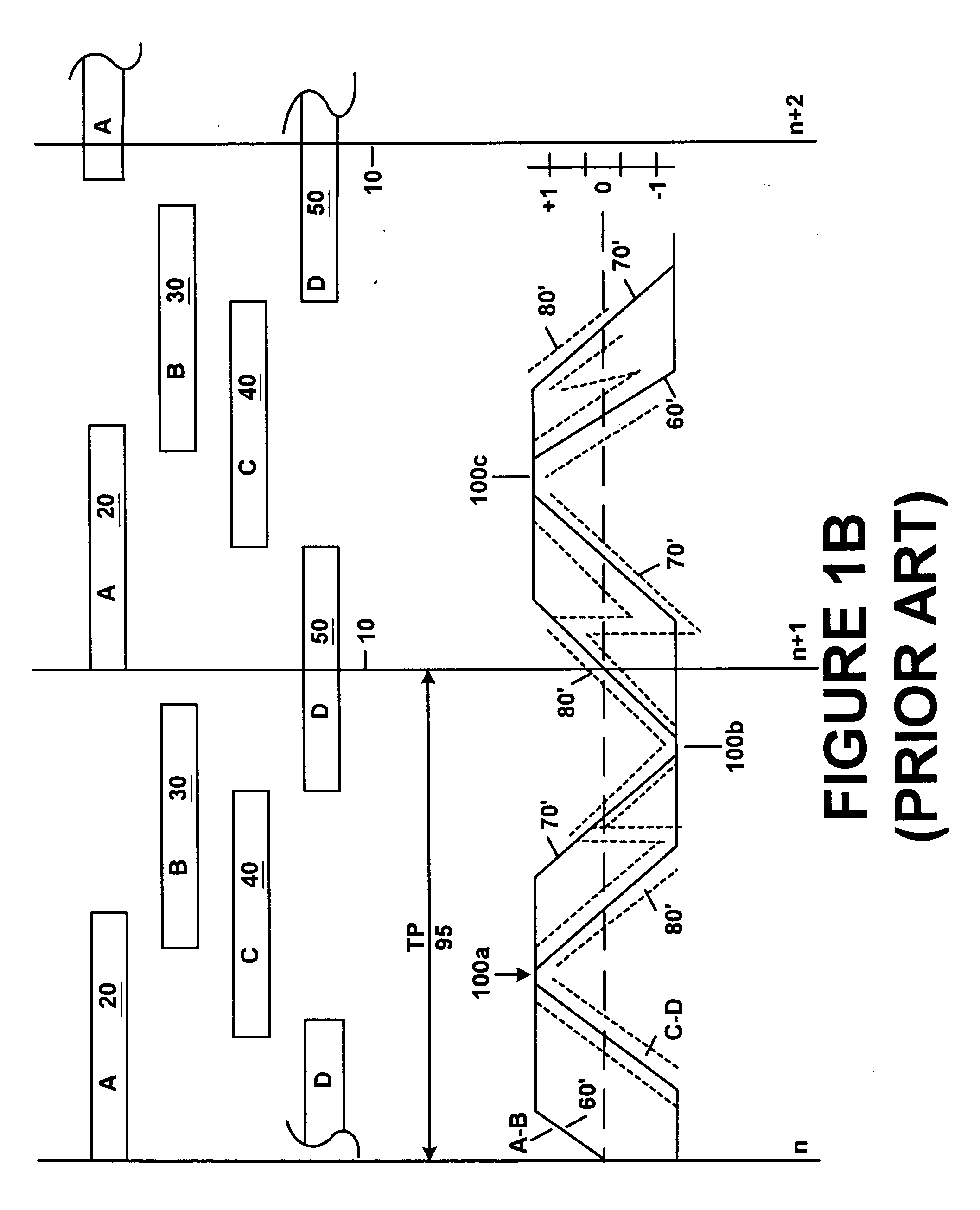

Seamless and untrimmed primary servo burst with multiple secondary servo bursts

InactiveUS20050207051A1High sensitivityEliminate the problemRecord information storageAlignment for track following on disksEngineeringData storing

A disk storage system having servo data stored thereon for accurate head position control over a magnetic or other storage medium. The servo data is seamless and untrimmed and consists of a primary servo burst set (AB burst) in which the difference defines the desired tract pitch for the surface. Multiple secondary servo burst sets (e.g., CD burst and EF burst) are written at the desired track pitch but radially offset from the primary burst set. In one embodiment, two secondary servo burst sets are used, but alternatively, any number of secondary servo burst sets could be used. In this exemplary embodiment having two secondary servo burst sets, the CD servo burst set is offset by ⅓ of the track pitch from the primary servo burst set. Also in this embodiment, the EF servo burst set is offset by ⅔ of the track pitch from the primary servo burst set. There are six bursts per set. The servo data is written in multiple servo sectors around the surface of the medium. From the servo data, three PES (position error signals) are generated, A-B, C-D and E-F, for providing linear position sensitivity information to the head position control logic. The resulting PES is more linear for smaller head sizes.

Owner:WESTERN DIGITAL TECH INC

Method for preparing large-size sheet by using small-diameter wood

ActiveCN103341890AIncrease profitReduce curvatureWood veneer joiningWood mortising machinesFinger jointEngineering

The invention discloses a method for preparing a large-size sheet by using small-diameter wood. The method comprises the steps of: cutting small-diameter wood with a diameter of 6-11cm into wood sections with lengths of 1m, grouping into 5 groups according to the diameter of the small head and the 10mm difference, and drying until the water content is 12 percent; sawing the wood sections into rough regular hexagonal prisms, inscribed circles of bottom surfaces of which are 46mm, 56mm, 66mm, 76mm and 86mm, extending through a finger joint tenon and cutting according to the specification, milling into refine regular hexagonal prisms, inscribed circles of bottom surfaces of which are 40mm, 50mm, 60mm, 70mm and 80mm; symmetrically splitting the regular hexagonal prisms into quadraprisms through the maximum diagonal plane; symmetrically splitting the regular hexagonal prisms into pentagonal prisms through a plane vertical to the side surfaces of the hexagonal prisms; and selecting the quantities of the refine regular hexagonal prisms, and the pentagonal prisms and the quadraprisms, thereby obtaining a rectangular large-section glued wood beam through coating, assembling and bidirectional-pressurizing, and sawing into the large-size sheet with the thickness of 5-20mm. According to the method, the utilization rate and the use value of the small-diameter wood are improved.

Owner:江西兴创木业有限责任公司

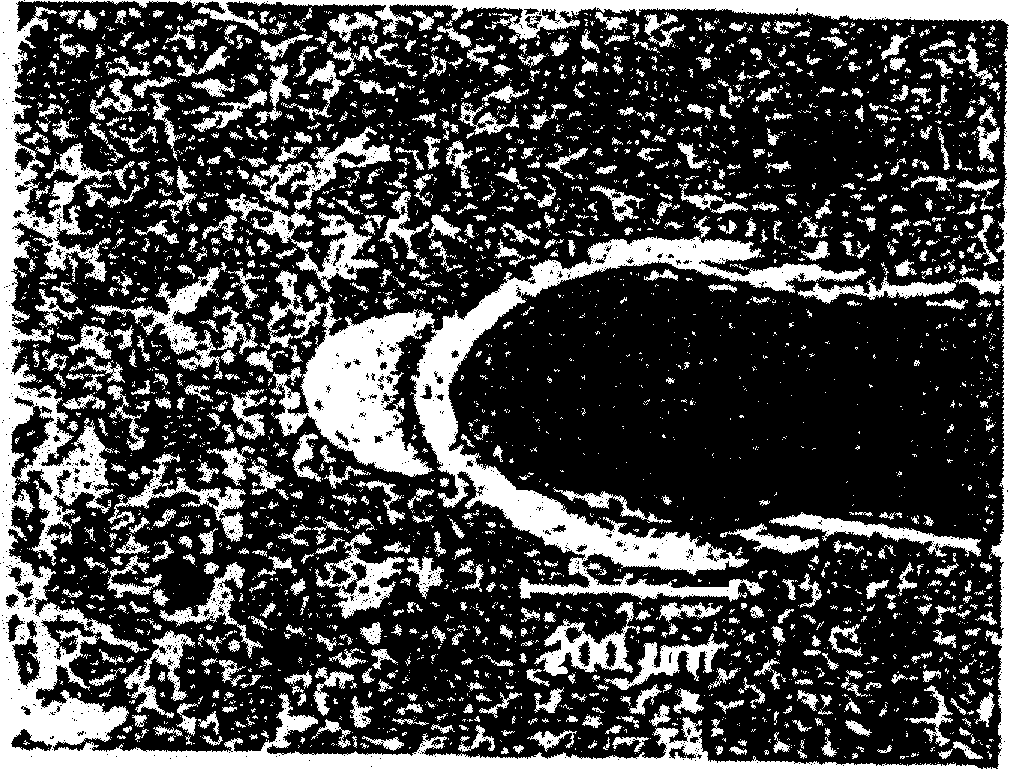

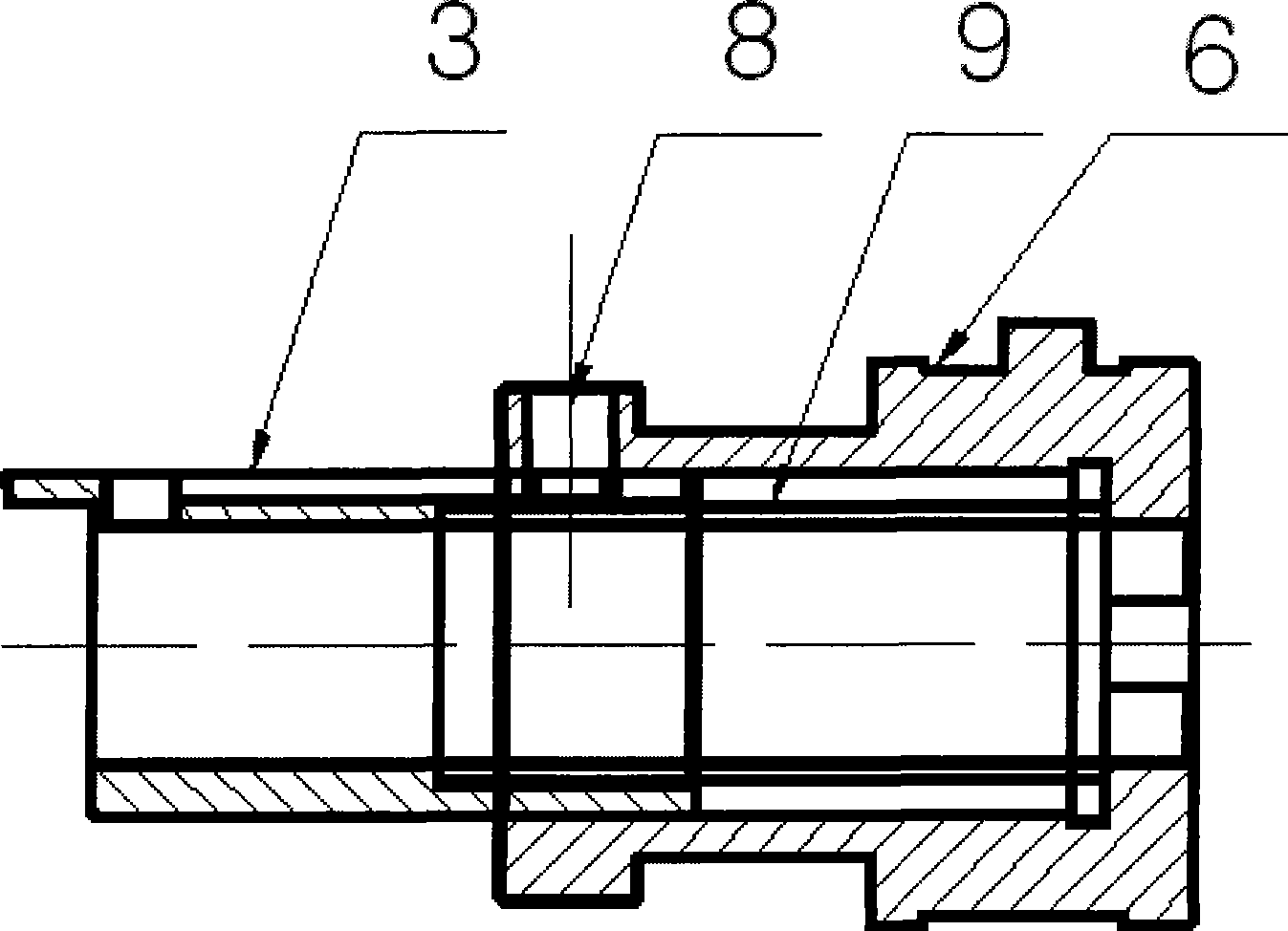

Wedged connecting rod bushing press fitting positioning mechanism

ActiveCN102729034AGuaranteed positioning accuracyImprove the pressing effectMetal working apparatusSet screwSurface phase

The invention relates to a wedged connecting rod bushing press fitting positioning mechanism, comprising a large-head positioning mechanism, a small-head positioning mechanism and a bushing press fitting positioning mechanism all arranged on the top of a worktable; the bushing press fitting positioning mechanism adopts a mandrel with a split structure for press fitting; a wedged bushing is mounted on the mandrel; a circumferential phase angle between the wedged inclined surface of a pressing sleeve and a positioning steel ball subjected to fine adjustment through a fastening screw; the wedge surface phase angle of the wedged bushing is adjusted through a hold-down screw; and the connecting rod bushing is press-fitted into a hole formed at the small head of the wedged connecting rod positioned by the large-head positioning mechanism and the small-head positioning mechanism. The wedged connecting rod bushing press fitting positioning mechanism is convenient for press fitting and accurate in positioning.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

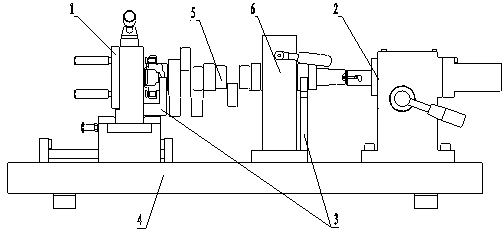

Comprehensive inspection device for measuring position of crankshaft hole

ActiveCN102721341ASolve the high detection costImprove general performanceMechanical measuring arrangementsEngineeringCrankshaft

The invention discloses a comprehensive inspection device for measuring the position of a crankshaft hole. The comprehensive inspection device comprises a crankshaft output end detecting and supporting part, a crankshaft small-head end detecting and supporting part, a prepositioning support, a crankshaft first connecting rod shaft journal positioning mechanism and a bottom plate, wherein the crankshaft output end detecting and supporting part is matched with a crankshaft output end; the crankshaft small-head end detecting and supporting part is matched with a crankshaft small-head end; the prepositioning support and the crankshaft first connecting rod shaft journal positioning mechanism is arranged between the crankshaft output end detecting and supporting part and the crankshaft small-head end detecting and supporting part; and the crankshaft output end detecting and supporting part, the crankshaft small-head end detecting and supporting part, the prepositioning support and the crankshaft first connecting rod shaft journal positioning mechanism are fixedly arranged on the bottom plate. The comprehensive inspection device has the characteristics of high universality and operation convenience, the working efficiency of detecting the position of the crankshaft hole can be obviously improved, the detection cost is reduced, and high economic benefits are brought to an enterprise.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com