Crank pulley assembly method and guiding tool

A crankshaft pulley and assembly method technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of increased strength and difficulty of the crankshaft, increased assembly of the crankshaft pulley, position deviation between the crankshaft pulley and the small end of the crankshaft, etc. Achieve the effect of overcoming the change of mutual angle, ensuring assembly accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

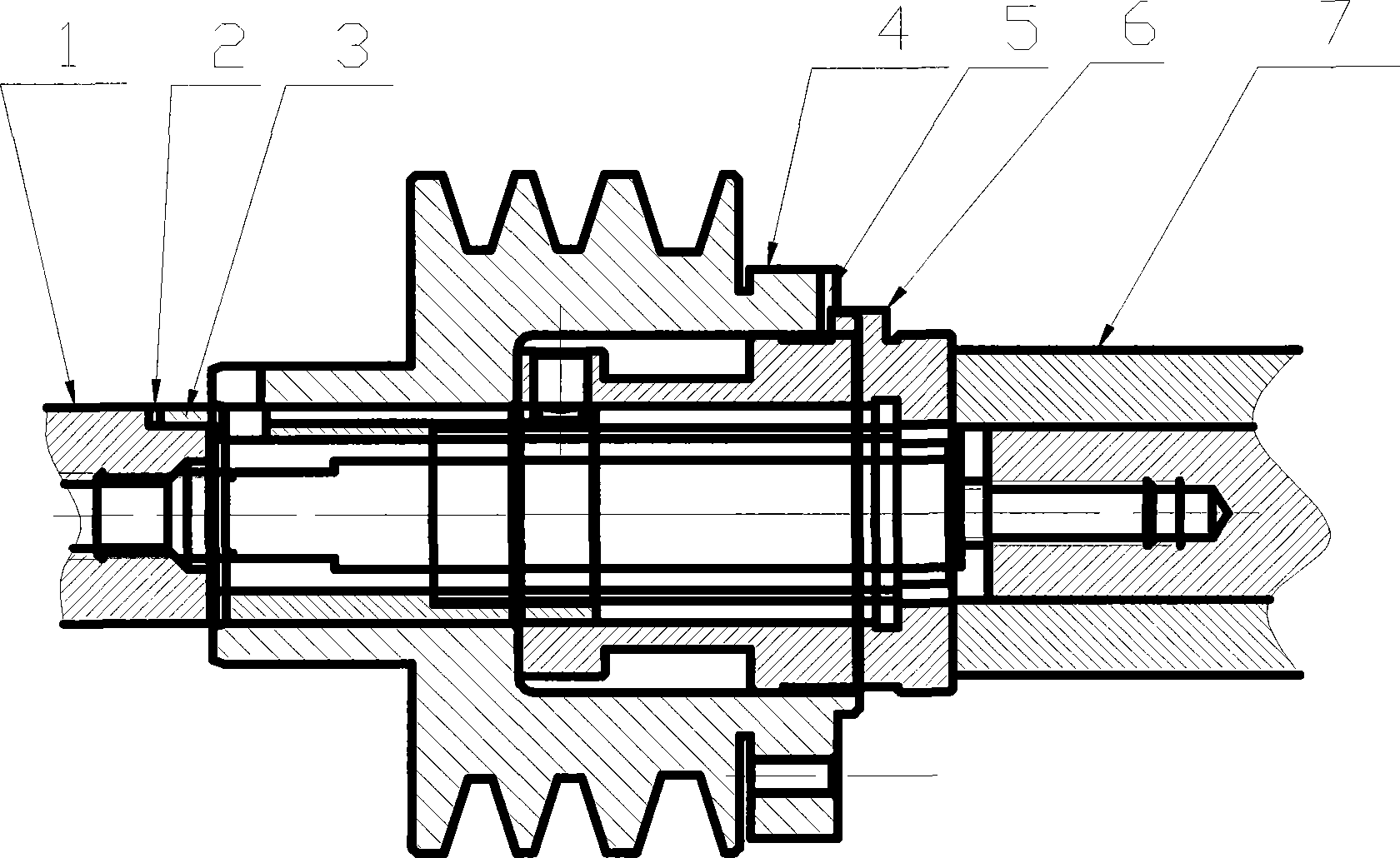

[0014] The assembly method of the crankshaft pulley and the guide tooling of the present invention can realize the press-fitting of the crankshaft belt with an interference fit, determine the relative position between the crankshaft pulley and the crankshaft, and keep the mutual angle between the crankshaft pulley and the crankshaft constant during the press-fitting process. Change, to ensure the stability of quality.

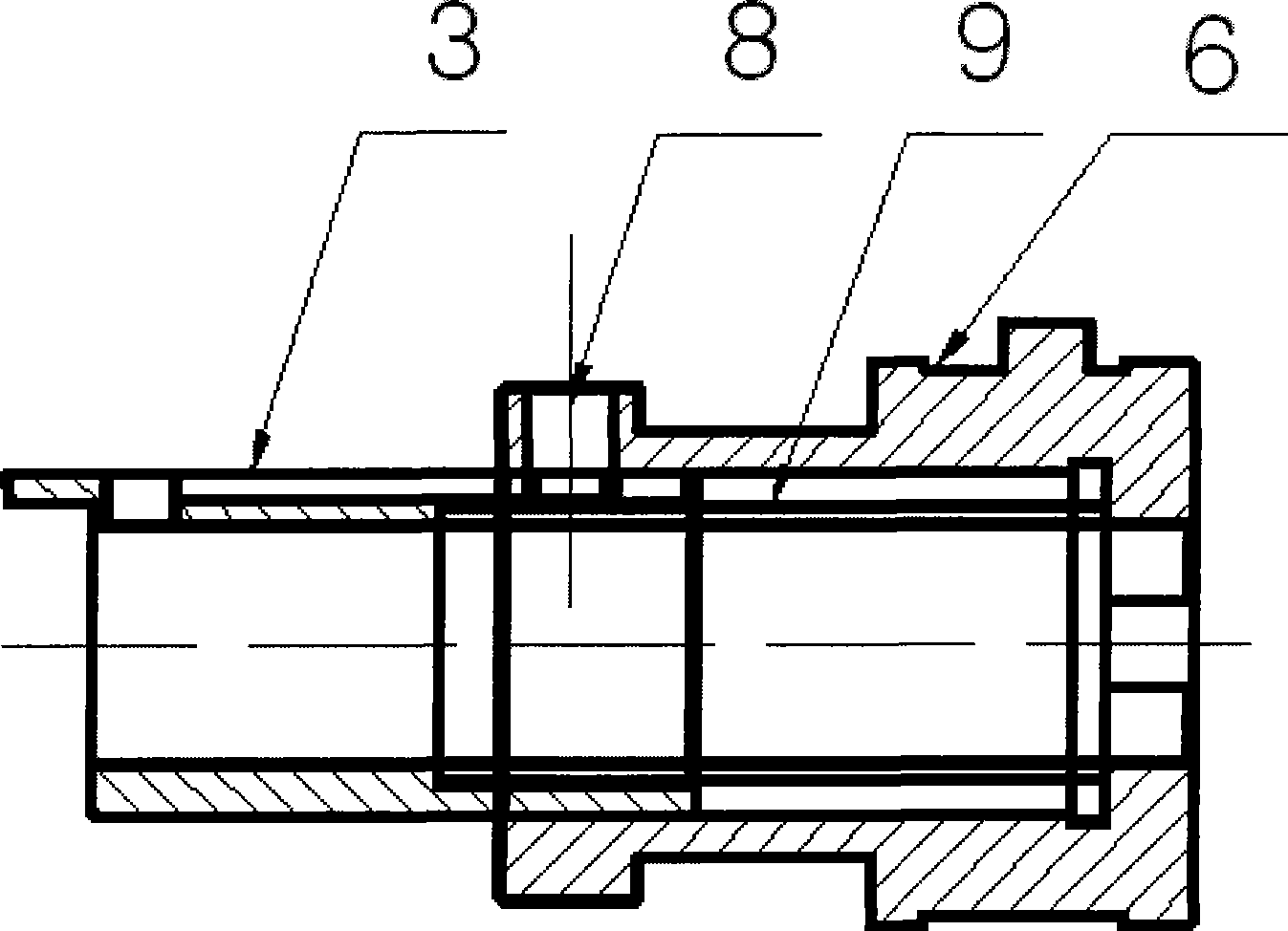

[0015] The crankshaft pulley assembly guide tooling is designed according to the small end of the crankshaft and the pulley of the crankshaft, that is, according to the structural size of the small end of the crankshaft, the size of the positioning groove of the small end of the crankshaft, the structural size of the pulley, the size of the positioning groove of the pulley, and the assembly requirements of the pulley. The belt pulley assembly guide tooling is divided into two main parts, the inner sleeve and the outer sleeve. The inner sleeve and the outer sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com