Synchronous vertical swing lift construction method for double inclination arc tower

A technology of vertical rotation and inclined arch, which is applied in the erection/assembly of bridges, bridges, buildings, etc., which can solve the problems of long construction period and large investment, and achieve the effect of less machinery and equipment, safe operation and easy organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

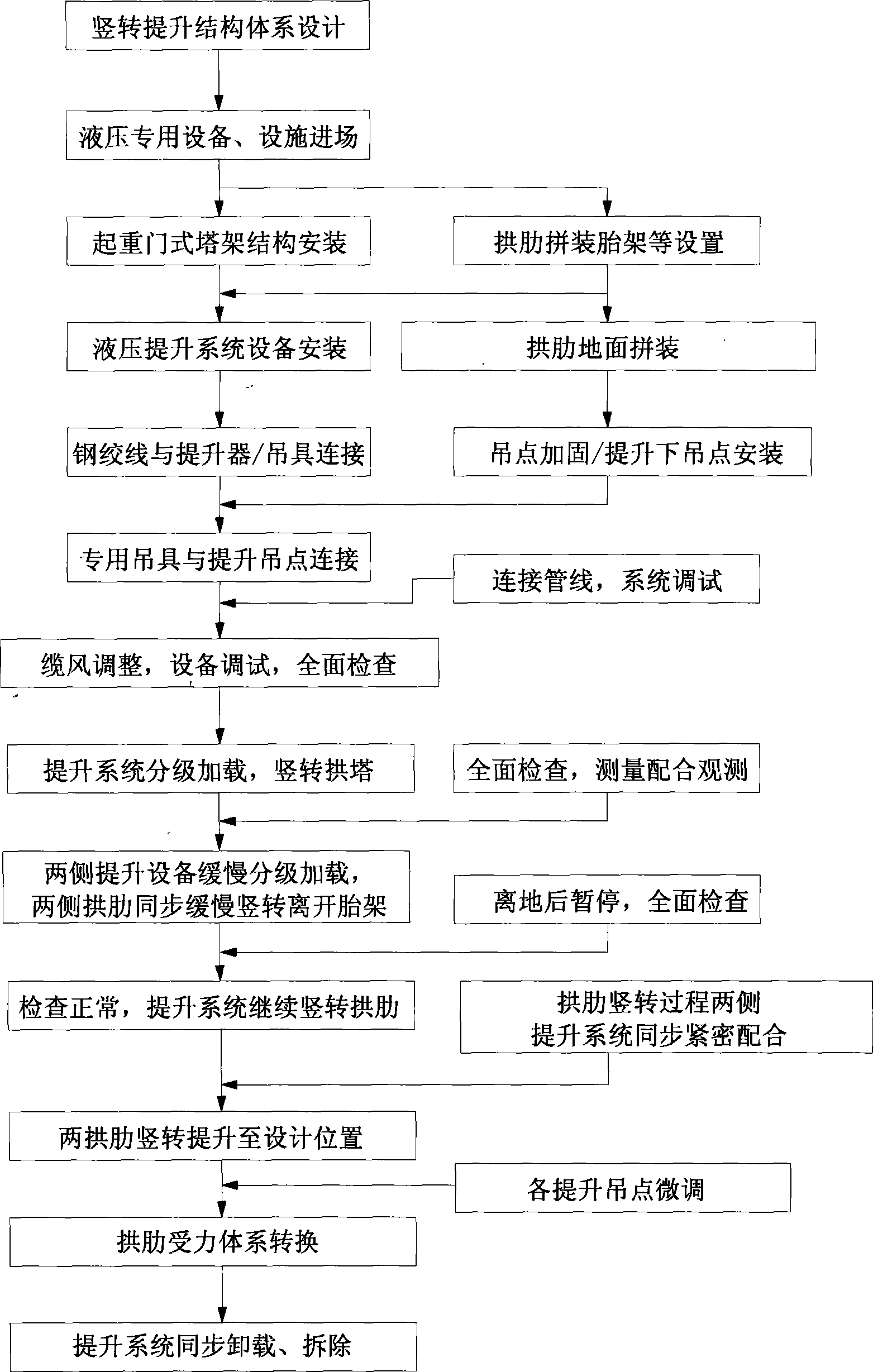

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with a specific implementation example.

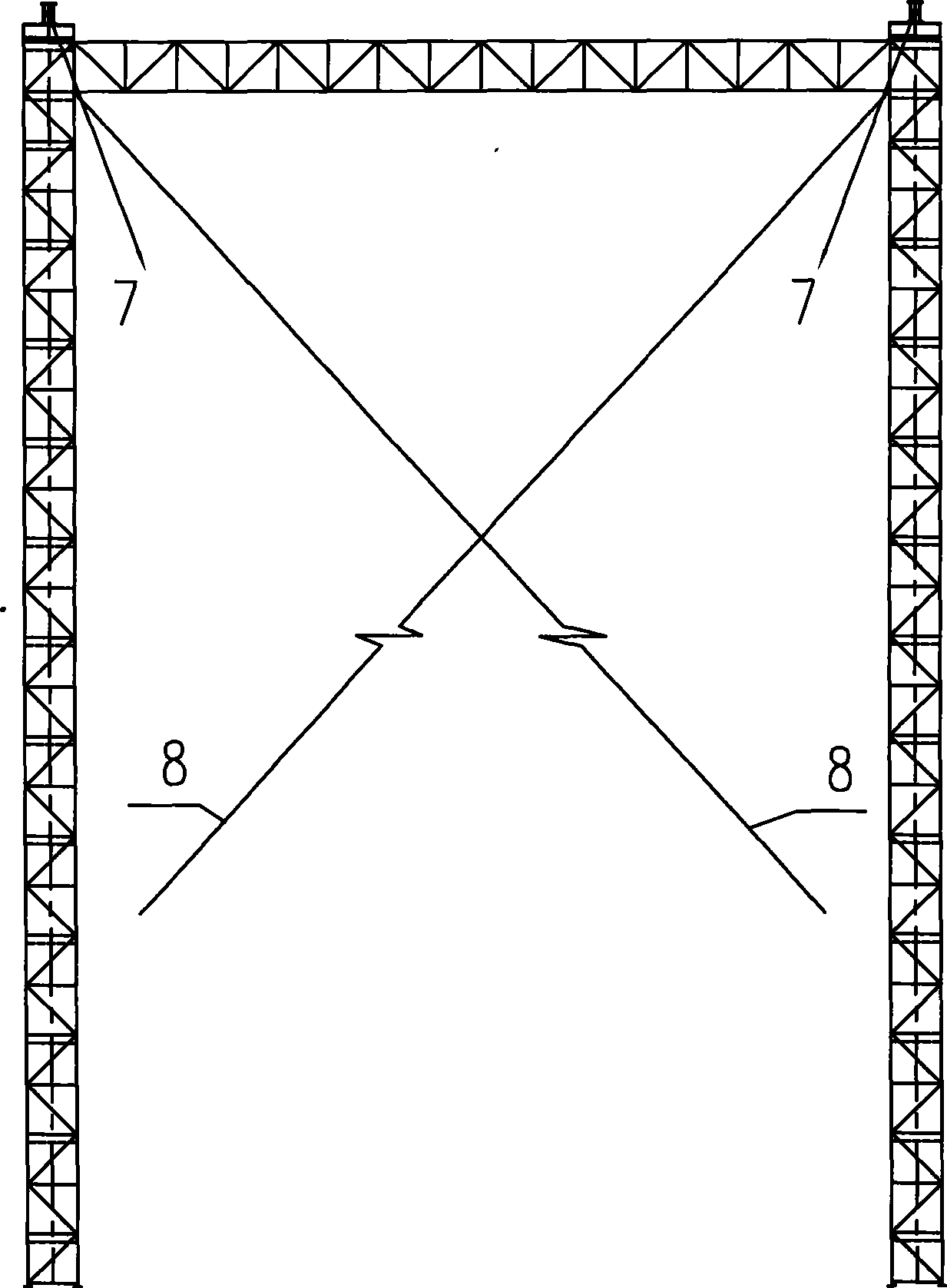

[0044] The application example of this construction method is to carry out the design of the portal tower through the comprehensive analysis of the overall layout of the lifting arch rib and the width, height and maximum vertical rotation force of the arch rib. The main technical parameters are as follows: the height of the portal tower is 72 meters ( 51 meters above the bridge deck and 21 meters below the bridge deck), the cross-section of the columns and branches is 2.8 meters x 2.8 meters (center distance), and the span of the portal tower is 48.6 meters (center distance). Through force calculation and analysis, the tower can withstand 6-level wind (13.8m / s) during the vertical rotation and lifting process, and can withstand 10-level strong wind (25.3m / s) in Shenyang during the static process.

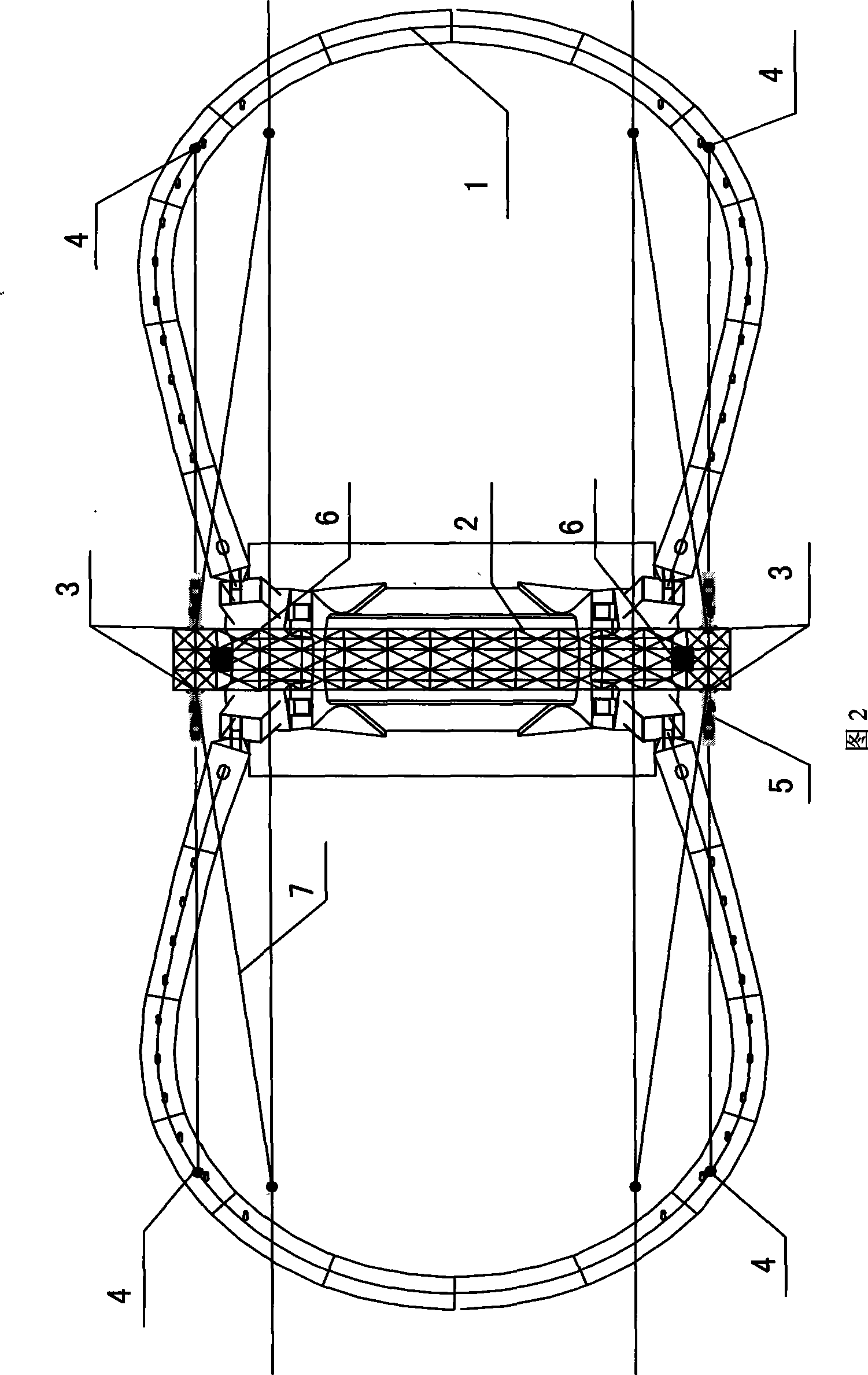

[0045] As shown in Figure 2, this construction method is main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com